Page 1

RE 150, 170

Instruction Manual2 - 24

Page 2

English

Contents

1 Introduction................................................. 2

2 Guide to Using this Manual.........................2

3 Overview..................................................... 3

4 Safety Precautions......................................4

5 Preparing the pressure washer for operation

.................................................................. 10

6 Assembling the pressure washer..............10

7 Connecting to a water source................... 12

8 Connecting the pressure washer to the

power supply.............................................14

9 Switching the pressure washer on and off 14

10 Operating the pressure washer.................15

11 After Finishing Work..................................17

12 Transporting..............................................18

13 Storing.......................................................19

14 Cleaning....................................................19

15 Maintenance............................................. 20

16 Repairing...................................................20

17 Troubleshooting........................................ 20

18 Specifications............................................21

19 Spare Parts and Accessories....................23

20 Disposal.................................................... 23

21 EC Declaration of Conformity................... 23

1 Introduction

Dear Customer,

Thank you for choosing STIHL. We develop and

manufacture our quality products to meet our

customers’ requirements. The products are

designed for reliability even under extreme con‐

ditions.

STIHL also stands for premium service quality.

Our dealers guarantee competent advice and

instruction as well as comprehensive service

support.

STIHL expressly commit themselves to a sus‐

tainable and responsible handling of natural

resources. This user manual is intended to help

you use your STIHL product safely and in an

environmentally friendly manner over a long

service life.

We thank you for your confidence in us and hope

you will enjoy working with your STIHL product.

2 Guide to Using this Manual

2.1 Applicable documents

The local safety regulations apply.

► In addition to this Instruction Manual please

read the following documents, make sure you

have understood them and keep them in a

safe place for future reference:

Instruction Manual and packaging of the

–

accessory used

Instruction Manual and packaging of the

–

detergent used

2.2 Warning Notices in Text

DANGER

■ This notice refers to risks which result in seri‐

ous or fatal injury.

► Serious or fatal injuries can be avoided by

taking the precautions mentioned.

WARNING

■ This notice refers to risks which can result in

serious or fatal injury.

► Serious or fatal injuries can be avoided by

taking the precautions mentioned.

NOTICE

■ This notice refers to risks which can result in

damage to property.

► Damage to property can be avoided by tak‐

ing the precautions mentioned.

2.3 Symbols in Text

This symbol refers to a chapter in this

instruction manual.

Translation of Original Instruction Manual

0000008682_005_GB

Printed on chlorine-free paper

Printing inks contain vegetable oils, paper can be recycled.

© ANDREAS STIHL AG & Co. KG 2022

0458-603-0121-B. VA1.C22.

Dr. Nikolas Stihl

IMPORTANT! READ BEFORE USING AND

KEEP IN A SAFE PLACE FOR REFERENCE.

2 0458-603-0121-B

Page 3

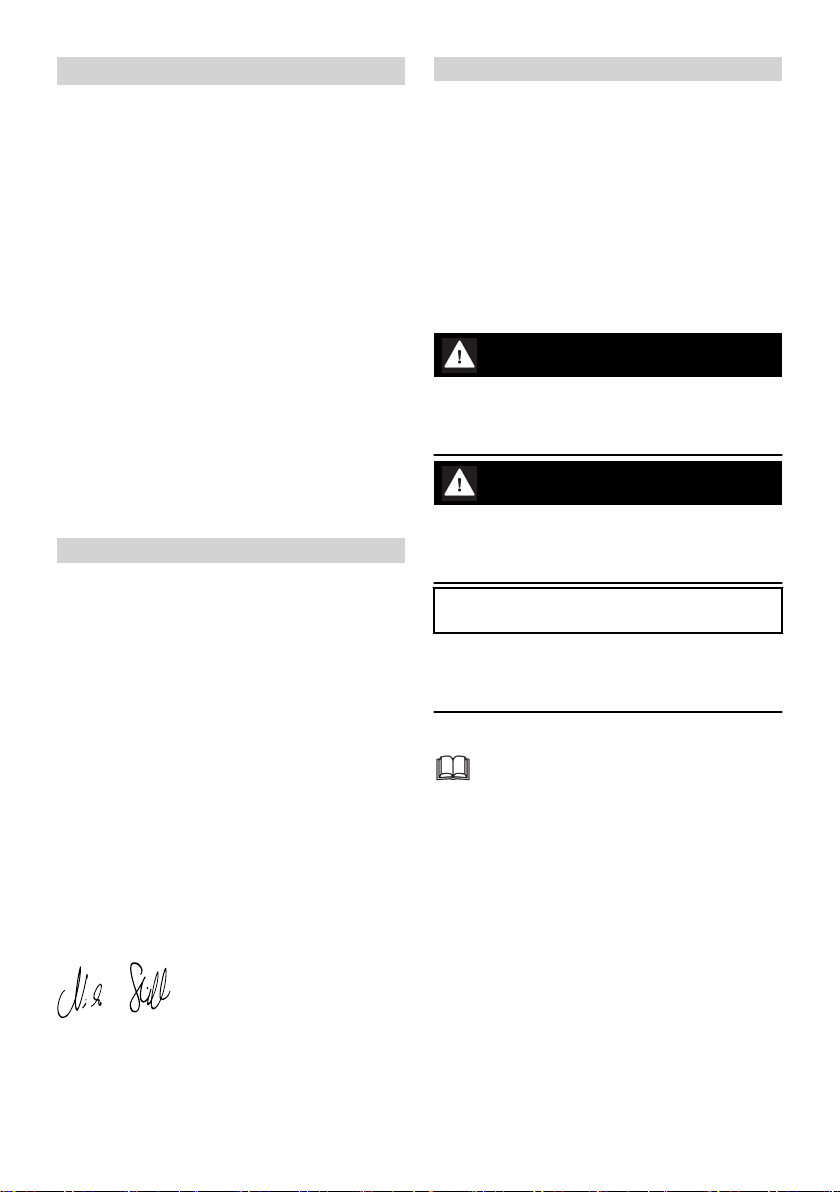

11

14

15

16

4

2

3

5

6

7

10

8

11

9

12

13

13

13

#

0000-GXX-9863-A0

1 2 3

4

5

78 6

0000-GXX-9164-A0

3 Overview English

3 Overview

3.1 Pressure washer

1 Rotary control

The rotary control is used to set the working

pressure and water flow rate.

2 Connecting cord

The connecting cord connects the pressure

washer to the mains plug.

3 Mains plug

The mains plug connects the connecting cord

to a socket.

4 Holder with clip

The holder serves to remove and store the

connecting cord and can be rotated. The clip

attaches the mains plug to the coiled connect‐

ing cord.

5 Trigger switch lockout

The trigger switch lockout blocks the adjust‐

ment of the handle.

0458-603-0121-B 3

6 Dosing handle

The dosing handle is used to set the desired

dosage of cleaning agent.

7 Rotary switch

The rotary switch is used to switch the pres‐

sure washer on and off.

8 Pressure gauge

The pressure of the high-pressure pump is

indicated by the pressure gauge.

9 Flap

The flap covers the supplied nozzles and

cleaning needle.

10 Connector

The connector is used to connect the highpressure hose.

11 Connector

The connector is used to connect the water

hose.

12 Carrying handle

The carrying handle is used to carry the pres‐

sure washer.

13 Support

The supports are used to store the spray gun.

14 Handle

The handle is used when carrying and mov‐

ing the pressure washer.

15 Support

The support is used to store the high-pres‐

sure hose.

16 Detergent container

The detergent container is used for cleaning

with cleaning agent.

