Page 1

STIH)

Technical Information

TI_40_2010_13_01_02.fm

englisch / English

New clearing saw STIHL FS 460 C – Series 4147

Contents

1. Overview

2. STIHL M-Tronic

3. Technical description

4. Specifications

5. Cutting attachments

6. Accessories

7. Service accessories

8. Spare parts

9. Servicing

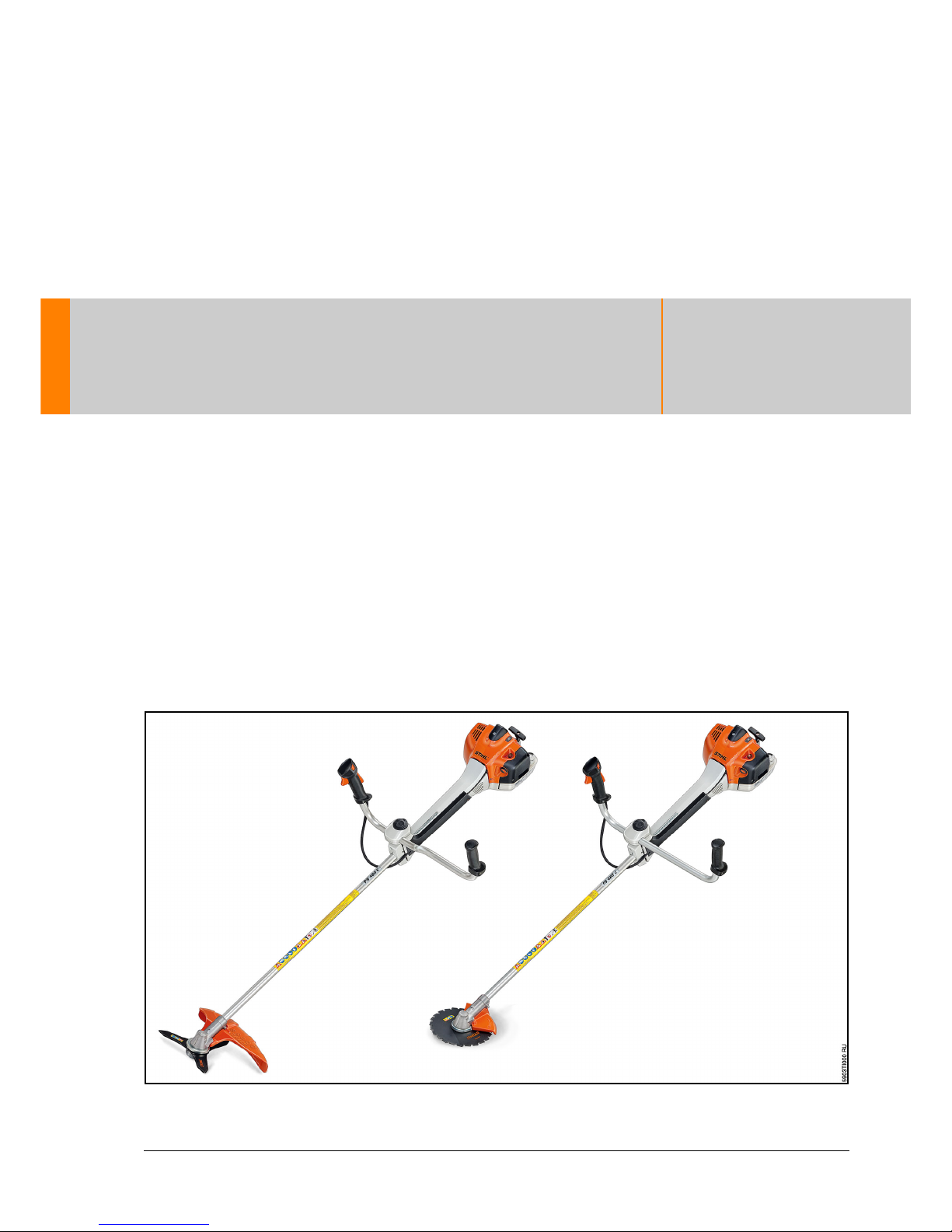

FS 460 C FS 460 C K

40.2010

Page 2

Page 2 Technical Information 40.2010

TI_40_2010_13_01_02.fm

The new clearing saw STIHL FS 460 C is the

newest member of the clearing saw line and, in

future, will be the follow-up model to the

STIHL FS 450.

The STIHL FS 460 C stands out because of the

following strengths:

– STIHL M-Tronic – optimal engine performance

at all times, see b 2

– Modern, low-emission 2-MIX engine

– High torque over a wide range of engine speeds

– Easy starting – fewer steps to start

– ErgoStart standard

– Functional, modern shape – outstanding

handling and ergonomics

– Very reliable and rugged

The new clearing saws are ideally suited for

professional users in landscaping and forestry.

Depending on the version, the scope of application

extends from mowing and thinning to mowing tough

grass, clearing scrub and thorny hedges, shredding

and sawing. The clearing saw STIHL FS 460 C with

a short drive tube is designed especially for use in

forests.

1. Overview

The new clearing saw STIHL FS 460 C is available

in various versions with varying features.

1.1 Versions with mowing handlebars

– Versions with varying drive tube lengths,

see b 4.4

– Drive tube diameter: 28 mm

– New, maintenance-free gearbox

– Gearhead angle 35°, see b 3.6.1, b 4.5

– New deflectors and limit stops,

see b 3.7.1, b 5.1

– New, 4-point anti-vibration system - very low

vibration levels, see b 3.8

– Can be used with the new PolyCut 41-3 mowing

head

– New universal harness ADVANCE included,

see b 3.9.1

1.2 Version with sawing handlebars for use

in forests

– Version with short drive tube, see b 4.4

– Drive tube diameter: 28 mm

– New, maintenance-free gearbox

– Gearhead angle 25°, see b 3.6.2

– New limit stops, see b 3.7.2, b 5.2

– New, 4-point anti-vibration system – very low

vibration levels, see b 3.8

– Only for sawing

– New forestry harness ADVANCE included,

see b 3.9.2

Page 3

Technical Information 40.2010 Page 3

TI_40_2010_13_01_02.fm

2. STIHL M-Tronic

The FS 460 C is the first STIHL clearing saw to be

equipped with the innovative M-Tronic fully

electronic engine management system. It regulates

the ignition timing and electronically adjusts the fuel

flow, taking external conditions into account.

Electronic cold / warm start detection permits a

position "Start } " on the choke lever for starting the

engine and ensures easy starting with fewer pulls of

the starter rope. The very good acceleration is

realized using the electronic controller. By means of

the engine temperature and speed, the control unit

continually checks the operating state of the

clearing saw and adjusts the fuel flow so that

optimal engine power is always available. The

electronic memory (memory function) remembers

the settings from the last time the machine was

used. Thus if the machine is restarted under the

same general conditions, the full power of the

engine is available immediately.

According to the system of product names for

convenience features (C-versions), machines with

M-Tronic are denoted with an "M".

