Page 1

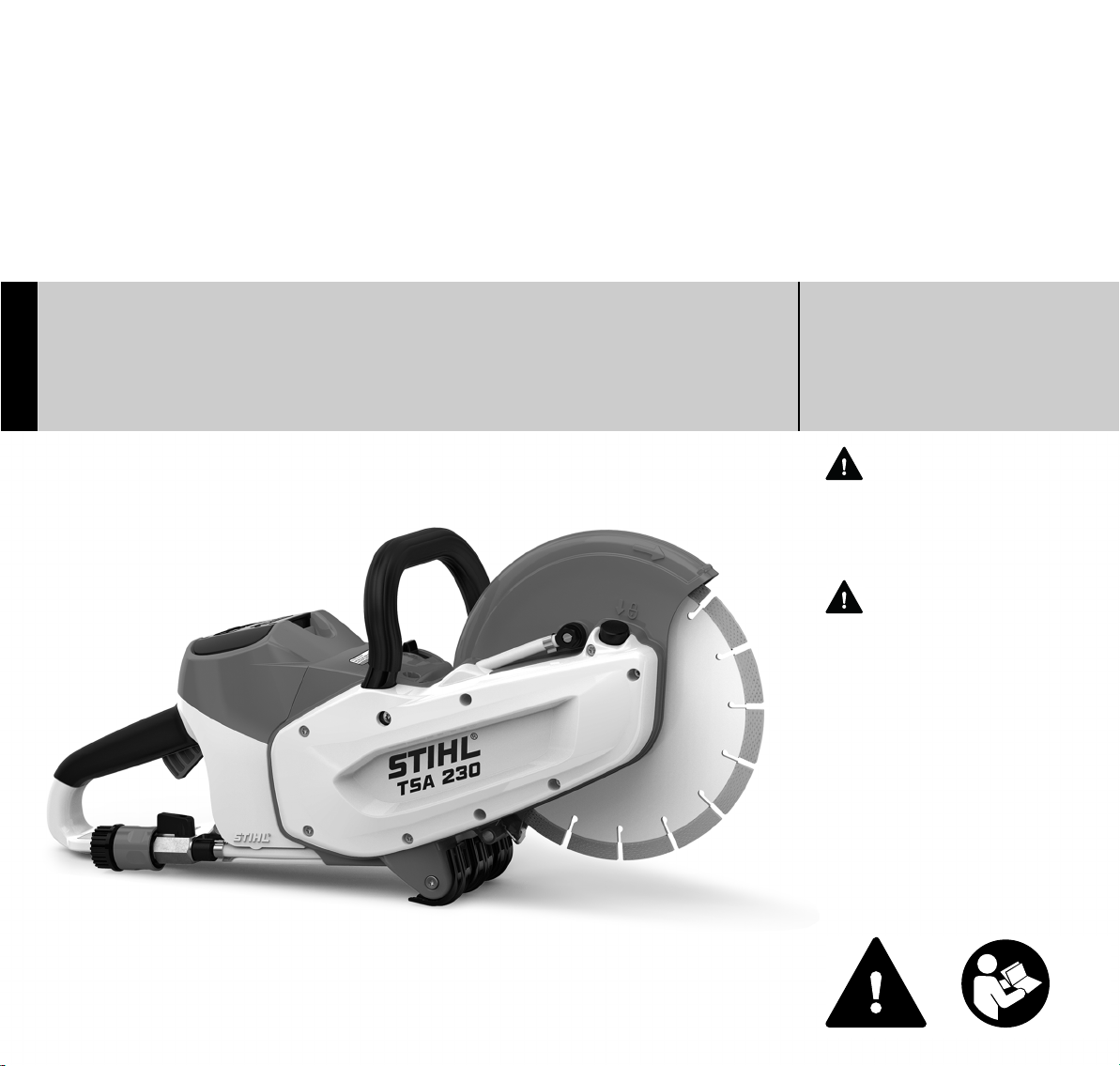

STIHL TSA 230

WARNING

Read Instruction Manual thoroughly

before use and follow all safety

precautions – improper use can

cause serious or fatal injury.

ADVERTENCIA

Antes de usar la máquina lea y siga

todas las precauciones de

seguridad dadas en el manual de

instrucciones – el uso incorrecto

puede causar lesiones graves o

mortales.

{

Instruction Manual

Manual de instrucciones

Page 2

Instruction Manual

1 - 44

Manual de instrucciones

45 - 92

Page 3

Contents

English

Guide to Using this Manual 2

Safety Precautions and Working

Techniques 2

General Power Tool Safety

Warnings 16

Sample applications 20

Cutting wheels 24

Composite resin cutting wheels 24

Diamond cutting wheels 25

Original Instruction ManualPrinted on chlorine-free paper

Fitting / replacing an abrasive

wheel 28

Connecting Charger to Power

Supply 29

Charging the Battery 29

LEDs on Battery 30

LED on Charger 32

Connecting the water supply 32

Switching On 33

Switching Off 33

Storing the Machine 34

Maintenance and Care 35

Main Parts 36

Printing inks contain vegetable oils, paper can be recycled.

Specifications 37

Troubleshooting 40

Maintenance and Repairs 42

Battery Recycling 42

Disposal 42

Trademarks 43

Addresses 44

Allow only persons who fully understand

this manual to operate your cut-off

machine.

To receive maximum performance and

satisfaction from your STIHL Cutquik

cut-off machine, it is important that you

read, understand and follow the safety

precautions and the operating and

maintenance instructions in the chapter

"Safety Precautions and Working

Techniques" before using your cut-off

machine. For further information you can

go to www.stihlusa.com

Contact your STIHL dealer or the STIHL

distributor for your area if you do not

understand any of the instructions in this

manual.

WARNING

Because a cut-off machine is a highspeed cutting tool, some special safety

precautions must be observed to reduce

the risk of personal injury. Careless or

improper use may cause serious or even

fatal injury.

{

© ANDREAS STIHL AG & Co. KG, 2014

0458-707-8621-A. VA8.L14.

0000006714_003_GB

TSA 230

This instruction manual is protected by copyright. All rights reserved, especially the rights to reproduce, translate and process

with electronic systems.

1

Page 4

English

Guide to Using this Manual Safety Precautions and

This Instruction Manual refers to a

STIHL battery-powered cut-off machine,

also called the power tool or machine in

this Instruction Manual.

Pictograms

All the pictograms attached to or

embossed on the machine are shown

and explained in this manual.

Symbols in Text

Many operating and safety instructions

are supported by illustrations.

The individual steps or procedures

described in the manual may be marked

in different ways:

N A bullet marks a step or procedure.

A description of a step or procedure that

refers directly to an illustration may

contain item numbers that appear in the

illustration. Example:

N Loosen the screw (1).

N Lever (2) ...

In addition to the operating instructions,

this manual may contain paragraphs

that require your special attention. Such

paragraphs are marked with the

following symbols and signal words:

DANGER

Indicates an imminent risk of severe or

fatal injury.

WARNING

Indicates a hazardous situation which, if

not avoided, could result in severe or

fatal injury.

NOTICE

Indicates a risk of property damage,

including damage to the machine or its

individual components.

Engineering Improvements

STIHL’s philosophy is to continually

improve all of its products. As a result,

engineering changes and improvements

are made from time to time. Therefore,

some changes, modifications and

improvements may not be covered in

this manual. If the operating

characteristics or the appearance of

your machine differs from those

described in this manual, please contact

your STIHL dealer or the STIHL

distributor for your area for assistance.

Working Techniques

The use of any cut-off

machine may be hazardous. Because a cut-off

machine is a high-speed,

fast-cutting power tool

that can create sparks,

special safety precautions must be observed to

reduce the risk of personal injury and fire.

It is important that you

read, fully understand

and observe the following

safety precautions and

warnings. Read the

instruction manual and

the safety precautions

before use and periodically thereafter.

WARNING

Careless or improper use of any cut-off

machine may cause serious or fatal

injury.

Have your STIHL dealer show you how

to operate your cut-off machine.

Observe all applicable national, state

and local safety regulations, standards

and ordinances.

WARNING

Your cut-off machine is for professional

use only. Do not lend or rent your cut-off

machine without the instruction manual.

Be sure that anyone using it

understands the information contained

in this manual.

2

TSA 230

Page 5

English

A first-time operator should obtain

practical instruction before using the

machine. Employers should establish a

training program for operators of handheld portable cut-off machines to assure

safe operation of these machines and

proper choice of cutting attachments.

These safety precautions and warnings

apply to the use of all current STIHL

Cutquiks.

WARNING

Use your cut-off machine only for

authorized uses. For instance, it is not

suitable for cutting wood or wooden

objects. Misuse may result in personal

injury or property damage, including

damage to the machine.

Operate this cut-off machine with STIHL

type AP batteries only.

To reduce the risk of loss of control

and/or balance from carrying extra

weight and/or using a connecting cord,

only operate the cut-off machine with

STIHL battery type AP placed directly in

the machine when not cutting at ground

level.

WARNING

Minors should never be allowed to use a

cut-off machine. Bystanders, especially

children, and animals should not be

allowed in the area where a cut-off

machine is in use.

WARNING

To reduce the risk of injury to bystanders

and damage to property, never leave

your power tool unattended if it is in

operating condition. When it is not in use

(e.g. during a work break), shut it off,

move retaining latch to ƒ and remove

the battery.

Different models may have different

parts and controls. See the appropriate

section of your instruction manual for a

description of the controls and function

of the parts of your model cut-off

machine.

Safe use of a cut-off machine involves

1. the operator

2. the power tool

3. the use of the power tool.

THE OPERATOR

Physical Condition

You must be in good physical condition

and mental health and not under the

influence of any substance (drugs,

alcohol, etc.) which might impair vision,

dexterity or judgment. Do not operate a

cut-off machine when you are fatigued.

Be alert – if you get tired while operating

your cut-off machine, take a break;

tiredness may result in loss of control.

Working with any cut-off machine can be

strenuous. If you have any condition that

might be aggravated by strenuous work,

check with your doctor before operating

a cut-off machine.

WARNING

Prolonged use of cut-off machines (or

other machines) exposing the operator

to vibrations may produce whitefinger

disease (Raynaud's phenomenon) or

carpal tunnel syndrome. These

conditions reduce the hand's ability to

feel and regulate temperature, produce

numbness and burning sensations and

cause nerve and circulation damage and

tissue necrosis. All factors which

contribute to whitefinger disease are not

known, but cold weather, smoking and

diseases or physical conditions that

affect blood vessels and blood transport,

as well as high vibration levels and long

periods of exposure to vibration are

mentioned as factors in the development

of whitefinger disease. In order to

reduce the risk of whitefinger disease

and carpal tunnel syndrome, please

note the following:

– Wear gloves and keep your hands

warm.

