STIHL RE 108, 118, 128 PLUS

{

Instruction Manual

Notice d’emploi

G Instruction Manual

1 - 23

F Notice d’emploi

25 - 49

Contents

English

Guide to Using this Manual 2

Safety Precautions and Working

Techniques 2

Assembling the Unit 6

Transporting the Unit 7

Fitting, removing spray lance 8

Fitting, removing high-pressure

hose 8

Connecting the water supply 9

Original Instruction ManualPrinted on chlorine-free paper

Connecting to a pressureless water

supply 10

Connecting to Power Supply 10

Switching On 11

Working 11

Adding detergent 12

Switching Off 13

Storing the Machine 13

Maintenance and Care 14

Maintenance 15

First use after long periods of

storage 15

Main Parts 16

Printing inks contain vegetable oils, paper can be recycled.

Specifications 17

Special Accessories 19

Troubleshooting 21

Maintenance and Repairs 23

Disposal 23

Dear Customer,

Thank you for choosing a quality

engineered STIHL product.

This machine has been built using

modern production techniques and

comprehensive quality assurance.

Every effort has been made to ensure

your satisfaction and troublefree use

of the machine.

Please contact your dealer or our

sales company if you have any

queries concerning your machine.

Your

Hans Peter Stihl

{

© ANDREAS STIHL AG & Co. KG, 2011

0458-650-8221. M999.A11.TP.

0000004010_001_GB

RE 108, RE 118, RE 128 PLUS

1

English

Guide to Using this Manual

Pictograms

All the pictograms attached to the

machine are shown and explained in this

manual.

Symbols in text

Warning where there is a risk of

an accident or personal injury or

serious damage to property.

Caution where there is a risk of

damaging the machine or its

individual components.

Engineering improvements

STIHL's philosophy is to continually

improve all of its products. For this

reason we may modify the design,

engineering and appearance of our

products periodically.

Therefore, some changes, modifications

and improvements may not be covered

in this manual.

Safety Precautions and

Working Techniques

The high water pressure

generated and the power

connection are particular

sources of danger.

It is important that you

carefully read the entire

Instruction Manual before

using the machine for the

first time and keep it in a

safe place for future reference. Non-compliance

with the Instruction Manual may cause serious or

even fatal injury.

Warning!

– This appliance is not intended for

use by children and other persons

whose physical, sensory, or mental

capabilities or lack of experience

and knowledge prevents them from

using the appliance safely without

supervision or instruction by a

responsible person.

– Minors should never be allowed to

use the high-pressure cleaner –

except for young trainees over the

age of 16 when working under

supervision.

– Children should be supervised by

responsible person to ensure that

they do not play with the appliance.

– The machine should only be

provided or loaned to people

familiar with this model and its

operation. The instruction manual

should always be handed over with

the machine.

– Do not use the machine if anyone

not wearing protective clothing is in

the working area.

– Before starting any work on the

machine, e. g., cleaning, servicing,

replacement of parts – unplug the

power plug!

Observe the national safety regulations

issued, for example, by the employers'

liability insurance association, social

security institutions, occupational safety

and health authorities or other

organizations.

When not using the machine, it must be

put down in such a way that it does not

endanger anyone. Ensure that the

machine cannot be used without

authorization, unplug the power cord.

The user is responsible for accidents or

risks involving third parties or their

property.

If using the machine for the first time:

Have your STIHL dealer or another

expert show you how to use it safely.

In some countries, operation of

machines that emit noise may be

restricted by municipal regulations.

Observe national regulations.

Unsuitable extension cords may be

dangerous. When working outdoors,

use only extension cords that are

approved for this use and

correspondingly marked and have a

sufficient cross-section.

2

RE 108, RE 118, RE 128 PLUS

English

Never touch the power plug, power cord

and extension cord and electrical plug

connections with wet hands.

Always check that the machine is in

good working order before starting work.

Pay particular attention to the power

cord, mains plug, high-pressure hose,

spray attachment and safety

mechanisms.

Never operate the machine with a

defective high-pressure hose – ensure

that it is replaced immediately.

The machine may only be used when all

parts are in perfect working order.

The high-pressure hose must not be

driven over, pulled, buckled or twisted.

Never pull the high-pressure hose or the

power cord in order to move the

machine.

The high-pressure hose must be

approved for the permissible excess

pressure of the machine.

The permissible excess pressure, the

maximum permitted temperature and

the date of manufacture are stated on

the cladding of the high-pressure hose.

The permissible pressure and date of

manufacture are specified on the fittings.

Accessories and spare parts

or technically equivalent parts may

be mounted on the machine.

Contact a servicing dealer if in

doubt. Use only high-quality

accessories, in order to avoid the

risk of accidents or damage to the

machine.

– STIHL recommends the use of

genuine STIHL parts and

accessories. These have been

optimized for the product and the

user's requirements.

Never modify the machine in any way,

as this could be extremely dangerous.

STIHL excludes all liability for personal

injury and damage to property caused

while using unauthorized attachments.

Physical suitability

The machine may only be operated by

people who are fit, in good physical

health and in good mental condition. If

you have any condition that might be

aggravated by strenuous work, check

with your doctor before operating a

machine.

Anyone who has consumed alcohol,

medicines affecting their ability to react

or drugs must not operate the machine.

Applications

Clothing and equipment

Wear shoes with non-slip soles.

Wear goggles and protective clothing. STIHL

recommends that a

boilersuit be worn in

order to reduce the risk of

injury due to accidental

exposure to the highpressure jet.

Transporting the machine

When transporting the machine in or on

a vehicle, it must be secured, e.g. with

straps, so that it cannot slip or tip over.

Antifreeze is recommended if the

machine and accessories are to be

transported at temperatures near or

below 0° C (32 °F) – see “Storing the

Machine".

Warning!

– High-pressure hoses, fittings and

couplings are important for machine

safety. Only high-pressure hoses,

fittings, couplings and other

accessories which have been

approved by STIHL for this machine

RE 108, RE 118, RE 128 PLUS

The high-pressure cleaner can be used

to clean motor vehicles, machines,

tanks, facades or stables and to remove

rust without dust or sparks.

Other uses are not permitted and may

lead to accidents or damage to the

machine.

3

English

Detergents

Warning!

– Unsuitable detergents can cause

damage to health, as well as to the

machine and the object to be

cleaned. Contact a servicing dealer

if in doubt.

– STIHL recommends the use of

genuine STIHL detergents. Follow

the instructions for use.

– Chemical detergents may contain

physiologically harmful (toxic,

caustic, irritant), flammable or

explosive substances. In the event

of skin or eye contact with

detergent, flush the affected body

parts with plenty of clean water

immediately. If detergent is

swallowed, seek medical attention

immediately. Note the

manufacturer's safety data

sheets!

Detergents should always be used in the

proportions specified by the

manufacturer.

Before starting work

Do not connect the highpressure cleaner directly

to the drinking water

main.

Only connect the high-pressure cleaner

to the drinking water main in conjunction

with a backflow preventer – see "Special

accessories".

Warning!

– If drinking water has passed

through the backflow preventer, it

can no longer be regarded as

drinking water.

Do not use the machine with dirty water.

If there is a risk that dirty water will occur

(e. g., flowing sand), an appropriate

water filter must be used.

Inspecting the high-pressure cleaner

Warning!

– The high-pressure cleaner should

only be used if it is in full working

order – risk of accident!

– It must be possible to move the

switch to the 0 position easily

– The switch must be in the 0 position

– Inspect the high-pressure hose,

spray attachment and safety

mechanisms for damage

– High-pressure hose and spray

attachment in good condition

(clean, moving easily) and correctly

assembled

– For good control of the machine, the

handles should be clean and dry

with no oil or dirt on them

– Never attempt to modify the controls

or safety devices

Electrical connection

Warning!

Minimize the risk of electrical shock:

– Voltage and frequency of the

machine (see rating plate) must

match the voltage and frequency of

the mains supply

– Examine the power cord, power

plug and extension cord for

damage. Damaged cords,

couplings and plugs or power cords

that do not comply with the

regulations must not be used

– Only connect the machine to a

correctly installed power socket

– The insulation on the power cord

and any extension cord, the plug

and the coupling must be fully intact

Warning!

Route the power cord and extension

cord properly:

– Observe the minimum cross-section

of the individual cords – see

"Connecting the machine to the

power supply"

– Route and mark the power cord so

that it cannot become damaged and

no one is endangered – danger of

stumbling!

– The connector and coupling of the

extension cord must be waterproof

or routed in such a way that they

cannot come into contact with water

– the connector and coupling of the

extension cord must not lie in water

– don't let the cord rub against edges

or pointed or sharp objects

– don't squeeze the cord under doors

or windows

4

RE 108, RE 118, RE 128 PLUS

English

– if cords become snarled – unplug

the power plug and unsnarl the cord

– always unroll the power cord from

the cable drum completely to avoid

risk of fire due to overheating

During work

Warning!

– Never draw in fluids containing

solvents or undiluted acids and

solvents (e. g., gasoline, heating oil,

paint thinner or acetone). These

substances damage the materials

used in the machine. The spray is

highly combustible, explosive and

poisonous.

Never direct the highpressure jet or water

hose against the machine

itself or against other

electrical appliances and

equipment – danger of

short-circuiting!

Never direct the highpressure jet or water

hose against electrical

equipment, connections

and power cords – dan-

ger of short-circuiting!

Never direct the highpressure jet against yourself or other people, not

even to clean clothing or

shoes – risk of injury!

Ensure you always have a firm and safe

footing.

Beware of slipping on ice, water, snow

or uneven ground!

Keep the high-pressure cleaner as far

away as possible from the object being

cleaned.

The machine may only be operated in an

upright position. Do not cover the

machine and ensure adequate motor

ventilation.

The plug must be disconnected immediately if the

cord is damaged – dan-

ger of electrocution!

Do not direct the high-pressure jet

against animals.

Do not direct the high-pressure jet onto

places you cannot see.

Children, animals and bystanders must

remain at a distance.

Hazardous substances (e. g., asbestos

or oil) must not be allowed to escape into

the environment unchecked when

working with the machine. The

applicable environmental regulations

must be observed without fail.

Surfaces of asbestos cement must

never be cleaned with a high-pressure

jet. Hazardous, breathable asbestos

fibers may be released in addition to the

dirt. The danger is greatest when the

washed surface has dried.

Delicate parts made of rubber, fabric

or similar materials must not be cleaned

with a pencil jet, e. g., from the rotary

nozzle. Maintain a sufficient distance

between the high-pressure hose and the

surface when cleaning to avoid any

damage to the surface being cleaned.

The trigger on the spray gun must move

easily and automatically return to its

starting position when released.

Hold the spray attachment firmly with

both hands in order safely to withstand

the kickback force and additional torque

produced when using spray

attachments with angled spray lance.

Ensure that the power cord and the highpressure hose are not damaged by

being driven over, squashed or pulled;

protect them against heat and oil.

Do not touch the power cord with the

high-pressure jet.

If the machine is subjected to unusually

high loads for which it was not designed

(e.g., heavy impact or a fall), always

check that it is in good condition before

continuing work - refer also to the

chapter "Before starting work". Also

make certain that the safety

mechanisms are working properly.

Never continue using a machine that is

not in perfect working order. Consult a

servicing dealer if in doubt.

Before leaving the machine: Switch off

the machine – unplug the power cord.

Safety equipment

When the safety equipment is activated,

excessive pressure is returned to the

intake side of the pump via a safety

valve. This safety feature has been set

by the manufacturer and must not be

adjusted.

