STIHL OILOMATIC RAPID Micro Harvester (RMHS), OILOMATIC RAPID Micro Harvester (RMH) Instruction Manual

STIH)

Harvester Chain Manual

2015-01

Introduction

Contents

1. The Right Choice – STIHL Harvester Saw Chain..........2

2. Safety Precautions and General Information................3

3. STIHL Harvester Saw Chain ............................................. 5

4. Spare Parts .......................................................................... 9

Notes.......................................................................................10

1

1. The Right Choice – STIHL Harvester Saw Chain

STIHL harvester chains are precision made in STIHL’s

Switzerland based factories. These chains are produced

on special machinery custom designed and built by

STIHL. STIHL has determined the ideal material mix for

every component of the chain. Meticulous production

processes and strict quality controls combined with

proper chain maintenance ensure less friction for smooth

operation and a long wear life.

This STIHL Harvester Chain Manual was created for and

is provided to STIHL Dealers and owners/operators of

harvester equipment utilizing STIHL chain in the cutting

attachment. This manual provides information, that when

followed, results in a properly sharpened and well

maintained harvester chain. Good cutting performance,

positively contributes to the service life of the cutting

attachment. However, the design and power of the drive

unit, the quality/condition of the harvester guide bar along

with working technique are also factors impacting

harvester performance.

STIHL OILOMATIC® System of Chain

Lubrication

Chain lubrication has a decisive influence on the service

life of a chain.

The patented OILOMATIC® principle of chain lubrication

extends the useful life of the chain, guide bar and chain

sprocket. Unlike conventional chains, each drive link of

STIHL OILOMATIC

channel which is angled upwards and backwards.

