Page 1

STIH)

STIHL MS 311, 391

2009-06

Page 2

Contents

1. Introduction and

Safety Precautions 3

1.1 Introduction 3

1.2 Safety Precautions 4

2. Specifications 5

2.1 Engine 5

2.2 Fuel System 5

2.3 Ignition System 5

2.4 Chain Lubrication 5

2.5 Tightening Torques 6

3. Troubleshooting 8

3.1 Clutch 8

3.2 Chain Drive,

Chain Brake,

Chain Tensioner 9

3.3 Chain Lubrication 10

3.4 Rewind Starter 11

3.5 Ignition System 12

3.6 Carburetor 13

3.7 Engine 16

4. Clutch 17

4.1 Clutch Drum 19

5. Chain Brake 20

6. Engine 27

6.1 Muffler 27

6.2 Leakage Test 28

6.2.1 Preparations 28

6.2.2 Vacuum Test 29

6.2.3 Pressure Test 29

6.3 Oil Seals 30

6.4 Shroud 31

6.5 Cylinder / Crankshaft 32

6.6 Bearings / Crankshaft 35

6.7 Piston 36

6.8 Piston Rings 38

6.9 Decompression Valve 38

7. Ignition System 39

7.1 Ignition Timing 39

7.2 Preseparator 39

7.3 Ignition Module 39

7.4 Testing the

Ignition Module 41

7.5 Spark Plug Boot /

Ignition Lead 42

7.6 Flywheel 43

7.7 Short Circuit Wire 44

7.7.1 Testing 44

7.7.2 Removing and

Installing 44

7.7.3 Ground Wire 46

7.7.4 Contact Spring 46

7.8 Ignition System

Troubleshooting 48

9. Servicing the

AV System 57

9.1 Buffer on Oil Tank 57

9.2 AV Spring on Oil Tank 57

9.3 AV Spring on

Fuel Tank 57

9.4 AV Spring on

Front Handle 58

9.5 Stop Buffer at

Clutch Side 59

9.6 Annular Buffer at

Ignition Side 59

9.7 Handlebar 59

10. Control Levers 61

10.1 Master Control Lever 61

10.2 Throttle Trigger/Interlock

Lever 61

10.2.1 Choke Rod 63

10.2.2 Throttle Rod 64

11. Chain Lubrication 65

11.1 Pickup Body 65

11.2 Oil Suction Hose 65

11.3 Oil Pump 66

11.4 Valve 67

RA_542_00_01_01

5.1 Checking Operation 20

5.2 Brake Band 20

5.3 Brake Lever 22

5.4 Cam Lever 24

5.5 Pins 25

5.6 Chain Tensioner 25

5.7 Bar Mounting Studs 26

8. Rewind Starter 51

8.1 General 51

8.2 Fan housing 51

8.2.1 Segment 51

8.3 Pawls 51

8.4 Rope Rotor 52

8.5 Starter Rope / Grip 53

8.6 Tensioning the

Rewind Spring 54

8.7 Replacing the

Rewind Spring 55

q

© ANDREAS STIHL AG & Co. KG, 2009

1MS 311, MS 391

Page 3

Contents

12. Fuel System 68

12.1 Air Filter 68

12.2 Baffle 68

12.3 Filter Base 68

12.4 Air Guide Shroud 69

12.5 Carburetor 71

12.5.1 Leakage Test 71

12.6 Servicing the

Carburetor 72

12.6.1 Metering Diaphragm 72

12.6.2 Inlet Needle 73

12.6.3 Pump Diaphragm 74

12.6.4 Air Valve 76

12.6.5 Levers on

Throttle Shaft 76

12.6.6 Adjusting Screws 77

12.7 Carburetor

Adjustment 79

12.7.1 Basic Setting 79

12.7.2 Standard Setting 80

12.8 Carburetor Carrier 81

12.9 Intake Manifold 82

12.10 Tank Vent 83

12.10.1 Testing 83

12.10.2 Removing and

Installing 84

12.11 Fuel Intake 84

12.11.1 Pickup Body 84

12.11.2 Fuel Hose 85

12.11.3 Fuel Suction Hose 86

12.11.4 Tank Housing 87

13. Special Servicing

Tools 88

14. Servicing Aids 90

2 MS 311, MS 391

Page 4

1. Introduction and Safety Precautions

1.1 Introduction

This service manual contains

detailed descriptions of all the repair

and servicing procedures specific to

this power tool.

You should make use of the

illustrated parts lists while carrying

out repair work. They show the

installed positions of the individual

components and assemblies.

Refer to the latest edition of the

relevant parts list to check the part

numbers of any replacement parts.

A fault on the machine may have

several causes. To help locate the

fault, consult the chapter on

"Troubleshooting" and the

"STIHL Service Training System"

for all assemblies.

Refer to the “Technical Information”

bulletins for engineering changes

which have been introduced since

publication of this service manual.

