Page 1

{

STIHL FS 40, 50

Instruction Manual

Notice d’emploi

Page 2

G Instruction Manual

1 - 34

F Notice d’emploi

35 - 70

Page 3

Original Instruction ManualPrinted on chlorine-free paper

Printing inks contain vegetable oils, paper can be recycled.

© ANDREAS STIHL AG & Co. KG, 2009

0458-546-8221-A. M0-7.L09.PM.

0000001091_004_GB

FS 40, FS 40 C, FS 50, FS 50 C

English

1

{

Contents

Dear Customer,

Thank you for choosing a quality

engineered STIHL product.

This machine has been built using

modern production techniques and

comprehensive quality assurance.

Every effort has been made to ensure

your satisfaction and troublefree use

of the machine.

Please contact your dealer or our

sales company if you have any

queries concerning your machine.

Your

Hans Peter Stihl

Guide to Using this Manual 2

Safety Precautions and Working

Techniques 2

Approved Combinations of Cutting

Attachment, Deflector, Handle and

Harness 9

Mounting the Loop Handle 10

Mounting the Deflector 10

Mounting the Cutting Attachment 11

Fuel 14

Fueling 15

Starting / Stopping the Engine 17

Operating Instructions 19

Cleaning the Air Filter 19

Engine Management 20

Adjusting the Carburetor 20

Checking the Spark Plug 21

Engine Running Behavior 22

Rewind Starter 22

Storing the Machine 23

Replacing Nylon Line 23

Inspections and Maintenance by

Dealer 26

Maintenance and Care 27

Main Parts 29

Specifications 30

Special Accessories 31

Maintenance and Repairs 32

STIHL Limited Emission Control

Warranty Statement 32

Page 4

FS 40, FS 40 C, FS 50, FS 50 C

English

2

Pictograms

All the pictograms attached to the

machine are shown and explained in this

manual.

Symbols in text

Engineering improvements

STIHL's philosophy is to continually

improve all of its products. For this

reason we may modify the design,

engineering and appearance of our

products periodically.

Therefore, some changes, modifications

and improvements may not be covered

in this manual.

Observe all application local safety

regulations, standards and ordinances.

If you have not used this type of power

tool before: Have your dealer or other

experienced user show you how to

operate your power tool or attend a

special course in power tool operation.

Minors should never be allowed to use a

power tool.

Bystanders, especially childeren, and

animals should not be allowed in the

area where a power tool is in use.

When the machine is not in use, shut it

off so that it does not endanger others.

Secure it against unauthorized use.

The power tool user is responsible for

avoiding injury to third parties or damage

to their property.

Do not lend or rent your machine without

the instruction manual. Be sure than

anyone using your machine

understands the information contained

in this manual.

The use of noise emitting power tools

may be restricted to certain times by

national or local regulations.

To operate the power tool you must be

rested, in good physical condition and

mental health.

If you have any condition that might be

aggravated by strenuous work, check

with your doctor before operating a

power tool.

Persons with pacemakers only: The

ignition system of your power tool

produces an electromagnetic field of a

very low intensity. This field may

interfere with some pacemakers. To

reduce health risks, STIHL recommends

that persons with pacemakers consult

their physician and the pacemaker

manufacturer before operating this tool.

Do not operate the power tool if you are

under the influence of any substance

(drugs, alcohol) which might impair

visions, dexterity or judgment.

Depending on the cutting attachment

fitted, use your trimmer only for cutting

grass, wild growth and similar materials.

It must not be used for any other

purpose because of the increased risk of

accidents and damage to the machine.

Never attempt to modify your power tool

in any way since this may result in

accidents or damage to the machine.

Only use cutting attachments and

accessories that are explicity approved

for this power tool model by STIHL or

Guide to Using this Manual

Warning where there is a risk of

an accident or personal injury or

serious damage to property.

Caution where there is a risk of

damaging the machine or its

individual components.

Safety Precautions and

Working Techniques

Because a trimmer is a

high-speed, fast-cutting

power tool, some special

safety precautions must

be observed to reduce

the risk of personal injury.

It is important you read

and understand the

instruction manual before

using your machine for

the first time and keep it

in a safe place for future

reference. Non-observ-

ance of the safety

precautions may result in

serious or even fatal

injury.

Page 5

FS 40, FS 40 C, FS 50, FS 50 C

English

3

are technically identical. If you have any

questions in this respect, consult a

servicing dealer. Use only high quality

parts and accessories in order to avoid

the risk of accidents and damage to the

machine.

STIHL recommends the use of genuine

STIHL replacement parts. These parts

are specifically designed to match your

machine model and meet your

performance requirements.

The deflector on this trimmer cannot

protect the operator from all objects

thrown by the cutting attachment

(stones, glass, wire, etc.). Such objects

may ricochet and then hit the operator.

Clothing and Equipment

Wear proper protective clothing and

equipment.

Avoid clothing that could get caught on

branches or brush or moving parts of the

machine. Do not wear a scarf, necktie or

jewelry. Tie up and confine long hair

(e.g. with a hair net, cap, hard hat, etc.).

A face shield alone does not provide

adequate eye protection.

Wear hearing protection, e.g. earplugs

or ear muffs.

STIHL offers a comprehensive range of

personal protective clothing and

equipment.

Transporting the Power Tool

Always turn off the engine.

Carry the unit properly balanced by the

drive tube or loop handle.

Transporting in a vehicle: Properly

secure your power tool to prevent

turnover, fuel spillage and damage.

Fueling

Always shut off the engine.before

refueling.

Do not fuel a hot engine – fuel may spill

and cause a fire.

Open the fuel cap carefully to allow any

pressure build-up in the tank to release

slowly and avoid fuel spillage.

Fuel your power tool only in well-

ventilated areas. If you spill fuel, wipe

the machine immediately – if fuel gets on

your clothing, change immediately.

This reduces the risk of unit vibrations

causing the fuel cap to loosen or come

off and spill quantities of fuel.

To reduce the risk of serious of fatal

burn injuries, check for fuel leakage. If

fuel leakage is found, do not start or run

the engine until leak is fixed.

Before Starting

Check that your power tool is properly

assembled and in good condition – refer

to appropriate chapters in the instruction

manual.

Clothing must be sturdy

but allow complete free-

dom of movement. Wear

snug-fitting clothing, an

overall and jacket combi-

nation, do not wear a

work coat.

Wear sturdy shoes with

non-slip soles.

To reduce the risk of

injury from thrown

objects, always wear a

face shield and safety

glasses.

Wear heavy-duty gloves.

546BA001 KN

Gasoline is an

extremely flammable

fuel. Keep clear of naked

flames. Do not spill any

fuel – do not smoke.

After fueling, insert the

fuel cap with hinged grip

(bayonet-type cap) cor-

rectly in the opening, turn

it clockwise as far as stop

and fold the grip down.

Page 6

FS 40, FS 40 C, FS 50, FS 50 C

English

4

– Use only an approved combination

of cutting attachment, deflector,

handle and harness. All parts must

be assembled properly and

securely. To reduce the risk of

injury, never use metal cutting

attachments.

– The stop switch must move easily to

0.

– Smooth action of choke lever,

throttle trigger interlock and throttle

trigger – the throttle trigger must

return automatically to the idle

position. The choke lever must

spring back from the g and <

positions to the run position F when

the throttle trigger interlock and

throttle trigger are squeezed.

– Check that the spark plug boot is

secure – a loose boot may cause

arcing that could ignite combustible

fumes and cause a fire.

– Cutting attachment Check for

correct and secure assembly and

good condition.

– Check protective devices (e.g.

deflector for cutting attachment) for

damage or wear. Always replace

damaged parts. Never operate the

unit with a damaged deflector.

– Never attempt to modify the controls

or the safety devices in any way.

– Keep the handles dry and clean –

free from oil and dirt – for safe

control of the power tool.

– Adjust the harness and handle(s) to

suit your height and reach.

To reduce the risk of personal injury,

do not operate your machine if it is

damaged or not properly assembled.

If you use a shoulder strap or full

harness: Practise removing and putting

down the machine as you would in an

emergency. To avoid damage, do not

throw the machine to the ground when

practising.

Starting the Engine

Start the engine at least 3 meters from

the fueling spot, outdoors only.

Place the unit on firm ground in an open

area. Make sure you have good balance

and secure footing. Hold the unit

securely. The cutting attachment must

be clear of the ground and all other

obstructions because it may begin to run

when the engine starts.

Your trimmer is a one-person unit. To

reduce the risk of injury from thrown

objects, do not allow other persons

within a radius of 15 meters of your own

position – even when starting.

Do not drop start the power tool – start

the engine as described in the

instruction manual.

Check idle speed: The cutting

attachment must not rotate when the

engine is idling with the throttle trigger

released.

To reduce the risk of fire, keep hot

exhaust gases and hot muffler away

from easily combustible materials (e.g.

wood chips, bark, dry grass, fuel).

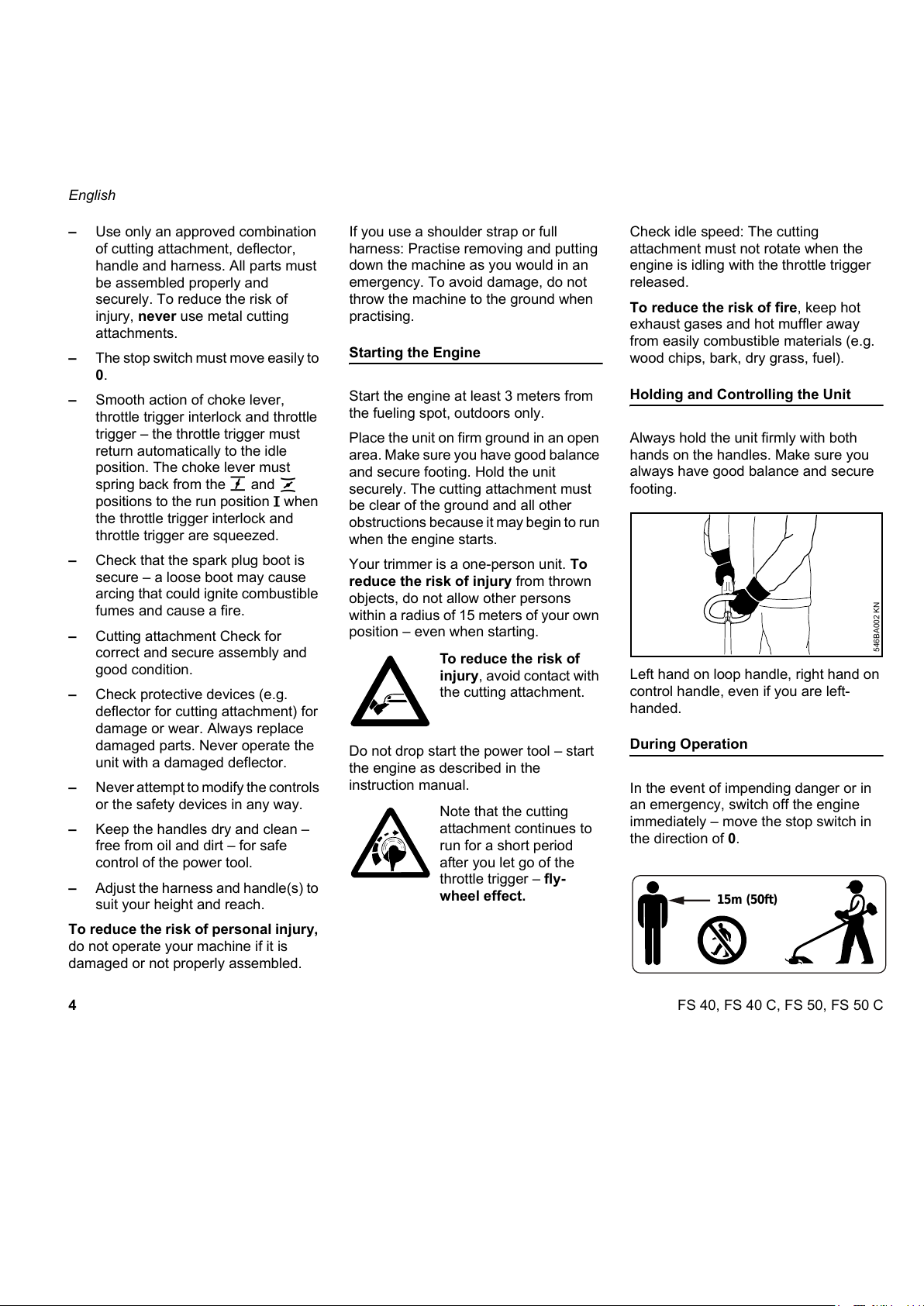

Holding and Controlling the Unit

Always hold the unit firmly with both

hands on the handles. Make sure you

always have good balance and secure

footing.

Left hand on loop handle, right hand on

control handle, even if you are left-

handed.

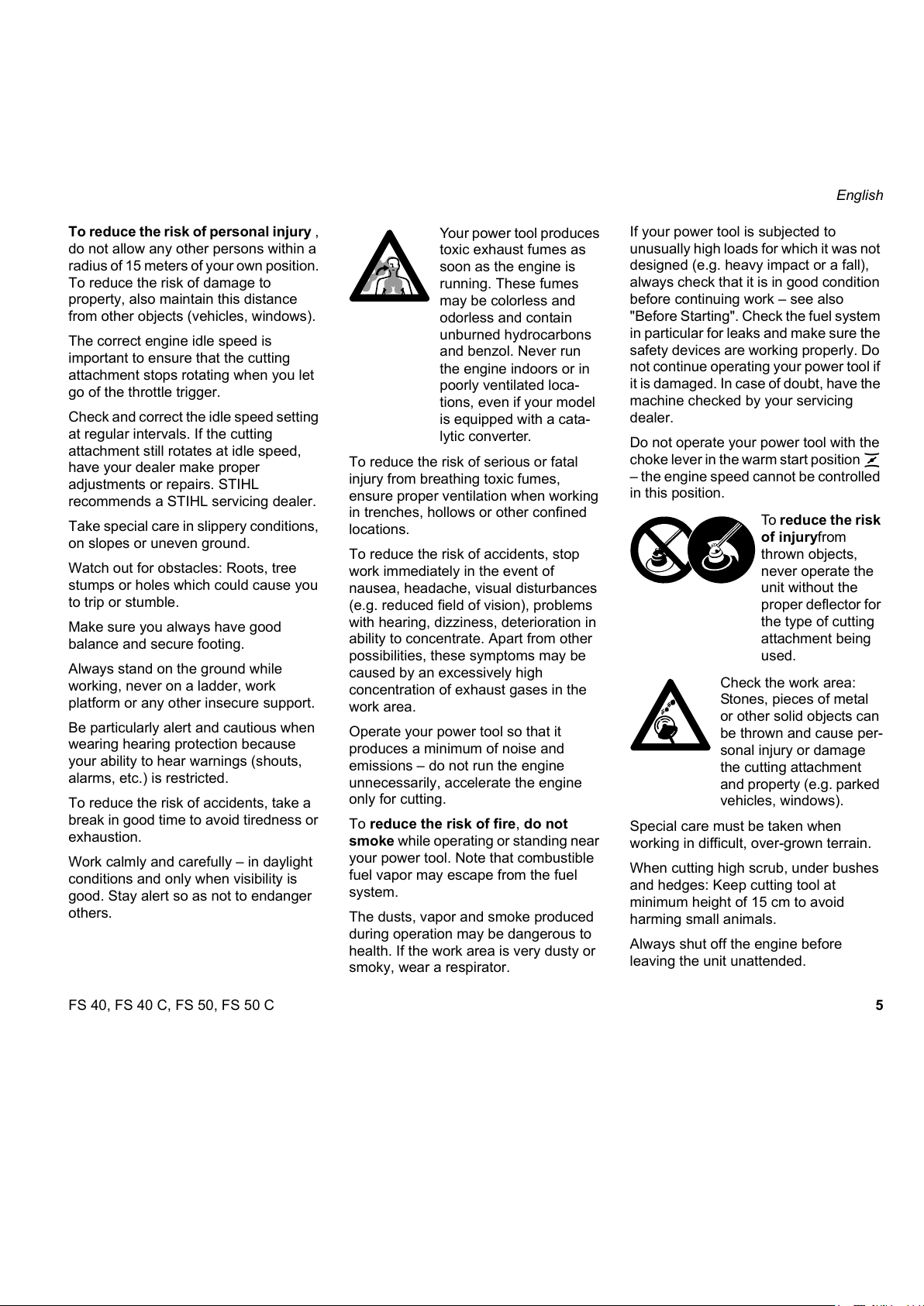

During Operation

In the event of impending danger or in

an emergency, switch off the engine

immediately – move the stop switch in

the direction of 0.

