Page 1

Setup and Service Procedures for the

1

MS 170, MS 180 Chain Saw

© STIHL Inc., Virginia Beach, VA 2013

Introduction

confidential

The MS 170, MS 180 chain saw has a 2-cycle engine

STIHL assigns a 4 digit series number to every product

The MS 170, MS 180 is assigned the 1130 series number

The 1130 series of saw was introduced to the market in

1995 as an 017, and then in 1998 the 018 was added

In 2002 the model designation changed from 017 to MS

170, and 018 to MS 180

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 2

Specifications

2

MS 170 MS 180

confidential

Engine Displacement 30.1 cc (1.8 cu.in) 31.8 cc(1.9 cu. in.)

Engine Power 1.3 kW (1.7bhp) 1.5kW (2.0 bhp)

Weight 3.9 kg (8.6 lbs) 4.0 kg (8.8 lbs.)

Fuel Capacity 250 cc (8.5 oz.)

Chain Oil Capacity 145 cc (4.9 oz.)

Recommended OILOMATIC® Chain 3/8” PMM3

Guide Bar Lengths Available 12” to 16”

Engine Idle Speed 2800 RPM

Wide Open Throttle 14,000 RPM (with bar and chain installed)

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Become Familiar With the Controls

Master Control Lever™

A single lever

operating the choke,

throttle lock and on-off

switch

0 = Off

I = Ignition on

Warm Start

confidential

Cold Start

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 3

Starting Features

3

The MS 170 is equipped with a

standard starter mechanism,

and with 2 bar nuts holding the

bar in place

The MS 180 C-B has the

Toolless Quick Chain Adjuster

(QCA) for fast and easy chain

and bar install and adjustment

The MS 180 C-BE also has the

Easy2Start™ starter

mechanism which allows

starting with less effort at a

lower cranking speed

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Starting Features

The MS 180 C-B has the standard starter mechanism, which

requires a brisk pull on the rope to it’s full extension to start

the engine

The MS 180 C-BE has the Easy2Start™ starter mechanism,

which allows starting by simply pulling out the rope slow and

easy, winding the auxiliary spring which then spins the motor

over to start it

Notice that the MS

180 C-BE has a

deeper recoil

confidential

housing and the

handle extends out

slightly farther for

clearance

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 4

© STIHL Inc., Virginia Beach, VA 2013 US/STR

4

confidential

Kickback!!!

