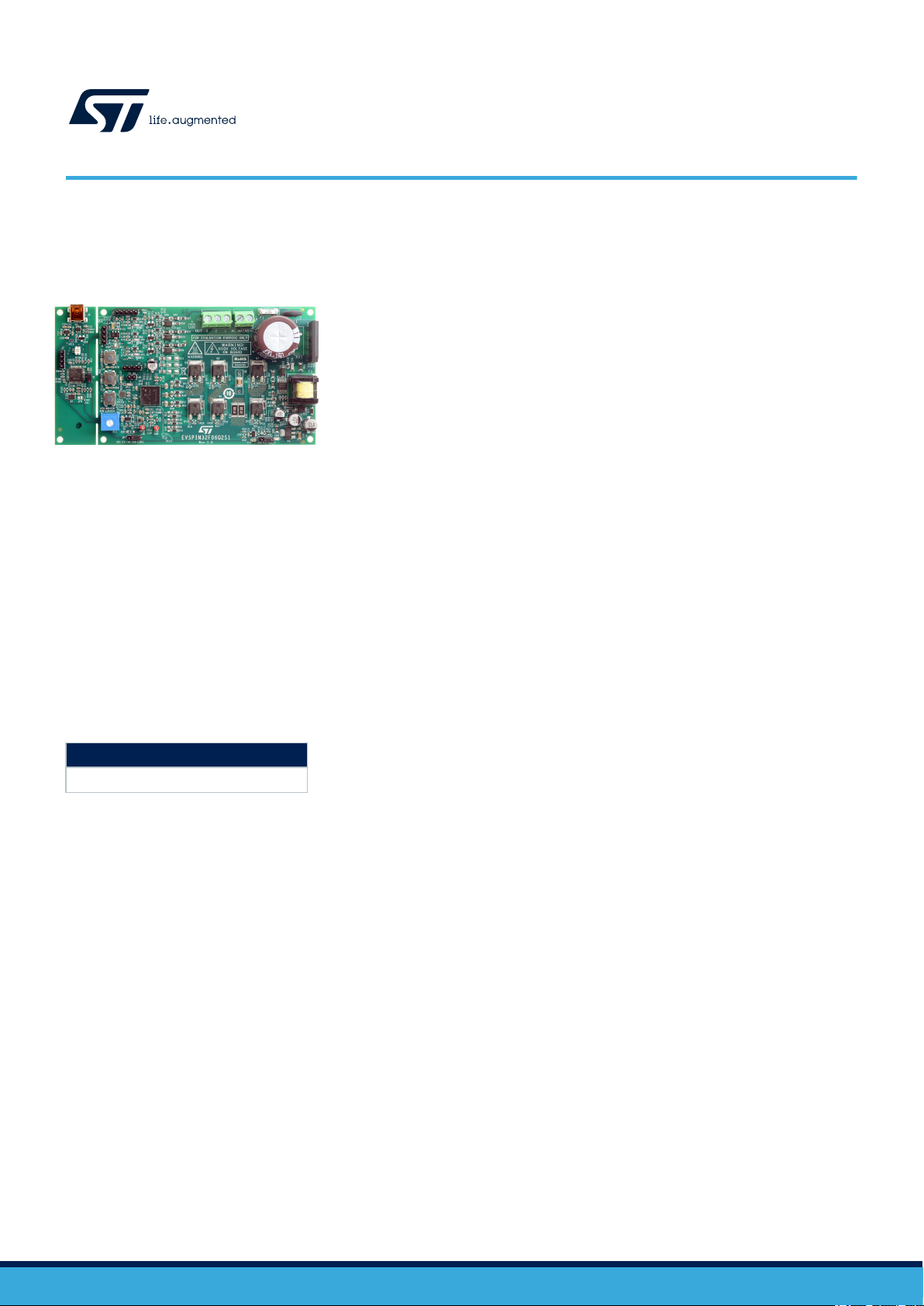

EVSPIN32F06Q2S1

3-phase inverter based on STSPIN32F0602

Features

• Input voltage from 35 VAC (50 VDC) to 280 VAC (400 VDC)

• STD18N65M5 MOS power stage featuring:

– V

– R

• Overcurrent threshold set to 8.5 A

• Dual footprint for IGBT/MOSFET package:

– DPAK

– PowerFlat 8x8 HV

• Single-shunt current sensing, suitable for:

– Sensored or sensorless 6-step algorithm

– Sensored or sensorless single-shunt vector (FOC) algorithm

• Smart shutdown overcurrent protection

• Digital Hall sensors and encoder input

• Bus voltage sensing

• 15 V VCC and 3.3 V VDD supplies

• Embedded ST-LINK/V2-1

• Easy user interface with buttons and trimmer

• RoHS compliant

@ T

(DS)

max. = 0.220 Ω

DS(on)

Jmax

= 710 V

peak

Data brief

Product status link

EVSPIN32F06Q2S1

Applications

• Home and Industrial refrigerators compressors

• Industrial drives, pumps, fans

• Air conditioning compressors & fans

• Corded power tools, garden tools

• Home appliances

• Industrial automation

Description

The EVSPIN32F06Q2S1 board is a 3-phase complete inverter based on the

STSPIN32F0602 controller, which embeds a 3‑phase 600 V gate driver and a

Cortex®-M0 STM32 MCU. The power stage features STD18N65M5 MOSFET, but

can be populated with any IGBT or Power MOSFET in DPAK or powerFLAT 8x8 HV

package.

The board has a single-shunt sensing topology, and both sensored and sensorless

FOC and 6-step control algorithms can be implemented. This allows driving

permanent magnet synchronous motors (PMSMs) and brushless DC (BLDC) motors.

The evaluation board is compatible with a wide range input voltage from 35 VAC

(50 VDC) to 280 VAC (400 VDC), and includes a power supply stage with the

VIPER06XS in flyback configuration to generate +15 V and +3.3 V supply voltage

required by the application.

DB4378 - Rev 1 - January 2021

For further information contact your local STMicroelectronics sales office.

www.st.com

EVSPIN32F06Q2S1

Debug and configuration of FW can be performed with standard STM32 tools through

the detachable ST-LINK‑debugger. SWD and UART TX‑RX connectors are also

available.

DB4378 - Rev 1

page 2/22

1 Safety and operating instructions

1.1 General terms

Warning:

During assembly, testing, and operation, the evaluation board poses several inherent hazards,

including bare wires, moving or rotating parts and hot surfaces.

EVSPIN32F06Q2S1

Safety and operating instructions

Danger:

There is danger of serious personal injury, property damage or death due to electrical shock and

burn hazards if the kit or components are improperly used or installed incorrectly.

The kit is not electrically isolated from the high-voltage supply AC/DC input. The evaluation board is

directly linked to the mains voltage. No insulation is ensured between the accessible parts and the high

voltage. All measuring equipment must be isolated from the mains before powering the board. When

using an oscilloscope with the demo, it must be isolated from the AC line. This prevents shock from

occurring as a result of touching any single point in the circuit, but does NOT prevent shock when

touching two or more points in the circuit.

All operations involving transportation, installation and use, and maintenance must be performed by skilled

technical personnel able to understand and implement national accident prevention regulations. For the purposes

of these basic safety instructions, “skilled technical personnel” are suitably qualified people who are familiar with

the installation, use and maintenance of power electronic systems.

1.2 Intended use of evaluation board

The evaluation board is designed for demonstration purposes only, and must not be used for electrical

installations or machinery. Technical data and information concerning the power supply conditions are detailed

in the documentation and should be strictly observed.

