Page 1

STIH)

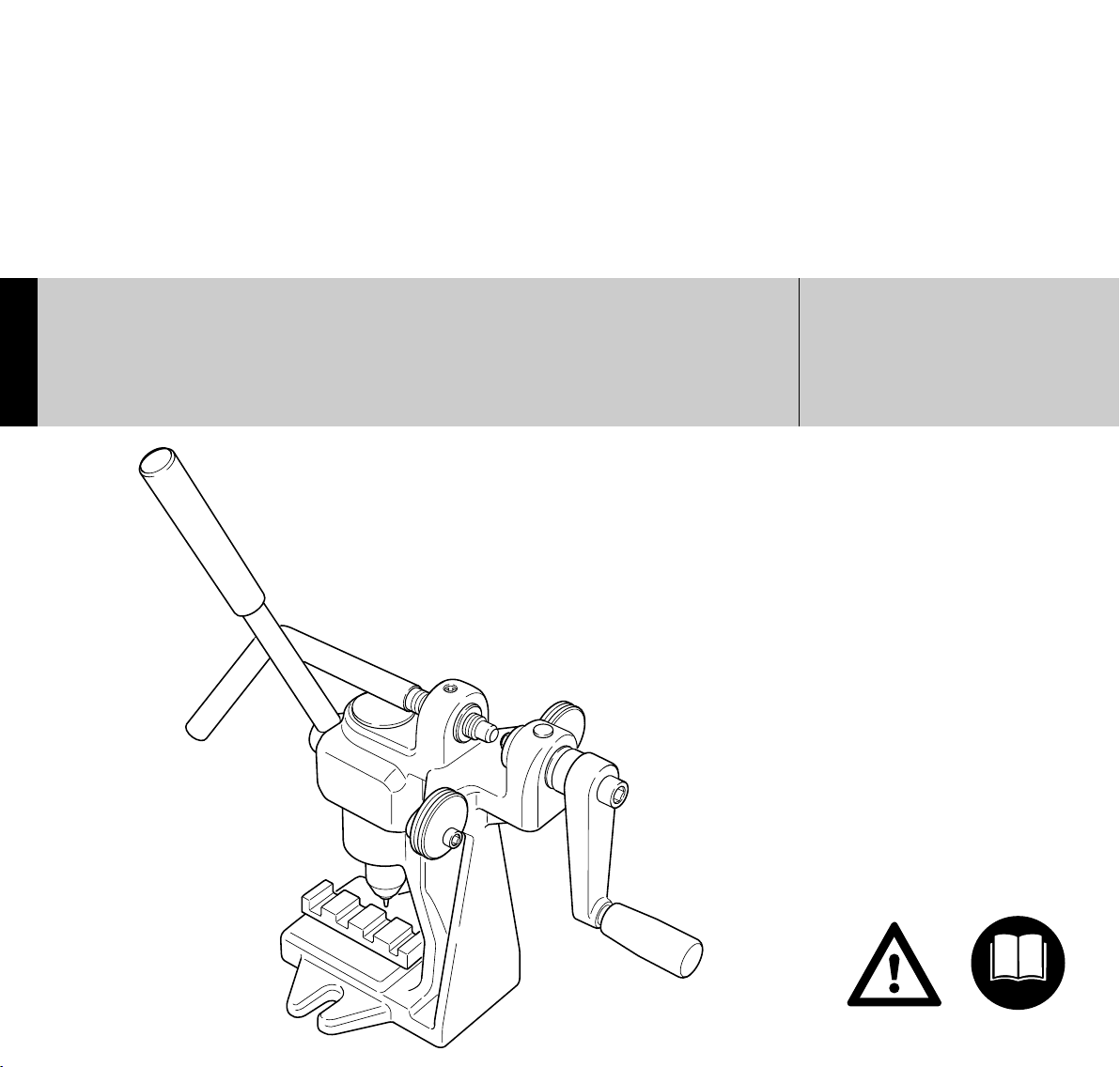

STIHL NG 7

Gebrauchsanleitung

Instruction Manual

Notice d’emploi

Instrucciones de servicio

Istruzioni d’uso

Instruções de serviço

Handleiding

Page 2

English

Contents

Guide to Using this Manual ............ 11

Assembling the Rivet Spinner ........ 12

Chain Breaking ............................... 13

Rivet Spinning ................................ 15

Main Parts ...................................... 17

Special Accessories ....................... 18

BA_SE_098_002_01_02.fm Printed on chlorine-free paper.

Guide to Using this Manual

Pictograms

All the pictograms attached to the

machine are shown and explained in

this manual.

The operating and handling instructions

are supported by illustrations.

Symbols in text

The individual steps or procedures

described in the manual may be marked

in different ways:

: A bullit marks a step or procedure

without direct reference to an

illustration.

A description of a step or procedure that

refers directly to an illustration may

contain item numbers that appear in the

illustration.

Example:

Loosen the screw (1)

Lever (2) ...