To reduce the risk of

injury, avoid contact with

the cutting attachment.

Note that the cutting

attachment continues to

run for a short period

after you let go of the

throttle trigger – fly-

wheel effect.

546BA002 KN

15m (50ft)

Page 7

FS 40, FS 40 C, FS 50, FS 50 C

English

5

To reduce the risk of personal injury ,

do not allow any other persons within a

radius of 15 meters of your own position.

To reduce the risk of damage to

property, also maintain this distance

from other objects (vehicles, windows).

The correct engine idle speed is

important to ensure that the cutting

attachment stops rotating when you let

go of the throttle trigger.

Check and correct the idle speed setting

at regular intervals. If the cutting

attachment still rotates at idle speed,

have your dealer make proper

adjustments or repairs. STIHL

recommends a STIHL servicing dealer.

Take special care in slippery conditions,

on slopes or uneven ground.

Watch out for obstacles: Roots, tree

stumps or holes which could cause you

to trip or stumble.

Make sure you always have good

balance and secure footing.

Always stand on the ground while

working, never on a ladder, work

platform or any other insecure support.

Be particularly alert and cautious when

wearing hearing protection because

your ability to hear warnings (shouts,

alarms, etc.) is restricted.

To reduce the risk of accidents, take a

break in good time to avoid tiredness or

exhaustion.

Work calmly and carefully – in daylight

conditions and only when visibility is

good. Stay alert so as not to endanger

others.

To reduce the risk of serious or fatal

injury from breathing toxic fumes,

ensure proper ventilation when working

in trenches, hollows or other confined

locations.

To reduce the risk of accidents, stop

work immediately in the event of

nausea, headache, visual disturbances

(e.g. reduced field of vision), problems

with hearing, dizziness, deterioration in

ability to concentrate. Apart from other

possibilities, these symptoms may be

caused by an excessively high

concentration of exhaust gases in the

work area.

Operate your power tool so that it

produces a minimum of noise and

emissions – do not run the engine

unnecessarily, accelerate the engine

only for cutting.

To reduce the risk of fire, do not

smoke while operating or standing near

your power tool. Note that combustible

fuel vapor may escape from the fuel

system.

The dusts, vapor and smoke produced

during operation may be dangerous to

health. If the work area is very dusty or

smoky, wear a respirator.

If your power tool is subjected to

unusually high loads for which it was not

designed (e.g. heavy impact or a fall),

always check that it is in good condition

before continuing work – see also

"Before Starting". Check the fuel system

in particular for leaks and make sure the

safety devices are working properly. Do

not continue operating your power tool if

it is damaged. In case of doubt, have the

machine checked by your servicing

dealer.

Do not operate your power tool with the

choke lever in the warm start position <

– the engine speed cannot be controlled

in this position.

Special care must be taken when

working in difficult, over-grown terrain.

When cutting high scrub, under bushes

and hedges: Keep cutting tool at

minimum height of 15 cm to avoid

harming small animals.

Always shut off the engine before

leaving the unit unattended.

Your power tool produces

toxic exhaust fumes as

soon as the engine is

running. These fumes

may be colorless and

odorless and contain

unburned hydrocarbons

and benzol. Never run

the engine indoors or in

poorly ventilated loca-

tions, even if your model

is equipped with a cata-

lytic converter.

To reduce the risk

of injuryfrom

thrown objects,

never operate the

unit without the

proper deflector for

the type of cutting

attachment being

used.

Check the work area:

Stones, pieces of metal

or other solid objects can

be thrown and cause per-

sonal injury or damage

the cutting attachment

and property (e.g. parked

vehicles, windows).

Page 8

FS 40, FS 40 C, FS 50, FS 50 C

English

6

Check the cutting attachment at regular

short intervals during operation or

immediately if there is a noticeable

change in cutting behavior:

– Turn off the engine. Hold the unit

firmly and wait for the cutting

attachment to come to a standstill.

– Check condition and tightness, look

for cracks.

– Replace damaged cutting

attachments immediately, even if

they have only superficial cracks.

Clean grass and plant residue off the

cutting attachment mounting at regular

intervals – remove any build up of

material from the cutting attachment and

deflector.

To reduce the risk of injury, shut off

the engine before replacing the cutting

attachment.

Do not continue using or attempt to

repair damaged or cracked cutting

attachments by welding, straightening or

modifying the shape (out of balance).

This may cause parts of the cutting tool

to come off and hit the operator or

bystanders at high speed and result in

serious or fatal injuries.

When using mowing heads

Use only the deflector with properly

mounted line limiting blade to ensure the

mowing lines are automatically trimmed

to the approved length.

To reduce the risk of injury, always

turn off the engine before adjusting the

nylon line of manually adjustable

mowing heads

Using the unit with over-long nylon

cutting lines reduces the engine's

operating speed. The clutch then slips

continuously and this causes

overheating and damage to important

components (e.g. clutch, polymer

housing components) – and this can

increase the risk of injury from the

cutting attachment rotating while the

engine is idling.

Vibrations

Prolonged use of the power tool may

result in vibration-induced circulation

problems in the hands ("white finger

disease").

No general recommendation can be

given for the length of usage because it

depends on several factors.

The period of usage is prolonged by:

– Hand protection (wearing warm

gloves)

– Work breaks

The period of usage is shortened by:

– Any personal tendency to suffer

from poor circulation (symptoms:

frequently cold fingers, tingling

sensation)

– Low outside temperatures

– Amount of gripping force (holding

the power tool tightly restricts

circulation)

Users who use the machine periodically

or for long periods or users who

repeatedly experience corresponding

symptoms (e.g., tingling sensation in

fingers), should undergo a medical

examination.

Maintenance and Repairs

Service the machine regularly. Do not

attempt any maintenance or repair work

not described in the instruction manual.

Have all other work performed by a

servicing dealer.

STIHL recommends that you have

servicing and repair work carried out

exclusively by an authorized STIHL

servicing dealer. STIHL dealers are

regularly given the opportunity to attend

training courses and are supplied with

the necessary technical information.

Only use high-quality replacement parts

in order to avoid the risk of accidents

and damage to the machine. If you have

any questions in this respect, consult a

servicing dealer.

STIHL recommends the use of genuine

STIHL replacement parts. These parts

are specifically designed to match your

machine model and meet your

performance requirements.

To reduce the risk of injury from

unintentional engine startup, always

shut off the engine and disconnect

the spark plug boot before performing

any repairs, maintenance or cleaning

work. – Exception: Carburetor and idle

speed adjustments.

Do not turn the engine over on the

starter with the spark plug boot or spark

plug removed since there is otherwise a

risk of fire from uncontained sparking.

To reduce the risk of fire, do not service

or store your machine near open flames.

Check the fuel filler cap for leaks at

regular intervals.

Page 9

FS 40, FS 40 C, FS 50, FS 50 C

English

7

Use only a spark plug of the type

approved by STIHL and make sure it is

in good condition – see "Specifications".

Inspect the ignition lead (insulation in

good condition, secure connection).

Check the condition of the muffler.

To reduce the risk of fire and damage

to hearing, do not operate your

machine if the muffler is damaged or

missing.

Do not touch a hot muffler since burn

injury will result.

Maintenance, replacement, or repair

of the emission control devices and

systems may be performed by any

nonroad engine repair establishment

or individual. However, if you make a

warranty claim for a component

which has not been serviced or

maintained properly or if

nonapproved replacement parts were

used, STIHL may deny coverage.

For any maintenance please refer to the

maintenance chart and to the warranty

statement near the end of the instruction

manual.

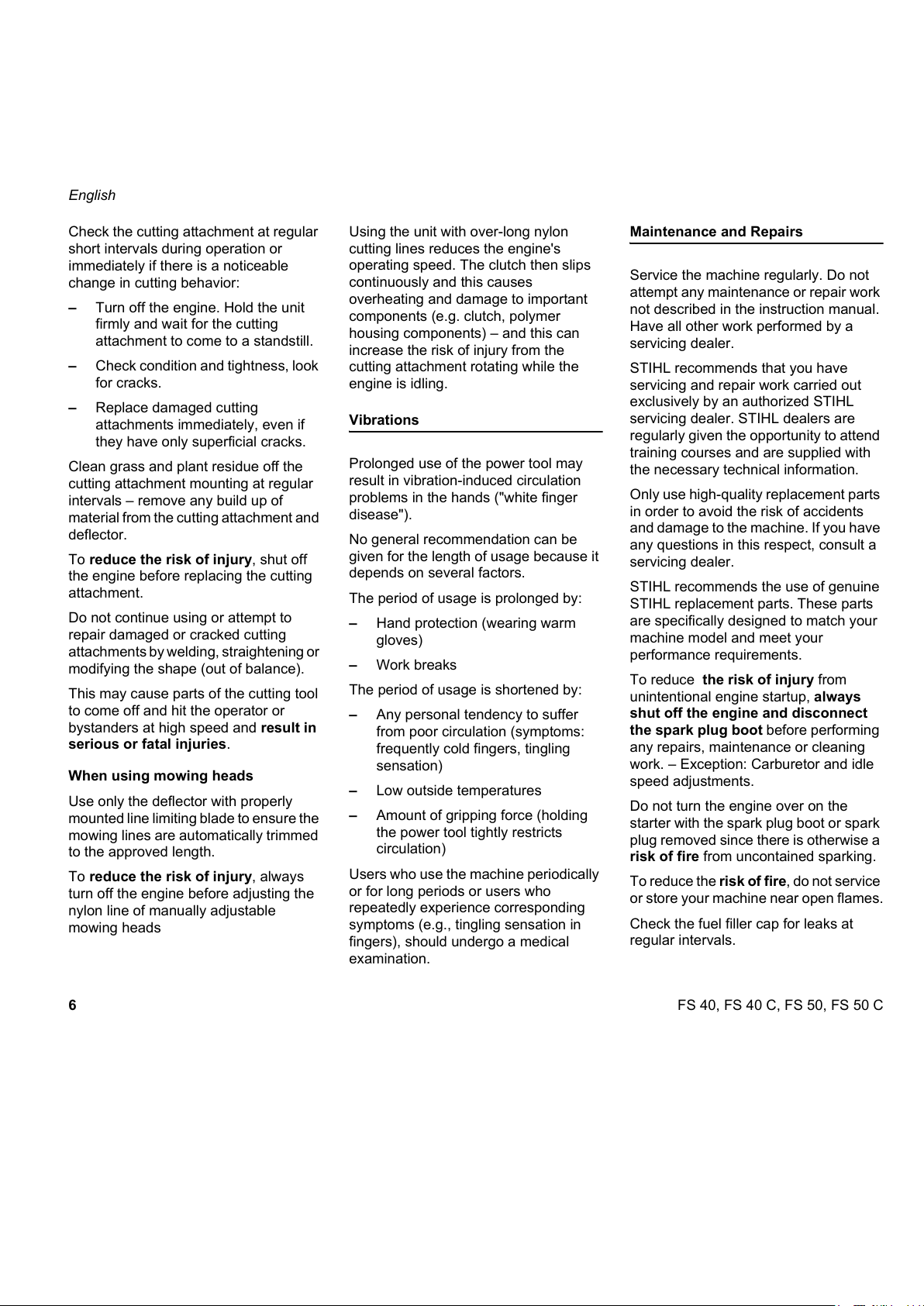

Symbols on Deflectors

An arrow on the deflector (inside and

outside) shows the correct direction of

rotation of the cutting attachments.

Mowing Head with Nylon Lines

Nylon line achieves a soft cut for edging

and trimming around fence posts, trees,

etc. – less risk of damaging tree bark.

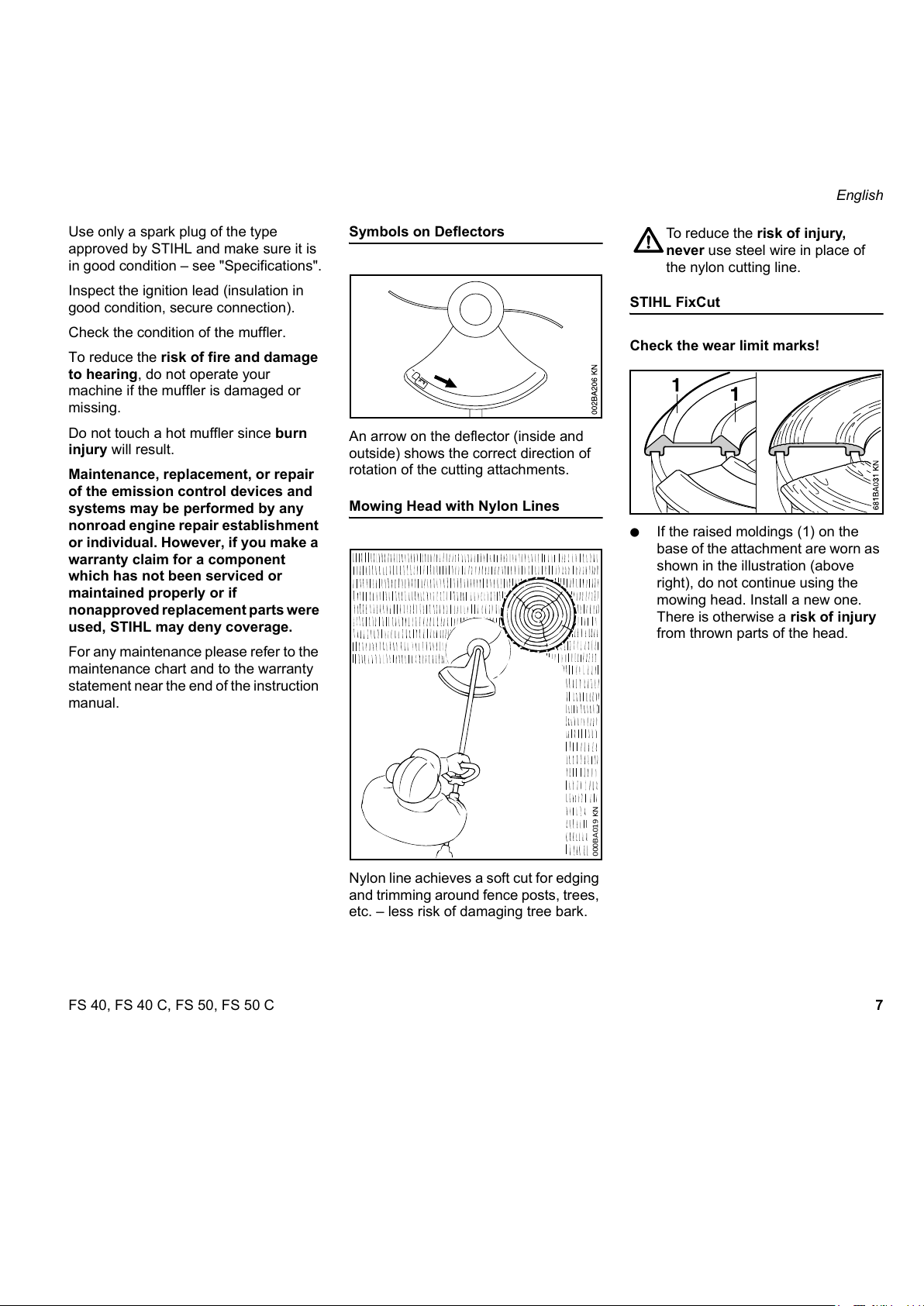

STIHL FixCut

Check the wear limit marks!

N If the raised moldings (1) on the

base of the attachment are worn as

shown in the illustration (above

right), do not continue using the

mowing head. Install a new one.

There is otherwise a risk of injury

from thrown parts of the head.

000BA019 KN

To reduce the risk of injury,

never use steel wire in place of

the nylon cutting line.

