Page 1

WORKSHOP MANUAL

VILLA 2000-2019

Page 2

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 1 General 1

1 General instructions

Contents in this chapter

1.1 Introduction ...............................2

1.1.1 Responsibility declaration ......2

1.1.2 How this manual is used .......2

1.1.3 Abbreviations .........................2

1.2 Safety Precautions ...................2

1.2.1 Symbols and general

warnings .................................3

1.2.2 Warm parts ............................3

1.2.3 Moving parts ..........................3

1.2.4 Lifting and blocking up ...........3

1.2.5 Cleanliness ............................3

1.2.6 Tightening torque ..................3

1.2.7 Sharp edges .......................... 3

1.2.8 Replacement parts ................3

1.2.9 Inspection ..............................3

1.3 Guarantee ..................................4

1.3.1 Component guarantee,

chassis .................................. 4

1.3.2 Exeptions ..

1.3.3 Conditions for validity of

the warranties ........................ 4

1.4 Unpacking and assembly ........ 5

1.4.1 Unpacking ........

1.4.2 Battery .................................. 6

1.4.3 Assembly .............................. 7

1.4.4 Final checks .......................... 9

1.5 Service ...................................... 10

1.5.1 First Service ........................11

1.5.2 Intermiadate Service ........... 11

1.5.3 Basic Service ...................... 12

1.5.4 Description of service points. 13

1.6 Technical specifications ........... 16

1.6.1 General tightening torque ...... 16

............................ 4

..................... 5

General

This Manual do not cover repair instructions for the motors. Regarding motors, contact the

respective representative in the actual country.

This Manual

modified or

The manual is divided in the following chapters:

Chapter 1 is this chapter

Chapter 2 Chassis

Chapter 3 Steering

Chapter 4 Hydraulic system

Chapter 5 Belts

Chapter 6 Control Wires

Chapter 7 Electrical system

and its specifications are valid for machines in their original design. In case of

changed machine, i.e. the motor is replaced, the manual accordance is limited.

Page 3

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 1 General 2

1.1 Introduction

1.1.1 Responsibility declaration

In spite of the great care we have taken there may be errors in this publication.

The author cannot be made liable for incorrect or missing information.

GGP SE reserves the right to regularly change product specifications without prior notice.

All the information in this book is based on the information available at the time of

production. Illustrations and photographs may be arranged schematically, which implies

that one picture may cover several models and therefore not correspond exactly with all

models.

1.1.2 How this manual is used

To make this manual easy to understand we have divided the machine into its main

systems and components. These parts are now the different chapters in the book.

Each chapter is divided up into sections.

There is a quick-guide on the cover of this book, which refers to the different chapters. In

each chapter there is a detailed table of contents so that you can easily and quickly find

what you are looking for.

For example, if you are looking for information on the Accessory Lifter you will find this in

chapter 3, Chassis and Body. On the first page in chapter 3 there is a detailed table of

contents which refers to the correct section, in this case section 3.1.

Always check that you are reading the right chapter for your particular machine before

starting the repair work.

1.1.3 Abbreviations

The following abbreviations are used in this manual:

HST Hydrostatic Transmission PTO Power Take Off

1.2 Safety Precautions

This manual has been written primarily for trained mechanics working in a well-equipped

workshop. Nevertheless, the manual contains such detailed information that it can also be

of use to owners who wish to carry out simple service and repairs on their machine.

A basic knowledge of repairs, tools and repair instructions is, however, always a

prerequisite for first-rate results.

A qualified mechanic should always be consulted if the owner does not have sufficient

knowledge to carry out repairs.

During the warranty period all service must be carried out by an Authorised Workshop for

the warranty to be valid.

The following basic points should be observed if the machine is to function perfectly:

• Follow the service schedule.

• Be on the alert for sudden vibrations or abnormal noise to avoid major breakdowns.

• Always use Genuine Spare Parts

• Follow the descriptions in this manual carefully. Do not take any short cuts.

Page 4

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 1 General 3

1.2.1 Symbols and general

warnings

Warning!

This symbol indicates a risk of

personal injury or damage if the

instructions are not followed.

Note!

This text indicates a risk of damage to

the material or risk of unnecessarily

complicated work if the instructions

are not followed.

1.2.2 Warm parts

Please observe that engine and exhaust

system picks up a lot of heat during use.

This applies above all to the silencer of

machines equipped with catalytic

converter.

To avoid injuries, allow the machine to cool

before any kind of repairs are made to or

near parts of the engine or exhaust

system.

1.2.5 Cleanliness

Clean the machine before starting repairs.

Dirt that penetrates into sensitive

components can seriously influence the

service life of the machine.

1.2.6 Tightening torque

Unless otherwise stated the tightening

torque in the tables in the section

Technical specifications must be used for

the different sizes of screws. This does not

refer to self-tapping screws, which are

mainly used for the assembly of body

parts.

1.2.7 Sharp edges

Watch out for sharp edges, especially

when working with the mower deck. The

blades can be very sharp. Always wear

gloves when working with the blades.

1.2.8 Replacement parts

1.2.3 Moving parts

The machines are all equipped with v-belt

transmissions. Always stop the engine and

remove the starter key before inspections

or repairs are carried out.

Always use extreme caution when testing

systems with moving parts to avoid

injuries.

Always use Genuine Spare Parts during

service work.

1.2.4 Lifting and blocking up

Before work under the machine, always

make sure that lifting devices and jackstands are approved for the weight.

Work safe!

Always use Genuine Spare Parts during

service work.

1.2.9 Inspection

Each part dismantled in conjunction with

service work must be inspected.

Examine for: wear, cracks, out of

roundness, straightness, dents,

discolouring, abnormal noise and

jamming.

Page 5

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 1 General 4

1.3 Guarantee

1.3.1 Component guarantee,

chassis

The guarantee is valid provided

prescribed basic services have been

carried out at an authorised service

workshop during the relevant guarantee

period. The services must be verified in the

service book.

that the

1.3.2 Exeptions

The extended warranty does not cover

damage due to the following:

• Neglect by users to acquaint themselves

with accompanying documentation.

• Carelessness.

• Incorrect and non-permitted use or

assembly.

• The use of non-genuine spare parts.

• The use of accessories not supplied or

approved by the manufacturer.

he purchaser is covered b

T

laws of each country. The rights to which

the purchaser is entitled with the support of

these laws are not restricted by this

warranty.

y the national

1.3.3 Conditions for validity of the

warranties

The fully completed warranty card must be

sent to Stiga´s subsidiary or distributor.

In the event of a claim, the service history

must be confirmed with a copy of the

service book.

Neither does the warranty cover:

• Wearing components such as blades,

belts, wheels,battery and cables.

• Normal wear.

• Engine and transmission. These are covered by the respective manufacturer’s

warranties, with separate terms and conditions.

Page 6

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 1 General 5

1.4 Unpacking and assembly

Every Stiga machine has undergone an

extensive control programme before delivery.