RE 108, RE 118, RE 128 PLUS

5

English

650BA003 KN

1 1

2

650BA000 KN

1

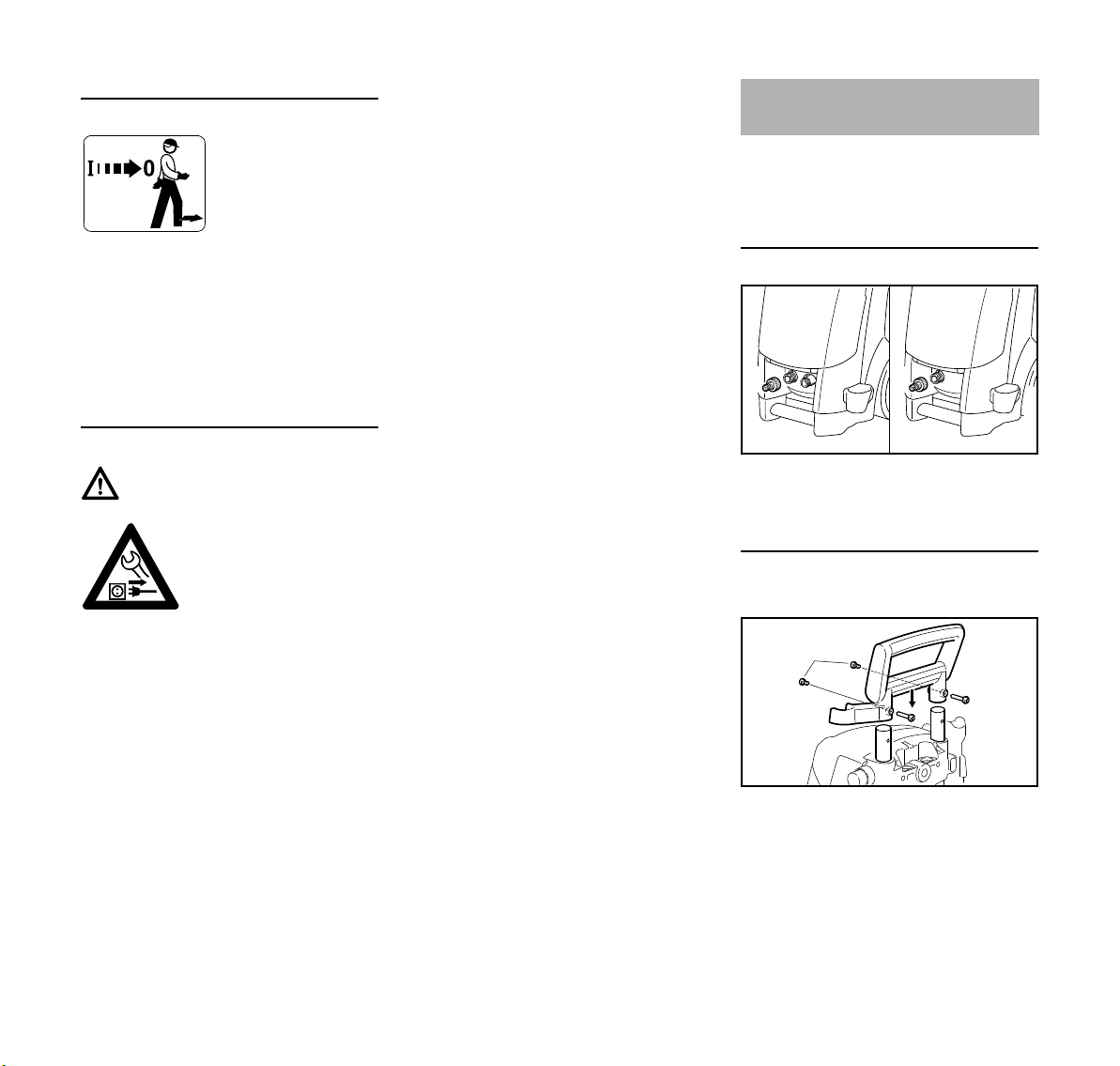

After finishing work

Switch off the

machine before leaving it!

– Unplug the power plug from the

socket

– Disconnect water intake hose

between machine and water supply

Never unplug the power plug by pulling

on the cord: always grip the plug itself.

Maintenance and repairs

Warning!

Before starting any work

on the machine: always

disconnect the machine

from the mains power

supply.

The machine must be serviced regularly.

Do not attempt any maintenance or

repair work not described in the

Instruction Manual. All other work should

be carried out by a servicing dealer.

STIHL recommends the use of genuine

STIHL spare parts. Such parts have

been optimized for the machine and the

user's requirements.

STIHL recommends that maintenance

and repair work be carried out only by

authorized STIHL dealers. STIHL

dealers receive regular training and are

supplied with technical information.

Assembling the Unit

The following accessory parts must be

fitted before using the machine for the

first time.

Connector on water inlet

N Attach the connector (1) to the

water inlet and tighten it by hand

RE 108, 118

Handle

– Use only high-quality spare parts. in

order to avoid the risk of accidents

or damage to the machine. Contact

a servicing dealer if in doubt.

– If the supply cord is damaged, it

must be replaced by authorized

STIHL dealers or qualified

electricians in order to avoid a

hazard.

Clean plastic parts with a cloth. Harsh

detergents can damage the plastic.

Cleaning ventilation slots in motor

housing as needed.

6

N Press the handle (1) onto the

telescopic shafts from above and

fasten it with the two bolts (2) and

nuts

RE 108, RE 118, RE 128 PLUS

English

650BA001 KN

1

2

650BA022 KN

1

650BA029 KN

2

1

2

650BA004 KN

650BA023 KN

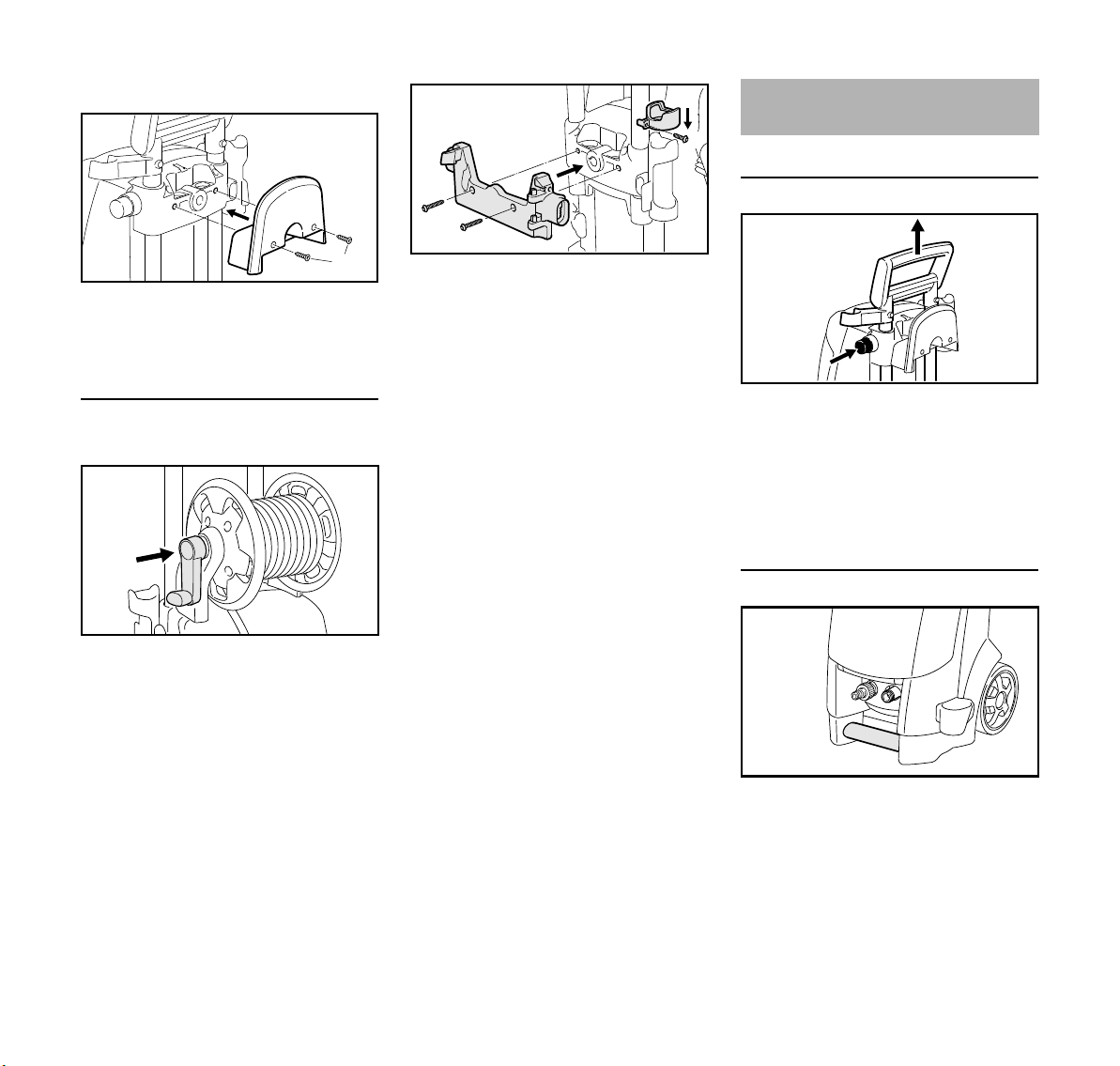

Holder for high-pressure hose

N Position the holder (1) for the high-

pressure hose on the adjuster and

fasten it with the screws (2)

RE 128 PLUS

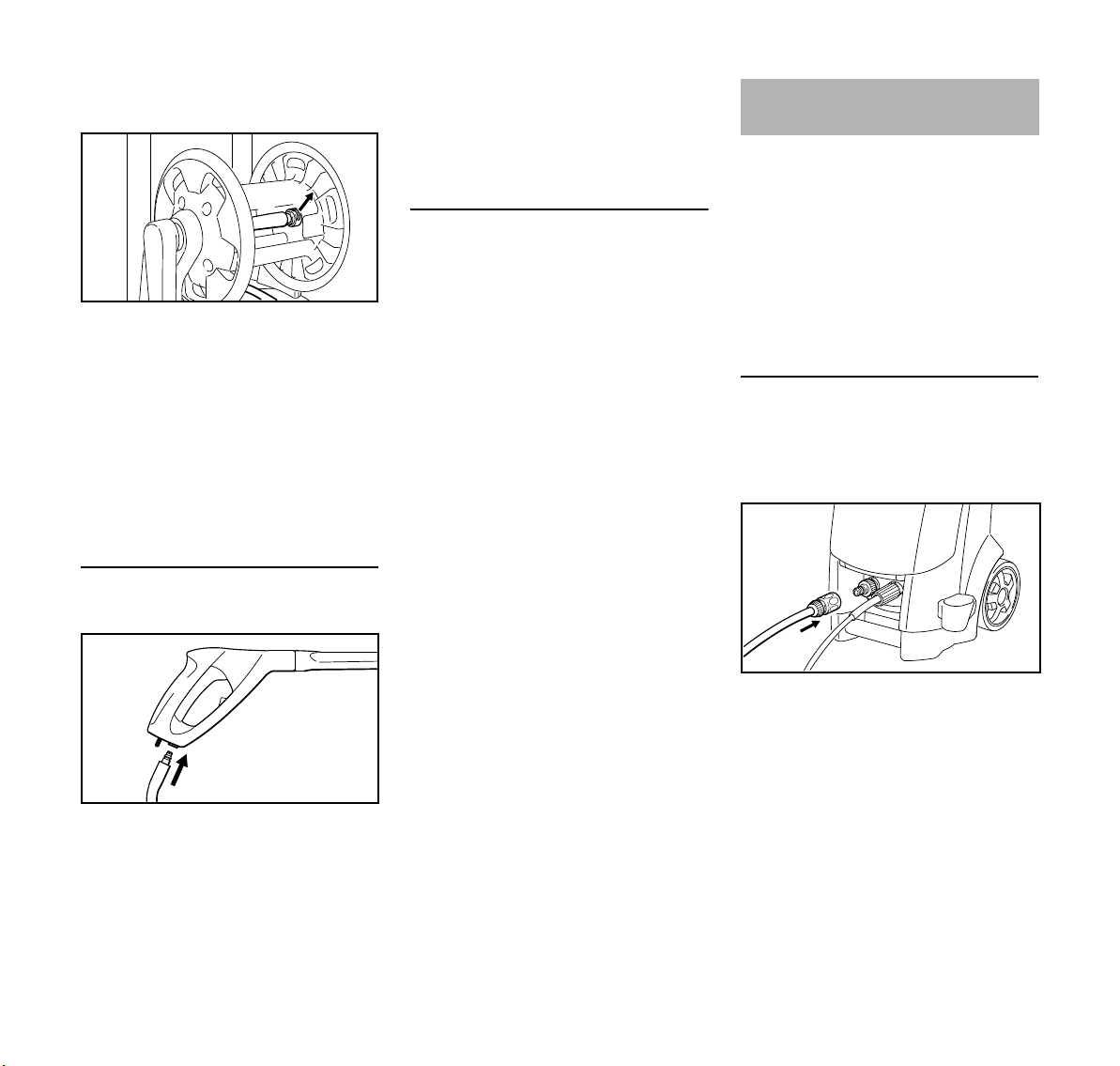

Crank for hose reel

Transporting the Unit

Height adjustable handle

N Slide the locking ring (1) over the

spray attachment holder

N Fasten the holder (2) for the flat

hose cassette with the included

screws

N Press button (1) and pull handle (2)

upward as far as it will go

N Release button and pull/push on the

handle again until the telescopic

shafts engage

Transport handle (RE 118, 128 PLUS

only)

N Engage crank handle in hose reel

Holder for flat hose cassette

A flat hose cassette is available as

special accessory.