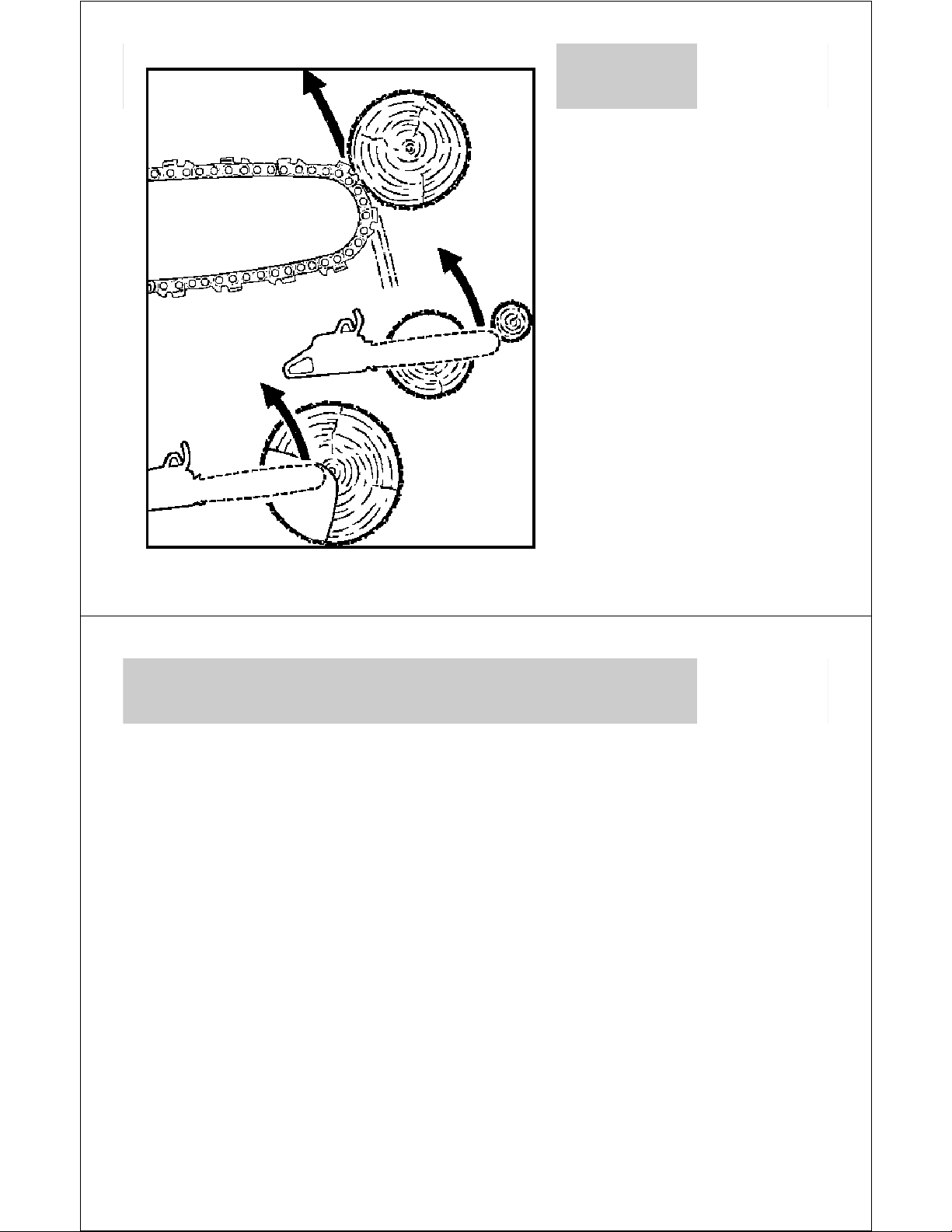

Kickback occurs when the

moving saw chain near

the upper quadrant of the

bar nose contacts a solid

object or is pinched

The greater the force of

the kickback reaction, the

more difficult it becomes

for the operator to control

the saw

Chain and Bar Color Code Marking

STIHL saw chain will have a green

or yellow tie strap to indicate if the

chain is low-kickback or other than

low-kickback

The bar will have two green or

yellow dots on the powerhead end

of the bar to identify if the bar is a

reduced kickback bar or not

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 5

Install the Bar and Chain

5

STIHL recommends the use of reduced

kickback bars and low kickback chains on

all STIHL chain saws

Yellow bar and chain combinations are for

trained professionals with extraordinary

cutting needs

Be sure the bar and chain are within the

recommended length for the model of

saw being assembled

Always wear gloves when handling saw

chain to protect your hands from the

sharp cutters

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Install Bar & Chain: Quick Chain Adjuster

Install the tensioning gear and fasten the screw securely

The bar can be installed with the STIHL logo facing up or

down; periodically the bar should be flipped to spread the

wear over both edges of the bar

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 6

Install Bar & Chain

6

Make sure the cutters on top of the bar are facing away from

the powerhead!

WRONG

WRONG

CORRECT

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Quick Chain Adjuster (QCA)

