Page 1

{

STIHL RB 302, 402

Instruction Manual

Notice d’emploi

Инструкция по эксплуатации

Instrucţiuni de utilizare

Page 2

G Instruction Manual

1 - 26

F Notice d’emploi

27 - 53

R Инструкция по

эксплуатации

55 - 82

W Instrucţiuni de utilizare

83 - 108

Page 3

Original Instruction ManualPrinted on chlorine-free paper

Printing inks contain vegetable oils, paper can be recycled.

© ANDREAS STIHL AG & Co. KG, 2009

0458-677-9921-A. M0-2.M09.DDS.

0000000846_001_GB

RB 302, RB 402 PLUS

English

1

{

Contents

Dear Customer,

Thank you for choosing a quality

engineered STIHL product.

This machine has been built using

modern production techniques and

comprehensive quality assurance.

Every effort has been mad e to ensure

your satisfaction and trouble free use

of the machine.

Please contact your dealer or our

sales company if you have any

queries concerning your machine.

Your

Hans Peter Stihl

Guide to Using this Manual 2

Safety Precautions and Working

Techniques 2

Fitting, removing spra y lan ce 6

Fitting, removing high-pressure

hose 6

Connecting the water supply 7

Connecting to a pressurel ess water

supply 8

Switching On 8

Working 9

Adding detergent 10

Switching Off 1 1

Storing the Machine 11

Transporting the Unit 11

Maintenance and Care 13

Maintenance 14

Checking the oil level 15

Oil change 15

Minimize Wear and Avoid Damage 16

Main Parts 18

Specifications 20

Special Accessories 21

Troubleshooting 23

Maintenan c e and Repairs 25

EC Declaration of Conformity 25

Quality Certification 26

Page 4

RB 302, RB 402 PLUS

English

2

Pictograms

All the pictograms attached to the

machine are shown and explained in this

manual.

Symbols in text

Engineering improvements

STIHL's philosophy is to continually

improve all of its products. For this

reason we m ay modify the design,

engineering and appearance of our

products periodically.

Therefore, some chang es, modifications

and improvements may not be covered

in this manual.

Observe the national safety regulations

issued, for example, by the employers'

liability insurance association, social

security institutions , occupationa l safety

and health authorities or other

organizations.

When not using the ma chine , it m ust be

put down in such a way that it does not

endanger anyone. Ensure that the unit

cannot be used without authoriz ati on.

The user is responsibl e fo r acc id ents or

risks involving third parties or their

property.

Anyone using a high-pressure cleaner

for the first time: Have your STIHL

dealer or another expert show you how

to use it safely.

Minors should never be allowed to use

the machine – except for yo ung trainees

over the age of 16when working under

supervision.

Do not use the machine if anyone not

wearing protective clothing is in the

working a rea.

The machine should only be provided or

loaned to people familiar wit h this mod el

and its operation. The instruction

manual should always be handed over

with the machine.

In some countries, operation of

machines that emit noise may be

restricted by municipal regulations.

Observe national regulations.

Always check that the machine is in

good working order before starting work.

Particular attention must be devoted to

the high-pressure hose, the spray

attachment and the safety parts.

Never operate the machine with a

defective high-pressure hose – ensure

that it is replaced immediately.

The high-pressure hose must not be

driven over, pulled, buckled or twisted.

Never pull the high-pressure hose in

order to move the machine.

The high-pressure hose must be

approved for the permissible excess

pressure of the machine.

The permissible excess pressure, the

maximum permitted temperature and

the date of manufacture are stated on

the cladding of the high-pressure hose.

The permissible pressure and date of

manufacture are specifi ed on the fittings.

Accessories and spare parts

High-pressure hoses, fittings and

couplings are important for machine

safety. Only high-pressure hoses,

fittings, couplings and other accessories

Guide to Using this Manual

Warning where there is a risk of

an accident or personal injury or

serious damage to property.

Caution where there is a risk of

damaging the machine or its

individual components.

Safety Precautions and

Working Techniques

The high water pressure

generated is a particular

source of danger.

It is important that you

carefully read the entire

Instruction Manual befo re

using the machi ne fo r the

first time and keep it in a

safe place for future reference. Non-compliance

with the Instruction Manual may cause se rio u s o r

even fatal injury.

Page 5

RB 302, RB 402 PLUS

English

3

which have been approved by STIHL for

this machine or technically equivalent

parts may be mounted on the machine.

Contact a dealer if in doubt. Use only

high-quality accessories, in order to

avoid the risk of accid ents or dam age to

the machine.

STIHL recommends the use of genuine

STIHL parts and accessories. These

have been opti mized for the product a nd

the user's requirements.

Never modify the machine in any way,

as this could be extremely dangerous.

STIHL excludes all liability for personal

injury and damage to property caused

while using unauthorized attachments.

Physical suitability

The machine may only be operated by

people who are fit, in good physical

health and in good mental condition. If

you have any condition tha t might be

aggravated by strenuous work, check

with your doctor before operating a

machine.

Anyone who has consumed alcohol,

medicines affecting their ability to react

or drugs must not operate the machine.

If you have a pacemaker: The ignition

system of your machine produces an

electromagnetic field of very low

intensity. An effect on individual

pacemaker types cannot be excluded

entirely. STIHL recommends that you

consult your doctor and the

manufacturer of your pacemaker in

order to avoid health hazards.

Applications

The high-pressure cleaner can be used

to clean motor vehicles, machines,

tanks, facades or s tables and to re move

rust without dust or sparks.

Other uses are not permitted and may

lead to accidents or damage to the

machine.

Clothing and equipment

Wear shoes with non-slip soles.

Clothing which c ould becom e trapped i n

moving parts of the machine should not

be worn. Do not wear a scarf, tie or

jewelry when operating the machine.

Long hair must be tied up and covered

(headscarf, cap, helmet, etc.).

Transporting the machine

Always switch off the engine.

Do not touch any hot parts of the

machine, in particular the muffle r

surface or the gear housing – risk of

burns!

So that the mac hin e ca n b e tran sported

safely on or in a vehicle, it must be

secured with stra ps so that it canno t slip

or tip over and to protec t it from d amage

and prevent fuel spills.

Antifreeze is recommended if the

machine and accessories are to be

transported at temperatures near or

below 0° C (32 °F) – see “Storage”.

Refueling

Switch off the engine before refueling.

Never refu el the machine while the

engine is still ho t – the fuel may spi ll over

– risk of fire!

Open the fuel filler cap carefully so that

any excess pressure is relieved

gradually and fuel does not splash out.

The machine may only be ref ueled in a

well ventilated pl ace. Clean the machin e

immediately if fuel is spilled. Change

your clothes immediately if they are

contaminated with fuel.

Close the filler cap as tightly as possib le

after refueling.

This helps reduce the risk of unit

vibrations causing an incorrectly

tightened filler cap to loosen or come off

and spill quantities of fuel.

Check for leaks. Do not st art th e engin e

if there is a fuel leak – serious or fatal

burns could result.

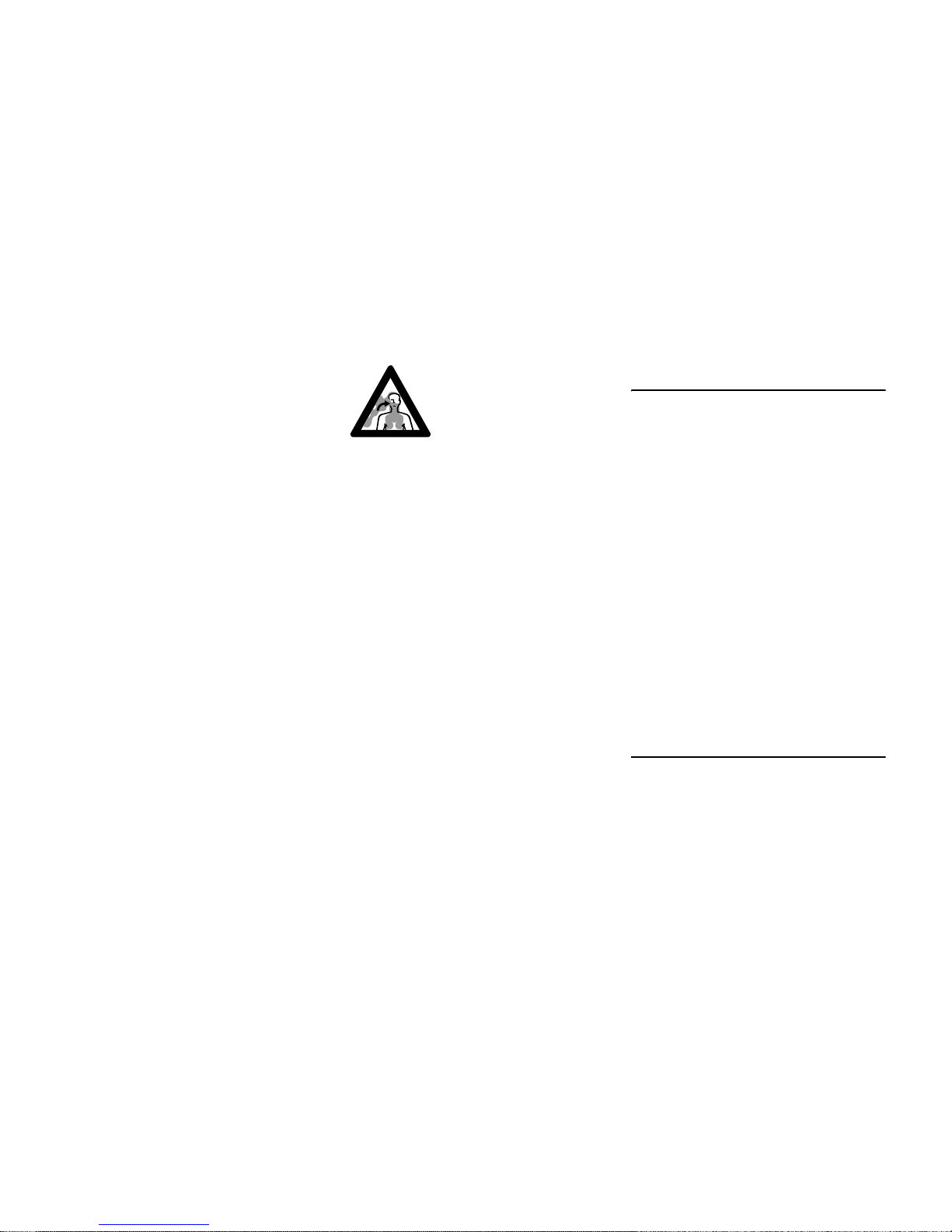

Wear goggles and protective clothing. STIHL

recommends that a

boilersuit be worn in

order to reduce the risk of

injury due to accidental

exposure to the highpressure jet.

Gasoline is an

extremely flammable

fuel – keep clear of

naked flames and fire –

do not spill any fuel – no

smoking.

Page 6

RB 302, RB 402 PLUS

English

4

Detergent

Unsuitable detergents can cause

damage to health, as well as to the

machine and the object to be cleaned.

Contact a dealer if in doubt.

STIHL recommends the use of genuine

STIHL detergents. Follow the

instructions for use.

Chemical detergents may contain

physiologically harmful (toxic, caustic,

irritant), flammable or explosive

substances. Note the manufacturer's

safety data sheets!

Detergents should alwa ys be used in the

proportions specified by the

manufacturer.

Before starting work

Only connect the hi gh -pres su re c le ane r

to the drinking wa ter main in conju nction

with a backflow prev enter – see "Special

accessories".

Do not use the machine with dirty w ater.

If there is a risk that dirty wate r will occur

(e. g., flowing sand), an appropriate

water filter must be used.

Check that the high-pressure cleaner is

in full working order. Pay particular

attention to the high-pressu re hos e, the

spray attachment, the safety parts and

the fuel system. Note the relevant

chapter of the instruction manual:

Inspecting the high-pressure cleaner

The high-pressure cleaner should only

be used if it is in ful l working order – risk

of accident!

– It must be possible to move the

switch to the 0 position easily

– Check that the spark plug boot is

secure. A loose boot can lead to

flying sparks which may ignite the

escaping fuel/air mixture – risk of

fire!

– Inspect the high-pressure hose,

spray attachment and safety

mechanis ms for damage

– High-pressure hose and spray

attachment in good condition

(clean, moving easi ly) and corr ectly

assembled

– For good control of the machine, the

handles should be clean and dry

with no oil or dirt on them

– Check the oil level

– Never attempt to modify the controls

or safety devices

Starting the engine

Start the engine as described in the

engine manual.

Move at least 3 meters away from the

place at which the machine was refueled

and never start the ma chine in e nclosed

spaces.

Place the machine on a flat surface and

ensure a firm and safe footing.

The machi ne is operated by only one

person. There should not be any other

person within the work ing area, not even

when starting the machine.

Check that the speed drops: the engine

must idle when the operator releases the

trigger on the spray gun.

During work

Ensure you always have a firm and safe

footing.

Beware of slipping on ice , wate r, snow

or uneven ground!

Keep the high-pressure cleaner as far

away as possible from the object being

cleaned. Keep the ma ch ine at least 1 m

away from buildings while working.

Switch off the engine imme diately in th e

event of imminent danger or in an

emergency.

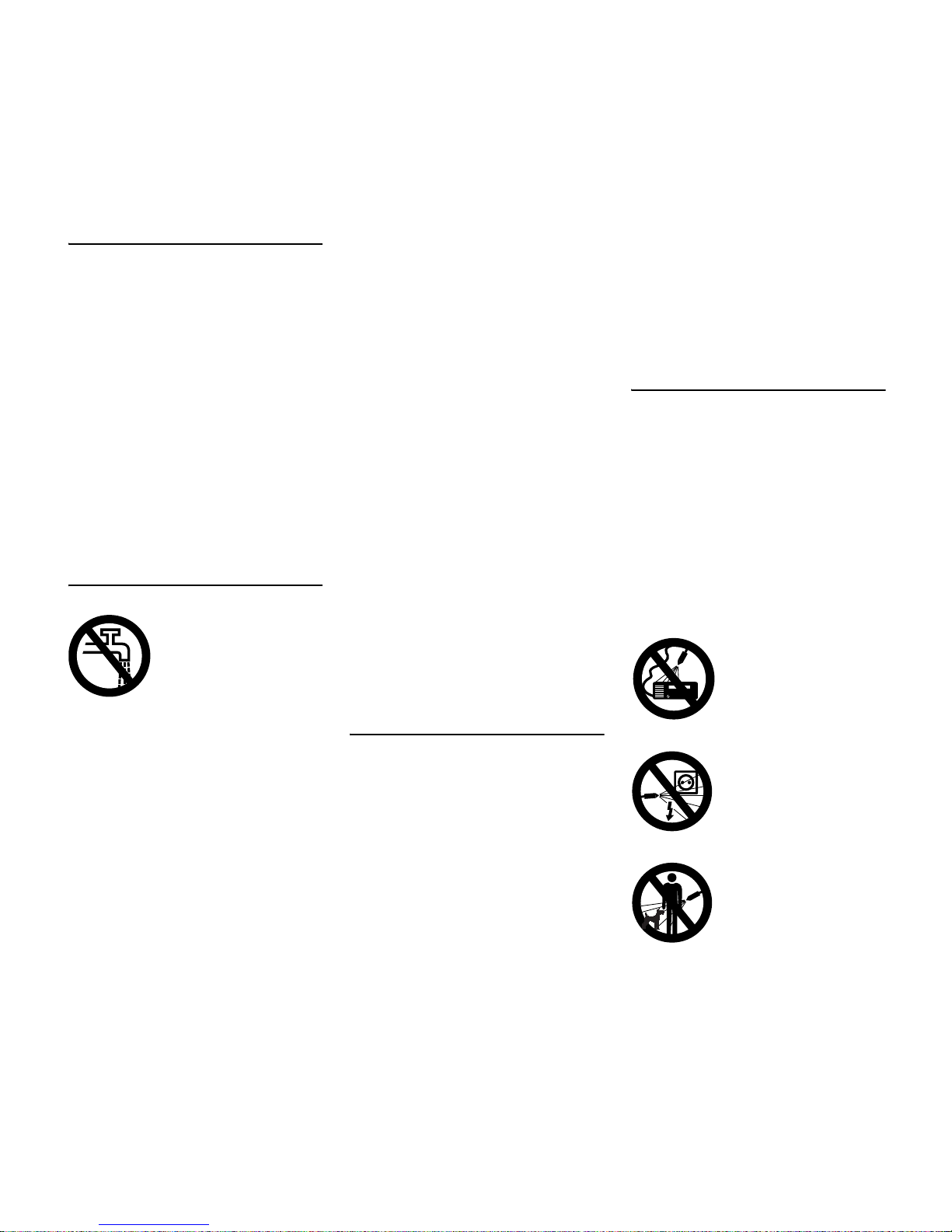

Do not connect the highpressure cleaner directly

to the drinking water

main.