The holder for the flat hose cassette is

included and can be installed as

needed.

RE 108, RE 118, RE 128 PLUS

The machine can be carried using the

transport handle.

7

English

650BA012 KN

12

666BA014 KN

3

4

-

+

2

650BA024 KN

1

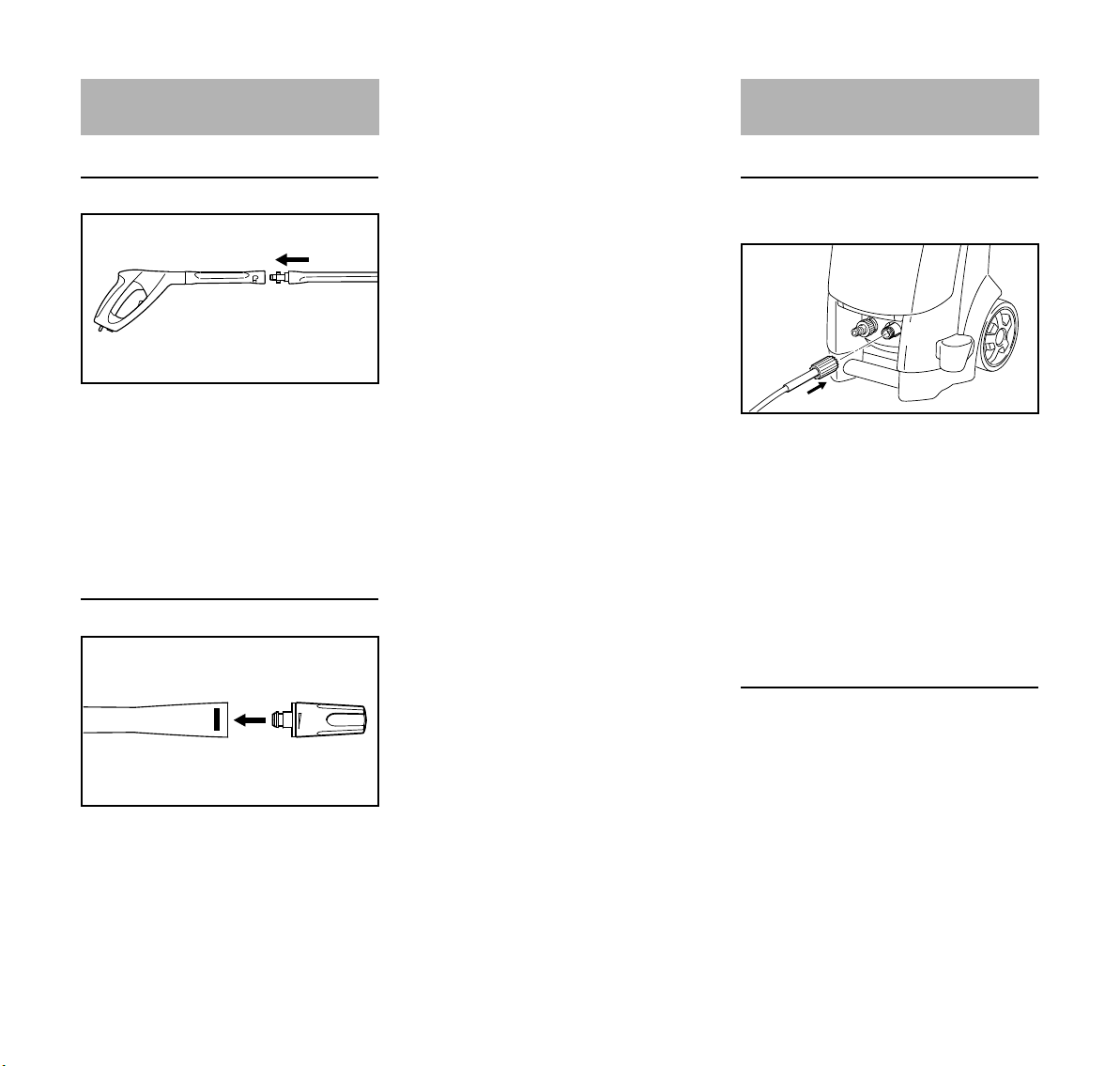

Fitting, removing spray

lance

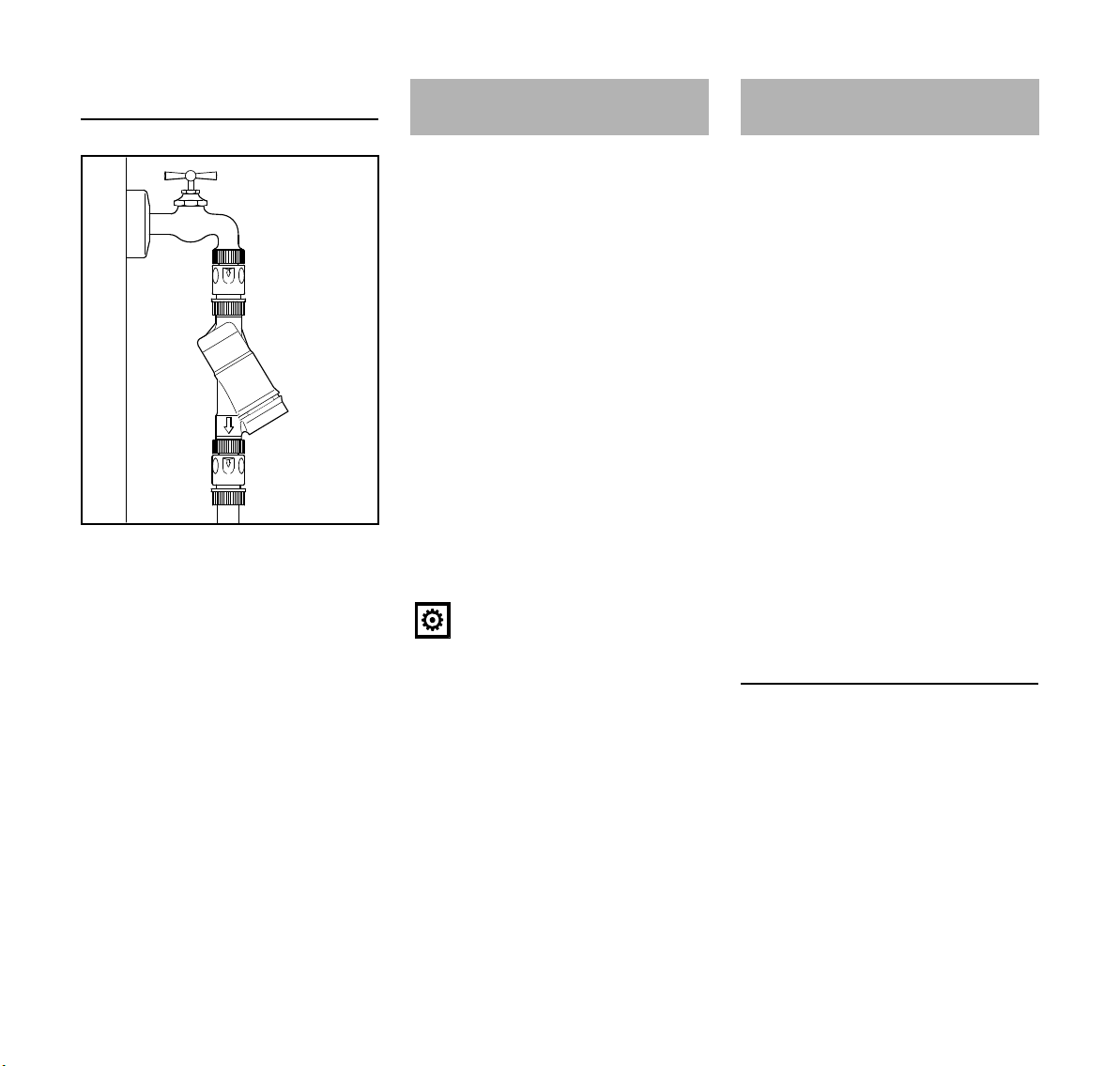

Spray lance

N Press the spray lance (1) into the

mount on the spray gun (2), turn it

by 90° so that it engages

Removing

N Press the spray lance (1) into the

mount on the spray gun (2), turn it

by 90° and pull it out of the mount

Nozzle

Removing

N Press the safety latch (4) and pull

out the nozzle (3)

Fitting, removing highpressure hose

RE 108, RE 118

Connecting the high-pressure hose

N Push high-pressure hose onto the

connector (2)

N Attach union nut (1) and screw it on

and tighten by hand

Disconnecting the high-pressure

hose

N Unscrew the union nut (1)

N Pull high-pressure hose off of

connector (2)

N Insert nozzle (3) in spray lance until

the safety latch (4) engages – at

which point the safety latch button

will spring out again – the adjustable

fan jet nozzle has an anti-twist

device; orient this according to the

groove on the spray lance

8

RE 128 PLUS

The high-pressure hose is already

connected.

RE 108, RE 118, RE 128 PLUS

English

1

2

650BA006 KN

650BA013 KN

4

5

3

2

650BA025 KN

1

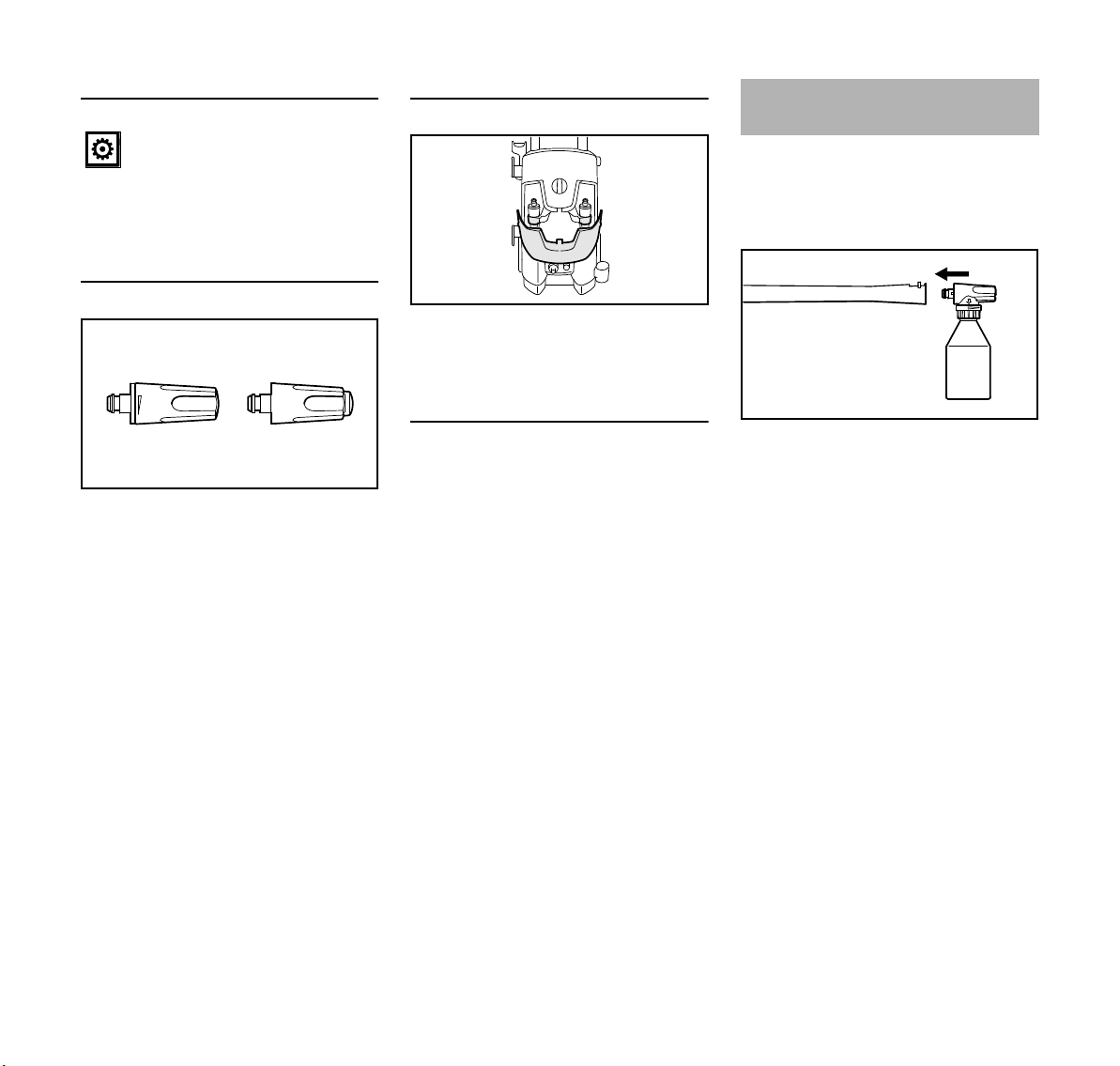

Disconnecting the high-pressure

hose

N Pull out the spring clip (1) and pull

the high-pressure hose (2) out of

the connector

Connecting the high-pressure hose

N Push the high-pressure hose (2)

onto the connector of the hose reel

N Push the spring clip (1) into the

connector

Connecting the high-pressure hose

to the spray gun

Fitting

Removing

N Actuate the safety catch (5) and pull

the high-pressure hose (3) out of

the mount on the spray gun

High-pressure hose extension

As a rule, always use only one highpressure hose extension – see "Special

accessories"