# Rating plate with serial number

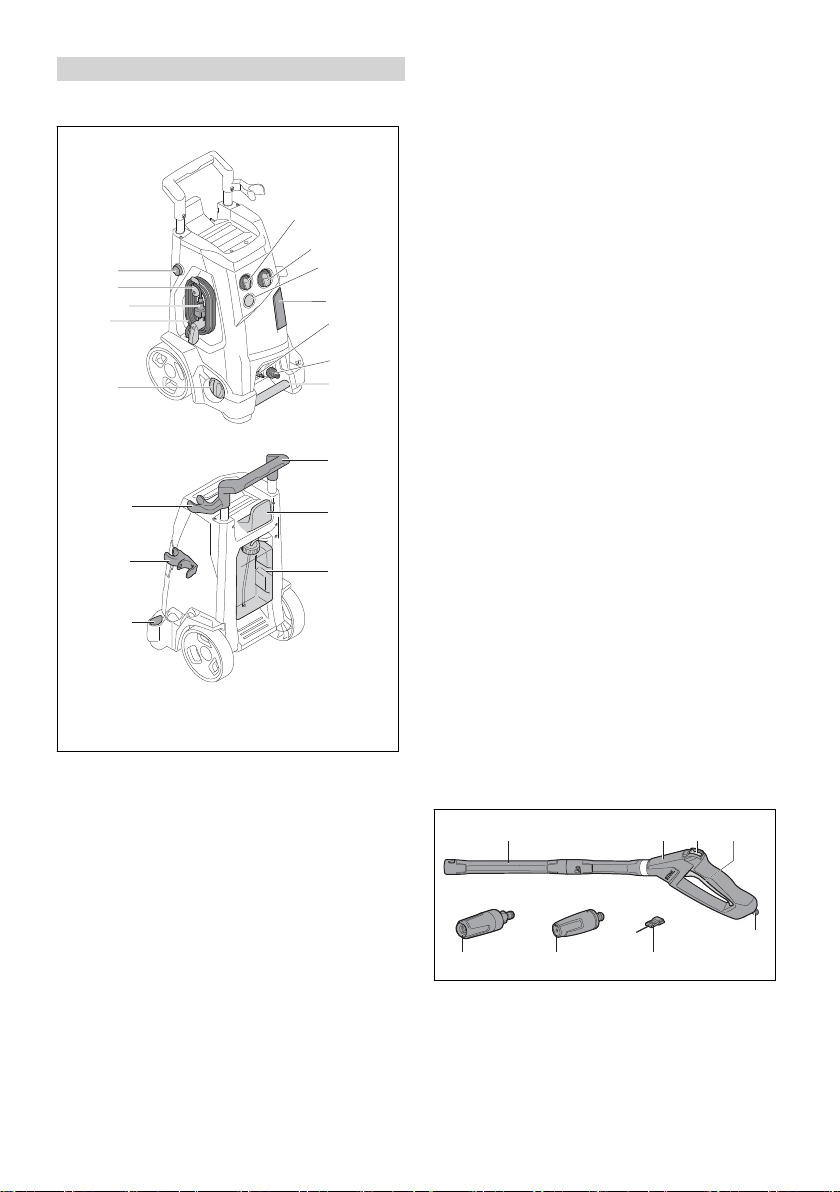

3.2 Spray attachment

1 Spray lance

The spray lance connects the spray gun with

the nozzle.

2 Spray gun

The spray gun is used to hold and guide the

spray attachment.

Page 4

L

W

A

English 4 Safety Precautions

Do not direct the water jet at

3 Retaining latch

The retaining latch unlocks the trigger.

4 Trigger

The trigger opens and closes the valve in the

spray gun. The trigger starts and stops the

water jet.

5 Locking lever

The locking lever holds the connector in the

spray gun.

6 Cleaning pin

The cleaning pin is provided to clean the noz‐

zles.

7 Fan-jet nozzle

The fan-jet nozzle creates a flat water jet.

8 Rotary nozzle

The rotary nozzle creates a hard, rotating

water jet.

3.3 Symbols

The symbols may appear on the pressure

washer and the spraying equipment. Their mean‐

ing is as follows:

In this position, the locking lever unlocks

the lever.

In this position, the locking lever locks the

lever.

Do not dispose of product with the house‐

hold waste.

Guaranteed sound power level in

accordance with Directive 2000/14/EC

in dB(A) to allow noise emissions of

different products to be compared.

These symbols indicate original STIHL

spare parts and original STIHL acces‐

sories.

4 Safety Precautions

4.1 Warning Symbols

The warning symbols on the high-pressure

washer have the following meanings:

Observe safety notices and take the

necessary precautions.

4.2 Intended use

The pressure washer STIHL RE 150 or RE 170

is used for example to clean vehicles, trailers,

patios, paths and facades.

The pressure washer must not be used in the

rain.

WARNING

■

Using the pressure washer other than for its

intended use can result in serious injuries or

death and damage to property.

►

Always use the pressure washer as descri‐

bed in this Instruction Manual.

The pressure washer STIHL RE 150 or RE 170

is not designed to be used for:

Cleaning asbestos cement and similar surfa‐

–

ces

Cleaning surfaces painted or varnished with

–

paints containing lead

Cleaning surfaces which come into contact

–

with foodstuffs.

Cleaning the pressure washer itself

–

4.3 Requirements concerning the

–

people and animals.

Do not direct the water jet at

–

electrical systems, electrical

connections, sockets and live

cables.

Do not direct the water jet at

–

electrical appliances and the

high-pressure washer itself.

If the connecting cable or the extension

cord is damaged: Unplug the mains

plug from the socket.

Do not connect the high-pressure

washer directly to the drinking water

main.

Switch off high-pressure washer during

breaks from operation and before

transport, storage, servicing or repair.

Do not use, transport and store the

high-pressure washers at temperatures

below 0 °C.

user

Read, understand and keep the User

Manual.

Wear safety glasses.

WARNING

■

Users who have not received instruction are

not aware of and cannot assess the dangers

of the pressure washer. The user or other peo‐

ple may be seriously injured or killed.

4 0458-603-0121-B

Page 5

4 Safety Precautions English

►

► Read the Instruction Manual, make

sure you have understood it and

keep it in a safe place for reference.

► If allowing another person to use the pres‐

sure washer: Give them the Instruction

Manual as well.

►

Make sure that the user fulfills the following

requirements:

The user is rested.

–

This machine must not be

–

used by persons (including

children) with reduced

physical, sensory or men‐

tal capabilities or lack of

experience and knowl‐

edge.

The user can identify and assess the

–

dangers of the pressure washer.

The user is of legal age or

–

the user is trained in a pro‐

fession in accordance with

national regulations under

supervision.

The user has received

–

instruction from a STIHL

servicing dealer or other

expert before operating

the pressure washer for

the first time.

The user is not under the influence of

–

alcohol, medicines or drugs.

►

If in any doubt: Contact a STIHL servicing

dealer.

4.4 Clothing and equipment

WARNING

■

Objects may be thrown into the air at high

speed while working. The user may be injured.

► Wear close fitting safety glasses.

Suitable safety glasses tested to

standard EN 166 or national stand‐

ards and bearing the corresponding

mark are available to buy.

Wear a long sleeved, close fitting top and

long trousers.

■ Spray (aerosols) may form while operating.

Breathing in aerosols can be harmful to health

and trigger allergic reactions.

►

Carry out a risk assessment according to

the surface to be cleaned and the surround‐

ing area.

►

If the risk assessment shows formation of

aerosols: Wear a respirator of protection

class FFP2 or equivalent protection class.

■

Wearing unsuitable footwear can cause the

user to slip and fall. The user may be injured.

► Wear sturdy, enclosed footwear with non-

slip soles.

4.5 Work area and surroundings

WARNING

■ Bystanders, children and animals are not

aware of the dangers of the pressure washer

and objects being thrown into the air and can‐

not assess them. Bystanders, children and

animals may be seriously injured and property

may be damaged.

►Keep bystanders, children

and animals away from the

work area.

►Do not leave the pressure

washer unattended.

►Ensure that children cannot

play with the pressure

washer.

■

If you work in the rain or in a damp environ‐

ment, an electric shock may occur. The user

may be seriously injured or killed and the pres‐

sure washer may be damaged.

►

Do not use in rain.

► Position the pressure washer so that it will

not be wet by dripping water.