– Maintain a firm grip at all times, but

do not squeeze the handles with

constant, excessive pressure. Take

frequent breaks.

All the above-mentioned precautions do

not guarantee that you will not sustain

whitefinger disease or carpal tunnel

syndrome. Therefore, continual and

regular users should monitor closely the

condition of their hands and fingers. If

any of the above symptoms appear,

seek medical advice immediately.

Proper Clothing

WARNING

To reduce the risk of injury, the operator

should wear proper protective apparel.

TSA 230

3

Page 6

English

Clothing must be sturdy

and snug-fitting, but allow

complete freedom of

movement. Avoid loosefitting jackets, scarfs,

neckties, jewelry, flared

or cuffed pants, unconfined long hair or

anything that could

become caught on any

obstacles or moving parts

of the unit. Wear overalls

or long pants to protect

your legs. Do not wear

shorts.

WARNING

When cutting metal, a cut-off machine

generates sparks that can ignite

clothing. Most fabrics used in clothing

are flammable – even flame-retardant

fabrics will ignite at higher temperatures.

To reduce the risk of burn injury STIHL

recommends wearing clothing made of

leather, wool, flame-retardant-treated

cotton or a tightly woven, heavier cotton

such as denim. Some flame-retardant

synthetic fabrics are also suitable, but

others such as polyester, nylon, rayon

and acetate can melt during a fire into a

tar-like matter that burns into the skin.

Check the clothing manufacturer's

instructions. Keep clothing free of oil,

fuel, grease and other flammable

substances.

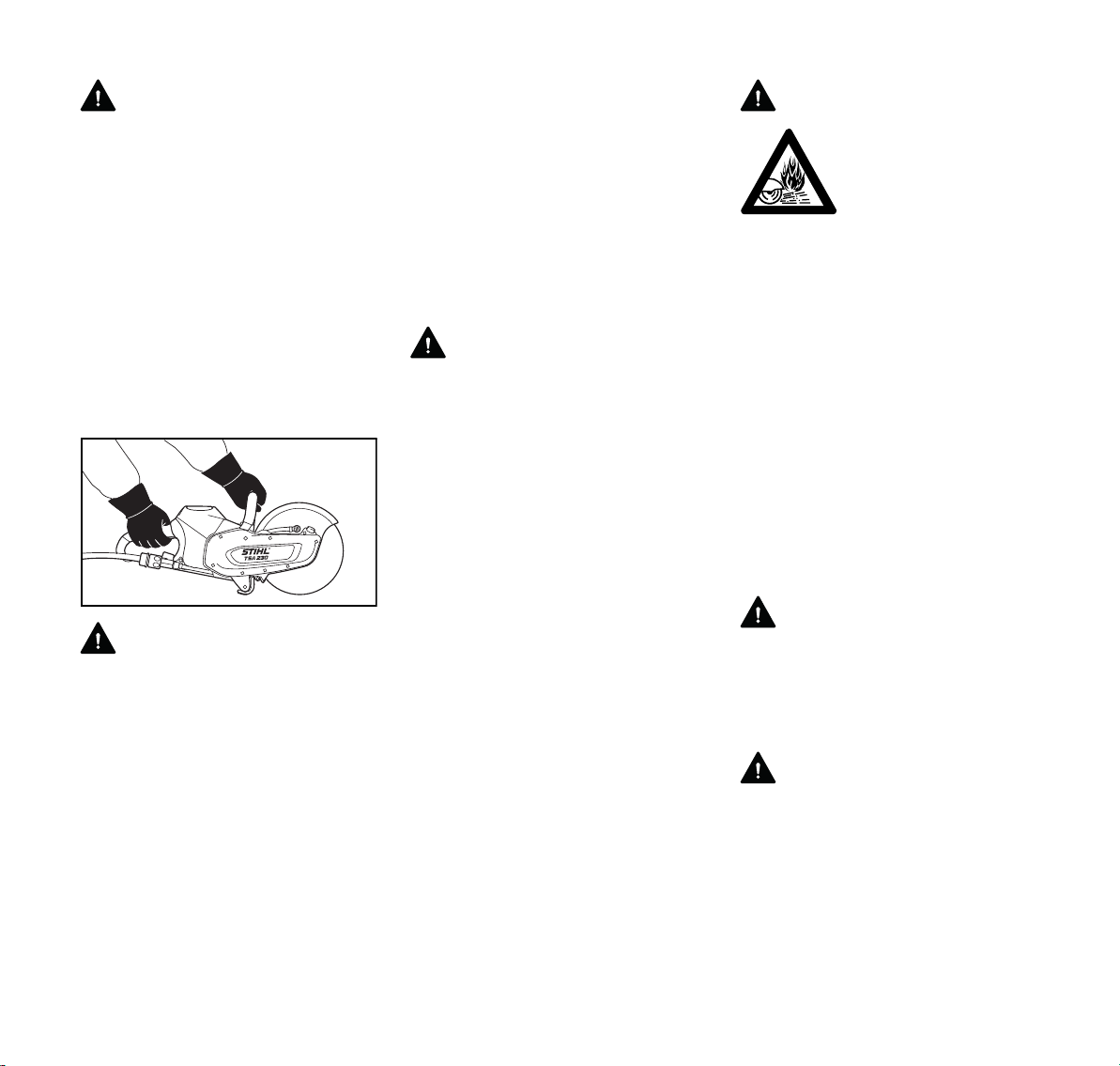

Always wear heavy duty

work gloves (e.g. made of

leather or other wear

resistant material) when

handling the cut-off

machine. Heavy-duty,

nonslip gloves improve

your grip and help to protect your hands.

Good footing is important

in cut-off machine work.

Wear sturdy boots with

nonslip soles. Steel-toed

safety boots are

recommended.

WARNING

Loose objects may be thrown toward the

operator by the cutting tool.

To reduce the risk of

injury to your eyes never

operate a cut-off machine

unless wearing goggles

or close-fitting protective

glasses with adequate

side protection that are

impact-rated and marked

as complying with

ANSI Z87 "+". Proper eye

protection is a must.

Wear an approved safety hard hat to

protect your head. Cut-off machine

noise may damage your hearing. Always

wear sound barriers (ear plugs or ear

mufflers) to help protect your hearing.

Regular users should have their hearing

checked regularly.

WARNING

When wet cutting at the

recommended flow rate

is not utilized, the operator should always wear a

respirator approved by

NIOSH/MSHA for the

material being cut to

reduce the risk of serious

or fatal respiratory illness.

For additional details and

warnings on this subject,

see information under

"Working Conditions" in

this instruction manual.

THE POWER TOOL

For illustrations and definitions of the

parts of the cut-off machine, see the

chapter "Main Parts."

WARNING

Never modify a cut-off machine in any

way. Only STIHL replacement parts are

authorized, and only STIHL-branded

cutting attachments expressly approved

by STIH L fo r use with the spec ific STIH L

cut-off machine models are

recommended. Although certain other

parts or attachments may be useable

with the STIHL powerhead, their use

may, in fact, be extremely dangerous.

If your power tool is subjected to

unusually high loads for which it was not

designed (e.g. heavy impact or a fall),

always check that it is in good condition

before continuing work – see also

"Before Starting Work." Make sure the

safety devices are working properly. Do

not continue operating your power tool if

4

TSA 230

Page 7

English

it is damaged. In case of doubt, have the

machine checked by your STIHL

servicing dealer.

Battery

WARNING

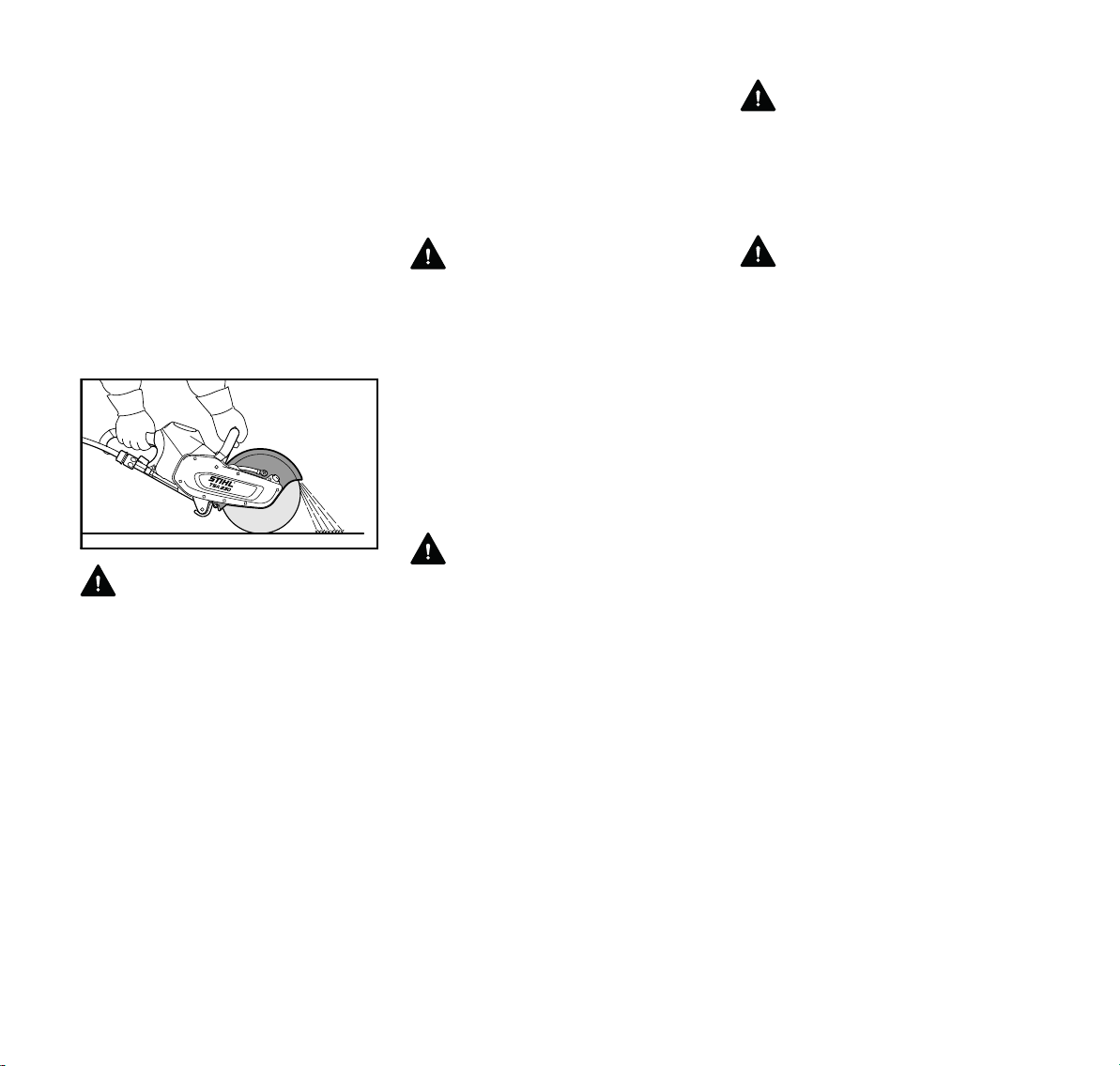

Risk of fire, explosion

and/or burns, including

chemical burns. Do not

disassemble, crush, heat

above 212 °F (100 °C),

expose to fire or incinerate. Never expose the

battery to microwaves or

high pressures.