Technical information bulletins also

supplement the parts list until a

revised edition is issued.

The special tools mentioned in the

descriptions are listed in the chapter

on "Special Servicing Tools" in this

manual. Use the part numbers to

identify the tools in the

"STIHL Special Tools" manual. The

manual lists all special servicing

tools currently available from

STIHL.

Symbols are included in the text and

pictures for greater clarity.

The meanings are as follows:

In the descriptions:

N Action to be taken as shown in

the illustration above the text

– Action to be taken that is not

shown in the illustration above

the text

In the illustrations:

A Pointer

a Direction of movement

@ 4.2 =Reference to another

chapter, i.e. chapter 4.2

in this example.

1

3

2

219RA000 TG

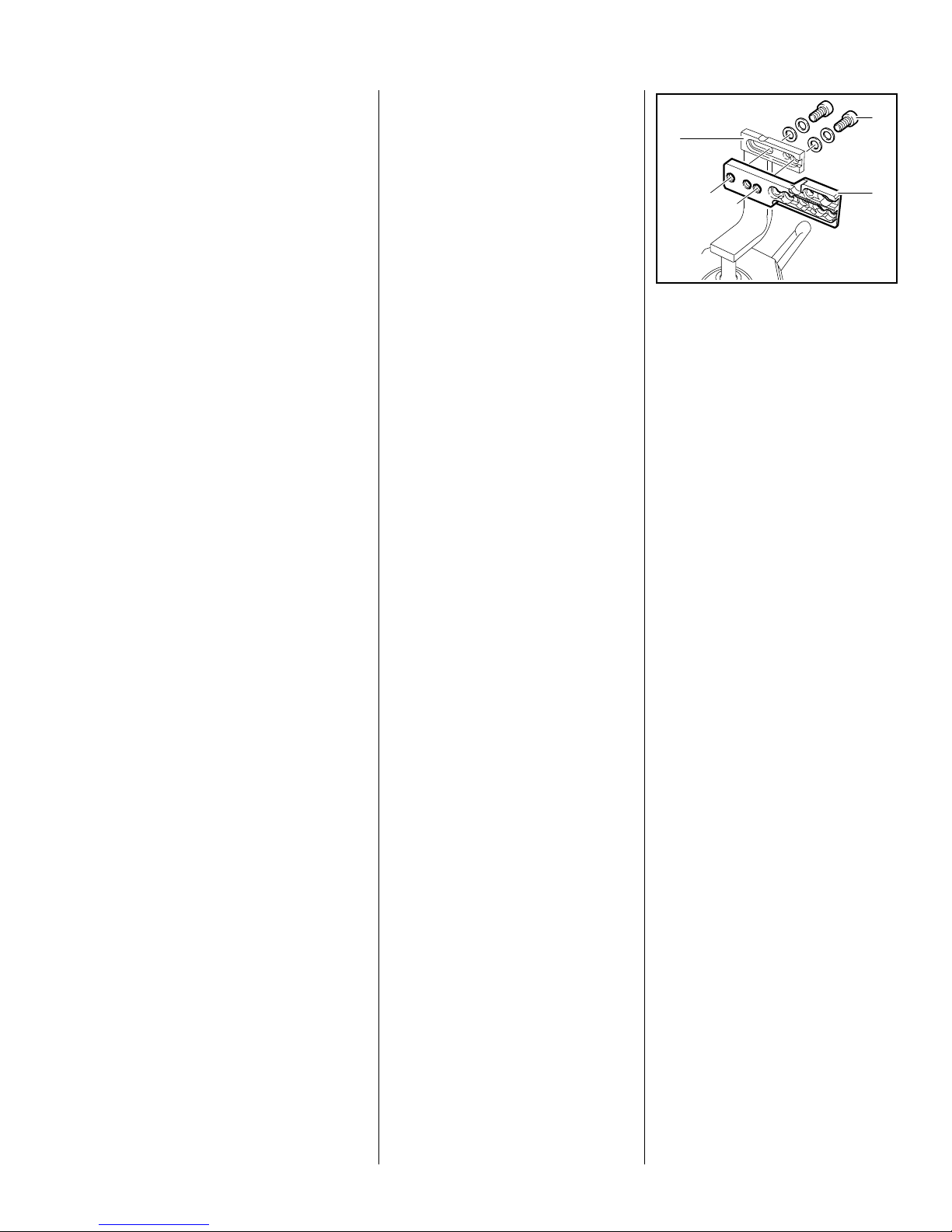

Servicing and repairs are made

considerably easier if the machine

is mounted to assembly stand (3)

5910 890 3100. To do this, secure

the mounting plate (2)

5910 850 1650 to the assembly

stand with two screws (1) and

washers.

The screws must not project since

they, depending on the machine,

may damage housings when the

machine is clamped in position.

The above operation is not

necessary with the new assembly

stand 5910 890 3101 since the

mounting plate is already fitted.