The QCA allows the user to adjust the

chain tension without tools

Loosen the wing nut

Rotate the

adjusting wheel

confidential

Tighten the wing nut

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 7

Install Bar & Chain

7

confidential

If the saw does not have a QCA simply remove the 2 bar nuts,

install the bar and chain, making sure the adjusting pin is in the

hole in the bar

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Install Bar & Chain

confidential

Install the cover and the 2 nuts leaving them just snug against

the cover

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 8

Chain Adjustment

8

The 1130 saws have a front

chain tensioner

Most STIHL chain saws have a

side chain tensioner that is more

convenient to use

Saws come with a combination

wrench, commonly referred to as

a “Scrench”, to make bar and

chain service easy to do

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Install Bar & Chain

Adjust the chain tension with the “Scrench” by holding up on

the nose of the bar, tightening the chain tension screw, then

tightening the nuts

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 9

Correct Chain Tension

9

With the chain brake

disengaged, pull the

chain through from the

top side and it should

rotate freely without any

slack appearing

If the chain goes from

tight to loose the

sprocket and chain may

not be of the same pitch,

or the sprocket and chain

may have excessive

wear and no longer have

the same pitch

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Correct Chain Tension

Regardless of bar

length, check for

correct chain tension

by pulling up on the

chain at the center of

the bar

The tension is correct

confidential

when the bottom of the

drive link will just clear

the bar groove

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 10

Cutterless Chain for Service

10

For any chain saw, to properly tune the carb or verify running

RPM at idle and wide open throttle a bar and chain should be

installed

Cutterless chains are available to provide a safe way for the

service technician to do this without fear of the chain coming

into contact with anything

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Chain Brake

confidential

All Current Models of STIHL Chain Saws are Equipped with

the STIHL Quickstop® Chain Braking System

The chain is stopped and locked when the hand guard is

pushed toward the guide bar nose by the left hand – or when

the brake is activated by enough inertia in certain kickback

situations

Brake

Brake

Band

Band

Engaged

Disengaged

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 11

Starting the 1130 Saw

11

Fill the tank with 89

octane brand name fuel

with STIHL two-stroke oil

mixed at a 50:1 ratio, or

use STIHL MotoMix

Add bar oil to the oil tank

for chain lubrication

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Starting the 1130 Saw

Push down on the interlock

on the top of the handle and

then squeeze the throttle all

the way open and hold it

Place the Master Control

confidential

Lever™ in the full choke

position, down to the #1

position

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 12

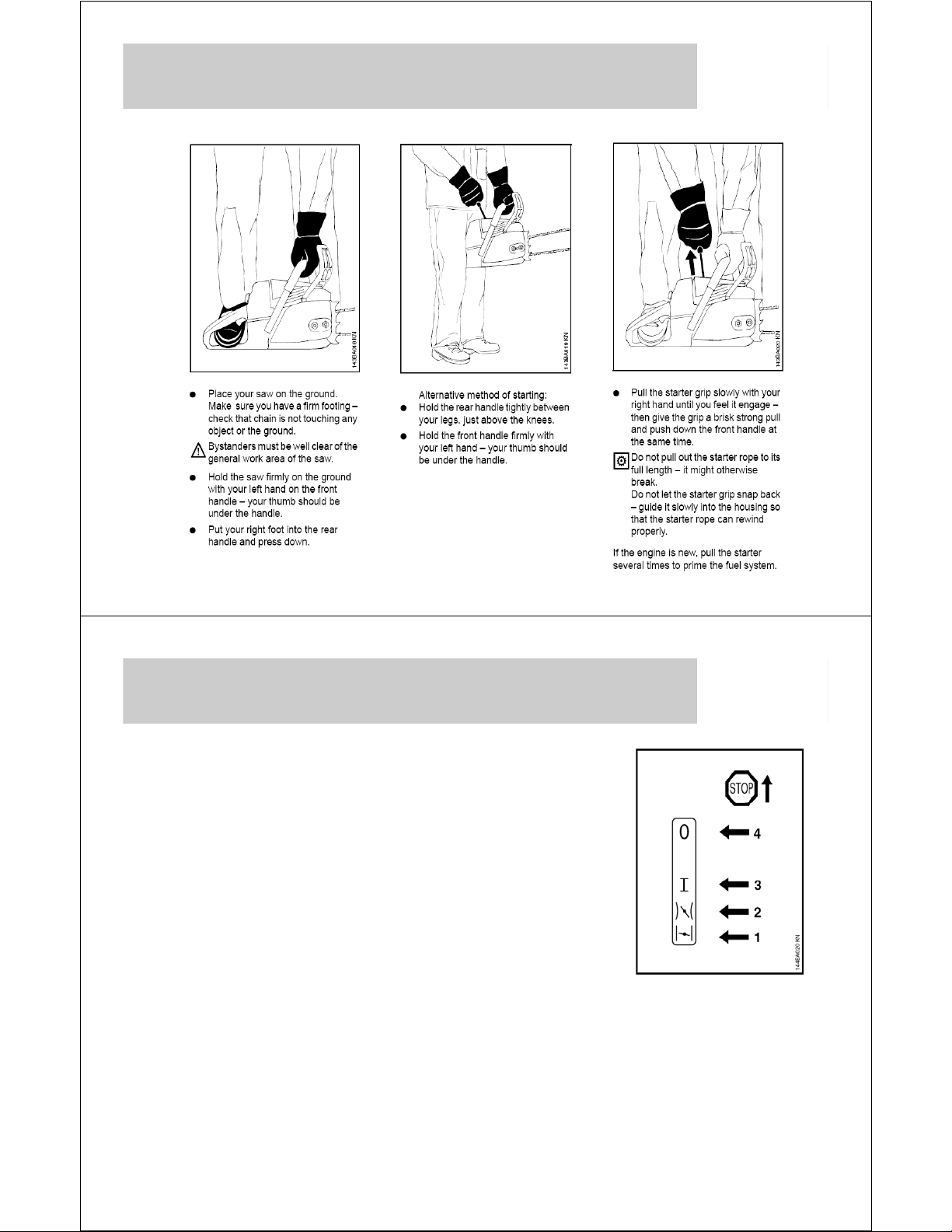

Instruction Manual Directions for Safely

12

Starting a Chain Saw

(Never Drop Start a Chain Saw!)