► Position the pressure washer outside the

wet work area.

■ Electrical components of the pressure washer

can produce sparks. Sparks can cause fires

and explosions in a flammable or explosive

environment. This can result in serious injuries

or death and damage to property.

►

Do not work in a flammable environment or

in an explosive environment.

0458-603-0121-B 5

Page 6

English 4 Safety Precautions

4.6 Safe condition

The high-pressure washer is in a safe condition if

the following conditions are fulfilled:

The high-pressure washer is undamaged.

–

The high-pressure hose, the couplings and the

–

spray attachment are undamaged.

The high-pressure hose, the couplings and the

–

spray attachment are correctly attached.

The connecting cable, the extension cord and

–

their plugs are undamaged.

The high-pressure washer is clean and dry.

–

The spray attachment is clean.

–

The controls function properly and have not

–

been modified.

An original STIHL accessory for this high-pres‐

–

sure washer is fitted.

The accessories are correctly attached.

–

WARNING

■ If not in safe condition, components may no

longer operate correctly and safety devices

may be disabled. This may result in serous or

fatal injury to people.

►

Never use a damaged high-pressure

washer.

► Never use a damaged high-pressure hose,

couplings or spray attachment.

► Attach the high-pressure hose, couplings

and spray attachment as described in this

user manual.

►

Never use a damaged connecting cable,

extension cord or mains plug.

► If the high-pressure washer is dirty or wet:

clean the high-pressure washer and allow it

to dry.

►

If the spray attachment is dirty: Clean the

spray attachment.

► Do not modify the high-pressure washer.

► If the controls do not work: Do not operate

the high-pressure washer.

► Fit original STIHL accessories for this high-

pressure washer.

► Attach accessories as described in this

User Manual or in the User Manual for the

accessories.

►

Do not insert objects into the openings in

the high-pressure washer.

► Replace worn or damaged labels.

► If you have any doubts, be sure to consult a

STIHL dealer.

4.7 Working

WARNING

■

In certain situations, the user may no longer

be able to concentrate on their work. This may

result in the user stumbling, falling and suffer‐

ing serious injury.

►

Keep calm and plan your work.

► In poor light conditions and poor visibility:

Do not operate the high-pressure washer.

► Use the high-pressure washer on your own.

► Watch out for obstacles.

► Work standing on the ground and keep your

balance. If you have to work at a height:

Use a mobile elevating work platform or

secure scaffolding.

►

If you start feeling fatigue: Take a break.

■ If the high-pressure washer starts behaving

differently or in an unusual way while operat‐

ing, the high-pressure washer may be in an

unsafe condition. This may result in serious

injury to people and damage to property.

►

Stop working, unplug the mains plug from

the socket and consult a STIHL dealer.

► The high-pressure washer must always be

operated in an upright position.

► To ensure an adequate exchange of cool‐

ing air, do not cover the high-pressure

washer.

■

When the spray gun trigger is released, the

high-pressure pump switches off automatically

and water stops flowing out of the nozzle. The

high-pressure washer is then in stand-by

mode and is still switched on. If the spray gun

trigger is squeezed, the high-pressure pump

switches on again automatically and water

flows out of the nozzle. This may result in seri‐

ous injury to people and damage to property.

► When not operating the machine: Lock the

spray gun trigger.

► Switch off the high-pressure washer.

► Unplug the mains plug of the high-pressure

washer from the socket.

■ At temperatures below 0° C water can freeze

on the surface to be cleaned and in the com‐

ponents of the high-pressure washer. The

user may slip, fall and be seriously injured.

Damage to property may occur.

►

Do not use the high-pressure washer at

temperatures below 0° C.

■ Pulling on the high-pressure hose, water hose

or connecting cable can cause the high-pres‐

6 0458-603-0121-B

Page 7

4 Safety Precautions English

sure washer to move and topple over. Dam‐

age to property may occur.

► Do not pull on the high-pressure hose,

water hose or connecting cable.

■ If the high-pressure washer is placed on a

sloping, uneven or soft surface it may move

and topple over. Damage to property may

occur.

►

Place the high-pressure washer on a hori‐

zontal, flat, hard surface.

■ If working at a height, the high-pressure

washer or the spray attachment may fall to the

ground. This may result in serious injury to

people and damage to property.

►

Use a lift bucket or secure scaffolding.

► Do not place the high-pressure washer in a

lift bucket or on scaffolding.

► If the high-pressure hose does not have

sufficient reach: Extend the high-pressure

hose by connecting a high-pressure hose

extension.

►

Secure the spray attachment so that it can‐

not fall.

■ The water jet may detach asbestos fibers from

surfaces. Asbestos fibers may spread through

the air after drying and be breathed in. Breath‐

ing in asbestos fibers can be harmful to health.

►

Do not clean surfaces containing asbestos.

■ The water jet may remove oil from vehicles or

machinery. The oily water may enter the soil,

the water system or the drains. That would

create an environmental hazard.

►

Vehicles or machinery should only be

cleaned at places where there is an oil trap

in the water drain.

■

In combination with leaded paint the water jet

can form leaded aerosols and leaded water.

Leaded aerosols and leaded water may enter

the soil, the water system or the drains. Inhal‐

ing aerosols can be harmful to health and trig‐

ger allergic reactions. That would create an

environmental hazard.

►

Do not clean surfaces that are painted or

lacquered with leaded paint.

■ The water jet can damage sensitive surfaces.

Damage to property may occur.

► Do not clean sensitive surfaces with the

rotary nozzle.

► Sensitive surfaces made of rubber, fabric,

wood and similar materials should be

cleaned at a lower operating pressure and

from a greater distance.

■

If while in use the rotary nozzle is immersed in

dirty water and then operated, the rotary noz‐

zle may be damaged.

►

Do not use the rotary nozzle with dirty

water.

► If cleaning a container: Empty the container

and allow the water to flow away while

cleaning it.

■

Easily combustible and explosive liquids that

are sucked in can cause fires and explosions.

Persons may be seriously or fatally injured

and property may be damaged.

►

Do not suck in or spread easily combustible

or explosive liquids.

■ Drawing in irritant, corrosive and toxic liquids

can endanger health and damage components

of the high-pressure washer. Persons may be

seriously or fatally injured and property may

be damaged.

►

Do not suck in or spread irritating, caustic

or toxic liquids.

■ The strong water jet can seriously injure peo‐

ple and animals and cause damage to prop‐

erty.

► Do not direct the water jet at

people and animals.

► Do not direct the water jet at places that are

not fully visible.

► Do not use the water jet to clean clothing

while wearing it.

► Do not use the water jet to clean shoes or

boots while wearing them.

■ If electrical equipment, electrical connections,

sockets and live power cords come into con‐

tact with water, electric shock may result. Per‐

sons may be seriously or fatally injured and

property may be damaged.

► Do not direct the water jet at

electrical systems, electrical

connections, sockets and live

cables.

►

Do not direct the water jet at the connecting

cable or extension cable.

■ If electrical appliances or the high-pressure

washer come into contact with water, electric

shock may result. The user may be seriously

injured or killed and property may be dam‐

aged.

► Do not direct the water jet at

electrical appliances and the

high-pressure washer itself.

► Keep electrical appliances and the high-

pressure washer away from the surface to

be cleaned.

0458-603-0121-B 7

Page 8

English 4 Safety Precautions

■ An incorrectly routed high-pressure hose may

suffer damage. As a result of the damage,

water under high pressure may escape uncon‐

trolled into the surrounding area. This may

result in serious injury to people and damage

to property.

►

Do not direct the water jet at the high-pres‐

sure hose.

► Route the high-pressure hose so that it is

not under tension or tangled.

► Route the high-pressure hose so that it will

not be damaged, kinked or crushed, or cha‐

fed.

►

Protect the high-pressure hose from heat,

oil and chemicals.

■ An incorrectly routed water hose may suffer

damage and people may trip over it. People

may be injured and the water hose may be

damaged.