Page 10

FS 40, FS 40 C, FS 50, FS 50 C

English

8

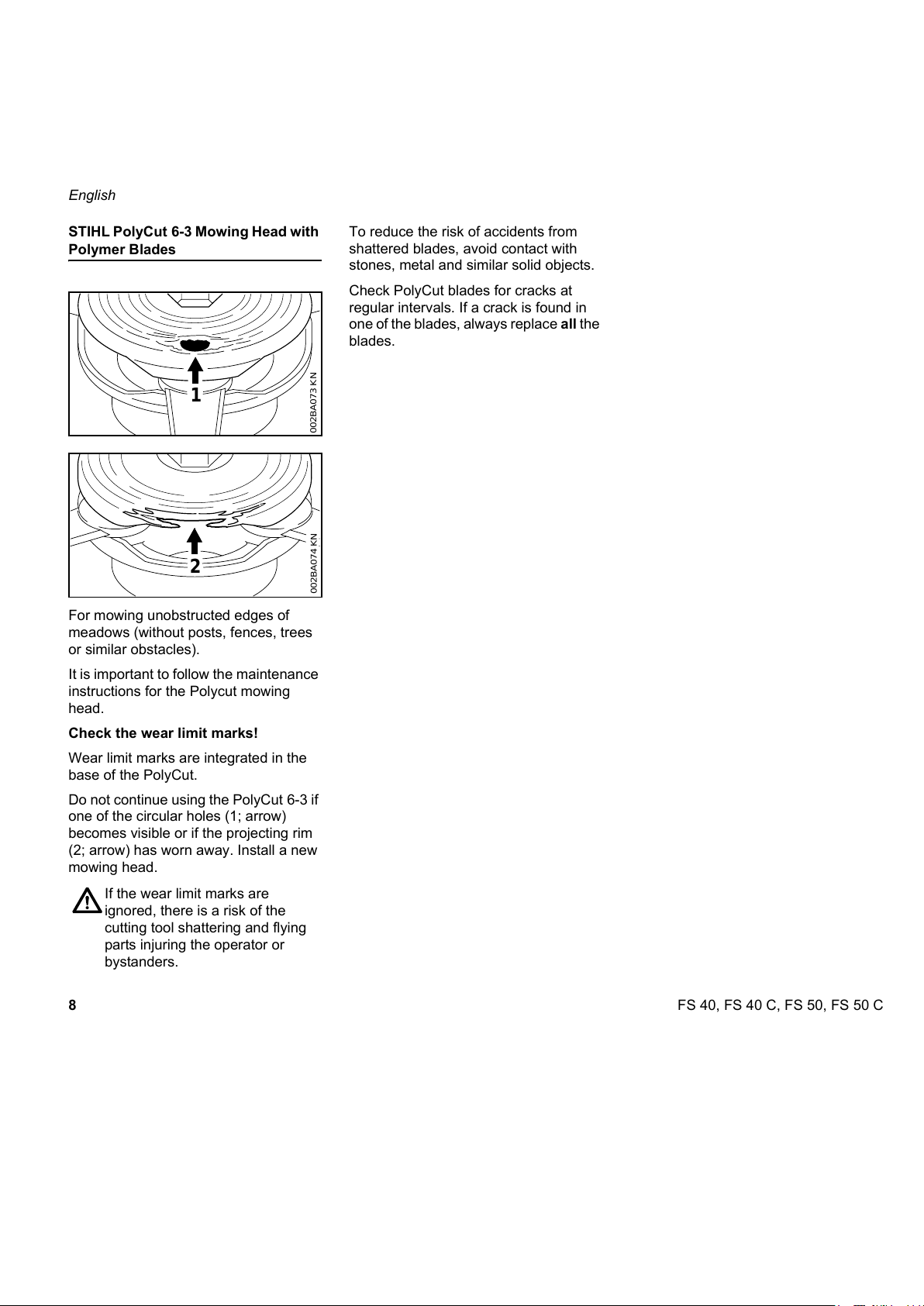

STIHL PolyCut 6-3 Mowing Head with

Polymer Blades

For mowing unobstructed edges of

meadows (without posts, fences, trees

or similar obstacles).

It is important to follow the maintenance

instructions for the Polycut mowing

head.

Check the wear limit marks!

Wear limit marks are integrated in the

base of the PolyCut.

Do not continue using the PolyCut 6-3 if

one of the circular holes (1; arrow)

becomes visible or if the projecting rim

(2; arrow) has worn away. Install a new

mowing head.

To reduce the risk of accidents from

shattered blades, avoid contact with

stones, metal and similar solid objects.

Check PolyCut blades for cracks at

regular intervals. If a crack is found in

one of the blades, always replace all the

blades.

If the wear limit marks are

ignored, there is a risk of the

cutting tool shattering and flying

parts injuring the operator or

bystanders.

1

002BA073 KN

2

002BA074 KN

Page 11

FS 40, FS 40 C, FS 50, FS 50 C

English

9

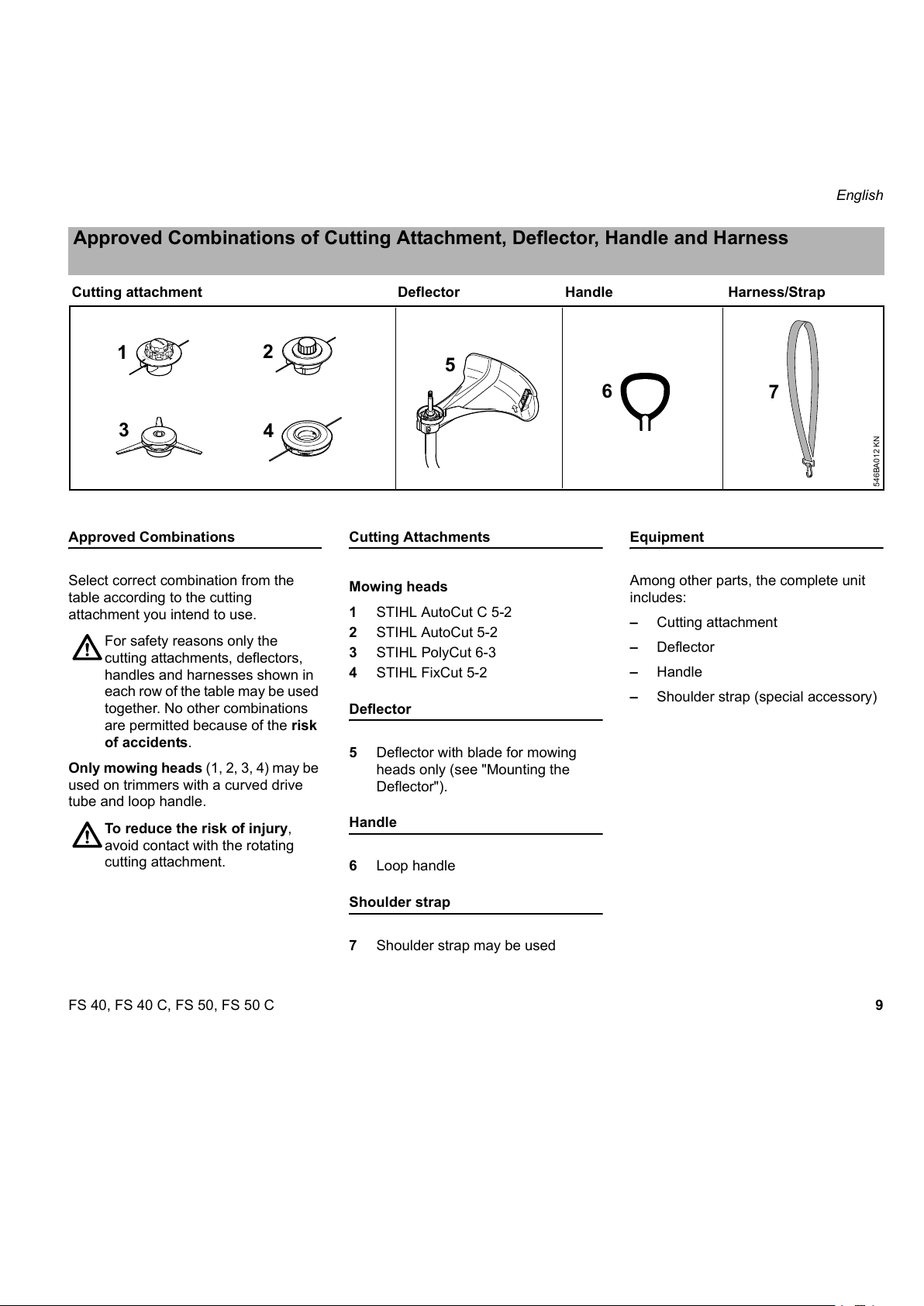

Approved Combinations

Select correct combination from the

table according to the cutting

attachment you intend to use.

Only mowing heads (1, 2, 3, 4) may be

used on trimmers with a curved drive

tube and loop handle.

Cutting Attachments

Mowing heads

1 STIHL AutoCut C 5-2

2 STIHL AutoCut 5-2

3 STIHL PolyCut 6-3

4 STIHL FixCut 5-2

Deflector

5 Deflector with blade for mowing

heads only (see "Mounting the

Deflector").

Handle

6 Loop handle

Shoulder strap

7 Shoulder strap may be used

Equipment

Among other parts, the complete unit

includes:

– Cutting attachment

– Deflector

– Handle

– Shoulder strap (special accessory)

Approved Combinations of Cutting Attachment, Deflector, Handle and Harness

Cutting attachment Deflector Handle Harness/Strap

546BA012 KN

1

2

6

7

5

Schnur/LINE 2

Schnur/LINE 1

3

4

For safety reasons only the

cutting attachments, deflectors,

handles and harnesses shown in

each row of the table may be used

together. No other combinations

are permitted because of the risk

of accidents.

To reduce the risk of injury,

avoid contact with the rotating

cutting attachment.

Page 12

FS 40, FS 40 C, FS 50, FS 50 C

English

10

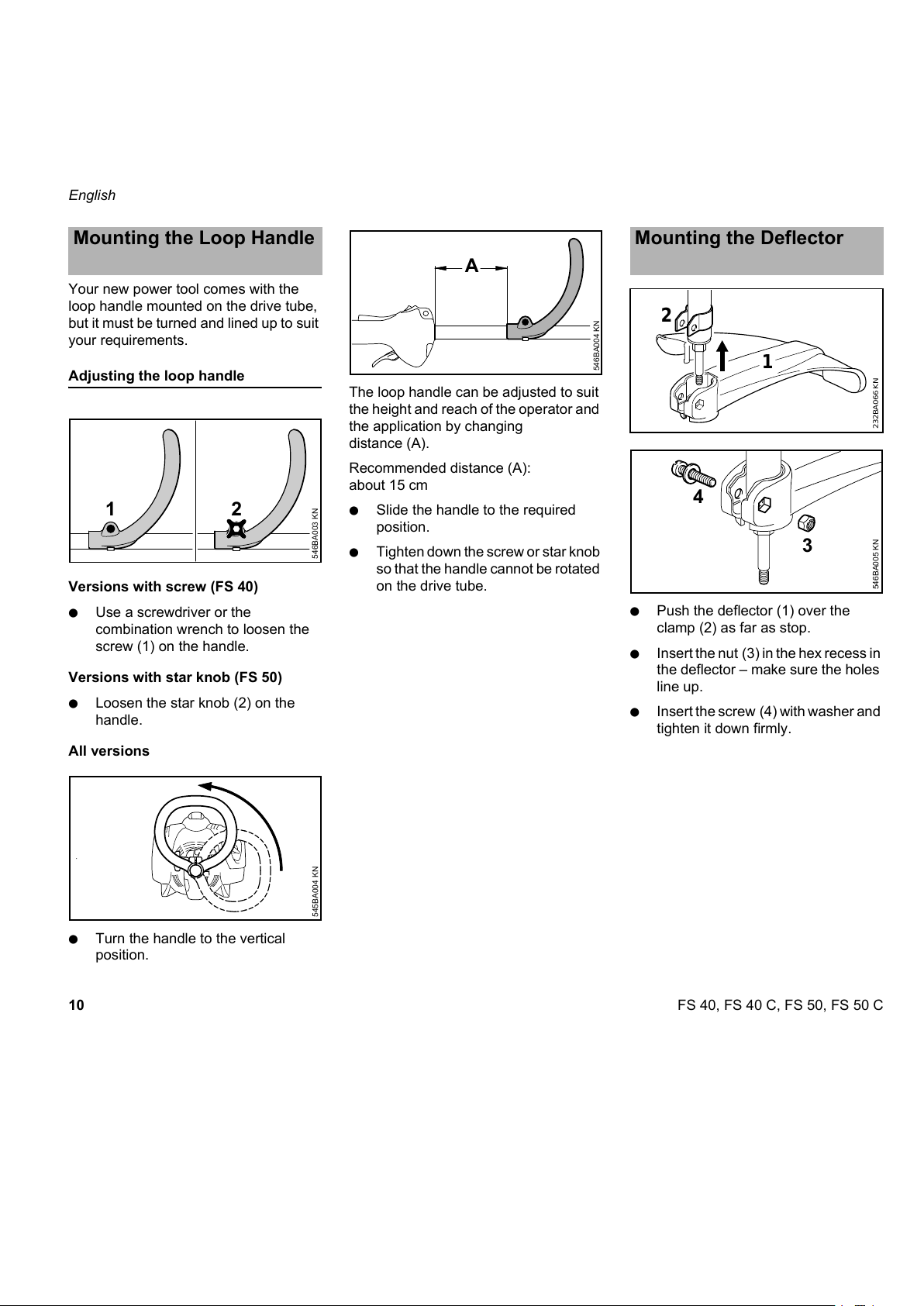

Your new power tool comes with the

loop handle mounted on the drive tube,

but it must be turned and lined up to suit

your requirements.

Adjusting the loop handle

Versions with screw (FS 40)

N Use a screwdriver or the

combination wrench to loosen the

screw (1) on the handle.

Versions with star knob (FS 50)

N Loosen the star knob (2) on the

handle.

All versions

N Turn the handle to the vertical

position.

The loop handle can be adjusted to suit

the height and reach of the operator and

the application by changing

distance (A).

Recommended distance (A):

about 15 cm

N Slide the handle to the required

position.

N Tighten down the screw or star knob

so that the handle cannot be rotated

on the drive tube.

N Push the deflector (1) over the

clamp (2) as far as stop.

N Insert the nut (3) in the hex recess in

the deflector – make sure the holes

line up.

N Insert the screw (4) with washer and

tighten it down firmly.