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

First Time Start-Up

When the engine starts, commonly referred

to as a “false start”, move the Master

Control Lever™ up to #2, to open the

choke and then pull the rope again

The engine should start and run at fast idle

Quickly “blip” the throttle to release the

engine from the fast idle position

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 13

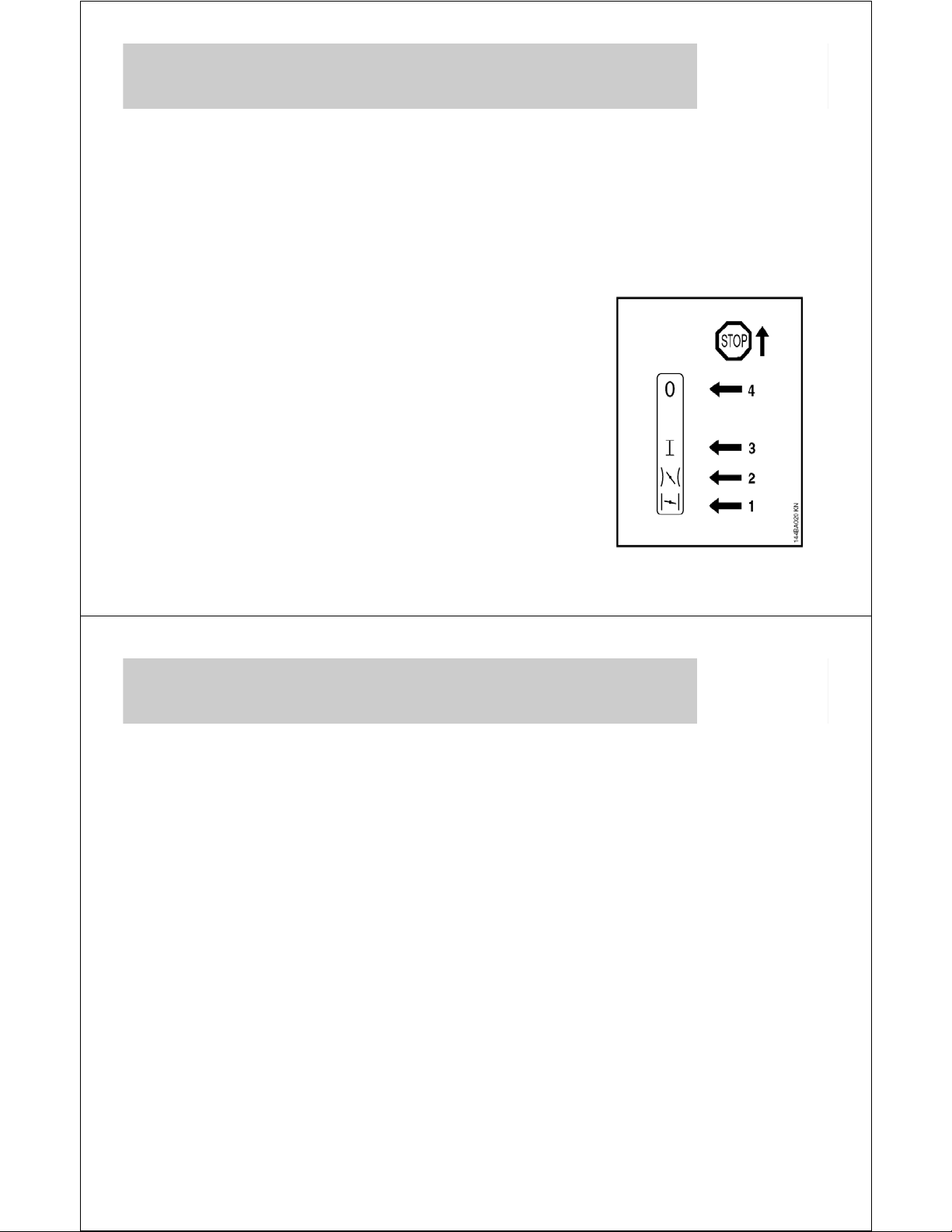

First Time Start-Up

13

If a saw is left in the fast idle position with the chain brake

engaged for even a very short period of time it may overheat

the clutch and chain brake components and possibly ruin the

tank housing as well

To stop the engine raise the Master Control Lever™ to the 0

(off) position, #4 in the picture

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

First Time Start-Up: Warm Up

After the engine has started and the chain brake has been

released, slowly squeeze the throttle about half way open and

then slowly release it back to idle

Do this several times, for at least 20 seconds, to completely

purge any remaining air from the carburetor circuits and to

allow the chain lubrication pump time to prime the system with

bar and chain oil

confidential

Never allow any chain saw engine to run at full throttle without

a load, regardless if it is new or broken-in, for more than a few

seconds

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 14

Bar & Chain Oiler Check

14

Carefully hold the

tip of the bar over a

piece of wood or

cardboard

Run the saw at half

throttle and verify

that a line of bar

and chain lubricant

is being slung off

the end of the bar

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Factory Testing of All STIHL Products