Never direct the highpressure jet or water

hose against electrical

appliances and equipment – danger of short-

circuiting!

Never direct the highpressure jet or water

hose against electrical

equipment, connections

and power c ables – dan-

ger of short-circuiting!

Never direct the highpressure jet against yourself or other people, not

even to clean clothing or

shoes – risk of injury!

Page 7

RB 302, RB 402 PLUS

English

5

Do not direct the high-pressure jet

against animals.

Do not direct the high-pressure jet onto

places you cannot see.

Children, animals and bystanders must

remain at a distance.

Hazardous substances (e. g ., asbestos

or oil) must not be allowed to escape into

the environment unchecked when

working with the machine. The

applicable environmental regulations

must be observed without fail.

Surfaces of asbestos cement must

never be cleaned with a high-pressu re

jet. Hazardous, breathable asbestos

fibers may be relea sed in addition to the

dirt. The danger is greatest when the

washed surface has dried.

Never draw in fluids containin g solvents

or undiluted acids and solvents

(e. g., gasoline, heating oi l, paint thinne r

or acetone). These substan ces damage

the materials used in the machine. The

spray is highly combustible, explosive

and poisonous.

Delicate parts made of rubber, fabric

or sim ilar material s must not be cle aned

with a pencil jet, e. g., from the rotary

nozzle. Maintain a sufficient distance

between the high-pres sure hose and the

surface when cleaning to avoid any

damage to the surface being cleaned.

The trigger on the spray gun mu st move

easily and automatically return to its

starting position when released.

Always hold the spra y attachm ent firmly

with both hands on th e handles in orde r

safely to withstand the kickback force

and additional torque produced when

using spray attachments with an angle d

spray lance.

Ensure that the high-pressure hose is

not damaged by being driven over,

squashed or pulled; protect it against

heat and oil.

The machine must not be covered.

Ensure that the engine is cooled

sufficiently.

Ensure proper ventil ation w hen wo rking

in trenches, hollows or other confined

locations – risk of serious or fatal

injury from breathing toxic fumes!

If you feel si ck, if you have a he ada ch e,

vision problems (e.g., your field of vis ion

gets smaller), hearing problems,

dizziness or inability to concentrate, stop

work immediately. Such symptoms may

be caused by an excessively high

concentration of exhaust emissions –

risk of accident!

No smoking when working with or near

the machine - risk of fire! The f uel ta nk

may give off inflammable vapors.

Safety equipment

When the safety equipmen t is activated,

excessive pressure is returned to the

intake side of the pump via a safety

valve. This safety feature has been set

by the manufacturer and must not be

adjusted.

After finishing work

If the machine is sub jec te d to u nus ua lly

high loads for which it w as not de signed

(e. g., heavy impact or a fall), always

check that it is in good condition before

continuing work - refer also to the

chapter "Before starting work".

In particular, make certain that the safety

mechanisms are worki ng prop erl y.

Never use the ma chine if it is not in good

condition. Consul t a servicing dealer if i n

doubt. STIHL recommends STIHL

servicing dealers.

Before leaving the machine:

– Switch off machine

– Disconnect water intake hose

between machine and water supply

Maintenance and repairs

The machine must be serviced regularly.

Do not attempt any maintenance or

repair work not described in the

Instruction Manual. All o ther work should

be carried out by a servicing dealer.

STIHL recommends that maintenance

and repair work be carried out only by

authorized STIHL dealers. STIHL

dealers receive regular training and are

supplied with technical information.

Y our po wer tool produ ces

toxic exhaust fumes as

soon as the engine is

running. These gases

may be colorless and

odorless and may c ontain

unburnt hydrocarbons

and benzene. Never run

the engine indoors or in

poorly ventilated areas,

even if your model is

equipped with a catalytic

converter.

Page 8

RB 302, RB 402 PLUS

English

6

Use only high-quality replacement parts,

in order to avoid the risk of accide nts or

damage to the machine. Contact a

dealer if in doubt.

STIHL recommends the use of genuine

STIHL spare parts. Such parts have

been optimized fo r the ma ch ine an d the

user's requirements.

Before starting any maintenance or

repair work and before cleaning the

machine, always stop the engine – risk

of injury!

Do not service or store your unit near

any fire or flame.

Check fuel cap regularly fo r tightness.

Inspect ignition lead (insulation in good

condition, secure conn ect ion ).

Check that the muffler is in perfect

working condition.

Do not use the machine if the muffler is

damaged or missing – risk of fire! –

Hearing damage!

Never touch a hot muffler – risk of

burns!

Stop the engine before remedying

malfunctions.

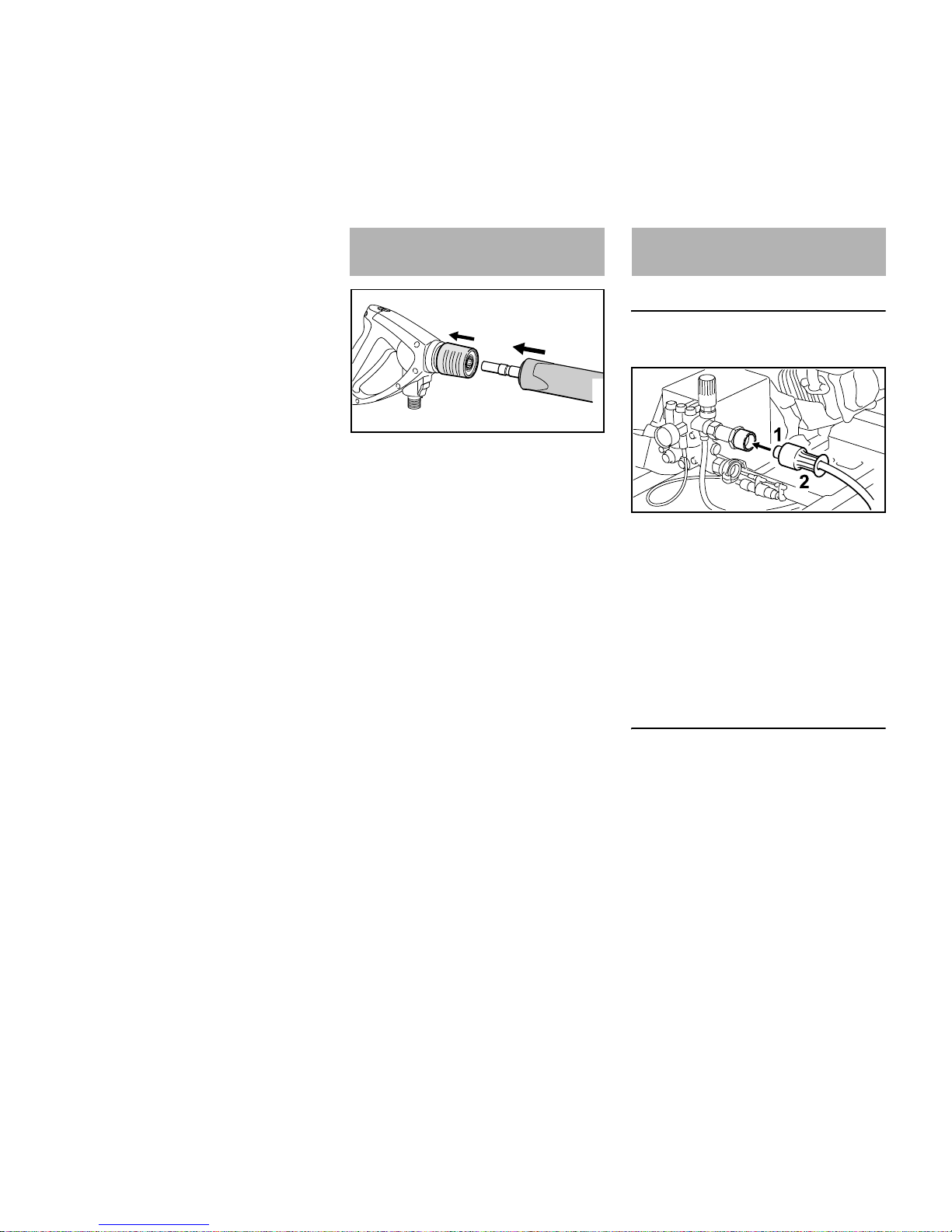

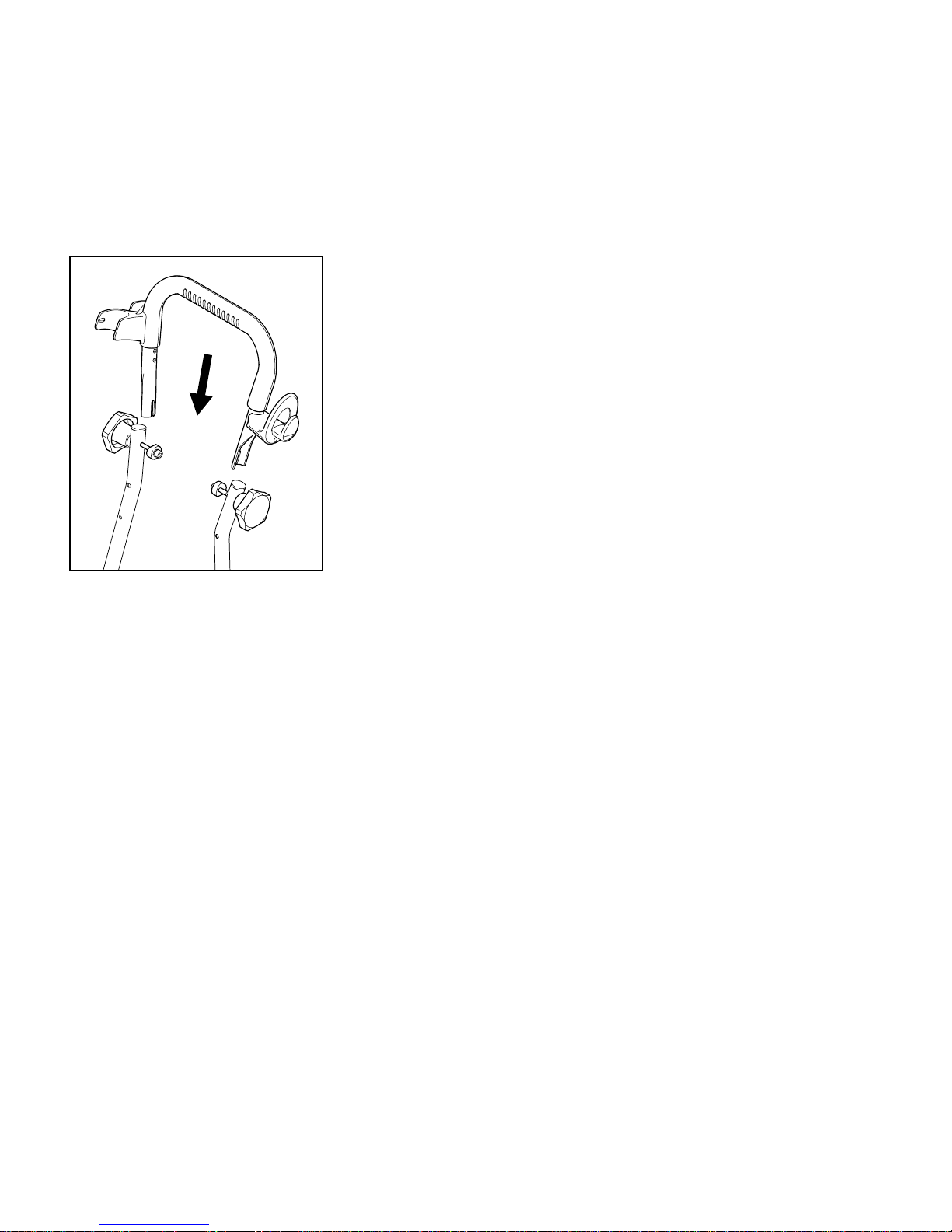

N Pull back and hold the coupling (1)

N Push the spray lance (2) into the

mount on the spray gun, or pull it out

to remove the spray gun,

respectively

N Release the coupling (1)