Mounting the Loop Handle

2

1

546BA003 KN

545BA004 KN

546BA004 KN

A

Mounting the Deflector

1

2

232BA066 KN

4

546BA005 KN

3

Page 13

FS 40, FS 40 C, FS 50, FS 50 C

English

11

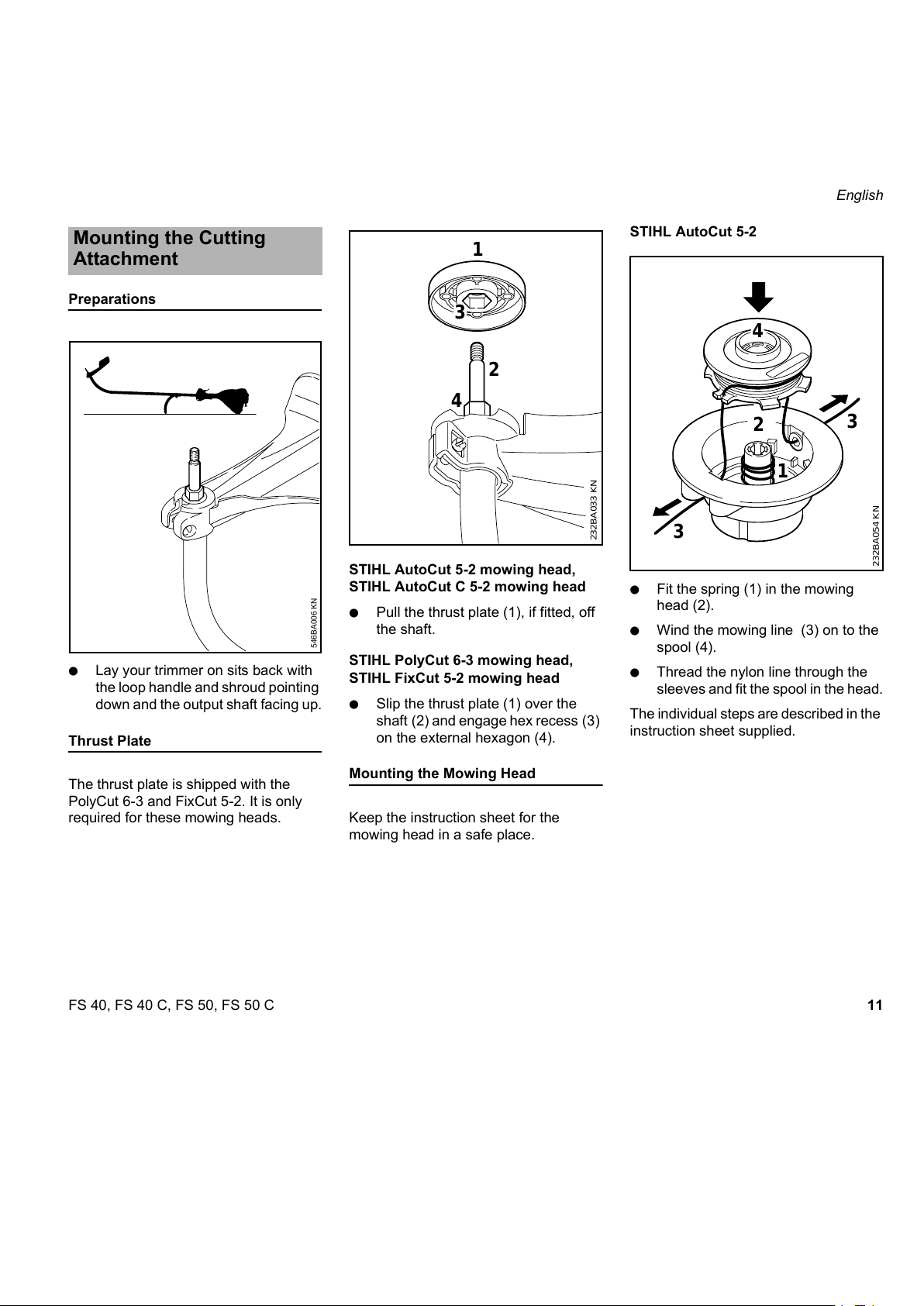

Preparations

N Lay your trimmer on sits back with

the loop handle and shroud pointing

down and the output shaft facing up.

Thrust Plate

The thrust plate is shipped with the

PolyCut 6-3 and FixCut 5-2. It is only

required for these mowing heads.

STIHL AutoCut 5-2 mowing head,

STIHL AutoCut C 5-2 mowing head

N Pull the thrust plate (1), if fitted, off

the shaft.

STIHL PolyCut 6-3 mowing head,

STIHL FixCut 5-2 mowing head

N Slip the thrust plate (1) over the

shaft (2) and engage hex recess (3)

on the external hexagon (4).

Mounting the Mowing Head

Keep the instruction sheet for the

mowing head in a safe place.

STIHL AutoCut 5-2

N Fit the spring (1) in the mowing

head (2).

N Wind the mowing line (3) on to the

spool (4).

N Thread the nylon line through the

sleeves and fit the spool in the head.

The individual steps are described in the

instruction sheet supplied.

Mounting the Cutting

Attachment

546BA006 KN

232BA033 KN

1

2

3

4

1

232BA054 KN

2

3

4

3

Page 14

FS 40, FS 40 C, FS 50, FS 50 C

English

12

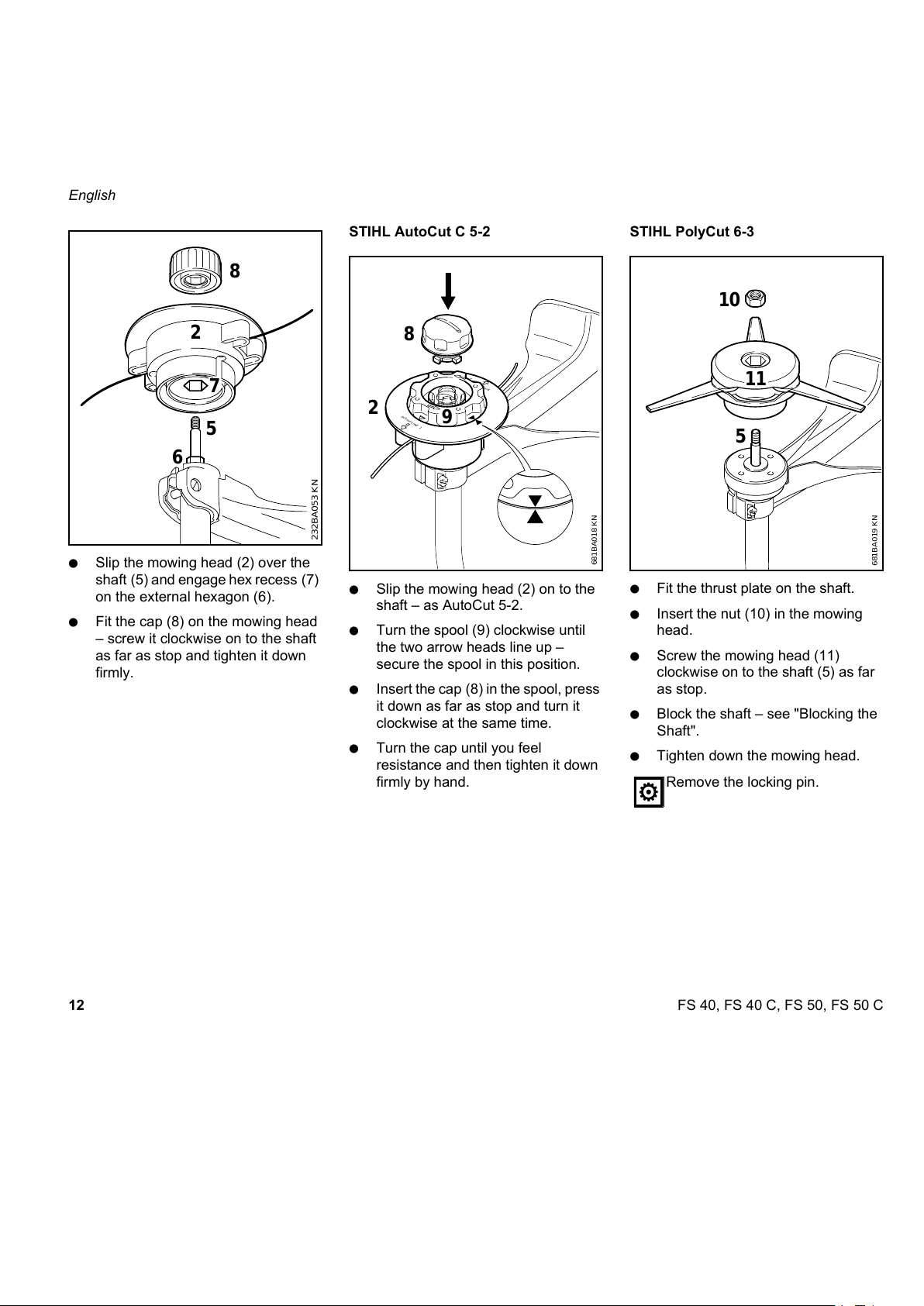

N Slip the mowing head (2) over the

shaft (5) and engage hex recess (7)

on the external hexagon (6).

N Fit the cap (8) on the mowing head

– screw it clockwise on to the shaft

as far as stop and tighten it down

firmly.

STIHL AutoCut C 5-2

N Slip the mowing head (2) on to the

shaft – as AutoCut 5-2.

N Turn the spool (9) clockwise until

the two arrow heads line up –

secure the spool in this position.

N Insert the cap (8) in the spool, press

it down as far as stop and turn it

clockwise at the same time.

N Turn the cap until you feel

resistance and then tighten it down

firmly by hand.

STIHL PolyCut 6-3

N Fit the thrust plate on the shaft.

N Insert the nut (10) in the mowing

head.

N Screw the mowing head (11)

clockwise on to the shaft (5) as far

as stop.

N Block the shaft – see "Blocking the

Shaft".

N Tighten down the mowing head.

7

5

2

232BA053 KN

6

8

9

681BA018 KN

Schnur/LINE 2

Schnur/LINE 1

2

8

Remove the locking pin.

11

5

681BA019 KN

10

Page 15

FS 40, FS 40 C, FS 50, FS 50 C

English

13

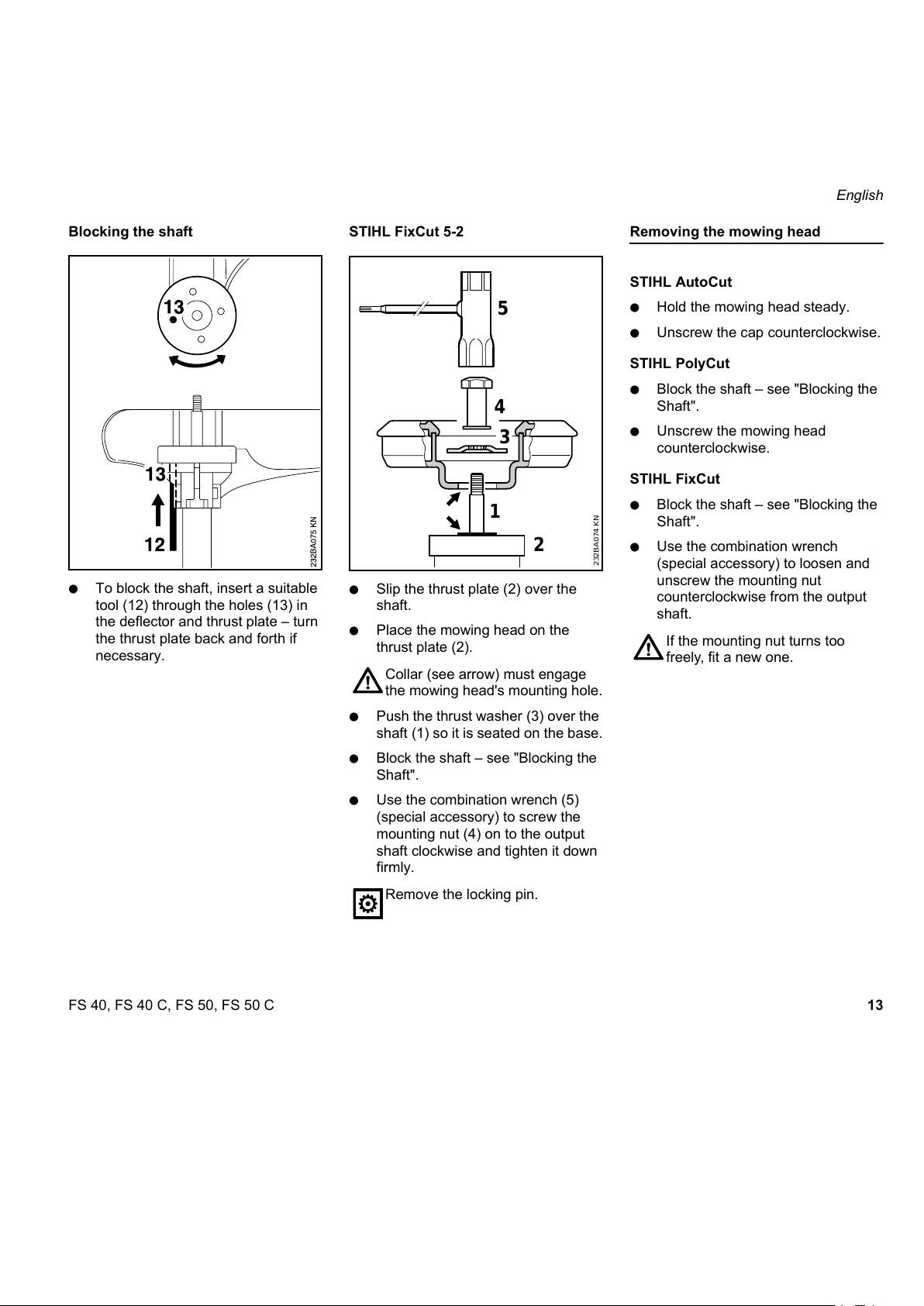

Blocking the shaft

N To block the shaft, insert a suitable

tool (12) through the holes (13) in

the deflector and thrust plate – turn

the thrust plate back and forth if

necessary.

STIHL FixCut 5-2

N Slip the thrust plate (2) over the

shaft.

N Place the mowing head on the

thrust plate (2).

N Push the thrust washer (3) over the

shaft (1) so it is seated on the base.

N Block the shaft – see "Blocking the

Shaft".

N Use the combination wrench (5)

(special accessory) to screw the

mounting nut (4) on to the output

shaft clockwise and tighten it down

firmly.

Removing the mowing head

STIHL AutoCut

N Hold the mowing head steady.

N Unscrew the cap counterclockwise.

STIHL PolyCut

N Block the shaft – see "Blocking the

Shaft".

N Unscrew the mowing head

counterclockwise.

STIHL FixCut

N Block the shaft – see "Blocking the

Shaft".

N Use the combination wrench

(special accessory) to loosen and

unscrew the mounting nut

counterclockwise from the output

shaft.

Collar (see arrow) must engage

the mowing head's mounting hole.

Remove the locking pin.

3

1

2

4

232BA074 KN

5

If the mounting nut turns too

freely, fit a new one.

Page 16

FS 40, FS 40 C, FS 50, FS 50 C

English

14

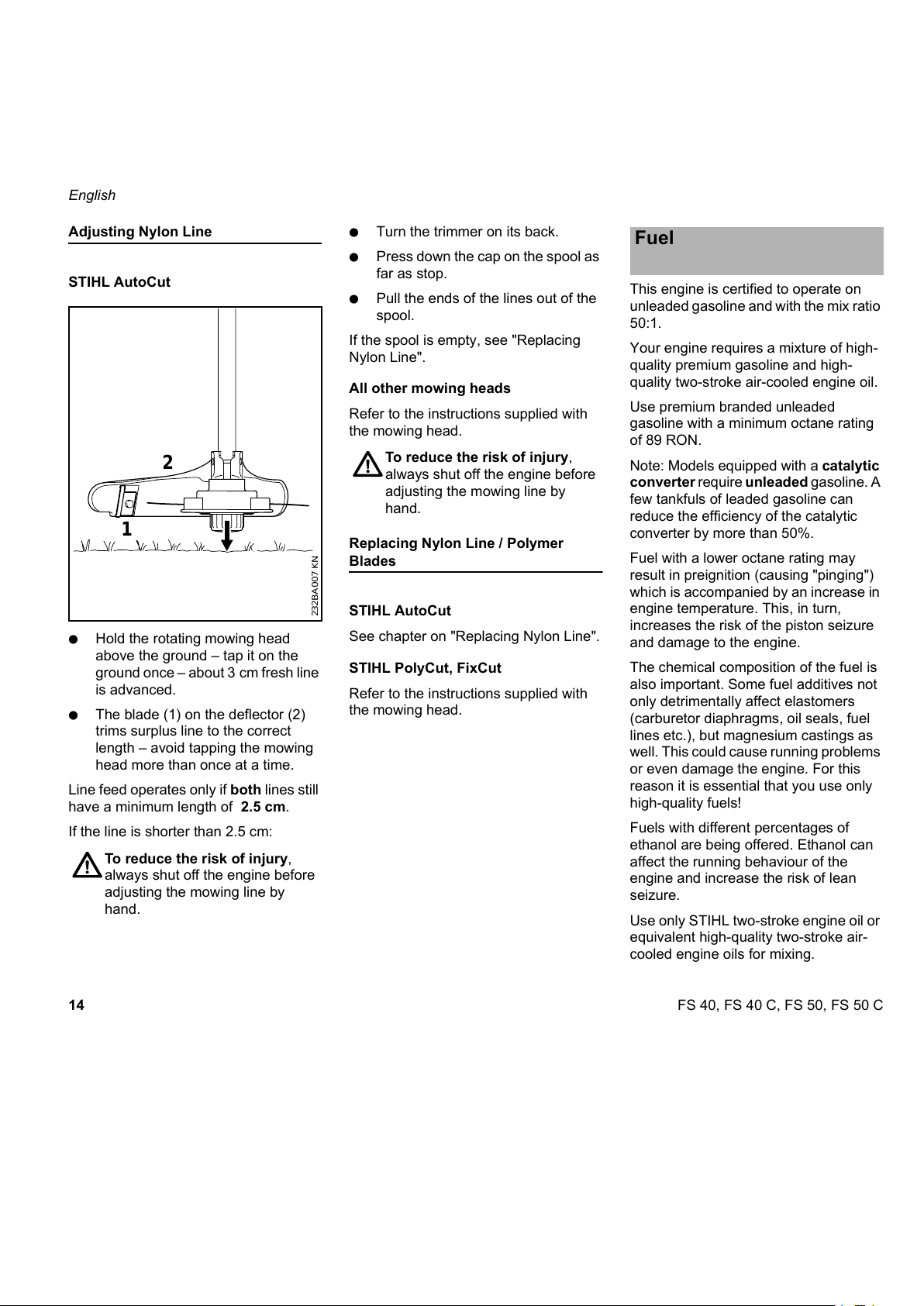

Adjusting Nylon Line

STIHL AutoCut

N Hold the rotating mowing head

above the ground – tap it on the

ground once – about 3 cm fresh line

is advanced.