The machines are delivered as completely

assembled as possible.

Thanks to this the assembly on delivery is rapid

and easy.

The correct and careful assembly of the

machine on delivery is a simple way of ensuring

satisfied customers!

Note!

The machine shall remain placed on the

pallet during the unpacking and

assembly.

1.4.1 Unpacking

Open up the crate and release the part as

follows:

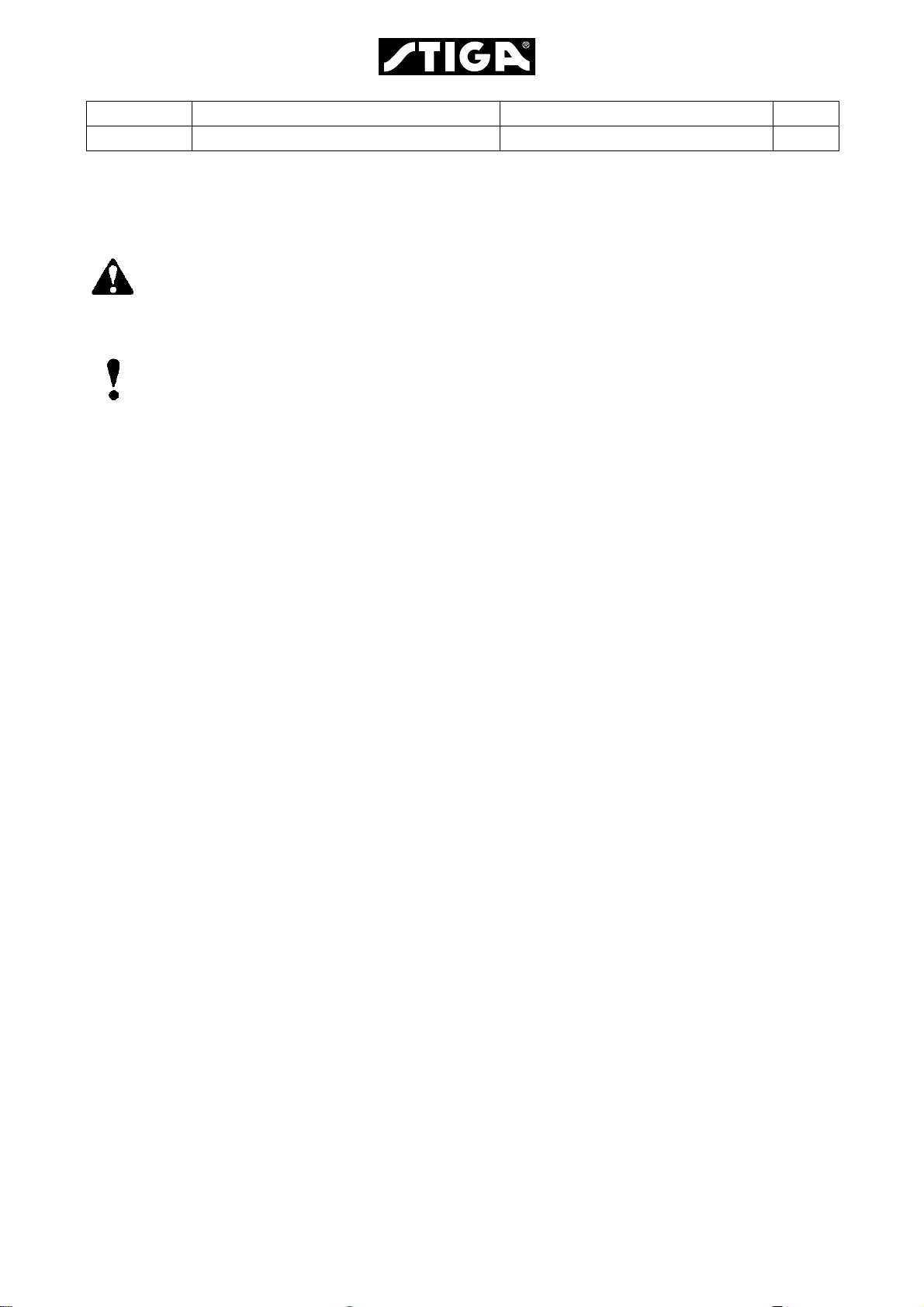

1. Check the air pressure in the tyres. The

pressure is designated on the floor mat.

The air pressure in the tyres is of critical

importance for the performance and

handling of the machine. The correct air

pressure for mowing is:

Front: 0,4 bar (6 psi)

Rear: 1,2 bar (17 psi)

When using some accessories it may be

necessary to increase the pressure

somewhat. However, the maximum

permitted pressure is always

1.2 bar (17 psi).

Too high pressure in the tyres leads to that

the machine drives poor due to:

• A small surface in contact to the ground.

• Hard tyre = less flexibility = self cleaning characteristic deteriorate.

Too high pressure Correct pressure

2. Remove the following parts from the

package and put them on the floor.

• The battery (some models).

• The steering wheel.

• The plastic bag, containing owners manuals,

and assembly screws.

Page 7

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 1 General 6

1.4.2 Battery

The battery is a valve regulated type.

Depending on the battery type, load and

assemble the battery, following the actual

instruction below.

Valve regulated battery

This battery needs limited maintenance. Is has

no electrolyte levels or plugs.

Warning!

Do not wear rings, metallic bracelet,

chain round the neck or similar metal

objects when working with the

battery. It can cause short-circuit,

burns and fire.

Warning!

The battery must be fully charged be-

fore being used for the first time. The

battery must always be stored fully

charged. If the battery is stored while

discharged, serious damage will occur.

Charging with the engine

The battery can be charged using the engine’s

generator as follows:

1. Install the battery in the machine as shown

below.

2. Place the machine outdoors or install an

extraction device for the exhaust fumes.

3. Start the engine according to the

instructions in the user guide.

4. Allow the engine to run continuously for 45

minutes.

5. Stop the engine. The battery will now be

fully charged.

Charging using battery charger

When charging using a battery charger, a

battery charger with constant voltage must

be used.

The battery can be damaged if a standard

type battery charger is used.

Installation of battery

See also the respective installation

manual, delivered with the machine.

After the battery is charged, remove the

motor casing and install it in the machine.

Connect first the red cable to plus (+) and

then the black cable to minus (-).

If the cables are disconnected/

connected in the wrong order,

there is a risk of a short-circuit

and damage to the battery.

If the cables are interchanged,

the generator and the battery

will be damaged.

The engine must never be driven

with the battery disconnected.

There is a risk of serious damage to the generator and the

electrical system.

Page 8

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 1 General 7

1.4.3 Assembly

The assembly procedure shall take place in a

clean, well illuminated and dry place.