Printing inks contain vegetable oils; paper can be recycled.

STIHl

© ANDREAS STIHL AG & Co. KG, 2004

0458 588 7721. M0,5. E4. Ext. Printed in Switzerland

11NG 7

Page 3

English

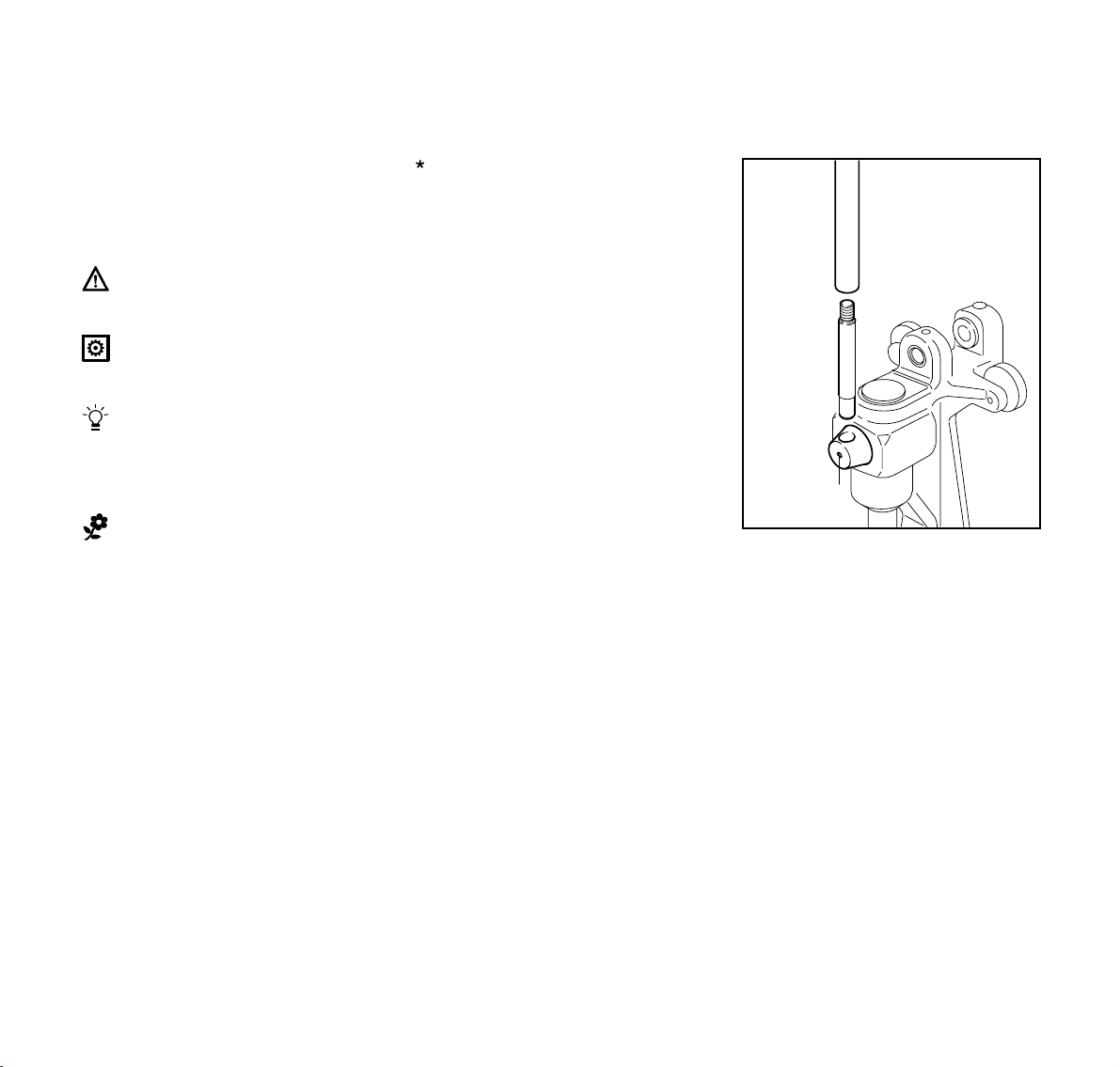

Assembling the Rivet Spinner

In addition to the operating instructions,

this manual may contain paragraphs

that require your special attention. Such

paragraphs are marked with the

symbols described below:

Warning where there is a risk of an

accident or personal injury or

serious damage to property.

Caution where there is a risk of

damaging the machine or its

individual components.

Note or hint which is not essential

for using the machine, but may

improve the operator’s understanding of the situation and result

in better use of the machine.

Note or hint on correct procedure in

order to avoid damage to the

environment.

Equipment and features

This instruction manual may refer to

several models with different

features. Components that are not

installed on all models and related

applications are marked with an

asterisk (*). Such components may

be available as special accessories

from your STIHL dealer.