1.3 Installing the evaluation board

• The installation and cooling of the evaluation board must be in accordance with the specifications and target

application.

• The motor drive converters must be protected against excessive strain. In particular, components should not

be bent or isolating distances altered during transportation or handling.

• No contact must be made with other electronic components and contacts.

• The board contains electrostatically-sensitive components that are prone to damage if used incorrectly. Do

not mechanically damage or destroy the electrical components (potential health risks).

DB4378 - Rev 1

page 3/22

1.4 Operating the evaluation board

To operate properly the board, follow these safety rules.

1. Work Area Safety:

– The work area must be clean and tidy.

– Do not work alone when boards are energized.

– Protect against inadvertent access to the area where the board is energized using suitable barriers and

signs.

– A system architecture that supplies power to the evaluation board must be equipped with additional

control and protective devices in accordance with the applicable safety requirements (i.e., compliance

with technical equipment and accident prevention rules).

– Use non-conductive and stable work surface.

– Use adequately insulated clamps and wires to attach measurement probes and instruments.

2. Electrical Safety:

– Remove power supply from the board and electrical loads before performing any electrical

measurement.

– Proceed with the arrangement of measurement setup, wiring or configuration paying attention to high

voltage sections.

– Once the setup is complete, energize the board.

EVSPIN32F06Q2S1

Operating the evaluation board

Danger:

Do not touch the evaluation board when it is energized or immediately after it has been

disconnected from the voltage supply as several parts and power terminals containing potentially

energized capacitors need time to discharge.

Do not touch the boards after disconnection from the voltage supply as several parts like heat

sinks and transformers may still be very hot.

The kit is not electrically isolated from the AC/DC input. The USB interface of the board does not

insulate host computer from high voltage. When the board is supplied at a voltage outside the ELV

range, a proper insulation method such as a USB isolator must be used to operate the board.

3. Personal Safety

– Always wear suitable personal protective equipment such as, for example, insulating gloves and safety

glasses.

– Take adequate precautions and install the board in such a way to prevent accidental touch. Use

protective shields such as, for example, insulating box with interlocks if necessary.

DB4378 - Rev 1

page 4/22

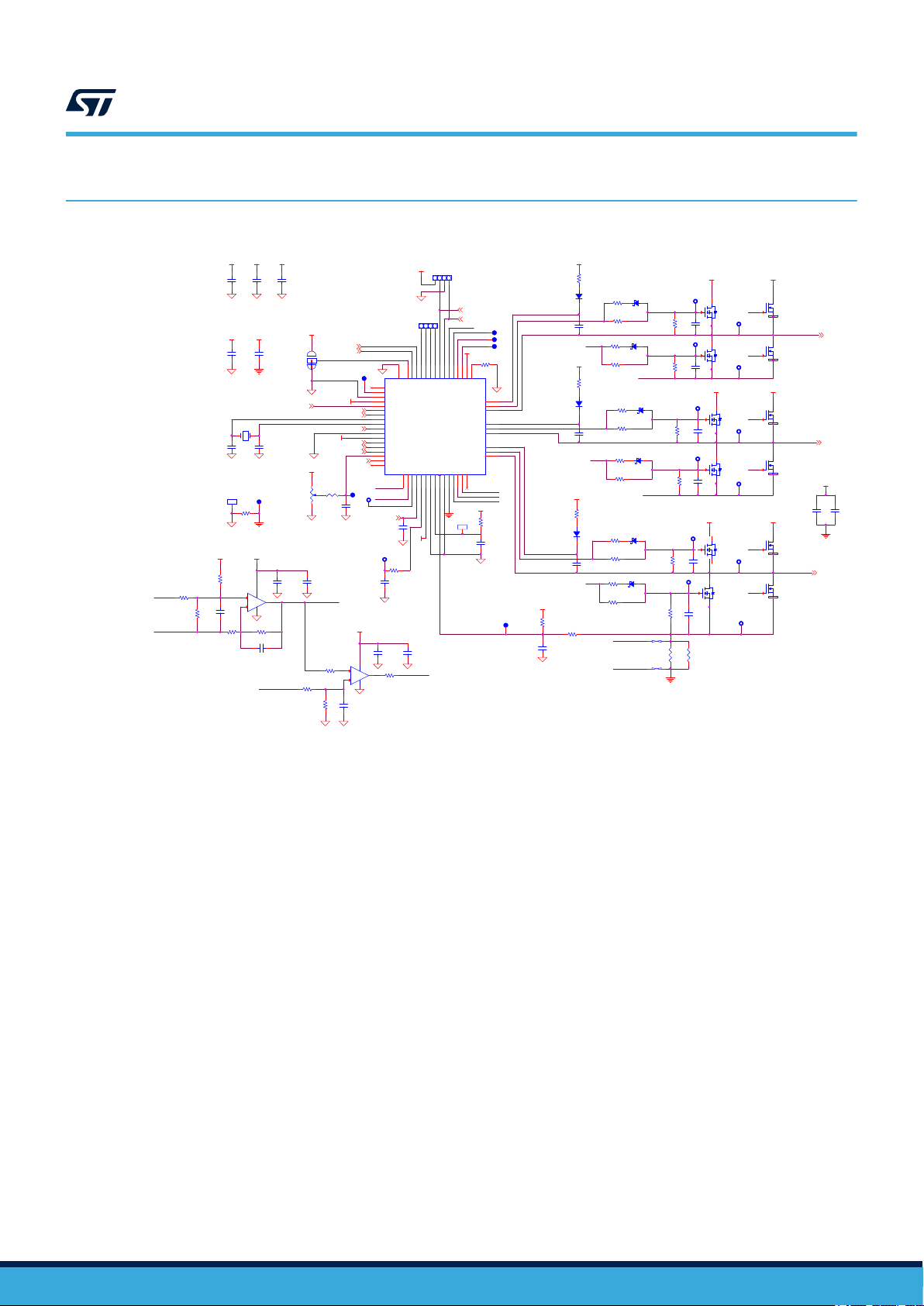

2 Schematic diagrams

SPEED

OD

ZCR

SPI1_NSS/PROC

SPI1_MOSI/GPIO

SPI1_MISO/GPIO

SPI1_CLK/COMM

Boot from:

CLOSED 2-3 Flash

OUT3

OUT2

OUT1

GND

CLOSED 1-2 System/SRAM

PGND

CIN

VDD

VCC

VCC

VDD

VDD

VDDVDD

VDD

VDD

VDD

VCC

VCC

VCC

HV

HV

HV

HV

VDD VDD VDD

VCCVCC

VDD

HV

HV

HV

VDD

UART1_TX

UART1_RX

SWD_C LK

SWD_IO

GPIO_BE MF

PA0

PA1

PA2

PC14

PC15

NRST

OUT1

OUT2

OUT3

Temp_fdbk

VBUS_fdbk

R59 0R

R56

22R

C8

N.M.

Q6A

N.M.

1

2 3 4

5

TP20

TP4

TP8

Q9A

N.M.