2.1 Functional description

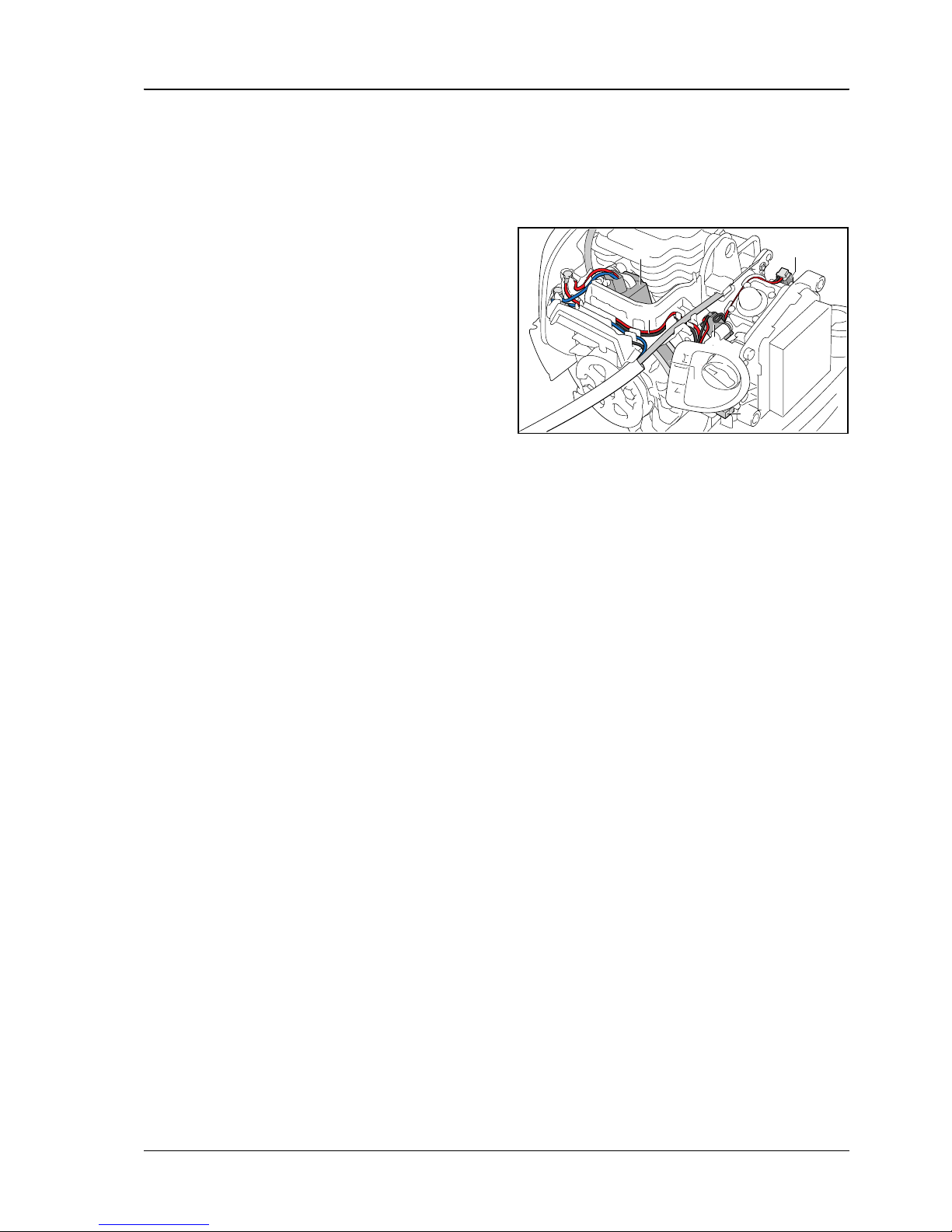

2.2 Components

Control unit (1)

Control center for the optimum adjustment of fuel

flow, the exact ignition timing and the memory

function.

Second pair of poles (2)

Supplies power to the control unit and solenoid

valve

Wiring harness (3)

Connects control unit, solenoid valve, micro switch

(integrated in switch gear) and diagnostic jack

Solenoid valve (4)

Electronically switched solenoid valve adjusts the

overall fuel flow in milliseconds – this permits

adjustment from 0 % to 100 % fuel

Micro switch (5)

Reports the position of the choke shutter – start

detection;

the micro switch (5) is integrated in the switch gear

Diagnostic jack (6)

Preparation for a software-based diagnostic unit

6

5

4

1

2

5903TI001 KN

3

Page 4

Page 4 Technical Information 40.2010

TI_40_2010_13_01_02.fm

2.2.1 Starting

Set the choke lever to } (Start) – choke shutter is

closed. Simultaneously, the micro switch on the

switching device is closed. During starting and if the

engine is running, the control unit is powered via the

second pair of poles.

The following processes occur within the space of

milliseconds.

The microprocessor detects that the micro switch

has been actuated and thus the choke shutter is

closed and computes the necessary amount of fuel

and the ignition timing for the start.

During starting, the fuel-air mixture in the carburetor

is highly concentrated ("enriched") – a large quantity

of fuel flows through the solenoid valve. After initial

combustion, the quantity of fuel is reduced. The

engine does not stall out because the fuel-air

mixture is too rich; it keeps running and can be

accelerated immediately. After the throttle trigger is

actuated, the choke shutter and micro switch open

and the choke lever jumps to the operating

position F . The control unit receives the information

"choke shutter open" and the microprocessor

adjusts the amount of fuel.

2.2.2 Idle

The target idle speed is controlled by adjusting the

ignition timing and the fuel flow.

The engine speed can be influenced instantly by

adjusting the ignition timing. Changing the fuel flow

only influences the engine speed after 5 to

10 revolutions of the crankshaft.

For this reason, to establish steady idling, the

ignition timing is adjusted first and then the fuel flow.

The fuel flow control is designed so that the target

idle speed is attained with the target ignition timing.

2.2.3 Acceleration

If the control unit detects that the engine is being

accelerated, the ignition timing is set earlier and the

fuel flow is increased – the fuel-air mixture is

enriched. Optimal, spontaneous acceleration.

2.2.4 Full throttle

A regulating cycle only starts if the clearing saw is

operated for approximately 2 seconds under

constant conditions.

The solenoid valve closes for approx. 0.1 seconds –

the current fuel-air mixture is made leaner.

The speed change due to the brief leaning of the mix

is so slight as to be imperceptible to the user.

The resulting engine speed pattern is analyzed by

the microprocessor.

The following results are possible:

Engine speed increases

. The mix was too rich before the solenoid valve

closed – the fuel flow is reduced for next phase

of operation

Engine speed decreases

. The mix was too lean before the solenoid valve

closed – the fuel flow is increased for the next

phase of operation

Engine speed does not change

. The current carburetor setting is optimal – the

current setting will be maintained

2.2.5 Cut-off speed

The cut-off speed is kept constant by controling the

fuel-air mixture and the ignition timing.

Page 5

Technical Information 40.2010 Page 5

TI_40_2010_13_01_02.fm

2.2.6 Advantages

Easy starting

With M-Tronic there is only one start position on the

choke lever because the system detects cold or

warm starts and electronically computes the exact

fuel flow. Starting with a few pulls of the starter rope

and immediate full throttle.

Permanent optimum engine performance

By means of the engine temperature and speed, the

control unit continually checks the operating state of

the clearing saw and adjusts the fuel flow for

constant optimum engine performance.

Very good acceleration

The FS 460 C accelerates spontaneously and

quickly by virtue of electronic ignition timing control

and fuel flow adjustment.

No manual carburetor adjustments

M-Tronic electronically adjusts the fuel-air mixture in

the carburetor: for all operating states such as start,

idle, part throttle and full throttle as well as taking

into account the external conditions, e. g., use at

varying altitudes, changing temperatures or fuel

quality (caloric value – energy content of the fuel,

alcohol content, knock resistance).

Memory function (electronic memory)

M-Tronic remembers, for an unlimited period of

time, the settings from the last time the clearing saw

was used and retrieves them the next time the

clearing saw is started. Thus full engine power is

available immediately each time the machine is

started under the same external conditions.