RB 302

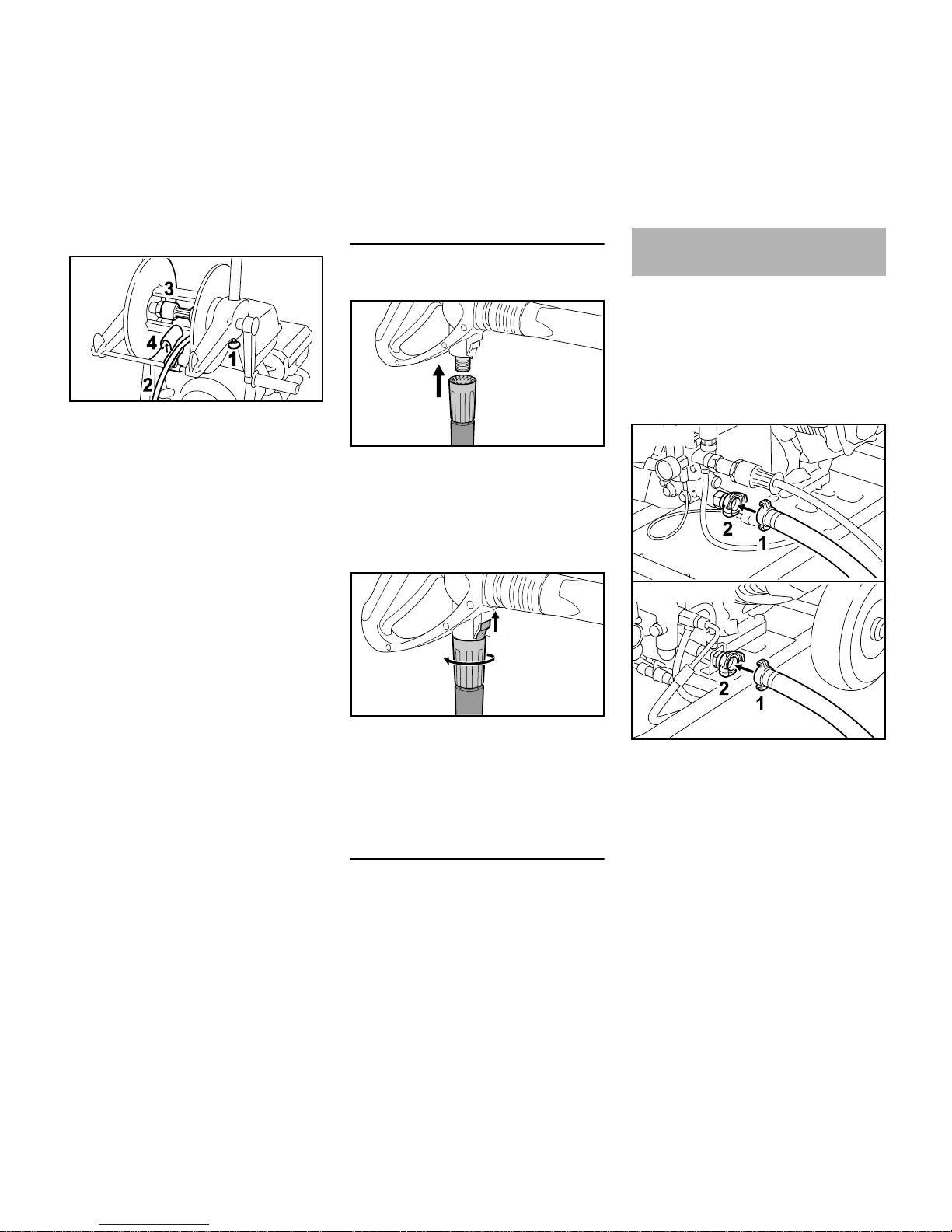

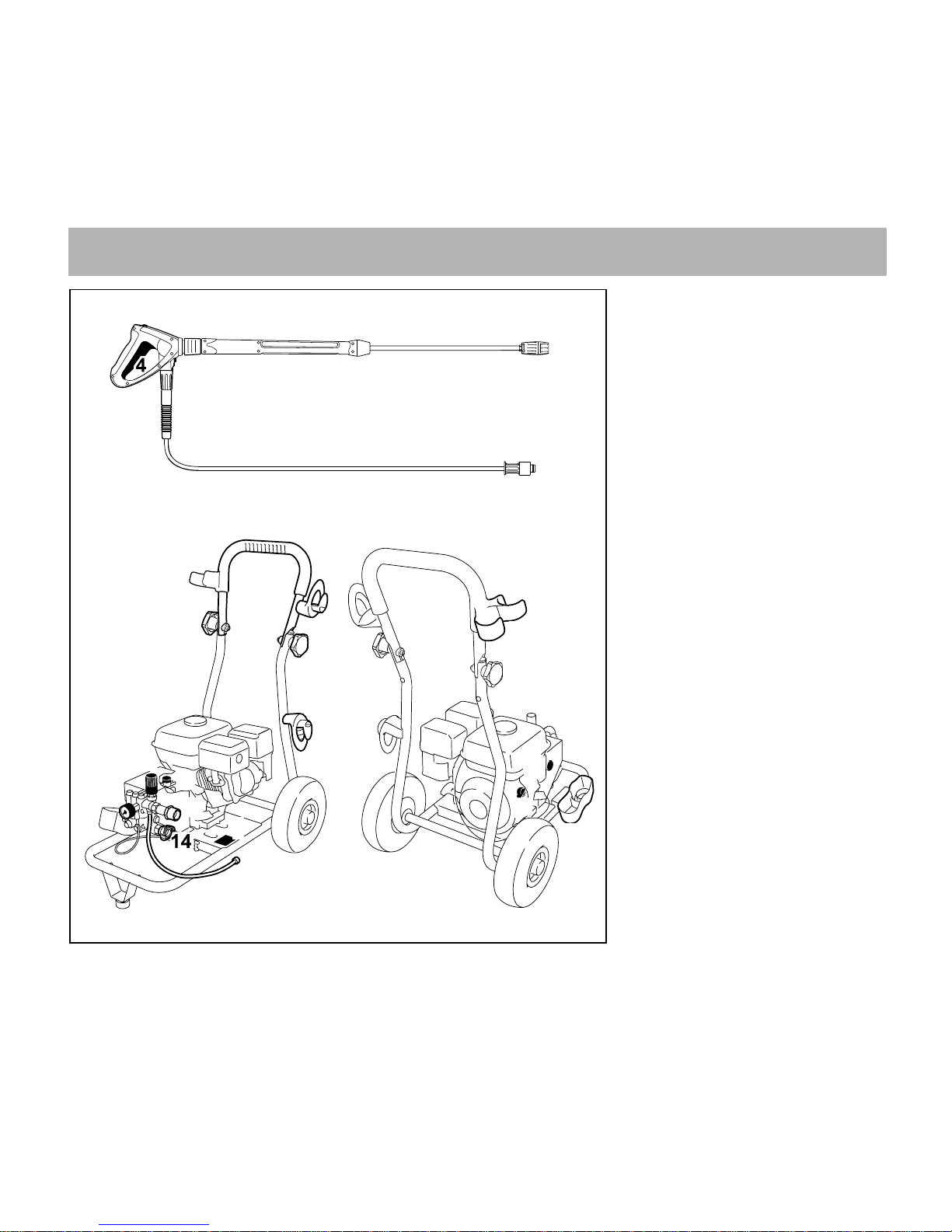

Connecting the high-pressure hose

N Push high-pressure hose (1) onto

the connector

N Attach union nut (2) and screw it on

and tighten by hand

Disconnect the high-pressure hose

N Unscrew the union nut (2)

N Pull high-pressure hose (1) off of

connector

RB 402 PLUS

The high-pressure hose is already

connected.

Fitting, removing spray

lance

647BA021 KN

1

2

Fitting, removing highpressure hose

677BA001 KN

Page 9

RB 302, RB 402 PLUS

English

7

Disconnect the high-pressure hose

N Release the hose reel brake

To release the hose reel brake, pull the

handle (1) downward.

To lock the brake, press the handle (1)

firmly upward until the hose reel is

locked.

N Unroll the high-pressure hose(2)

N Unscrew the union nut (3)

N Open the hose guide (4)

N Pull high-press ure hose (2) off of

connector

Connecting the high-pressure hose

N Push the high-pressure hose (2)

onto the connector of the hose reel

N Attach union nut (3) and s crew it on

and tighten by hand

N Push the high-pressure hose into

the hose guide (4) and close the

hose guide.

N Release the brake (1) on the hose

reel and wind up the high-pressure

hose

High-pressure hose and spray gun

Connection

N Push the high-pressure hose (1)

onto the connector (2)

N Attach union nut (3) and screw it on

and tighten by hand

Disconnection

N Push the coupling (4) in the

direction of the arrow and hold it

N Loosen the union nut (3) and

unscrew it from the conn ector in the

direction of the arrow

High-pressure hose extension

As a rule, always use only one highpressure hose ext ens ion – s ee "Spe cial

accessories"

Briefly r inse out the water hose before

connecting it to the machine to prevent

sand and other particles from entering

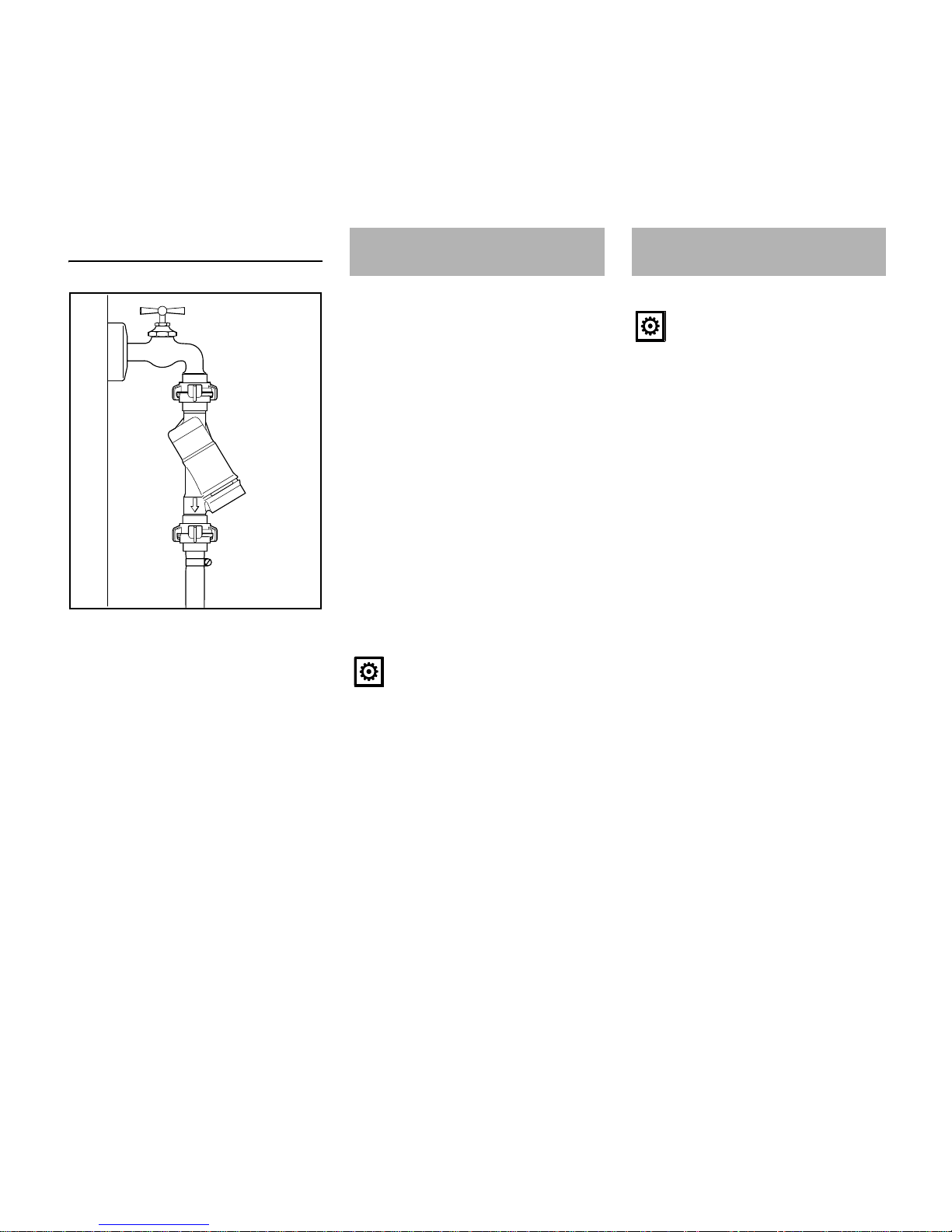

the machine.

N Connect hose (3/4" diameter, length

at least 10 m to absorb pressure

surges)

N Mesh the jaws of the hose

connector (1) and coupling (2) with

each other and turn right as far as

possible

N Turn on water supply

In suction operation, the machine can

also be connected to rivers, lakes,

cisterns and tanks, etc. – see

"Connecting to a pressureless water

supply".

677BA023 KN

1

2

3

647BA022 KN

647BA023 KN

3

4

Connecting the water

supply

677BA004 KN

RB 302

RB 402 PLUS

Page 10

RB 302, RB 402 PLUS

English

8

Connection to the drinking water

main

When hooking up to the drinking water

main, a backflow prev ent er (Ty pe BA in

accordance with EN1717) must be

installed between the water tap and the

hose.

Follow the rules laid down by the local

water supply company to prevent water

flowing b ack from the high-pressure

cleaner into the drinking water main.

N Connect the machine to the

pressurized water suppl y and start it

up briefly in accordance with the

Instruction Manual

N Switch off machine

N Disconnect the high-pressure hose

N Replace water intake hose with

suction ho se (special acce ssory)

Always use t he connecting element

supplied with the int ake hose t o connect

the hose. The standard connecting

elements are waterti ght only when used

with a pressurized water supply and for

this reason are not suitable for suction

operation.

N Fill the suction hose with water and

immerse the suction cup of the

suction hose in the wate r tank – do

not use dirty water

N Switch on the machine

N Wait until a steady jet exits the high-

pressure hose connection

N Switch off machine

N Connect high-pressure hose

N Switch on the machine with the

spray gun open

N Actuate the spray gun several time s

briefly in order to bleed the air out of

the machine as quickly as possible

N Turn on water supply

N Completely unroll the high-pressure

hose

N Start the engine as described in the

engine manual.

N Point the spray gun at the object to

be cleaned – neve r at persons!

003BA004 KN

Connecting to a

pressureless water supply

As a rule, it is advisable to use a

water filter.

Switching On

The machine may only be

switched on when the water int ake

hose is connected and the water

supply has been turned on.

Otherwise the machine may be

damaged due to lack of water.

Page 11

RB 302, RB 402 PLUS

English

9

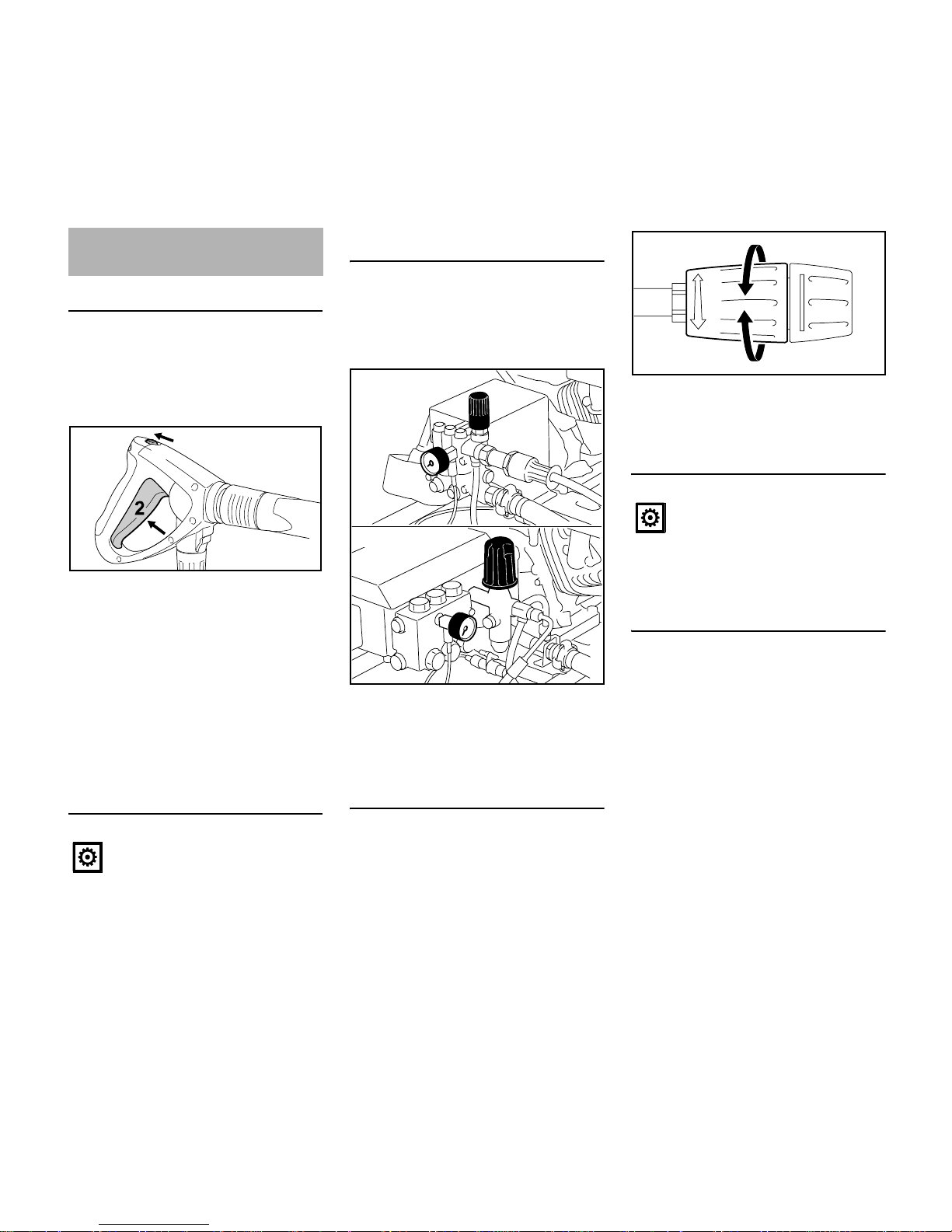

Actuate the spray gun

N Direct the spray attachment toward s

the object to be cleaned

N Point the rotary nozzle downwards

when starting (if fitted)

N Press the safety latch (1) in the

direction of the arrow – th e lever (2)

is unlatched

N Squeeze the lever (2)

The engine runs at reduced speed in

standby mode to reduce energy

consumption and noise levels.