Assemble the machine as follows:

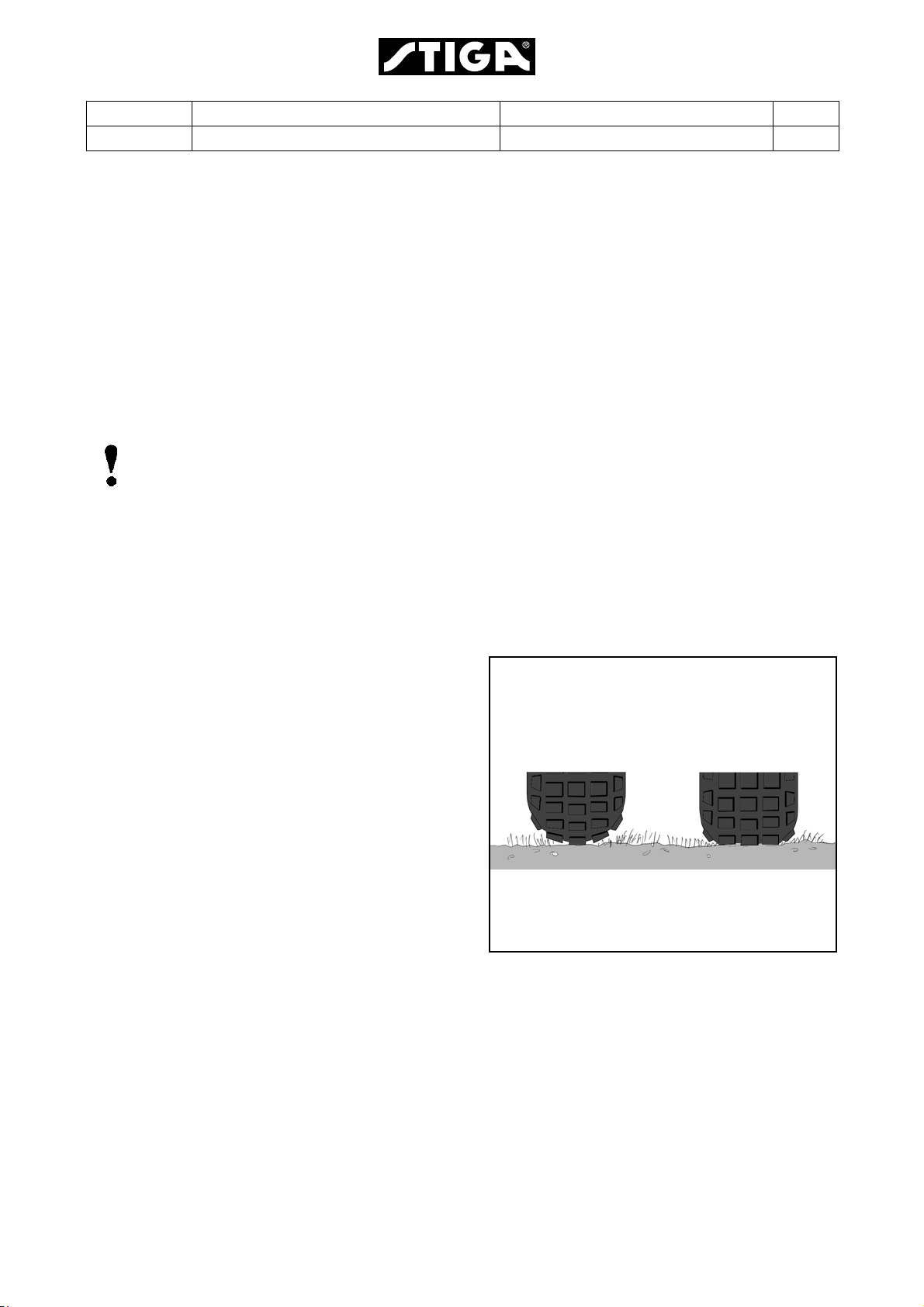

Assembly of steering wheel

The machine is delivered with two shims, one

with a thickness of 0.5 mm and one with a

thickness of 1.0 mm.

In order to minimise the axial play in the

steering column, the shim washers (0.5 mm)

and/or (1.0 mm) must be installed on the

steering column between the steering column

jacket and the bracket as follows.

1. Install the steering column jacket on the

steering column and secure by knocking in

the tension pin approximately 1/3 of its

length.

2. Pull the steering column jacket and the

steering column up.

3. From the outside, check whether no

washers, the 0.5 mm washer, the 1.0 mm

washer or both washers can be inserted into

the gap. The washer/washers must not be

forced in, as there must be a little axial play.

4. Pull out the cotter pin and dismantle the

steering wheel jacket.

5. Install the washer/washers in accordance

with point 3 above.

6. Install the steering column jacket on the

steering column and secure by knocking in

the tension pin fully. Use a counterhold.

Also make sure that the logo on the steering

wheel is in the correct position.