Connecting the water

supply

In suction operation, the machine can

also be connected to rivers, lakes,

cisterns and tanks, etc. – see

"Connecting to a pressureless water

supply".

Briefly rinse out the hose before

connecting it to the machine to prevent

sand and other particles from entering

the machine.

Connect hose

N Connect hose to water supply (1/2"

diameter, length at least 10 m to

absorb pressure surges. Maximum

length 25 m)

N Push the connector of the high-

pressure hose (3) into the mount on

the spray gun (4) – until it engages

RE 108, RE 118, RE 128 PLUS

N Push the coupling (1) on to the hose

connector (2)

N Turn on water supply

9

English

003BA003 KN

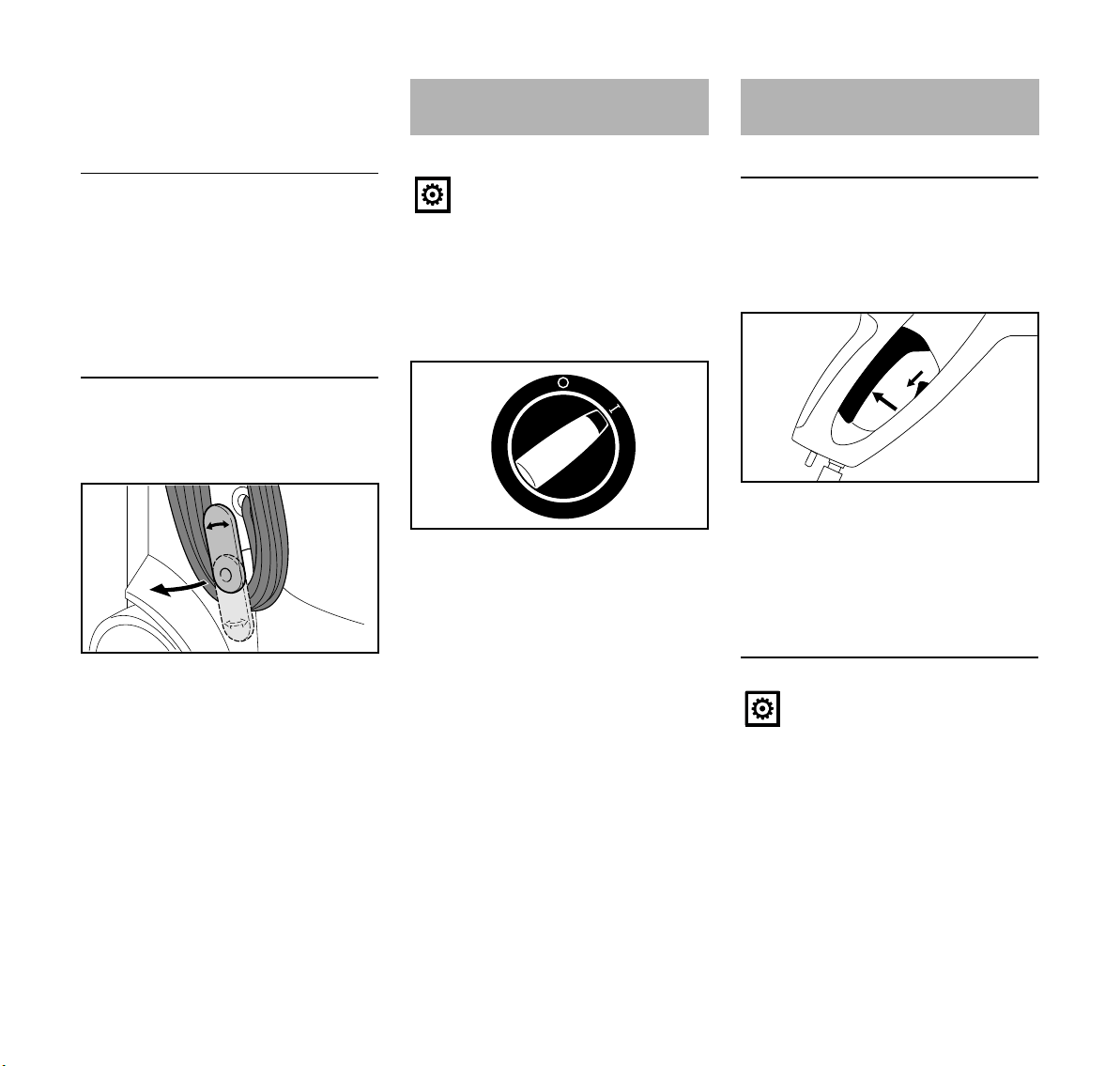

Connection to the drinking water

main

When hooking up to the drinking water

main, a backflow preventer (Type BA in

accordance with EN 60335-2-79) must

be installed between the water tap and

the hose.

If drinking water has passed through the

backflow preventer, it can no longer be

regarded as drinking water.

Follow the rules laid down by the local

water supply company to prevent water

flowing back from the high-pressure

cleaner into the drinking water main.

Connecting to a

pressureless water supply

N Connect the machine to the

pressurized water supply and start it

up briefly in accordance with the

Instruction Manual

N Switch off machine

N Disconnect the spray attachment

from the high-pressure hose

N Replace water intake hose with

suction hose (special accessory)

Always use the connecting element

supplied with the intake hose to connect

the hose. The standard connecting

elements are watertight only when used

with a pressurized water supply and for

this reason are not suitable for suction

operation.

N Fill the suction hose with water and

immerse the suction cup of the

suction hose in the water tank – do

not use dirty water

As a rule, it is advisable to use a

water filter.

N Hold down the high-pressure hose

by hand

N Switch on the machine

N Wait until a steady jet exits the high-

pressure hose

N Switch off machine

N Connect spray attachment

N Switch on the machine with the

spray gun open

N Actuate the spray gun several times

briefly in order to bleed the air out of

the machine as quickly as possible

Connecting to Power

Supply

The voltage and frequency of the

machine (see rating plate) must match

the voltage and frequency of the power

connection.

The minimum fuse protection of the

power connection must comply with the

specifications – see "Specifications".

The machine must be connected to the

power supply via an earth-leakage

circuit breaker to disconnect the power

supply if the differential current to earth

exceeds 30 mA for 30 ms.

The power connection must correspond

to IEC 60364-1 and relevant national

regulations.

When the machine is switched on,

voltage fluctuations that occur under

unfavorable mains conditions (high

power line impedance) may negatively

affect other connected electrical

appliances. Trouble is not anticipated at

power line impedances less than

0.15 ohms.

Extension Cords

Make sure your electrical cord set is in

good condition. When using an

extension cord, be sure to use one

heavy enough to carry the current your

product will draw. An undersized

extension cord may cause a drop in line

voltage resulting in loss of power and

overheating. The table below shows the

correct size (AWG) to use for your

machine (Cord types SJW or SJTW)

depending on cord length and

10

RE 108, RE 118, RE 128 PLUS

English

1607BA035 KN

1607BA011 KN

1

2

650BA014 KN

nameplate ampere rating. If in doubt,

use the next heavier gauge. The smaller

the gauge number, the heavier the cord.

Cord length (ft) Wire gage (AWG)

50 16

100 14

150 12

Appropriate extension cords are

available in special stores for electrical

equipment or from your STIHL dealer.

Connection to the power supply

socket

Before connection to the power supply,

check that the machine is switched off –

see "Switching off the machine"

Switching On

N Turn on water supply

The machine may only be

switched on when the water intake

hose is connected and the water

supply has been turned on.

Otherwise the machine may be

damaged due to lack of water.

N Completely unroll the high-pressure

hose

N Turn the master switch to I – now

the machine is in standby mode

Working

Actuating the spray gun

N Point the spray gun at the object to

be cleaned – never at persons!

N Point the rotary nozzle downwards

when starting (if fitted)

N Press the safety latch (2) downward

– the lever (1) is unlatched

N Squeeze the lever (1)

The motor stops when the lever is

released.

N Swivel the lower holder upward and

remove the power cord

N Plug the power cord or extension

cord into a properly installed outlet

RE 108, RE 118, RE 128 PLUS

Standby mode

The machine must not be

operated in standby mode for

more than 5 minutes. If work is

interrupted for more than 5 min.,

during breaks or if the machine is

left unattended, switch off the

machine at the master switch –

see "Switching off the machine".

11

English

666BA015 KN

1

2

-

+

650BA026 KN

4

666BA016 KN

3

1

High-pressure hose

Do not buckle or loop the highpressure hose.

Do not place any heavy objects on

the high-pressure hose, and do

not drive any vehicles over it.

Nozzles

Fan-jet nozzle (1)

The operating pressure can be infinitely

adjusted at the nozzle.

Jet angle 15°, maximum effect at a

distance of approx. 7 cm.

N Turn nozzle sleeve

Rotary nozzle (2)

Nozzle with rotating jet for stubborn dirt

on hard surfaces. Maximum effect at a

distance of 10 cm.

The spray attachment can also be used

without nozzles at low pressure, e.g., for

rinsing with a large flow of water.

Storage compartment for nozzles

N Open the flap – the rotary nozzle

and fan jet nozzle can be stored in

the holders

Storing accessories

Spray gun, spray lance, detergent bottle

and cleaning pin can be stored directly

on the machine – see "Main Parts".

Adding detergent

Detergent must not be allowed to dry on

the object to be cleaned.

N Remove nozzle from spray lance –

see "Fitting, removing spray lance"

N Install spray set (3) on spray

lance (1) – the spray set has an antitwist device; orient this according to

the groove on the spray lance

Fill the container of the spray set with

STIHL detergent diluted as directed

(approx. 0.5 liters).

N Use the adjusting ring (4) to set the

quantity of detergent to be added

N When applying detergent, start at

the bottom and work upwards

Maximum effect at a distance of 1 m.

12

RE 108, RE 118, RE 128 PLUS

English

1607BA018 KN

650BA015 KN

666BA017 KN

-

+

Switching Off

N Turn the master switch to 0 and turn

off the water supply

N Actuate the spray gun until water

only drips from the spray head (the

machine is now depressurized)

N Release trigger

After use

N Rinse the connection latches of the

spray lance and nozzle with water

so that no deposits form

N Roll the high-pressure hose and

power cable up on the holders

provided for this purpose – see

"Main Parts"

Storing the Machine

Store the machine in a dry room where it

is protected from frost.