The engine switches from operating

speed to idling speed when the spray

gun is not actuated.

Standby mode

Pressure/quantity control on the

machine

Working pressure and water flow rate

can be set on the high-pressure pump

for long-term adjustment in line with the

cleaning job concerne d.

N Turn the knob (3) to set the working

pressure and water flow rate

The pressure in th e high-pressure pum p

is indicated by a pressure gauge (4).

Pressure control at the nozzle

The operating pressu re ca n be infin itely

adjusted at the nozzle.

N Turn the nozzle sleeve – the

quantity of water delivered remains

unchanged

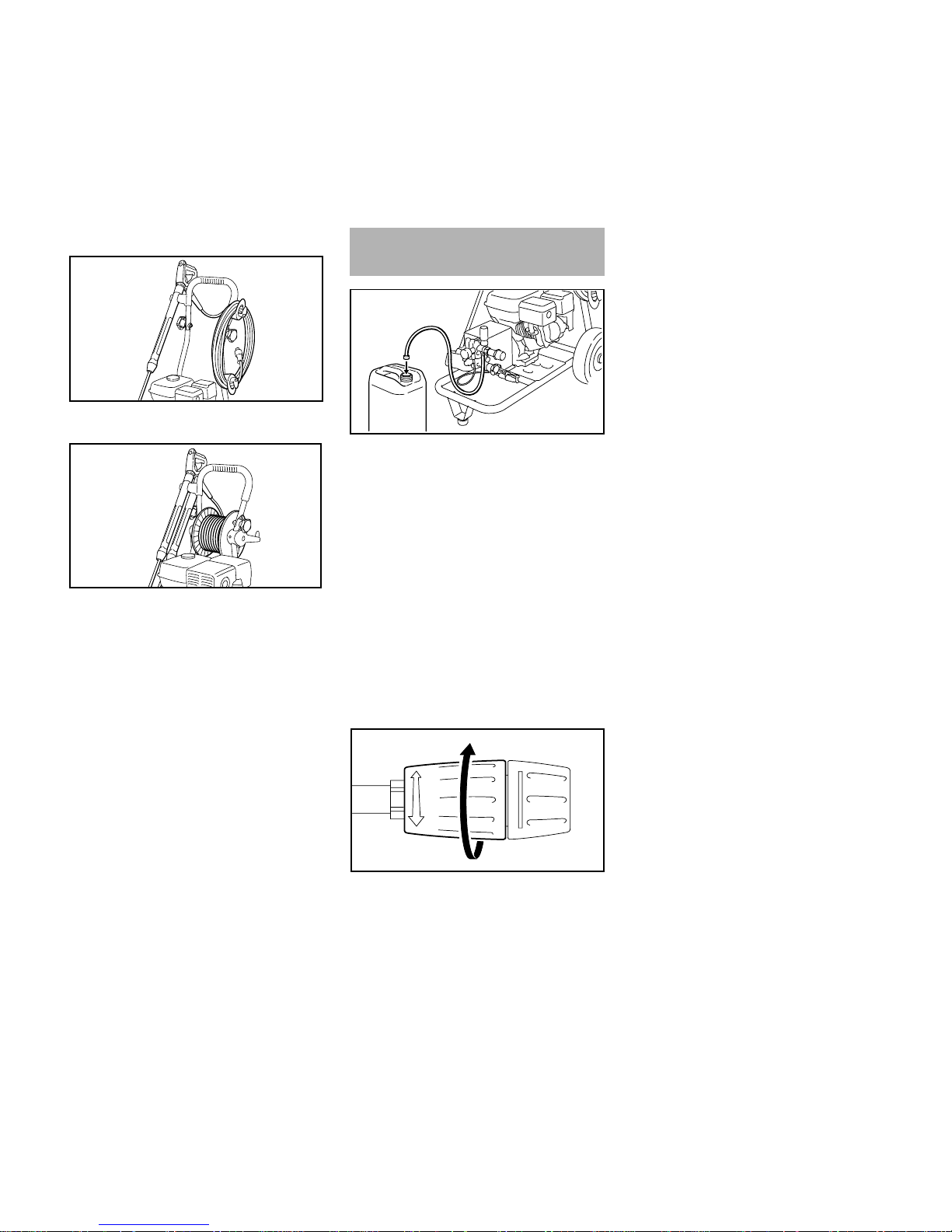

High-pressure hose

Storing accessories

Roll up the high-pressure hose. Store

the spray attachment directly on the

machine.

Working

The machine must not be

operated in standby mode for

more than 5 minutes. If work is

interrupted for more than 5 min.,

during breaks or if the machine is

left unattended, switch off the

engine – as described in the

engine manual.

1

647BA024 KN

4

677BA005 KN

RB 302

RB 402 PLUS

3

3

4

Do not buckle or loop the highpressure hose.

Do not place any heavy obje cts on

the high-pressure hose, and do

not drive any vehicles over it.

647BA025 KN

Page 12

RB 302, RB 402 PLUS

English

10

RE 302

RE 402 PLUS

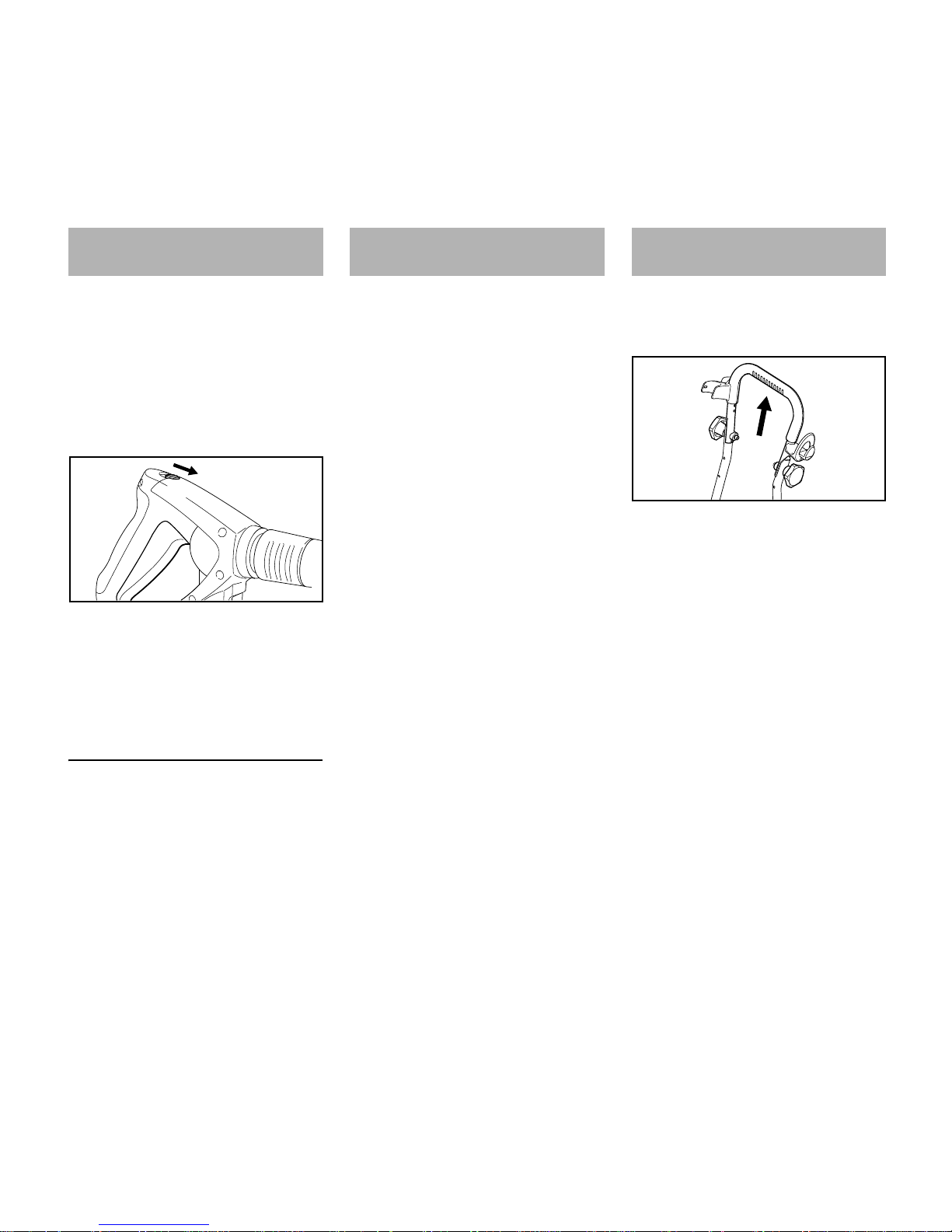

With the intake hose, detergent can be

drawn in and added from a separate

container.

N Fill the separate detergent container

with STIHL detergent diluted as

specified

N Slide the pickup body of the intake

hose as far as possible into the

detergent container

If high-pressure hose extensions are

connected, it is impossible to draw in

detergent from the detergent container.

Detergent can only be drawn into the

machine in low-pressure operation.

N Turn sleeve as far as possible in the

direction of the arrow (low-pressure

operation)

N When applying detergent, start at

the bottom and work upwards

Detergent must not be allow ed to d ry on

the object to be cleaned.

If detergent is no longer to be added:

N Immerse the pickup body in clear

water

N Let the high-pressure cleaner

continue to run with the spray gun

open until no more deterge nt comes

out of the nozzle

N see “Switching off the machine”

677BA018 KN

677BA019 KN

Adding detergent

631BA008 KN

647BA028 KN

Page 13

RB 302, RB 402 PLUS

English

11

N Switch off engine as described in

the engine instruction manual

supplied

N Turn off water supply

N Actuate the spray gun until water

merely drips from the spray head –

the machine is now depressurized

N Release trigger

N Press the safety latch (1) in the

direction of the arrow – the spray

gun is locked to preven t inadvertent

operation

N Disconnect water intake hose from

machine and water supply

After use

N Roll the high-pressure hose up on

the brackets provided for this

purpose – see "Main parts of the

machine"

Store the machine in a dry room where it

is protected from frost.

If protection from frost cannot be

guaranteed, draw glycol-based

antifreeze – like that used in motor

vehicles – into the pump:

N Disconnect water intake hose

N Remove spray lance – see "Fitting,

removing spray lance"

N Switch on the machine, switch it off

again after a maximum of 1 minute

N Connect suction hose (special

accessory) to the water intake of the

machine and immerse it in th e

container with antifreeze

N Insert spray gun without spray lance

in the same container

N Starting the engine

N Actuate the spray gun until a

uniform jet emerges

N Remove suction hose from the

container with antifreeze

N Actuate the spray gun to pump out

the rest of the antifreeze

N Switch off the engine

N Keep leftover antifreeze in a sealed

container

Removing the pushbar

The pushbar can be removed to si mplify

transport in vehicles:

N Undo both star handles (1)

N Lift off the pushbar (2)

Switching Off

1

647BA029 KN

Storing the Machine Transporting the Unit

2

677BA017 KN

1

1

Page 14

RB 302, RB 402 PLUS

English

12

Attaching the pushbar

N Push both ends of the pushbar (2)

between the retaining bushes (3)