3. Technical description

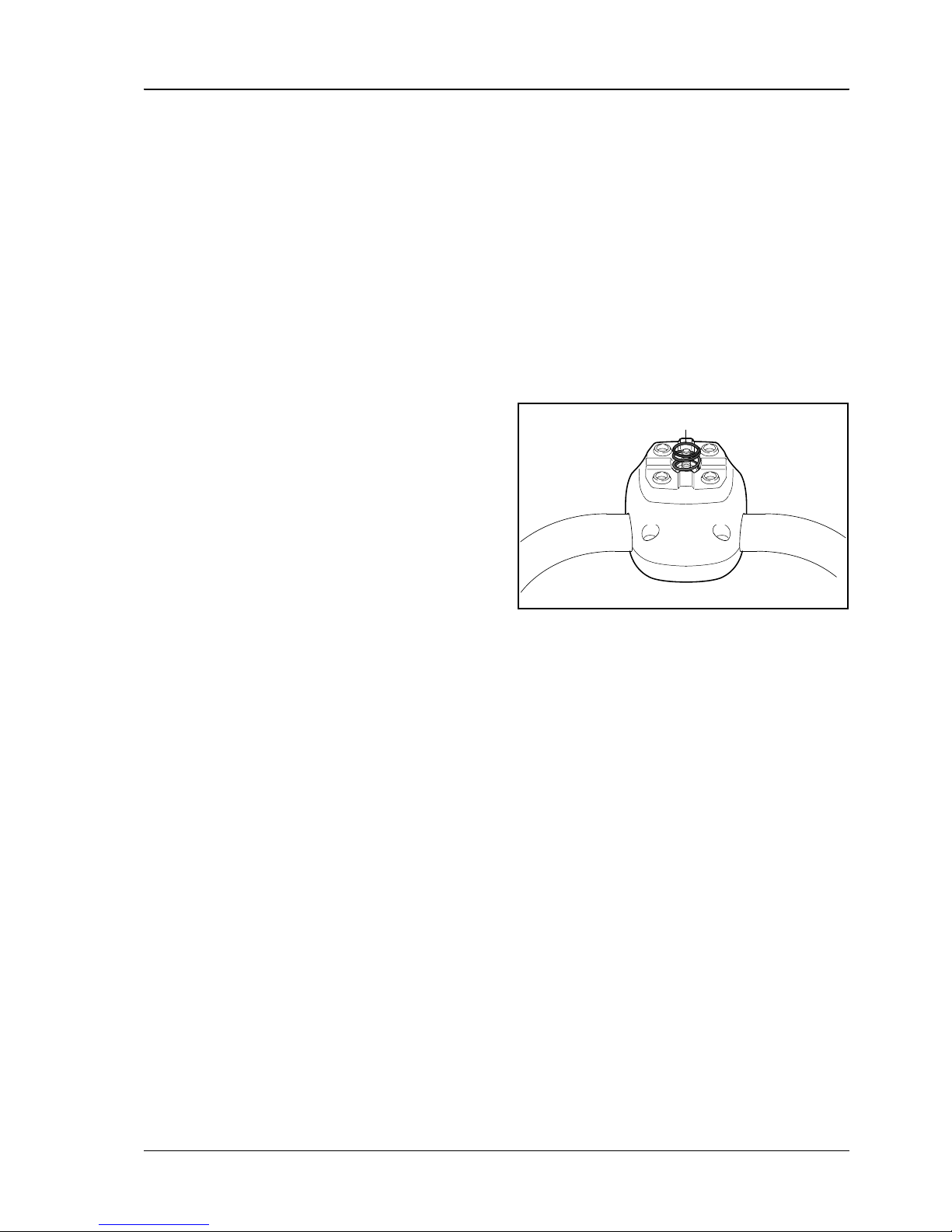

3.1 Attaching the bicycle handle with

rotating handlebar support

The clamps are already attached to the handlebar at

the factory.

. Attaching the control handle

To assemble the rotating handlebar support, the

clamps must be fitted with a spring and fastened to

the handlebar support on the machine.

. Remove spring (1) from the set of parts included

with the machine

. Fit spring (1) in the lower clamp (2)

. Carry out further assembly in accordance with

Instruction Manual

1

2

317TI003 KN

Page 6

Page 6 Technical Information 40.2010

TI_40_2010_13_01_02.fm

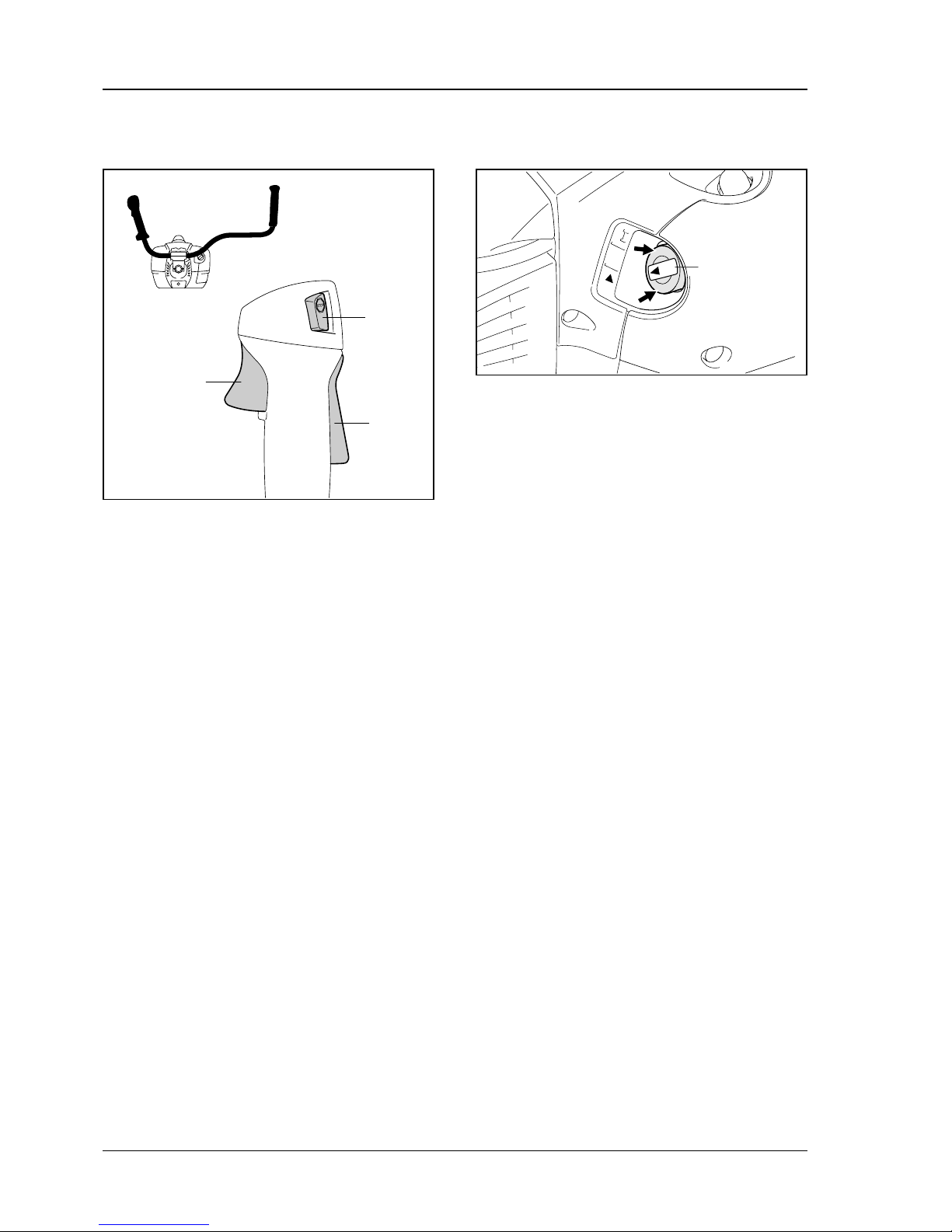

3.2 Operating elements

1 Throttle trigger lockout

2 Throttle trigger

3 Stop switch – with the positions for Run and

Stop. To switch off the engine, the stop switch

(STOP) must be pressed.