N The blade (1) on the deflector (2)

trims surplus line to the correct

length – avoid tapping the mowing

head more than once at a time.

Line feed operates only if both lines still

have a minimum length of 2.5 cm.

If the line is shorter than 2.5 cm:

N Turn the trimmer on its back.

N Press down the cap on the spool as

far as stop.

N Pull the ends of the lines out of the

spool.

If the spool is empty, see "Replacing

Nylon Line".

All other mowing heads

Refer to the instructions supplied with

the mowing head.

Replacing Nylon Line / Polymer

Blades

STIHL AutoCut

See chapter on "Replacing Nylon Line".

STIHL PolyCut, FixCut

Refer to the instructions supplied with

the mowing head.

This engine is certified to operate on

unleaded gasoline and with the mix ratio

50:1.

Your engine requires a mixture of high-

quality premium gasoline and high-

quality two-stroke air-cooled engine oil.

Use premium branded unleaded

gasoline with a minimum octane rating

of 89 RON.

Note: Models equipped with a catalytic

converter require unleaded gasoline. A

few tankfuls of leaded gasoline can

reduce the efficiency of the catalytic

converter by more than 50%.

Fuel with a lower octane rating may

result in preignition (causing "pinging")

which is accompanied by an increase in

engine temperature. This, in turn,

increases the risk of the piston seizure

and damage to the engine.

The chemical composition of the fuel is

also important. Some fuel additives not

only detrimentally affect elastomers

(carburetor diaphragms, oil seals, fuel

lines etc.), but magnesium castings as

well. This could cause running problems

or even damage the engine. For this

reason it is essential that you use only

high-quality fuels!

Fuels with different percentages of

ethanol are being offered. Ethanol can

affect the running behaviour of the

engine and increase the risk of lean

seizure.

Use only STIHL two-stroke engine oil or

equivalent high-quality two-stroke air-

cooled engine oils for mixing.

To reduce the risk of injury,

always shut off the engine before

adjusting the mowing line by

hand.

1

232BA007 KN

2

To reduce the risk of injury,

always shut off the engine before

adjusting the mowing line by

hand.

Fuel

Page 17

FS 40, FS 40 C, FS 50, FS 50 C

English

15

We recommend STIHL 50:1 two-stroke

engine oil since it is specially formulated

for use in STIHL engines.

Do not use BIA or TCW (two-stroke

water cooled) mix oils!

Use only STIHL 50:1 heavy-duty

engine oil or an equivalent quality two-

stroke engine oil for the fuel mix in

models equipped with a catalytic

converter.

Take care when handling gasoline.

Avoid direct contact with the skin and

avoid inhaling fuel vapour.

The canister should be kept tightly

closed in order to avoid any moisture

getting into the mixture.

The fuel tank and the canister in which

fuel mix is stored should be cleaned

from time to time.

Fuel mix ratio

Only mix sufficient fuel for a few days

work, not to exceed 3 months of storage.

Store in approved safety fuel-canisters

only. When mixing, pour oil into the

canister first, and then add gasoline.

Dispose of empty mixing-oil canisters

only at authorized disposal locations.

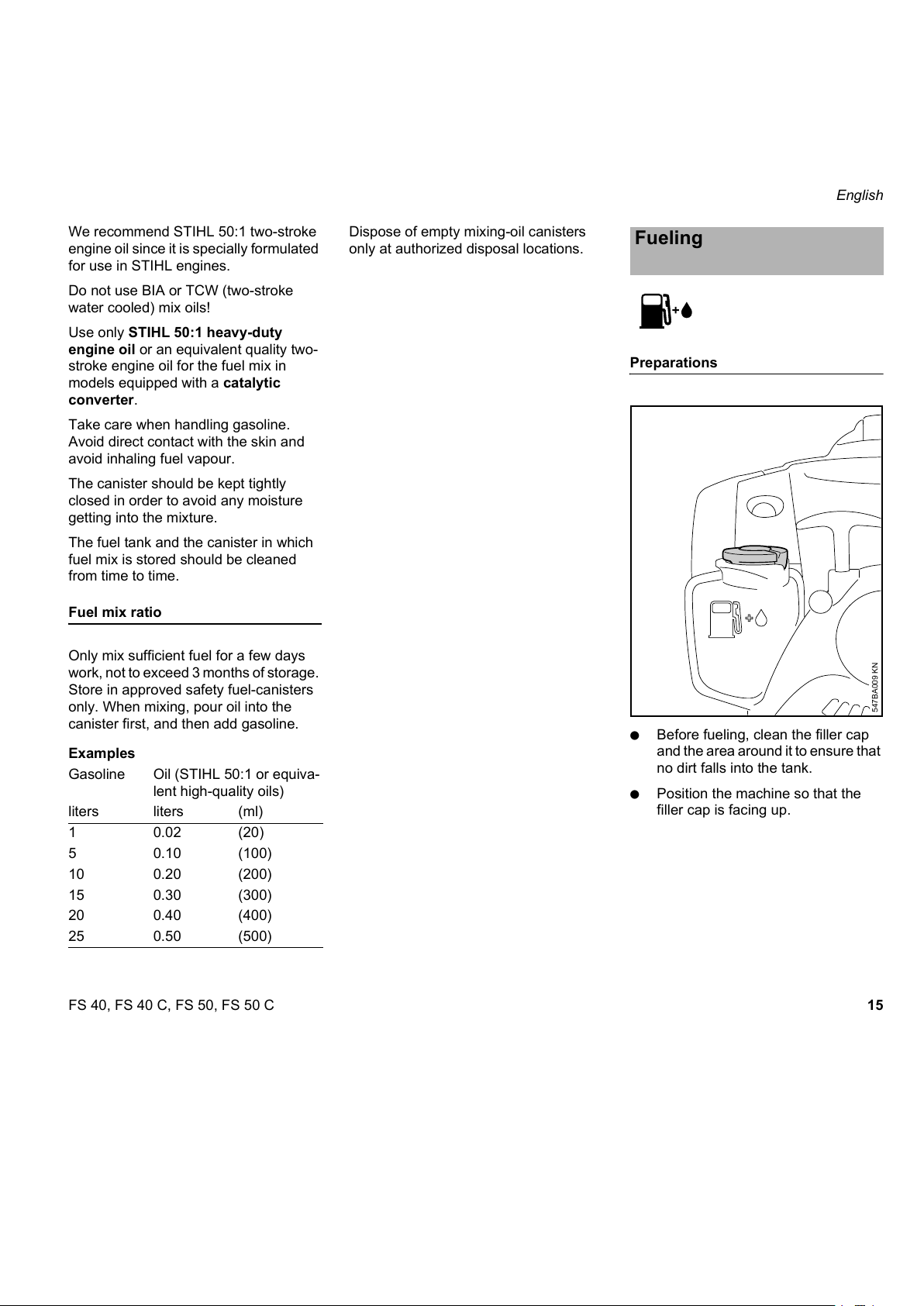

Preparations

N Before fueling, clean the filler cap

and the area around it to ensure that

no dirt falls into the tank.

N Position the machine so that the

filler cap is facing up.

Examples

Gasoline Oil (STIHL 50:1 or equiva-

lent high-quality oils)

liters liters (ml)

1 0.02 (20)

5 0.10 (100)

10 0.20 (200)

15 0.30 (300)

20 0.40 (400)

25 0.50 (500)

Fueling

547BA009 KN

Page 18

FS 40, FS 40 C, FS 50, FS 50 C

English

16

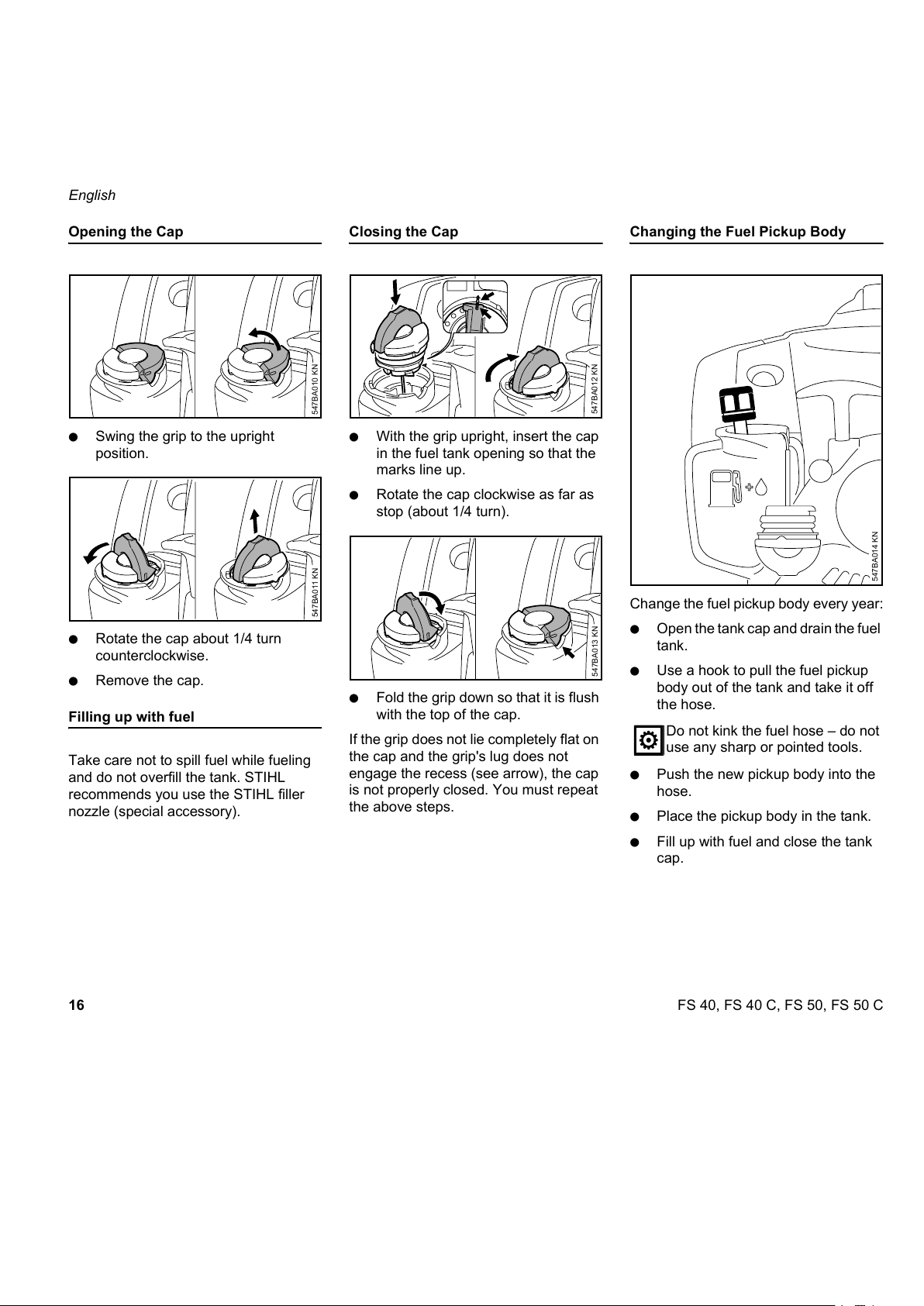

Opening the Cap

N Swing the grip to the upright

position.

N Rotate the cap about 1/4 turn

counterclockwise.

N Remove the cap.

Filling up with fuel

Take care not to spill fuel while fueling

and do not overfill the tank. STIHL

recommends you use the STIHL filler

nozzle (special accessory).

Closing the Cap

N With the grip upright, insert the cap

in the fuel tank opening so that the

marks line up.

N Rotate the cap clockwise as far as

stop (about 1/4 turn).

N Fold the grip down so that it is flush

with the top of the cap.

If the grip does not lie completely flat on

the cap and the grip's lug does not

engage the recess (see arrow), the cap

is not properly closed. You must repeat

the above steps.

Changing the Fuel Pickup Body

Change the fuel pickup body every year:

N Open the tank cap and drain the fuel

tank.

N Use a hook to pull the fuel pickup

body out of the tank and take it off

the hose.

N Push the new pickup body into the

hose.

N Place the pickup body in the tank.

N Fill up with fuel and close the tank

cap.

547BA010 KN

547BA011 KN

547BA012 KN

547BA013 KN

Do not kink the fuel hose – do not

use any sharp or pointed tools.

547BA014 KN

Page 19

FS 40, FS 40 C, FS 50, FS 50 C

English

17

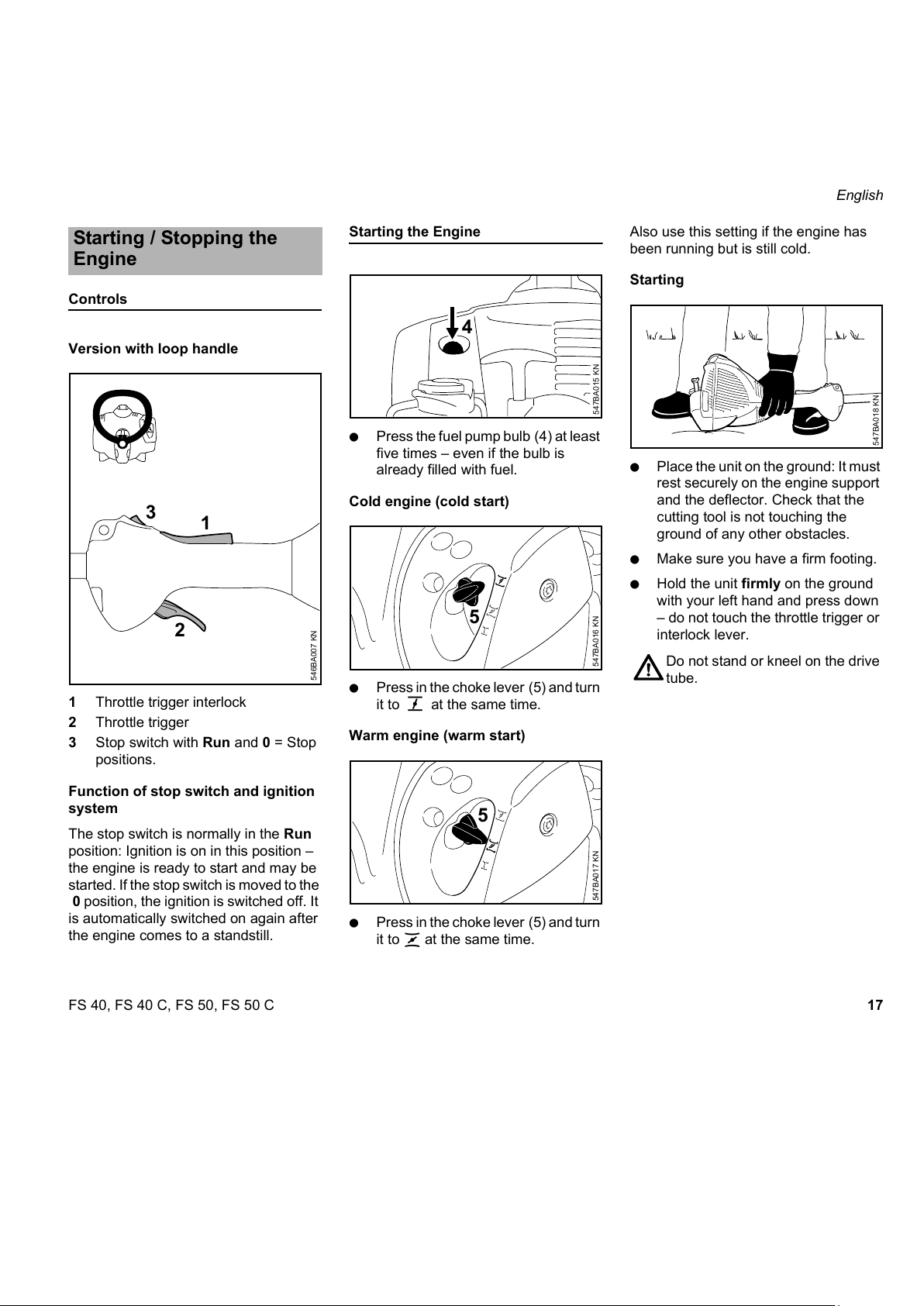

Controls

Version with loop handle

1 Throttle trigger interlock

2 Throttle trigger

3 Stop switch with Run and 0 =Stop

positions.