and the tubes of the chassis over

the screw

N Tighten both star handles (1) by

hand – the pushbar is secured

1

3

3

677BA022 KN

2

1

Page 15

RB 302, RB 402 PLUS

English

13

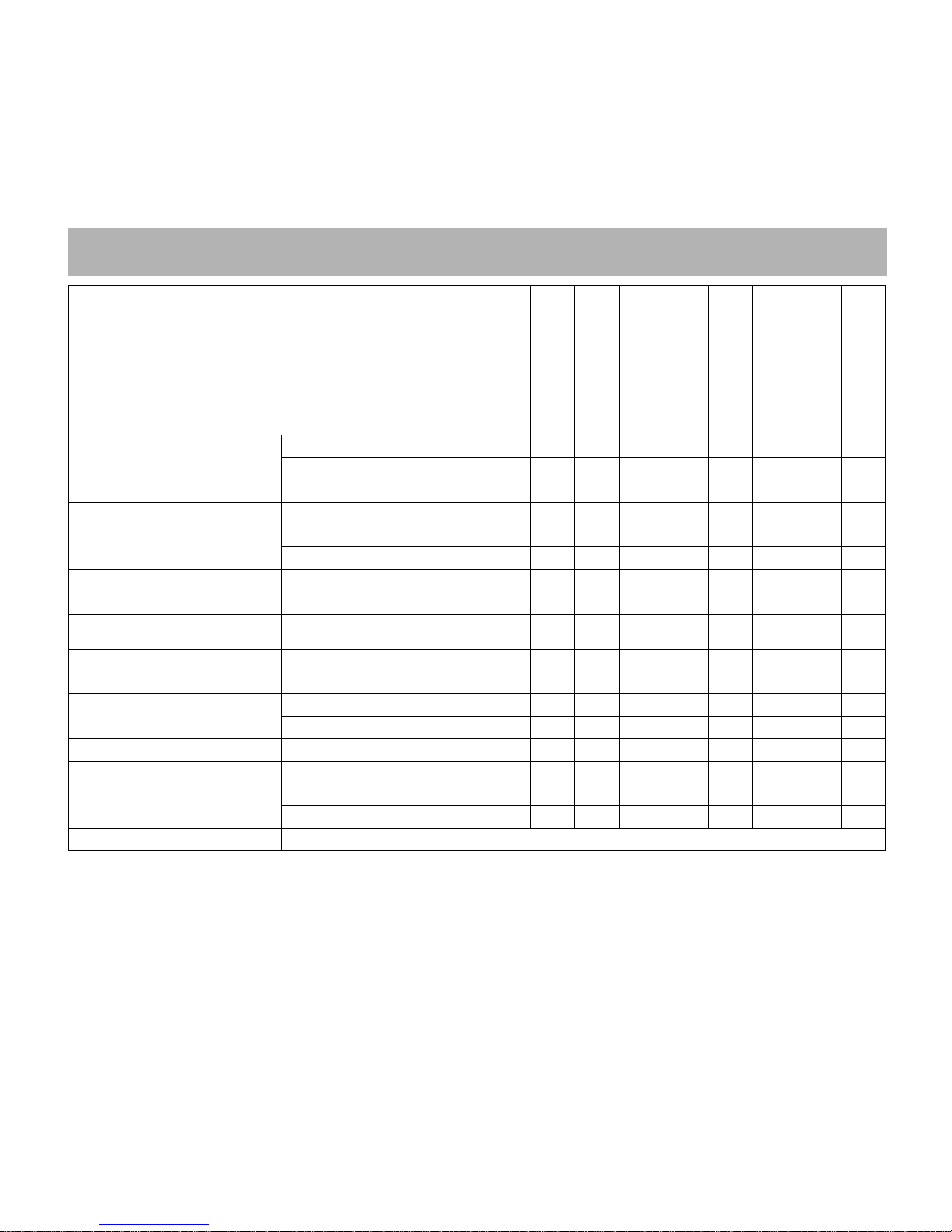

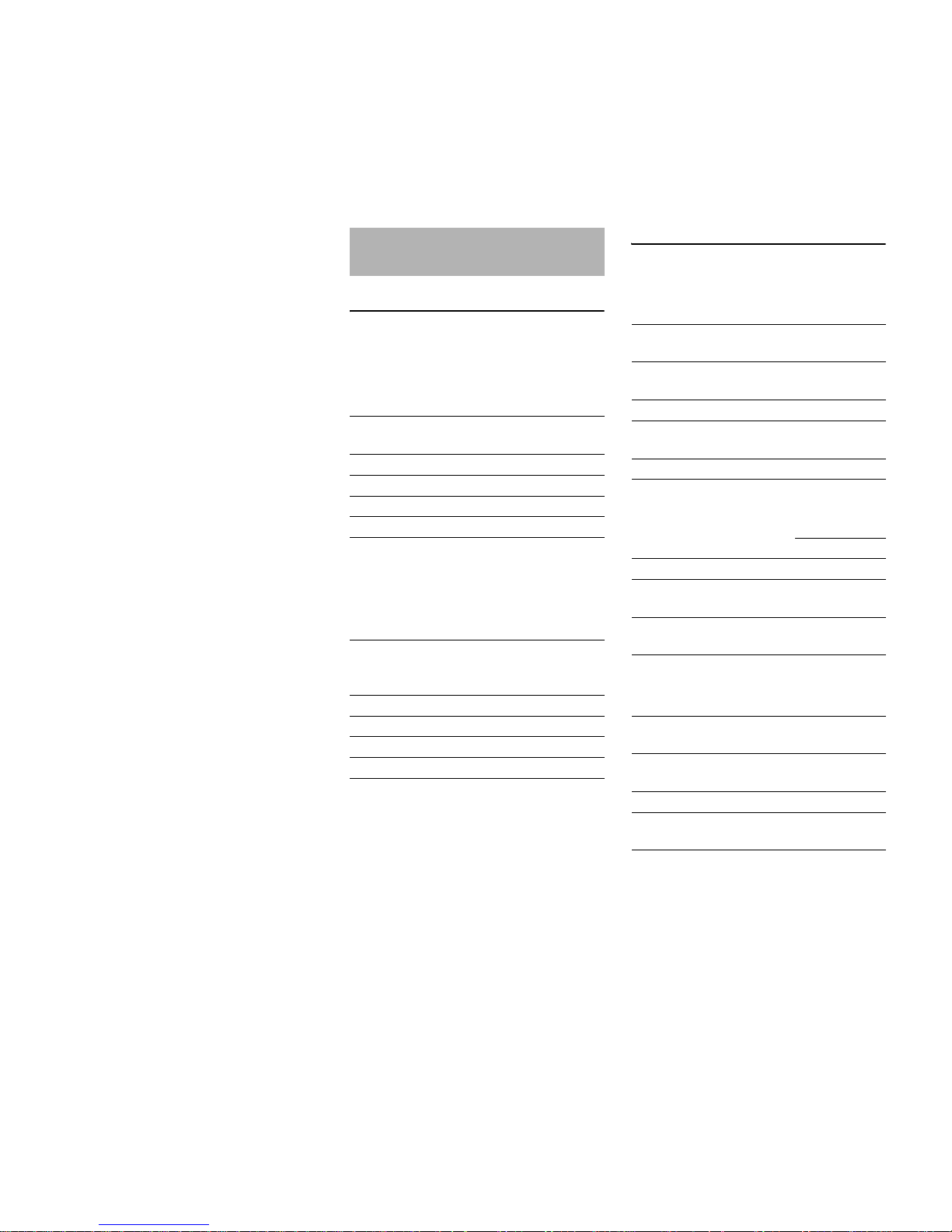

Maintenance and Care

The following maintenance intervals apply in normal operating conditions. The specified intervals must be shortened accordingly for longer daily working hours. If the

machine is only used occasionally, the intervals can be extended accordingly.

before starting work

at the end of work and/or

daily

weekly or every 40 hours of

operation

monthly

quarterly or every 200 hours

of operation

every six months or every

500 hours of operation

if faulty

if damaged

as required

Complete machine

Visual inspection (condition, leaks) X

clean XX

Oil level of the high-pressure pump check X

Oil of the high-pressure pump change

1) 2)

X

Gearbox oil (RB 402 PLUS only)

check X

change

1)

X

Connectors on high-pressure hose

clean XX

grease X

Plug-type coupling of the spray lance and

the coupling sleeve of the spray gun

clean XX

Water intake strainer in the high-pressure

inlet

clean XX

replace X

High pressure nozzle

clean X

replace X

Ventilation openings clean X

Injector clean X

Rubber buffers

check X

replace X

Engine maintain as described in the enclosed engine instruction manual

1)

for the first time after 50 hours of operation

2)

for RB 302, additional oil changes every six months or after every 200 hours of operation

Page 16

RB 302, RB 402 PLUS

English

14

Always switch off the engine before

servicing or cleaning the machine.

In order to ensure tr ouble free operation ,

we recommend carrying out the

following steps when ever the machine is

used:

N Rinse the water hose, high-

pressure hose, spray lance and

accessories with wa ter before fitting

them

N Remove all sand and dust from the

plug-type coupling of the spray

lance and the cou pling sleeve o f the

spray gun

Cleaning the high-pressure nozzle

Since the pump pressure increases if

the nozzle is clo gged, it must be cle aned

immediately.

N Switch off the engine

N Actuate the spray gun until water

merely drips from the spray head –

the machine is now depressurized

N Remo ve spray lance

N Clean nozzle with a suitable needle

N Rinse spray lance with water from

the nozzle end

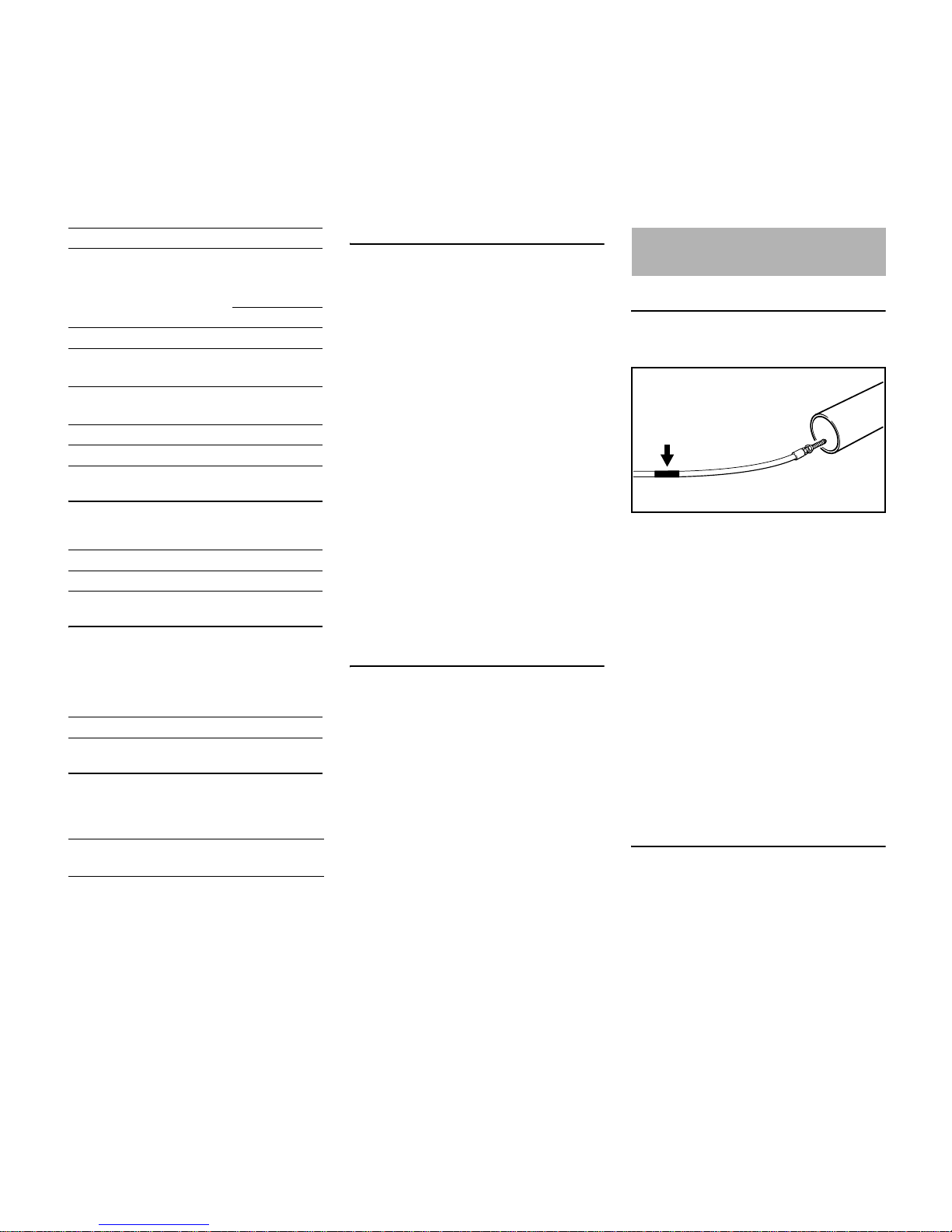

Cleaning the water intake screen

The water intake screen must be

cleaned every week or more often if

necessary.

N Disconnect hose (1)

N Carefully release the screen (2) with

pliers and rinse it

N Before refitting the screen, ensure

that it is undamaged and replace if

necessary

Clean ventilation openings

The machine must be kept clean so that

cooling air can flow freely through the

openings in the engine.

Cleaning the injector

The injector mu st be c le aned whenever

detergent has been used.

N Immerse the pickup body in clear

water

N Actuate the spray gun for

approx. 5 seconds

Lubricate connections

Lubricate the connections on the highpressure hose as needed

Servicing the engine

The engine must be serviced as

described in the engine instruction

manual supplied.

Check the rubber buffers

The front rubber buffers must be

replaced if damaged or worn, to ensure

the stabil ity of the machine.

Maintenance

647BA031 KN

Always remove the spray lance

before cleaning the nozzle.

1

677BA013 KN

2

631BA008 KN

Page 17

RB 302, RB 402 PLUS

English

15

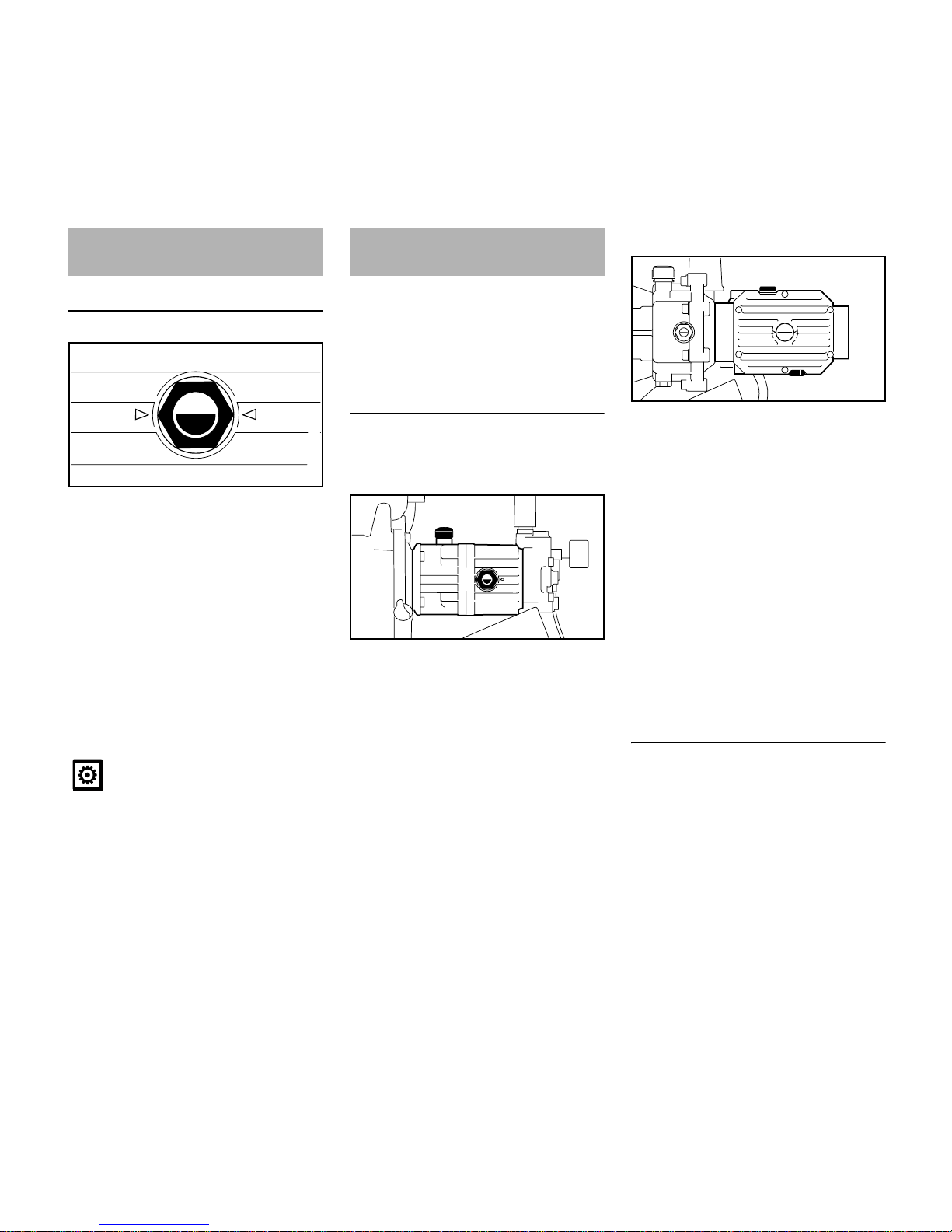

High-pressure pump

The oil level in the high-pressure pump

and the gearbox (RB 402 PLUS only)

must be checked at monthly intervals.

N Place the machine on a flat

horizontal surface

N Check that the oil is level with the

center of the oil sight glass

N If necessary, add oil (SAE 15 W 40)

Engine

Check the engine oil level as described

in the engine instruction manual

supplied.

N Let the machine warm up – this will

simplify the oil change

Waste oil must be disposed of in

accordance with the statutory

regulations.