Do not place the battery on or near fires,

stoves or in other high-temperature

locations. Do not place the battery in

direct sunlight or store it inside a vehicle

in hot weather. Doing so may cause the

battery to generate heat, rupture or

ignite. Using the batteries in this manner

may also result in a loss of performance

and a shortened battery life.

In case of fire: stay clear of any vapors

or gases generated, taking wind

direction into account. If possible without

danger, remove battery from the vicinity

of the fire. In principle, cooling the

battery or extinguishing the fire with

water is possible. It is preferable to

extinguish the fire with a multipurpose

dry chemical fire extinguisher. As for any

fire, evacuate the area and fight the fire

from a safe distance. Once the fire has

been extinguished, the area should be

monitored (fire watch) in case of a flareup, until the battery has cooled

sufficiently. Restrict access to the area

until completion of clean-up. Do not

touch the burnt battery or any spilled

liquids. Use inert absorbent to absorb

spilled liquids.

Use and store the battery only within a

temperature range from

14 °F (-10 °C) up to no

more than 122 °F

(+ 50 °C). Protect the battery from direct sunlight.

WARNING

Use STIHL batteries only with STIHL

power tools, and charge them only with

STIHL chargers. Replace battery with

STIHL battery only. Use only genuine

STIHL rechargeable batteries.

Charge the battery before use.

Do not immerse the battery in fluids.

WARNING

Do not open, drop, hit or damage

battery. Never insert objects into the

battery's cooling slots, since they may

damage the battery. The battery

contains safety features and devices

which, if damaged, may cause the

battery to generate heat, rupture or

ignite. Never use or charge a

malfunctioning, damaged, cracked or

deformed battery.

Immediately discontinue use of the

battery if, while using, charging or

storing, it emits an unusual smell, feels

hot or appears abnormal in any other

way.

WARNING

Fluid may leak from the battery if it is

damaged or is not used properly – avoid

contact with the skin! Leaking battery

fluid can cause skin irritation and

chemical burns. In the event of

accidental contact, immediately rinse

thoroughly with mild soap and water. If

fluid gets into your eye(s), do not rub

your eye(s) but rinse water over the

open eye(s) for 15 minutes at least. Also

seek medical attention immediately.

WARNING

Never bridge (short circuit) the battery

terminals with metallic objects, since this

may damage the battery and possibly

cause a fire. Keep a battery that is not in

use away from metal objects (e.g. nails,

coins, jewelry). Do not use metal

containers for transporting batteries.

Store the battery out of reach of children

in a cool and dry area away from direct

sunlight and excessive heat or cold

(14 °F – 122 °F (-10 °C – +50 °C)).

Protect STIHL batteries and the STIHL

battery belt from flying sparks when

cutting steel – risk of battery fire or

explosion and/or damage to the belt.

Keep STIHL batteries away from

conductive liquids, such as dirty water

(e.g. from additives or solid matter) or

slurry and from metal objects (e.g. nails,

coins, jewelry, metal chips). The

batteries can be damaged by a short

circuit – risk of fire or explosion!

Charger

Use only genuine STIHL chargers.

TSA 230

5

Page 8

English

Use only for charging geometrically

matching STIHL batteries with a

maximum capacity of 50 Ah and a

maximum voltage of 42 V.

Never charge malfunctioning, leaking or

deformed batteries.

Connect the charger only to a power

supply with the voltage and frequency

specified on the rating plate. Always

plug the charger into a properly installed

wall outlet. Do not use an extension cord

unless absolutely neccessary (see

below).

Never use a charger with damaged

housing, damaged power supply cord or

damaged plug. Do not operate the

charger if it has received a sharp blow,

been dropped or otherwise damaged in

any way.

Do not open or dissassemble charger –

there are no user serviceable parts

inside.

Store charger out of the reach of

children.

Protect the charger from

rain and dampness. Keep

charger dry.

Use and store charger

only indoors in dry rooms.

Operate charger at temperatures

between 41 °F (5 °C) and 104 °F

(40 °C).

Allow the charger to cool down normally

– do not cover it.

Never bridge the contacts of the charger

with metallic objects (e.g. nails, coins,

jewelry) – which can cause a short

circuit. The charger will be damaged by

a short circuit.

In the event of smoke or fire in the

charger, disconnect it from outlet

immediately.

WARNING

To reduce the risk of electric shock or

short circuit, do not insert any objects

into the charger's cooling slots.

WARNING

The charger heats up during the

charging process. Do not operate on an

easily combustible surface (e.g. paper,

cardboard, textiles) or in an easily

combustible environment – risk of fire.

WARNING

Do not operate in a hazardous location,

i.e. in a location where there are

combustible liquids (fumes), vapors or

dusts. Chargers can produce sparks,

which may ignite the dust or vapors –

risk of explosion.

Check the charger's

power supply cord and

plug regularly for damage. If the power supply

cord or plug is damaged,

immediately disconnect

the plug from the wall

outlet to avoid the risk of

electric shock.

Never jerk the charger’s power supply

cord to disconnect it from the wall outlet.

To unplug, grasp the plug, not the cord.

Have a damaged power supply cord or

plug repaired by an experienced

electrician.

Do not use the power supply cord for

any other purpose, e.g. for carrying or

hanging up the charger.

Never use power supply cords that do

not comply with regulations.

Make sure the power supply cord is

located and/or marked so that it will not

be stepped on, tripped over, come in

contact with sharp edges or moving

parts or otherwise be subjected to

damage or stress.

An extension cord should not be used

for your charger unless absolutely

necessary. If an extension cord must be

used, plug the charger into a properly

wired 16 gauge (AWG 16) or heavier

gauge extension cord with blades that

are the same number, size and shapes

as the blades on the charger.

To reduce the risk of electric shock:

– Always connect the charger to a

properly installed wall outlet.

– Make sure the insulation of the

power supply cord and plug is in

good condition.

Unplug the power supply cord from the

outlet when charger is not in use.

Never store a battery in the charger.

Abrasive Wheels

WARNING

Before mounting the cutting wheel,

make sure that the maximum operating

wheel speed is above or equal to the

maximum spindle speed of your cut-off

6

TSA 230

Page 9

English

machine as provided in the

specifications of this manual. A wheel

that is not so rated may shatter or break

and poses a threat of serious or fatal

injury to the operator and other nearby

persons.

Abrasive wheels for free-hand cutting

are subjected to particularly high

bending and compression stresses.

WARNING

Never use a reducer bushing inserted

into the wheel to reduce the diameter of

the arbor hole. It may slip out of place,

causing out-of-roundness, vibration and

wheel breakage.

WARNING

Wheels that are not STIHL branded may

be more likely to shatter or break or

create other hazards, such as increased

reactive forces. Use only wheels with

approved RPM ratings. Read and follow

any addional safety precautions that

accompany the wheel.

WARNING

Inspect the abrasive

wheel frequently and

replace immediately if the

abrasive wheel is

cracked or warped.

Cracked or warped

wheels may shatter or

break and cause serious

or fatal personal injury.

Out-of-round or unbalanced abrasive wheels

increase vibration and

reduce the service life of

the cut-off machine.

Some diamond abrasive wheels that are

not STIHL branded utilize poor quality

steel cores, are not properly tensioned,

or have other design or manufacturing

defects. As a result, they may begin to

wobble during use, which can cause

wheel breakage. Such wobbling can

also lead to a severe binding of the

wheel in the kerf, that, under certain

circumstances, can then result in

serious or fatal injury from reactive

forces. See the section entitled

"Reactive Forces including Kickback."

Never use a wheel that wobbles or that

has ever wobbled. Even though such a

wheel may temporarily cease to wobble,

e.g., if run without load, it will always be

prone to wobble again under certain

conditions. Replace it immediately

before further use.

Composite abrasive wheels are heat

sensitive. During a break, always place

your cut-off machine in a location where

the composite wheel is not exposed to

direct sunlight or other sources of heat.

Store spare composite wheels flat on a

level surface in a dry place where there

is no risk of frost damage. Failure to

follow these directions may cause the

wheel to shatter or crack in use causing

serious or fatal injury.

WARNING

Never use circular saw

blades, carbide tipped

blades, rescue blades,

wood-cutting blades or

toothed blades of any

nature. They can cause

severe personal injury

from blade contact,

thrown objects and/or

reactive forces, including

kickback. See section on

"Reactive Forces including Kickback." Your

STIHL dealer stocks a

range of special abrasive

wheels for the many

applications of the cut-off

machine.

WARNING

Use of the wrong abrasive wheel or the

cutting of material for which the wheel

was not designed may cause the wheel

to wobble, shatter or increase reactive

forces, causing serious or fatal injury.

See below and section "Reactive Forces

including Kickback."

Only use the abrasive wheel approved

for the type of material to be cut. There

are different types of abrasive wheels,

each specially marked.

For cutting composite materials please

ask your STIHL dealer.

Diamond Abrasive Wheels

Diamond abrasive wheels have a much

better cutting performance than

composite abrasive wheels. The

TSA 230

7

Page 10

English

diamond wheels are steel centered, and

diamond particles are imbedded in their

cutting edges.

They can be used for concrete, asphalt,

natural stone, clay pipe, brick and the

like. STIHL also offers diamond wheels

for cutting ductile iron and some

structural steel.

They are not, however, suitable for

cutting all metals and other materials.

Wet or dry cutting is possible. Water

attachments are included with your

STIHL cut-off machine. See the

appropriate section of your instruction

manual.