1

2 3 4

5

TP19

1 2

TP5

U1

72

BOOT0

STSP IN32F0 602Q

BOOT1

40

47

BOOT2

53

BOOT3

CIN

27

EXP

EPAD

GND

28

HVG1

39

HVG2

46

HVG3

52

LVG1

30

LVG2

31

LVG3

32

NRST

10

OD

26

OUT1

38

OUT2

45

OUT3

51

PA0

13

PA1

14

PA12

63

PA1364PA14

65

PA15

66

PA2

15

PA3

16

PA4

17

PA5

19

PA620PA7

21

PB0

22

PB1

23

PB3

67

PB468PB569PB6

70

PB7

71

PB8

2

5

PC1 3

6

PC1 4

7

PC1 5

8

PF0

9

PF1

PGND

29

RES 1

60

RES 2

61

RES 3

62

RES 4

33

RES 5

VCC

58

1

RES 6

RES 7

18

59

4

VDD

VDD

24

VDDA

12

3

VSS

VSS

25

VSSA

11

C26

1uF/50 V

C13

N.M.

R49

4R7

TP14

C24

4.7uF/1 0V

R15

27R

TP16

TP18

C69

100nF /25V

D7

BAT54J

TP25

D4

BAT54J

D2

BAT54J

V+

+

V-

U3

TS302 1ILT

R13

22R

Q4

3

1

STD18 N65M5

2

TP17

C19

1

100nF /25V

2

C33

N.M.

R10

4R7

R16

4R7

J1

123

4

R57

100k

R58 0R

R42

22R

V-

V+

+

-

U2

TSV911 ILT

TP10

R52 10k

C9

33nF/6 30V

R27

4R7

R39

N.M.

R26

0R

TP6

Q6

3

1

STD18 N65M5

2

C30

100nF /25V

C16

4.7nF/2 5V

R14

100k

R2

4R7

D11

N.M.

D13

BAT54J

C31

4.7uF/1 0V

C23

100nF /25V

R111

N.M.

D6

N.M.

R36

0R1-2W-1 %

R18

22R

C10

10pF/5 0V

R1

27R

R23

100k

13

2

R29

0R

C27

33pF/2 5V

C4

N.M.

Q1A

N.M.

1

2 3 4

5

C18

47nF/2 5V

R44

100k

C11

10pF/5 0V

R35

27R

J9

123

4

Q4A

N.M.

1

2 3 4

5

R5

100k

C7

N.M.

R3

22R

C12

1uF/50 V

R55

3k

R32

47k

D9

BAT54J

X1

8MHz

R38 1k

TP23

R33

63.4k

JP1

1

3

CLOSED 2-3

2

Q9

3

1

STD18 N65M5

2

R60 33k

TP7

C1

100nF /25V

C3

1uF/50 V

0R

R109

C32 N.M.

C17

N.M.

C35

100nF /25V

C21

100nF /25V

Q3

3

1

STD18 N65M5

2

C2

220nF /25V

TP11

C22

1nF/25 V

TP22

Q7A

N.M.

1

2 3 4

5

D12

BAT54J

R30

22R

Q3A

N.M.

1

2 3 4

5

D1

N.M.

Q7

3

1

STD18 N65M5

2

TP1

Q1

3

1

STD18 N65M5

2

R31

100k

R61

10M

TP24

TP21

TP12

TP2

C67

47nF/2 5V

R19

100k

TP13

C20

100nF /25V

R34

0R1-2W-1 %

R40

4R7

R113

33k

R41

3k

TP3

C25

N.M.

CPOUT

CURRE NT_REF

SENS E_P

CURRE NT_REF

CPOUT

SENS E

LVG3

GH3

GL3

GH2

GL2

GL1

LVG1

GH1

LVG2

Curr_fdbk

LVG3

LVG2

LVG1

SENS E

SENS E

GH1

GL1

GH2

GL2

GH3

GL3

CIN

Curr_fdbk

SENS E_P

SENS E_N

SENS E_N

Figure 1. EVSPIN32F06Q2S1 schematic – Driver output stages

EVSPIN32F06Q2S1

Schematic diagrams

DB4378 - Rev 1

Figure 2. EVSPIN32F06Q2S1 schematic – Feedback network

page 5/22

RESET

USER1

USER2

10k

BEMF2

BEMF1

BEMF3 HALL

VDD

HALL PWR

Z+/H3

GND

A+/H1

B+/H2

5V

VDD

VCC

VDD

VDD

VDD

HV

VDD

VDD

VDD

VDD

VDD VDD

VDD VDD

VDD VDD

+5V

VCC

VCC

+5V

VDD

NRST

OUT3

OUT2

OUT1

PA0

PA1

PA2

VBUS_fdbk

Temp_fdbk

PC1 4

PC1 5

GPIO_BE MF

GPIO_BE MF

GPIO_BE MF

D8

STTH1L06 A

R51

2.7k

C68

4.7uF /50V

C36

1nF/25 V

J3

1

2

3

4

5

D5

BAT54J

R53

10k

R43

1M

Q2

2

1

3

R66

BC817 -25 or E quivalent

100R

R74

N.M.

C28

N.M.

R22

0R

C15

4.7pF/5 0V

R25

2.7k

JP 4

1 3

CLOSE D 1-2

2

C43

100n F/25V

R72

1

N.M.

2

SW3

13

4

4304 83025 816

2

R20

180k

R28

10k

R80

1k

SW1

13

4

4304 83025 816

2

D3

STTH1L06 A

R24

1k

R68 1.8k

R8

0R

R81

4.7k

Q8

2

1

3

R77

BC817 -25 or E quivalent

120R

R21

180k

C14

N.M.

D19

BAT54J

C39

10pF/1 0V

R17

1M

D18

BAT54J

C41

100n F/25V

C6

4.7pF/5 0V

SW2

13

4

4304 83025 816

2

C40

N.M.

1

JP 11

3

24

R54

100R

D10

BAT54J

R76

N.M.

R70 1.8k

R12

10k

JP 5

1 3

CLOSE D 1-2

2

D15

BAT54J

C38

10pF/1 0V

JP 6

CLOSE D

JP 10

OPE N

JP 3

1 3

2

CLOSE D 1-2

C5

N.M.

Q11

1

2

3STF 1640

3

D14

STTH1L06 A

LD2

YELLOW

R75

N.M.