3.3 Stop switch function

When the stop switch is not actuated, it is in the

position Run: The ignition is switched on – the

engine is ready for starting and can be started. If the

stop switch is actuated, the ignition is switched off.

Once the engine comes to a standstill, the ignition is

automatically switched on again.

3.4 Choke lever

To start the engine, the choke lever (1) must be

pressed in at the edge (arrows) and rotated to the

position }. Once the engine has been started and

the throttle trigger lockout and throttle trigger have

been pressed, the choke lever automatically returns

to the position Run F

. It is not necessary to move the

choke lever to Run F by hand.

After a cold start, let the engine warm up with a few

load cycles.

1

2

3

317TI005 KN

1

5903TI002 KN

Page 7

Technical Information 40.2010 Page 7

TI_40_2010_13_01_02.fm

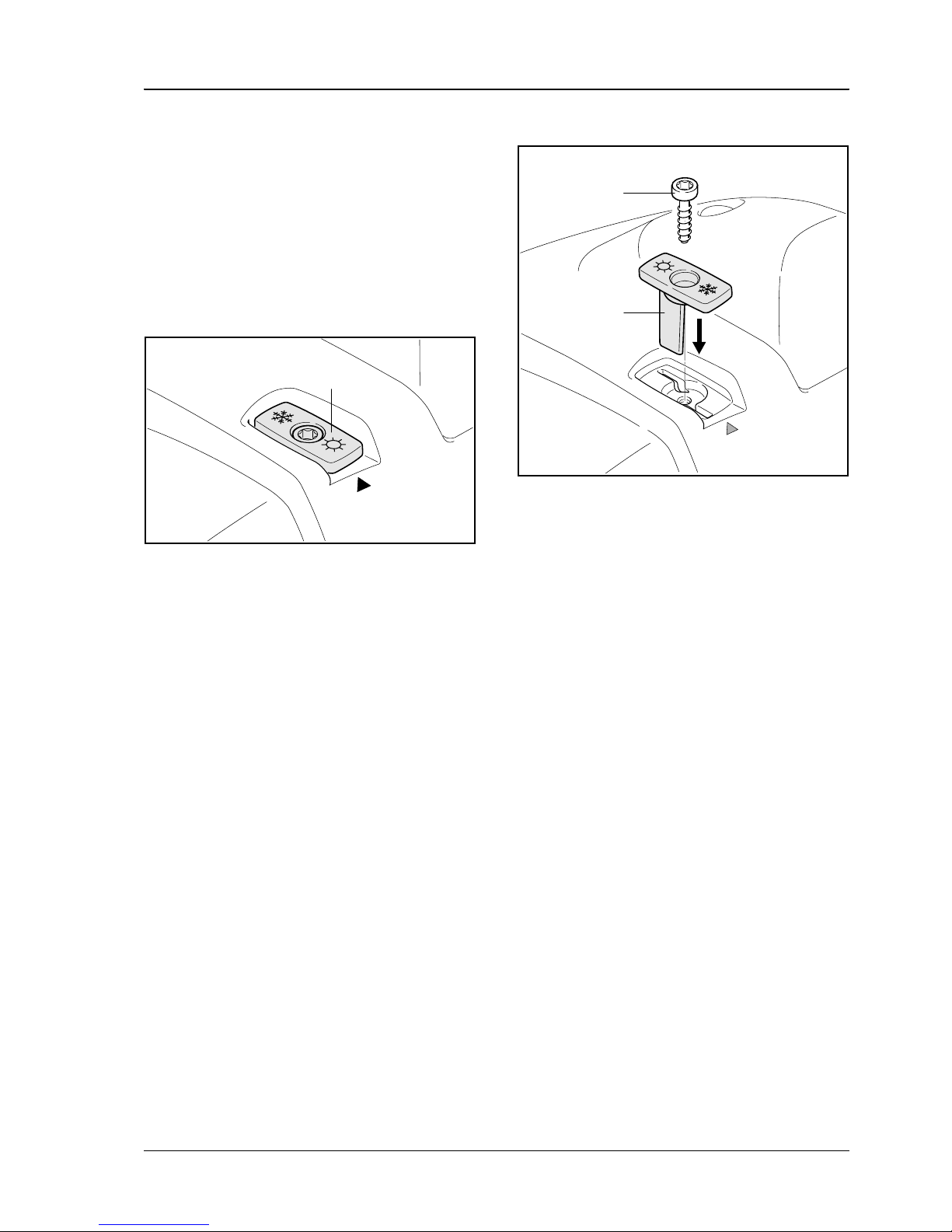

3.5 Summer and winter operation

3.5.1 At temperatures below +10 °C

Pre-heat carburetor

Moving a shutter causes heated air to be drawn in

from around the cylinder and mixed with cold air in

order to prevent carburetor icing.

An arrow on the shroud (1) shows the position of the

shutter (2) for summer or winter operation.

Key to symbols

Symbol "Sun" = summer operation

Symbol "Snowflake" = winter operation

. Unscrew and remove screw (3) on shutter

. Remove shutter (2) from the shroud

. Rotate shutter (2) from summer position to

winter position and reinsert

. Screw the screw (3) through the shutter into the

shroud

3.5.2 At temperatures between +10 °C and

+20 °C

Within this temperature range, the machine can

normally be operated with the shutter (2) in summer

position. Change the position of the shutter as

necessary.

2

317TI008 KN

1

2

3

317TI009 KN

Page 8

Page 8 Technical Information 40.2010

TI_40_2010_13_01_02.fm

3.5.3 At temperatures above +20 °C

. Always return the shutter (2) to summer position

. Do not use the machine in winter operation at

temperatures above +20 °C, otherwise there is

a risk of engine damage due to overheating

3.5.4 At temperatures below -10 °C

Under extreme winter conditions with the following

conditions

– Temperatures below -10 °C

– Powdered or drifting snow

use of the "cover plate kit", which is available as a

special accessory, is recommended.

3.5.5 Cover plate kit

The "cover plate kit" contains the following parts for

covering the machine:

4 Cover plate for partially covering the slits in the

starter housing

5 Filter insert made of cloth and plastic for the air

filter

– O-ring for the filler cap

– Information sheet describing conversion of the

machine

After installation of the cover plate kit:

. Set shutter (2) to winter operation

. if the chain saw is extremely cold (frost

formation) – after starting, bring the engine up to

operating temperature at increased idle speed

(cutting attachment rotates!)

3.5.6 At temperatures above -10 °C

. Reconvert the machine and replace the parts

from the "cover plate kit" with the parts for

summer operation

The O-ring installed on the filler cap with the "cover

plate kit" can remain on the machine.