►

Do not direct the water jet at the water

hose.

► Route and mark the water hose so that

people will not trip over it.

► Route the water hose so that it is not under

tension or tangled.

► Route the water hose so that it will not be

damaged, kinked or crushed, or chafed.

► Protect the water hose from heat, oil and

chemicals.

■ The strong water jet produces reactive forces.

The user may lose control of the spraying sys‐

tem due to the reaction forces that occur. The

user may be seriously injured and property

damage may occur.

►

Hold the spray gun with both hands.

► Work as described in this user manual.

4.8 Detergents

WARNING

■

If detergents come into contact with the skin or

eyes, the skin or eyes may be irritated.

► Observe the user manual for the detergent.

► Avoid contact with detergents.

► If skin contact occurs: Wash affected areas

of skin with plenty of water and soap.

► If eye contact occurs: Flush eyes with

plenty of water for at least 15 minutes and

consult a doctor.

■

Using the wrong or inappropriate detergent

can damage the pressure washer or the sur‐

face of the object being cleaned and be harm‐

ful to the environment.

►

STIHL recommends the use of genuine

STIHL detergents.

► Observe the user manual for the detergent.

► If you have any doubts, be sure to consult a

STIHL dealer.

4.9 Connecting the water supply

WARNING

■

Releasing the spray gun trigger causes a kick‐

back in the water hose. A kickback can force

dirty water back into the drinking water main.

This can pollute the drinking water.

► Do not connect the high-pressure

washer directly to the drinking water

main.

► Observe the regulations of the water supply

company. If required, use proper system

separation (e.g. backflow preventer) when

connecting to the drinking water system.

■

Dirty or sandy water can damage components

of the pressure washer.

► Use clean water.

► If using dirty or sandy water: Use a water fil‐

ter with the pressure washer.

■ If the water supply to the pressure washer is

insufficient, components of the pressure

washer may be damaged.

►

Turn tap fully on.

► Make sure there is a sufficient supply of

water to the pressure washer, 18.

4.10 Connecting to the power supply

Contact with live parts can occur for the following

reasons:

The connecting cord or the extension cord is

–

damaged.

The mains plug of the connecting cord or

–

extension cord is damaged.

The socket is not properly installed.

–

DANGER

■

Contact with live parts can result in electric

shock. The user may be seriously injured or

killed.

►

Make sure that the connecting cord, exten‐

sion cord and their plugs are undamaged.

If the connecting cord or the extension

cord is damaged:

► Do not touch the damaged areas.

► Unplug the mains plug from the

socket.

►

Make sure your hands are dry before touch‐

ing the connecting cord, extension cord or

plugs.

►

Plug the mains plug of the connecting cord

or extension cord into a properly installed,

fused socket with the correct fuse rating.

8 0458-603-0121-B

Page 9

4 Safety Precautions English

► The mains connection must be carried out

by a qualified electrician and meet the

requirements of IEC 60364-1. It is recom‐

mended that the power supply to this

machine should either be connected via an

earth leakage circuit breaker, which inter‐

rupts the power supply as soon as the leak‐

age current to earth exceeds 30 mA for 30

ms, or has an earth tester.

■ A damaged or unsuitable extension cord can

result in electric shock. People can be seri‐

ously injured or killed.

►

Use an extension cord with the correct

cross-section, 18.3.

► Only use an extension cord which is splash-

proof and approved for outdoor use.

► Use an extension cord that has the same

characteristics as the connecting cord of

the pressure washer, 18.3.

►

It is recommended to use a cable reel that

holds the socket at least 60 mm above the

floor.

►

Route the connecting cord and extension

cord so that they are not under tension or

tangled.

►

Route the connecting cord and extension

cord so that they will not be damaged,

kinked or crushed and will not be chafed.

►

Protect the connecting cord and extension

cord from heat, oil and chemicals.

► Lay the connecting cord and extension cord

on a dry surface.

■ The extension cord warms up in operation. If

that heat cannot escape, it may cause a fire.

► If using a cable reel: Completely unroll the

cable reel.

4.11 Transport

WARNING

■ The pressure washer may topple over or move

during transport. This can result in injuries and

damage to property.

►

Lock spray gun trigger.

► Switch off pressure washer.

WARNING

■ During operation, an incorrect mains voltage

or incorrect mains frequency may result in an

overvoltage in the pressure washer. The pres‐

sure washer may be damaged.

►

Make sure that the mains voltage and the

mains frequency of the power supply match

the data on the rating plate of the pressure

washer.

■

Electrical components may be overloaded dur‐

ing operation if more than one electric power

tool is connected to a multiple socket. The

electrical components may heat up and a fire

may break out. This can result in serious inju‐

ries or death and damage to property.

►

Only ever connect one pressure washer to

one socket.

► Do not connect pressure washers to multi‐

ple sockets.

■ An incorrectly routed connecting cord or

extension cord may be damaged and people

may trip over it. People may be injured and the

connecting cord or extension cord may be

damaged.

►

Route the connecting cord and extension

cord so that the water jet cannot touch

them.

►

Route and mark the connecting cord and

extension cord so that people will not trip

over them.

► Unplug the mains plug of the pressure

washer from the socket.

► Empty detergent container and insert it into

the pressure washer.

► Secure the pressure washer using lashing

straps, belts or a net so that it cannot topple

over and cannot move.

■

At temperatures below 0 °C water may freeze

in components of the pressure washer. The

pressure washer may be damaged.

►

Drain high-pressure hose and spray attach‐

ment.

► If the pressure washer cannot be

transported in a frost-proof envi‐

ronment: Protect the pressure

washer using a glycol-based anti‐

freeze.

4.12 Storage

WARNING

■

Children are not aware of and cannot assess

the dangers of the pressure washer. Children

can be seriously injured.

►

Lock spray gun trigger.

► Switch off pressure washer.

► Unplug the mains plug of the pressure

washer from the socket.

0458-603-0121-B 9

Page 10

1

3

2

4

0000-GXX-9166-A0

English 5 Preparing the pressure washer for operation

► Store the pressure washer out of the reach

of children.

■ Moisture may cause the electrical contacts on

the pressure washer and metal components to

corrode. The pressure washer may be dam‐

aged.

►

Store the pressure washer in a clean, dry

state.

■ At temperatures below 0 °C water may freeze

in components of the pressure washer. The

pressure washer may be damaged.

►

Drain high-pressure hose and spray attach‐

ment.

► If the pressure washer cannot be

stored in a frost-free environment:

Protect the pressure washer using

a glycol-based antifreeze.

4.13 Cleaning, Maintenance and

Repair

WARNING

■ If the mains plug is plugged into a socket

when carrying out cleaning, servicing or

repairs, it is possible that the high-pressure

washer may be switched on inadvertently.

This may result in serious injury to people and

damage to property.

►

Lock the spray gun trigger.

► Switch off the high-pressure washer.

5 Preparing the pressure

washer for operation

5.1 Making the pressure washer ready for use.

The following steps must be performed before

commencing work:

► Make sure that the pressure washer, the high-

pressure hose, the hose coupling and the con‐

necting cord are in a safe condition, 4.6.

►

Cleaning the pressure washer,

► Set up the pressure washer on a firm and level

base, where it will not slide or tip over.

►

Connect the high-pressure hose, 6.3.

►

Connect spray gun, 6.4.

►

Fit spray lance, 6.5.

►

Attach nozzle, 6.6.

►

If using a detergent: Using detergents,

10.5.

► Connect pressure washer to a water source,

7.

►

Connect pressure washer to power supply,

8.1.

► If it is not possible to carry out these steps: Do

not use the pressure washer. Consult a STIHL

servicing dealer.

14.

6 Assembling the pressure

washer

► Unplug the mains plug of the high-pressure

washer from the socket.

■ Harsh detergents, cleaning with a water jet or

sharp objects can damage the high-pressure

washer. If the high-pressure washer is not

properly cleaned, parts may not function prop‐

erly and safety devices can be disabled. They

may cause serious injury to persons.