Page 9

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 1 General 8

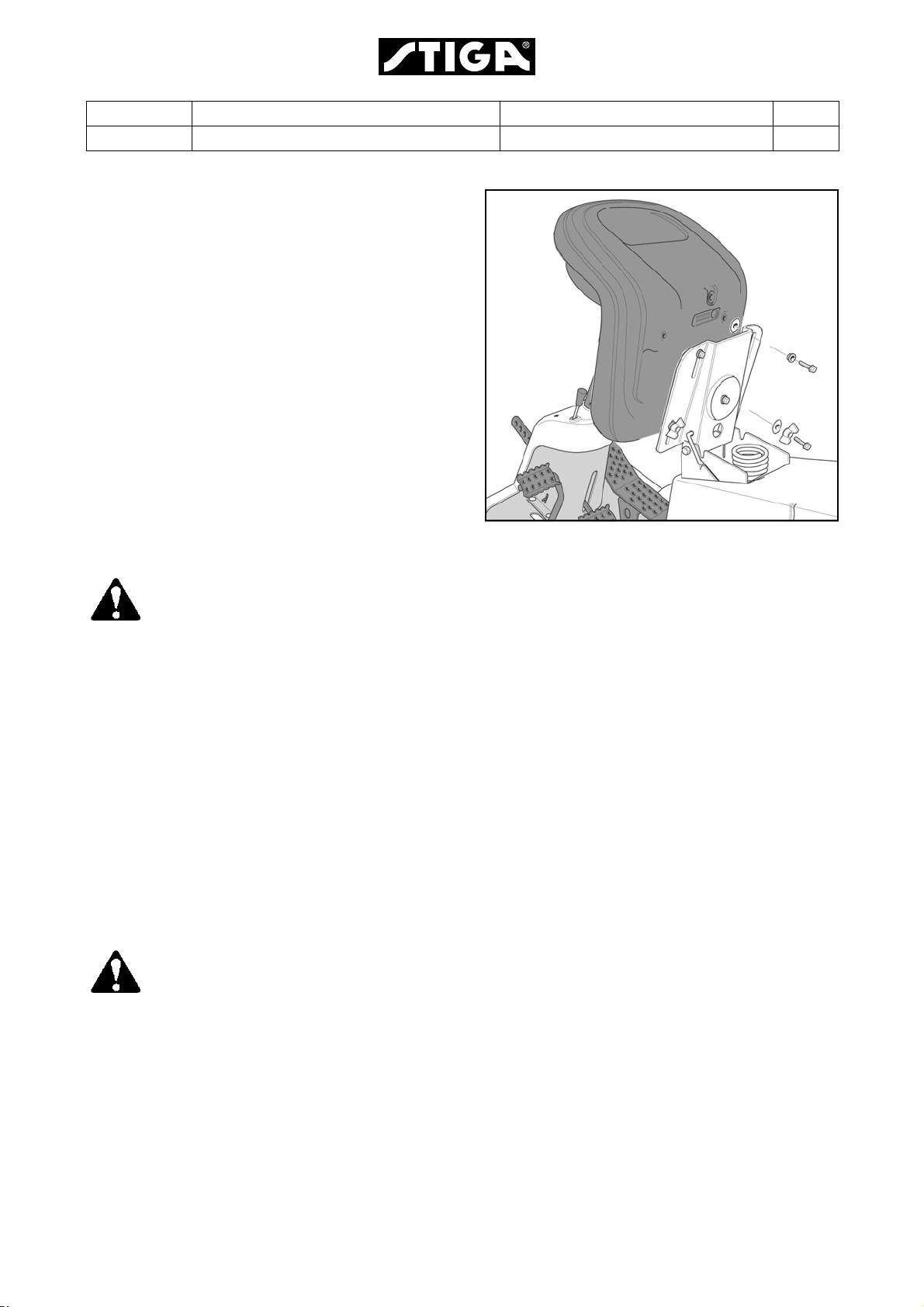

Assembly of seat (adjusting wings under)

Release the catch (S) and fold up the seat

bracket.

NOTE! To facilitate installation of the seat,

apply a drop of oil to the four screws before

I

screwing them into the seat.

F

Install the mounting in the rear (upper) holes as

follows:

K

1. Install the shoulder washers (F) on the screws

(K).

2. Insert the screws through the slots in the

bracket. Place a washer (I) between the seat

and the bracket.

3. Tighten the screws in the seat. Tightening

torque: 9±1.7 Nm.

If the screws are tightened more than

9±1.7 Nm, the seat will be damaged.

4. Check that the seat moves easily in the slots

in the bracket.

Install the mounting in the front (lower) holes as

follows:

1. Install the screw knobs (H) on the screws (G).

2. Install a washer (I) on each screw.

3. Insert the screws through the slots in the

bracket and tighten by hand in the seat.

I

H

G

S

4. Fold the seat down and place it in the desired

position.

5. Tighten the screw knobs (H) by hand.

The screw knobs (H) and the seat will

be damaged if tools are used.

Towing plate

Fitting according to customer requirements.

Engine oil

Check the oil level in the engine and top up if

necessary.

Page 10

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 1 General 9

1.4.4 Final checks

Removing from pallet

All the above measures shall have been done

with the machine standing on the pallet. Now,

loosen ev. remaining attachments and roll off

the machine from the pallet.

Accessories

Fit and adjust accessories.

Test driving

Warning!

Do not drive without a work

equipment (mover deck) attached.

Risk for turning over.

Drive the machine for a few minutes. Test all

the functions. Pay special attention to the

safety functions. If the machine is to be

delivered with mower deck or other

accessories, fit these before test driving the

machine.

Steering chain / Steering wire

Check that the steering chain / steering

wire is sufficiently taut. Adjust if

necessary.

Miscellaneous

Give the machine a general inspection.

• Is the machine clean?

• Is there any oil leakage?

• Abnormal noise or rattle?

Receipt

By filling in the guarantee certificate you

guarantee that the delivery service has

been correctly conducted.

Remember to make sure that the

customer receives all the documentation

when the machine is collected / delivered.

HST oil

Check the oil level in the HST’s expansion tank

after test driving, and top up if necessary.

Page 11

Edition Manual Chapter Page

f

T

a

T

2008-05-19 Workshop Manual, Stiga Villa/Ready 1 General 10

1.5 Service

Every new machine is delivered with a service book. This service book is part of the active

post-market programme and shall be kept in a safe place during the entire lifetime of the

machine. Hand over the service book if the machine is sold in 2:nd hand.

Service should generally be carried out at least every 50 operating hours (exception of the

irst service), although in accordance with the conditions below.

here are three different grades of service events. Every service event consists of a

number of service points as described in the following paragraphs. Every service point has

number which refer to a describing text after the schedules.

Some service points do not coincide with the scheduled service intervals, but shall be

performed in connection with a scheduled service when possible. E.g. some items shall be

performed at every second service and some also between two services. These service

points are described with procedure and interval in the respective “Instruction for use”.

ypical service points wich not coincide with scheduled service intervals are:

• Cleaning/changing air filter in some motors.

• Change of oil in some motors.

• Valve adjustments for some motors.

• Change of spark plug in some motors.