Q5

2

1

3

R11

BC817 -25 or E quivalent

2.7k

JP 2

OPE N

R78

6.49k

R64

10k

D26

DDZ9690 T

R62

120R

R46

180k

R69

470k

R67

470k

R50

1k

R7

180k

C42

1nF/25 V

R63

10k

D17

BAT54J

R45

180k

R65

10k

R71 1.8k

R112

8k2

R47

0R

R73 0R

D16

BAT54J

R9

1k

R48

39k

R79

100R

R4

1M

C29

4.7pF/5 0V

LD1

YELLOW

R6

180k

C34

3.3NF/2 5V

C37

10pF/1 0V

PA0_BE MF PA0_Ha ll

PA1_BE MF PA1_Ha ll

PA2_BE MF PA2_Ha ll

Z+/H3_C

B+/H2_C

A+/H1_C

PA1_Ha ll

PA2_Ha ll

PA0_Ha ll

PA2_BE MF

PA1_BE MF

PA0_BE MF

EVSPIN32F06Q2S1

Schematic diagrams

DB4378 - Rev 1

page 6/22

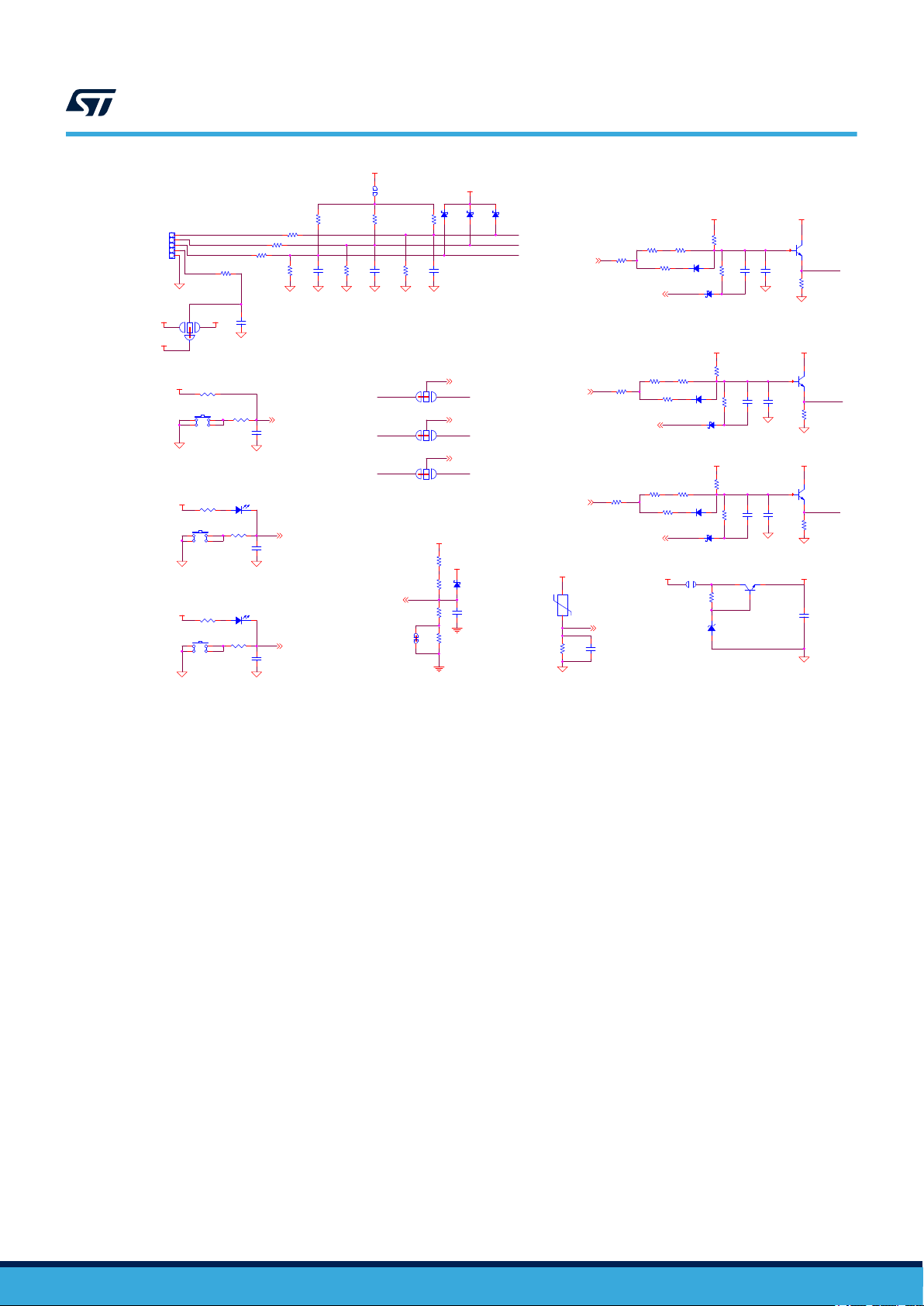

Figure 3. EVSPIN32F06Q2S1 schematic – Power Supply

AC MAINS ~

Vcc_F

VCC

VDD

E3V3

GND

3V3_STLINK

OUT3

OUT2

OUT1

E3V3

HV

Vcc_F

HV

Vcc_F VCC

VDDE3V3

3V3_S TLINK

VDD

OUT1

OUT2

OUT3

R88

1.5k

1/4W

D21

3V3 N.M.

R82

330R

R110

220K 1/3 W

R83 0 R

-+

D20

2

GBU805

3

4 1

R85

10R

D24

BAT54J

C52

680n F/10V

R89

10k

J2

1

2

3

D25

12

STTH1L06 A

C51

820p F/25V

R87

22k

U4

2

Vout

LD1117S 33CTR

1

GND

3

Vin

J4

1

2

R86

22k

RV1

N.M.

+

C46

470u F/10V

+

C49

47uF /25V

U5

F1 10A/277 V slow

FB

4

VIPER0 6XS

3

LIM

8

DRAIN

1

GND

2

VDD

5

COMP

7

DRAIN6DRAIN

10

DRAIN9DRAIN

D23

12

STP S11 50A

LD3

RED

JP 7

1

2

3

CLOSE D 1-2

C47

100n F/25V

C44A

N.M.

C44

150u F/420V

C48

10uF /10V

LD4

GRE EN

+

C50

10uF /35V

NTC1

2R2

1 2

F1A N. M.

T1

3

4

2

1

5

8

C66

220p F/630V

R84

36k

+

C45

22uF /25V

D22

12

STP S05 60Z

JP 8

1

2

CLOSE D 1-2

3

EVSPIN32F06Q2S1

Schematic diagrams

DB4378 - Rev 1

page 7/22

TXRX

D-

D+

3V3_S TLINK

STRIP 1x4

STLINK FW LOAD

VDD

3V3_S TLINK

3V3_S TLINK

3V3_S TLINK

VUSB

3V3_S TLINK

VUSB

VUSB

VDD

3V3_S TLINK

UART1_TX

UART1_RX

SWD_IO

SWD_C LK

NRST

R102

100R

R107

100R

R94

4.7k

R108

100R

J5

6510 051612 1

1

USB_VCC

2

USBDM

3

USBDP

5

USB_GND

6

SHELL

7

SHELL

8

SHELL

ID

4

9

SHELL

C59

10pF /50V

R101 0R

C61

100n F/50V

R97 0R

R98

4.7k

C57

10nF /25V

R99 0R

U7

2

GND

LD3985M33R

OUT

5

1

VIN

4

BYPASS

3

INHIBIT

C62

100n F/25V

R104

N.M.