►

Always clean the high-pressure washer as

described in this user manual.

■ If the high-pressure washer is not properly

serviced or repaired, parts may not function

properly and safety devices can be disabled.

This may result in serous or fatal injury to peo‐

ple.

►

Do not attempt to service or repair the highpressure washer yourself.

► If the connecting cable is faulty or dam‐

aged: Have the connecting cable replaced

by a STIHL dealer.

►

If the high-pressure washer needs to be

serviced or repaired: Contact a STIHL

dealer.

10 0458-603-0121-B

6.1 Assembling the pressure washer

Insert nozzles and cleaning pin

► Open flap (1).

► Insert fan-jet nozzle (2) and rotary nozzle (3).

► Insert cleaning pin (4).

Page 11

2

1

0000-GXX-9864-A0

2

1

0000-GXX-9865-A0

1

2

0000-GXX-9877-A0

1

0000-GXX-9878-A0

0000-GXX-5095-A0

1

2

0000-GXX-5096-A0

1

2

6 Assembling the pressure washer English

6.2 Pulling out and pushing in the

6.3.2 Removing the high-pressure hose

handle

6.2.1 Removing the handle

► Pull off coupling (1)

6.4 Attaching and removing the

► Press locking knob (1) and pull out handle (2).

► Release locking knob (1) and pull out the han‐

dle (2) until it audibly engages.

6.2.2 Inserting the handle

► Press locking knob (1) and insert handle (2).

► Release locking knob (1) and insert handle (2)

until it audibly engages.

6.3 Fitting and removing the high-

6.4.1 Attaching the spray gun

► Push connector (1) into spray gun (2).

► If the connector cannot be pushed easily into

6.4.2 Removing the spray gun

spray gun

The connector (1) audibly engages.

the spray gun (2): Grease the gasket on the

connector (1) with grease for fittings.

pressure hose

6.3.1 Connecting the high-pressure hose

► Press and hold the locking lever (1).

► Pull out connector (2).

► Push the coupling (1) onto the connector (2).

The coupling (1) audibly engages.

► If it is difficult to slide the coupling (1) onto the

connector: Grease the gasket on the connec‐

tor (2) with a fitting grease.

0458-603-0121-B 11

Page 12

0000-GXX-4350-A0

1

2

0000-GXX-4351-A0

2

1

2

1

0000-GXX-9849-A0

2

1

0000-GXX-9850-A0

2

1

0000-GXX-9869-A0

English 7 Connecting to a water source

6.5 Attaching and removing the

6.6.2 Removing the nozzle

spray lance

6.5.1 Attaching the spray lance

► Press nozzle (1) and spray lance (2) together

and turn until stop.

► Pull nozzle (1) and spray lance (2) apart.

► Push spray lance (1) into spray gun (2).

► Twist the spray lance (1) until it engages.

► If the spray lance (1) cannot be pushed easily

into the spray gun (2): Grease the gasket on

the spray lance (1) with grease for fittings.

6.5.2 Removing the spray lance

► Squeeze spray lance (1) and spray gun (2)

together and twist as far as they will go.

► Pull spray lance (1) and spray gun (2) apart.

7 Connecting to a water

source

7.1 Connecting the pressure washer to the water supply

Connecting the water filter

If the pressure washer is operated with sandy

water or water from cisterns, a water filter must

be connected to the pressure washer. The water

filter filters sand and dirt out of the water and

thus protects the components of the pressure

washer from damage.

Depending on the market, the water filter may be

included with the pressure washer.

6.6 Attaching and removing the nozzle

6.6.1 Attaching the nozzle

► Unscrew connector (1).

► Screw water filter (2) onto the water supply

and tighten by hand.

► Screw connector (1) onto water filter (2) and

tighten by hand.

Connecting the water hose

► Push nozzle (1) onto the spray lance (2).

► Twist nozzle (1) until it locks into position.

► If it is difficult to slide the nozzle (1) into the

spray lance: Grease the gasket on the nozzle

(1) with a fitting grease.

The water hose must meet the following require‐

ments:

The water hose has a diameter of 1/2”.

–

The water hose is between 10 m and 25 m

–

long.

► Connect water hose to a water tap.

12 0458-603-0121-B

Page 13

2

1

0000-GXX-9870-A0

1

2

0000-GXX-9871-A0

a

0000-GXX-9880-A0

1

2

0000-GXX-9872-A0

5

2

3

1

4

1

0000-GXX-9873-A0

7 Connecting to a water source English

► Turn on the water tap fully and rinse the water

hose with water.

Sand and dirt will be rinsed out of the water

hose. The water hose will be vented.

► Turn off water tap.

So that the water can be drawn in, the height dif‐

ference between the pressure washer and the

water source must not exceed the max. suction

18.

► Push the coupling (1) onto the connector (2).

The coupling (1) audibly engages.

► Open water tap fully.

► If the spray lance is fitted to the spray gun:

Remove spray lance.

► Keep the trigger of the spray gun pressed until

an even jet of water is delivered by the spray

gun.

► Release spray gun trigger.

► Lock spray gun trigger.

► Fit spray lance.

► Attach the nozzle.

Removing the water hose

lift (a),

The appropriate STIHL suction set must be used.

The suction set includes a water hose with a

special coupling.

Depending on the market, the appropriate STIHL

suction set may be included.

Connect the water filter

If the pressure washer is operated with water

containing sand from water butts, cisterns or

from flowing or still rivers and lakes, a water filter

must be connected to the pressure washer.

Depending on the market, the water filter may be

included with the pressure washer.

► Turn off water tap.

► To release the coupling: Pull or turn ring (1)

and hold.

► Pull the coupling off the connector (2).

► Unscrew connector (1).

► Screw water filter (2) onto the water supply

and tighten by hand.

Connect the water hose

7.2 Connecting the pressure

washer to another water supply

The pressure washer can draw in water from

water butts, cisterns and flowing or still rivers and

lakes.

0458-603-0121-B 13

► Fill the water hose (1) with water so that no air

is present in the water hose any more.

Page 14

1

3

4

2

0000-GXX-9866-A0

0000-GXX-4357-A0

0000-GXX-4358-A0

English 8 Connecting the pressure washer to the power supply

► Screw coupling (2) onto the connector of the

water filter (3) and tighten by hand.

► Attach suction cup (4) to the water source so

that the suction cup (4) does not touch the

ground.

► Turn rotary control (5) in direction + up to the

stop.

► If the spray gun is fitted to the high-pressure

hose: Remove spray gun.

► Hold high-pressure hose downwards.

► Switch on pressure washer until an even water

jet flows out of the high-pressure hose.

NOTICE

■ If the pressure washer does not suck in water,

the pump may run dry and the pressure

washer may be damaged.

►

If no water escapes from the high-pressure

hose after two minutes: Switch off pressure

washer and check water supply.

►

Switch off pressure washer.

► Connect the spray gun to the high-pressure

hose.

► Press and hold down spray gun trigger.

► Switch on pressure washer.

8 Connecting the pressure

washer to the power supply

8.1 Connecting the pressure

washer to the power supply

9 Switching the pressure

washer on and off

9.1 Switch on high-pressure washer

When the pressure washer is switched on, volt‐

age fluctuations may occur under unfavorable

mains conditions. The voltage fluctuations may

negatively affect other connected electrical appli‐

ances.

► Turn the rotary switch to the I position.

9.2 Switching off the pressure washer

► Turn the rotary switch to the 0 position.

► Turn the rotary switch (1) to the 0 position.

► Swivel lower holder (2) downwards.

► Remove connecting cord (3).

► Plug the plug (4) of the connecting cord into a

correctly installed socket.

14 0458-603-0121-B

Page 15

0000-GXX-4359-A0

1

2

0000-GXX-9836-A0

0000-GXX-4360-A0

1

2

0000-GXX-4612-A0

1

2

10 Operating the pressure washer English

10 Operating the pressure

washer

10.1 Holding and controlling the

10.3 Pressing and locking the spray gun lever

Press spray gun lever

spray gun

►

► Hold the spray gun by the handle with one

hand, wrapping your thumb around the han‐

dle.