Depending on the ambient temperature:

. Set shutter to summer or winter operation

2

317TI010 KN

2

4

5

317TI011 KN

Page 9

Technical Information 40.2010 Page 9

TI_40_2010_13_01_02.fm

3.6 Gearbox

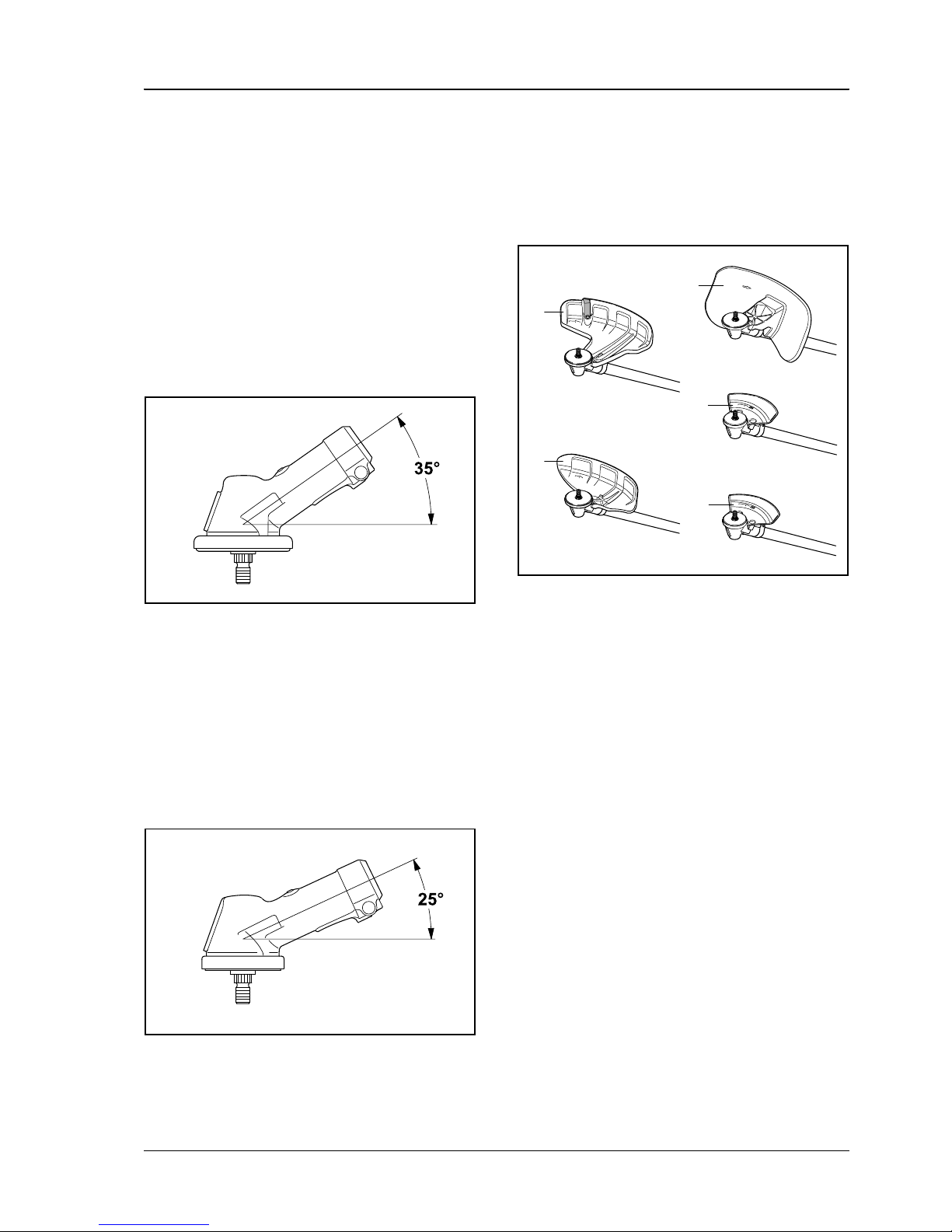

3.6.1 Versions with standard drive tube and

long drive tube, see b 4.4

A new, maintenance-free gearbox with a gearhead

angle of 35° is used for the series FS 460 C in the

version with a standard drive tube and long drive

tube.

Gearhead angle 35°

3.6.2 Version with short drive tube, see b 4.4

A new, maintenance-free gearbox with a gearhead

angle of 25° is used for the series FS 460 C in the

version with a short drive tube and sawing

handlebars.

Gearhead angle 25°

3.7 New deflectors and limit stops

3.7.1 Versions with standard drive tube and

long drive tube, see b 4.4

The optimal deflector is available for each

application:

1 Deflector for mowing heads,

Diameter of cutting circle: 480 mm

2 Deflector for grass cutting blades and brush

knives

3 Deflector for shredder blade

4 Limit stop 200 mm for circular saw blades

5 Limit stop 225 mm for circular saw blades

All new deflectors and limit stops are fastened with

3 screws secured against loss.

For details about the approved deflectors and limit

stops, see b 5.1.

317TI012 KN

317TI013 KN

317TI014 KN

5

4

3

2

1

Page 10

Page 10 Technical Information 40.2010

TI_40_2010_13_01_02.fm

3.7.2 Version with short drive tube, see b 4.4

1 Limit stop 200 mm for circular saw blades

2 Limit stop 225 mm for circular saw blades

The new limit stops are fastened with 3 screws

secured against loss.

For details about the approved deflectors and limit

stops, see b 5.2.

3.8 4-point anti-vibration system

Four anti-vibration elements for damping vibrations

are installed between the engine and the drive tube,

In addition to rubber buffers and annular buffers as

anti-vibration elements in the area of the engine,

steel springs are used as anti-vibration elements in

the area of the handlebars. The 4-point antivibration system ensures a very low vibration level,

optimal control and reduced operating effort.

3.9 New full harnesses

3.9.1 Universal harness ADVANCE

– Functional, modern shape – outstanding

handling and ergonomics

– Very low weight: 0.74 kg

– Available in two sizes

The new universal harness ADVANCE includes an

exhaustive information sheet about putting on the

harness properly and the ways in which it can be

adjusted.

1

2

317TI015 KN

317TI017 KN

317TI018 KN

Page 11

Technical Information 40.2010 Page 11

TI_40_2010_13_01_02.fm

3.9.2 Forestry harness ADVANCE

– Functional, modern shape – outstanding

handling and ergonomics when sawing

– Central chest clasp

– Closed hip belt

– Freely suspended leg panel – high freedom of

movement

– Low weight: 0.97 kg

– Available in two sizes

The new forestry harness ADVANCE includes an

exhaustive information sheet about putting on the

harness properly and the ways in which it can be

adjusted.

4. Specifications

4.1 Engine

4.2 Fuel system

The STIHL one-cylinder, two-stroke engine uses

mixture lubrication and requires a mixture of

gasoline and engine oil.