WARNING

Do not remount a used diamond

abrasive wheel without first inspecting

for under-cutting, flatness, core fatigue,

segment damage or loss, signs of

overheating (discoloration) and possible

arbor hole damage. See the chapter

"Diamond Cutting Wheels." Check the

wheel for cracks and make sure that no

pieces have broken off the wheel before

use.

Always fit the wheel so that the arrow on

the wheel points in the direction of the

rotation of the spindle.

THE USE OF THE POWER TOOL

Remove the battery from

the cut-off machine

before:

– Carrying out tests and adjustments

or cleaning work

– Fitting or changing the abrasive

wheel

– Mounting and removing

accessories

– Leaving the cut-off machine

unattended

– Transport

– Storage

– Performing repairs and

maintenance work

This avoids the risk of the motor starting

unintentionally.

Transporting the STIHL Cutquik

WARNING

To reduce the risk of injury from

unintended activation and/or contact

with a moving wheel, always switch off

the machine and move retaining latch to

ƒ when you carry the unit for short

distances. The abrasive wheel

continues to rotate (coast down) for a

short while after the trigger switch is

released (flywheel effect). Bring the

wheel to a stop by lightly contacting the

bottom of the wheel on a hard surface or

wa it u ntil the w heel com es t o a com ple te

stop on its own.

When carrying the machine for more

than a few steps, remove the battery

from the cut-off machine.

By hand: When carrying your cut-off

machine by hand, the cut-off machine

must be in the proper position. Grip the

front handle and place the cutting

attachment to the rear.

WARNING

Always protect the cutting wheel from

hitting the ground or any other objects.

Damaged wheels may shatter and

cause serious or fatal injury.

By vehicle: Properly secure your cut-off

machine to prevent turnover and

damage to the cut-off machine. Never

transport with cutting wheel mounted. A

wheel damaged during transportation

may shatter during operation and cause

serious personal injury.

Allow the cut-off machine and battery to

dry out separately if they are wet after

use. During transport, make sure that

the cut-off machine and battery remain

dry. Only transport the battery in clean

and dry containers, do not use metallic

transport containers.

Before Starting

For wheel installation, follow the

procedure described in the appropriate

chapter of your instruction manual.

WARNING

Never operate a cut-off machine if it is

damaged, improperly maintained, or not

completely or securely assembled.

Check machine that it is ready for proper

operation.

Keep the handles dry and clean for a

proper grip.

WARNING

Before operation of your cut-off

machine, be sure the controls (e.g.

trigger switch, trigger switch lockout and

retaining latch) and other safety devices

8

TSA 230

Page 11

English

are working properly, the wheel is

properly mounted, and the wheel guard

is in place and securely fastened to your

unit. All wheels should be carefully

inspected for good condition before

mounting.

Trigger switch must be locked when the

trigger switch lockout is not depressed.

The retaining latch must be easy to set

to ‚ or ƒ.

Check contacts in battery compartment

for foreign matter. Keep clean.

Fit the battery correctly – it must engage

audibly.

Do not use malfunctioning or deformed

batteries.

Starting

WARNING

Your cut-off machine is a one-person

tool. Do not allow other persons in the

general work area, even when starting.

For specific starting instructions, see the

appropriate section of your instruction

manual.

Maintain good balance and secure

footing. Be absolutely sure that the

cutting wheel is clear of you and all other

obstructions and objects, including the

ground. Never attempt to start the cut-off

machine when the abrasive wheel is in a

cut.

Working Conditions

Operate the cut-off machine under good

visibility and daylight conditions only.

Wearing of hearing protection reduces

sound perception. Be alert not to miss

voice signals from co-workers. Keep

within calling distance to other persons

who may assist in case of emergency.

WARNING

Use of this product to cut

masonry, concrete, metal

and other materials can

generate dust and fumes

containing chemicals

known to cause serious

or fatal injury or illness,

such as respiratory disease, cancer, birth

defects or other reproductive harm. If you are

unfamiliar with the risks

associated with the particular material being cut,

review the material safety

data sheet and/or consult your employer, the

material manufacturer/supplier,

governmental agencies

such as OSHA and

NIOSH and other

sources on hazardous

materials. California and

some other authorities,

for instance, have published lists of substances

known to cause cancer,

reproductive toxicity, etc.

Control dust and fumes at

the source where

possible.

In this regard use good work practices

and follow the recommendations of the

manufacturer/supplier, OSHA/NIOSH,

and occupational and trade

associations. A water attachment kit is

provided with your cut-off machine and

should be used to reduce dust whenever

wet cutting is feasible. For dust

suppression purposes, the flow rate

should be at least 0.6 liters (20 fl.oz) of

water per minute. If wet cutting at the

recommended flow rate is not utilized,

the operator and any bystanders should

always wear a respirator approved by

NIOSH/MSHA for the material being cut.

See also the section on "Respiratory

Protection" in the chapter "Sample

Applications" in the instruction manual.

Even if wet cutting at the recommended

flow rate, an operator who is actively

cutting for more than two hours in one

day should wear at least a NIOSHapproved disposable respirator. Consult

and follow any federal, state or local

laws or regulations with respect to dry

and wet cutting.

WARNING

Cutting masonry, concrete and other

materials with silica in their composition

may give off dust containing crystalline

silica. Silica is a basic component of

sand, quartz, brick clay, granite and

numerous other minerals and rocks.

Repeated and/or substantial inhalation

of airborne crystalline silica can cause

serious or fatal respiratory diseases,

including silicosis. In addition, California

and some other authorities have listed

respirable crystalline silica as a

substance known to cause cancer.

When cutting such materials, always

follow the respiratory precautions

mentioned above.

TSA 230

9

Page 12

English

8016BA002 KN

WARNING

Breathing asbestos dust is dangerous

and can cause severe or fatal injury,

respiratory illness or cancer. The use

and disposal of asbestos-containing

products have been strictly regulated by

OSHA and the Environmental Protection

Agency. Do not use your cut-off machine

to cut or disturb asbestos, asbestoscontaining products, or products such as

pipes which are wrapped or covered

with asbestos insulation. If you have any

reason to believe that you might be

cutting asbestos, immediately contact

your employer or a local OSHA

representative.

WARNING

Your STIHL cut-off machine is designed

for hand-held use. Cutting with your cutoff machine resting on the ground or

other surface can cause excessive wear

to the guide plate designed to protect the

bottom of the front handle. Replace a

damaged or badly worn guide plate

immediately.

Grip: Never use the cut-off machine with

one hand. Always hold the cut-off

machine firmly with both hands. Place

your left hand on front handle bar and

your right hand on rear handle and

trigger switch. Left-handed users should

follow this instruction too.

Wrap your fingers tightly around the

handles, keeping the handles cradled

between your thumbs and forefingers.

Make sure your cut-off machine handles

and grip are in good condition and free

of moisture, pitch or grease.

Never touch a rotating wheel with your

hand or any part of your body.

WARNING

Clear the area where you are working.

Avoid stumbling on obstacles and watch

out for holes or ditches. Be extremely

cautious when working on slopes or

uneven ground. Take extreme care in

wet and freezing weather (rain, snow,

ice.)

WARNING

Sparks are created when

cutting metal and some

other materials. They can

burn or cause clothing to

catch fire. Always direct

sparks away from the

operator or any flammable surroundings.

Flammable items can

include dry vegetation

and brush, particulary

when weather conditions

are hot and dry. Never

cut metal or other sparkcreating materials while

standing on a flammable

surface, such as wood,

dry vegetation or tar

paper. Where there is a

risk of fire, have appropriate fire extinguishing

equipment readily

available.

WARNING

To reduce the risk of injury from fire, do

not cut into any pipe, drum or other

container without first ensuring that it

does not contain a volatile or flammable

substance.

WARNING

When cutting into existing walls, floors or

similar structures, be alert for hidden

hazards such as electrical cables, water

and gas pipes and flammable

substances. Make sure that power,

water and gas have been shut off and

pipes drained before starting to cut.

10

TSA 230

Page 13

English

8016BA028 KN

After finishing work turn off the cut-off

machine, set the locking lever to ƒ and

remove the battery from the cut-off

machine.

If the battery is not removed after

finishing work, there is the risk that the

plug-in contacts on the cut-off machine

and battery become corroded. Such

corrosion can cause irreparable damage

to the cut-off machine and battery. Allow

the cut-off machine and battery to dry

out separately if they are wet after use.

Operating Instructions

WARNING

It is extremely important that the wheel

guard is in place and set to suit the type

of work and your stance. By adjusting

the angle of the cut-off machine to the

work piece, you can influence the

direction of debris from the cutting

process. Operate your cut-off machine

so that the user is not endangered by

particles of the material being cut,

sparks or pieces of damaged wheels

either directly or by ricochet. Failure to

follow this instruction could result in

serious or fatal injury.

In case of imminent danger or in an

emergency, switch off the machine

immediately and move the retaining

latch to ƒ.

This cut-off machine can be used for

work in the rain or wet. Allow the cut-off

machine or battery to dry out separately

if they are wet after use.

Do not submerge the battery. Do not

leave the cut-off machine outdoors in the

rain.

WARNING

Always check the wheel before use and

after unintentionally striking any object;

frequently check it during use when it is

stopped. Look for cracks and make sure

that it is undamaged and in good

condition and that no pieces have

broken off. See sections on "Abrasive

Wheels" and "Reactive Forces including

Kickback" in this manual. Check the

wheel guard for cracks. If you discover

any breaks or cracks, fit a new guard

before further use.

WARNING

It is essential to determine the exact

direction of the cut before applying the

abrasive wheel to the work. Wheels are

constructed for radial pressure only.

Lateral pressure must be avoided. Hold

the cut-off machine steady. To reduce

the risk of serious or fatal injury, do not

change the direction of the cut during the

cut as this may produce a high torsional

load on the abrasive wheel and may

cause it to bind, break or shatter. A

binding of the wheel can also result in

reactive forces. See section on

"Reactive Forces including Kickback."

WARNING

Do not use abrasive wheels for rough

grinding. Large bending stresses occur

during such work, which may cause

abrasive wheels to shatter or break and

result in serious or fatal injury.

WARNING

To reduce the risk of injury from

shattered abrasive wheels:

1. Do not exceed the maximum

operating speed marked on the

wheel.

2. Do not use a wheel that has been

dropped.

3. Test each new wheel immediately

after installation for approximately

one minute at maximum speed

without cutting, making sure to keep

bystanders away.

4. Do not cut any material for which the

abrasive wheel is not authorized.

5. Do not grind on the side of the

abrasive wheel.