► Hold the spray lance firmly with your other

hand, wrapping your thumb around the spray

lance.

► Point the nozzle at the ground.

10.2 Setting the working pressure and the water flow rate

Move retaining latch (1) to the

► Press and hold lever (2).

The high pressure pump switches on automat‐

ically and water flows out of the nozzle.

Lock spray gun lever

► Release lever (2)

The high pressure pump switches off automat‐

ically and water no longer flows out of the noz‐

zle. The pressure washer is still switched on.

►

Move retaining latch (1) to the

position.

position.

10.4 Cleaning

The following nozzles can be used depending on

the application:

Fan-jet nozzle: The fan jet nozzle is suitable

–

for cleaning large surfaces.

Rotary nozzle: The rotary nozzle is suitable for

–

removing stubborn dirt.

Work can be carried out at a small distance if

Increase working pressure and water flow rate

► Turn rotary control (1) towards +.

Decrease working pressure and water flow rate

► Turn rotary control (1) towards –.

The pressure in the high-pressure pump is indi‐

cated by the pressure gauge (2).

stubborn dirt is to be removed.

Work can be carried out at a great distance if the

following surfaces are to be cleaned:

Varnished surfaces

–

Surfaces made of wood

–

Rubber surfaces

–

0458-603-0121-B 15

Page 16

0000-GXX-9848-A0

0000-GXX-5094-A0

1

2

0000-GXX-9837-A1

0000-GXX-9838-A0

2

1

0000-GXX-9876-A0

3

0000-GXX-9170-A0

English 10 Operating the pressure washer

► Grasp the recessed grip (1) of the detergent

container and remove it.

► Unscrew cover (2).

► Dose and use detergent as described in the

Instruction Manual of the surface cleaner.

► Turn the cover onto the detergent container

and tighten it firmly by hand.

► Grasp the recessed grip of the detergent con‐

tainer and insert it into the pressure washer.

The fan jet nozzle can be adjusted.

If the flat jet nozzle is turned in the + direction,

the working pressure increases.

If the flat jet nozzle is turned in the – direction,

the working pressure decreases.

► Before cleaning, point the water jet at an

10.5.2 Suction of detergent from separate

detergent container

The cover ot the detergent container has a

standard thread and fits all standard detergent

containers. A separate detergent container may

be used.

inconspicuous spot on the surface and check

that the surface is not damaged.

► Select the distance between the nozzle and

the surface to be cleaned so that the surface

to be cleaned is not damaged.

► Adjust the flat spray nozzle so that the surface

to be cleaned is not damaged.

► Remove detergent container.

► Unscrew cover of detergent container

► Screw the cap with intake hose onto a sepa‐

rate detergent container

10.5.3 Working with detergent

► Move the spraying equipment evenly along the

surface to be cleaned.

► Move forward slowly, in a controlled manner.

10.5 Working with detergent

10.5.1 Suction of detergent

Detergents can increase the cleaning effect of

the water.

STIHL recommends the use of genuine STIHL

detergents.

16 0458-603-0121-B

► Turn rotary control (1) in direction + up to the

stop.

► Turn fan jet nozzle (2) in direction - up to the

stop.

Page 17

A

x 100 = V

x 100 = 33,3%

( A + B )

1

( 1 + 2 )

0000-GXX-9861-A0

QR

Q

x V = K

0000-GXX-9862-A0

11 After Finishing Work English

► Set the desired dosage.

► Turn dosing handle (3) to the right (up to

5 %).

The addition of detergents is increased.

► Turn dosing handle (3) to the left (up to

0 %).

The addition of detergents is reduced.

► If the detergent concentration needs to be

adjusted accurately: Measure and calculate

detergent concentration.

► Soak extremely dirty surfaces with water

before cleaning them.

► Press the spray gun lever and spray the deter‐

gent onto the surface to be cleaned.

► Apply the detergent starting at the bottom and

working up and do not allow to dry.

► Turn the dosing handle to the left as far as it

will go.

Detergent is no longer sucked in.

► Clean surface.

Measuring and calculating the detergent concen‐

tration.

► Turn the rotary control to set the working pres‐

sure and water quantity in the + direction up to

the stop.

► Turn the dosing handle for cleaning detergent

to the right as far as it will go.

► Fill the detergent container with cleaning agent

up to the 0.5 liter mark.

► Turn the fan jet nozzle in the direction - up to

the stop.

► Switch on pressure washer.

► Hold the spray gun in an empty collecting con‐

tainer.

► Actuate the spray gun and fill 2 liters into the

collecting container.

► Determine the consumption of detergent

„QR“ from the detergent container.

Calculation of the actual detergent concentration:

10.5.4 Measuring and calculating the deter‐

gent concentration

For a few detergents, the concentration must be

precisely set. In this case, the water flow rate

and the consumption of detergent must be meas‐

ured.

Calculating the predilution of the detergent in %

If the predilution is not indicated as a % value on

the packaging of the detergent used, it can be

determined as follows:

Ratio value

1:1 = 50 %

–

1:2 = 33.3 %

–

1:3 = 25 %

–

1:5 = 16.6 %

–

1:10 = 9 %

–

Example: Calculation ratio value 1:2.

A = 1

–

B = 2

–

QR = Quantity of detergent used (in liters).

–

Q = 2 liters.

–

V = Pre-dilution of the cleaning agent (in %).

–

K = Concentration of the cleaning agent..

–

► If the calculated concentration differs from the

desired one: Reduce dosage at the dosing

handle and repeat measurement and calcula‐

tion.

11 After Finishing Work

11.1 After finishing work

► Switch off the pressure washer and pull the

mains plug out of the socket.

► If the pressure washer is connected to the

water supply: Turn off water tap.

► Press spray gun trigger.

The water pressure is released.

► Lock spray gun trigger.

► Disconnect pressure washer from the water

supply.

► Remove water hose.

► Remove high-pressure hose and let the

0458-603-0121-B 17

remaining water run out of the high-pressure

hose.

Page 18

2

1

0000-GXX-9867-A0

3

0000-GXX-9853-A0

5

4

0000-GXX-9840-A0

7

6

0000-GXX-9874-A0

8

8

8

8

8

8

8

0000-GXX-9868-A0

English 12 Transporting

► Remove and clean the nozzle and spray

lance.

► Remove the spray gun and let the remaining

water run out of the spray gun.

► Clean the pressure washer.

► Store the spray attachment in the holders (8)

on the pressure washer.

11.2 Protecting the pressure washer

with antifreeze

► Swivel lower holder (1) upwards

► Coil the connecting cord (2) on the holder (1).

► Secure the connecting cord (2) using the clip

on the support (1).

► Insert detergent container (3).

► Insert fan-jet nozzle (4) or rotary nozzle (5).

If the pressure washer cannot be protected from

frost during transport or storage, the pressure

washer should be protected by a glycol-based

antifreeze. The antifreeze prevents water inside

the pressure washer from freezing and causing

damage to the pressure washer.

► Remove spray lance

► Connect the shortest possible water hose to

the pressure washer.

The shorter the water hose, the less antifreeze

is needed.

► Mix the antifreeze as described in the anti‐

freeze Instruction Manual.

► Pour antifreeze into a clean container.

► Insert water hose into container of antifreeze.

► Squeeze and hold spray gun trigger.

► Switch on pressure washer.

► Hold down spray gun trigger until an even jet

of antifreeze is delivered from the spray gun

and point the spray gun into the container.

► Press and release spray gun trigger several

times.

► Switch off pressure washer and unplug mains

plug from the socket.

► Detach spray gun, high-pressure hose and

water hose and allow antifreeze to run into the

container.

► Store and dispose of antifreeze in accordance

with the applicable regulations and in an envi‐

ronmentally responsible manner.