Function of stop switch and ignition

system

The stop switch is normally in the Run

position: Ignition is on in this position –

the engine is ready to start and may be

started. If the stop switch is moved to the

0 position, the ignition is switched off. It

is automatically switched on again after

the engine comes to a standstill.

Starting the Engine

N Press the fuel pump bulb (4) at least

five times – even if the bulb is

already filled with fuel.

Cold engine (cold start)

N Press in the choke lever (5) and turn

it to g at the same time.

Warm engine (warm start)

N Press in the choke lever (5) and turn

it to < at the same time.

Also use this setting if the engine has

been running but is still cold.

Starting

N Place the unit on the ground: It must

rest securely on the engine support

and the deflector. Check that the

cutting tool is not touching the

ground of any other obstacles.

N Make sure you have a firm footing.

N Hold the unit firmly on the ground

with your left hand and press down

– do not touch the throttle trigger or

interlock lever.

Starting / Stopping the

Engine

546BA007 KN

1

3

2

4

547BA015 KN

5

547BA016 KN

5

547BA017 KN

Do not stand or kneel on the drive

tube.

547BA018 KN

Page 20

FS 40, FS 40 C, FS 50, FS 50 C

English

18

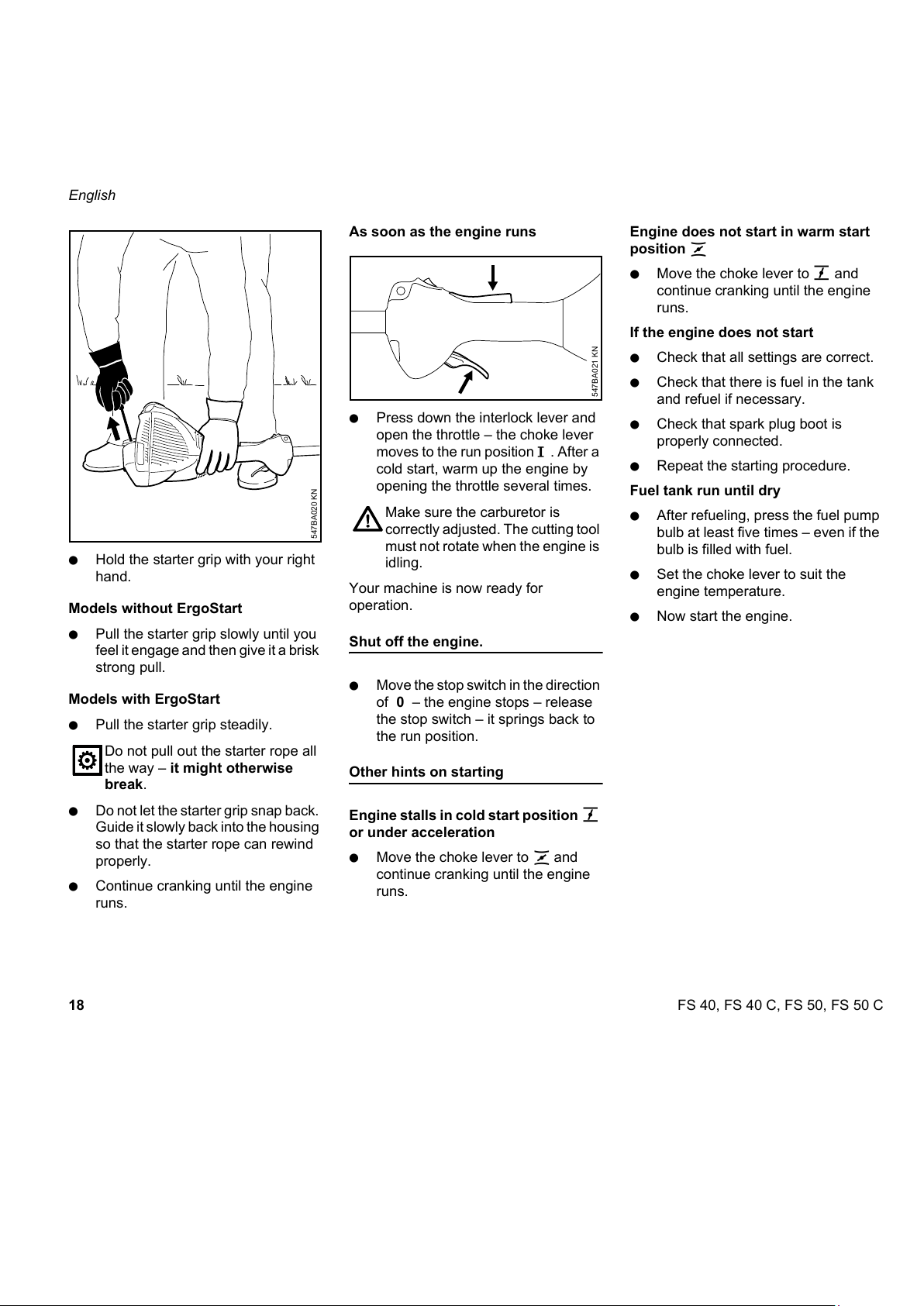

N Hold the starter grip with your right

hand.

Models without ErgoStart

N Pull the starter grip slowly until you

feel it engage and then give it a brisk

strong pull.

Models with ErgoStart

N Pull the starter grip steadily.

N Do not let the starter grip snap back.

Guide it slowly back into the housing

so that the starter rope can rewind

properly.

N Continue cranking until the engine

runs.

As soon as the engine runs

N Press down the interlock lever and

open the throttle – the choke lever

moves to the run position F . After a

cold start, warm up the engine by

opening the throttle several times.

Your machine is now ready for

operation.

Shut off the engine.

N Move the stop switch in the direction

of 0 – the engine stops – release

the stop switch – it springs back to

the run position.

Other hints on starting

Engine stalls in cold start position g

or under acceleration

N Move the choke lever to < and

continue cranking until the engine

runs.

Engine does not start in warm start

position <

N Move the choke lever to g and

continue cranking until the engine

runs.

If the engine does not start

N Check that all settings are correct.

N Check that there is fuel in the tank

and refuel if necessary.

N Check that spark plug boot is

properly connected.

N Repeat the starting procedure.

Fuel tank run until dry

N After refueling, press the fuel pump

bulb at least five times – even if the

bulb is filled with fuel.

N Set the choke lever to suit the

engine temperature.

N Now start the engine.

Do not pull out the starter rope all

the way – it might otherwise

break.

547BA020 KN

Make sure the carburetor is

correctly adjusted. The cutting tool

must not rotate when the engine is

idling.

547BA021 KN

Page 21

FS 40, FS 40 C, FS 50, FS 50 C

English

19

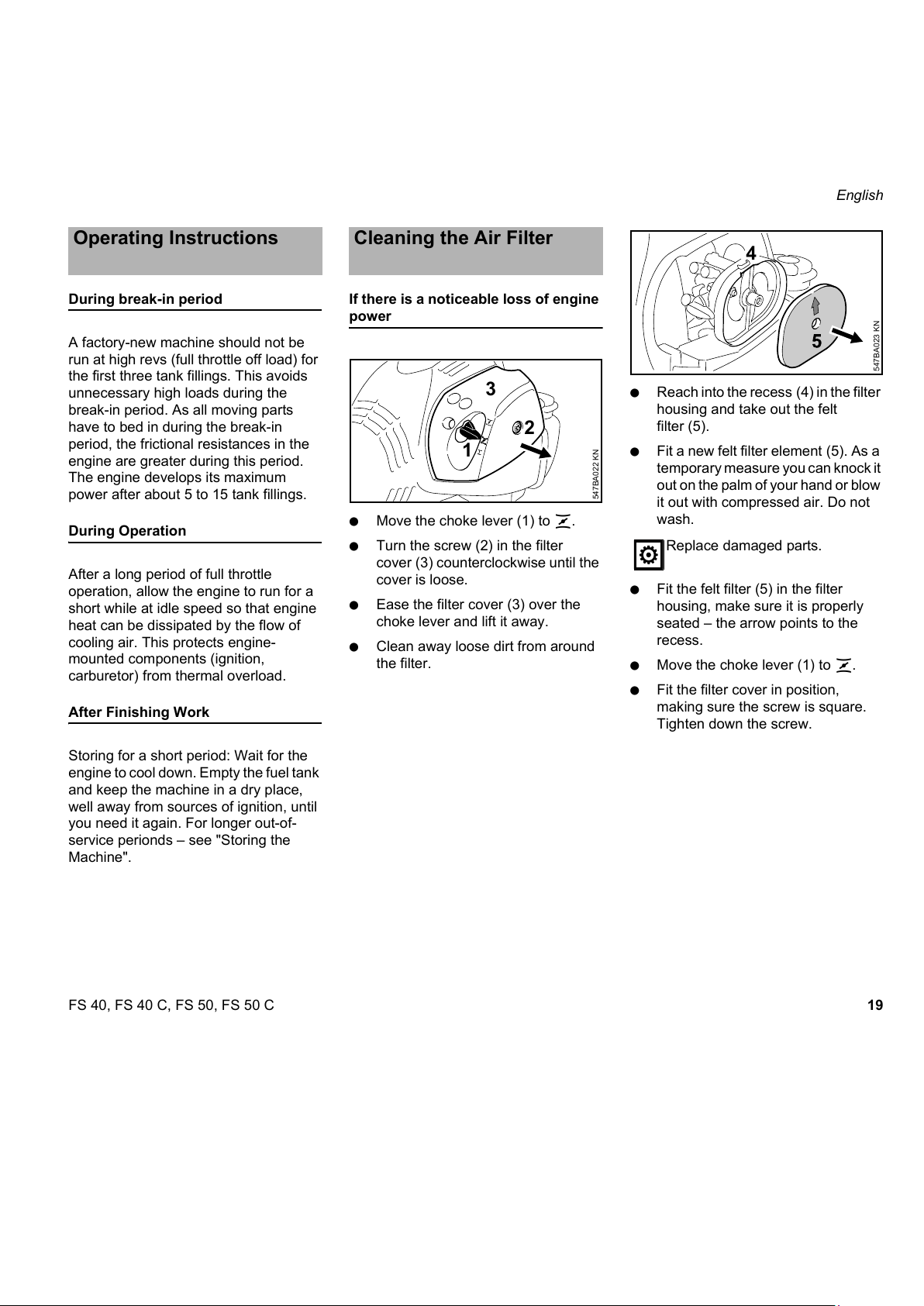

During break-in period

A factory-new machine should not be

run at high revs (full throttle off load) for

the first three tank fillings. This avoids

unnecessary high loads during the

break-in period. As all moving parts

have to bed in during the break-in

period, the frictional resistances in the

engine are greater during this period.

The engine develops its maximum

power after about 5 to 15 tank fillings.

During Operation

After a long period of full throttle

operation, allow the engine to run for a

short while at idle speed so that engine

heat can be dissipated by the flow of

cooling air. This protects engine-

mounted components (ignition,

carburetor) from thermal overload.

After Finishing Work

Storing for a short period: Wait for the

engine to cool down. Empty the fuel tank

and keep the machine in a dry place,

well away from sources of ignition, until

you need it again. For longer out-of-

service perionds – see "Storing the

Machine".

If there is a noticeable loss of engine

power

N Move the choke lever (1) to <.

N Turn the screw (2) in the filter

cover (3) counterclockwise until the

cover is loose.

N Ease the filter cover (3) over the

choke lever and lift it away.

N Clean away loose dirt from around

the filter.

N Reach into the recess (4) in the filter

housing and take out the felt

filter (5).

N Fit a new felt filter element (5). As a

temporary measure you can knock it

out on the palm of your hand or blow

it out with compressed air. Do not

wash.

N Fit the felt filter (5) in the filter

housing, make sure it is properly

seated – the arrow points to the

recess.

N Move the choke lever (1) to <.

N Fit the filter cover in position,

making sure the screw is square.

Tighten down the screw.

Operating Instructions Cleaning the Air Filter

1

547BA022 KN

2

3

Replace damaged parts.

547BA023 KN

4

Page 22

FS 40, FS 40 C, FS 50, FS 50 C

English

20

Exhaust emissions are controlled by the

design of the fundamental engine

parameters and components (e.g.

carburation, ignition, timing and valve or

port timing) without the addition of any

major hardware.

The carburetor comes from the factory

with a standard setting.

This setting provides an optimum fuel-air

mixture under most operating

conditions.

With this carburetor it is only possible to

make corrections with the adjusting

screws within fine limits.

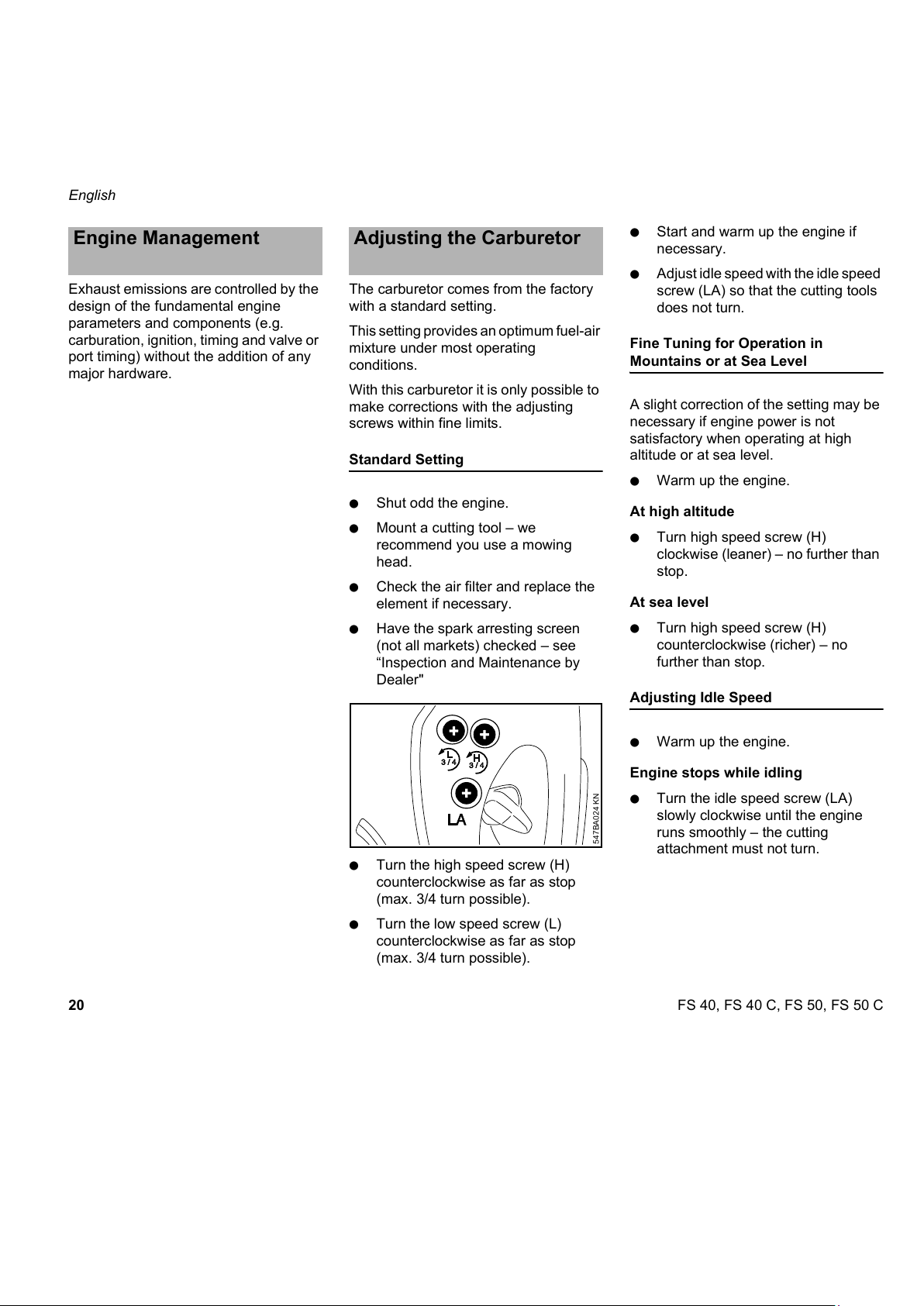

Standard Setting

N Shut odd the engine.