6. Do not twist, thrust, knock or drop

the machine. This can cause

damage to the wheel.

To achieve a clean and efficient cut, pull

the abrasive wheel across the work. Do

not use force to push the abrasive wheel

into the work.

Insert the wheel into the material only as

deep as necessary to make the cut. To

reduce the amount of dust created, do

not cut all the way through stone and

concrete materials – leave a thin piece

uncut. For most such materials, this

TSA 230

11

Page 14

English

8016BA005 KN

piece can be easily broken afterwards.

Do not cock, jam or wedge the wheel in

the cut.

Always switch off the machine, move

retaining latch to ƒ and be sure the

wheel has stopped rotating before

setting down the cut-off machine.

Wet Cutting with Abrasive Wheels

Before wet cutting, make sure water will

not damage the floor or building.

WARNING

To reduce the risk of electrocution to you

or bystanders, do not allow water or

sludge to contact live electric wires.

WARNING

To reduce the risk of injury from wheel

breakage when wet cutting with any

composite wheel:

1. Make certain water does not flow on

a wheel that is not running, since the

wheel will absorb water, which will

affect wheel balance.

2. After finishing work, run the cutting

wheel at normal operating speed for

about 3 to 6 seconds without water

so that the remaining water is flung

off.

WARNING

To reduce the risk of injury from wheel

breakage when wet cutting with a

composite wheel that is not specifically

designed for wet cutting, never store and

reuse such a wheel that has been used

with water. Use these wheels up the

same day.

Reactive Forces including Kickback

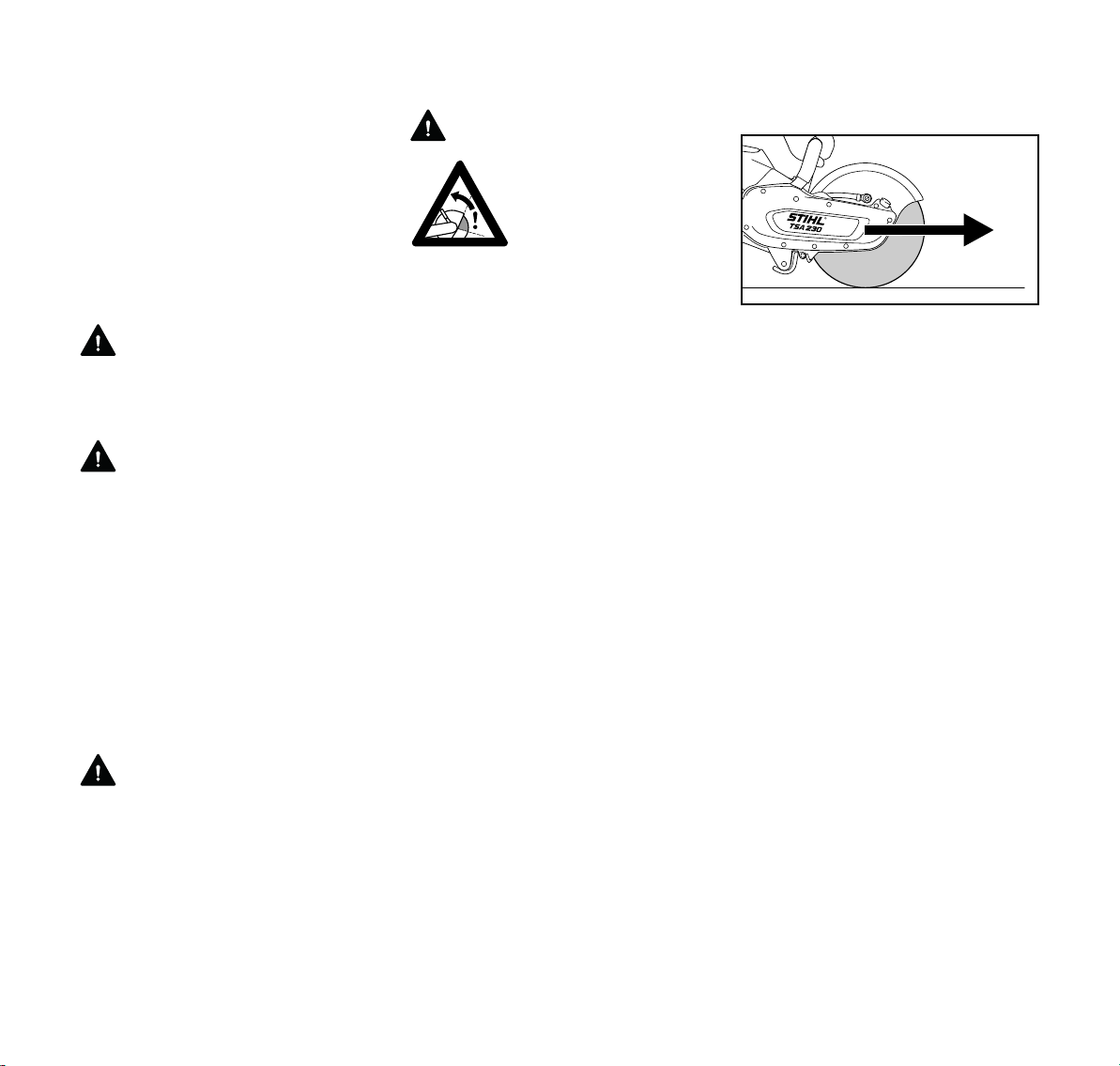

WARNING

Reactive forces may

occur at any time the cutting wheel on a cut-off

machine is rotating.

The powerful force used to cut through a

workpiece can be reversed and work

against the operator. If the wheel is

slowed or stopped by frictional contact

with any solid object or by a pinch or

binding, reactive forces can occur

instantly and may result in the operator

losing control of the cut-off machine,

which, in turn, may result in serious or

fatal injury.

An understanding of the causes of these

reactive forces may help you avoid loss

of control. Reactive forces are exerted in

a direction opposite to the direction in

which the wheel is moving at the point of

contact or of pinching/binding. If the

wheel is slowed solely by frictional

contact with a solid object, such as the

workpiece, the resulting reactive forces

are normally moderate and readily

controllable by an operator who is

holding the machine properly. If,

however, the wheel is abruptly slowed or

stopped by a pinch or severe bind, the

reactive forces may be substantially

greater. The greater the force

generated, the more difficult it will be for

the operator to control the cut-off

machine. Loss of control can result in

severe personal injury or death.

Pull-away, Climbing, Pinching and

Rotational Kickback Forces

The most common reactive forces are

pull-away and climbing. If the contact is

at the bottom of the wheel, a cut-off

machine will try to pull away from the

operator (pull-away.) If the contact is at

the front of the wheel, the wheel may

attempt to climb the object being cut

(climbing.)

Pinching occurs when the piece being

cut closes on the wheel. A severe

binding may also occur if the wheel is

substantially sideloaded in the kerf or if

an improper or damaged diamond wheel

begins or ceases to wobble in the kerf. If

the wheel is severely pinched or bound

in the upper quadrant, the wheel may be

instantly thrown up and back towards

the operator with great force in a

rotational kickback motion. Such

kickback situations can and should

always be avoided. Pinching of the

wheel can be prevented by proper

support of the workpiece. Severe

binding of the wheel can be prevented

by proper cutting techniques, e.g., not

sideloading the wheel, and by the use of

properly designed, manufactured and

maintained wheels.

12

TSA 230

Page 15

English

8016BA030 KN

002BA146 KN

002BA603 KN

Reducing the Risk of Kickback Injury

WARNING

To reduce the risk of kickback injury,

avoid cutting with the upper quadrant of

the wheel where possible. Be especially

cautious for a pinching or binding of the

wheel in this area, which can cause

severe reactive forces in a rotational

kickback motion.

Avoid wedge action. The severed part

must not bind the abrasive wheel.

Be alert to potential movement of the

workpiece or anything else that could

cause the cut to close and pinch the

wheel. In order to reduce the risk of

pinching, support the workpiece in such

a way that the cut remains open during

the cutting process and when the cut is

finished (see illustration). Never make a

cut that results in a binding of the wheel.

If you cannot properly support the

workpiece, do not use a cutting-off

machine to make the cut; select another

tool or cutting technique that is not

subject to kickback.

Where there is a possibility of a pinch,

you can leave an uncut part that

prevents the kerf from closing and

pinching the wheel, which can later be

broken manually. If you are making a

complete cut, make sure that the final,

separating cut is made at the top of the

workpiece with the bottom of the wheel.

In this way, if there is any residual

pinching, it will be at the bottom of the

wheel, where it may result in pull-away,

but not in kickback. Be alert for pullaway.

Objects to be cut must therefore be

properly supported and must be secured

against rolling away, slipping or

vibrations.

Support an exposed pipe in a trench so

that it is stable and capable of bearing

weight. If the ends of the pipe are firmly

in the ground, the ground may act as a

support where the pipe emerges into the

open. Additional support will be needed

closer to the cut, however, to prevent

sagging (see illustration). Be alert for

pipe that is under stress that may cause

it to shift when cut; pipe in the ground

may be under stress because of uneven

surfaces.

Make sure any section of pipe to be

removed is also properly supported and

will not shift. After the first cut, you may

need to move the supports or add

additional support for the second cut so

that both sides of that cut are fully

supported, including the section to be

removed. That section can also be

supported by means of a strap from

above, e.g., suspended from a backhoe.

It must be evenly supported and

properly tensioned, however, so that the

section remains in its position and does

not tend to go up or down as a whole or

on one side when separated.

Always pay attention in

subgrade/subsurface work areas –

supporting material can crumble or slide

away.

TSA 230

13

Page 16

English

8016BA006 KN

WARNING

Be particularly alert when cutting a

workpiece such as a pipe with a belled

end or cutting out a section of pipe in a

trench that, if not properly supported,

can sag or drop upon completion of the

cut, creating a pinch not where you are

actually cutting but, rather, at or near the

top of the workpiece. If the pinch is in the

upper quadrant of the abrasive wheel,

kickback can result.

WARNING

Use wet-cutting whenever feasible,

since the water can act as a lubricant in

a pinch situation and thus reduce the

likelihood of reactive forces occurring

and the energy of any such forces that

do occur, making it easier to maintain

control of the machine.