12 Transporting

12.1 Transporting the high-pressure

► Roll up the high-pressure hose (6) and hang it

on the holder (7).

18 0458-603-0121-B

► Switch off the high-pressure washer and pull

► Empty or secure the detergent container so

washer

the mains plug out of the socket.

that it cannot topple over, fall down and cannot

move.

Page 19

1

2

1

0000-GXX-9875-A0

0000098883_A1

0000-GXX-4370-A0

2

1

0000-GXX-9881-A0

13 Storing English

Carrying or pulling the high-pressure washer

14.2 Cleaning nozzle and spray

lance

► Pull the high-pressure washer using handle

(1).

► Carry the pressure washer by the handle (1)

and the carrying handle (2).

Transporting the high-pressure washer in a vehi‐

cle

► Secure the high-pressure washer so that it

cannot turn over or move.

► If the high-pressure washer cannot be trans‐

ported in a frost-proof environment: Protect

the high-pressure washer using antifreeze.

13 Storing

13.1 Storing the pressure washer

► Switch off pressure washer and unplug mains

plug from the socket.

► The pressure washer should be stored in such

a way that the following conditions are fulfilled:

The pressure washer is out of the reach of

–

children.

The pressure washer is clean and dry.

–

The pressure washer is in an enclosed

–

room.

The pressure washer is in a temperature

–

range above 0 °C.

If the pressure washer cannot be protected

–

from frost in storage: Protect the pressure

washer with antifreeze.

14 Cleaning

14.1 Cleaning the high-pressure washer and accessories

► Switch off the high-pressure washer and pull

the mains plug out of the socket.

► Clean the high-pressure washer, high-pres‐

sure hose, spray gun and accessories with a

damp cloth.

► Clean the connectors and couplings on the

high-pressure washer, high-pressure hose and

spray gun with a damp cloth.

► Clean vents with a paintbrush.

► Rinse the nozzle and spray lance under run‐

ning water and dry with a cloth.

► If the nozzle is clogged: Clean the nozzle with

the cleaning pin.

14.3 Cleaning the water intake screen

► Unscrew the connector (1) of the water con‐

nection.

► Pull water intake screen (2) out of the water

connection.

► Rinse out the water intake screen (2) under

running water.

► Insert water intake screen (2) into water con‐

nection.

► Attach the connector (1) and tighten it by

hand.

14.4 Cleaning the water filter

The water filter must be disassembled to clean it.

0458-603-0121-B 19

Page 20

5

1

0000-GXX-4373-A0

2

3

1

4

English 15 Maintenance

15 Maintenance

15.1 Maintenance intervals

Maintenance intervals depend on the ambient

conditions and the operating conditions. STIHL

recommends the following maintenance inter‐

vals:

Monthly

► Remove gasket (1) from the fastener (2).

► Unscrew fastener (2) from filter housing (5).

► Remove gasket (3) from the fastener (2).

► Remove filter (4) from the filter housing (5).

► Rinse gaskets (1 and 3), fastener (2) and fil‐

ter (4) under running water.

► Grease the gaskets (1 and 3) with grease for

fittings.

► Reassemble the water filter.

► Clean water intake screen.

16 Repairing

16.1 Repairing the pressure washer

The user cannot personally repair the pressure

washer and accessory.

► If the pressure washer or accessory is dam‐

aged: Do not use the pressure washer or

accessory. Consult a STIHL servicing dealer.

17 Troubleshooting

17.1 Correcting faults in the pressure washer

Fault Cause Remedy

The pressure washer

does not start, even

though the trigger of

the spray gun is

pressed.

The pressure washer

does not start when

switched on. The

electric motor buz‐

zes.

The pressure washer

switches off while in

operation.

The plug of the connecting cord or

extension cord is not plugged in.

The circuit-breaker (fuse) or the earthleakage circuit breaker has tripped.

The circuit is electrically overloaded or

defective.

The fuse rating of the socket is too

low.

The extension cord has an incorrect

cross-section.

The extension cord is too long ► Use an extension cord with the cor‐

The electric motor is too warm. ► Allow the pressure washer to cool

The mains voltage is too low. ► Press the trigger of the spray gun

The extension cord does not have the

correct cross-section.

The extension cord is too long. ► Use an extension cord with the cor‐

The plug of the connecting cord or

extension cord has been pulled out of

the socket.

► Plug in connecting cord or extension

cord plug.

► Find and resolve the cause for the

trip. Engage circuit-breaker (fuse) or

the earth-leakage circuit breaker.

► Switch off other electrical consum‐

ers on the same circuit.

► Plug the connecting cord into a

socket with the correct fuse rating,

18.1.

► Use an extension cord with a suffi‐

cient cross-section. 18.3

rect length. 18.3

for 5 minutes.

► Clean the nozzle.

and keep it pressed and switch on

pressure washer.

► Switch off other loads connected to

the same circuit.

► Use an extension cord with an ade‐

quate cross-section, 18.3

rect length. 18.3

► Insert the plug of the connecting

cord or of the extension cord.

20 0458-603-0121-B

Page 21

1

1

1

1

1

0000-GXX-9879-A0

18 Specifications English

Fault Cause Remedy

The circuit-breaker (fuse) or the earth-

The high-pressure

pump switches on

and off repeatedly,

without the trigger of

the spray gun being

pressed.

The working pressure

fluctuates or drops.

The water jet has

changed shape.

Additional detergent

is not drawn in.

Venturi nozzle is worn Have the tool repaired by a STIHL

Connections on pres‐

sure washer, highpressure hose, spray

gun or spray lance

are difficult to con‐

nect to each other.

17.2 Greasing the gaskets

leakage circuit breaker has tripped.

The circuit is electrically overloaded or

defective.

The fuse rating of the socket is too

low.

The electric motor is too warm. ► Allow the pressure washer to cool

The high-pressure pump, the highpressure hose or the spray attachment

are leaking.

There is a water shortage. ► Open water tap completely.

The nozzle is blocked. ► Clean the nozzle.

The water intake screen or water filter

are blocked.

The high-pressure pump, the high-

pressure hose or the spray attachment

are leaking or are defective.

The nozzle is blocked. ► Clean the nozzle.

The nozzle is worn. ► Replace nozzle.

The detergent container is empty. ► Fill the detergent container with

Fan jet nozzle is not turned in direction

- up to the stop.

The connection seals are not lubrica‐

ted.

18 Specifications

► Find and resolve the cause for the

trip. Engage circuit-breaker (fuse) or

the earth-leakage circuit breaker.

► Switch off other electrical consum‐

ers on the same circuit.

► Plug the connecting cord into a

socket with the correct fuse rating,

18.1.

for 5 minutes.

► Clean the nozzle.

► Ask a STIHL servicing dealer to

check the pressure washer.

► Ensure that a sufficient quantity of

water is available.

► Clean water intake screen and water

filter.

► Ask a STIHL servicing dealer to

check the pressure washer.

detergent.

► Turn fan jet nozzle in direction - up

to the stop.

servicing dealer.

►

Lubricate the gaskets 17.2

18.1 Pressure washer STIHL RE 150

Version 230 V / 50 Hz

Fuse (characteristic "C" or "K"): 13 A

–

Power consumption: (EU) 2019/1781 §2(2) (j):

–

2.9 kW

Maximum permitted network impedance: 0.32

–

Ohm

Protection class: I

► Grease gaskets (1) with grease for fittings.