Page 12

Edition Manual Chapter Page

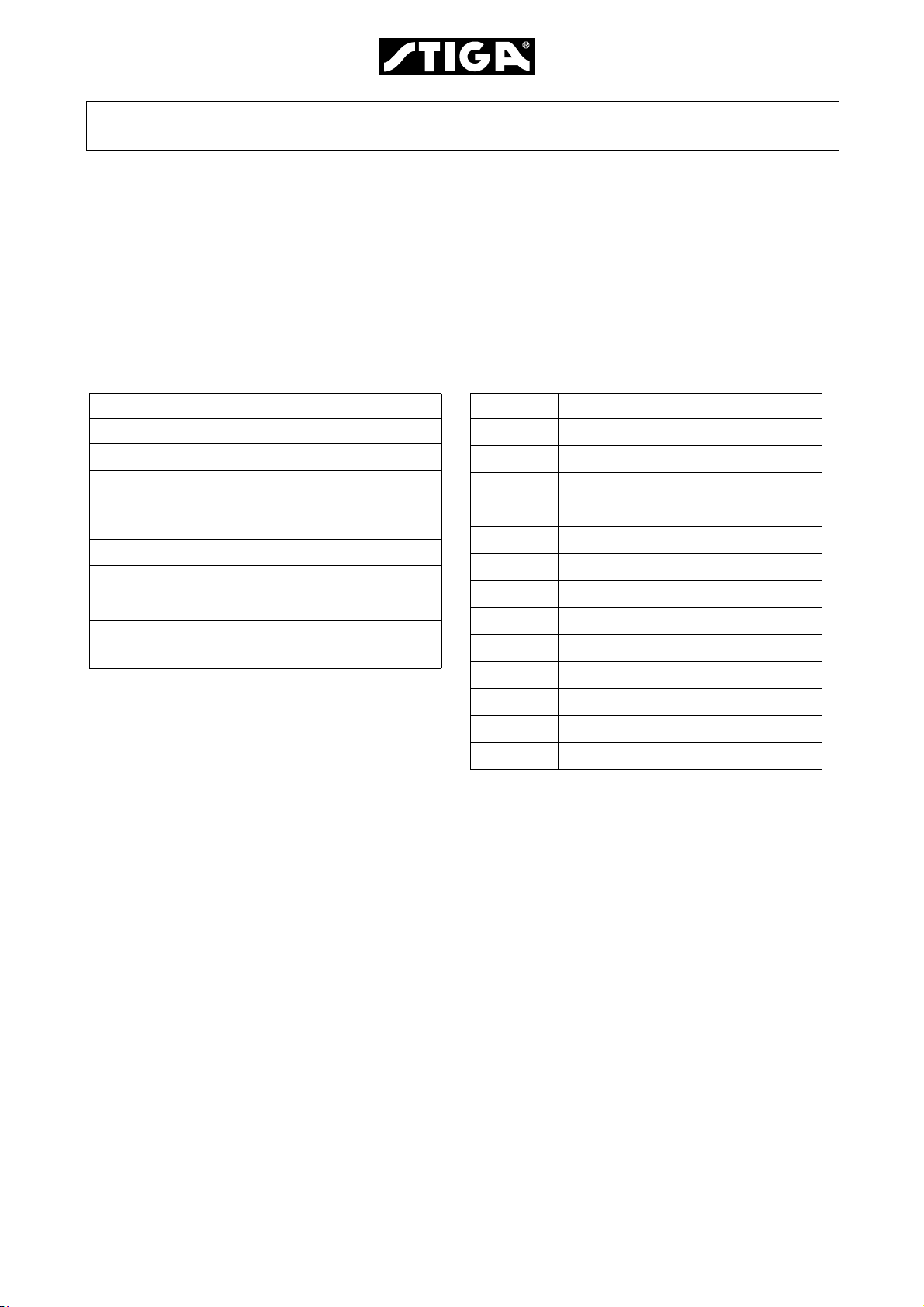

1.5.1 First S

1.5.2 Int

2008-05-19 Workshop Manual, Stiga Villa/Ready 1 General 11

The first service shall be performed within 5

hours of running and includes the service

points as per the table below.

This service is very important to safeguard

the continuing function of the machine.

Number Service point

1

2

3

4

5

6

21

ervice

Safety check.

Tyres, air pressure.

Engine oil, change.

Machines with filter, replace it

together with the oil.

Oil level in HST, check

(Valid for machines with HST

only).

Belt transmissions, check.

Steering adjustment.

Test driving.

ermediate Service

The intermediate service shall be conducted

between two basic services. That means 50

hours after a basic service.

Number Service point

1

2

3

4

6

8

11

12

The intermediate service is not as extensive

as the Basic Service and can therefore be

conducted by the customer, or by an

authorised Service Workshop. Regardless of

who conducts the service, it must be

documented in the service book.

Safety check.

Tyres, air pressure.

Engine oil, change.

Oil level in HST, check.

(Valid for machines with HST

only).

Steering adjustment.

Air filter, cleaning.

Cooling fins, clean.

Lubrication

Page 13

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 1 General 12

1.5.3 Basic Service

The basic service shall be conducted every 100

hours or once every year, which first occur.

The Basic Service must always be conducted by

an authorized Service Workshop, and

documented with a stamp in the service book.

Number Service item

1 Safety check

2

3

4

5

6

8

*) See also “Safety check”.

**) See also the mover deck manual.

Tires, air pressure

Engine oil, change.

Machines with filter, replace it

together with the oil.

Oil in HST, check.

Belt transmissions, check

Steering adjustment

Air filter for engine, clean/

replace

Number Service item

10

11

13

14

15

16

17

18

19

20

21

22

23

Cooling fins, clean

Spark plug, check/replace

Transmission, check

Speed check

Bearing boxes, check**

Exhaust system, check*

Electrical system, check*

Mower deck, check**

Blades, check**

Power take-off, check

Control check

Valve play***

Test driving

***) See the motor manual.

Page 14

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 1 General 13

1.5.4 Description of service points

1. Safety check

Check the safety functions. It is often appropriate to do this check in conjunction with test

driving. The following items shall be checked at all machines:

• No leakage on fuel lines and connections.

• No mechanical damages to the electrical cables. All insulation intact.

• The muffler shall be undamaged and its screws tightened. No exhaust leakage in connections.

The electrical check items at the respective machine up to model 2004 are listed in the

tables below. For models 2005 and up, see the respective “Instructions for use”.

Models with manual gearbox

Test Status Action Result

1 PTO activated.

No gear activated.

2 PTO not activated.

A gear is activated.

3 Motor running.

PTO activated.

4 Motor running.

A gear activated.

5 Motor running. Disconnect cable from the

Turn the key and make a

start attempt.

Turn the key and make a

start attempt.

Operator rises from the

seat.

Operator rises from the

seat.

shut off valve.

Motor shall not

start.

Motor shall not

start.

Motor shall

stop.

Motor shall

stop.

Motor shall

stop after a few

minutes.

HST models

Test Status Action Result

1 Brake pedal not pressed.

PTO not activated.

2 Brake pedal pressed.

PTO activated.

3 Motor running.

PTO activated.

4 Motor running. Disconnect cable from the

Turn the key and make a

start attempt.

Turn the key and make a

start attempt.

Operator rises from the

seat.

shut off valve.

Motor shall not

start.

Motor shall not

start.

Motor shall

stop.

Motor shall

stop after a few

minutes.

Page 15

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 1 General 14

2 Tyres, air pressure

Check the air pressure. Adjust if necessary.

The recommended air presure is

designated at the floor mat.

3 Engine oil and oil filter

See “Motors” at page 18. and the

“Instructions for use”, delivered with the

machine, see “Instructions for use” at

page 19. See also the engine manufacturer

manual.

4 Oil, HST

See the “Instructions for use”, delivered

with the machine.

5 Belt transmissions, check

Check the condition of all the belts and belt

tensioners.

11 Spark plug

Remove the spark plug and clean it or

replace if necessary. See also the engine

manufacturer manual.

12 Lubrication

Lubricate the 5 nipples and all moving

parts such as wires and levers. See

section 2.

13 Transmission

Listen for abnormal noise.

Manual models: Check that the drive

function works properly at all gears. Adjust

if required.

14 Speed check

Check that the speed corresponds to the

specified value.

6 Steering, adjustment

See section 3.

7 Not applicable

8 Engine air filter

See the “Instructions for use”, delivered

with the machine. See also the engine

manufacturer manual.

9 Not applicable

10 Cooling fins

Remove protective covers from the engine

and cleans between cooling fins. Use a

brush and compressed air. See also the

engine manufacturer manual.

15 Bearing boxes

Listen for abnormal noise from the

bearings. Check that there are no wear,

play or seizure.

16 Exhaust system

Check that there are no cracks, leakage or

other damages. Check the attachment

devices. See also the engine

manufacturer manual.