Every engine manufactured by STIHL has been started and

operated in a test cell

The test cell makes carburetor adjustments and verifies

that the engine runs properly at idle, acceleration, and at

full throttle under load

The test cell measures the running performance and

emissions and verifies that they are within acceptable

parameters

confidential

All the dealer needs to do is service the unit and verify it is

ready for the customer to operate it

It is extremely rare that a new unit will need any major

adjustments or repair

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 15

Fault Analysis: STIHL Engine Check

15

When a unit is running poorly or not at all, using a systematic

approach to identify any and all faults present will allow the

Service Technician to quickly and efficiently determine what is

wrong

It is just as

important to

know what

faults are not

present as well

as faults that

do need to be

addressed

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

DG Screws

STIHL uses the DG type of

confidential

fastener in manufacturing because

they cut their own threads the first

time they are used

Notice that the ones holding into

plastic have a different pitch and

profile than the ones that hold into

For Plastic

For Metal

metal

It is imperative that the Service Technician keep track of which

screw is which and not screw them into the wrong base

material or the threads will be damaged

It is also best practice that when starting a DG screw into the

hole, slowly rotate it backwards until it “clicks” to index the

threads, then turn it clockwise to tighten it

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 16

1. Deflectors, Shrouds, Covers, Fasteners

16

Visually look the unit over for damage, missing items, loose

fasteners, or anything else that is obvious

Damaged shroud may be a

safety hazard for the operator

Operated without

an air filter or cover

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

2. Warning Labels

Verify that warning labels

are present and readable

On a chain saw the only

label the service technician

should be concerned with

is the one on the chain

brake handle

If this label is damaged or

worn away, a universal

confidential

replacement label is

available from STIHL

White Chain Saw Label:

0000 967 3613

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 17

3. Cutting Attachment

17

Note type and condition

Inspect for wear or damage

Bar, chain, and sprocket

within wear limits

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

3. Cutting Attachment 4. Belt Tension

If the unit is a trimmer or a concrete saw:

Tap head eyelets worn, spool worn, retainer secure

Belt tension correct; belt worn or frayed

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 18

5. Operator Controls

18

The interlock should

be sticking up out of

the handle, and it

must be depressed

flush with the handle

before the throttle

trigger will move

Be sure the throttle

moves freely

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

5. Operator Controls

The throttle must be squeezed all the way open before the

Master Control Lever™ can be actuated to the full choke

position, then release the throttle and the Master Control

Lever™ should stay in the choke position

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 19

5. Operator Controls

19

Now raise the Master

Control Lever™ up one

notch with your thumb, and

it should stay in the warm

start, half choke position

Now squeeze the trigger

and it should snap up to the

I position automatically

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

5. Operator Controls

Finally the Master

Control Lever™

should easily slide up

to the O position

Any problem with the

Master Control

confidential

Lever™ should be

noted for repair

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 20

5. Operator Controls

20

When the chain

brake handle is

actuated back

and forth, there

should be an

audible “click”