N Mount a cutting tool – we

recommend you use a mowing

head.

N Check the air filter and replace the

element if necessary.

N Have the spark arresting screen

(not all markets) checked – see

“Inspection and Maintenance by

Dealer"

N Turn the high speed screw (H)

counterclockwise as far as stop

(max. 3/4 turn possible).

N Turn the low speed screw (L)

counterclockwise as far as stop

(max. 3/4 turn possible).

N Start and warm up the engine if

necessary.

N Adjust idle speed with the idle speed

screw (LA) so that the cutting tools

does not turn.

Fine Tuning for Operation in

Mountains or at Sea Level

A slight correction of the setting may be

necessary if engine power is not

satisfactory when operating at high

altitude or at sea level.

N Warm up the engine.

At high altitude

N Turn high speed screw (H)

clockwise (leaner) – no further than

stop.

At sea level

N Turn high speed screw (H)

counterclockwise (richer) – no

further than stop.

Adjusting Idle Speed

N Warm up the engine.

Engine stops while idling

N Turn the idle speed screw (LA)

slowly clockwise until the engine

runs smoothly – the cutting

attachment must not turn.

Engine Management Adjusting the Carburetor

547BA024 KN

Page 23

FS 40, FS 40 C, FS 50, FS 50 C

English

21

Cutting attachment rotates when

engine is idling

N Turn the idle speed screw (LA)

counterclockwise until the tool stops

moving and then turn the screw

another full turn in the same

direction.

Erratic idling behavior, engine stops

even though setting of LA-screw has

been corrected, poor acceleration

Idle setting is too lean

N Turn the low speed screw (L)

counterclockwise, no further than

stop, until the engine runs and

accelerates smoothly.

Erratic idling behavior, engine speed

drops when swinging the machine

Idle setting is too rich

N Turn the low speed screw (L)

clockwise (1/8 of a turn or 45° at a

time) until the engine runs smoothly

and accelerates well.

It is usually necessary to change the

setting of the idle speed screw (LA) after

corrections to the low speed screw (L).

If the engine is down on power, difficult

to start or runs poorly at idle speed, first

check the spark plug.

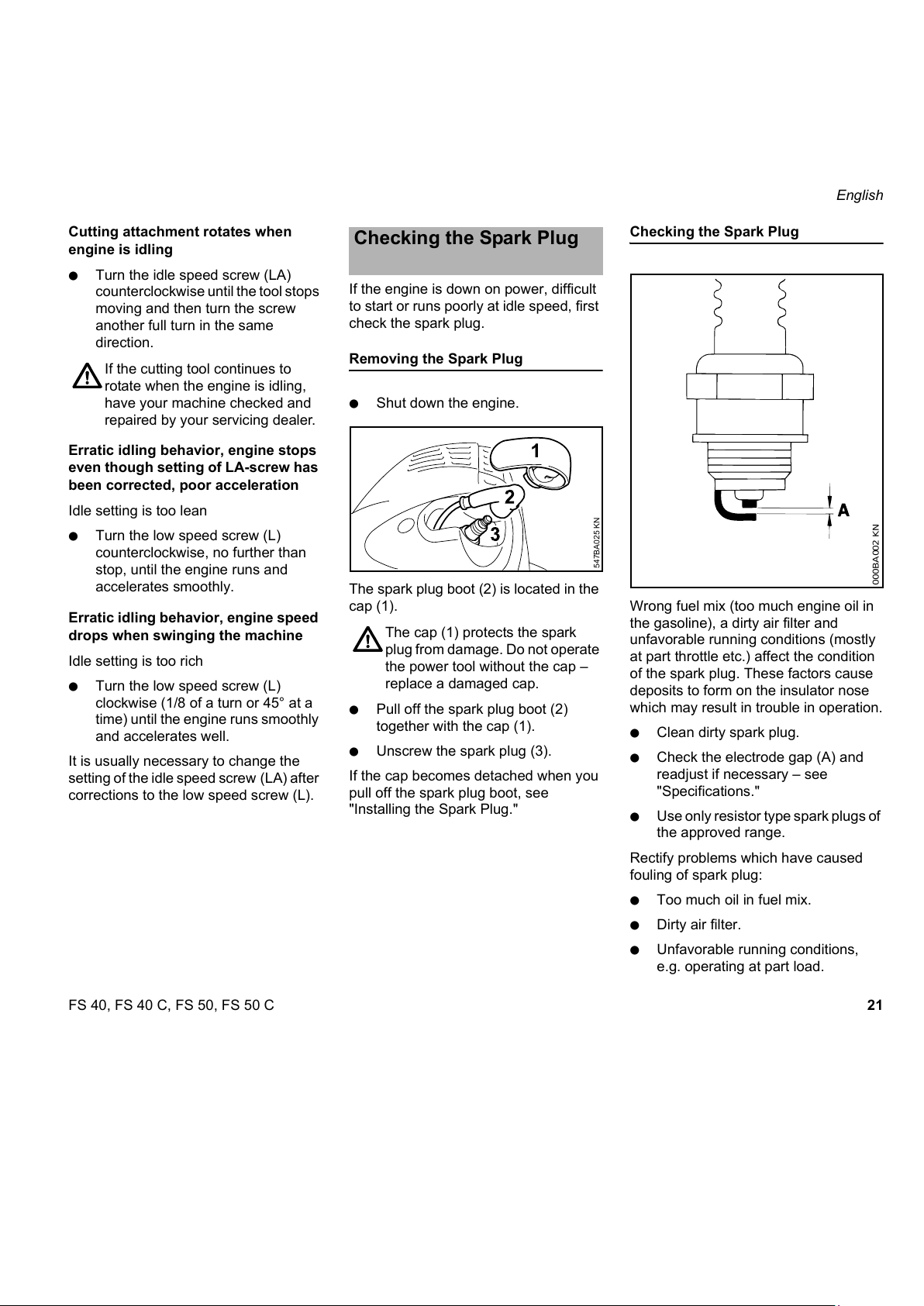

Removing the Spark Plug

N Shut down the engine.

The spark plug boot (2) is located in the

cap (1).

N Pull off the spark plug boot (2)

together with the cap (1).

N Unscrew the spark plug (3).

If the cap becomes detached when you

pull off the spark plug boot, see

"Installing the Spark Plug."

Checking the Spark Plug

Wrong fuel mix (too much engine oil in

the gasoline), a dirty air filter and

unfavorable running conditions (mostly

at part throttle etc.) affect the condition

of the spark plug. These factors cause

deposits to form on the insulator nose

which may result in trouble in operation.

N Clean dirty spark plug.

N Check the electrode gap (A) and

readjust if necessary – see

"Specifications."

N Use only resistor type spark plugs of

the approved range.

Rectify problems which have caused

fouling of spark plug:

N Too much oil in fuel mix.

N Dirty air filter.

N Unfavorable running conditions,

e.g. operating at part load.

If the cutting tool continues to

rotate when the engine is idling,

have your machine checked and

repaired by your servicing dealer.

Checking the Spark Plug

The cap (1) protects the spark

plug from damage. Do not operate

the power tool without the cap –

replace a damaged cap.

547BA025 KN

1

000BA002 KN

Page 24

FS 40, FS 40 C, FS 50, FS 50 C

English

22

Fit a new spark plug after approx. 100

operating hours or earlier if the

electrodes are badly eroded.

If engine running behavior is

unsatisfactory even though the air filter

is clean and the carburetor is properly

adjusted, the cause may be the muffler.

N Have the muffler checked for

contamination (carbonization).

STIHL recommends that you have

servicing and repair work carried out

exclusively by an authorized STIHL

servicing dealer.

To help prolong the wear life of the

starter rope, observe the following

points:

N Pull the starter rope only in the

direction specified.

N Do not pull the rope over the edge of

the guide bushing.

N Do not pull out the rope more than

specified.

N Do not allow the starter grip to snap

back, guide it back into the housing

slowly – see chapter on "Starting /

Stopping the Engine."

Have a damaged starter rope replaced

by your dealer before it breaks

completely. STIHL recommends that

you have servicing and repair work

carried out exclusively by an authorized

STIHL servicing dealer.

To reduce the risk of fire and burn

injury, use only spark plugs

authorized by STIHL. Always

press spark plug boot (2) snugly

onto terminal (1) of the proper

size. (Note: If terminal has

detachable SAE adapter nut, it

must be attached.) A loose

connection between spark plug

boot and ignition wire connector in

the boot may create arcing that

could ignite combustible fumes

and cause a fire.

000BA036 TR

1

Engine Running Behavior Rewind Starter

Page 25

FS 40, FS 40 C, FS 50, FS 50 C

English

23

For periods of 3 months or longer

N Drain and clean the fuel tank in a

well ventilated area.

N Dispose of fuel properly in

accordance with local

environmental requirements.

N Run the engine until the carburetor

is dry – this helps prevent the

carburetor diaphragms sticking

together.

N Remove, clean and inspect the

cutting attachment.

N Thoroughly clean the machine –

pay special attention to the cylinder

fins and air filter.

N Store the machine in a dry and

secure location – out of the reach of

children and other unauthorized

persons.

STIHL AutoCut C 5-2

Always check the mowing head for signs

of wear before replacing the nylon line.

Preparations

N Shut off the engine.

N Put the machine on the ground with

the mowing head facing up.

Disassembling the mowing head and

removing remaining nylon line

In normal operation, the supply of nylon

line in the head is used up almost

completely.

N Hold the mowing head steady and

rotate the cap (1) counterclockwise

until it can be removed.

N Pull the spool (2) out of the mowing

head (3) and remove the remaining

line.

Storing the Machine Replacing Nylon Line

If there are signs of serious wear,

replace the complete mowing

head.

Schnur/LINE 1

681BA021 KN

1

2

3

Page 26

FS 40, FS 40 C, FS 50, FS 50 C

English

24

Assembling the mowing head

N Fit the empty spool in the mowing

head.

If the spring (4) has popped out,

N push it into the spool (2) until it

engages in position with an audible

click.

N Mount the mowing head – see

"Mounting the Cutting Attachment".

Winding Line onto Spool

N Use green-coded nylon line with a

diameter of 2.0 mm.

N Cut two 2 m lengths of line from the

replacement reel (special

accessory).

N Rotate the spool (2)

counterclockwise until the two arrow

points are in alignment.

N Push the straight end of each line

through one sleeve (5) in the

mowing head (3) until you feel a

noticeable resistance – and then

continue pushing as far as stop.

N Hold the mowing head steady.

N Rotate the spool counterclockwise

until the shortest line is about

10 cm.

N If necessary, cut the longer line to a

length of about 10 cm.

The mowing head is now full.

STIHL AutoCut 5-2

Always check the mowing head for signs

of wear before replacing the nylon line.

Preparations

N Shut off the engine.

N Put the machine on the ground with

the mowing head facing up.

Schnur/LINE 1

681BA022 KN

2

4

Schnur/LINE 2

681BA023 KN

5

Schnur/LINE 1

3

3

2

If there are signs of serious wear,

replace the parts concerned or

install a new mowing head.

681BA024 KN

Schnur/LINE 2

Schnur/LINE 1

Page 27

FS 40, FS 40 C, FS 50, FS 50 C

English

25

Removing Remaining Nylon Line

N Open the mowing head – hold it

steady with one hand.

N Turn the cap (1) counterclockwise.

N Disengage the spool (2), take it out

of the mowing head and remove the

remaining line.

Winding Line onto Spool

A prewound spool (special accessory)

may be used as an alternative to the

following procedure.

N Use green-coded nylon line with a

diameter of 2.0 mm.

N Cut two 3 m lengths of line from the

replacement reel (special

accessory).

N Insert the ends of each line (3) in the

holes (4) in the spool.

N Bend the ends of the lines over the

edge of the holes to form a hook.

N Straighten out the nylon lines and

wind them tightly on to the spool –

one nylon line in each chamber.

N Engage the ends of the lines in the

notches (5).

Assembling the mowing head

681BA008 KN

1

2

681BA009 KN

4

3

3

Check that the spring is installed

(see "Mounting the Cutting

Attachment").

681BA010 KN

5

5

Page 28

FS 40, FS 40 C, FS 50, FS 50 C

English

26

N Thread the ends of the lines (6)

through the sleeves (7) and push

the spool (2) into the head so that it

snaps into position.

The nylon lines must disengage from the

notches (5) as the spool is pushed into

position.

N Pull out the ends of the lines as far

as stop.

N Mount the mowing head on the

machine.

Spark Arresting Screen in Muffler

Spark arresting screen in muffler (not all

markets)

N If the engine is down on power,

check the spark arresting screen in

the muffler.

STIHL recommends that you have

servicing and repair work carried out

exclusively by an authorized STIHL

servicing dealer.

7

681BA011 KN

2

6

6

Inspections and

Maintenance by Dealer

Page 29

FS 40, FS 40 C, FS 50, FS 50 C

English

27

Maintenance and Care

The following intervals apply to normal operating conditions only. If your daily work-

ing time is longer or operating conditions are difficult (very dusty work area, etc.),

shorten the specified intervals accordingly.

before starting work

after finishing work or daily

after each refueling stop

weekly

monthly

every 12 months

if problem

if damaged

if required

Complete machine

Visual inspection (condition, leaks) XX

Clean X

Control handle Check operation XX

Air filter

Clean XX

Replace X

Pickup body in fuel tank

Check X

Replace XXX

Fuel tank Clean XX

Carburetor

Check idle adjustment – the cutting tool

must not turn

XX

Readjust idle X

Spark plug

Readjust electrode gap X

Replace after every 100 operating hours

Cooling inlets

Visual inspection X

Clean X

Spark Arresting Screen in Muffler

1)

Check XX

Have cleaned or replaced by servicing

dealer

2)

XX

All accessible screws and nuts (not adjust-

ing screws)

Retighten X

Page 30

FS 40, FS 40 C, FS 50, FS 50 C

English

28

Cutting tool

Visual inspection XX

Replace X

Check tightness XX

Safety labels Replace X

1)

not in all versions, market-specific

2)

STIHL recommends a STIHL servicing dealer.

The following intervals apply to normal operating conditions only. If your daily work-

ing time is longer or operating conditions are difficult (very dusty work area, etc.),

shorten the specified intervals accordingly.

before starting work

after finishing work or daily

after each refueling stop

weekly

monthly

every 12 months

if problem

if damaged

if required

Page 31

FS 40, FS 40 C, FS 50, FS 50 C

English

29

1 Loop handle

2 Carrying ring

3 Momentary stop switch

4 Throttle trigger interlock

5 Throttle trigger

6 Carburetor adjusting screws

7 Choke lever

8 Air filter cover

9 Cap with spark plug boot

10 Machine support

11 Fuel pump

12 Fuel filler cap

13 Tank

14 Starter grip

15 Muffler (some versions with spark

arresting screen)

16 Mowing head

17 Line limiting blade

18 Deflector

19 Drive tube

# Serial number

Main Parts

11

546BA009 KN

3

2

5

4

#

1

7

6

8

9

10

12

13

14

15

17

18

19

16

Page 32

FS 40, FS 40 C, FS 50, FS 50 C

English

30

Definitions

1 Loop Handle.

For easy control of machine during

cutting work.

2 Carrying Eye.

The device to connect the trimmer

to the harness.

3 Momentary Stop Switch.

Switches the engine's ignition

system off and stops the running

engine.

4 Throttle Trigger Interlock.

Must be depressed before the

throttle trigger can be activated.