WARNING

Only STIHL branded cutting

attachments are recommended. Use of

certain non-STIHL branded wheels may

be extremely dangerous. Many

substandard diamond wheels, for

instance, are available in the market. If

they are not manufactured with the

proper quality steel in their core, if they

are not properly tensioned, or if other

design or manufacturing defects exist,

they may, e.g., begin to wobble during

use, lose segments or exhibit other

operational problems that can

substantially increase the risk of

personal injury or death. If a diamond

wheel begins or ceases to wobble within

the kerf, the change in the behavior of

the wheel may cause a severe binding

that can lead to loss of control and/or

kickback. If the wheel you are using

begins to wobble or has ever wobbled,

discard it immediately. Although such a

wheel may temporarily cease to wobble,

e.g., if run without load, it will always be

prone to wobble again under certain

conditions.

WARNING

Some other non-STIHL branded

diamond wheels are manufactured with

abrasive material on their sides. Do not

use such wheels, since the abrasive

material may lead to substantially

increased reactive forces in a pinch or

sideloading situation.

WARNING

Never use chipped abrasive wheels or

circular saw blades, carbide-tipped

blades, rescue blades or wood-cutting or

toothed blades of any nature on a cut-off

machine. The use of such wheels or

blades will greatly increase the risk of

loss of control and severe personal

injury or death from reactive forces,

since the chipped section of an abrasive

wheel or the teeth of a saw blade may

catch in the material being cut and

generate substantially greater reactive

forces, including rotational kickback.

Cut-off machines are designed for use

with abrasive wheels in good condition

only. Machines designed for use with

wood-cutting or other toothed blades

use different types of guarding systems

that provide the protection necessary for

those types of blades. Machines, such

as a cut-off machine, that are designed

for use with abrasive wheels require a

different guarding system, which is not

designed to provide protection against

all dangers presented by circular saw

blades, carbide-tipped blades, rescue

blades or wood-cutting or toothed

blades of any nature.

WARNING

To reduce the risk of injury from loss of

control from reactive forces, including

kickback:

1. Hold the cut-off machine firmly with

both hands.

2. Maintain good balance and footing

at all times. Never cut while

standing on a ladder.

3. Position the cut-off machine in such

a way that your body is clear of the

cutting attachment. Avoid standing

in direct line with the wheel (See

illustration.) Never bend over the

cutting attachment, especially when

the guard is pulled back towards the

top and there is a risk of reactive

forces. Ensure sufficient freedom of

movement, especially in trenches.

Make sure there is sufficient space

for the user and the fall of the

severed part.

4. Do not cut above shoulder height.

14

TSA 230

Page 17

English

5. Only STIHL branded diamond and

composite abrasive wheels are

recommended. The use of nonSTIHL branded wheels can be

extremely dangerous. Never work

with a diamond wheel that wobbles

or that has ever wobbled or that is

manufactured with abrasive

material on its sides.

6. Do not cut wood or any other

material for which the abrasive

wheel is not authorized.

7. Never use circular saw blades,

carbide-tipped blades, rescue

blades, wood-cutting blades or

toothed blades of any nature. Their

use increases the risk of injury from

blade contact, thrown tips and

reactive forces, including kickback.

8. Do not overreach.

9. Never sideload a wheel in the kerf.

10. Use your cut-off machine for cutting

only. It is not designed for prying or

shoveling away any objects.

11. Be especially alert for reactive

forces, including kickback, when

cutting with the front and upper

quadrant of the wheel.

12. Be alert to shifting of the workpiece

or anything that could cause the cut

to close and pinch the wheel,

especially in the upper quadrant.

Support the workpiece in such a

way that the cut remains open.

Never make a cut that results in a

binding of the wheel.

13. Use wet-cutting whenever feasible.

In a pinch situation the water ca n act

as a lubricant and reduce the

energy of reactive forces.

14. Release the pressure on the cut-off

machine as you reach the end of the

cut. Too much pressure may cause

the operator to lose control of the

cut-off machine when the abrasive

wheel completes the cut. The

abrasive wheel may contact the

operator or strike some foreign

object and shatter.

15. Use extreme caution when

reentering a cut and do not turn the

wheel at an angle or push the wheel

into the cut as this may result in a

binding of the wheel.

Gyroscopic Forces

Be alert for gyroscopic forces that are

caused by the rapid spinning of the cutoff wheel. These forces result in

opposition to directional change, e.g.,

when the operator attempts to move the

machine in a sideways direction.

Maintenance, Repair and Storing of the

Cut-Off Machine

Never operate a cut-off machine that is

damaged, improperly adjusted or not

completely or securely assembled.

Follow the maintenance and repair

instructions in the appropriate sections

of your instruction manual.

If you make a warranty claim for a

component that has not been serviced

or maintained properly or if

nonapproved replacement parts were

used, STIHL may deny warranty

coverage.

WARNING

Use only STIHL replacement parts for

maintenance and repair. Use of parts

manufactured by others may cause

serious or fatal injury.

WARNING

Always move retaining latch to ƒ and

remove the battery from the power tool

and make sure that the wheel is stopped

before doing any maintenance or repair

work or cleaning the cut-off machine. Do

not attempt any maintenance or repair

work not described in your instruction

manual. Have such work performed only

at your STIHL servicing dealer.

Regularly check the electrical contacts

and ensure that the insulation of the

power cord and plug of the charger is in

good condition and show no sign of

aging (brittleness).

Electrical components, e.g. power cord

of charger, may only be repaired or

replaced by a qualified electrician.

Clean plastic components with a cloth.

Do not use aggressive detergents. They

may damage the plastic.

Clean the ventilation slots if necessary.

Keep the battery guides free from

foreign matter – clean as necessary.

Clean off grinding dust after finishing

work.

Do not clean your machine with a

pressure washer. The solid jet of water

will damage parts of the machine.

TSA 230

15

Page 18

English

For any maintenance please refer to the

maintenance chart and to the warranty

statement near the end of the instruction

manual.

Store composite wheels on a flat surface

in a dry place, preferably at a constant

temperature, where there is not a risk of

frost. Do not store a cut-off machine with

a wheel mounted on the machine.

Store the power tool in a dry, locked

location with retaining latch on ƒ, the

battery removed and out of reach of

children.

If the battery is not removed, there is the

risk that the plug-in contacts on the cutoff machine and battery become

corroded. Such corrosion can cause

irreparable damage to the cut-off

machine and battery. Allow the cut-off

machine and battery to dry out

separately if they are wet after use.

General Power Tool Safety

Warnings

This chapter relays the prescribed

wording of general safety advice for

handheld motor-operated electric cut-off

machines contained in UL 60745-1 and

UL 60745-2-22.

The safety precautions and warnings on

avoiding an electric shock given under

"2) Electrical safety" do not apply to

STIHL cordless electric power tools.

WARNING

Read all safety warnings and all

instructions. Failure to follow the

warnings and instructions may result in

electric shock, fire and/or serious injury.

Save all warnings and instructions for

future reference.

The term "power tool" in the warnings

refers to your mains-operated (corded)

power tool or battery-operated

(cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite

accidents.

b) Do not operate power tools in

explosive atmospheres, such as in

the presence of flammable liquids,

gases or dust. Power tools create

sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away

while operating a power tool.

Distractions can cause you to lose

control.

2) Electrical safety

a) Power tool plugs must match the

outlet. Never modify the plug in any

way. Do not use any adapter plugs

with earthed (grounded) power

tools. Unmodified plugs and

matching outlets will reduce risk of

electric shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric

shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or

wet conditions. Water entering a

power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use

the cord for carrying, pulling or

unplugging the power tool. Keep

cord away from heat, oil, sharp

edges or moving parts. Damaged or

entangled cords increase the risk of

electric shock.

e) When operating a power tool

outdoors, use an extension cord

suitable for outdoor use. Use of a

cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a

residual current device (RCD)

protected supply. Use of an RCD

reduces the risk of electric shock.

16

TSA 230

Page 19

English

3) Personal safety

a) Stay alert, watch what you are doing

and use common sense when

operating a power tool. Do not use a

power tool while you are tired or

under the influence of drugs,

alcohol or medication. A moment of

inattention while operating power

tools may result in serious personal

injury.

b) Use personal protective equipment.

Always wear eye protection.

Protective equipment such as dust

mask, non-skid safety shoes, hard

hat, or hearing protection used for

appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting.

Ensure the switch is in the offposition before connecting to power

source and/or battery pack, picking

up or carrying the tool. Carrying

power tools with your finger on the

switch or energizing power tools

that have the switch on invites

accidents.

d) Remove any adjusting key or

wrench before turning the power

tool on. A wrench or a key left

attached to a rotating part of the

power tool may result in personal

injury.

e) Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the

power tool in unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewelry. Keep your hair,

clothing and gloves away from

moving parts. Loose clothes,

jewelry or long hair can be caught in

moving parts.

g) If devices are provided for the

connection of dust extraction and

collection facilities, ensure these

are connected and properly used.

Use of dust collection can reduce

dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the

correct power tool for your

application. The correct power tool

will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the

switch does not turn it on and off.

Any power tool that cannot be

controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories,

or storing power tools. Such

preventive safety measures reduce

the risk of starting the power tool

accidentally.

d) Store idle power tools out of the

reach of children and do not allow

persons unfamiliar with the power

tool or these instructions to operate

the power tool. Power tools are

dangerous in the hands of untrained

users.

e) Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any

other condition that may affect the

power tool's operation. If damaged,

have the power tool repaired before

use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools

with sharp cutting edges are less

likely to bind and are easier to

control.

g) Use the power tool, accessories

and tool bits etc. in accordance with

these instructions, taking into

account the working conditions and

the work to be performed. Use of the

power tool for operations different

from those intended could result in a

hazardous situation.

5) Battery tool use and care

a) Recharge only with the charger

specified by the manufacturer. A

charger that is suitable for one type

of battery pack may create a risk of

fire when used with another battery

pack.

b) Use power tools only with

specifically designated battery

packs. Use of any other battery

packs may create a risk of injury and

fire.

TSA 230

17

Page 20

English

c) When battery pack is not in use,

keep it away from other metal

objects, like paper clips, coins,

keys, nails, screws or other small

metal objects, that can make a

connection from one terminal to

another. Shorting the battery

terminals together may cause burns

or a fire.

d) Under abusive conditions, liquid

may be ejected from the battery;

avoid contact. If contact accidentally

occurs, flush with water. If liquid

contacts eyes, additionally seek

medical help. Liquid ejected from

the battery may cause irritation or

burns.

6) Service

a) Have your power tool serviced by a

qualified repair person using only

identical replacement parts. This

will ensure that the safety of the

power tool is maintained.