C53

100n F/25V

TP15

J8

1

CLOSE D

2

Q10

1

BC847 B

2 3

R100

4.7k

1

U6 USBLC6-2 SC6

I/O1#1

GND

2

5

VBUS

4

I/O2#4

6

I/O1#6

3

I/O2#3

J6

1

2

STRIP 1x2

R96

2.7k

C55

100n F/25V

JP 9

1

OP EN

2

C63

100n F/25V

R92

1.5k

C56

100n F/25V

X2

8MHz

C65

100n F/25V

R106

100k

R91

100R

C60

10pF /50V

J7

1

2

3

4

U8

PB7

43

STM32F 103CBT6

PB6

42

PB5

41

40

PB4/J NTRST

39

PB3/J TDO

10

PA0-WKUP

PA1

11

PA2

12

PA3

13

PA4

14

PA5

15

PA6

16

PA7

17

PA8

29

PA9

30

PA10

31

PA11

32

PA12

33

PA13

34

PB0

18

PB1

19

20

PB2/BO OT1

PB8

45

PB9

46

PB10

21

PB11

22

PB12

25

PB13

26

PB14

27

PB15

28

2

PC1 3-TAMPER -RTC

3

PC1 4-OSC3 2_IN

4

VSS_ 1

23

PC1 5-OSC3 2_OUT

5

OSC IN/PD0

7

NRST

6

OSC OUT/PD1

8

VSSA

35

VSS_ 2

47

VSS_ 3

1

VBAT

PA14

37

PA15

38

24

VDD_1

BOOT0

44

VDD_3

48

36

VDD_2

9

VDDA

C58

1uF/1 0V

R105

100k

C54

1uF/1 0V

R93

36k

LD5

K1

RED-GR EEN

A1

K2 A2

R103 1 0k

R90

10k

R95 0R

C64

100n F/25V

USB_DP

USB_DM

USB_R ENUM

SWDIO

STLINK_TX

STLINK_RX

T_NRS T

LED_STLINK

LED_STLINK

USB_DM USB_R ENUM

USB_DP

FM_SW CLK

FM_SW DIO

T_JTC K

T_JTC K

T_JTC K

T_JTMS

T_JTMS

T_NRS T

EVSPIN32F06Q2S1

Figure 4. EVSPIN32F06Q2S1 schematic – STLINK debugger

Schematic diagrams

DB4378 - Rev 1

page 8/22

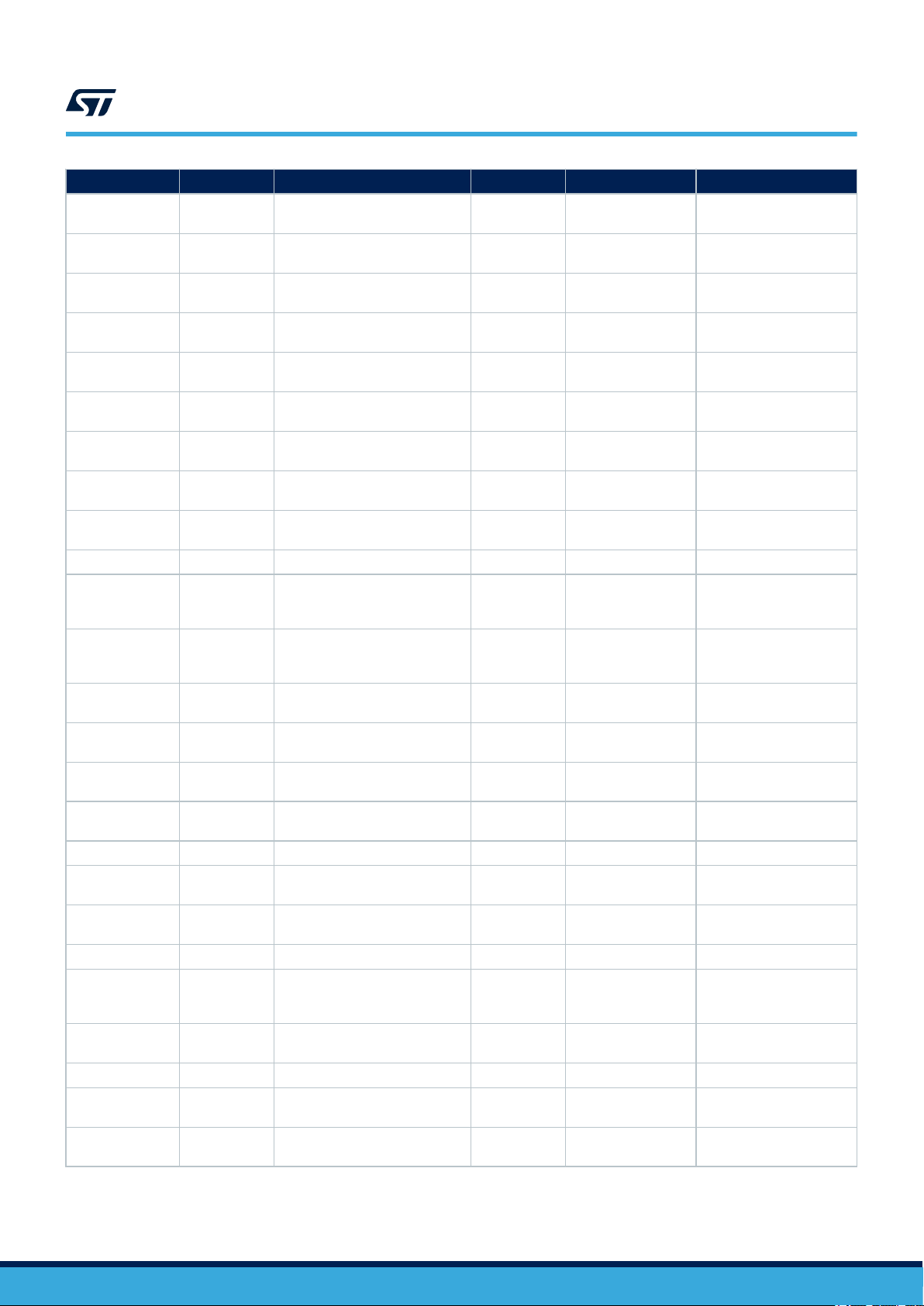

EVSPIN32F06Q2S1

Bill of materials

3 Bill of materials

Table 1. EVSPIN32F06Q2S1 Bill of Materials

Components common to all device variants

Reference Part Value Description Package Manufacturer Part Number

C1, C19, C20,

C21, C23, C30,

C35, C41, C43,

C47, C53, C55,

C56, C62, C63,

C64, C65, C69

C2 220nF/25V SMT Ceramic Capacitor Size 0603

C3, C12, C26 1uF/50V SMT Ceramic Capacitor Size 0805

C4, C5, C7, C13,

C14, C17, C25,

C28, C32, C33,

C40

C6, C15, C29 4.7pF/50V SMT Ceramic Capacitor Size 0603

C8 N.M. Film, Metallized Polypropylene

C9 33nF/630V SMT Ceramic Capacitor Size 1210

C10, C11, C59,

C60

C16 4.7nF/25V SMT Ceramic Capacitor Size 0603

C18, C67 47nF/25V SMT Ceramic Capacitor Size 0603

C22, C36, C42 1nF/25V SMT Ceramic Capacitor Size 0603

C24, C31 4.7uF/10V SMT Ceramic Capacitor Size 0805

C27 33pF/25V SMT Ceramic Capacitor Size 0603

C34 3.3NF/25V SMT Ceramic Capacitor Size 0603

C37, C38, C39 10pF/10V SMT Ceramic Capacitor Size 0603

C44A N.M.

C44 150uF/420V

C45 22uF/25V SMD Aluminum Elect. Capacitor 5x5.4 mm

C46 470uF/10V SMD Aluminum Elect. Capacitor 6.3x7.7 mm Panasonic EEEFTA471XAP

C48 10uF/10V SMT Ceramic Capacitor Size 1206

C49 47uF/25V SMD Aluminum Elect. Capacitor 6.3x5.8 mm

100nF/25V SMT Ceramic Capacitor Size 0603

N.M. SMT Ceramic Capacitor Size 0603

4x13 mm,

Pitch 10 mm

10pF/50V SMT Ceramic Capacitor Size 0603

THT Electrolytic Capacitor, Radial

p7.5 d18h25

THT Electrolytic Capacitor, Radial

p10 d22h27 105C

Radial p7.5

d18h25 mm

Radial p10

d22h27.5 mm

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

KEMET R71MF31004030K

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

Rubycon 450BXW68MEFC18X25

United Chemi-Con EKMZ421VSN151MP25S

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

885012206071

885012206073

885012207103

885012006049

885342209004

885012006051

885012206063

885012206069

885012206059

885012207025

885012006035

885012206062

885012006002

865090442004

885012208018

865060443004

DB4378 - Rev 1

page 9/22

EVSPIN32F06Q2S1

Bill of materials

Reference Part Value Description Package Manufacturer Part Number

C50 10uF/35V SMD Aluminum Elect. Capacitor 5x5.4 mm

C51 820pF/25V SMT Ceramic Capacitor Size 0603

C52 680nF/10V SMT Ceramic Capacitor Size 0603

C54, C58 1uF/10V SMT Ceramic Capacitor Size 0603

C57 10nF/25V SMT Ceramic Capacitor Size 0603

C61 100nF/50V SMT Ceramic Capacitor Size 0603

C66 220pF/630V SMT Ceramic Capacitor Size 1206 Multicomp MC1206N221J631CT

C68 4.7uF/50V SMT Ceramic Capacitor Size 1206

D1, D6, D11 N.M.