Service manuals and all technical

information bulletins are intended

exclusively for the use of properly

equipped repair shops. They must

not be passed to third parties.

3MS 311, MS 391

Page 5

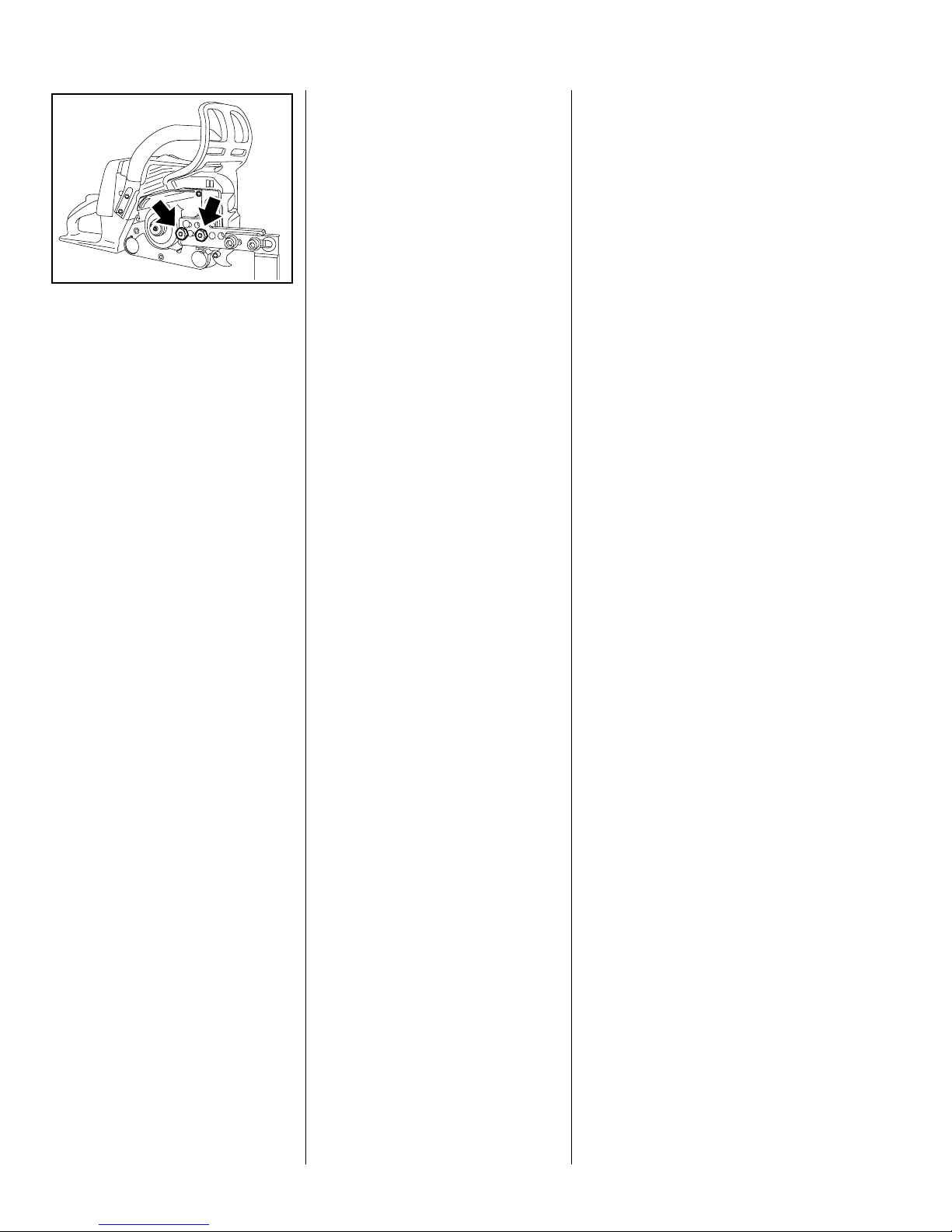

Engage the bar mounting studs in

the outer bores in the mounting

plate and secure the machine in

position with the nuts (arrows).

Preparations for servicing

Remove the chain sprocket cover,

saw chain and guide bar before

carrying out repairs or mounting the

machine to the assembly stand.

Always use original STIHL

replacement parts.

They can be identified by the STIHL

part number, the { logo

and the STIHL parts symbol K

This symbol may appear alone on

small parts.

Storing and disposing

of oils and fuels

Collect fuel or lubricating oil in a

clean container and dispose of it

properly in accordance with local

environmental regulations.

1.2 Safety Precautions

If the machine is started up in the

course of repairs or maintenance

work, observe all local and countryspecific safety regulations as well

as the safety precautions and

warnings in the instruction manual.

Gasoline is an extremely flammable

216RA000 TG

fuel and can be explosive in certain

conditions.