If protection from frost cannot be

guaranteed, draw glycol-based

antifreeze – like that used in motor

vehicles – into the pump:

N Insert water intake hose in container

with antifreeze

N Insert spray gun without spray lance

in the same container

N Switch on the machine with the

spray gun open

N Actuate the spray gun until a

uniform jet emerges

N Keep leftover antifreeze in a sealed

container

N Press the safety latch upward – the

spray gun is locked to prevent

inadvertent operation

N Unplug the power plug from the

socket

N Disconnect hose from the water

supply and from the machine

RE 108, RE 118, RE 128 PLUS

13

English

Maintenance and Care

The following maintenance intervals apply in normal operating conditions. The specified intervals must be shortened accordingly for longer daily working hours. If the

machine is only used occasionally, the intervals can be extended accordingly.

before starting work

Complete machine

Connectors on high-pressure hose

Plug-type coupling of the spray lance and

the coupling sleeve of the spray gun

Water intake screen in the high-pressure

inlet

High pressure nozzle

Ventilation openings clean X

Machine supports

visual inspection (condition, leaks) X

clean XX

clean XX

grease X

clean XX

clean XX

replace X

clean X

replace X

check X

replace X

at the end of work and/or

daily

monthly

if damaged

as required

14

RE 108, RE 118, RE 128 PLUS

English

666BA018 KN

650BA027 KN

Maintenance

Always unplug the power cord before

servicing or cleaning the machine.

In order to ensure trouble free operation,

we recommend carrying out the

following steps whenever the machine is

used:

N Rinse the water hose, high-

pressure hose, spray lance and

accessories with water before fitting

them

N Remove all dust and sand from the

couplings

N Rinse out the spray set after use

Cleaning the nozzle

Since the pump pressure increases if

the nozzle is clogged, it must be cleaned

immediately.

Always remove the nozzle before

cleaning it

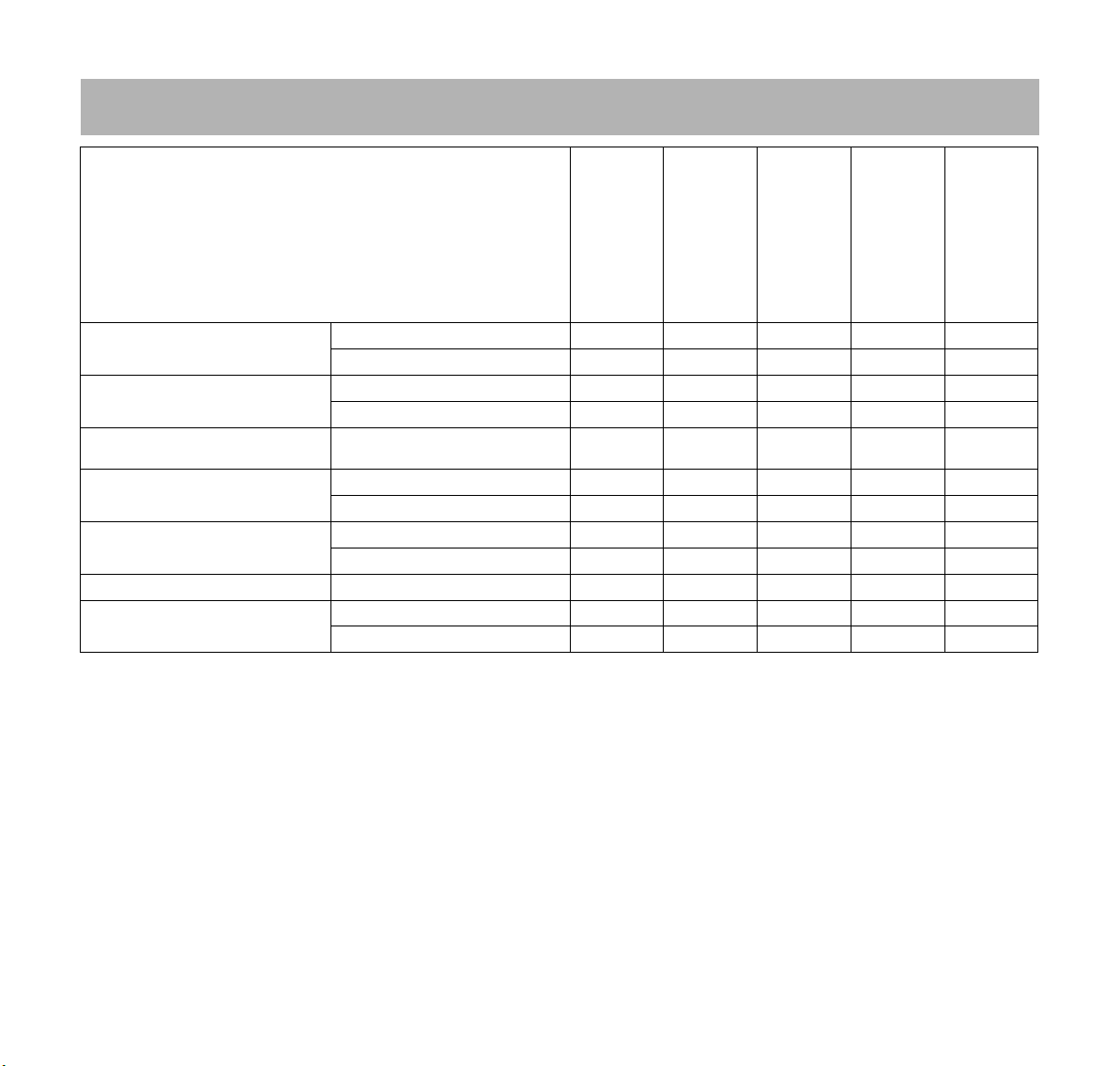

N Rinse the nozzle with water from the

front

Cleaning the water intake screen

The water intake screen must be

cleaned once per month or more often if

necessary.

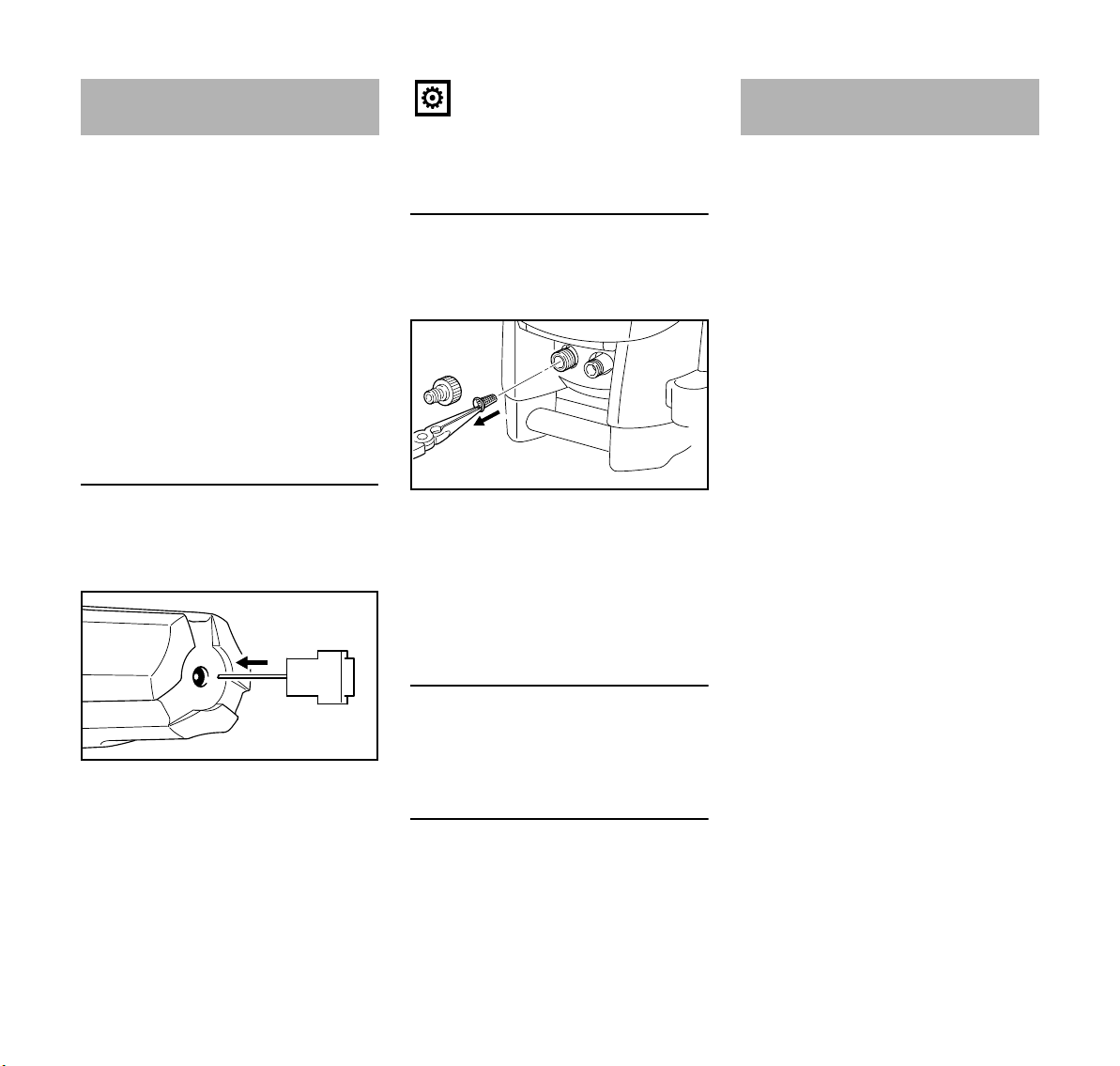

N Unscrew the hose connection

N Carefully remove the screen with

pliers and rinse it with water

N Before refitting the screen, ensure

that it is undamaged and replace if

necessary

First use after long periods

of storage

During long periods of storage, mineral

residue from the water may be

deposited in the pump. This may cause

the motor to start with difficulty or not at

all.

N Connect the machine to the water

supply and flush thoroughly with tap

water, leave the power cord

unplugged while doing so

N Plug the power plug into the wall

socket

N Switch on the machine with the

spray gun open

N Switch off machine

N Actuate the spray gun until water

merely drips from the spray head –

the machine is now depressurized

N Remove the nozzle

N Clean the nozzle with the cleaning

pin

RE 108, RE 118, RE 128 PLUS

Cleaning the ventilation openings

The machine must be kept clean so that

cooling air can flow freely through the

openings in the machine.

Greasing couplings

The couplings on the spray gun for

connecting the high-pressure hose and

the spray lance must be greased as

required.

15

English

25

17

17

16

2

16

10

21

21

13

21

13

17

10

4

650BA028 KN

RE 128 PLUS

RE 118

RE 108

1

3

6 7

8

-

+

9

20

14

15

19

12

12

13

19

11

20

24

23

12

19

18

12

11

18

12

18

12

10

22

RE 108

RE 118

22

16

20

12

12

#

11

5

24

12

12

#

24

Main Parts

16

RE 108, RE 118, RE 128 PLUS

English

1 Spray gun

2 Lever

3 Safety catch

4 Trigger interlock

5 High-pressure hose

6 Spray lance

7 Fan jet nozzle, adjustable

8 Rotary nozzle

9 Spray set

10 Handle

11 Bracket for surface washing brush

12 Bracket for spray lance

13 High-pressure hose connection

14 Hose reel

15 Crank for hose reel

16 Bracket for cleaning pin

17 Machine switch

18 Button for height adjustment of

handle

19 Bracket for power cable

20 Flap for storage compartment

21 Water attachment

22 Carrying handle

23 Hose holder

24 Bracket for spray set

25 Holder for flat hose cassette

# Model plate

Specifications

Electrical Specifications

RE 108

Power supply: 230 V / 1~ / 50 Hz

230 V - 240 V

1~ / 50 Hz

220 V / 1~ / 50 Hz

110 V / 1~ / 60 Hz

120 V / 1~ / 60 Hz

Power output: 1.7 kW

1.4 kW

Ampere rating: 7.5 A

9A

13 A

11.7 A

Fuse: 10 A

15 A

Protection class: I

Type of

protection: IP X5

2)

1) 2) 3)

4) 5)

3)

1) 2)

4)

5)

1) 2) 3)

4) 5)

RE 118

Power supply: 230 V / 1~ / 50 Hz

230 V - 240 V

1~ / 50 Hz

110 V / 1~ / 60 Hz

Power output: 2.1 kW

1)

Ampere rating: 9.2 A

1.4 kW

13 A

Fuse: 10 A

3)

4)

Protection class: I

5)