D2, D4, D5, D7,

D9, D10, D12,

D13, D15, D16,

D17, D18, D19,

D24

D3, D8, D14, D25 STTH1L06A

D20 GBU805

D21 N.M. ZENER 3V3 SOD-123

D22 STPS0560Z 60V, 0.5A Schottky rectifier SOD-123 STMicroelectronics STPS0560Z

D23 STPS1150A 150V, 1A Power Schottky rectifier SMA STMicroelectronics STPS1150A

D26 DDZ9690T

F1A N.M.

F1 10A/277V slow

JP1 CLOSED 2-3 SMT Jumper Soldering pad

JP2, JP10 OPEN SMT Jumper Soldering pad

JP3, JP4, JP5 CLOSED 1-2 SMT Jumper Soldering pad

JP6 CLOSED SMT Jumper Soldering pad

JP7, JP8 CLOSED 1-2 Strip connector 3 pos, 2.54 mm 1x3 pins

JP9 OPEN SMT Jumper Soldering pad

JP11 CLOSED 2-4 SMT Jumper Soldering pad

J1, J7, J9 STRIP 1x4 Strip connector 4 pos, 2.54 mm 1x4 pins

J2

J3 STRIP 1x5 Strip connector 5 pos, 2.54 mm 1x5 pins

BAT54J

MORSV-508-3

P_screw

Turbo 2 Ultrafast High-Voltage

Rectifier

40V, 300mA Small signal

Schottky SMT Diode

Turbo 2 Ultrafast High-Voltage

Rectifier

8A Glass Passivated SinglePhase Bridge Rectifier

SURFACE MOUNT ZENER

DIODE

Time Lag radial lead Micro Fuse,

250Vac

Suface Mount Fuse, Time-Lag T,

250Vac125Vdc

Connector terminal block T.H. 3

positions 5.08 mm

SMA STMicroelectronics STTH1L06A

SOD-323 STMicroelectronics BAT54JFILM

SMA STMicroelectronics STTH1L06A

GBU

SOD523 DIODES Incorporated DDZ9690T-7

RST-BELFUSE belfuse 0697-xx

UMT250-

SHURTER

3 poles, Pitch

5.08

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

Taiwan

Semiconductor or

Diodes Incorporated

Schurter 3403.0176.24

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

865230542002

885012206025

885012206026

885012206065

885012206095

885012208094

GBU805 or GBU806

61300311121

61300411121

691213510003

61300511121

DB4378 - Rev 1

page 10/22

EVSPIN32F06Q2S1

Reference Part Value Description Package Manufacturer Part Number

J4

J5 65100516121 MINI USB 2.0 TYPE B SMD USB MINI B

J6 STRIP 1x2 Strip connector 2 pos, 2.54 mm 1x2 pins

J8 CLOSED Strip connector 2 pos, 2.54 mm 1x2 pins

LD1, LD2 YELLOW Yellow LED Size 0603

LD3 RED Red LED Size 0603

LD4 GREEN Green Led Size 0805

LD5 RED-GREEN

NTC1 2R2

Net1, Net2 N.M.

Q1, Q3, Q4, Q6,

Q7, Q9

Q1A, Q3A, Q4A,

Q6A, Q7A, Q9A

Q2, Q5, Q8 BC817-25

Q10 BC847B

Q11 3STF1640

RV1 N.M. Varistor

R1, R15, R35 27R SMT resistor Size 0805

R2, R10, R16,

R27, R40, R49

R3, R13, R18,

R30, R42, R56

R4, R17, R43 1M SMT Resistor Size 0603

R5, R14, R19,

R31, R44, R57,

R105, R106

R6, R7, R20, R21,

R45, R46

R8, R22, R47 0R SMT Resistor Size 0805

R9, R24, R50,

R80

R11, R25, R51,

R96

MORSV-508-2

P_screw

STD18N65M5

N.M.

4R7 SMT Resistor Size 0805

22R SMT Resistor Size 0805

100k SMT Resistor Size 0603

180k SMT Resistor Size 1206

1k SMT Resistor Size 0805

2.7k SMT Resistor Size 0603

Connector terminal block T.H. 2

positions 5.08 mm

LED indicators, PLCC-4 Red /

Yellow Green

NTC Thermistor for Inrush current

limiting

N-channel 650 V, 0.198 O typ.,

15 A, MDmesh™ M5 Power

MOSFETs

N-channel 600 V, 0.195 Ohm

typ., 15 A MDmesh DM2 Power

MOSFET

45V NPN SMALL SIGNAL

TRANSISTOR

GENERAL

PURPOSE_45V_100mA_225mW

Low voltage high performance

NPN power transistor

2 poles, Pitch

5.08

PLCC 4 AVAGO HSMF-A201-A00J1

DPAK STMicroelectronics STD18N65M5

PowerFLAT

8x8

SOT23 BC817-25

SOT23

SOT-89 STMicroelectronics 3STF1640

Pitch 2.3x7.5

mm

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

WURTH

ELEKTRONIK

TDK B57236S0229M000

STMicroelectronics STL24N60DM2

ON

SEMICONDUCTOR

691213510002

65100516121

61300211121

61300211121

150060YS75000

150060RS75000

150080GS75000

BC847BL

Bill of materials

DB4378 - Rev 1

page 11/22

EVSPIN32F06Q2S1

Bill of materials

Reference Part Value Description Package Manufacturer Part Number

R12, R28, R52,

R53, R63, R64,

R65, R89, R90,

R103

R23 100k

R26, R29, R58,

R59, R73, R95,

R97, R99, R101

R32 47k SMT Resistor Size 0603

R33 63.4k SMT Resistor Size 0603

R34, R36 0R1-2W-1% SMT Resistor Size 2512

R38 1k SMT Resistor Size 0603

R39, R74, R75,

R76, R104, R111

R41, R55 3k SMT Resistor Size 0603

R48 39k SMT Resistor Size 0603

R54, R66, R79,

R91, R102, R107,

R108

R60, R113 33k SMT Resistor Size 0603

R61 10M SMT Resistor Size 0603

R62, R77 120R SMT Resistor Size 0603

R67, R69 470k SMT Resistor Size 1206

R68, R70, R71 1.8k SMT Resistor Size 0603

R72 N.M. NTC Resistor Hole 0.8 mm

R81, R94, R98,

R100

R78 6.49k SMT Resistor Size 0805

R82 330R SMT Resistor Size 0603

R83 0R SMT Resistor Size 1206

R84, R93 36k SMT Resistor Size 0603

R85 10R SMT Resistor Size 0603

R86, R87 22k SMT Resistor Size 0603

R88 1.5k SMT Resistor Size 1206

R92 1.5k SMT Resistor Size 0603

R109 0R SMT Resistor Size 0603

R110 220K 1/3W SMT Resistor Size 0805 TE Connectivity CRGH0805J220K

R112 8k2 SMT resistor Size 0603

SW1, SW2, SW3 430483025816

TP1 N.M. (TPHIN1)