Always wear suitable protective

gloves for operations in which

components are heated for

assembly or disassembly.

Improper handling may result in

burns or other serious injuries.

Do not smoke or bring any fire,

flame or other source of heat near

the fuel. All work with fuel must be

performed outdoors only. Spilled

fuel must be wiped away

immediately.

Always perform leakage test after

working on the fuel system and the

engine.

Always replace damaged parts.

Check disassembled parts for wear

or damage before re-installing –

replace as necessary.

Run the machine only with the

shroud mounted in position – there

is otherwise a risk of injury from the

fanwheel and a risk of engine

damage due to overheating.

The chapter on tightening torques

lists all machine components that

have to be tightened to a specific

torque or coated with threadlocking

adhesive. The specifications must

be maintained when tightening

down screws, nuts and other

fasteners in all the procedures

described in this service manual.

Fuel system – hose barb

connectors

Pull off or push on fuel hoses in line

with the connector, preferably by

hand, to ensure the tightness of the

fuel system.

Avoid damaging the hose barb

– do not use sharp-edged pliers,

screwdrivers, etc.

Do not cut open fuel hoses with a

knife or similar tool.

Do not re-use fuel hoses after

removal. Always install new hoses

– fuel hoses can be overstretched

during removal.

Install new fuel hoses either dry or

with the aid of STIHL press fluid,

b 14.

Other press fluids are not approved

and may result in damage to the fuel

hoses.

Coat the ends of the hoses and the

connectors with STIHL press fluid

and then push the new hoses on to

the hose barbs, b 14.

4 MS 311, MS 391

Page 6

2. Specifications

2.1 Engine

MS 311 MS 391

Displacement: 59 cm

3

64.1 cm

3

Bore: 47 mm 49 mm

Stroke: 34 mm 34 mm

Engine power to ISO 7293: 3 kW (4 bhp)

at 9,500 rpm

3.2 kW (4.4 bhp)

at 9,500 rpm

Maximum permissible engine speed

with guide bar and chain: 13,000 rpm 13,000 rpm

Idle speed: 2,800 rpm 2,800 rpm

Clutch: Centrifugal clutch without

linings

Centrifugal clutch without

linings

Clutch engages at: 3,500 rpm 3,500 rpm

Engine housing leakage test

at gauge pressure: 0.5 bar

under vacuum: 0.5 bar

2.2 Fuel System

Carburetor leakage test at

0.8 bar

gauge pressure:

Operation of tank vent at

0.5 bar

gauge pressure:

Fuel: as specified in instruction

manual

2.3 Ignition System

2.4 Chain Lubrication

Air gap between ignition

module and fanwheel: 0.20...0.30 mm

Spark plug (resistor type): NGK BPMR 7 A

BOSCH WSR6F

Electrode gap: 0.5 mm

Speed-controlled oil pump with reciprocating piston and

manual flow control

Oil delivery rate:

Ematic oil pump

Oil delivery rate:

Adjustable oil pump

11.5 (+2.5) cm

at 10,000 rpm

6.0 (+/-2.0)...17.5 (+3.0 / -4.5)

3

cm

/min at 10,000 rpm

3

/min

5MS 311, MS 391

Page 7

2.5 Tightening Torques

DG and P (Plastoform) screws are used in polymer and light metal components. These screws form a

permanent thread when they are installed for the first time. They can be removed and installed as often as

necessary without impairing the strength of the screwed assembly, providing the specified tightening torque is

observed.

For this reason it is essential to use a torque wrench.

Fastener Thread size For component Torque

Remarks

Nm

Screw P 4x14 Chain tensioner cover/engine housing 1.5

Screw P 4x12 Brake band/engine housing 2.0

Collar screw M 10 Collar stud for bar / engine pan 30.0 1)

Collar screw D 8x24 Collar stud for bar / engine housing 16.0

Screw P 5x16 Cover, chain brake / engine housing 4.0

M 10x1 Decompression valve 14.0

Screw P 5x16 Handlebar/plug, AV spring 3.0

Screw P 6x26.5 Handlebar / tank housing, right (polymer) 7.0

Screw P 6x26.5 Handlebar / tank housing, bottom (polymer) 7.0

Screw P 6x25 Hand guard / fan housing 8.0

Screw M 6x30 Shroud / engine housing 10.0

Screw P 6x38 Chain catcher / bearing plug 6.0

Screw P 5x16 Spiked bumper / engine housing 4.0

Screw M 4x12 Manifold/cylinder 4.0 3)

Screw P 6x21.5 Bearing plug / engine housing 6.0

Screw M 5x16 Bearing plug/cylinder 10.0 4)

Screw P 5x20 Fan housing / engine housing 4.0

Screw P 4x12 Air baffle / engine housing 2.0

Carrier M 12x1 LH Carrier / crankshaft 50.0

Screw M 6x25 Engine housing / cylinder, stage 1 4.0 3)