4.2.1 Fuel

4.2.2 Fuel tank

317TI019 KN

STIHL single cylinder two-stroke engine

Displacement: 45.6 cm

3

Bore: 44 mm

Stroke: 30 mm

Engine power to ISO 8893: 2.2 kW

Speed at max. output: 9500 rpm

Max. torque: 2.7 Nm

Idle speed: 2700 rpm

Clutch engages at: 4200 rpm

Cut-off speed: 12300 rpm

Starter

Starter rope: 3.0 mm x 1010 mm

Pull-out reserve: 1 to 2 turns

Mixing fuel: See Instruction Manual

Capacity: 750 cm

3

(0.75 l)

Page 12

Page 12 Technical Information 40.2010

TI_40_2010_13_01_02.fm

4.2.3 Carburetor

4.3 Ignition system

4.4 Handle version, drive tube, antivibration

system

1)

Version with standard drive tube

2)

Version with long drive tube

3)

Version with short drive tube

4.5 Gearbox

1)

Version with standard drive tube, see b 4.4

2)

Version with long drive tube, see b 4.4

3)

Version with short drive tube, see b 4.4

4)

maintenance-free

4.6 Weight / dimensions

1)

Version with standard drive tube, see b 4.4

2)

Version with long drive tube, see b 4.4

3)

Version with short drive tube, see b 4.4

4.7 Sound and vibration levels

See Instruction Manual; for further details

concerning compliance with the Physical Agents

Directive Vibration 2002/44/EC, see

www.stihl.com/vib/

All-position diaphragm carburetor with integral fuel

pump

No manual carburetor

adjustment required see b 2.2.6

Service work on carburetor see b 9.9

Ignition module with integrated electronic speed

limiter

Spark plug (suppressed): NGK CMR6H

Electrode gap: 0.5 mm

Handle version: Mowing

handlebars

1) 2)

Sawing

handlebars

3)

Drive tube diameter: 28 mm

Drive tube length: 1360 mm

3)

1475 mm

1)

1535 mm

2)

Antivibration system: 4-point

Drive shaft: Hollow shaft, multi-

splined

Transmission ratio: 1:1.45

1) 2)

1:1.27

3)

Gearhead angle: 35°

1) 2)

25°

3)

Max. output shaft speed

(tool):

8450 rpm

1) 2)

9690 rpm

3)

Lubricant: STIHL gear lubricant

for brushcutters

Fill quantity: 9.8 g

Top-up quantity: --

4)

dry, without cutting attachment

and deflector:

8.4 kg

3)

8.5 kg

1)

8.6 kg

2)

Total length without cutting

attachment:

1675 mm

3)

1790 mm

1)

1850 mm

2)

Page 13

Technical Information 40.2010 Page 13

TI_40_2010_13_01_02.fm

5. Cutting attachments

Observe the permissible combinations of cutting

attachments, deflectors, limit stops and harnesses,

which vary depending on the version. Observe the

additional information in the Instruction Manual

5.1 Versions with standard drive tube and

long drive tube, see b 4.4

5.1.1 Mowing heads and deflector

Full harness must be used.

5.1.2 Grass cutting blades, brush knives and

deflector

Full harness must be used.

5.1.3 Shredder blade and deflector

Full harness must be used.

Designation Part number

1 Mowing head

STIHL SuperCut 40-2 4003 710 2140

2 Mowing head

STIHL AutoCut 40-2 4003 710 2125

3 Mowing head

STIHL AutoCut 40-4 4005 710 2100

4 Mowing head

STIHL TrimCut 41-2 4003 710 2104

5 Mowing head

STIHL PolyCut 41-3 4003 710 2113

6 Deflector only for mowing

heads 4147 710 8100

4

1

5

6

3

2

5903TI003 KN

Designation Part number

7 Grass cutting blade 230-4 4000 713 3801

8 Grass cutting blade 255-8 4000 713 3802

9 Grass cutting blade 250-40

Spezial 4000 713 3806

10 Brush knife 305-2 Spezial 4000 713 4103

11 Brush knife 300-3 4119 713 4100

12 Deflector for grass cutting

blades and brush knives 4147 710 8101

Designation Part number

13 Shredder blade 270-2 4000 713 3903

14 Deflector for shredder

blade 4147 710 8102

9

11

10

7

8

12

5903TI004 KN

13

14

5903TI005 KN

Page 14

Page 14 Technical Information 40.2010

TI_40_2010_13_01_02.fm

5.1.4 Circular saw blades and limit stop

Full harness must be used.

5.2 Version with short drive tube, see b 4.4

5.2.1 Circular saw blades and limit stop

Full harness must be used.

Designation Part number

15 Circular saw blade 200-44,

scratcher tooth 4000 713 4200

16 Circular saw blade 200-22,

chisel tooth 4119 713 4200

17 Limit stop 200 4147 710 8200

18 Circular saw blade 225-48,

scratcher tooth 4000 713 4205

19 Circular saw blade 225-24,

chisel tooth

4110 713 4204

4000 713 4207

20 Circular saw blade 225-36,

carbide tipped 4000 713 4211

21 Limit stop 225 4147 710 8201

15

16

17

18

19

20

21

5903TI006 KN

Designation Part number

1 Circular saw blade 200-44,

scratcher tooth 4000 713 4200

2 Circular saw blade 200-22,

chisel tooth 4119 713 4200

3 Limit stop 200 4147 710 8210

4 Circular saw blade 225-48,

scratcher tooth 4000 713 4205

5 Circular saw blade 225-24,

chisel tooth

4110 713 4204

4000 713 4207

6 Circular saw blade 225-36,

carbide tipped 4000 713 4211

7 Limit stop 225 4147 710 8211

1

2

3

4

5

6

7

317TI027 KN

Page 15

Technical Information 40.2010 Page 15

TI_40_2010_13_01_02.fm

6. Accessories

Designation Part number Use

STIHL gear lubricant for brushcutters Lubrication between rope rotor and starter post

– Tube 80 g 0781 120 1117

– Tube 225 g 0781 120 1118

STIHL special lubricant 0781 417 1315 Coating the rewind spring in the starter

Cover plate kit 4147 007 1001 Under extreme winter conditions

Full harnesses:

– Universal harness ADVANCE 4147 710 9002

– Universal harness ADVANCE XXL 4147 710 9004

– Forestry harness ADVANCE 4147 710 9003

– Forestry harness ADVANCE XXL 4147 710 9009

Chest strap 0000 790 7700 for universal harness ADVANCE

Tool backpack 4147 881 5700

Page 16

Page 16 Technical Information 40.2010

TI_40_2010_13_01_02.fm

7. Service accessories

7.1 New special tools

7.2 Existing special tools

The existing special tools are listed in the Service

Manual for STIHL FS 240 C, FS 260 C, FS 360 C,

FS 410 C, FS 460 C.

Designation Part number Use

1 Setting gauge 0000 890 6400 Setting the air gap between ignition module and

flywheel

2 Press sleeve 4147 893 2400 Press in oil seal

3 Flange 5910 850 4201 Leak testing

4 Puller 5910 890 4408 Removing the drive pinion of the gearbox

5 Sleeve 5910 893 1709 Mounting the hookless snap ring

6 Ring 5910 893 7005 Place on the clutch housing to protect the guide

sleeves

7 Puller 5910 890 4503 Removing the flywheel and the starter-side half of the

crankcase

2

3

1

4

5

6

7

317TI028 KN

Page 17

Technical Information 40.2010 Page 17

TI_40_2010_13_01_02.fm

7.3 Aids

8. Spare parts

The spare parts lists will be available in time for the

market launch and are already contained on the

03/2010 edition of the STIHL Service

Communication System DVD.

9. Servicing

The specific national safety regulations and the

safety instructions in the instruction manual must be

observed if the machine has to be started up during

servicing.

9.1 Troubleshooting plan

The flow charts that follow deal with specific parts

diagnosis and troubleshooting for the M-Tronic

engine management system.

The flow charts help you to take the correct step at

the correct time.