17 Electrical system

Check that there are no damaged cables,

contacts or other devices. Check that all

cables are properly secured to the chassis

and with cable holders. Check that there is

no friction between cables and chassis,

which can result in cable damage and

short circuit.

Page 16

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 1 General 15

18 Mower deck

Warning!

The blades are sharp. Always

wear gloves when working with

the blades to avoid injury.

Check if there are collision damages or

wear at the deck body and painting. Align,

repair and touch up the painting as

required.

Check the tightening of the bearing boxes

screws and tighten.

Rotate the blades and check the the shafts

are correct, not bent, no abnormal bearing

noise and no plays.

Check the belts and their tensions, see

section 4.

Check that the lifting mechanism moves

evenly, not jammed and no play and that it

locks in desired position.

20 Power take-off (PTO)

Check that the magnetic clutch (if

applicable) engage the work equipment

rotation in the desired time and that it not

slips during normal load. Replace the

clutch if necessary.

Check that the power take-off belt (if

applicable) engage the work equipment

rotation in the desired time and that it not

slips during normal load. Adjust if

necessary. See section 5.

Check that the power take-off brake (if

applicable) brakes the rotation movement

in the desired time. Adjust if necessary.

See section 5.

21 Control check

Check that all controls function properly,

that there are no jammings or excessive

plays. Adjust if nesaccary. See section 6.

Check the electrical function of the

electrical mower lifter (if applicable).

Check the plastic guide bar between the

blades. Replace if required.

19 Blades

Warning!

The blades are sharp. Always

wear gloves when working with

the blades to avoid injury.

Check that the blades are sharp. Replace if

necessary.

22 Valve play

See the engine manual regarding

procedure and interval.

23 Test driving

Drive the machine during a few minutes

and make the following attentions in

different speeds and turnings in right and

left. Check that all functions work evenly

and proper and without any abnormal

noise.

• Brake function

• Clutch function

•Power take-off

• Steering

Check that there are no abnormal

vibrations.

Page 17

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 1 General 16

1.6 Technical specifications

Tightening torques

6.1 General tightening torque

1.

Unless otherwise stated, the following tightening

torque are applicable for screws and nuts on the

machine:

Thread Torque

M5 5 Nm

M6 9 Nm

M8 22 Nm

M10 45 Nm

Page 18

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 2 Chassis and Body 1

2 Chassis and body

Contents in this chapter

2.1 Lifting mechanism,

manual ..........................................2

2.1.1 General.....................................2

2.1.2 Description................................2

2.1.3 Dismantling...............................2

2.1.4 Repair of lifting lock ..................6

2.1.5 Assembly ..................................6

2.2 Lubrication chassis .................... 8

2.2.1 Steering pivot pins

and beam pivot........................ 8

2.2.2 Control wires............................ 8

2.2.3 Tensioning arms ...................... 9

2.2.4 Steering chain.......................... 9

2.2.5 Bearings................................... 9

General

To facilitate the driving, handling of work equipment and to make it comfortable for the

driver, the machines are equipped with a various number of aid equipments. These

equipments are mainly the same for all the machines covered by this manual, but in some

cases configurated in different ways. Where divergences occour between the machines,

particular instructions are given for each particular equipment.

This chapter gives a brief description of the equipments and describes their repair and

replacements.

Page 19

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 2 Chassis and Body 2

2.1 Lifting mechanism,

manual

2.1.1 Description

The work equipment lifting arm is automatic

locked in elevated position by pressing down

the lifting pedal. Next time the pedal is pressed,

the mechanism will release and the arm drops

down.

The locking function is created in the lifting lock.

The principle is described below and shown in

the figure.

A. Locked in lifted position by the ratchet (C).

B. Unlocked. Ratchet (C) is released.

C. Ratchet which is tilted by the pin (D) every

time the pedal is pressed down.

2.1.2 Dismantling

To dismantle the lifting lock it is normally

necessary to dismantle the steering console.

Nevertheless, it is possible for a skilful person

to dismantle the lifting lock without releasing

the steering console.

C

C

D

AB

The dismantling is performed as follows:

1. Dismantle the steering wheel by tapping out

the pin.

If applicable, observe the spacers and the

location when disassembly the steering

wheel.

See section 1.

Page 20

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 2 Chassis and Body 3

2. Remove the screws for the top cover.

If applicable, remove also the following:

• The bullet from the throttle handle by twisting and pulling it simultaneously.

• The ignition switch nut. To aviod damage

at the plastic cover, use a 22 mm ring

wrench.

• The cutting heigth switch by pressing its

locking tabs at the underside.

3. Dismantle the front cover by unscrewing the

two screws at the under side.

4. Unhook the return spring.

Page 21

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 2 Chassis and Body 4

5. Dismantle the lifting pedal located on the lifting arm.

6. Loosen the throttle control as follows:

1. Loosen the lever.

2. Observe where the wire conductor is

fitted to reassemble in the same position.

7. Remove the screws that hold the steering

console at the floor plate, and lift off the

steering console.

8. Remove the screws that hold the lifting fork

at the lifting lock.

Page 22

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 2 Chassis and Body 5

9. Remove the nut that holds the lifting lock on

the underside of the floor plate, and remove

the lifting lock.

10.Carefully dismantle the left bearing in the

support with a screwdriver.

11.Remove the lifting fork from the support.

Page 23

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 2 Chassis and Body 6

2.1.3 Repair of lifting lock

The lifting lock can be purchased as a complete

spare part.

The parts can be lubricated with a thin

lubricant, e.g. silicon spray, 5-56, WD40, or the

like, if the lock jams.

Note!

Viscous lubricant such as consistent

grease must not be used.

2.1.4 Assembly

Assemble in reverse order.

Check that the accessory lifter functions as

intended by repeatedly lifting and lowering it.

Note!

Pay attention to the following notes

during the assembly:

A. Apply a thin layer of universal grease to the

plastic bushings at the lifter arm.

B. It does not matter how the lifting lock

is fitted since it is symmetrical.

UNIVERSAL GREASE

Page 24

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 2 Chassis and Body 7

C. When fitting the throttle control, install the

wire conduit as observed at the dismantling.

D. Fit the top cover before the consol screws

are tightened.

The consol is aligned against the top cover.

E. If applicable, observe the spacers and the

location when reassembly the steering

wheel.

See section 1.

Page 25

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 2 Chassis and Body 8

2.2 Lubrication chassis

All moving parts shall be lubricated once per

season, although at least every 50 operating

hours.

Note!

Lubrication is equally important for a

machine that is only used for a few hours

per year.

Note!

The lubricant provides not only

protection from wear but also from rust.

Note!

The machine should always be

lubricated before prolonged storage.

2.2.1 Steering pivot pins and beam

pivot

Use a grease gun, filled with universal grease

and lubricate the steering pivot pins (A) and the

beam pivot (B). Lubricate until grease

emerges.

Note!

To lubricate the beam pivot (B) it might

be nessecary to dismount the towing

hitch.