Screw M 6x25 Engine housing / cylinder, stage 2 12.0 3)

Screw D 4x18 Oil pump 4.0 3)

Screw M 5x16 Muffler / cylinder 10.0 1) 3)

Screw M 8x1 Flywheel/crankshaft 33.0 5)

Nut M 5 Carburetor/collar stud 3.5

Screw P 4x14 Pre-separator / engine housing 2.0

Screw P 4x12 Cover plate/fan housing 2.0

Spark plug M 14x1.25 Spark plug 25.0

Screw D 4x18 Ignition module / engine pan 4.0 3)

6 MS 311, MS 391

Page 8

Remarks:

1) Loctite 242 or 243, medium strength

2) Loctite 648, high strength

3) Screws with antifricton coated binding head

4) Screws with micro-encapsulated binding head

5) Degrease crankshaft/flywheel and mount oil-free

Use the following procedure when refitting a DG or P screw in an existing thread:

Place the screw in the hole and rotate it counterclockwise until it drops down slightly.

Tighten the screw clockwise to the specified torque.

Coat micro-encapsulated screws with medium-strength threadlocking adhesive before re-installing.

This procedure ensures that the screw engages properly in the existing thread and does not form a new thread

and weaken the assembly.

Power screwdriver setting for polymer: DG and P screws max. 500 rpm

Do not use an impact wrench for releasing or tightening screws.

Do not mix up screws with and without binding heads.

7MS 311, MS 391

Page 9

3. Troubleshooting

3.1 Clutch

Condition Cause Remedy

Saw chain stops under load at full

Clutch shoes badly worn Install new clutch

throttle

Clutch drum badly worn Install new clutch drum

Saw chain rotates at idle speed Engine idle speed too high Readjust with idle speed screw

LA (counterclockwise)

Clutch springs stretched or fatigued Replace the clutch springs or install

new clutch

Clutch spring hooks broken Replace the clutch springs or install

new clutch

Loud noises Clutch springs stretched or fatigued Replace the clutch springs or install

new clutch

Needle cage damaged Fit new needle cage

Clutch shoe retainer broken Install new retainer or clutch

Clutch shoes and carrier worn Install new clutch

8 MS 311, MS 391

Page 10

3.2 Chain Drive, Chain Brake, Chain Tensioner

Condition Cause Remedy

Chain sprocket wears rapidly Chain not properly tensioned Tension chain as specified

Wrong chain pitch Fit chain of correct pitch

Insufficient chain lubrication Check chain lubrication

Chain sprocket worn Fit new chain sprocket

Saw chain stops under load at full

Clutch shoes badly worn Install new clutch

throttle

Clutch drum badly worn Install new clutch drum

Brake band blocked Check freedom of movement and

operation of brake band

Saw chain rotates at idle speed Engine idle speed too high Readjust with idle speed screw

LA (counterclockwise)

Clutch springs stretched or fatigued Replace the clutch springs or install

new clutch

Clutch spring hooks broken Replace the clutch springs

Saw chain does not stop

Brake spring stretched or broken Fit new brake spring

immediately when brake is

activated

Brake band stretched or worn Fit new brake band

Clutch drum worn Install new clutch drum

9MS 311, MS 391

Page 11

3.3 Chain Lubrication

In the event of trouble with the

chain lubrication system, check and

.

rectify other sources of faults

before disassembling the oil pump.

Condition Cause Remedy

Chain receives no oil Oil tank empty Fill up with oil and check setting of

oil pump if necessary

Oil inlet hole in guide bar is blocked Clean oil inlet hole

Intake hose or pickup body clogged

or intake hose ruptured

Fit new intake hose and pickup

body

Valve in oil tank blocked Clean or replace valve

Teeth on worm worn Install new worm

Worm drive spring broken Install new worm

Oil pump damaged or worn Install new oil pump

Machine losing chain oil Oil pump body damaged Install new oil pump

Oil pump damaged or worn Install new oil pump

Oil intake hose connection

Install new oil intake hose

damaged

Oil pump delivers insufficient oil Oil pump worn Install new oil pump

Worm drive spring not engaged in

clutch drum

Oil pump delivery rate set too low Adjust oil pump

10 MS 311, MS 391

Engage drive spring in notch in

clutch drum

(only on version with adjustable oil

pump)

Page 12

3.4 Rewind Starter

Condition Cause Remedy

Starter rope broken Rope pulled out too vigorously as

Fit new starter rope

far as stop or over edge,

i.e. not vertically

Normal wear Fit new starter rope

Starter rope does not rewind Very dirty or corroded Clean or replace rewind spring

Insufficient spring tension Check rewind spring and increase

tension

Rewind spring broken Fit new rewind spring

Starter rope cannot be pulled out

far enough

Starter rope can be pulled out

almost without

Spring overtensioned Check rewind spring and reduce

tension

Guide peg on pawl or pawl itself is

Fit new pawl

worn

resistance (crankshaft does not

turn)