In the forward

position the

sprocket must

not turn

In the back

position the

sprocket must

spin easily

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

6. Verify Anti-vibration Components

Most STIHL chain saws and line

trimmers have an anti-vibration

system that should be inspected for

wear and damage

Some models do not have any anti-

vibration components so this step

would not apply

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 21

6. Verify Anti-vibration Components

21

Hold the bumper spike

against the edge of the

workbench and put

pressure against the

handle assemble

There should be strong

resistance to movement

but there should be

some “give” to the antivibe rubber bushings

There should not be any

looseness to the handle

assembly

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

7. Inspect Starter System

Inspect rope, handle, and eyelet for wear or damage

Pull the rope to it’s full extended length and be sure it is

not about to break at the very end

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 22

8. Inspect Air Filter 9. Inspect Air Filter Housing

22

Remove cover and the top

of the filter is the clean side

There should not be dirt or

debris on this side of the

filter or down in the throat of

the air intake

Remove the filter and the

bottom side is the dirty side

There should be a pinch

mark all the way around the

edge of the filter to seal it

Verify that the housing is not

cracked or damaged

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

10. Carburetor Mixture Screws

Most STIHL products have

mixture adjustment screws on

the carburetor and will be

equipped with a limiter cap on

the H mixture screw and may

have one on the L screw also

The limiter cap allows the

operator to adjust the carb

leaner only to compensate

for operation in high

altitude

confidential

If a cap is missing it should

be considered as a fault and

it is possible the screw may

be set too lean

© STIHL Inc., Virginia Beach, VA 2013 US/STR

L mixture screw with

cone to guide the

screwdriver in place

H mixture screw

with limiter cap in

the up, or released

position to allow the

technician to make

adjustments

Page 23

10. Carburetor Mixture Screws

23

The 1130 saws do not have

mixture screws or limiter caps

Notice that the H and L holes are

not threaded and are blocked off

internally

The only adjustment on a 1130

saw is to set the idle speed with

this screw

It also makes slight mixture

adjustments as the idle speed is

tuned

This carburetor uses a fixed

orifice jet to regulate the amount

of fuel available to the engine

confidential

and is not adjustable

© STIHL Inc., Virginia Beach, VA 2013 US/STR

10. Carburetor Screw Settings

Limiter caps can be removed by

the service technician for carb

service

Removal of this style of limiter

cap is done with the 5910 890

4501 tool

Anytime a cap is removed best

practice is to replace it with a

new one

confidential

4229 121 2701

On the 1130 saws this step

does not apply

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 24

Hose Removal

24

The 5910 890 4501 tool also works well to remove fuel,

impulse, or vent hoses

Use a side to side rocking

motion while pushing against

the hose to walk it off of the

fitting

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

11. Spark Plug Connection

Use a twisting motion to remove the spark plug connection

and be careful not to pull the clip out of the high tension

lead

Inspect it for damage, hardness or cracks

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 25

12. Spark Test

25

Connect a spark

tester and pull the

rope through as if

trying to start the

engine

If no spark is present

try again with a new

plug

A fouled or

defective spark

plug may not show

spark on the tester

even if the ignition

system is OK

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

12. Spark Test

If there is still a no

spark condition with a

new plug, carefully

disconnect the ground

wire from the terminal

on the ignition module

and now see if spark

is present

If there is no spark the

confidential

module is faulty

If there is spark the

stop circuit is faulty

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 26

12. Ignition Shut-Off Function

26

If spark is present then place the Master Control Lever™ in

the off position and pull the rope through and verify that no

spark is present

This verifies that the stop switch and connecting wiring is in

order

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

13. Spark Plug

Verify that the correct plug is installed for an 1130 saw:

Bosch WSR6F STIHL Part Number 1110 400 7005

NGK BPMR7A STIHL Part Number 0000 400 7000

Other units may use a different part number with a different

heat range, so always look it up!

Set all STIHL spark plugs at .020”

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 27

13. Spark Plug Appearance

27

Normal color,

normal electrode

wear due to high

run time

Normal color and

wear

confidential

Heavy

carbon buildup and oil

fouled

Mix ratio

incorrect.

Carbon buildup

due to high run

time

Both of these

plugs have served

their useful life

© STIHL Inc., Virginia Beach, VA 2013 US/STR

14. Muffler

Remove the 2 muffler nuts and

Black, sooty

appearance

Caused by

rich fuel/air

mixture

confidential

deflector plate and inspect the

spark arrester screen

It must be present for all hand

held engines used in the United

States

The screen may be blocked

with carbon deposits

If necessary shine a light

through the screen to verify

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 28

Remove Starter Housing

28

Remove fuel and oil tank caps

Rock the cap retainer to the side

Remove starter housing

Reinstall the caps if necessary to prevent fuel or oil from

running out on the work area

© STIHL Inc., Virginia Beach, VA 2013 US/STR

confidential

15. Cylinder Leak Down Test

This test typically is not

necessary on a two-stroke

engine but can be done to verify

how well the rings are sealing

with the flywheel blocked so the

piston is slightly down from TDC

A leak down test should always

be done on a four-stroke engine

because the piston and rings

cannot be observed visually

The leak down test also verifies

that the intake and exhaust

valves are sealing properly

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 29

16. Inspect Exhaust Port and Piston

29

With the muffler removed use

a flashlight and look through

the exhaust port to be sure

the port is not clogged up

with carbon deposits

Move the piston up and down

and inspect the surface of the

piston skirt for scoring or

damage

A piston in good condition

will still have the radial

machine marks across the

skirt indicating little or no

wear

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

16. Inspect Exhaust Port and Piston

Spray some lubricant on

the rings and when the

flywheel is turned back

and forth slightly it will be

apparent if the rings are

free in the lands

Lower the piston to BDC

confidential

Inspect the intake side of

the cylinder wall for wear

or damage

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 30

17. Cooling System

30

Verify that the cooling fins are in good condition and that the

air path to the flywheel and through the engine from the

flywheel is not blocked or restricted in any way

Verify that the flywheel fins are in good condition

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

18. Magneto Air Gap

Line up the pole shoes in the

flywheel with the magneto

Observe the gap between the

ignition module and the

flywheel

The specification is .008”