15 A

Type of

protection: IP X5

RE 128 PLUS

Power supply: 230 V / 1~ / 50 Hz

230 V - 240 V

1~ / 50 Hz

220 V / 1~ / 60 Hz

120 V / 1~ / 60 Hz

Power output: 2.3 kW

1.4 kW

Ampere rating: 10 A

13 A

13.5 A

Fuse: 10 A

15 A

Protection class: I

Type of

protection: IP X5

1)

230 V / 50 Hz version

2)

230 V - 240 V / 50 Hz version

3)

220 V / 50 Hz version

4)

110 V / 60 Hz version

5)

120 V / 60 Hz version

1)

2)

4)

1) 2)

4)

1) 2)

4)

1) 2)

4)

1)

2)

3)

5)

5)

1) 2)

3)

5)

1) 2)

3) 5)

RE 108, RE 118, RE 128 PLUS

17

English

Hydraulic specifications

RE 108

Working pressure: 11 Mpa

1) 2) 3)

(110 bar)

8.4 Mpa

4) 5)

(84 bar)

Max. permissible

pressure:

12 Mpa

(120 bar)

10 Mpa

1) 2) 3)

4) 5)

(100 bar)

Max. water feed

pressure: 1 Mpa (10 bar)

Max. water

throughput:

Water throughput, as

per EN 60335-2-79:

440 l/h

430 l/h

380 l/h

370 l/h

355 l/h

Max. suction lift: 1 m

0.5 m

1) 2) 3) 5)

4)

1) 2) 3)

4)

5)

1) 2) 3)

4) 5)

Max. water feed temperature

With pressurized

water supply: 40 °C

Suction operation: 20 °C

Max. kickback force: 15.6 N

13.2 N

12.7 N

1) 2) 3)

4)

5)

RE 118 RE 128 PLUS

Working pressure: 12.5 Mpa

1) 2)

(125 bar)

1) 2)

4)

4)

1) 2)

4)

1) 2)

4)

1) 2)

4)

Max. permissible

pressure:

Max. water feed

pressure:

Max. water throughput: 500 l/h

Water throughput, as

per EN 60335-2-79:

Max. suction lift: 1 m

8.6 Mpa

(86 bar)

14 Mpa

(140 bar)

10 Mpa

(100 bar)

1Mpa

(10 bar)

445 l/h

400 l/h

390 l/h

0.5 m

Max. water feed temperature

With pressurized water

supply: 60 °C

Suction operation: 20 °C

14.2 N

1) 2)

4)

Max. kickback force: 17.7 N

Working pressure: 13.5 Mpa

(135 bar)

14 Mpa

(140 bar)

9.5 Mpa

(95 bar)

Max. permissible

pressure:

15 Mpa

(150 bar)

11.1 Mpa

(111 bar)

Max. water feed

pressure:

1Mpa

(10 bar)

Max. water throughput: 500 l/h

440 l/h

Water throughput, as

per EN 60335-2-79:

420 l/h

355 l/h

Max. suction lift: 1 m

5)

0.5 m

Max. water feed temperature

With pressurized water

supply: 60 °C

Suction operation: 20 °C

19.5 N

13.6 N

1) 2)

3)

5)

Max. kickback force: 19.2 N

1)

230 V / 50 Hz version

2)

230 V - 240 V / 50 Hz version

3)

220 V / 50 Hz version

4)

110 V / 60 Hz version

5)

120 V / 60 Hz version

1) 2)

3)

5)

5)

5)

5)

18

RE 108, RE 118, RE 128 PLUS

English

650BA016 KN

2

1

Dimensions

RE 108

Length approx.: 360 mm

Width approx.: 340 mm

Height approx.: 610 mm / 870 mm

RE 118

Length approx.: 360 mm

Width approx.: 340 mm

Height approx.: 640 mm / 900 mm

RE 128 PLUS

Length approx.: 319 mm

Width approx.: 366 mm

Height approx.: 696 mm / 900 mm

Weight

RE 108

Device: 16 kg

Ready for operation: 18.3 kg

High-pressure hose

*

RE 108

: 8 m, textile braided

8 m, steel braided

RE 118: 8 m, steel braided

RE 128 PLUS: 9 m, steel braided

*)

According to equipment version

Special Accessories

Notes and restrictions for use

Spray lance extension

As a rule, only one spray lance

extension (1) may be used between

spray gun and standard spray lance (2).

RA 101

Use the RA 101 either directly or

together with the included spray lance

extension on the spray gun. Do not

install any additional spray lance

extension.

RE 118

Device: 17 kg

Ready for operation: 18.8 kg

RE 128 PLUS

Device: 17 kg

Ready for operation: 20 kg

RE 108, RE 118, RE 128 PLUS

Wet sand jet-stream appliance

Use the wet sand jet-stream appliance

either directly or together with a spray

lance extension on the spray gun. Do

not install any additional spray lance

extension.

19

English

669BA010 KN

1607BA024 KN

Pipe cleaning set, 15 m

There is a mark on the cleaning hose

underneath the nozzle (see arrow).

N Push the hose into the pipe to be

cleaned until this mark is reached –

then switch on the machine

When this mark appears as the hose is

pulled out of the pipe:

N Switch off machine

N Actuate the spray gun until the

machine has been depressurized

N Pull the hose out of the pipe

completely

The hose must never be pulled out of the

pipe when the machine is switched on.

Always connect only one high-pressure

hose extension between machine and

high-pressure hose.

Rotating washing brush

Use the rotating wash brush either

directly or together with a spray lance

extension on the spray gun. Do not

install any additional spray lance

extension.

Angled spray lance

Use the angled spray lance either

directly or together with a spray lance

extension on the spray gun. Do not

install any additional spray lance

extension.

The nozzle can be cleaned with the aid

of the cleaning pin supplied.

Angled spay lance, long

Water filter

For filtering water from the water main,

as well as for use in pressureless

suction operation.

Backflow preventer

Type BA in accordance with

EN 60335-2-79: For connecting the

high-pressure cleaner to the drinking

water supply.

Other special accessories

– Wash brush

– Cleaning kit

– Suction set

– Detergents and care products for

various spheres of application

Ask your STIHL servicing dealer for

current information about this and other

special accessories.

Flat textile hose with cassette

Low-pressure hose for connecting the

high-pressure cleaner to the water

supply. The cassette permits reeling in

and unreeling of the flat textile hose as

well as storage in a minimum of space

right on the machine

High-pressure hose extensions

– 7 m, textile braided

– 7 m, steel braided

– 10 m, steel braided

20

Use the long, angled spray lance only

directly on the spray gun. Do not install a

spray lance extension.

Do not aim around blind corners behind

which people may be concealed. The

nozzle can be cleaned with the aid of the

cleaning pin supplied.

RE 108, RE 118, RE 128 PLUS

English

Troubleshooting

Before working on the machine, unplug the power cord, turn off the water supply and actuate the spray gun until the pressure has

been relieved.

Fault Cause Remedy

Motor does not run when switched on

(hums when switched on)

Motor constantly switches on and off High-pressure pump or spray attachment is

Engine stops Machine switches off because the motor is

Weak, ragged, unclean jet Nozzle fouled Clean nozzle, see "Maintenance"

Mains voltage is too low or improper Check electrical connection

Check plug, cable and switch

Extension cord with wrong cross-section Use an extension cord with a sufficient

cross-section, see "Connecting the

machine to the power supply"

Extension cord is too long Connect the machine without an exten-

sion cord or with a shorter one

Mains circuit-breaker has been tripped Switch off the machine, actuate the spray

gun until water only drips out of the head,

engage the safety catch, reset the mains

circuit-breaker

Spray gun not actuated Actuate spray gun when switching on the

machine

Have the machine checked by a servicing

leaky

overheating

1)

dealer

Check whether the supply voltage and

machine voltage match; let the motor cool

down for at least 5 minutes

RE 108, RE 118, RE 128 PLUS

21

English

Before working on the machine, unplug the power cord, turn off the water supply and actuate the spray gun until the pressure has

been relieved.

Fault Cause Remedy

Pressure fluctuates or drops Shortage of water Open water tap completely

Comply with permissible suction lift (suction mode only)

High-pressure nozzle in spray head is dirty Clean high-pressure nozzle; see

"Maintenance"

Water intake strainer in pump inflow clogged Clean water intake strainer; see

"Maintenance"

High-pressure pump is leaky, valves are

defective

Have the machine checked by a servicing

1)

dealer

Nozzle clogged Clean nozzle

No supply of detergents Detergent tank is empty Fill detergent tank

Detergent intake is clogged Eliminate clog

1)

STIHL recommends STIHL servicing dealers

22

RE 108, RE 118, RE 128 PLUS

Maintenance and Repairs Disposal

Users of this machine may only carry out

the maintenance and service work

described in this user manual. All other

repairs must be carried out by a

servicing dealer.

STIHL recommends that you have

servicing and repair work carried out

exclusively by an authorized STIHL

servicing dealer. STIHL dealers are

regularly given the opportunity to attend

training courses and are supplied with

the necessary technical information.

When repairing the machine, only use

replacement parts which have been

approved by STIHL for this power tool or

are technically identical. Only use highquality replacement parts in order to

avoid the risk of accidents and damage

to the machine.

STIHL recommends the use of original

STIHL replacement parts.

Original STIHL parts can be identified by

the STIHL part number, the {

logo and the STIHL parts symbol K

(the symbol may appear alone on small

parts).

Electrical appliances must not be

disposed of as household refuse.

Machine, accessories and packaging

must be collected and recycled in an

environmentally beneficial manner.

English

RE 108, RE 118, RE 128 PLUS

23

English

24

RE 108, RE 118, RE 128 PLUS

Table des matières

français

Indications concernant la présente

Notice d'emploi 26

Prescriptions de sécurité et

techniques de travail 26

Assemblage du dispositif 31

Transport de l'appareil 32

Démontage, montage de la lance 32

Montage, démontage du flexible

haute pression 33

Notice d'emploi d'origineImprimé sur papier blanchi sans chlore

Établissement de l'alimentation en

eau 34

Établissement d'une alimentation

en eau hors pression 35

Branchement électrique du

dispositif 35

Mise en marche du dispositif 36

Utilisation 36

Apport de détergent 37

Arrêt du dispositif 38

Rangement du dispositif 38

Instructions pour la maintenance et

l'entretien 39

Maintenance 40

L'encre d'imprimerie contient des huiles végétales, le papier est

recyclable.

Mise en service après un arrêt

prolongé 41

Principales pièces 42

Caractéristiques techniques 43

Accessoires optionnels 45

Dépannage 47

Instructions pour les réparations 49

Mise au rebut 49

Chère cliente, cher client,

nous vous félicitons d'avoir choisi un

produit de qualité de la société

STIHL.

Ce produit a été fabriqué avec les

procédés les plus modernes et les

méthodes de surveillance de qualité

les plus évoluées. Nous mettons tout

en œuvre pour que ce dispositif vous

assure les meilleurs services, de telle

sorte que vous puissiez en être

parfaitement satisfait.

Pour toute demande de

renseignements complémentaires,

veuillez vous adresser à votre

revendeur ou directement à

l'importateur de votre pays.

Hans Peter Stihl

{

© ANDREAS STIHL AG & Co. KG, 2011

0458-650-8221. M999.A11.TP.

0000004010_001_F

RE 108, RE 118, RE 128 PLUS

25

français

Indications concernant la

présente Notice d'emploi

Pictogrammes

Tous les pictogrammes appliqués sur le

dispositif sont expliqués dans la

présente Notice d'emploi.

Repérage des différents types de

textes

Avertissement contre un risque

d'accident et de blessure ainsi

que de graves dégâts matériels.

Avertissement contre un risque de

détérioration du dispositif ou de

certains composants.

Développement technique

La philosophie de STIHL consiste à

poursuivre le développement continu de

toutes ses machines et de tous ses

dispositifs ; c'est pourquoi nous devons

nous réserver tout droit de modification

de nos produits, en ce qui concerne la

forme, la technique et les équipements.

On ne pourra donc en aucun cas se

prévaloir des indications et illustrations

de la présente Notice d'emploi à l'appui

de revendications quelconques.

Prescriptions de sécurité

et techniques de travail

La forte pression d’eau

produite et le branchement électrique

constituent des sources

de danger particulières.

Lire attentivement l’intégralité du mode d’emploi

avant la première mise

en service et le conserver

en lieu sûr pour pouvoir

le consulter ultérieurement. Le non-respect du

mode d’emploi peut

entraîner un danger de

mort.