Starter rope is difficult to pull or

rewinds very slowly

Spring clip on pawl fatigued Fit new spring clip

Starter mechanism is very dirty Thoroughly clean complete starter

mechanism

Lubricating oil on rewind spring

becomes viscous at very low

outside temperatures (spring

windings stick together)

Coat rewind spring with a small

amount of standard solvent-based

degreasant (containing no

chlorinated or halogenated

hydrocarbons), then pull rope

carefully several times until normal

action is restored

Decompression valve is not open Open, check and replace

decompression valve if necessary

11MS 311, MS 391

Page 13

3.5 Ignition System

Exercise extreme caution while

carrying out maintenance and

repair work on the ignition system.

The high voltages which occur can

cause serious or fatal accidents.

Condition Cause Remedy

Engine runs roughly, misfires,

temporary loss of power

Spark plug boot is loose Press boot firmly onto spark plug

and fit new spring if necessary

Spark plug sooted, smeared with oil Clean the spark plug or replace if

necessary.

If sooting keeps recurring, check air

filter

Ignition lead loose in ignition

Secure ignition lead properly

module

Fuel/oil mixture

Use correct mixture of fuel and oil

– too much oil

Incorrect air gap between ignition

Set air gap correctly

module and flywheel

Flywheel cracked or

Install new flywheel

damaged or pole shoes have

turned blue

Ignition timing out of adjustment,

flywheel warped, machined key in

flywheel sheared

Install new flywheel, check

crankshaft stub for damage and

replace crankshaft if necessary

Weak magnetization in flywheel Install new flywheel

Irregular spark Check operation of switch shaft/

Engine housing damaged (cracks) Install new engine housing

12 MS 311, MS 391

contact springs and ignition

module.

Faulty insulation or break in ignition

lead or short circuit wire. Check

ignition lead/ignition module and

replace ignition module if

necessary.

Check operation of spark plug.

Clean the spark plug or replace if

necessary.

Page 14

3.6 Carburetor

Condition Cause Remedy

Carburetor floods; engine stalls Inlet needle not sealing

– foreign matter in valve seat or

Remove and clean the inlet needle,

clean the carburetor

cone

Inlet needle worn Replace the inlet needle

Inlet control lever sticking on

spindle

Helical spring not located on nipple

of inlet control lever

Perforated disc on diaphragm is

Check the inlet control lever and

replace if necessary.

Remove the inlet control lever and

refit it correctly

Fit a new metering diaphragm

deformed and presses constantly

against the inlet control lever

Metered diaphragm deformed Fit a new metering diaphragm

Poor acceleration Setting of low speed screw too lean Check basic carburetor setting,

correct if necessary

Setting of high speed screw too

lean

Check basic carburetor setting,

correct if necessary

Inlet needle sticking to valve seat Remove inlet needle, clean and

refit

Diaphragm gasket leaking Fit new diaphragm gasket

Metering diaphragm damaged or

Fit a new metering diaphragm

shrunk

Tank vent faulty Replace tank vent

Leak on fuel hose from tank to

carburetor

Seal connections or install new fuel

hose

13MS 311, MS 391

Page 15

Condition Cause Remedy

Engine will not idle, idle speed too

high

Throttle shutter opened too wide by

idle speed screw LA

Oil seals/engine housing leaking Seal or replace oil seals/engine

Throttle shutter does not close Replace throttle shutter and shaft

Air valve does not close Replace end cover with air valve.

Engine stops while idling Idle jet bores

or ports blocked

Low speed screw too rich or

too lean

Setting of idle speed screw LA

incorrect – throttle shutter

completely closed

Tank vent faulty Replace tank vent

Reset idle speed screw LA

correctly

housing

Clean the carburetor

Reset low speed screw L correctly

Reset idle speed screw LA

correctly

Leak on fuel hose from tank to

carburetor

Seal connections or install new fuel

hose

Saw chain rotates at idle speed Engine idle speed too high Readjust with idle speed screw

LA (counterclockwise)

Clutch springs stretched or fatigued Replace the clutch springs or install

new clutch

Clutch spring hooks broken Replace the clutch springs

14 MS 311, MS 391

Page 16

Condition Cause Remedy

Engine speed drops quickly under

load – low power

Air filter dirty Clean air filter or replace if

necessary

Throttle shutter not opened fully Check throttle cable and rod

Tank vent faulty Replace tank vent

Fuel pickup body dirty Install new pickup body

Fuel strainer dirty Clean fuel strainer in carburetor,

replace if necessary

Leak on fuel hose from tank to

carburetor

Setting of high speed screw H too

rich

Seal connections or install new fuel

hose

Check basic carburetor setting,

correct if necessary

Main jet bores or ports blocked Clean the carburetor

Pump diaphragm damaged or

Fit new pump diaphragm

fatigued

Fit key if necessary and secure

flywheel properly or install new

flywheel

or replace if necessary.