It is not absolutely

necessary to measure this

with a gauge, just be sure

confidential

the flywheel is not rubbing

on the module and that the

gap does not look

excessively wide

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 31

19. Fuel Tank

31

confidential

If the tank is empty look down in the tank to see if it appears

contaminated with debris or anything else that shouldn’t be

there

If the unit has fuel in it carefully remove the cap and wave your

hand over the opening while smelling for a sour odor that may

indicate old stale fuel

© STIHL Inc., Virginia Beach, VA 2013 US/STR

19. Fuel Tank

If fuel is present carefully pour the fuel out in a pan and see if

there is trash or debris, or any evidence of other contaminants

such as water in the fuel

This sample is

contaminated with

water and debris

Dispose of fuel properly

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 32

20. Fuel Filter

32

confidential

Use the 5910 893 880 hook tool to fish the fuel filter out of the

tank for inspection

The filter body screen should be clear and in good condition,

and the element may have oil staining but should not be dark

or fouled or have any kind of coating on it

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Pressure Vacuum Tester

0000 850 1300 Pump

With the knurled ring to

the right the gauge

indicates pressure

With the knurled ring to

the left the gauge

confidential

indicates vacuum

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 33

20. Fuel Filter

33

It is a good idea to backflow a fuel filter with the pressure

pump to verify that it is not restricted

Hook up the tester and place the filter on a towel and pump

the tester 2 times

No pressure should build up and if the filter is wet with fuel

it should clearly flow out

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

21. Pressure Test Fuel Line

confidential

Connect the pressure tester to the fuel line where the filter was

removed and gently pump it up no higher than 10 PSI

If it holds steady then the fuel line is OK, and the carb itself

passes the pressure test

If the gauge does not

hold then either the fuel

line or the carb may be

leaking, so isolate the

fuel line and test it by

itself to determine

where the fault is

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 34

Remove Carb

34

Hold the choke shutter closed and carefully remove the link

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Remove Carb

Carefully slide the fuel line off of the fitting

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 35

Remove Carb

35

Hold the throttle wide open and carefully remove the link

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Remove Carb

Gently pry the Master Control Lever™ up on the left side

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 36

Remove Carb

36

Slide the Master Control Lever™ to the left and let it hang

out of the way by the ground wire

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Remove Carb

Hold the fuel line down out of the way and slide the carb off

of the studs

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 37

21. Pressure Test Fuel Line

37

confidential

To test the fuel line by itself, plug one end and test through the

other

It should hold steady at 10 PSI

© STIHL Inc., Virginia Beach, VA 2013 US/STR

22. Pressure Test Tank

Be sure there is no fuel

in the tank before

applying any pressure to

the fuel tank!