Engineering improvements

STIHL’s philosophy is to continually

improve all of its products. As a result,

engineering changes and improvements

are made from time to time. If the

operating characteristics or the

appearance of your machine differ from

those described in this manual, please

contact your STIHL dealer for

assistance.

Therefore some changes, modifications

and improvements may not be covered

in this manual.

4

1

2

3

588BA009 KN

: Use two wood screws and washers

to mount the base to the workbench.

: Insert lever (1) in hole in eccentric

pin (2) and secure with screw (3).

: Screw extension (4) on to lever (1).

12

NG 7

Page 4

Chain Breaking

English

: Select punch that matches the

chain pitch

6

5

: Fit the crank handle (5) and secure

with screw (6).

.404R

3/8R

.325R

+Picco

1/4

588BA010 KN

The die has machined recesses for

STIHL saw chains which are marked as

follows:

Die for STIHL Oilomatic

saw chain

1/4" Rapid,

3/8" Picco 1/4 + Picco

0.325" Rapid .325R

3/8" Rapid 3/8R

0.404" Rapid .404R

Marking

STIHL

Oilomatic saw chain

Punch

diameter

mm inch

1/4" Rapid 1.6 0.063

0.325" Rapid 2.2 0.087

3/8" Picco,

3/8" Rapid 2.2 0.087

0.404" Rapid 2.2 0.087

588BA002 KN

588BA003 KN

13NG 7

Page 5

English

3

2

1

: Fit required punch (1) in the

toolholder (2) and secure in position

with grub screw (3).

Improper repairs may result in

damage to the chain and increase

the risk of injury.

Wear protective gloves when

working with the saw chain to

protect your hands from the sharp

cutters.

588BA004 KN

4

: Place the die (4) on the base plate.

: Position the chain on the die so that

the cutter is on top and the tie strap

is in the appropriate recess.

Example: Use recess 3/8R for

3/8“ Rapid.

588BA005 KN

: Bring down the lever (5) until the

punch (1) touches the rivet.

The rivet to be removed must be

centered under the punch.

: Push the lever down until the rivet

head is pressed out.

5

1

588BA006 KN

14

NG 7

Page 6

Rivet Spinning

English

Non-approved combinations of

cutters and/or chain links can

increase the kickback tendency of

the chain and expose the user to

injury.

Wear protective gloves when

working with the saw chain to

protect your hands from the sharp

cutters.

: Select spinning head and thrust

screw to suit the chain pitch

STIHL Oilomatic

chain

1/4" Rapid,

3/8" Picco,

0.325" Rapid C C

3/8" Rapid ,

0.404" Rapid A A, B

1/2", 15 mm

Rapid Micro B A, B

A, B

Spinning

head

A

Thrust

screw

: Do not alter the chain link assembly

pattern.

: Use only identical replacement

chain links.

2

4

3

1

: Screw the thrust screw (1) into

the threaded bushing (2) clockwise.

: Place spinning head (3) in the

holder (4).

5

6

588BA008 KN

: Fit the matching chain links on a

preset tie strap and place the saw

chain over the two guide pulleys (5)

- the drive link tangs engage the

groove.

: Loosen screws (6) and rotate the

eccentric guide pulleys until the

rivets in the chain links are

horizontal and in alignment with

spinning head. The preset head of

the tie strap must locate in the

recessed end of the thrust screw.

: Tighten down the screws.

5

6

588BA011 KN

585BA003 KN

588BA007 KN

15NG 7

Page 7

English

Oil

1

3

: Advance the thrust screw (1) until

the shank of the rivet butts against

the spinning head (3).

: Apply a few drops of oil to the rivet

and the face of the spinning head.

: Turn the thrust screw (1) clockwise

with one hand until moderate

pressure is applied to the rivet.

: Turn the crank handle (7) steadily

with the other hand – the spinning

head forms the new rivet head.

Continue turning the thrust screw to

maintain a constant pressure on the

rivet.

: Spin the rivet until the chain links

are firmly connected but still flexible.

7

The new chain link must be matched to

the size and shape of the other links:

: Grind back cutter and depth gauge

to size of master cutter (the master

cutter is the shortest cutter in the

chain, see user manual of grinder).

: File back surface of the new tie

588BA012 KN

strap to size and shape of other

links.

16

NG 7

Page 8

Main Parts

10

English

1 Extension

1

2

3

5

4

6

7

8

14

9

17

15

16

14

2 Lever

3 Thrust screw

4 Threaded bush

5 Spinning head

6 Thrust bearing

7 Grub screw

8 Eccentric pin

9 Grub screw

10 Die

11 Base

12 Punch

13 Toolholder

14 Guide pulley

15 Screw

16 Crank handle

17 Screw

11

13

12

588BA001 KN

17NG 7

Page 9

English

Special Accessories

For breaking and riveting 15 mm

chain:

Die (15 mm)

Punch (15 mm)

Guide pulley (15 mm)

Spinning head (1/2 “ and 15 mm)

18

NG 7

Page 10

0458 588 7721

MF

Loading...

Loading...