Engine running extremely rich, has

no power and a very low maximum

Ignition timing wrong, flywheel out

of adjustment, key in flywheel has

sheared off

Air valve does not open Check the carburetor and service

speed

Engine running too rich, loss of

power and maximum speed too low

Air valve does not open fully in full

throttle position

Check the carburetor and service

or replace if necessary.

Erratic idle – too lean Air valve does not close completely Check the end cover with air valve

and replace if necessary

Intake manifold faulty Install new intake manifold

15MS 311, MS 391

Page 17

3.7 Engine

Always check and, if necessary,

repair the following parts before

looking for faults on the engine:

- Air filter

- Fuel system

- Carburetor

- Ignition system

Condition Cause Remedy

Engine does not start easily, stalls

at idle speed, but operates normally

at full throttle

Engine does not deliver full power

or runs erratically

Oil seals in engine housing

Replace the oil seals

damaged

Engine housing leaking/

Seal or replace the engine housing

damaged (cracks)

Piston rings worn or broken Fit new piston rings

Muffler / spark arresting screen

carbonized

Clean the muffler (inlet and

exhaust), replace spark arresting

screen, replace muffler if necessary

Air filter dirty Replace air filter

Fuel/impulse hose severely kinked

or damaged

Fit new hoses or position them free

from kinks

Decompression valve is not closed Close, check and replace

decompression valve if necessary

Engine overheating Insufficient cylinder cooling. Air

inlets in fan housing blocked or

cooling fins on cylinder very dirty

16 MS 311, MS 391

Thoroughly clean all cooling air

openings and the cylinder fins

Page 18

4. Clutch

– Troubleshooting, b 3.1

– Remove the shroud, b 6.4.

– Remove the clutch drum, b 4.1

1

: Pull boot (1) off the spark plug.

– Unscrew the spark plug.

: The locking strip (1)

0000 893 5903 must butt against

the cylinder wall (arrow) as

shown.

4903RA001 TG

1

1

4903RA106 TG

– Pull the clutch shoes off the

carrier.

: Remove the retainers (1).

1

4903RA005 TG

1

: Push the locking strip (1)

0000 893 5903 into the spark

plug hole, wide end first, so that

"OBEN-TOP" faces up.

: Apply wrench to hexagon (arrow)

and unscrew the clutch (1).

Note that the clutch has a left-hand

thread.

4903RA002 TG

Disassembling

21

: Use hook (2) 5910 890 2800 to

remove the clutch springs (1).

4903RA003 TG4903RA004 TG

– Clean all parts, b 14

– Replace any damaged parts.

If the clutch is noticeably worn,

replace all three clutch shoes at the

same time – not individual shoes –

since runout may otherwise affect

correct operation of the clutch.

4903RA006 TG

17MS 311, MS 391

Page 19

1

2

: Fit the retainers (1).

1

2

: Fit the clutch shoes (2) over the

arms (1).

1

4903RA007 TG

Attach the springs (1) on the side

with the raised hexagon (arrow).

: Attach one end of each spring (1)

to the clutch shoes.

: Use the hook (2) 5910 890 2800

to attach the other ends of the

springs and press them firmly into

the clutch shoes.

4903RA008 TG

1

4903RA010 TG

Make sure the washer (1) is in

place.

Installed position is correct when

TOP (arrow) faces outwards.

4903RA012 TG

4903RA013 TG

: Clamp the clutch in a

vise (arrow).

: Position the clutch on the

crankshaft stub so that the raised

hexagon (arrow) faces outwards.

4903RA011 TG

: Check the clutch – all springs

(arrows) must be properly

attached.

4903RA009 TG

18 MS 311, MS 391

Page 20

4.1 Clutch Drum

– Remove and install the clutch

1

drum, see instruction manual.

: Screw the clutch (1) on to the

crankshaft stub and tighten down

the hexagon (arrow) firmly – lefthand thread.

– Remove the locking strip from the

cylinder.

– Reassemble all other parts in the

reverse sequence.

1

4903RA014 TG

4903RA015 TG

: Pull off the needle cage (1).

– Clean the needle cage and

crankshaft stub, b 14

– Lubricate the needle cage and

crankshaft stub, b 14

1

100%

80%

!

– Inspect the clutch drum (1) for

signs of wear.

If there are signs of serious wear on

the inside diameter of the clutch

drum (1), check the remaining wall

thickness. If it is less than about

80% of the original thickness, install

a new clutch drum.

– Install the clutch drum.

165RA029 TG

19MS 311, MS 391

Page 21

5. Chain Brake

5.1 Checking Operation

The chain brake is one of the most

important safety devices on the

machine. Its efficiency is measured

in terms of the chain braking time,

i.e. the time that elapses between

activating the brake and the saw

chain coming to a complete

standstill.