®

saw chain incorporates an oil

2

2. Safety Precautions and General Information

2.1 Safety Precautions for working with

mechanical timber harvesting

machines

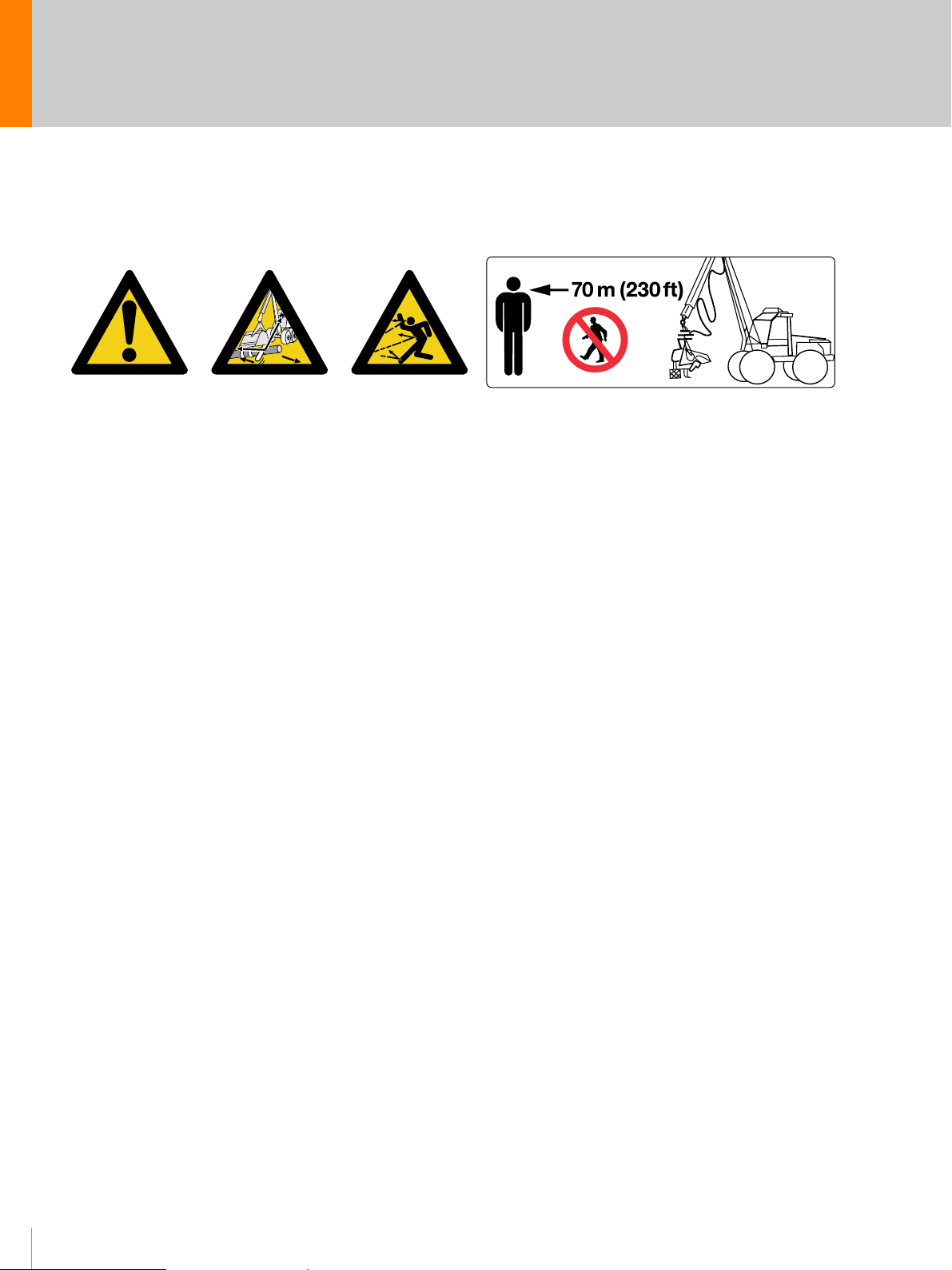

Saw chain breakage and thrown parts of chain, called

"chain shot" (chain shot is the term commonly used by

manufacturers as well as forestry professionals to

describe the parts of the chain that are thrown through

the air when a chain breaks).

These harvester machines impose a very heavy load on

the cutting attachment. For this reason it is necessary to

observe the notes and instructions on reducing the risk of

chain breakage and possible injury.

It is important you read and understand the instruction

manual before using your machine for the first time and

keep it in a safe place for future reference. Nonobservance of the safety precautions may result in

serious or even fatal injury.

Observe all applicable safety regulations, standards and

ordinances.

The following information is intended to supplement the

machine-specific instruction manual, but not replace it:

Position the guide bar and chain so that parts are not

thrown in the direction of the operator.

The timber harvester's cab should be equipped with

appropriate safety windows.

A chain speed of 40 m/s (131.23 ft./sec.) must not be

exceeded when using STIHL RAPID

Harvester saw chains (RMH, RMHS).

The area around the chain sprocket must be fitted

with a suitable guard.

Make sure that bystanders keep a minimum distance

of 70 m (230 ft.) from the harvester when it is in

cutting operations.

Inspect the chain regularly for damage – do not

continue working with a damaged chain – replace a

damaged chain or replace chipped cutters and other

damaged parts of the chain.

STIHL recommends the use of original STIHL

replacement parts for repairs – do not install used

parts. Repairing the chain with used or non-OEM parts

could cause a premature failure resulting in severe

injury or death and possible damage to the machine

components.

™

Micro™

STIHL recommends that the complete saw chain

must be replaced after it has broken twice.

Always resharpen STIHL chains to factory

specifications.

Make sure the chain is always properly tensioned.

Replace the chain sprocket as soon as it shows any

visible signs of wear. A specific wear depth that can

be measuered to 0.6 mm (0.025 in.) indicates that the

sprocket needs replacement. It is recommended that

a sprocket should be replaced after the use of 10

chains.

3

2. Safety Precautions and General Information

When the chain is running, no persons may stand at

the same level as the guide bar.

™

STIHL RAPID

for use on timber harvesters only. They must not be

used on handheld chain saws or for any other

purpose.

The components of the cutting attachment must

match, i.e. chain pitch and drive link gauge.

STIHL recommends that chain links, chain drivers and

chain cutters be inspected for cracks and other

damage before the chain is placed into use, before

maintenance procedures such as sharpening or repair

are initiated.

STIHL recommends that machine operators check

with a labor or industries representative (i.e. OSHA)

and/or timber harvesting machine manufacturer in

regards to required guarding and appropriate

windshield thickness on harvesting machinery using

chain.