5 Throttle Trigger.

Controls the speed of the engine.

6 Carburetor Adjusting Screw.

For tuning carburetor.

7 Choke Lever.

Eases engine starting by enriching

mixture.

8 Air Filter Cover.

Covers the air filter element.

9 Cap with Spark Plug Boot.

Connects the spark plug to the

ignition wire.

10. Machine Support.

For resting machine on the ground.

11 Fuel Pump.

Provides additional fuel feed for a

cold start.

12 Fuel Filler Cap.

For closing the fuel tank.

13 Fuel Tank.

For fuel and oil mixture.

14 Starter Grip.

The grip of the pull starter, which is

the device to start the engine.

15 Muffler (with spark arresting

screen).

Attenuates exhaust noises and

diverts exhaust gases away from

operator.

16 Mowing Head.

The cutting attachment for different

purposes.

17 Line Limiting Blade.

Metal blade at the deflector in order

to keep the line of the mowing head

at the proper length.

18 Deflector (for mowing heads).

The deflector is designed to reduce

the risk of injury from foreign objects

flung backwards toward the

operator by the cutting attachment

and from contact with the cutting

attachment.

19 Drive Tube.

Device to connect the engine with

the gearbox.

EPA / CEPA

The Emission Compliance Period

referred to on the Emissions

Compliance Label indicates the number

of operating hours for which the engine

has been shown to meet Federal

emission requirements.

Category

Engine

Single cylinder two-stroke engine

FS 40, FS 40 C

Specifications

A = 300 hours

B = 125 hours

C = 50 hours

Displacement: 27.2 cm

3

Bore: 34 mm

Stroke: 30 mm

Engine power to

ISO 8893:

0.7 kW at

8,500 rpm

Idle speed: 2,800 rpm

Cut-off speed (rated): 10,000 rpm

Max. output shaft

speed (cutting tool): 8,900 rpm

Page 33

FS 40, FS 40 C, FS 50, FS 50 C

English

31

FS 50, FS 50 C

Ignition System

This spark ignition system meets all

requirements of the Canadian

Interference-Causing Equipment

Regulations ICES-002.

Electronic magneto ignition

Fuel System

All position diaphragm carburetor with

integral fuel pump

Weight

Overall length

Cutting attachments

Mowing heads

1 STIHL AutoCut C 5-2

2 STIHL AutoCut 5-2

3 STIHL FixCut 5-2

4 STIHL PolyCut 6-3

Special accessories for cutting

attachments

– Mowing line, 2.0 mm diameter,

green, different lengths; for mowing

heads 1 and 2

– Mowing line, different diameters,

pack of 50, 200 mm long; for

mowing head 3

– Thermoplastic blades, pack of 12;

for mowing head 4

Mounting hardware for cutting

attachments

– Locking pin

– Thrust plate

– Thrust washer

– Nut

Displacement: 27.2 cm

3

Bore: 34 mm

Stroke: 30 mm

Engine power to

ISO 8893:

0.8 kW at

8,500 rpm

Idle speed: 2,800 rpm

Cut-off speed (rated): 10,000 rpm

Max. output shaft

speed (cutting

attachment): 8,900 rpm

Spark plug

(suppressed): NGK CMR 6 H

Electrode gap: 0.5 mm

Fuel tank capacity: 0.34 l

dry, without cutting attachment and

deflector

FS 40: 4.4 kg

FS 50: 4.4 kg

FS 50: with long shaft: 4.5 kg

FS 40 C: with ErgoStart: 4.5 kg

FS 50 C: with ErgoStart: 4.5 kg

FS 50 C: with ErgoStart

and long shaft:

4.6 kg

without cutting attachment

FS 40: 1450 mm

FS 40 C: 1450 mm

FS 50: 1450 mm

FS 50 C: 1450 mm

FS 50 with long shaft: 1650 mm

FS 50 C with long shaft: 1650 mm

Special Accessories

Use cutting attachments only as

specified in the chapter on

"Approved Combinations of

Cutting Attachment, Deflector,

Handle and Harness".

Page 34

FS 40, FS 40 C, FS 50, FS 50 C

English

32

Other special accessories

– Safety glasses

– Shoulder strap / Harness

– Combination wrench

– Offset screwdriver

– Carburetor screwdriver

– STIHL ElastoStart (starter rope with

grip)

Contact your STIHL dealer for more

information on these and other special

accessories.

Users of this machine may only carry out

the maintenance and service work

described in this user manual. All other

repairs must be carried out by a

servicing dealer.

STIHL recommends that you have

servicing and repair work carried out

exclusively by an authorized STIHL

servicing dealer. STIHL dealers are

regularly given the opportunity to attend

training courses and are supplied with

the necessary technical information.

When repairing the machine, only use

replacement parts which have been

approved by STIHL for this power tool or

are technically identical. Only use high-

quality replacement parts in order to

avoid the risk of accidents and damage

to the machine.

STIHL recommends the use of original

STIHL replacement parts.

Original STIHL parts can be identified by

the STIHL part number, the {

logo and the STIHL parts symbol K

(the symbol may appear alone on small

parts).

This statement is given voluntarily,

based on the MOU (Memorandum of

Understanding) as agreed in April

1999 between Environmental Canada

and STIHL Limited

Your Warranty Rights and

Obligations

STIHL Limited is pleased to explain the

Emission Control System Warranty on

your equipment type engine. In Canada

new 1999 and later model year small off-

road equipment engines must be

designed, built and equipped, at the time

of sale, to meet the U.S. EPA

regulations for small non road engines.

The equipment engine must be free from

defects in materials and workmanship

which cause it to fail to conform with

U.S. EPA standards for the first two

years of engine use from the date of sale

to the ultimate purchaser.

STIHL Limited must warrant the

emission control system on your small

off-road engine for the period of time

listed below provided there has been no

abuse, neglect or improper maintenance

of your small off-road equipment engine.

Your emission control system includes

parts such as the carburetor and the

ignition system. Also included may be

hoses, and connectors and other

emission-related assemblies.

Where a warrantable condition exists,

STIHL Limited will repair your small off-

road equipment engine at no cost to you,

Maintenance and Repairs STIHL Limited Emission

Control Warranty

Statement

Page 35

FS 40, FS 40 C, FS 50, FS 50 C

English

33

including diagnosis (if the diagnostic

work is performed at an authorized

dealer), parts, and labor.

Manufacturer's Warranty Coverage

In Canada 1999 and later model year

small off-road equipment engines are

warranted for two years. If any emission-

related part on your engine is defective,

the part will be repaired or replaced by

STIHL Limited free of charge.

Owner's Warranty Responsibilities:

As the small off-road equipment engine

owner, you are responsible for the

performance of the required

maintenance listed in your instruction

manual. STIHL Limited recommends

that you retain all receipts covering

maintenance on your small off-road

equipment engine, but STIHL Limited

cannot deny warranty solely for the lack

of receipts or for your failure to ensure

the performance of all scheduled

maintenance.

Any replacement part or service that is

equivalent in performance and durability

may be used in non-warranty

maintenance or repairs, and shall not

reduce the warranty obligations of the

engine manufacturer.

As the small off-road equipment engine

owner, you should be aware, however,

that STIHL Limited may deny you

warranty coverage if your small off-road

equipment engine or a part has failed

due to abuse, neglect, improper

maintenance or unapproved

modifications.

You are responsible for presenting your

small off-road equipment engine to a

STIHL service center as soon as a

problem exists. The warranty repairs will

be completed in a reasonable amount of

time, not to exceed 30 days.

If you have any questions regarding your

warranty rights and responsibilities,

please contact a STIHL customer

service representative at www.stihl.ca

or you can write to:

STIHL Ltd.,

1515 Sise Road

Box 5666

CA-LONDON ONTARIO; N6A 4L6

Coverage by STIHL Limited

STIHL Limited warrants to the ultimate

purchaser and each subsequent

purchaser that your small off-road

equipment engine will be designed, built

and equipped, at the time of sale, to

meet all applicable regulations. STIHL

Limited also warrants to the initial

purchaser and each subsequent

purchaser that your engine is free from

defects in materials and workmanship

which cause the engine to fail to conform

with applicable regulations for a period

of two years.

Warranty Period

The warranty period will begin on the

date the utility equipment engine is

purchased by the initial purchaser and

you have signed and sent back the

warranty card to STIHL Ltd. If any

emission-related part on your engine is

defective, the part will be replaced by

STIHL Limited at no cost to the owner.

Any warranted part which is not

scheduled for replacement as required

maintenance, or which is scheduled only

for regular inspection to the effect of

"repair or replace as necessary" will be

warranted for the warranty period. Any

warranted part which is scheduled for

replacement as required maintenance

will be warranted for the period of time

up to the first scheduled replacement

point for that part.

Diagnosis

You, as the owner, shall not be charged

for diagnostic labor which leads to the

determination that a warranted part is

defective. However, if you claim

warranty for a component and the

machine is tested as non-defective,

STIHL Limited will charge you for the

cost of the emission test. Mechanical

diagnostic work will be performed at an

authorized STIHL servicing dealer.

Emission test may be performed either

at

STIHL Incorporated,

536 Viking Drive, P.O. Box 2015,

Virginia Beach, VA 23452

or at any independent test laboratory.

Warranty Work

STIHL Limited shall remedy warranty

defects at any authorized STIHL

servicing dealer or warranty station. Any

such work shall be free of charge to the

owner if it is determined that a warranted

part is defective. Any manufacturer-

approved or equivalent replacement

part may be used for any warranty

maintenance or repairs on emission-

related parts and must be provided

without charge to the owner. STIHL

Limited is liable for damages to other

engine components caused by the

failure of a warranted part still under

warranty.

The following list specifically defines the

emission-related warranted parts:

Page 36

FS 40, FS 40 C, FS 50, FS 50 C

English

34

– Air Filter

– Carburetor

– Fuel Pump

– Choke (Cold Start Enrichment

System)

– Control Linkages

– Intake Manifold

– Magneto or Electronic Ignition

System (Ignition Module)

– Spark Plug

– Catalytic Converter (if applicable)

– Fuel Tank

– Fuel Cap

– Fuel Line

– Fuel Line Fittings

– Clamps

– Fasteners

Where to make a Claim for Warranty

Service

Bring the product to any authorized

STIHL servicing dealer and present the

signed warranty card.

Maintenance Requirements

The maintenance instructions in this

manual are based on the application of

the recommended 2-stroke fuel-oil

mixture (see also instruction "Fuel").

Deviations from this recommendation

regarding quality and mixing ratio of fuel

and oil may require shorter maintenance

intervals.

Limitations

This Emission Control Systems

Warranty shall not cover any of the

following:

1. repair or replacement required

because of misuse, neglect or lack

of required maintenance

2. repairs improperly performed or

replacements not conforming to

STIHL Limited specifications that

adversely affect performance

and/or durability, and alterations or

modifications not recommended or

approved in writing by STIHL

Limited

3. replacement of parts and other

services and adjustments

necessary for required maintenance

at and after the first scheduled

replacement point

Page 37

Notice d'emploi d'origineImprimé sur papier blanchi sans chlore

L'encre d'imprimerie contient des hui les végétales, le papier est

recyclable.

© ANDREAS STIHL AG & Co. KG, 2009

0458-546-8221-A. M0-7.L09.PM.

0000001091_004_F

FS 40, FS 40 C, FS 50, FS 50 C

français

35

{

Table des matières

Chère cliente, cher client,

nous vous félicitons d'avoir choisi un

produit de qualité de la société

STIHL.

Ce produit a été fabriqué avec les

procédés les plus modernes et les

méthodes de surveillance de qualité

les plus évoluées. Nous mettons tout

en œuvre pour que ce dispositif vous

assure les meilleurs services, de telle

sorte que vous puissiez en être

parfaitement satisfait.

Pour toute demande de

renseignements complémentaires,

veuillez vous adresser à votre

revendeur ou directement à

l'importateur de votre pays.

Hans Peter Stihl

Indications concernant la présente

Notice d'emploi 36

Prescriptions de sécurité et

techniques de travail 36

Combinaisons autorisées d'outil de

coupe, de capot protecteur, de

poignée et de harnais 44

Montage de la poignée circulaire 45

Montage des dispositifs de sécurité 45

Montage de l'outil de coupe 46

Carburant 49

Ravitaillement en carburant 50

Mise en route / arrêt du moteur 52

Instructions de service 54

Nettoyage du filtre à air 54

Gestion moteur 55

Réglage du carburateur 55

Contrôle de la bougie 57

Fonctionnement du moteur 58

Lanceur 58

Rangement du dispositif 59

Remplacement du fil de coupe 59

Contrôle et maintenance par le

revendeur spécialisé 62

Instructions pour la maintenance et

l'entretien 63

Principales pièces 65

Caractéristiques techniques 66

Accessoires optionnels 67

Instructions pour les réparations 68

Garantie de la Société STIHL

Limited relative au système

antipollution 68

Page 38

FS 40, FS 40 C, FS 50, FS 50 C

français

36

Pictogrammes

Tous les pictogrammes appliqués sur le

dispositif sont expliqués dans la

présente Notice d'emploi.

Repérage des différents types de

textes

Développement technique

La philosophie de STIHL consiste à

poursuivre le développement continu de

toutes ses machines et de tous ses

dispositifs ; c'est pourquoi nous devons

nous réserver tout droit de modification

de nos produits, en ce qui concerne la

forme, la technique et les équipements.

On ne pourra donc en aucun cas se

prévaloir des indications et illustrations

de la présente Notice d'emploi à l'appui

de revendications quelconques.

Respecter les prescriptions de sécurité

nationales spécifiques publiées par ex.

par les caisses professionnelles

d'assurances mutuelles, caisses de

sécurité sociale, services pour la

protection du travail et autres

organismes compétents.

Une personne qui travaille pour la

première fois avec le dispositif à moteur

doit demander au vendeur ou à une

personne compétente de lui montrer

comment l'utiliser en toute sécurité – ou

participer à un stage de formation.

Les jeunes encore mineurs ne sont pas

autorisés à travailler avec le dispositif à

moteur – une seule exception est

permise pour des apprentis de plus de

16 ans travaillant sous surveillance.

Veiller à ce que des spectateurs

éventuels, en particulier des enfants, ou

des animaux restent à une distance

suffisante.

Lorsque le dispositif à moteur n'est pas

utilisé, il faut le ranger de telle sorte qu'il

ne présente pas de risque pour d'autres

personnes. Assurer le dispositif à

moteur de telle sorte qu'il ne puisse pas

être utilisé sans autorisation.

L'utilisateur est responsable des

blessures qui pourraient être infligées à

d'autres personnes, de même que des

dégâts matériels causés.

Ne prêter ou louer le dispositif à moteur

qu'à des personnes familiarisées avec

ce modèle et sa manipulation – et

toujours y joindre la Notice d'emploi.

Le cas échéant, tenir compte des

prescriptions nationales et des

réglementations locales qui précisent

les créneaux horaires à respecter pour

le travail avec des dispositifs à moteur

bruyants.

L'utilisateur du dispositif à moteur doit

être reposé, en bonne santé et en bonne

condition physique.

Une personne à laquelle il est interdit

d'effectuer des travaux fatigants – pour

des questions de santé – devrait

consulter son médecin et lui demander

si elle peut travailler avec un dispositif à

moteur.

Uniquement pour les personnes qui

portent un stimulateur cardiaque : le

système d'allumage de ce dispositif à

moteur engendre un champ

électromagnétique de très faible

intensité. Une influence sur certains

types de stimulateurs cardiaques ne

peut pas être totalement exclue. Afin

Indications concernant la

présente Notice d'emploi

Avertissement contre un risque

d'accident et de blessure ainsi

que de graves dégâts matériels.

Avertissement contre un risque de

détérioration du dispositif ou de

certains composants.

Prescriptions de sécurité

et techniques de travail

En travaillant avec ce dis-

positif à moteur, il faut

respecter des prescrip-

tions de sécurité

particulières, parce que

l'outil de coupe tourne à

très haute vitesse.

Avant la première mise

en service, lire attentive-

ment et intégralement la

présente Notice d'emploi.

La conserver précieuse-

ment pour pouvoir la

relire lors d'une utilisa-

tion ultérieure. Le fait de

ne pas respecter les ins-

tructions de la Notice

d'emploi peut présenter