Avertissement !

– Cet appareil n’est pas destiné à être

utilisé par des enfants ni par des

personnes dont les aptitudes

physiques, sensorielles ou

mentales ou encore le manque

d’expérience et de connaissances

les empêche d’utiliser l’appareil en

toute sécurité en l’absence de

surveillance ou d’instructions d’une

personne responsable.

– L’utilisation du nettoyeur à haute

pression par des mineurs est

interdite, sauf par des jeunes de

plus de 16 ans qui sont formés sous

surveillance.

– Les enfants doivent être surveillés

par une personne responsable afin

de les empêcher de jouer avec

l’appareil.

– L’appareil ne doit être remis ou

prêté qu’à des personnes qui sont

familiarisées avec ce modèle et sa

manipulation et toujours

accompagné du mode d’emploi.

– Ne pas utiliser l’appareil lorsque des

personnes ne portant pas de

vêtements de protection se trouvent

sur la surface de travail.

– Avant toute intervention sur

l’appareil, par exemple nettoyage,

maintenance, remplacement de

pièces – Retirer la fiche secteur !

Respecter les consignes de sécurité

nationales spécifiques, par exemple des

caisses de prévoyance des accidents,

des caisses d’assurance maladie, des

autorités chargées de la protection du

travail, etc.

Arrêter l’appareil lorsqu’il n’est pas

utilisé afin que personne ne soit exposé

à des risques inutiles. L’appareil doit

être inaccessible aux personnes non

autorisées, retirer la fiche secteur.

L’utilisateur est responsable des

accidents ou des risques que pourraient

subir d’autres personnes ou leurs biens.

Toute personne qui utilise pour la

première fois l’appareil doit se faire

expliquer par le vendeur ou par un autre

spécialiste comment utiliser celui-ci en

toute sécurité.

Dans certains pays, l’utilisation

d’appareils émettant du bruit peut être

restreinte par des dispositions locales.

Respecter les consignes nationales

spécifiques.

Des rallonges électriques inappropriées

peuvent s’avérer dangereuses. Lors

d’une utilisation à l’air libre, il faut

26

RE 108, RE 118, RE 128 PLUS

français

exclusivement utiliser des rallonges

homologuées à cet effet et identifiées en

conséquence qui possèdent une section

suffisante.

Ne jamais saisir la fiche secteur, le câble

de raccordement et la rallonge ainsi que

les connecteurs électriques avec des

mains mouillées.

Avant toute utilisation, vérifier si

l’appareil est en bon état de

fonctionnement et conforme aux règles

de sécurité. Il faut être particulièrement

attentif au câble électrique, à la fiche

secteur, au flexible haute pression, au

dispositif de projection et aux dispositifs

de sécurité.

Ne jamais travailler avec un flexible

haute pression endommagé - le

remplacer immédiatement.

L’appareil ne doit être mis en service

que si aucun de ses composants n’est

endommagé.

Il ne faut pas rouler sur le flexible haute

pression, ni l’étirer, le plier ou le vriller.

Ne pas déplacer l’appareil en tirant sur

le flexible haute pression ou sur le câble

de raccordement.

Le flexible haute pression doit être

homologué pour la pression de service

maximale admissible du nettoyeur.

La pression de service maximale

admissible, la température maximale

admissible et la date de fabrication sont

indiquées sur la gaine du flexible haute

pression. La pression admissible et la

date de fabrication sont indiquées sur

les éléments de robinetterie.

Accessoires et pièces de rechange

Avertissement !

– Les flexibles haute pression, les

raccords et les éléments de

robinetterie sont essentiels pour la

sécurité de l’appareil. Il faut

exclusivement monter des flexibles

haute pression, des éléments de

robinetterie, des raccords et autres

accessoires qui sont autorisés par

STIHL pour cet appareil ou alors

des pièces techniquement

équivalentes. Consulter un

distributeur agréé pour toute

question à ce sujet. N’utiliser que

des accessoires de haute qualité

afin de réduire au maximum tout

risque d’accident ou de dommages

à l’appareil.

– STIHL recommande d’utiliser des

pièces et des accessoires originaux

STIHL. Les propriétés de ceux-ci

sont adaptées de manière optimale

au produit et aux exigences de

l’utilisateur.

N’apporter aucune modification à

l’appareil – la sécurité risquerait d’en

être affectée. STIHL exclue toute

responsabilité pour les dommages

corporels et matériels qui résultent de

l’utilisation d’accessoires non

homologués.

Condition physique

Quiconque utilise l’appareil doit être

reposé, en bonne santé et en bonne

condition physique. Il est conseillé à

toute personne qui ne doit pas se

fatiguer pour des raisons de santé de

consulter son médecin pour savoir si

l’utilisation de cet appareil ne présente

aucun risque.

Il est interdit d’utiliser l’appareil après

avoir consommé de l’alcool, des

médicaments qui affectent la réactivité

ou des drogues.

Domaines d’applications

Le nettoyeur haute pression convient

tout spécialement pour le nettoyage de

véhicules automobiles, machines,

réservoirs, façades, locaux d’une

exploitation agricole et pour le décapage

d’objets rouillés, sans dégagement de

poussière ni d’étincelles.

Il est interdit d’utiliser cet appareil pour

d’autres travaux – cela pourrait causer

des accidents ou détériorer l’appareil.

Vêtements et équipements

Porter des chaussures munies d’une

semelle antidérapante.

Porter des lunettes de

protection et des vêtements de protection.

STIHL recommande de

porter une salopette pour

réduire le risque de blessures en cas de contact

accidentel avec le jet

haute pression.

RE 108, RE 118, RE 128 PLUS

27

français

Transport de l’appareil

Pour transporter l’appareil en toute

sécurité dans ou sur un véhicule, le fixer

avec des sangles de telle sorte qu’il ne

risque pas de glisser ou de se renverser.

Si l’appareil et les accessoires doivent

être transportés à des températures

proches de 0 °C ou moins, il est

recommandé d’utiliser un produit

antigel, voir « Rangement de

l’appareil ».

Produits de nettoyage

Avertissement !

– Des détergents inadéquats peuvent

présenter des risques pour la santé

ou endommager l’appareil et l’objet

à nettoyer. Consulter un distributeur

agréé pour toute question à ce

sujet.

– STIHL recommande d’utiliser des

détergents STIHL. Respecter les

directives d’utilisation à cet effet.

– Les détergents peuvent renfermer

des substances nocives (toxiques,

caustiques, irritantes), combustibles

ou facilement inflammables. Si du

détergent devait entrer en contact

avec les yeux ou la peau, rincer

immédiatement et abondamment à

l’eau claire. Consulter

immédiatement un médecin en cas

d’ingestion. Se conformer aux

fiches techniques de sécurité du

fabricant !

Il faut toujours utiliser le détergent avec

le dosage préconisé par le fabricant.

Avant le travail

Ne pas brancher le nettoyeur haute pression

directement au réseau

d’eau potable.

Avertissement !

– De l’eau potable qui a traversé le

clapet de non-retour n’est plus

considérée comme de l’eau

potable.

Ne pas utiliser l’appareil avec de l’eau

sale.

S’il y a risque de présence d’eau sale

(par exemple sable mouvant), il faut

employer un filtre à eau en

conséquence.

Contrôle du nettoyeur haute pression

Avertissement !

– Le nettoyeur haute pression ne doit

être utilisé que s’il présente une

parfaite sécurité de fonctionnement

– risque d’accident !

– L’interrupteur de l’appareil doit

pouvoir être facilement amené sur

0.

– L’interrupteur de l’appareil doit se

trouver sur 0.

– Il faut vérifier si le flexible haute

pression, le dispositif de projection

et les dispositifs de sécurité ne sont

pas endommagés.

– Flexible haute pression et dispositif

de pulvérisation en parfait état

(propres, faciles à manipuler),

montage correct

28

Il faut impérativement utiliser un clapet

de non-retour pour raccorder le

nettoyeur haute pression au réseau

d’eau potable – voir « accessoires

optionnels ».

RE 108, RE 118, RE 128 PLUS

français

– Pour une conduite en toute sécurité,

les poignées doivent être propres et

sèches, exemptes d’huile et

propres.

– N’apporter aucune modification aux

dispositifs de commande et de

sécurité

Branchement électrique

Avertissement !

Précautions à prendre pour réduire les

risques d’électrocution :

– La tension et la fréquence de

l’appareil (voir la plaque

signalétique) doivent coïncider avec

la tension et la fréquence du réseau

électrique.

– Il faut vérifier si le câble de

raccordement, la fiche secteur et la

rallonge ne sont pas endommagés.

Il est interdit d’utiliser des câbles,

prises et fiches endommagés ou

des câbles électriques non

conformes aux instructions.

– Branchement électrique

uniquement à une prise installée

conformément à la réglementation

– Isolation du câble de raccordement

et de la rallonge, fiches et prises en

parfait état

Avertissement !

Le câble de raccordement et la rallonge

doivent être posés correctement :

– Il faut tenir compte des sections

minimales des différents câbles

(voir « Branchement électrique de

l’appareil »).

– Poser et identifier le câble de

raccordement de telle sorte qu’il ne

puisse pas être endommagé et ne

constitue pas un danger – risque

de trébucher !

– La fiche et la prise de la rallonge

électrique utilisée doivent être

protégées contre les projections

d’eau, ou alors il faut les poser de

telle sorte qu’elles ne risquent pas

d’entrer en contact avec de l’eau. La

fiche et la prise de la rallonge

électrique ne doivent pas reposer

dans l’eau.

– Ne pas risquer de les cisailler au

niveau des arêtes, pointes ou

autres objets acérés

– Ne pas les coincer dans les

ouvertures de porte ou de fenêtre

– Si les câbles sont emmêlés, retirer

la fiche secteur et démêler le câble

– Avant d’utiliser des câbles

électriques sur enrouleur, toujours

les débobiner complètement afin

d’écarter le risque de surchauffe et

d’incendie

Pendant le travail

Avertissement !

– Ne pas aspirer de liquides

contenant un solvant ou des acides,

ni des solvants non dilués (par

exemple essence, mazout, diluant

pour peinture ou acétone) ! Ces

substances endommagent les

matériaux employés sur l’appareil.

Le brouillard pulvérisé est

hautement inflammable, explosible

et toxique.

Ne jamais nettoyer

l’appareil lui-même ou

d’autres appareils électriques avec le jet haute

pression ou au jet d’eau –

risque de court-circuit !

Ne pas nettoyer les équipements électriques,

branchements et câbles

sous tension avec le jet

haute pression ou au jet

d’eau – risque de court-

circuit !

L’utilisateur ne doit

jamais orienter le jet

d’eau sur lui-même ou

sur d’autres personnes,

pas même pour nettoyer

des vêtements ou des

chaussures – Risque de

blessure !

Toujours veiller à une position stable et

sécurisée.

Attention aux risques de glissade sur le

verglas, l’eau, la neige ou un terrain

irrégulier !

Positionner le nettoyeur haute pression

le plus loin possible de l’objet à nettoyer.

L’appareil ne doit être utilisé qu’en

position verticale. Ne pas recouvrir

l’appareil et veiller à ce que la ventilation

du moteur soit suffisante.

RE 108, RE 118, RE 128 PLUS

29

français

Retirer immédiatement la

fiche de la prise de courant si le câble secteur

est endommagé – dan-

ger de mort par

électrocution !

Ne pas diriger le jet haute pression sur

des animaux.

Ne pas diriger le jet haute pression vers

des endroits non visibles.

Les enfants, les animaux et les

spectateurs doivent être tenus à

distance.

Au cours du nettoyage, veiller à ce que

des substances dangereuses (p. ex.

amiante, huile) provenant de l’objet

nettoyé ne parviennent pas dans

l’environnement. Il faut impérativement

respecter les directives en vigueur pour

la protection de l’environnement !

Ne pas nettoyer des surfaces en

amiante-ciment avec le jet haute

pression. Outre les saletés, le jet peut

détacher des fibres d’amiante

dangereuses car elles risquent de

pénétrer dans les poumons. Il existe

notamment un danger après le séchage

de la surface traitée.

Ne pas nettoyer les pièces sensibles en

caoutchouc, en tissu ou similaire avec

un jet rond, par exemple avec la

turbobuse. Lors du nettoyage, laisser un

espace suffisant entre la buse à haute

pression et la surface pour éviter

d’endommager la surface à nettoyer.