TP2 N.M. (TPHIN2)

10k SMT Resistor Size 0603

Square trimpot trimming

potentiometer

0R SMT Resistor Size 0603

N.M. SMT Resistor Size 0603

100R SMT Resistor Size 0603

4.7k SMT Resistor Size 0603

CMS TACTILE SWITCHES - 6x6

J-bend

Test Point - PCB 1mm

DIAMETER

Test Point - PCB 1mm

DIAMETER

3386P BOURNS 3386P-1-104-LF

Copper Pad TPSMD-1mm

Copper Pad TPSMD-1mm

WURTH

ELECTRONIK

430483025816

DB4378 - Rev 1

page 12/22

EVSPIN32F06Q2S1

Bill of materials

Reference Part Value Description Package Manufacturer Part Number

TP3 N.M. (TPHIN3)

TP4, TP6, TP7,

TP11, TP14,

TP17, TP18,

TP19, TP20,

TP21, TP22,

TP23, TP24, TP25

TP5 N.M. (ZCR)

TP8, TP12

TP10 N.M. (SPEED)

TP13, TP16

TP15

T1 750318434

U1

U2 TSV911ILT

U3 TS3021ILT

U4

U5 VIPER06XS Fixed-frequency VIPer plus family SSO10 STMicroelectronics VIPER06XS

U6 USBLC6-2SC6

U7 LD3985M33R

U8

X1, X2 8MHz CRYSTAL 8.0000MHZ 8PF SMD 2.5x3.2 mm NDK

J8, JP7, JP8

N.M. TP for Probe

TPTH-

ANELLO-1mm

N.M. (CIN,

PGND)

NEEDLE-

PAD-1.7mm

STSPIN32F06

02Q

LD1117S33CT

R

STM32F103C

BT6

Test Point - PCB 1mm

DIAMETER

Test Point - PCB 1mm

DIAMETER

THT Ring Test Point Keystone 5003

Test Point - PCB 1mm

DIAMETER

Test Point - PCB 1mm

DIAMETER

Test Point - PCB 1.7mm

DIAMETER

Switch mode Transformer 2.3W

60kHz 3.15mH 7-15V

600V three-phase controller with

ARM Cortex MCU

Single Rail-to-Rail input/output 8

MHz operational amplifiers

Rail-to-rail 1.8 V high-speed

comparator

800mA, 3.3V Adjustable and

Fixed low drop positive voltage

regulator

Very low capacitance ESD

protection

3.3V_150mA_ULTRA LOW

DROP VOLTAGE REGULATOR

64/182KB

FLASH_USB_72MHz_3.6V

Rubber feet Hammond 1421T6CL

Female Jumper Isolated, pitch

2.54mm

P.C.B. EVSPIN32F06Q2S1

Rev.1.0

Copper Pad TPSMD-1mm

Diam. 1.27,

Hole 0.8mm

Copper Pad TPSMD-1mm

Copper Pad TPSMD-1mm

Copper Pad TPSMD-1mm

Copper Pad NEEDLE-PAD-1.7mm

WURTH

ELECTRONIK

QFN72-10X10 STMicroelectronics STSPIN32F0602Q/TR

SOT23-5 STMicroelectronics TSV911ILT

SOT23-5 STMicroelectronics TS3021ILT

SOT-223 STMicroelectronics LD1117S33CTR

SOT23-6L STMicroelectronics USBLC6-2SC6

SOT23-5L STMicroelectronics LD3985M33R

LQFP48 - 7x7

mm

Dim. 75, 2 x

141.6 mm

STMicroelectronics STM32F103CBT6

ASSMANN WSW AKSCT/Z BLACK

STMicroelectronics

750318434

NX3225GD-8MHZ-STD-

CRA-3

DB4378 - Rev 1

page 13/22

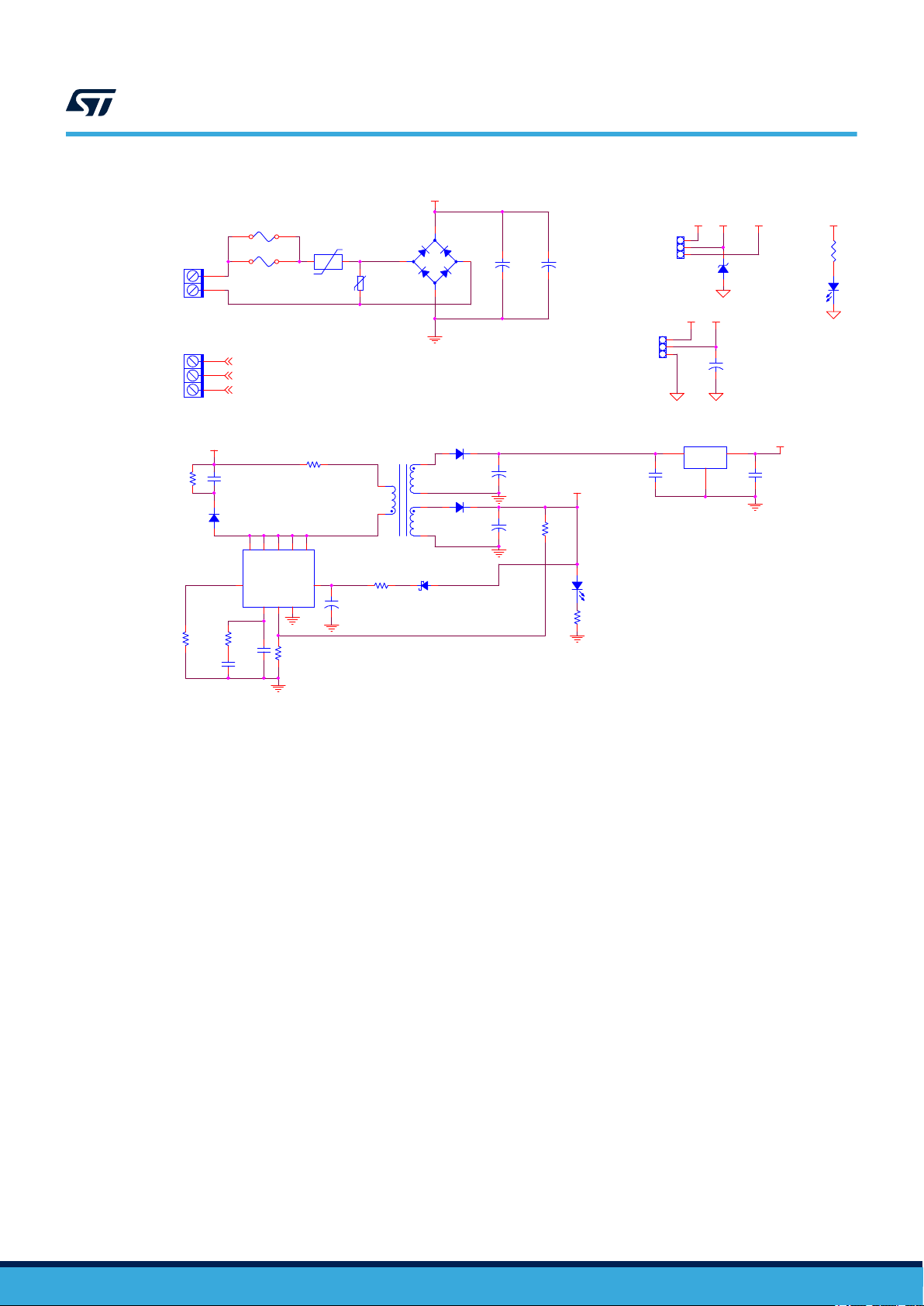

4 Layout and component placements

Figure 5. EVSPIN32F06Q2S1 - functional blocks

EVSPIN32F06Q2S1

Layout and component placements

Warning

The kit is not electrically isolated from the AC/DC input. The USB interface of the board does not insulate

host computer from high voltage. When the board is supplied at a voltage outside the ELV range, a proper

insulation method such as a USB isolator must be used to operate the board.