7) Safety instructions for abrasive

cutting-off operations

Cut-off machine safety warnings

a) The guard provided with the tool

must be securely attached to the

power tool and positioned for

maximum safety, so the least

amount of wheel is exposed

towards the operator. Position

yourself and bystanders away from

the plane of the rotating wheel. The

guard helps to protect operator from

broken wheel fragments and

accidental contact with wheel.

b) Use only bonded reinforced or

diamond cut-off wheels for your

power tool. Just because an

accessory can be attached to your

power tool, it does not assure safe

operation.

c) The rated speed of the accessory

must be at least equal to the

maximum speed marked on the

power tool. Accessories running

faster than their rated speed can

break and fly apart.

d) Wheels must be used only for

recommended applications. For

example: do not grind with the side

of cut-off wheel. Abrasive cut-off

wheels are intended for peripheral

grinding, side forces applied to

these wheels may cause them to

shatter.

e) Always use undamaged wheel

flanges that are of correct diameter

for your selected wheel. Proper

wheel flanges support the wheel

thus reducing the possibility of

wheel breakage.

f) Do not use worn down reinforced

wheels from larger power tools.

Wheels intended for a larger power

tool are not suitable for the higher

speed of a smaller tool and may

burst.

g) The outside diameter and the

thickness of your accessory must

be within the capacity rating of your

power tool. Incorrectly sized

accessories cannot be adequately

guarded or controlled.

h) The arbour size of wheels and

flanges must properly fit the spindle

of the power tool. Wheels and

flanges with arbour holes that do not

match the mounting hardware of the

power tool will run out of balance,

vibrate excessively and may cause

loss of control.

i) Do not use damaged wheels.

Before each use, inspect the wheels

for chips and cracks. If power tool or

wheel is dropped, inspect for

damage or install an undamaged

wheel. After inspecting and

installing the wheel, position

yourself and bystanders away from

the plane of the rotating wheel and

run the power tool at maximum no

load speed for one minute.

Damaged wheels will normally

break apart during this test time.

j) Wear personal protective

equipment. Depending on

application, use face shield, safety

goggles or safety glasses. As

appropriate, wear dust mask,

hearing protectors, gloves and shop

apron capable of stopping small

abrasive or workpiece fragments.

The eye protection must be capable

of stopping flying debris generated

by various operations. The dust

mask or respirator must be capable

of filtrating particles generated by

your operation. Prolonged exposure

to high intensity noise may cause

hearing loss.

18

TSA 230

Page 21

English

k) Keep bystanders a safe distance

away from work area. Anyone

entering the work area must wear

personal protective equipment.

Fragments of workpiece or of a

broken wheel may fly away and

cause injury beyond immediate

area of operation.

l) Hold the power tool by insulated

gripping surfaces only, when

performing an operation where the

cutting accessory may contact

hidden wiring. Cutting accessory

contacting a "live" wire may make

exposed metal parts of the power

tool "live" and could give the

operator an electric shock.

n) Never lay the power tool down until

the accessory has come to a

complete stop. The spinning wheel

may grab the surface and pull the

power tool out of your control.

o) Do not run the power tool while

carrying it at your side. Accidental

contact with the spinning accessory

could snag your clothing, pulling the

accessory into your body.

p) Regularly clean the power tool’s air

vents. The motor’s fan will draw the

dust inside the housing and

excessive accumulation of

powdered metal may cause

electrical hazards.

q) Do not operate the power tool near

flammable materials. Sparks could

ignite these materials.

8) Further safety instructions for

abrasive cutting-off operations

Kickback and related warnings

Kickback is a sudden reaction to a

pinched or snagged rotating wheel.

Pinching or snagging causes rapid

stalling of the rotating wheel which in

turn causes the uncontrolled power tool

to be forced in the direction opposite of

the wheel’s rotation at the point of the

binding.

For example, if an abrasive wheel is

snagged or pinched by the workpiece,

the edge of the wheel that is entering

into the pinch point can dig into the

surface of the material causing the

wheel to climb out or kick out. The wheel

may either jump toward or away from the

operator, depending on direction of the

wheel’s movement at the point of

pinching. Abrasive wheels may also

break under these conditions.

Kickback is the result of power tool

misuse and/or incorrect operating

procedures or conditions and can be

avoided by taking proper precautions as

given below.

a) Maintain a firm grip on the power

tool and position your body and arm

to allow you to resist kickback

forces. Always use auxiliary handle,

if provided, for maximum control

over kickback or torque reaction

during start-up. The operator can

control torque reactions or kickback

forces, if proper precautions are

taken.

b) Never place your hand near the

rotating accessory. Accessory may

kickback over your hand.

c) Do not position your body in line

with the rotating wheel. Kickback

will propel the tool in direction

opposite to the wheel’s movement

at the point of snagging.

d) Use special care when working

corners, sharp edges etc. Avoid

bouncing and snagging the

accessory. Corners, sharp edges or

bouncing have a tendency to snag

the rotating accessory and cause

loss of control or kickback.

e) Do not attach a saw chain,

woodcarving blade, segmented

diamond wheel with a peripheral

gap greater than 10 mm or toothed

saw blade. Such blades create

frequent kickback and loss of

control.

f) Do not "jam" the wheel or apply

excessive pressure. Do not attempt

to make an excessive depth of cut.

Overstressing the wheel increases

the loading and susceptibility to

twisting or binding of the wheel in

the cut and the possibility of

kickback or wheel breakage.

g) When wheel is binding or when

interrupting a cut for any reason,

switch off the power tool and hold

the power tool motionless until the

wheel comes to a complete stop.

Never attempt to remove the wheel

from the cut while the wheel is in

motion otherwise kickback may

occur. Investigate and take

corrective action to eliminate the

cause of wheel binding.

TSA 230

19

Page 22

English

h) Do not restart the cutting operation

in the workpiece. Let the wheel

reach full speed and carefully reenter the cut. The wheel may bind,

walk up or kickback if the power tool

is restarted in the workpiece.

i) Support panels or any oversized

workpiece to minimize the risk of

wheel pinching and kickback. Large

workpieces tend to sag under their

own weight. Supports must be

placed under the workpiece near

the line of cut and near the edge of

the workpiece on both sides of the

wheel.

j) Use extra caution when making a

"pocket cut" into existing walls or

other blind areas. The protruding

wheel may cut gas or water pipes,

electrical wiring or objects that can

cause kickback.

Sample applications

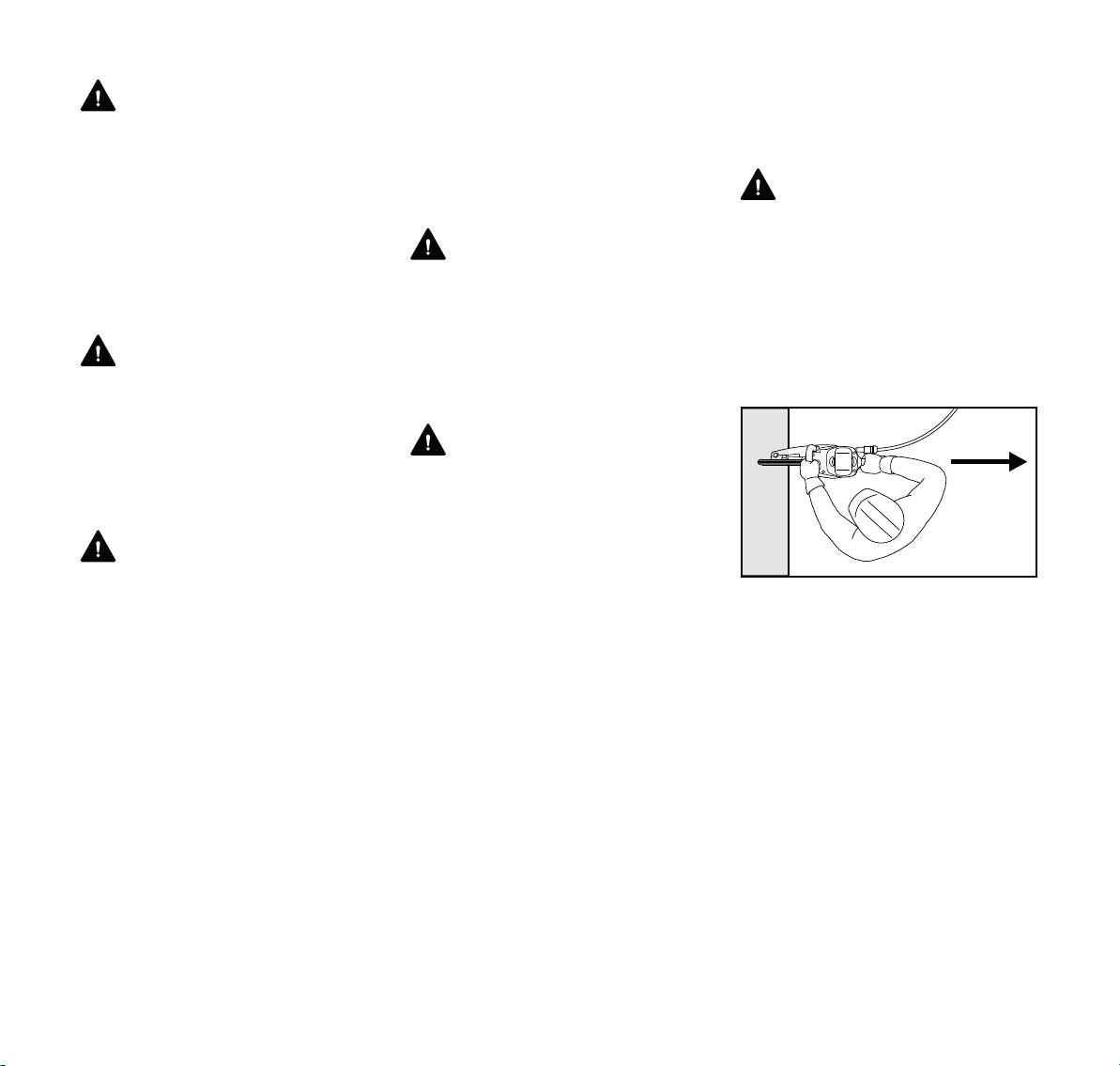

Water connection

– A water attachment kit is mounted

on the machine for use with all types

of water supply.

– A pressurized 2.6 gallons (10 liter)

water tank is available from STIHL

for wet cutting.

Use clean water for binding dust.

Most diamond cutting wheels are

suitable for wet cutting

Wet cut whenever feasible. It increases

the service life and cutting speed of

diamond cutting wheels.

Ensure that the cutting wheel is

generously supplied with water.

Wet cutting helps to suppress dust. The

water binds the dust. The cutting wheel

must be supplied with at least 20 fl. oz

(0.6 liters) water per minute.