The pressure test

verifies that the tank

does not have a leak in

any location, such as a

grommet, seam, cap or

confidential

hose

Apply about 8 PSI max and it must hold steady

If it leaks down at all use soapy water in a spray bottle

to locate where the leak is

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 38

23. Vacuum Test Tank Vent

38

Reverse the tester into

vacuum mode and pump

hard and fast to see the

needle indicates that

some negative pressure

is present in the tank

Stop pumping and watch

the gauge and the

needle should move

back up towards zero

rapidly

If the needle does not

leak back to zero quickly

the tank vent must be

replaced and then re-test

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

24. Inspect Intake Side Of Piston

With the carb removed

look through the inlet port

and rotate the crankshaft

to inspect the intake side

of the piston

The machine marks

should be present on a

piston in good condition

Scoring or a dull gray

appearance would

indicate lack of

lubrication, dirt ingestion,

or possibly other

problems that would

prevent the engine from

running properly

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 39

25. Impulse Signal Present

39

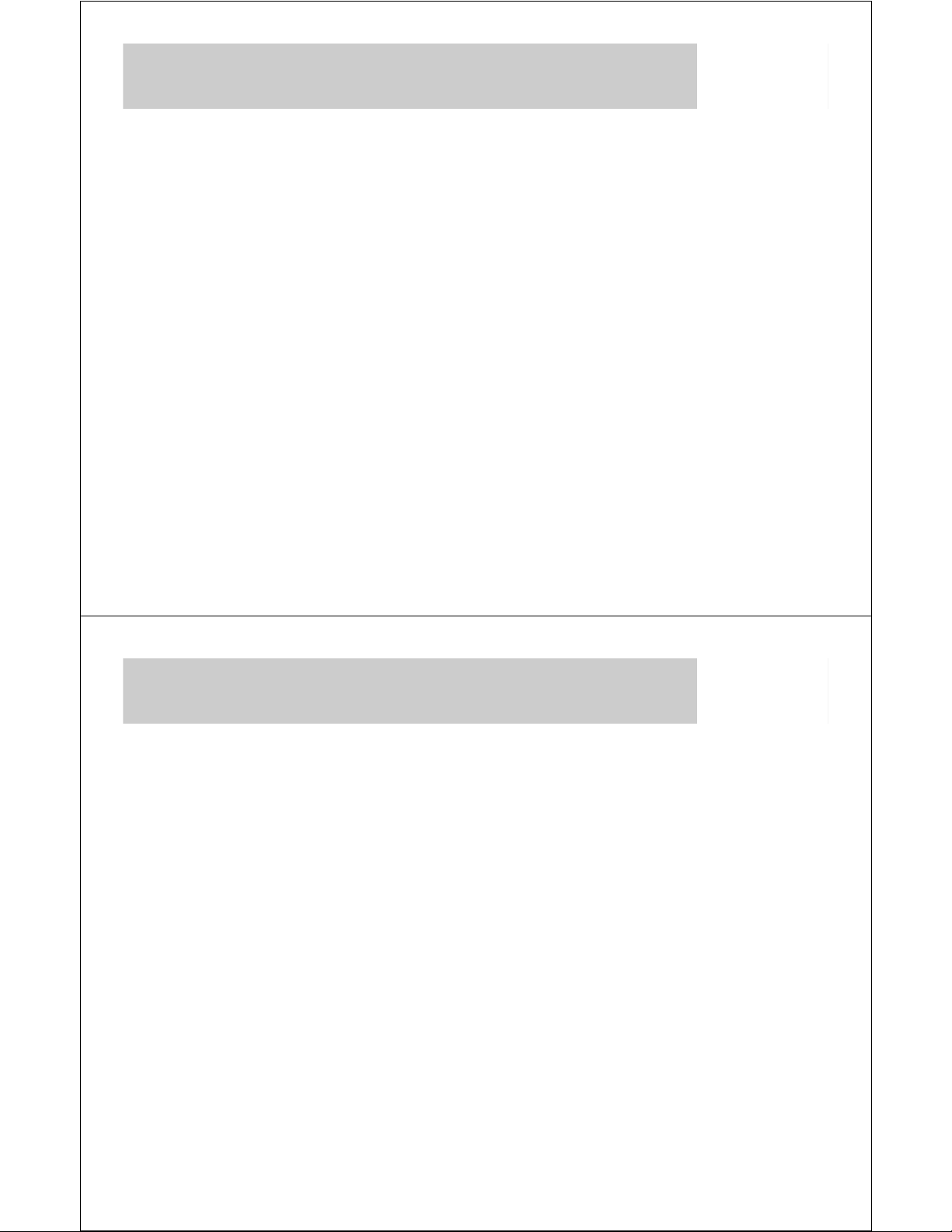

Most two-stroke engines have a

passageway between the

crankcase and the fuel pump side of

the carburetor to cause the fuel

pump diaphragm to flex back and

forth with the pressure/vacuum that

is created by the piston moving up

and down

It is rare that there is no impulse

signal, but always verify that it is

present because no impulse signal

will cause a hard to diagnose,

unusual running behavior that will

appear to be carburetor related

confidential

For this blower engine the

impulse signal comes out

through the flange here:

© STIHL Inc., Virginia Beach, VA 2013 US/STR

25. Impulse Signal Present

confidential

For the 1130 saw, remove the white plastic sealing ring, use

the tapered adapter and connect the tester to the impulse port

By hand, rotate the flywheel back and forth and the needle on

the gauge should bounce back and forth indicating the

impulse signal is present

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 40

26. Vacuum and Pressure Test of Crankcase

40

confidential

A two-stroke engine needs an air tight crankcase since the air

fuel mix is coming through the crankcase on the way to the

combustion chamber

Test to verify that there are no leaks at places like gaskets or

RTV silicone sealed mating surfaces, and that crankshaft seals

are not leaking under pressure or vacuum

Block off the exhaust port

by slipping a rubber block

off plate in between the

cylinder and the adapter

plate, then install spacers

and snug up the nuts

while pulling the rubber up

to get a complete seal

© STIHL Inc., Virginia Beach, VA 2013 US/STR

26. Vacuum and Pressure Test of Crankcase

The Service Manual for each

model describes how to do

this test and gives the part

number for the adapters

For the 1130 saw the special

adapter for the carb side is

part number 1118 850 4200

confidential

Be sure the spark plug is

installed and tight

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 41

26. Vacuum and Pressure Test of Crankcase

41

Use the tester to pull a 0.5 bar vacuum; it should hold steady

or not leak back to 0.3 bar within 20 seconds

Rotate the crankshaft back and forth while the crankcase is

under vacuum to verify that the seals are holding properly

Pump 0.5 bar of pressure into the engine and it should hold

steady for at least 20 seconds

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Pressure Test Results

confidential

If the unit fails the pressure test check obvious things first, such

as the rubber sealing plate on the exhaust and the spark plug,

by spraying with soapy water and looking for bubbles

If they are sealing properly then the engine may need to be

taken apart far enough to be able to check the crankshaft seals

and the seal between the cylinder and the crankcase

If an engine leaks under vacuum but holds under pressure it is

most likely a crankshaft seal

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 42

27. Crankshaft and Bearing Condition

42

See if the flywheel moves in and out or up and down

There should not be any loose play in the crankshaft

bearings

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

28. Carburetor

confidential

Pressure test the carb no higher than 10 PSI and it should hold

steady

Open and close the butterfly and it should open smoothly

Verify that the throttle shaft does not have any excessive side

to side play

Inspect the carb for any physical damage

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 43

29. Other Observations; Final Running

43

This is where any other observations about the unit not

specifically covered by one of the numbered items on the

STIHL Engine Check can be recorded

Once repairs have

been made the last

part of the STIHL

Engine Check

document can be used

as a quality control

check to be sure the

engine starts easily

and is running to

specification

confidential

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Final Check: Roll Out Test

With the engine warmed

up and idling, and the

chain brake engaged on

a saw, slowly roll the

engine over so one side

faces the ground

Now roll it back upright,

then roll the other side

towards the ground

Idle RPM should not

change more than 200300 RPM

confidential

If the idle changes the

engine may have an air

leak or other fault

© STIHL Inc., Virginia Beach, VA 2013 US/STR

Page 44

This presentation has been prepared by:

44

Eddie Anderson

Technical Training Supervisor

STIHL Inc.

Virginia Beach, VA

eddie.anderson@stihl.us

© STIHL Inc., Virginia Beach, VA 2013 US/STR

confidential

Loading...

Loading...