High-pressure pump

N Remove shroud

RB 302

First oil change after 50 hours of

operation, then every six months or

every 200 hours of operation.

N U nscrew oil filler cap (1)

N Place a suitable container (1 liter)

under the pump

N Unscrew the oil sight glass (2) and

tilt the machine to drain it

N Drain oil into container

N Screw in and tighten the oil sight

glass (2)

N Ad d oil (180 ml, SAE 15 W 40)

N Check the oil level

N Refit and tighten oil filler cap

N Refit the shroud

RB 402 PLUS

First oil change after 50 hours of

operation, then every six months or

every 500 hours of operation.

N Unscrew oil filler cap (1)

N Place a suitable container (1 liter)

under the pump

N Unscrew the oil dra in plug (3)

N Drain oil into container

N Refit and tighten oil drain plug

N Add oil (560 ml, SAE 15 W 40)

N Chec k the oil level

N Refit and tighten oil filler cap

N Refit the shroud

Engine

The engine oil must be changed as

described in the engine instruction

manual supplied.

Checking the oil level

The engine stops automatically if

the oil level is too lo w. The en gin e

cannot be started without the

correct oil level.

677BA012 KN

Oil change

677BA009 KN

1

2

1

3

677BA010 KN

Page 18

RB 302, RB 402 PLUS

English

16

Gearbox (RB 402 PLUS)

First oil change after 50 hours of

operation, then every six months or

every 500 hours of operation.

N Unscrew oil filler cap (1)

N Place a suitable container (1 lite r)

under the pump

N Unscrew the oil drain plug (3)

N Drain oil into container

N Refit and tighten oil drain plug

N Add oil (275 ml, SAE 15 W 40)

N Check the oil level

N Refit and tighten oil filler cap

Compliance with the specifications of

this Instruction Manual will avoid

excessive wear and damage to the

machine.

The machine must be used , main tained

and stored as carefully as desc ribed in

this Instruction Manual and th e enclosed

engine instruction manua l.

The user is responsible for all damage

caused by failure to comply with the

safety, operating and maintenance

instructions. This applies in particular

for:

– product modifications not

authorized by STIHL

– use of accessories that are not

approved for the machine,

unsuitable or of inferior quality

– use of the machine in a manne r not

in keeping with the intended use

– Use of the machine in sporting

events or competitions

– Consequential damages due to

continued use of a machine with

defective components

– Damage due to freezing

– Damage due to improper power

supply voltage

– Damage due to poor water supply

(e. g., cross-section of the intake

hose too small)

Maintenance work

All of the tasks listed under

"Maintenance and Repairs" and in the

enclosed engine instruction manual

must be carried out periodically. If the

user does not carry out these

maintenance tasks hi m- o r he rse lf, th ey

should be delegated to a dealer.

STIHL recommends that maintenance

and repair work be carried out only by

authorized STIHL dealers. STIHL

dealers receive regular training and are

supplied with technical information.

If these tasks are not performed or are

performed improperly, this ma y result in

damage for which the user is

responsible. Among other things, this

includes:

– Damage to machine components

due to delayed or insufficient

performance of maintenance

– Corrosion da mage and other

consequential damages due to

improper storage

– Damage to the machine as a result

of using replacement parts of

inferior quality

Parts Subject to Wear a nd Tear

Some parts of the machine ar e subject

to normal wear and tear even when the

machine is used in conformity with its

intended use. These parts must be

replaced in due time, depending on the

nature and duration of use. These

include, among others:

3

1

677BA011 KN

Minimize Wear and Avoid

Damage

Page 19

RB 302, RB 402 PLUS

English

17

– High-pressure nozzles

– High-pressure hoses

Page 20

RB 302, RB 402 PLUS

English

18

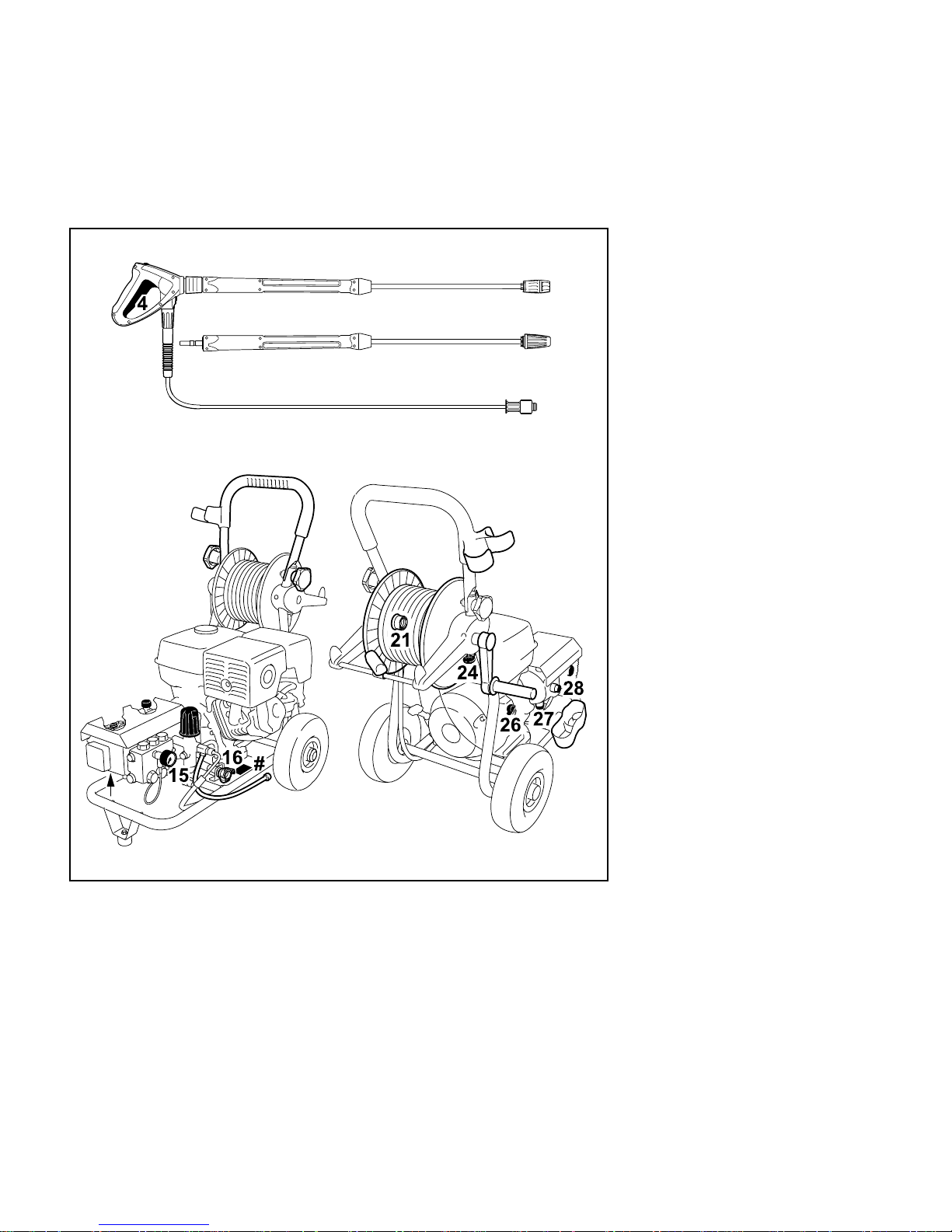

RB 302

1 Spray gun

2 Coupling for spray lance

3 Safety catch

4 Lever

5 Safety latch for high-pressure hose

6 Union nut for high-pressure hose

7 Nozzle

8 Selector sleeve for the working

pressure

9 High-pressure hose

10 Pressure gauge

11 Pressure/quantity control knob

12 Oil filler cap

13 Connector high-pressure hose

14 Water inlet with screen

15 Suction hose for detergent

16 Push bar

17 Star knob

18 Holder for high-pressure hose

19 Holder for spray attachment

20 Oil viewgl ass (oil drain plug)

21 Engine switch

# Model plate

Refer to the engine instruction manual

for the main engine components.

Main Parts

17

18

17

18

11

12

15

10

13

21

20

19

#

19

677BA020 KN

2

8

5

6

1

3

7

9

16

Page 21

RB 302, RB 402 PLUS

English

19

RB 402 PLUS

1 Spray gun

2 Coupling for spray lance

3 Safety catch

4 Lever

5 Safety latch for high-pressure hose

6 Union nut for high-pressure hose

7 Nozzle

8 Selector sleeve for the working

pressure

9 Rotary nozzle

10 High-pressure hose

11 Oil filler cap for hig h-p res sur e pu mp

12 Oil filler cap for gearbox

13 Oil drain plug for high-pressure

pump

14 Pressure/quantity control knob

15 Pressure gauge

16 Water inlet with screen

17 Suction hose for detergent

18 Push bar

19 Star knob

20

22

29

23

25

14

12

11

23

13

17

677BA021 KN

2

8

5

6

1

3

7

10

9

18

19

19

Page 22

RB 302, RB 402 PLUS

English

20

20 Guide for high-pressure hose

21 Connect or high-pressure hose

22 Hose reel

23 Holder for spray attachment

24 Hose reel brake

25 Crank for hose reel

26 Engine switch

27 Oil drain screw for gearbox

28 Oil viewglass gear box

29 Oil viewglass high-pressure pump

# Model plate

Refer to the engine instruction manual

for the main engine components .

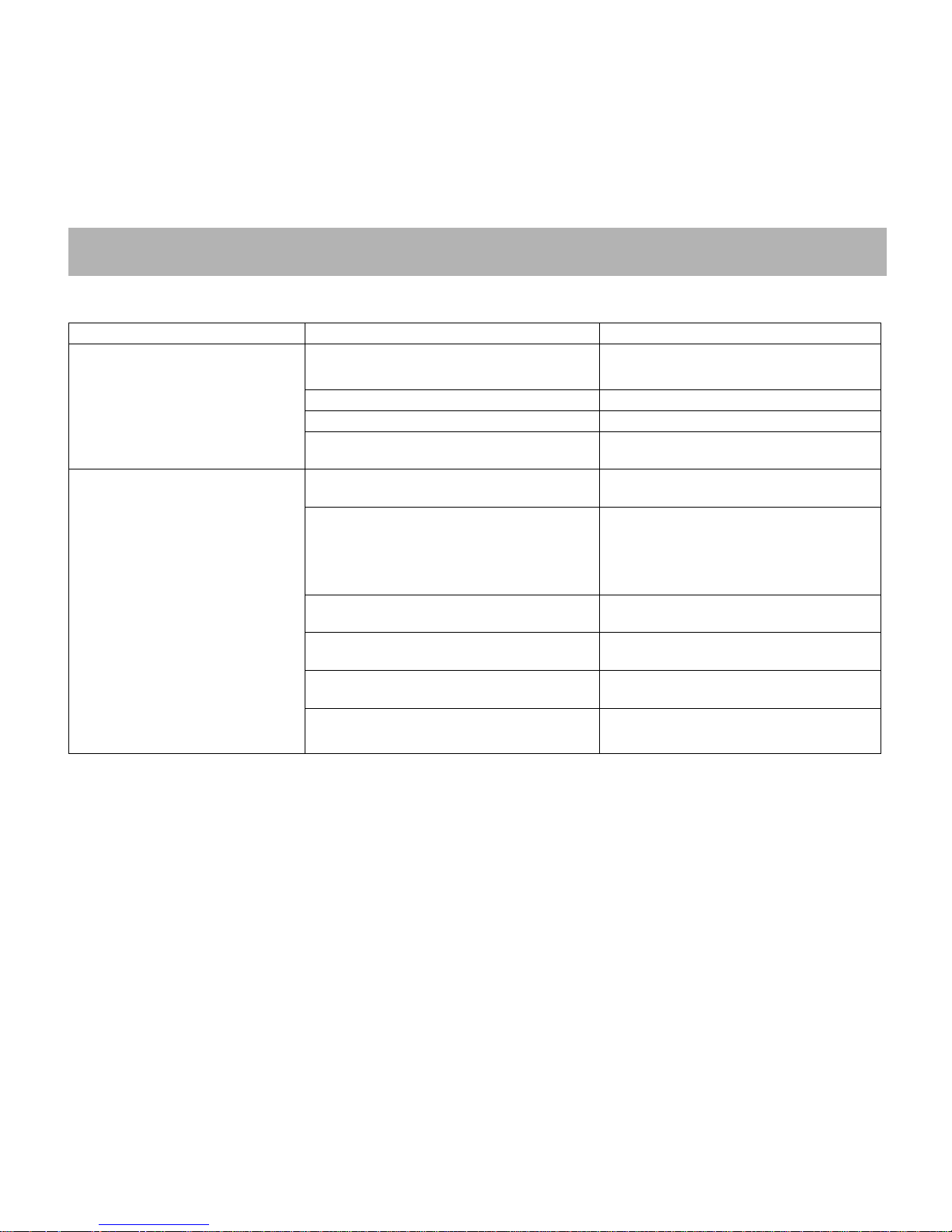

Engine

Single cylinder four-stroke engine

RB 302

See engine instruction manual for

additional specifications

RB 402 PLUS

See engine instruction manual for

additional specifications

Hydraulic specifications

RB 302

RB 402 PLUS

Specifications

Displacement: 163 cm

3

Power output: 4 kW (5.5 HP) at

3600 rpm

Oil specification: SAE 15W-40

Oil capacity: 600 ml

Fuel: Gasoline

Fuel tank capacity: 3.6 l

Displacement: 389 cm

3

Power output: 9.6 kW

(13.2 HP) at

3600 rpm

Oil specification: SAE 15W-40

Oil capacity: 1100 ml

Fuel: Gasoline

Fuel tank capacity: 6.5 l

Working pressure: 10 - 140 bar

Max. permissible

pressure: 250 bar

Max. water feed

pressure: 10 bar

Max. water throughput: 840 l/h

Water throughput as per

EN 60335-2-79: 750 l/h

Max. suction lift: 1.0 m

Max. water feed temperature

With pressurized water

supply: 60 °C

Suction operation: 50 °C

Max. kickback force: 34 N

Oil grade, high-pressure

pump: SAE 15W-40

Oil quantity, high-pres-

sure pump 180 ml

Working pressure: 10 - 230 bar

Max. permissible

pressure: 250 bar

Max. water feed

pressure: 10 bar

Max. water throughput: 1146 l/h

Water throughput as per

EN 60335-2-79: 1098 l/h

Page 23

RB 302, RB 402 PLUS

English

21

Dimensions

Weight

With spray attachment and highpressure hose:

High-pressure hose

Sound and vibration levels

Sound pressure level L

p

to ISO 3744

(at a distance of 1 m)

Sound power level Lw to ISO 3744

Vibration level a

hv

at the handle

according to ISO 5349

For the sound pressure level and the

sound power level, the K-factor in

accordance with Di rective 2006/42/EG =

1.0 dB(A); for the vibration level, the

K-factor in accordance with

Directive 2006/42/EG = 2.0 m/s

2

.

REACH

REACH is an EC regulation and stands

for the Registration, Evaluation,

Authorisation and Restriction of

Chemical substances.

For information on compliance with the

REACH regulation (EC) No. 1907/2006

see www.stihl.com/reach.

Pipe cleaning kit

in lengths 10 or 20 m

There is a mark (arrow) at t he end of the

cleaning hose:

N Push the hose into the pipe to be

cleaned until this mark is rea ched –

then switch on the machine

When this mark appears as the hose is

pulled out of the pipe:

N Switch off machine

N Actuate the spray gun until the

machine has been depressurized

N Pull the hose out of the pipe

completely

The hose must never be pulled out of the

pipe when the machine is switched on.