2.2.2 Implement mountings

Lubricate the lubricating cup for the mountings

using a grease gun until grease penetrates

along side the shaft.

A

B

A

Page 26

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 2 Chassis and Body 9

2.2.3 Control wires

Drop a little unversal oil or lubricating spray in

the ends of the control wires two or three times

a year.

This procedure must be carried out by two

persons. One lubricates and one activates the

lever

Note!

Wires on machines used in freezing

conditions should not be lubricated with

engine oil since this can lead to the

control cables seizing in the cold.

The wires on such machines should be

lubricated with a fluent, strongly

penetrating lubricant, e.g. 5-56 or WD40.

2.2.4 Tensioning arms

Lubricate the bearing points with an oil can

when each control is activated. Ideally carried

out by two persons.

2.2.5 Steering chain

The steering chain must be lubricated with

chain spray two or three times per season.

If the chains are heavily fouled: dismantle the

chains and wash them.

Refit and lubricate them.

2.2.6 Bearings

Plastic bearings, e.g. the brake pedal bearing,

hydrogear pedal bearing and steering-column

bearing, must be lubricated with grease or

lubricating spray at least once per year.

Page 27

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 3 Steering 1

3 Steering

Contents in this chapter

3.1 Steering wire/chain....................2

3.1.1 Description .............................2

3.1.2 Dismantling.............................2

3.1.3 Assembly................................3

3.1.4 Steering pulleys......................5

3.1.5 Adjusting the steering wire .....5

3.2 Bearings, steering shaft........... 6

3.2.1 Replacement of sliding

bearings................................. 6

General

The Villa and Ready machines are equipped with a mechanical steering system, working

with wires or chains, depending on the model.

This chapter contains a brief description of the function and describes repair, replacements

and adjustments of stressed parts of the steering system.

This chapter is valid for the actual machines where the actual system occur.

Page 28

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 3 Steering 2

3.1 Steering wire/chain

3.1.1 Description

There are two configurations regarding to

transmit the steering power from the steering

wheel to the rear wheels:

• Wire; One single wire with a defined location

at the drive pulley.

• Chain/wire; Two wires, left and right, fitted to

a chain which is connected to the steering

pulley.

3.1.2 Dismantling

1. Wire:

Remove the four steering pulleys (A and B).

Use a 15 mm and a 17 mm wrench.

Chain/Wire:

Remove the two steering pulleys (A). Use a

15 mm and a 17 mm wrench.

2. Remove the nut and screw, holding the wire

ends (C). Use a 13 mm wrench and a pliers

to hold the wire ends.

AB

BA

3. Remove the wire from the machine.

Wire:

Pull out the wire rivet from the steering pulley

and release the wire.

Chain/Wire:

Open the chain locks and release the wires

from the chain.

Wire

Chain/Wire

Page 29

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 3 Steering 3

3.1.3 Assembly

One single wire

1. Assemble the left wire part into the two left

steering pulleys (A and B). Fit the pulleys into

their respective place.

See “3.1.4 Steering pulleys”.

2. Locate the wire in the recess (C) in the

steering disc and fasten with the screw. Use

a 13 mm wrench and a pliers to hold the wire

ends.

3. Turn the steering wheel until the wire rivet

hole is facing backwards and push in the

rivet.

4. Turn carefully the steering wheel 1,5 turn to

the left and simultaneously check that the

wire winds up correctly upwards on the drive

pulley.

Keep the left wire part stretched by blocking

or holding the rear wheels.

ABC

5. Assemble the right wire part into the two right

steering pulleys (A and B). Fit the pulleys into

their respective place.

See “3.1.4 Steering pulleys”.

6. Turn the wire 1,5 turns to the right on the

drive pulley. Keep the wire stretched.

7. Keep the wire stretched and locate the wire

in the recess (D) in the steering disc and

fasten with the parts below. Use a 13 mm

wrench and a pliers to hold the wire ends.

•Spring

• Washer

• M8 self locking nut

Adjust the wire.

See “3.1.5 Adjusting the steering wire”.

BAD

Page 30

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 3 Steering 4

Chain/Wire

1. Assemble the left wire part into the left

steering pulley (AL). Fit the pulley into place.

See “3.1.4 Steering pulleys”.

2. Locate the wire in the recess (C) in the

steering disc and fasten with the screw. Use

a 13 mm wrench and a pliers to hold the wire

end.

3. Assemble the right wire part into the right

steering pulley (AR). Fit the pulley into place.

See “3.1.4 Steering pulleys”.

4. Connect the wires to the chain with the chain

locks.

C

AL

AR

5. Stretched up the wire and and locate it in the

recess (D) in the steering disc and fasten

with the parts below. Use a 13 mm wrench

and a pliers to hold the wire ends.

•Spring

• Washer

• M8 self locking nut

Adjust the wire.

See “3.1.5 Adjusting the steering wire”.

D

Page 31

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 3 Steering 5

3.1.4 Steering pulleys

Every singel steering pulley consists of the

following parts:

A. Screw

B. Cable holder

C. Bushing

D. Steering pulley

E. Part of the frame

F. N ut

AB CDEF

Assembly instructions:

• Check the wear, specially of the steering pulley, and replace defective parts.

• Apply a thin layer of machine oil to the bushing (C).

• The cable holder (B) shall be centered

according to the wire, i.e. the angles in the figure shall be equal.

B

3.1.5 Adjusting the steering wire

Screw the nut and compress the spring until its

length is 108 mm. Hold the wire with a pliers.

Turn the wheels fully out in both directions.

Check that there is no abnormal noise or

abnormal resistance.

Page 32

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 3 Steering 6

3.2 Bearings, steering shaft

The steering shaft bearings consist of two sliding bearings of the composite type (A and B).

3.2.1 Replacement of sliding bearings

1. Remove the steering wire or wires. See

“3.1.2 Dismantling”.

2. Remove the stering wheel. See section 1.

3. If the machine is equipped with chain and

wire, release the chain from the sprocket.

4. Pull out the steering rod (F) downwards.

Don´t remove the washers and spacer (C, D

and E).

5. Replace the two bearings (A and B).

6. Assemble the steering rod (F) with its washers and spacer (C, D and E).

7. Assemble the stering wheel. See section 1.

8. Instructions for the chain, if applicable:

A

B

C

D

E

F

A. Apply a mark with a marking pencil at the

middle link of the chain (ev. there already

is a mark).

B. Turn the steering wheel to stright forward

position, i.e. the logo shall be correct

readable from the operators position.

C. Connect the chain to the sprocket with the

mark (G) backwards.

9. Assemble the steering wire or wires. See

“3.1.3 Assembly”.

G

Page 33

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 4 Hydraulic System 1

4 Hydraulic system

Contents in this chapter

4.1 Safety..........................................2

4.2 Description.................................2

4.3 Repair .........................................2

4.4 HST oil ........................................3

4.4.1 General...................................3

4.4.2 Oil filling..................................3

General

The engine power in Villa and Ready machines are transfered by a 5 gear gearbox

alternatively a stepless hydrostatic transmission (HST) to the front wheels. The steering is

performed by the rear wheels.