Designation Part number Use

Set of gaskets 4147 007 1600 Engine

Set of carburetor parts 4147 007 1700 Carburetor

Grease (225 g tube) 0781 120 1111 Lubr i c a ting oil se als, s l i d i ng and bear i n g

points

Press fluid OH 723 0781 957 9000

STIHL gear lubricant for brushcutters Lubricating the gearbox and lubrication

between the rope rotor and starter post

– Tube 80 g 0781 120 1117

– Tube 225 g 0781 120 1118

STIHL multi-purpose grease Lubricating the drive shaft

– Tube 80 g 0781 120 1109

– Tube 225 g 0781 120 1110

Tube of sealant Dirko HT red 0783 830 2000 Sealing the crankcase

Standard solvent-based degreasant not

containing any chlorinated or

halogenated hydrocarbons

Cleaning mating surfaces and

carburetor, cleaning the crankshaft stub

and the cone in the flywheel

Page 18

Page 18 Technical Information 40.2010

TI_40_2010_13_01_02.fm

9.1.1 Engine does not start

Is it possible to start the

engine?

no

Move choke lever to position }

Troubleshooting completed

Check ignition system

according to "Flow chart

ignition system troubleshooting“,

see Service Manual

Check ignition

(spark plug, spark plug boot, ignition

spark)

Ignition spark

present?

Mechanically check start detection

(

b 9.6.1)

Clean switch gear

replace if necessary

Electrically check start detection

(

b 9.6.2)

yes

Mechanically

OK?

Are target values

attained?

Look for a fault in the fuel path,

check engine for leaks

Replace switch gear if necessary

no

yes

no

no

Engine does not start

Is it possible to start

the engine?

yes

yes

no

Check solenoid valve (b 9.5)

Are target values

attained?

Replace switch gear and/or

carburetor

yes

yes

no

Page 19

Technical Information 40.2010 Page 19

TI_40_2010_13_01_02.fm

9.1.2 Engine does not start in position }

Is it possible to start

the engine?

Troubleshooting completed

Mechanically check start detection

(

b 9.6.1)

Clean switch gear

replace if necessary

Electrically check start detection

(

b 9.6.2)

yes

Mechanically

OK?

Are target values

attained?

Look for a fault in the fuel path

(inlet needle, lever, spring,

membrane),

check engine for leaks

Replace switch gear if necessary

yes

no

no

Engine does not start in position

} –

engine floods. The flooded engine can

be started in position F

yes

no

Page 20

Page 20 Technical Information 40.2010

TI_40_2010_13_01_02.fm

9.1.3 Engine speed drops under load –

low power

Look for a fault in the fuel path,

check engine for leaks

Check air filter, replace if necessary

Troubleshooting completed

Cut-off speed =

12300 rpm?

yes no

Engine speed drops under load – low

power

Remove cutting attachment, all

mounting hardware and thrust plate.

Let the machine run three to four

times for approx. 30 s in the cut-off

range

Page 21

Technical Information 40.2010 Page 21

TI_40_2010_13_01_02.fm

9.1.4 Ignition – no ignition spark

Is it possible to start

the engine?

no

Move choke lever to position }

Troubleshooting completed

Check the flywheel

(two pairs of poles?)

Combination

OK?

Check air gap

(control unit/flywheel)

Establish correct control

unit/flywheel combination

yes

Air gap

OK?

Check ignition system

according to "Flow chart

ignition system troubleshooting“,

see Service Manual

Set correct air gap

no

No ignition spark

yes

no

yes

Page 22

Page 22 Technical Information 40.2010

TI_40_2010_13_01_02.fm

9.1.5 Engine stops suddenly

Machine

OK?

Troubleshooting completed

Check fuel path

(fuel pick-up body, tank vent, fuel

hoses)

Service fuel

system

Check screw connection of switch

gear

yes

Fuel path

OK?

Connection

OK?

Tighten screws/bolts and push on

boot all the way,

replace switch gear if necessary

yes

no

no

Engine stops suddenly

no

yes

Mechanically check start detection

(

b 9.6.1)

Clean switch gear

replace if necessary

Electrically check start detection

(

b 9.6.2)

Mechanically

OK?

Replace switch gear if necessary

yes

no

Check solenoid valve (

b 9.5)

Are target values

attained?

Replace switch gear and/or

carburetor

yes

yes

Check engine for leaks

no

no

Are target values attained?

Page 23

Technical Information 40.2010 Page 23

TI_40_2010_13_01_02.fm

9.1.6 Cut-off speed not reached

Check air filter and spark arrestor

screen (present only in some

countries) in muffler,

replace if necessary

Remove cutting attachment, all

mounting hardware and thrust plate.

Let the machine run three to four times

for approx. 30 s in the cut-off range

Cut-off speed =

12300 rpm?

Cut-off speed lower than

12300 rpm

Look for a fault in the fuel path,

check engine for leaks

no

Troubleshooting completed

yes

Check screw connection of switch

gear

Connection

OK?

Tighten screws/bolts and push on

boot all the

way, replace switch gear if

necessary

no

yes

Check start detection (

b 9.6)

Replace switch gear if necessary

yes

no

Are target values attained?

Page 24

Page 24 Technical Information 40.2010

TI_40_2010_13_01_02.fm

9.2 Ohmmeter and plug connections

An ohmmeter (multimeter) with a diode tester is

required for the following test procedures.

To ensure a reliable contact:

– Use appropriate test probes

– Do not widen or bend plugs and connector tags

– Unplug and plug in plug connections by hand

whenever possible in the direction of the

connector tags – do not insert them on a slant or

tilt or widen them

– Plug must be seated firmly

9.3 Checking screwed and plug connections

A reliable connection must be ensured for

communication between control unit, switching

device and solenoid valve. If communication

between control unit and solenoid valve is

interrupted or faulty, the control unit does not initiate

an ignition spark. Thus if there is no ignition spark,

first check the plug connections and wiring harness

between control device and solenoid.

9.3.1 Checking screwed connections

. Screws (1) tight

. Leads (2) completely and firmly in the cable

lugs (3)

9.3.2 Checking plug connection on solenoid

. Plug (4) must be seated completely and firmly in

the recess of the solenoid

9.4 Connecting the M-Tronic test lead to the

diagnostic jack

. Remove the filter cover

. Remove stopper (1) – diagnostic jack is

accessible

. Connect M-Tronic test lead 5910 840 0903 to

the diagnostic jack

After disconnecting the test lead, reseal the

diagnostic jack with the stopper.

2

2

5903TI007 KN

3

1

3

4

5903TI008 KN

5903TI009 KN

1

5903TI010 KN

Page 25

Technical Information 40.2010 Page 25

TI_40_2010_13_01_02.fm

9.5 Checking the solenoid valve

Measure resistance

. Move choke lever to position F

. Connect M-Tronic test lead 5910 840 0903 to

the diagnostic jack, see b 9.4

. Measure resistance between the plugs of the

M-Tronic test lead

Target value: between 28 and 42 ohms

If the target value is not attained, check electrical

leads for interruption, short to voltage and short to

ground see b 9.7.3.

9.6 Checking the start detection system

. Remove the filter cover

. Remove starter

. Remove shroud

9.6.1 Mechanical check

. Set choke lever to position } – the cam (1)

must actuate the pin (2) of the micro switch (3)

9.6.2 Electrical check

. Disconnect the plug (1) from the solenoid (2)

3

1

5903TI012 KN

2

1

5903TI013 KN

2

Page 26

Page 26 Technical Information 40.2010

TI_40_2010_13_01_02.fm

. Unscrew bolts (1)

. Remove blue lead (2) and red lead (3)

. Move choke lever to position }

. Connect M-Tronic test lead 5910 840 0903 to

the diagnostic jack, see b 9.4

Connect M-Tronic test lead to Multimeter:

. Insert black plug in "com" / "ground" jack

. Insert red plug in "volt" / "ohm" jack

. Set multimeter to "diode test"

Test diode on micro switch – follow the direction

in the multimeter Instruction Manual:

If the micro switch (switching device) is intact,

readings will match the following target values:

– Choke lever in position Start } – measurement

in direction of flow

Target value: 0.3 volts to 0.7 volts (direction of

flow)

– Choke lever in position F – reverse-biased

measurement

Target value: 1.2 volts to infinity – observe

display, e.g., display [O.L.] or [1.] (reverse bias)

If target values are not attained, check wiring

harness, see b 9.7.