Other special accessories

Rotary washing brush – exchan geable

brush insert.

Wash brush – for mounting on s traight

or angled spray lances.

Max. suction lift: 2.5 m

Max. water feed temperature

With pressurized water

supply: 70 °C

Suction operation: 60 °C

Max. kickback force: 58 N

Oil grade, high-pressure

pump: SAE 15W-40

Oil quantity, high-pres-

sure pump 560 ml

Oil grade, gearbox: SAE 15W-40

Oil quantity, gearbox: 275 ml

Length approx.: 800 mm

Width approx.: 590 mm

Height approx.: 1015 mm

RB 302: approx. 38.5 kg

RB 402 PLUS: approx. 80 kg

RE 302: 10 m, DN 08, steel

braided

RB 402 PLUS: 20 m, DN 08, steel

braided

RB 302: 90.4 dB(A)

RB 402 PLUS: 90.2 dB(A)

RB 302: 103.8 dB(A)

RB 402PLUS: 103.6 dB(A)

RB 302: < 2.5 m/s

2

RB 402 PLUS: < 2.5 m/s

2

Special Acce ss or ies

669BA010 KN

Page 24

RB 302, RB 402 PLUS

English

22

Spray lance, straight – in lengths 350,

500, 1070, 1800 or 2500 mm.

Spray lance, angled – in length

1070 mm; spray lance, angled – do not

direct around blin d corners behind which

other people may be concealed.

Pencil-jet nozzle – 0°-jet angle for

extremely hard, narrow jet.

High-pressure nozzle – 15°, 30° or 60°

jet angle.

Rotary nozzle with spray lance – in

length 950 mm; for large areas and very

stubborn dirt. (supplied as standard with

PLUS models)

High-pressure hose extension –

DN 08, connection M27x1.5; steel

braided, reinforced, in lengths 10, 15 or

20 m. Connect between high-pressure

hose extension and spray gun. Always

use only one high-pressure hose

extension.

High-pressure hose adapter –

connection M27x1.5; for connection of

high-pressure hose and high-pressure

hose extension.

Adapter – for connection of acc essories

with screw coupling and spray guns with

push-in coupling.

Sand and wet-blasting unit w ith spray

lance – for sand-blast ing, e. g., stone or

metal.

Water filter – for filtering water from the

water main, as well as for use in

pressureless suction ope ratio n.

Backflow preventer – Type BA in

accordance with EN1717, for

connection of the hig h-pressur e cleaner

to the drinking water supply.

Suction set – professional version, 3/4",

length 3 m.

Ask your STIHL dealer for current

informati on on this and other special

accessories.

Page 25

RB 302, RB 402 PLUS

English

23

Troubleshooting

Before starting any work on t he ma chine, s witch off t he engine , turn off t he wate r supply and actu ate the s pray gun until the pressure has been relieved.

Fault Cause Remedy

Engine does not start w hen switched onNo fuel in tank Open the fuel cock

Refuel

1)

Shortage of oil in engine Add oil

1)

Pump has frozen Thaw out machine

Pump is blocked Have the machine checked by a servicing

dealer

2)

Pressure fluctuates or drops Speed control on engine or spray gun not se t

correctly

Adjust speed control

Shortage of water Open water tap completely

Comply with permi ssible suction lift ( suction

mode only)

check diameter and length of intake hose

Engine speed too low Have the machine checked by a servicing

dealer

2)

Water intake strainer in pump inflow clogged Clean water intake screen – see

"Maintenance"

Air in system Vent system by actuating the spray gun

several tim es at short inte rvals

High-pressure nozzle clogged / defective Clean nozzle – see "Maintenance"

replace nozzle

1)

See engine instruction manual

2)

STIHL recommends STIHL servicing dealers

Page 26

RB 302, RB 402 PLUS

English

24

Before starting any work on t he ma chine, s witch off t he engine , turn off t he wate r supply and actu ate the s pray gun until the pressure has been relieved.

Fault Cause Remedy

Pressure fluctuates or drops Pump partly frozen Thaw out machine

Pump draws in air (suction mode only) Check air-tightness of suction set, vent sys-

tem by actuating the spray gun several

times at short intervals

High-pressure pump is leaky, valves are

defective

Have the machine checked by a servicing

dealer

2)

Water temperature too high Permissible water temperature – see

“Specifications”

Pressure is too high Engine speed control not set correctly or

defective

Have the machine checked by a servicing

dealer

2)

Engine stops Shortage of oil in engine Add oil

1)

No supply of detergents Detergent tank is empty Fill detergent tank

Detergent intake is clogged Eliminate clog

Injector is soiled or suction hose is clogged Clean injector – see “Maintenance”, remove

blockage in suction hose

Sleeve on spray lance not set to low-pressure

operation

Turn sleeve co unterclockwi se as far a s possible – see “Adding detergent”

1)

See engine instruction manual

2)

STIHL recommends STIHL servicing dealers

Page 27

RB 302, RB 402 PLUS

English

25

Users of this machine may only carry out

the maintenance and service work

described in this user manual. All other

repairs must be carried out by a

servicing dealer.

STIHL recommends that you have

servicing and repair work carried out

exclusively by an authorized STIHL

servicing dealer. STIHL dealers are

regularly given the opport unity to attend

training courses and are supplied with

the necessary technical information.

When repairing the machine, only use

replacement parts which have been

approved by STIHL for this power tool or

are technically identical. Only use highquality replacement parts in order to

avoid the risk of accidents and damage

to the machine.

STIHL recommends the use of original

STIHL replacement parts.

Original STIHL parts can be identified by

the STIHL part number, the {

logo and the STIHL parts symbol K

(the symbol may ap pea r alo ne o n sm al l

parts).

ANDREAS STIHL AG & Co. KG

Badstr. 115

D-71336 Waiblingen

hereby confirms that

conforms to the specifications of

Directives 98/37/EC (until 12/2 8/0 9),

2006/42/EC (starting 12/29/09),

2004/108/EC and 2000/14/EC and has

been developed an d bui lt in comp lia nce

with the following standards:

EN ISO12100-1, EN ISO 12100-2,

EN 5501 2, EN60335-2-79,

EN 61000-6-1, EN 61000-6-3

The measured and guaranteed

equivalent sound power level has been

determined in ac cordance with D irective

2000/14/EC, Annex V, and standard

ISO 3744.

Measured sound power level

Guaranteed sound power level

The technical documentation has been

retained by:

ANDREAS STIHL AG & Co. KG

Produktzulassung

The year of construction and the serial

number are shown on the machine.

Waiblingen, 15.09.2009

ANDREAS STIHL AG & Co. KG

pp.

Elsner

Head of Product Group Management

Maintenance and Repairs EC De cl ara tion of

Conformity

Model: High-pressure

cleaner

Make: STIHL

Type: RB 302

Serial identification

number: 4772

Displacement: 163 cm

3

Type: RB 402 PLUS

Serial identification

number: 4773

Displacement: 389 cm

3

RB 302: 103.8 dB(A)

RB 402PLUS: 103.6 dB(A)

RB 302: 105 dB(A)

RB 402 PLUS: 105 dB(A)

Page 28

RB 302, RB 402 PLUS

English

26

All STIHL products comply with the

highest quality standards.

An independent organization has

certified that all products manufactured

by STIHL meet the st rict requirements o f

the ISO 9001 standard for quality

management systems in terms of

product development, materials

purchasing, production, assembly,

documentation and customer service.

Quality Certification

000BA025 LÄ

Page 29

Notice d'emploi d'origineImprimé sur papier blanchi sans chlore

L'encre d'imprimerie contient des hu iles végétales, l e papier est

recyclable.

© ANDREAS STIHL AG & Co. KG, 2009

0458-677-9921-A. M0-2.M09.DDS.

0000000846_001_F

RB 302, RB 402 PLUS

français

27

{

Table des matières

Chère cliente, cher client,

nous vous félicitons d'avo ir choisi un

produit de qualité de la société

STIHL.

Ce produit a été fabriqué avec les

procédés les plus modernes et les

méthodes de surveillance de qualité

les plus évoluées. Nous me ttons tout

en œuvre pour que ce dispositif vous

assure les meilleurs service s, de telle

sorte que vous puissiez en être

parfaitement satisfa it.

Pour toute demande de

renseignements complémentaires,

veuillez vous adresser à votre

revendeur ou directement à

l'importateur de votre pays.

Hans Peter Stihl

Indications concernant la présente

Notice d'emploi 28

Prescriptions de sécurité et

techniques de travail 28

Démontage, montage de la lance 33

Montage, démontage du flexible

haute pression 33

Établissement de l'alimentation en

eau 34

Établissement d'une alimentation

en eau hors pression 35

Mise en marche du dispositif 35

Utilisation 36

Apport de détergent 37

Arrêt du dispositif 38

Rangement du dispositif 38

Transport de l'appareil 38

Instructions pour la maintenan ce et

l'entretien 40

Maintenance 41

Contrôler le niveau d'huile 42

Vidange de l'huile 42

Conseils à suivre pour réduire

l'usure et éviter les avaries 43

Principales pièces 45

Caractéristiques techniques 47

Accessoires optionnels 49

Dépannage 50

Instructions pour les réparations 52

Déclaration de conformité CE 52

Certificat de qualité 53

Page 30

RB 302, RB 402 PLUS

français

28

Pictogrammes

Tous les pictogramm es appliq ués sur l e

dispositif sont expliqués dans la

présente Notice d'emploi.

Repérage des différents types de

textes

Développement technique

La philosophie de STIHL consiste à

poursuivre le développem ent continu de

toutes ses machines et de tous ses

dispositifs ; c'est pourquoi nous devons

nous réserver tout droit de modification

de nos produits, en ce qui concerne la

forme, la technique et les équipements.

On ne pourra donc en aucun cas se

prévaloir des indications et illustrations

de la présente Notice d'emploi à l'appui

de revendications quelconques.

Respecter les co nsi gn e s de séc uri té

nationales spéc ifiques, par exemple des

caisses de prévoyance des acc ide nts ,

des caisses d’assurance maladie, des

autorités chargées de la protection du

travail, etc.

Arrêter l'appareil lorsqu’il n’est pas

utilisé afin que person ne ne s oit ex posé

à des risques inutiles. L'appareil doit

être inaccessible aux personnes non

autorisées.

L’utilisateur est responsable des

accidents ou des risques que pourraien t

subir d’autres perso nnes ou leurs biens.

Toute personne qui utilise pour la

première fois l'appareil doit se faire

expliquer par le ve ndeur ou par un au tre

spécialiste comment utiliser celui-ci en

toute sécurité.

L’utilisation du nettoyeur à haute

pression par des mineurs est interdite,

sauf par des jeunes de plus de 16 ans

qui sont formés sous surveillance.

Ne pas utiliser l’appareil lorsque des

personnes ne portan t pas de vête ments

de protection se trouvent sur la surfac e

de travail.

L'appareil ne doit être remis ou prêté

qu’à des personnes qui sont

familiarisées avec ce modèle et sa

manipulation et toujours accompagné

du mode d’emploi.

Dans certains pay s, l'util isation d'engin s

motorisés émettant du bruit peut être

restreinte par des dispositi ons loca les .

Respecter les consignes nationales

spécifiques.

Avant toute utilisation, vérifier si

l’appareil est en bon état de

fonctionnement et conforme aux règles

de sécurité. Il faut être particulièrement

attentif au flexible haute pression, au

dispositif de projection et aux dispositifs

de sécurité.

Ne jamais travailler avec un flexible

haute pression endommagé - le

remplacer immé diatement.

Il ne faut pas rouler sur le fle xi ble haut e

pression, ni l'étirer, le plier ou le vriller.

Ne pas déplacer l'appareil en tira nt sur le

flexible haute pression.

Le flexible haute pression doi t être

homologué pour la pression de ser vic e

maximale admissible du nettoyeur.

La pression de service maxim al e

admissible, la température maximale

admissible et la d ate de fabric ation s ont

indiquées sur la gaine du flexible haute

pression. La pression admissible et la

date de fabrication sont indiquées sur

les éléments de robinetterie.

Indications concernant la

présente Notice d'emploi

Avertissement contre un risque

d'accident et de blessure ainsi

que de graves dégâts matér i els.

Avertissemen t contre un ri sque de

détérioration du dispositif ou de

certains composants.

Prescriptions de sécurité

et techniques de travail

La pression d'eau élevée

produite expose à des

sources de danger

spécifiques.

Lire attentivement l’intégralité du mode d’emploi

avant la première mise

en service et le conser ver

en lieu sûr pour pouvoir

le consulter ultérieurement. Le non-respect du

mode d'emploi peut

entraîner un danger de

mort.

Page 31

RB 302, RB 402 PLUS

français

29

Accessoires et pièces de rechange

Les flexibles haute pression, les

raccords et les éléments de robine tterie

sont essentiels pour la sécurité de

l’appareil. Il faut exclusive me nt mon ter

des flexibles haute pression, des

éléments de robinetterie, des raccords

et autres accessoi res qu i so nt auto risés

par STIHL pour cet app areil ou alors des

pièces techniqueme nt équ iv ale nte s.

Consulter un distributeur agréé pour

toute question à ce sujet. N’utiliser que

des accessoires de haute qualité afin de

réduire au maximum tout risque

d’accident ou de dommage s à l 'appareil.

STIHL recommande d’utiliser des

pièces et des accessoires originaux

STIHL. Les propriétés de ceux-ci sont

adaptées de manière optimale au

produit et aux exigences de l’utilisateur.

N'apporter aucune modification à

l'appareil – la sécurité risquerait d' en

être affectée. STIHL exclue toute

responsabilité pour les dommages

corporel s et matériels qui résultent de

l'utilisation d'accessoires non

homologués.

Condition physique

Quiconque utilise le dispositif à moteur

doit être reposé, en bonne santé et en

bonne condition physique. Il est

conseillé à toute personne qui ne doit

pas se fatiguer pour des raisons de

santé de consulter son médecin pour

savoir si l’utilisation d'un dispositif à

moteur ne présente aucun risque.

Il est interdit d’utiliser le dispositif à

moteur après avoir consommé de

l’alcool, des médicaments qui affectent

la réactivité ou des drogues.

Uniquement pour les personnes portant

un stimulateur cardiaque : le sys tème

d’allumage de cet appareil génère un

champ électromagnétique de très faible

intensité. Une influence sur certains

types de stimulateurs cardiaques ne

peut pas être totalement exclue. Pour

écarter tout risque pour la sa nté, STIHL

recommande de consulter le médecin

traitant ainsi que le constructeur du

stimulateur cardiaque.

Domaines d’applications

Le nettoyeur haute pression convient

tout spécialement pour le nettoyage de

véhicules automobiles, machines,

réservoirs, façades, locaux d’une

exploitation agr icole et pour le déca page

d’objets rouillés, san s dég age me nt de

poussière ni d’étincelles.

Il est interdit d’utiliser cet appareil pour

d’autres travaux – cela pourrait causer

des accidents ou détériorer l’appareil.

Vêtements et équipements

Porter des chaussures munies d’une

semelle ant idérapante.

Ne porter aucun vêtement qui risque

d'être happé dans le s parties mobiles de

l'appareil. Ne pas non plus porter

d'écharpe, de cravate ou de bijoux. Les

cheveux longs sont à attacher et à

protéger (foulard, casquette, casque,

etc.).