La gâchette du pistolet doit pouvoir être

actionnée facilement et revenir d’ellemême en position initiale lorsqu’on la

relâche.

Il faut toujours tenir le dispositif de

projection à deux mains pour pouvoir

maîtriser le recul ainsi que le couple

supplémentaire qui se produit dans le

cas des dispositifs de projection équipés

d’une lance coudée.

Il ne faut pas rouler sur le câble

électrique et sur le flexible haute

pression, ni l’écraser, l’étirer etc. pour ne

pas l’endommager. Le protéger de la

chaleur et de l’huile.

Le jet à haute pression ne doit pas entrer

en contact avec le câble de

raccordement.

Si l’appareil a subit des contraintes

inhabituelles (par exemple choc ou

chute), il faut impérativement vérifier

avant toute nouvelle utilisation s’il

présente une parfaite sécurité de

fonctionnement – voir aussi la section

« Avant le travail ». Il faut également

vérifier le bon fonctionnement des

dispositifs de sécurité. Il ne faut en

aucun cas continuer d’utiliser un

appareil qui ne présente pas une

parfaite sécurité de fonctionnement. En

cas de doute, prendre contact avec un

distributeur.

Avant de laisser l’appareil : Arrêter

l’appareil et retirer la fiche secteur.

Dispositif de sécurité

En cas de déclenchement du dispositif

de sécurité, une pression

excessivement élevée est renvoyée

dans le côté aspiration de la pompe

haute pression par le biais d’une

soupape de décharge. Le dispositif de

sécurité est réglé en usine et son

réglage ne doit pas être modifié.

Après le travail

Éteindre l’appareil

avant de le laisser !

– Retirer la fiche de la prise

électrique.

– Débrancher le tuyau d’arrivée d’eau

entre l’appareil et la source d’eau

Ne pas tirer sur le câble électrique pour

retirer la fiche de la prise électrique,

mais tenir la fiche !

Entretien et réparations

Avertissement !

Avant toute intervention

sur l’appareil : retirer la

fiche de la prise

électrique.

– N’utiliser que des pièces de

rechange de haute qualité afin de

réduire au maximum tout risque

d’accident ou de dommages à

l’appareil. Consulter un distributeur

agréé pour toute question à ce

sujet.

– Si le câble électrique est

endommagé, il faut le faire

remplacer par un distributeur

autorisé STIHL ou par un électricien

qualifié afin d’éviter tout risque.

30

RE 108, RE 118, RE 128 PLUS

français

650BA003 KN

1 1

2

650BA000 KN

1

650BA001 KN

1

2

650BA022 KN

Nettoyer les pièces en matière plastique

avec un chiffon. Les détergents trop

puissants risquent d’endommager la

matière plastique.

Si nécessaire, nettoyer les fentes

d’aération dans le carter du moteur.

Soumettre l’appareil à une maintenance

régulière. N’effectuer que les

interventions de maintenance et

réparations décrites dans le Mode

d’emploi. Faire exécuter toutes les

autres opérations par un distributeur

agréé.

STIHL recommande d’utiliser

exclusivement des pièces de rechange

originales STIHL. Les propriétés de

celles-ci sont adaptées de manière

optimale à l’appareil et aux exigences de

l’utilisateur.

STIHL recommande de faire effectuer

les opérations de maintenance et les

réparations exclusivement chez un

distributeur agréé STIHL. Les

distributeurs agréés STIHL participent

régulièrement à des stages de

perfectionnement et ont à leur

disposition les informations techniques

requises.

Assemblage du dispositif

Il faut monter les différents accessoires

avant la première mise en service.

Raccord sur l’arrivée d’eau

N Visser et serrer à la main le

manchon de raccordement (1) sur

l’arrivée d’eau.

RE 108, 118

Poignée

N Emmancher la poignée (1) par le

haut sur les rails télescopiques et la

fixer avec les deux vis (2) et les

écrous.

Support pour flexible haute pression

N Placer le support (1) du flexible

haute pression sur l’élément de

réglage et le fixer avec les vis (2).

RE 128 PLUS

Manivelle de l’enrouleur de flexible

N Enclipser la manivelle dans

l’enrouleur de flexible

Support pour cassette à tuyau plat

La cassette à tuyau plat est disponible

en option.

Le support pour cassette à tuyau plat est

fourni et peut être monté en cas de

besoin.

RE 108, RE 118, RE 128 PLUS

31

français

1

650BA029 KN

2

1

2

650BA004 KN

650BA023 KN

650BA012 KN

12

666BA014 KN

3

4

-

+

N Glisser l’anneau de retenue (1) sur

le support du dispositif de

pulvérisation

N Fixer le support (2) pour cassette à

tuyau plat avec les vis fournies

Transport de l'appareil

Poignée réglable en hauteur

N Enfoncer le bouton (1) et tirer la

poignée (2) vers le haut jusqu’en

butée.

N Relâcher le bouton et tirer / faire

coulisser une nouvelle fois la

poignée jusqu’à ce que les rails

télescopiques s’enclenchent.

Poignée de transport (RE 118, 128

PLUS seulement)

Démontage, montage de la

lance

Lance

N Insérer la lance (1) dans le

logement du pistolet

pulvérisateur (2), la tourner de 90°

et l’enclencher.

Démontage

N Insérer la lance (1) dans le

logement du pistolet

pulvérisateur (2), la tourner de 90°

et l’extraire du logement.

Buse

La poignée de transport permet de

porter l’appareil.

N Insérer la buse (3) dans la lance

jusqu’à ce que le verrou (4)

32

s’enclenche. La tête du verrou est

alors de nouveau projetée vers

l’extérieur. La buse à jet plat

RE 108, RE 118, RE 128 PLUS

français

2

650BA024 KN

1

1

2

650BA006 KN

650BA013 KN

4

5

3

réglable est équipée d’une sécurité

anti-torsion qu’il faut aligner sur la

rainure de la lance.

Démontage

N Pousser sur le verrou (4) est

extraire la buse (3)

Montage, démontage du

flexible haute pression

RE 108, RE 118

Montage du flexible haute pression

N Glisser le flexible haute pression sur

le raccord (2)

N Visser et serrer à la main l’écrou

d’accouplement (1)

Démontage du flexible haute

pression

N Dévisser l’écrou d’accouplement (1)

N Tirer le flexible haute pression du

raccord (2)

Démontage du flexible haute

pression

N Extraire la fiche à ressort (1), puis

tirer le flexible haute pression (2)

hors du raccord

Montage du flexible haute pression

N Glisser le flexible haute pression sur

le raccord (2) de l’enrouleur

N Insérer la fiche à ressort (1) dans le

raccord

Flexible haute pression sur le pistolet

pulvérisateur

Montage

RE 108, RE 118, RE 128 PLUS

RE 128 PLUS

Le flexible à haute pression est déjà

raccordé.

N Insérer le raccord du flexible haute

pression (3) dans le logement du

pistolet pulvérisateur (4) jusqu’à ce

qu’il s’enclenche

33

français

2

650BA025 KN

1

003BA003 KN

Démontage

N Actionner le levier d’arrêt (5) et

extraire le flexible haute

pression (3) du logement du pistolet

pulvérisateur

Rallonge pour flexible haute pression

Il ne faut utiliser qu’une seule rallonge

pour flexible haute pression à la fois

(voir « accessoires optionnels »)

Établissement de

l'alimentation en eau

En mode aspiration, l’appareil peut

également être alimenté à partir de

plans d’eau, de citernes, de réservoirs

ou équivalents, voir « Établissement

d’une alimentation en eau hors

pression ».

Rincer brièvement le tuyau avec de l’eau

avant de le raccorder à l’appareil afin

d’éviter que du sable et d’autres

impuretés ne puissent pénétrer dans

l’appareil.

Branchement du tuyau

N Raccorder le tuyau au robinet

(diamètre 1/2", longueur minimale

10 m pour absorber les impulsions

de pression. Longueur maximale

25 m).

N Glisser le coupleur (1) sur le raccord

pour flexible (2)

N Ouvrir le robinet d’eau

Raccordement au réseau d'eau

potable

Lors du raccordement au réseau d’eau

potable, il faut poser un clapet de nonretour (type BA) selon EN 60335-2-79

entre le robinet et le tuyau.

De l'eau potable qui a traversé le clapet

de non-retour n'est plus considérée

comme de l'eau potable.

Il faut respecter la réglementation du

réseau de distribution d'eau local afin

d'éviter que l'eau provenant du

nettoyeur haute pression ne puisse

revenir dans le réseau d'eau potable.

34

RE 108, RE 118, RE 128 PLUS

français

Établissement d'une

alimentation en eau hors

pression

N Raccorder l’appareil à la source

d’eau sous pression et le mettre en

service pendant un court instant

conformément au présent mode

d’emploi.

N Arrêter l’appareil

N Démonter le dispositif de

pulvérisation du flexible haute

pression

N Remplacer le tuyau d’arrivée d’eau

par le tuyau d’aspiration (accessoire

spécial).

Il faut impérativement utiliser le raccord

pour flexible fourni avec le tuyau

d’aspiration. Les raccords de série sont

seulement étanches avec une

alimentation en eau sous pression et, de

ce fait, ne conviennent pas pour

l’aspiration.

N Remplir le tuyau d’aspiration avec

de l’eau et immerger la crépine

d’aspiration dans un récipient d’eau,

ne pas utiliser d’eau sale

Il est conseillé d’utiliser

systématiquement un filtre à eau.

N Maintenir le flexible haute pression

vers le bas avec la main

N Allumer l’appareil

N Patienter jusqu’à ce qu’un jet

régulier sorte du flexible haute

pression

N Arrêter l’appareil

N Raccorder le dispositif de

pulvérisation

N Allumer l’appareil en tenant le

pistolet pulvérisateur ouvert.

N Actionner plusieurs fois brièvement

le pistolet pulvérisateur afin de

purger l’appareil le plus rapidement

possible

Branchement électrique du

dispositif

La tension et la fréquence de l'appareil

(voir la plaque signalétique) doivent

coïncider avec la tension et la fréquence

du réseau électrique.

La protection du branchement au

réseau doit être exécutée

conformément aux indications dans les

caractéristiques techniques – voir

« Caractéristiques techniques ».

L'appareil doit être branché au réseau

d'alimentation électrique par le biais d'un

disjoncteur différentiel à courant de fuite

qui coupe l'alimentation lorsque le

courant de fuite vers la terre dépasse

30 mA pendant 30 ms.

Le branchement secteur doit être réalisé

conformément à la norme CEI 60364-1

et à la réglementation nationale.

Lors de la mise sous tension de

l'appareil, si les conditions du réseau

sont défavorables (impédance élevée),

d'autres charges raccordées peuvent

être affectées par les fluctuations de

tension qui se produisent. Aucune

perturbation n'est à attendre en

présence d'impédances de réseau

inférieures à 0,15 ohm.

Rallonges électriques

Vérifier que la rallonge électrique est en

bon état. La rallonge électrique utilisée

doit avoir une section suffisante pour le

courant consommé par l'appareil. Une

rallonge électrique sous-dimensionnée

peut provoquer une chute de tension et

ainsi une baisse de puissance et une

surchauffe. Le tableau ci-dessous

RE 108, RE 118, RE 128 PLUS

35

français

1607BA035 KN

1607BA011 KN

1

2

650BA014 KN

indique la section de câble à utiliser

(rallonges SJW ou SJTW) en fonction de

la longueur de la rallonge et de l'intensité

nominale indiquée sur la plaque

signalétique. En cas de doute, utiliser la

section immédiatement supérieure. Le

câble est d'autant plus lourd que la

section est élevée.

Longueur du

câble (m)

Section des fils

(mm²)

15 1,5

30 2,5

45 4

Les rallonges électriques appropriées

sont disponibles dans les magasins

spécialisés ou auprès de votre

distributeur STIHL.

Raccordement à la prise secteur

Vérifier que l’appareil soit éteint avant de

le brancher à l’alimentation électrique –

voir « Arrêt de l’appareil ».

Mise en marche du

dispositif

N Ouvrir le robinet d’eau

L’appareil ne doit être mis en

marche que lorsque le tuyau

d’arrivée d’eau est branché et le

robinet ouvert, sinon le manque

d’eau peut provoquer des