Replace micro switch (switch gear) if necessary.

9.7 Checking the wiring harness

9.7.1 Checking the ground connection

. Move choke lever to position F

. Measure the resistance between lug (1) and

screw (2) at the control unit.

Target value: < 10 ohms

9.7.2 Checking leads between control unit and

diagnostic jack

. Move choke lever to position F

. Connect M-Tronic test lead 5910 840 0903 to

the diagnostic jack, see b 9.4

. Measure the resistance between red lead (1)

and black plug (2) of the diagnostic cable.

Target value: < 10 ohms

2

3

5903TI014 KN

1

2

5903TI015 KN

1

2

1

5903TI016 KN

Page 27

Technical Information 40.2010 Page 27

TI_40_2010_13_01_02.fm

. Measure the resistance between black lead (3)

and red plug (4) of the diagnostic cable.

Target value: < 10 ohms

9.7.3 Checking leads between solenoid and

diagnostic jack

. Move choke lever to F

. Connect M-Tronic test lead 5910 840 0903 to

the diagnostic jack, see b 9.4

. Disconnect the plug (1) from the solenoid (2)

. Measure the resistance between red lead (3) at

the plug of the solenoid and black plug (4) of the

diagnostic cable.

Target value: < 10 ohms

. Measure the resistance between black lead (5)

at the plug of the solenoid and red plug (6) of the

diagnostic cable.

Target value: < 10 ohms

9.8 Cable routing

9.8.1 Cable routing at the bushing

Leads between diagnostic jack and switch gear

. Insert the thin black lead (1) between diagnostic

jack (2) and switch gear (3) in the guides

. Insert the thin red lead (4) between diagnostic

jack (2) and switch gear (3) in the guides

Make certain that in area (A) the leads (1, 4) are in

two separate guides and in area (B) the leads are in

the same guide – black lead (1) under the red

lead (4).

4

5903TI017 KN

3

1

5903TI013 KN

2

3

5903TI018 KN

4

6

5

5903TI019 KN

A

B

3

4

2

5903TI020 KN

1

Page 28

Page 28 Technical Information 40.2010

TI_40_2010_13_01_02.fm

Leads between diagnostic jack and control unit

. Insert the thick black lead (5) between

diagnostic jack (2) and switch gear (3) in the

guides

. Insert the thick red lead (6) between diagnostic

jack (2) and switch gear (3) in the guides

Make certain that in area (A) the leads (5, 6) are in

two separate guides and in area (B) the leads are in

the same guide – black lead (5) under the red

lead (6).

9.8.2 Cable routing at the switch gear

. Insert the black lead (1) from the plug (2) of the

solenoid in the guide

. Insert the black lead (3) from the diagnostic

jack (4) in the guide

. Insert the red lead (5) from the diagnostic

jack (4) in the guide

. Insert the red lead (6) from the plug (2) of the

solenoid in the guide

9.8.3 Cable routing between switch gear and

solenoid

. Install bushing with switch gear – set choke

lever to position F

. Insert plug (1) at solenoid as far as it will go

. Insert black lead (2) and red lead (3) between

switch gear and solenoid in the guide – black

lead (2) under the red lead (3)

9.8.4 Cable routing in cable holder

. Fasten cable holder (1) to clutch housing with a

screw (2)

. Insert black lead (3) (switch gear) in the guide –

connector tag and terminal socket on the black

lead are welded and cannot be separated

3

B

2

5903TI021 KN

5

6

A

4

1

5903TI022 KN

2

3

5

6

3

1

5903TI023 KN

2

5903TI024 KN

1

2

3

Page 29

Technical Information 40.2010 Page 29

TI_40_2010_13_01_02.fm

. Insert black lead (4) (throttle cable) in the guide

– connector tag and terminal socket on the black

lead are welded and cannot be separated

. Fasten cable lugs and cable holder (1) to the

clutch housing with screw (5)

. Insert blue lead (6) (throttle cable) in the guide –

crimped side of the cable lug facing down

. Insert red lead (7) (switch gear) in the guide –

crimped side of the cable lug facing down

. Insert red lead (8) (control unit) in the guide –

crimped side of the cable lug facing down

. Insert blue lead (9) (control unit) in the guide –

crimped side of the cable lug facing down

. Tighten screws (10)

9.9 Service work on carburetor

Position of the special bolt (1) must not be changed,

because otherwise the factory default setting will no

longer be correct and this can lead to impaired

engine performance.

Solenoid valve (2) must not be dismantled.

9.10 Setting the flywheel air gap

Set the air gap between the arms of the control unit

and the pair of magnetic poles marked "N"/ "S" on

the flywheel – use setting gauge 0000 890 6400

(see b 7.1)

Air gap: 0.30 mm (+0.05 mm/-0.10 mm)

7

1

4

5903TI025 KN

6

5

10

9

8

5903TI026 KN

2

1

5903TI027 KN

5903TI028 KN

Page 30

Page 30 Technical Information 40.2010

TI_40_2010_13_01_02.fm

9.11 Calibrating the control unit

If the control unit or carburetor is replaced during

servicing, the M-Tronic must be calibrated.

. Remove cutting attachment, all mounting

hardware and thrust plate

. Move choke lever to Start }

. Start engine – do not blip the throttle trigger

. Let the engine run for at least 90 seconds in the

start position and then actuate the stop switch –

calibration is completed

The control unit is adjusted to the carburetor while

the engine runs in the position Start }. The engine

must be switched off immediately for the information

to be stored in the control unit.

9.12 Tightening torques

The tightening torques are listed in the Service

Manual for STIHL FS 240 C, FS 260 C, FS 360 C,

FS 410 C, FS 460 C.

9.13 Service notes

Service and repair procedures are included in the

Service Manual STIHL FS 240 C, FS 260 C,

FS 360 C, FS 410 C, FS 460 C.

9.14 Serial number

The serial number is on the bottom of the machine.

9.15 Repair times

The specified repair times apply for trained and

qualified personnel as well as for properly equipped

repair shops.

The repair times are specified in minutes.

* Trial run under load

© ANDREAS STIHL AG & Co. KG, 2010 Technical Documentation

D1/MTK-fr

317TI029 KN

Repair activity FS 460 C

1 Engine, mounting and

dismounting 10

2 Crankcase, pressure test* 100

3 Crankshaft, bearings, pressure

test* 100

4 Sealing rings, pressure test* 60

5 Test crankcase for leaks, trial run 40

6 Cylinder, piston, pressure test* 60

7 Ignition system, contact* 25

8 Fuel supply, tank vent, trial run 35

9 Manifold or flange, pressure test 20

10 Carburetor, test* 25

11 Handlebar and throttle control 10

12 Starter mechanism with trial run 20

13 Clutch, trial run 35

14 Muffler 10

15 Air filter 5

16 Stop switch with trial run 25

17 Clutch housing 35

18 Drive tube and drive shaft 15

19 Replacing the bearing in the drive

tube -

20 Gearbox replacement 5

21 Limit stop or deflector 10

22 Support tube 23 Drive shaft 10

24 Fuel tank 25

25 Shroud 5

Loading...

Loading...