–

Degree of of electrical protection: IPX5

–

Working pressure (p): 14 MPa (140 bar)

–

0458-603-0121-B 21

Page 22

English 18 Specifications

Max. permissible pressure (p max.): 18 MPa

–

(180 bar)

Max. water supply pressure (p in max.): 1 MPa

–

(10 bar)

Max. water throughput (Q max): 10.2 l/min

–

(612 l/h)

Minimum water throughput (Q min.): 9.0 l/min

–

(540 l/h)

Maximum kickback force: 21 N

–

Max. suction lift: 0.5 m

–

Max. water temperature in pressure mode

–

(t in max): 60 °C

Max. water temperature in suction mode:

–

20 °C

sample inspection

Length: 383 mm

–

Width: 380 mm

–

Maximum height: 981 mm

–

Minimu height: 792 mm

–

Length of high-pressure hose: 9 m

–

Weight (m) with accessory attached: 30 kg

–

Version 220-240 V / 50 Hz

Fuse (characteristic "C" or "K"): 10 A

–

Power consumption: (EU) 2019/1781 §2(2) (j):

–

2.2 kW

Maximum permitted network impedance: 0.45

–

Ohm

Protection class: I

–

Degree of of electrical protection: IPX5

–

Working pressure (p): 12 MPa (120 bar)

–

Max. permissible pressure (p max.): 18 MPa

–

(180 bar)

Max. water supply pressure (p in max.): 1 MPa

–

(10 bar)

Max. water throughput (Q max): 8.7 l/min

–

(522 l/h)

Minimum water throughput (Q min.): 7.8 l/min

–

(468 l/h)

Maximum kickback force: 16 N

–

Max. suction lift: 0.5 m

–

Max. water temperature in pressure mode

–

(t in max): 60 °C

Max. water temperature in suction mode:

–

20 °C

sample inspection

Length: 383 mm

–

Width: 380 mm

–

Maximum height: 981 mm

–

Minimu height: 792 mm

–

Length of high-pressure hose: 9 m

–

Weight (m) with accessory attached: 30 kg

–

Version 220 V / 60 Hz

Fuse (characteristic "C" or "K"): 15 A

–

Power consumption: (EU) 2019/1781 §2(2) (j):

–

2.8 kW

Maximum permitted network impedance: 0.32

–

Ohm

Protection class: I

–

Degree of of electrical protection: IPX5

–

Working pressure (p): 13 MPa (130 bar)

–

Max. permissible pressure (p max.): 18 MPa

–

(180 bar)

Max. water supply pressure (p in max.): 1 MPa

–

(10 bar)

Max. water throughput (Q max): 10 l/min

–

(600 l/h)

Minimum water throughput (Q min.): 9.3 l/min

–

(560 l/h)

Maximum kickback force: 20 N

–

Max. suction lift: 0.5 m

–

Max. water temperature in pressure mode

–

(t in max): 60 °C

Max. water temperature in suction mode:

–

20 °C

sample inspection

Length: 383 mm

–

Width: 380 mm

–

Maximum height: 981 mm

–

Minimu height: 792 mm

–

Length of high-pressure hose: 9 m

–

Weight (m) with accessory attached: 30 kg

–

Parameters dependent on pressure have been

measured at an inlet pressure of 0.3 MPa (3

bar).

18.2 Pressure washer STIHL RE 170

Version 230 V / 50 Hz

Fuse (characteristic "C" or "K"): 16 A

–

Power consumption: EU) 2019/1781 §2(2) (j):

–

3.3 kW

Maximum permitted network impedance: 0.32

–

Ohm

Protection class: I

–

Degree of of electrical protection: IPX5

–

Working pressure (p): 15 MPa (150 bar)

–

Max. permissible pressure (p max.): 18 MPa

–

(180 bar)

Max. water supply pressure (p in max.): 1 MPa

–

(10 bar)

Max. water throughput (Q max): 10.8 l/min

–

(648 l/h)

Minimum water throughput (Q min.): 9.5 l/min

–

(570 l/h)

Maximum kickback force: 24 N

–

Max. suction lift: 0.5 m

–

22 0458-603-0121-B

Page 23

19 Spare Parts and Accessories

Max. water temperature in pressure mode

–

(t in max): 60 °C

Max. water temperature in suction mode:

–

20 °C

sample inspection

Length: 383 mm

–

Width: 380 mm

–

Maximum height: 981 mm

–

Minimu height: 792 mm

–

Length of high-pressure hose: 9 m

–

Weight (m) with accessory attached: 30 kg

–

Parameters dependent on pressure have been

measured at an inlet pressure of 0.3 MPa (3

bar).

18.3 Extension Cords

If an extension cord is used, it must have a

ground wire and the wire gage of its conductors

must meet the following minimum requirements –

depending on the line voltage and length of the

extension cord:

If rated voltage on the rating label is 220V to

240V:

Cord length up to 20 m: AWG 15 / 1.5 mm²

–

Cord length 20 m up to 50 m: AWG 13 /

–

2.5 mm²

If rated voltage on the rating label is 100 V to

127 V:

Cord length up to 10 m: AWG 14 / 2.0 mm²

–

Cord length 10 m up to 30 m: AWG 12 /

–

3.5 mm²

18.4 Sound and vibration levels RE 150, 170

The K-value for sound pressure levels is 2 dB(A).

K-value for sound power levels is 2 dB(A). The

K-value for vibration level is 2 m/s².

Sound pressure level LpA measured according

–

to EN 60335-2-79:

71 dB(A)

–

Sound power level LwA measured according to

–

EN 60335-2-79:

85 dB(A)

–

Vibration level ah measured according to EN

–

60335‑2‑79, spray gun: ≤ 2.4 m/s².

18.5 REACH

REACH is an EC regulation and stands for the

Registration, Evaluation, Authorisation and

Restriction of Chemical substances.

For information on compliance with the REACH

regulation see www.stihl.com/reach.

English

19 Spare Parts and Accesso‐

ries

19.1 Spare parts and accessories

These symbols indicate original STIHL

spare parts and original STIHL acces‐

sories.

STIHL recommends the use of original STIHL

spare parts and accessories.

Despite ongoing market observation, STIHL is

unable to judge the reliability, safety and suitabil‐

ity of other manufacturers' spare parts and

accessories; accordingly, STIHL cannot warrant

for the use of those parts.

Original STIHL spare parts and original STIHL

accessories are available from STIHL dealers.

20 Disposal

20.1 Disposing of the pressure washer

Contact the local authorities or your STIHL

dealer for information on disposal.

Improper disposal can be harmful to health and

pollute the environment.

► Take STIHL products including packaging to a

suitable collection point for recycling in accord‐

ance with local regulations.

► Do not dispose with domestic waste.

21 EC Declaration of Con‐

formity

21.1 Pressure washers STIHL RE 150, 170

ANDREAS STIHL AG & Co. KG

Badstraße 115

D-71336 Waiblingen

Germany

declare under our sole responsibility that

Type: high-pressure washer

–

Manufacturer's brand: STIHL

–

Model: RE 150, RE 170

–

Serial number: RE01

–

conforms to the specifications of Directives

2011/65/EU, 2006/42/EC and 2014/30/EU,

2009/125/EC and has been developed and built

in compliance with the versions of the following

standards valid at the production date:

EN 55014‑1, EN 55014‑2, EN 60335‑1,

EN 60335‑2‑79, EN 61000‑3‑2, EN 61000‑3‑11.

0458-603-0121-B 23

Page 24

English 21 EC Declaration of Conformity

The measured and the guaranteed sound power

level have been determined in accordance with

Directive 2000/14/EC, Annex V, and standard

ISO 3744.

Measured sound power level: 85 dB(A)

–

Guaranteed sound power level: 87 dB(A)

–

The technical documents are stored at

ANDREAS STIHL AG & Co. KG Produktzulas‐

sung.

The year of construction, country of manufacture

and the serial number are shown on the highpressure washer.

Waiblingen, 03.02.2021

ANDREAS STIHL AG & Co. KG

HRA 260269, Stuttgart local court

pp

Dr. Jürgen Hoffmann, Director Product Certifica‐

tion & Regulatory Affairs

24 0458-603-0121-B

Page 25

21 EC Declaration of Conformity English

0458-603-0121-B 25

Page 26

English 21 EC Declaration of Conformity

26 0458-603-0121-B

Page 27

21 EC Declaration of Conformity English

0458-603-0121-B 27

Page 28

www.stihl.com

*04586030121B*

0458-603-0121-B

*04586030121B*

0458-603-0121-B

Loading...

Loading...