Micro™ Harvester chains are approved

2.2 General information

The guide bar and chain must always be well

lubricated at the proper oil flow rate. STIHL

recommends the use of STIHL Bar & Chain Oil or a

comparable quality bar and chain oil. In colder

temperatures use a STIHL "Winter" Grade Bar & Chain

oil or a comparable quality winter grade oil of another

manufacturer. Never use hydraulic oils for lubrication

of the chain and guide bar.

2.3 Before using for the first time –

changeover from other saw chains to

™

the STIHL RAPID

Micro™ Harvester

Special (RMHS)

The .404" RMHS chain has wide running faces to reduce

the load on the chain, guide bar and sprocket.

In order to utilize the benefits of the chain's wide running

faces and thus extend service life, it is necessary to check

that the widths of the running faces on the chain, guide

bar rails and chain sprocket match.

Higher chain speeds result in increased wear which

negatively impacts service life of the chain and bar and

increases the potential for chain breakage and

possible injury. Always monitor the factors that

influence chain performance. Influencing performance

factors such as feed force, chain speed, chain

sharpness, sprocket condition and guide bar integrity.

A chain speed of 40 m/s (131.23 ft./sec.) should not

be exceeded when using STIHL Harvester Chain.

Narrower saw chains cause a narrower wear pattern on

the guide bar and chain sprocket. If the new .404" RMHS

chain is mounted on a bar worn in such a way, the edge

pressure will be increased. This would result in excessive

wear or damage on the new chain.

It is recommended that a new chain sprocket and a new

guide bar be installed with the new chain to ensure

optimum break-in and operation.

Instead of a new guide bar, the rails of a used guide bar

can be deburred.

4

3. STIHL Harvester Saw Chain

A harvester chain is subjected to extremely high loads

during operation. The individual parts of the chain are

exposed to constantly alternating tensile forces which

can result in cracks and finally cause the chain to break.

™

The STIHL RAPID

™

RAPID

specifically developed to withstand the continuous high

loads imposed in highly mechanized timber harvesting

operations. All parts of the chain have been strengthened

to greatly minimize the risk of cracks, while maintaining

the same high cutting capacity.

Micro™ Harvester Special (RMHS) have been

Micro™ Harvester (RMH) and STIHL

STIHL RAPID™ Micro™ Harvester (RMH)

STIHL harvester chains are designed for professional

applications under the toughest of operating conditions.

STIHL harvester chains are available in two versions:

STIHL RAPID

RAPID

™

™

Micro™ Harvester (RMH) and STIHL

Micro™ Harvester Special (RMHS).

Cutters

Semi-chisel chain with slim, straight-sided cutter. The

narrow cutter shape reduces cutting resistance. Depth

gauge setting is 1.5 mm (0.059 in.).

Tie straps and drive links

The reinforced tie straps, drive links and rivets are rated

to take account of the high driving power of harvesters

and the resultant high loads imposed on the chain.

Reduced distance between tie straps increases flexural

strength and reduces the risk of chain breakage.

STIHL RAPID™ Micro™ Harvester Special (RMHS)

Identification

Each cutter is marked with "H" just below the depth

gauge.

Cutters

Semi-chisel chain with slim, straight-sided cutter. The

offset depth gauge makes this a smooth running chain.

As a result, the risk of chain breakage is greatly reduced

and service life is extended. Depth gauge setting is

1.0 mm (0.039 in.).

Sliding surface has been

increased by patented,

asymmetric shape of toe

and heel. This results in

considerably reduced

pressure on the cutters for

a longer wear life.

Identification

Each cutter is marked with "HS" just below the depth

gauge.

5

Tie straps

RMHSRMH

Drive links

3. STIHL Harvester Saw Chain

40 RMH:

Symmetrically shaped running faces. The tie straps are

non-directional.

40 RMHS:

Wear surface is increased by asymmetrically shaped

running faces. This greatly reduces the pressure on the

tie straps and prolongs the service life of the chain. Owing

to the different sizes of the running faces, the tie straps

are directional, i.e. there are left-hand and right-hand tie

straps.

The drive links are reinforced in the area of the rivet holes.

The part of the drive link that runs in the bar groove, the

tang, is stepped – 2.0 mm (0.080 in.) drive link gauge.

Reduced stress

All heavily stressed parts of the STIHL RMHS have been

specially strengthened. This means that the forces acting

on the drive links, tie straps, cutters and rivets can be

better spread over the whole chain. The strengthened

STIHL RAPID

therefore has an up to 70 % longer service life than

conventional harvester chains with a 2.0 mm (0.080 in.)

drive link gauge.