Transport de l'appareil

Il faut toujours arrêter le moteur.

Ne pas toucher les parties chaudes de

l'appareil, notamment la surface du

silencieux et le carter d'engrenage –

risque de brûlure !

Pour transporter l’appareil en toute

sécurité dans ou sur un véhic ule, le fixer

avec des sangles de telle sorte qu’il ne

risque pas de glisser ou de se renverse r

et le protéger contre les dommages et

l'écoulement de carburant.

Si l’appareil et les accessoires doivent

être transportés à des températures

proches de 0 °C ou moins, il est

recommandé d'utiliser un produit

antigel, voir « Rangement de

l’appareil ».

Porter des lunettes de

protection et des vêtements de protection.

STIHL recommande de

porter une salopette pour

réduire le risque de blessures en cas de contact

accidentel avec le jet

haute pression.

Page 32

RB 302, RB 402 PLUS

français

30

Avitaillement

Il faut arrêter le moteur avant

l'avitaillement.

Ne pas faire le plein tant que le moteur

est encore chaud, du carburant risque

de déborder – risque d'incendie !

Ouvrir le bouchon du réservoir avec

prudence afin que la surpressio n puisse

lentement se diss iper et pour éviter to ute

projection de carburant.

Le plein doit uniquement être effectué

en un endroit bien ventilé. Si du

carburant a été renversé, nettoyer

immédiatement le dispositif à moteur et

ne pas laisser le carburant entrer en

contact avec les vêtements. Le cas

échéant, les changer immédiatement.

Après avoir fait le plein, serrer le

bouchon le plus fermement possible.

On réduit ainsi le risqu e que le bo uchon

du réservoir se desserre sous l'e ffet des

vibrations du moteu r et que du carburant

ne s'échappe.

Vérifier l'absence de fuites – ne pas

démarrer le moteur si du carburant

s'écoule – risque de brûlures

mortelles !

Produit de nettoyage

Des détergents inadéquats peuvent

présenter des risque s pour la san té ou

endommager l’appareil et l’objet à

nettoyer. Consulter un distributeur agréé

pour toute question à ce sujet.

STIHL recommande d’utiliser des

détergents STIHL. Respecter les

directives d'utilisati on à cet effet.

Les détergents peuvent renfermer des

substances nocives (toxiques ,

caustiques, irritantes), combustibles ou

facilement inflam mables. Se conformer

aux fiches techniques de séc urité du

fabricant !

Il faut toujours utiliser le détergent avec

le dosage préconisé par le fabricant.

Avant le travail

Il faut impérativement utiliser un clapet

de non-retour pour raccorder le

nettoyeur haute pression au réseau

d’eau potable – voir « accessoires

optionnels ».

Ne pas utiliser l'appareil avec de l'eau

sale.

S'il y a risque de présence d'eau sale

(par exemple sable mouvant), il faut

employer un filtre à eau en

conséquence.

Vérifier si le nettoyeur haute pressi on

peut fonctionner en t oute sécurité. Il faut

notamment vérifier le flexible haute

pression, le dispositif de pulvérisation,

les dispositifs de sécurité et le circuit de

carburant. Observer le chapitre

correspondant du mode d'emploi :

Contrôle du nettoyeur haute pres sion

Le nettoyeur haute pression ne doit être

utilisé que s'il présente une parfaite

sécurité de fonctionnem ent – risque

d'accident !

– L'interrupteur de l'appareil doit

pouvoir être facilement amené sur

0.

– Vérifier la bonne assise de la fiche

du câble d'allumage – une fiche

relâchée peut provoquer des

étincelles qui risquent d'enflammer

le mélange carburant/air qui

s'échappe – risque d'incendie !

– Il faut vérifier si le flexible haute

pression, le dispositif de projection

et les dispositif s de sé curité ne sont

pas endommagés.

– Flexible haute pre ss io n et dispositif

de pulvérisation en parfait état

(propres, faciles à manipuler),

montage correct

– Pour une condui te en toute sécurité,

les poignées doi vent être prop res et

sèches, exemptes d’huile et

propres.

– Contrôler le niveau d'huile

– N'apporter aucun e modification a ux

dispositifs de commande et de

sécurité

L’es sence est extrêmement inflammable –

rester à distan ce de toute

flamme vive, ne pas renverser de carburant, ne

pas fumer.

Ne pas brancher le nettoyeur haute pression

directement au réseau

d’eau potable.

Page 33

RB 302, RB 402 PLUS

français

31

Démarrage du moteur

Démarrage en suivant la procédure

indiquée dans le mode d'emploi du

moteur.

Au moins à 3 m de distance du lieu

d'avitaillement, ne pas démarrer dans

un local fermé.

Uniquement sur un support plan, veiller

à une position stable et sécurisée.

L'appareil est utilisé par une seule

personne, aucune autre personne ne

doit être tolérée d ans l a z one d e tra va il,

pas même lors du démarrage.

Vérifier la baisse de régime : le moteur

doit passer au ra lenti après avoir relâc hé

la gâchette du pistolet pulvérisateur.

Au cours du travail

Toujours veiller à une position stable et

sécurisée.

Prudence en présence de sol glissant,

pluie, neige, vergl as da ns les pente s ou

les terrains irréguliers – risque de

glissade !

Positionner le nettoyeur haute pression

le plus loin p ossible de l ’objet à nettoy er.

Positionner l'apparei l en fonctionnement

à au moins 1 m de distance des

bâtiments.

Arrêter immédiatemen t le moteur en cas

de danger imminent ou en cas

d'urgence.

Ne pas diriger le jet haute pression sur

des animaux.

Ne pas diriger le jet h aute pres sion vers

des endroits non visibles.

Les enfants, les animaux et les

spectateurs doivent être tenus à

distance.

Au cours du nettoyage, veiller à ce que

des substances dangereuses (p. ex.

amiante, huile) provenant de l’objet

nettoyé ne parviennent pas dans

l’environnement. Il faut impérativement

respecter les dire cti ve s en vi gue ur p our

la protect ion de l'environnement !

Ne pas nettoyer des surfac es en

amiante-ciment ave c le jet hau te

pression. Outre les saletés, le jet peut

détacher des fibres d’amiante

dangereuses car elles risquent de

pénétrer dans les poumons. Il existe

notamment un dange r après le séch age

de la surface traitée.

Ne pas aspirer de l iquid es c ontena nt un

solvant ou des acides, ni des solvants

non dilués (par exemple essence,

mazout, diluant pour peinture ou

acétone) ! Ces substances

endommagent les matériaux employés

sur l'appareil. Le brouilla rd pulvéris é est

hautement inflammable, explosible et

toxique.

Ne pas nettoyer les pièce s sensibl es en

caoutchouc, en tissu ou similaire avec

un jet rond, par exemple avec la

turbobuse. Lors du nett oyage, laisser un

espace suffisant entre la buse à haute

pression et la surface pour éviter

d’endommager la surface à nettoyer.

La gâchette du p is tol et doi t p ouv oi r être

actionnée facilement et revenir d’ellemême en position initiale lorsqu’on la

relâche.

Il faut toujours tenir le dispositif de

projection à deux mains au niveau des

poignées pour pouvoir maî triser le recul

ainsi que le couple supplémentaire qui

se produit avec les dispositifs de

projection équipés d'une lance coudée.

Il ne faut pas rouler sur le fle xi ble haut e

pression, ni l’écraser, l’éti rer etc. pour ne

pas l’endommager. Le protéger de la

chaleur et de l'huile.

Ne jamais nettoyer des

appareils électriques

avec le jet haute pression

ou au jet d'eau – risque

de court-circuit !

Ne pas nettoyer les équipements électriques,

branchements et câbles

sous tension avec le jet

haute pression ou au jet

d'eau – risque de court-

circuit !

L’utilisateur ne doit

jamais orienter le jet

d’eau sur lui-même ou

sur d’autres personnes,

pas même pour nettoyer

des vêtements ou des

chaussures – Risque de

blessure !

Le dispositif à moteur

émet des gaz d’échappement toxiques dès que le

moteur est en marche.

Ces gaz peuvent être inodore et invisibles et

contenir des hydrocarbures et du benzène non

consumés. Ne jamais travailler avec le dispositif à

moteur dans des locaux

fermés ou mal ventilés,

même s'il est é quipé d'un

catalyseur.

Page 34

RB 302, RB 402 PLUS

français

32

Ne pas recouvrir le dis positif à moteu r et

veiller à un refroidissement suffisant du

moteur.

Il faut toujours veill er à un écha nge d’air

suffisant lors des travaux dans des

fossés, des puits ou dans un espace

restreint – Danger de mort par

intoxication !

Arrêter immédiatement le travail en cas

de nausées, ma ux de tête, troub les de la

vision (par exemple champ de vision

rétréci), troubles de l'audition, vertiges,

baisse de la capa cité de concentrati on –

ces symptômes peuve nt nota mm ent

être provoqués par une concentration

de gaz d'échappement – risque

d'accident !

Défense de fumer lors de l'utilisation de

l'appareil et à proximité immédiate de

celui-ci – Risque d'incendie ! Des

vapeurs inflammabl es peuve nt

s'échapper du réservoir de carburant.

Dispositif de sécurité

En cas de déclenchement du dispositif

de sécurité, une pression

excessivement élevée est renvoyée

dans le côté aspiration de la pompe

haute pression par le biais d’une

soupape de décharge. Le dispositif de

sécurité est réglé en usine et son

réglage ne doit pas être modifié.

Après le travail

Si l'appareil a subit des contraintes

inhabituelles (par exemple choc ou

chute), il faut impérativement vérifier

avant toute nouvelle utilisation s'il

présente une parfaite sécurité de

fonctionnement – voir la s ection « Avant

le travail ».

Il faut notamment vérifier le bon

fonctionnement des dispositifs de

sécurité. Il ne faut en aucun cas

réutiliser les appa reils qui ne prés entent

pas une parfaite sécurité de

fonctionnement. En cas de doute,

prendre contact avec un distributeur.

STIHL recommande de contacter un

distributeur STIHL.

Avant de laisser l'appareil :

– Arrêter l'appareil

– Débrancher le tuyau d'arrivée d' eau

entre l'appareil et la source d'eau

Entretien et réparations

Soumettre le dispositif à moteur à une

maintenance réguli ère. N’eff ec tuer que

les interventions de maintenance et

réparations décrites dans le Mode

d’emploi. Faire exécuter toutes les

autres opérations par un distributeur

agréé.

STIHL recommande de faire effectuer

les opérations de maintenance et les

réparations exclusivement chez un

distributeur agréé STIHL. Les

distributeurs agréés STIHL participent

régulièrement à des stages de

perfectionnement et ont à leur

disposition les informations techniques

requises.

N’utiliser que des pièc es de rechange de

haute qualité afin de réduire au

maximum tout risque d’accident ou de

dommages à l'appareil. Cons ult er un

distributeur agréé p our toute question à

ce sujet.

STIHL recommande d’utiliser

exclusivement des pièces de rechange

originales STIHL. Les propriétés de

celles-ci sont adaptées de manière

optimale à l'appa reil et aux exigences de

l’utilisateur.

Il faut toujours arrêter le moteur avant

d'effectuer une réparation, une

opération d'entretien ou de nettoyage –

Risque de blessure !

Ne pas effectuer l'entretien ou

entreposer le dispositif à moteur à

proximité d'une flamme vive.

Vérifier régulièrement l'ét anchéité du

bouchon du réservoir.

Vérifier le câble d'allumage (isol ati on

parfaite, connexion bien serrée).

Vérifier le bon état du silencieux.

Ne pas travailler avec un silencieux

défectueux ou manquant – risque

d'incendie ! – Dommages auditifs !

Ne pas toucher le silencieux chaud –

risque de brûlure !

Arrêter le moteur avant d'éliminer des

défauts.

Page 35

RB 302, RB 402 PLUS

français

33

N Tirer le coupleur (1) vers l'arrière et

le maintenir

N Insérer la lance (2) dans le

logement du pistolet pulvérisateur

ou la sortir de ce dernier pour la

démonter

N Relâcher le coupleur (1)

RB 302

Montage du flexible haute pression

N Glisser le flexible haute pres sion (1)

sur le raccord

N Visser et serrer à la main l'écrou

d'accouplement(2)

Démonter le flexible haute pression

N Dévisser l'écrou d'accouplement(2)

N Tirer le flexible haute pression (1)

du raccord

RB 402 PLUS

Le flexible à haute pression est déjà

raccordé.

Démonter le flexible haute pression

N Desserrer le frein de l'enrouleur de

flexible

Pour desserrer le frein de l'enroul eur de

flexible, tirer la poignée (1) vers le bas.

Pour serrer, pousser la poignée (1)

fermement vers le haut jusqu'à ce que

l'enrouleur de flexible soit bloq ué.

N Dérouler le flexible haute

pression (2)

N Dévisser l'écrou d'accouplement (3)

N Ouvri r le guide de flexible (4)

N Tirer le flexible haute pression (2)

du raccord

Montage du flexible haute pression

N Glisser le flexible haute p ression sur

le raccord (2) de l'enrouleur

N Visser et serrer à la main l'écrou

d'accouplement (3)

N Introduire le flexible haute pression

dans le guide (4) et fermer ce

dernier.

N Desserrer le frein (1) de l'enrouleur

de flexible, enroule r le flexible haute

pression.

Démontage, montage de la

lance

647BA021 KN

1

2

Montage, démont ag e du

flexible haute pression

677BA001 KN

677BA023 KN

Page 36

RB 302, RB 402 PLUS

français

34

Flexible haute pression et pistolet

pulvérisateur

Montage

N Glisser le flexible haute pressio n (1)

sur le raccord (2)

N Visser et serrer à la main l'écrou

d'accouplement (3)

Démontage

N Pousser le curseur (4) dans le sens

de la flèche et le maintenir

N Desserrer l'écrou

d'accouplement (3) et le dévisser du

raccord dans le sens de la flèche

Rallonge pour flexible haute pression

Il ne faut utiliser qu'une seule rallong e

pour flexible haute pression à la fois

(voir « accessoires optionnels »)

Rincer brièvement le tuyau avec de l'eau

avant de le r accorder à l'appareil afin

d'éviter que du sable et d'autres

impuretés ne puissent pénétre r dans

l'appareil.

N Raccorder le tuyau (diamètre 3/4",

longueur minimale 10m pour

absorber les impulsions de

pression)

N Introduire l'une dans l'autre les

griffes du raccord pour flexible (1) et

du coupleur (2) et les faire tourner

vers la droite jusqu'en butée

N Ouvrir le robinet d'eau

En mode aspiration, l'appareil peut

également être alimenté à partir de

plans d'eau, de citernes, de réservoirs

ou équivalents, voir « Établissement

d'une alimentation en eau hors

pression ».

Raccordement au réseau d'eau

potable

Lors du raccordement au réseau d’eau

potable, il faut poser un clapet de nonretour (type BA selon EN 1717) entre le

robinet et le tuyau.

Il faut respecter la réglementation du

réseau de distribution d'eau local afin

d'éviter que l'eau provenant du

nettoyeur haute pression ne puis s e

revenir dans le réseau d'eau potable.

1

2

3

647BA022 KN

647BA023 KN

3

4

Établ iss eme n t de

l'alimentation en eau

677BA004 KN

RB 302

RB 402 PLUS

003BA004 KN

Page 37

RB 302, RB 402 PLUS

français

35

N Raccorder l'appareil à la source