Wet cutting can also reduce the energy

of reactive forces. In a pinch situation,

the water can act as a lubricant.

Composite resin wheels can be used for

dry cutting of metals or for wet or dry

cutting of concrete, stone or masonry.

Composite resin wheels designed for

dry cutting

Special procedures must be followed

when wet cutting with a composite nondiamond wheel designed for dry cutting.

See the section entitled "Wet Cutting

with Abrasive Wheels" in the safety

precautions of this manual. Wet cutting

is generally not suitable for cutting

metals.

Composite resin wheels designed for

wet cutting

Adjust water flow rate

during cutting so it is sufficient to bind all the dust

that occurs (at least

20 fl. oz (0.6 L/min)).

If the water flow rate is too high, the

cutting wheel may skim on the water

surface in the cut and greatly reduce

cutting performance. To avoid this, do

not exceed a water flow rate of about

135 fl. oz (4 L/min).

Use water properly:

1. Make certain water does not flow on

wheel that is not running, since a

composite wheel will absorb water

and that will affect wheel balance.

2. After finishing work, run the cutting

wheel at normal operating speed for

about 3 to 6 seconds without water

so that the remaining water is flung

off.

Respiratory protection

WARNING

If wet cutting at the recommended flow

rate is not utilized, the operator and any

bystanders should always wear a

respirator approved by NIOSH/MSHA

for the material being cut. Even if wet

cutting, an operator who is actively

20

TSA 230

Page 23

English

A

8016BA007 KN

180BA028 AM

cutting for more than two hours a day

should wear at least a NIOSH-approved

disposable respirator.

Points to be noted with diamond and

composite cutting wheels

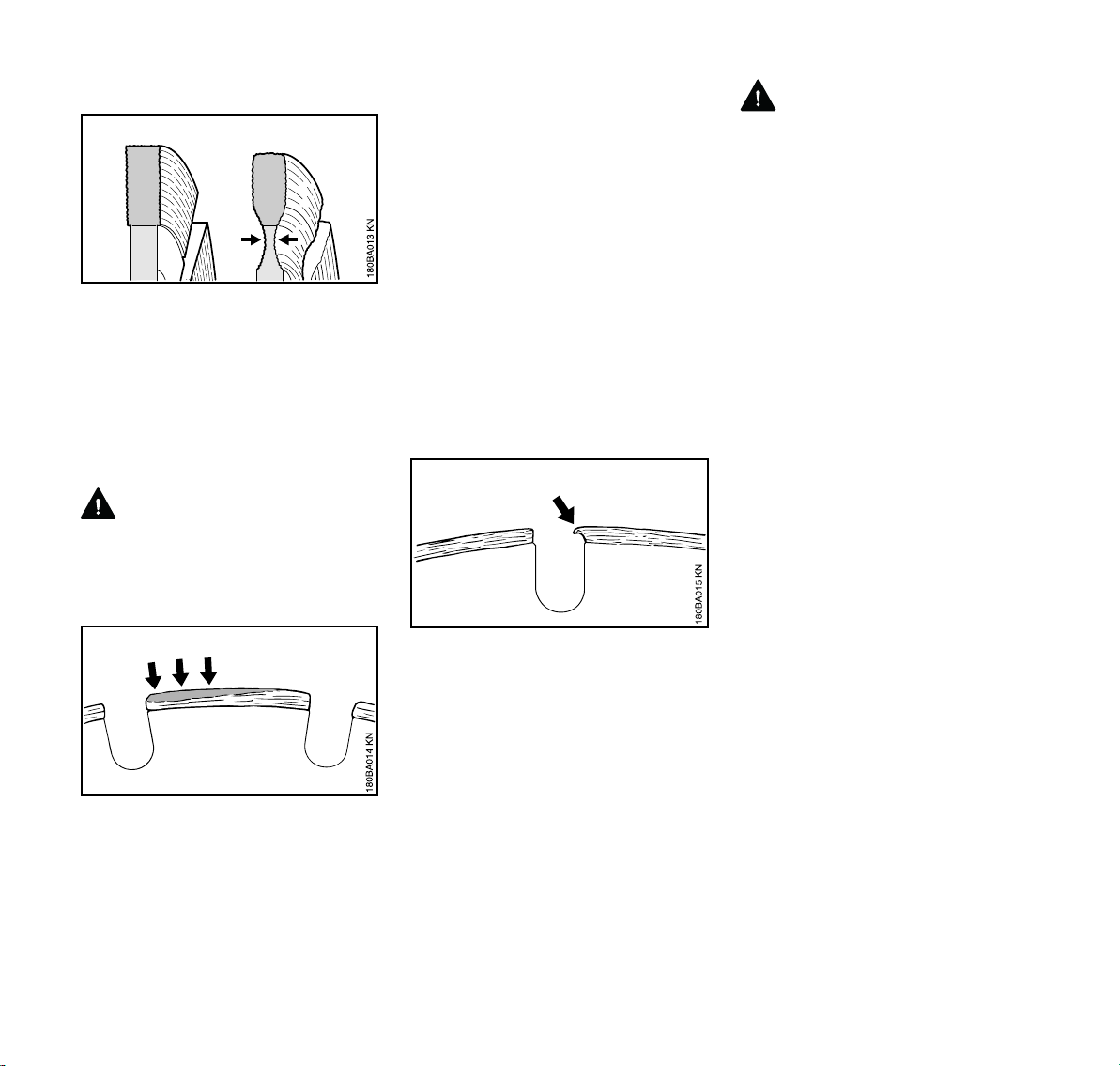

Object to be cut

– Must be fully supported

– Must be secured so that it cannot

roll or slip away

– Must be protected against vibration

The cutting sequence

The cutting sequence is important when

cutting openings and recesses, etc. The

last cut must always be made in such a

way that the cutting wheel cannot

become bound and so that the user is

not at risk of being injured by the part

that has been cut off or out.

If applicable, leave small ridges of uncut

material to hold the severed part in

position. These ridges can subsequently

be broken through.

A number of points must be decided

before the part is finally severed:

– How heavy is the part?

– In which direction can it move after

being severed?

– Is it under tension?

Helpers must not be put at risk of injury

when the part is broken off or out.

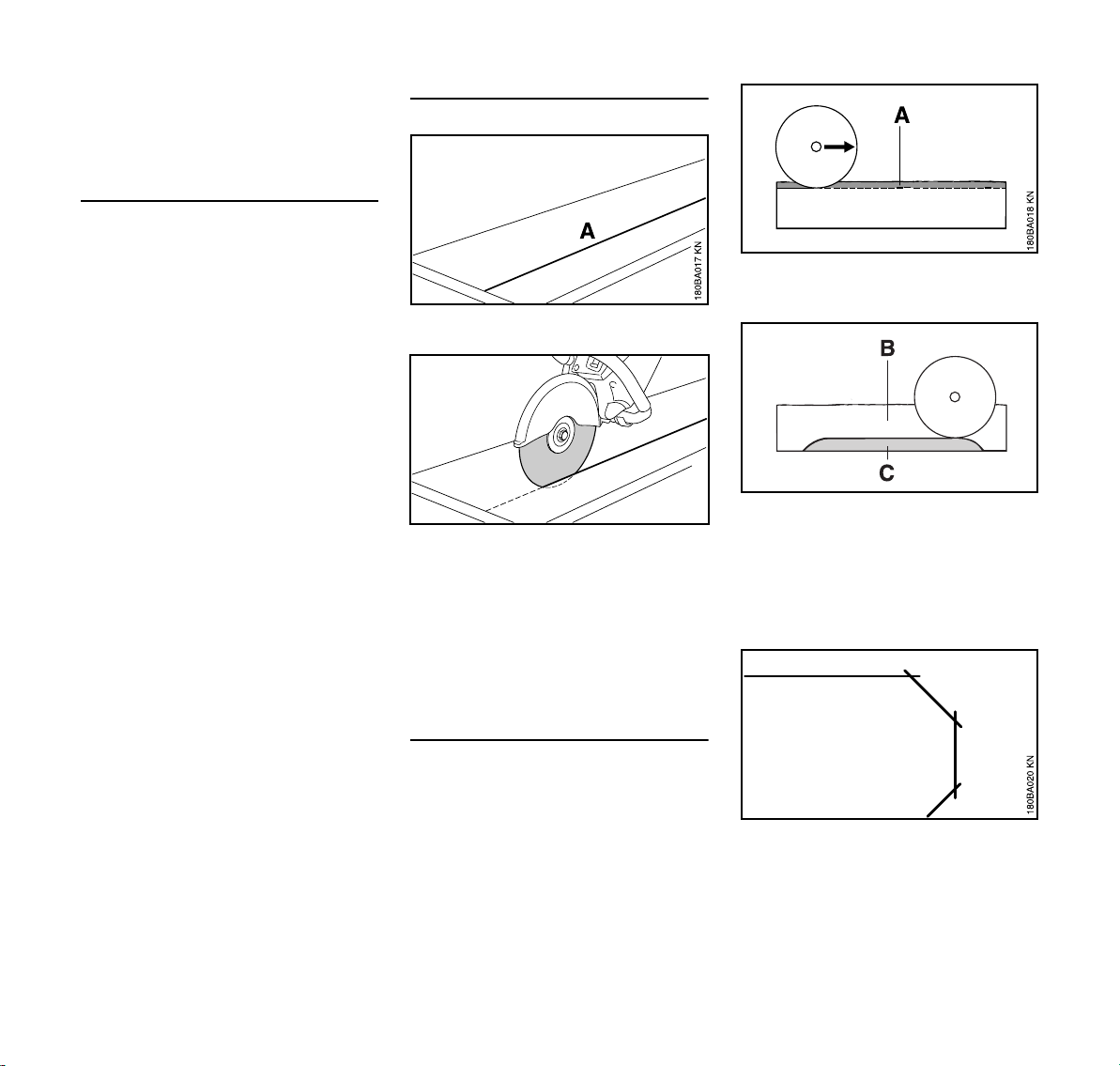

Cutting in several passes

N Mark cutting line (A).

N Work along the cutting line. If

corrections are necessary, always

reposition the cutting wheel, taking

care to ensure that it is not wedged.

The cutting depth per pass should

not exceed 2 cm (0.8“). Thicker

material must be cut in several

passes.

Cutting slabs

N Secure the slab (e. g. on a non-slip

surface, sandbed).

N Cut a guiding groove (A) along the

marked line.

N Cut deeper into the parting cut (B).

N Leave a ridge (C) of uncut material.

N Cut through the slab at the ends so

the material does not chip.

N Then break the slab.