™

Micro™ Harvester Special (RMHS)

6

3. STIHL Harvester Saw Chain

3.1 Specifications

Saw Chain Rapid Harvester Micro Rapid Harvester Special

Marketing number 40 RMH (Type 3996) 40 RMHS (Type 3620)

Chain pitch .404" .404"

Drive link gauge 2.0 mm (0.080 in.) 2.0 mm (0.080 in.)

Depth gauge setting 1.5 mm (0.059 in.) 1.0 mm (0.039 in.)

Chain speed 40 m/s (131.23 ft./sec.) 40 m/s (131.23 ft./sec.)

Driving power (harvester head) 40 kW (54,38 bhp) 65 kW (87,17 bhp)

Sharpening angle 30° 30°

Side plate angle 75° 75°

Identification "H" stamped in area of depth gauge "HS" stamped in area of depth gauge

3.2 Technical Data

Physical properties

Rapid Harvester Micro (40 RMH) Rapid Harvester Special (40 RMHS)

Tensile strength 12000 N 15000 N

Kerf 8.9 mm (0.350 in.) 10.1 mm (0.398 in.)

Operating properties

Rapid Harvester Micro (40 RMH) Rapid Harvester Special (40 RMHS)

Guide bar oil flow rate

min.

max.

Power

min.

max.

Guide bar feed load at center

min.

max.

recommended

Saw chain speed

min.

max.

recommended

900 cm³/h (54.2 cu. in./hr.)

1800 cm³/h (109.8 cu. in./hr.)

10 kW (13.4 bhp)

45 kW (60.4 bhp)

100 N

700 N

600 N

20 m/s (66 ft./sec.)

40 m/s (131 ft./sec.)

40 m/s (131 ft./sec.)

1200 cm³/h (73.2 cu. in./hr.)

2400 cm³/h (146.5 cu. in./hr.)

20 kW (26.8 bhp)

65 kW (87.2 bhp)

250 N

1000 N

900 N

20 m/s (66 ft./sec.)

50 m/s (164 ft./sec.)

40 m/s (131 ft./sec.)

7

3. STIHL Harvester Saw Chain

3.3 Saw Chain Reels

40 STIHL RAPID™ Micro™ Harvester (Type 3996)

Saw chain Lenght No. of drive links Drive link gauge Part No.

40 RMH 7.6 m (25 ft.) 370 2.0 mm (0.080 in.) 3996 000 0370

40 RMH 15.2 m (50 ft.) 740 2.0 mm (0.080 in.) 3996 000 0740

40 RMH 30.4 m (100 ft.) 1480 2.0 mm (0.080 in.) 3996 000 1480

40 STIHL RAPID™ Micro™ Harvester Special (Type 3620)

Saw chain Lenght No. of drive links Drive link gauge Part No.

40 RMHS 7.6 m (25 ft.) 370 2.0 mm (0.080 in.) 3620 000 0370

40 RMHS 15.2 m (50 ft.) 740 2.0 mm (0.080 in.) 3620 000 0740

8

4. Spare Parts

40 STIHL RAPID™ Micro™ Harvester (Type 3996)

Part No. Description Consisting of Item

3996 007 1000 Right hand cutter kit

3996 007 1001 Left hand cutter kit

3996 660 6020 Tie strap kit

3996 662 1050 Drive link kit 10x drive link 7

5x right hand cutter

5x left hand preset tie strap

5x left hand cutter

5x right hand preset tie strap

12x tie strap (without rivet)

12x preset tie strap

1

6

2

5

3

6

40 STIHL RAPID™ Micro™ Harvester Special (Type 3620)

Part No. Description Consisting of Item

3620 007 1000 Right hand cutter kit

3620 007 1001 Left hand cutter kit

3620 660 6000 Tie strap kit

3620 662 1050 Drive link kit 10x drive link 7

5x right hand cutter

5x left hand preset tie strap

5x left hand cutter

5x right hand preset tie strap

12x tie strap (without rivet)

12x preset tie strap

1

6

2

5

3

6

9

Notes

10

© ANDREAS STIHL AG & Co. KG, 2015

0456 690 3002. VA1.A15. Printed in the USA

Printed on chlorine-free paper.

Loading...

Loading...