Contamination (with chain oil,

chips, fine particles of abrasion,

etc.) and smoothing of the friction

surfaces of the brake band and

clutch drum impair the coefficient of

friction, which prolongs the braking

time. A fatigued or stretched brake

spring has the same negative effect.

– Starting the engine

– With the chain brake

activated (locked), open the

throttle wide for a brief

period (max. 3 seconds) – the

chain must not rotate.

5.2 Brake Band

– Remove the clutch drum, b 4.1

– Troubleshooting, b 3.2

1

: Pull off the bumper strip (1).

1

1

4903RA018 TG

– Engage the chain brake.

The brake band is now tensioned.

: Remove the screw (1) from the

underside of the machine.

4903RA016 TG

1

– With the chain brake released,

open the throttle wide and

activate the brake manually – the

chain must come to an abrupt

stop.

The braking time is in order if

deceleration of the saw chain (less

than a second) is imperceptible to

the eye.

If the chain brake does not operate

properly, refer to troubleshooting,

b 3.2.

: Take out the screws (arrows).

– Remove the cover (1).

: Pry the brake band (1) out of its

4903RA017 TG

seat (arrow).

– Remove the brake band (1).

Do not overstretch the brake band.

– Pull the hand guard towards the

handlebar to simplify assembly of

the brake band.

4903RA019 TG

20 MS 311, MS 391

Page 22

2

1

1

: Turn the brake band (1) to one

side and disconnect it from the

brake lever (2).

Install a new brake band if there are

noticeable signs of wear (large

areas on inside diameter and/or

parts of outside diameter – arrows)

and its remaining thickness is less

than 0.6 mm.

4903RA020 TG

: Position the brake band (1) it the

guide (arrow) first.

– Disengage the chain brake.

1

219RA049 TG

: Push the brake band (1) over the

guide lugs (arrows) and into its

seat.

4903RA022 TG4903RA023 TG

: Fit the screw (1) on the underside

of the machine and tighten it

down firmly.

1

: Engage the cover (1) in the slots

(arrows) first and then swing it

into position.

4903RA018 TG

4903RA025 TG

Installing

1

: Hold the brake band (1)

sideways, attach it to the brake

lever (2) and then swing it in the

direction of its seat.

2

: Push the brake band (1) into its

seat (arrow) as far as stop.

4903RA021 TG

1

4903RA024 TG

21MS 311, MS 391

Page 23

5.3 Brake Lever

1

1

: Insert the screws (arrows) and

tighten them down firmly.

– Fit the bumper strip.

– Install the clutch drum, b 4.1

– Check operation, b 5.1

– Reassemble all other parts in the

reverse sequence.

4903RA026 TG

– Troubleshooting, b 3

– Remove the brake band, b 5.2

– Engage the chain brake.

The brake spring is now relaxed.

: Use the assembly tool

1117 890 0900 to disconnect the

brake spring (1) from the anchor

pin (arrow).

– Remove the brake spring from

the brake lever.

: Remove the E-clip (1).

4903RA027 TG

1

: Lift and turn the strap (1) slightly,

push it towards the hole (arrow)

and remove it.

: Remove the spacer sleeve (2)

from the brake lever.

4903RA029 TG

2

4903RA030 TG

2

1

4903RA119 TG

– Remove the shroud, b 6.4

: Take out the screws (arrows).

– Remove the sleeve (1).

– Lift the hand guard a little and

remove the fan housing.

22 MS 311, MS 391

: Pull the hand guard (1) and brake

lever (2) off the pivot pins

(arrows) together.

– Remove the hand guard and

brake lever.

4903RA031 TG

Page 24

1 2

1

1

: Take the brake lever (2) out of the

hand guard (1).

– Inspect the pivot pins and replace

if necessary, b 5.5

– Inspect the cam lever and

replace if necessary, b 5.4

Installing

1

4903RA032 TG

: Push the hand guard with brake

lever (1) over the machine until

they are positioned against the

pivot pins (arrows).

: Lift the bearing boss of the hand

guard and the brake lever a little

and position them over the pivot

pins (arrows).

4903RA033 TG

4903RA034 TG

: Fit the spacer sleeve (1).

1

– Fit the strap (1).

4903RA035 TG4903RA036 TG

: Fit the E-clip (2).

4903RA272 TG

2

4903RA037 TG

– Clean all disassembled parts,

b 14

: Hold the brake lever (1) so that

the brake spring attachment point

(arrow) is at the top.

: Push the brake lever (1) into the

hand guard recess and line up

the holes.

1

: Turn the cam lever (1) to one side

until the cam of the hand

guard (arrow) slips passed it.

– Push the hand guard bearing

boss and the brake lever on to

the pivot pins.

23MS 311, MS 391

Page 25

BUYNOW

ThenInstantDownload

theCompleteManual

Thankyouverymuch!

Loading...

Loading...