DB4378 - Rev 1

page 14/22

EVSPIN32F06Q2S1

Layout and component placements

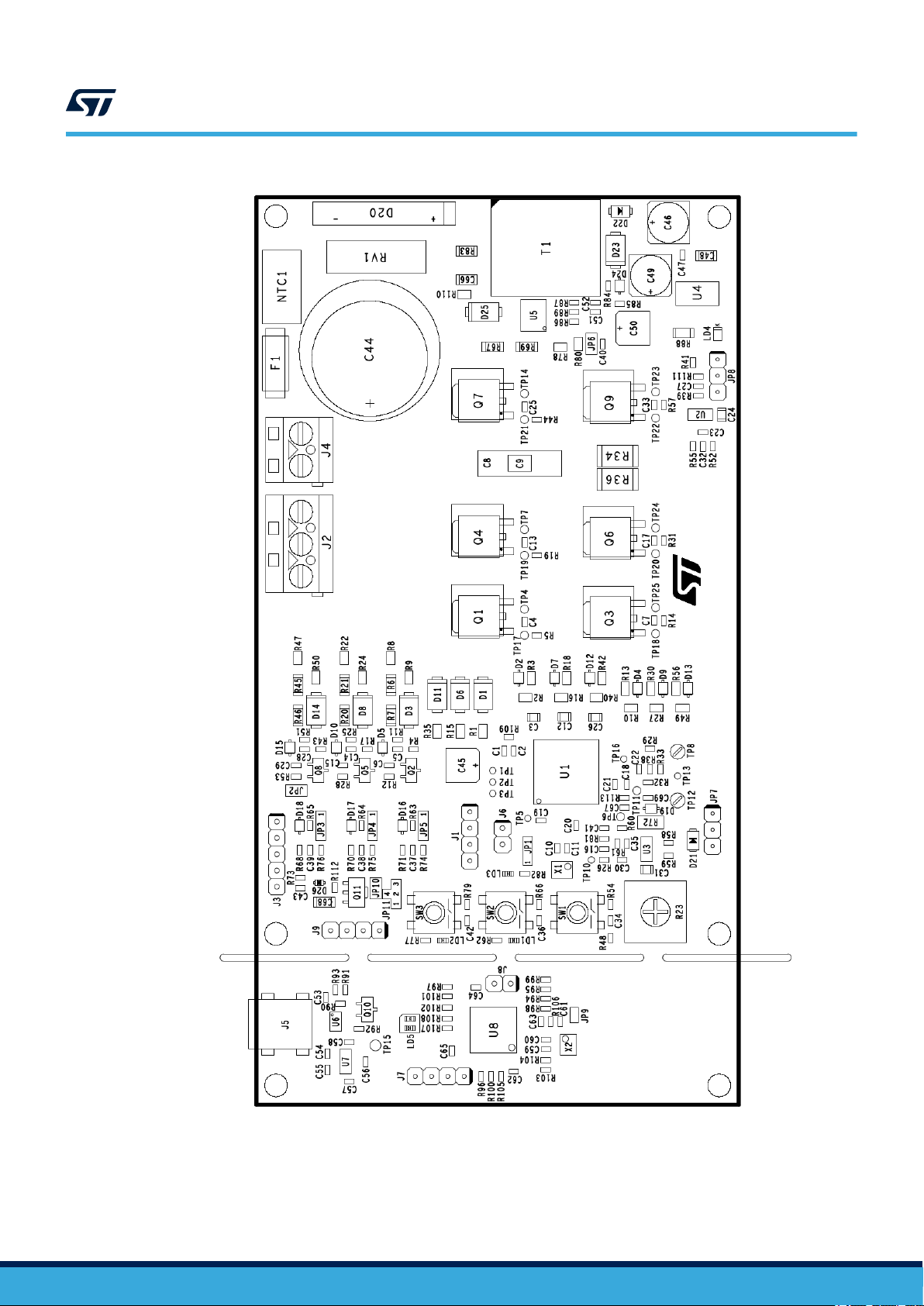

Figure 6. EVSPIN32F06Q2S1 – Layout (component placement top view)

DB4378 - Rev 1

page 15/22

Layout and component placements

Figure 7. EVSPIN32F06Q2S1 – Layout (top layer)

EVSPIN32F06Q2S1

DB4378 - Rev 1

page 16/22

Layout and component placements

Figure 8. EVSPIN32F06Q2S1 – Layout (bottom layer)

EVSPIN32F06Q2S1

DB4378 - Rev 1

page 17/22

Revision history

EVSPIN32F06Q2S1

Table 2. Document revision history

Date Version Changes

21-Jan-2021 1 Initial release.

DB4378 - Rev 1

page 18/22

EVSPIN32F06Q2S1

Contents

Contents

1 Safety and operating instructions ..................................................3

1.1 General terms .................................................................3

1.2 Intended use of evaluation board .................................................3

1.3 Installing the evaluation board....................................................3

1.4 Operating the evaluation board ...................................................4

2 Schematic diagrams ...............................................................5

3 Bill of materials ....................................................................9

4 Layout and component placements ...............................................14

Revision history .......................................................................18

Contents ..............................................................................19

List of tables ..........................................................................20

List of figures..........................................................................21

DB4378 - Rev 1

page 19/22

EVSPIN32F06Q2S1

List of tables

List of tables

Table 1. EVSPIN32F06Q2S1 Bill of Materials ......................................................9

Table 2. Document revision history ............................................................. 18

DB4378 - Rev 1

page 20/22

EVSPIN32F06Q2S1

List of figures

List of figures

Figure 1. EVSPIN32F06Q2S1 schematic – Driver output stages.........................................5

Figure 2. EVSPIN32F06Q2S1 schematic – Feedback network ..........................................5

Figure 3. EVSPIN32F06Q2S1 schematic – Power Supply .............................................7

Figure 4. EVSPIN32F06Q2S1 schematic – STLINK debugger ..........................................8

Figure 5. EVSPIN32F06Q2S1 - functional blocks .................................................. 14

Figure 6. EVSPIN32F06Q2S1 – Layout (component placement top view) ................................. 15

Figure 7. EVSPIN32F06Q2S1 – Layout (top layer) ................................................. 16

Figure 8. EVSPIN32F06Q2S1 – Layout (bottom layer) .............................................. 17

DB4378 - Rev 1

page 21/22

EVSPIN32F06Q2S1

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST

products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST

products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of

Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. For additional information about ST trademarks, please refer to www.st.com/trademarks. All other product or service

names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2021 STMicroelectronics – All rights reserved

DB4378 - Rev 1

page 22/22

Loading...

Loading...