This chapter contains a brief description of the hydrostatic transmission and the oil filling

procedure. Other measures are not applicable.

Page 34

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 4 Hydraulic System 2

4.1 Safety

Cleanliness is mandatory at all works with

the hydraulic system. Foreign substances

and contaminations will jeopardize the function and reliability of the system.

4.2 Description

The hydrostatic transmission (HST) consists of

a hydraulic pump and a hydraulic motor.

The hydraulic pump is mechanic connected to

the drive belt.

The powerfrom the pump is transmitted to the

motor by an oil flow, i.e. the transmission is

hydraulic.

The hydraulic motor is mechanic connected to

the wheel shaft.

Since both the oil flow and the flow direction is

controlled by the drive pedal, the machine can

move both forwards and backwards with a

stepless gear ratio.

4.3 Repair

Since trouble with the HST is very unusually,

there is no need for any repair instructions in

this book.

However, in some cases oil lekage can occur.

Therefor, the oil filling procedure is described

below.

Should major repair to the HST be needed,

please refer to the service provided of the

transmission manufacturer.

Page 35

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 4 Hydraulic System 3

4.4 HST oil

4.4.1 General

The HST casing is a sealed unit, which normally

not need any service. Oil filling is

recommended only if any of the cases or both

cases below are valid:

• There is a visible oil leakage.

• Drive problems.

4.4.2 Oil filling

Note!

It may be difficult to remove the entire

oil plug intact. It is recommended to

have a new plug available before

starting the oil filling.

1. Lift the machine.

2. Remove the oil plug.

The oil plug also works as a ventilation valve.

The oil plug consists of rubber and fits rather

hard in the housing hole.

Use a long pointed chisel to work up the

plug. Eventually, loosen the HST in the frame

and lower it for better access.

3. Check the oil level. Use a suitably bent steel

wire or similar.

The level shall reach up to just under the

lower part of the plug.

4. If neccesary, top up with new oil.

Use oil SAE 10W-40 or SAE 5W-50.

Elongate the discharge of an oil can with a

plastic hose of suitable length and diameter.

Put the other end into the HST oil hole and

pump until the oil flows over.

5. Fit a new oil plug and assemble in reverse

order.

Page 36

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 5 Belts 1

5 Belts

Contents in this chapter

5.1 Description.................................2

5.2 Belt theory..................................3

5.2.1 Why it is so important to use

original belts from

the retail dealer? ..................... 3

5.3 Replacement of belts................5

5.3.1 Disassembly of belt D ............ 5

5.3.2 Inspection and measures ....... 7

5.3.3 Assembly of belt D ................. 7

5.4 Adjustments...............................9

5.4.1 Adjustment of belt B ...............9

5.4.2 Adjustment of the

clutch/brake, HST.................... 10

5.4.3 Adjustment of the clutch, Man 10

General

All mechanical power, delivered by the motor, is conducted to the different power

consuments by a belt system. The belt system has in general the same configuration in all

the machines covered by this manual. Where divergences occour between the machines,

particular instructions are given for each machine. The maximum tension of each belt is

regulated by a spring loaded belt tensioner.

This chapter gives a brief description of the belt system and describes replacements of

belts and adjustments of their tensions.

This chapter is valid for the actual machines where the actual system occur.

Page 37

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 5 Belts 2

5.1 Description

AB

123 45678

Belt A

Belt A belongs to the work equipment and is

connected to the machine at the front right

pulley. The belt is tensioned by the tension

pulley (2) which is mounted on a spring

loaded lever.

Belt B

Belt B is intended to deliver motor power to

the front right pulley, where it can be picked

up of the work equipment.

Belt C

Belt C transmitts the power to belt B and

performs the mechanic PTO clutch function

together with the pulley (8).

Engagement/disengagement of the

mechanic PTO is performed by moving the

pulley (8) to stretch/slacken the belt.

Belt D

Belt D is intended to transmitt the motor

power to the transmission, where it is geared

to a suitable ratio for the drive shaft. The belt

is tensioned by the tension pulley (7) which

together with the belt performs the clutch

function.

D

C

Motor

10

9

Belts:

A. Work equipment belt (belongs to the

work equipment).

B. Work equipment belt.

C. Work equipment clutch belt.

D. Transmission belt.

Pulleys:

1. Pulley at the work equipment.

2. Tension pulley.

3. Pulley (double).

4. Pulley at the transmission.

5. Tension pulley with the clutch function

(works on the same lever as pulley 7).

6. Transmission pulley (double).

7. Tension pulley with the clutch function

(works on the same lever as pulley 5).

8. Tension pulley (for mechanic PTO also

clutch pulley for the PTO)

9. Drive pulley at the motor shaft.

10.Drive pulley at the motor shaft.

The tensioning force is disengaged from the

belt when the parking brake is activated.

Page 38

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 5 Belts 3

5.2 Belt theory

5.2.1 Why it is so important to use original belts from the retail dealer?

The table below shows the demands on normal commercial grade belts compared to

demands on original spare parts belts from the retail dealer. The later are designed and

manufactured in close connection between the subcontractor and the rider manufacturer.

The table is intended to display the importance to use the original belts.

Case Commercial

grade belts

Fitness to pulleys. The belt shall rest

with its angled

sides against the

pulleys. There

must be a space

between belt and

pulley bottom.

Acceleration. The belt follows

the motor rpm in a

continuous

.

acceleration up to

full speed.

Original spare

parts belts

The belt shall rest

with its angled

sides against the

pulleys. There must

be a space

between belt and

pulley bottom.

Some belts shall

engage to the

pulleys with the

motor running in full

speed, which gives

an excessive

generation of heat.

Remarks

Same demands.

Original belts

guarantee that the belt

fits against the pulleys.

Common belts are

made of natural rubber,

which can resist

temperatures up to 70°

only.

Original belts are made

of chloroprene rubber,

which can resist

temperatures up to 90°

Length Manufactured in

standard lengths

in steps..

Manufactured in

preedefined lengths

to fit between the

pulleys..

The distance between

the pulleys is fix. The

belt tensioner gives the

original belt an optimal

tension.

Page 39

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 5 Belts 4

Case Commercial

grade belts

Floating pulley at

the implement.

Bending in two

directions

Designed to

transmit power

between aligned,

paralell and fixed

pulleys.

Designed to bend

around pulleys in

one direction only

Original spare

parts belts

The original PTO

belt is designed to

operate, even if the

pulleys are moving

up and down and

are tilting at the

same time

Most of the belts at

the machine have

tension rollers,

actuating from the

outside of the belt.

This means the the

belt has to bend

both inwards and

outwards during the

operation.

Remarks

The implement follows

the ground which

involves that its pulley

is constant moving.

To resist the excessive

operating conditions,

the original belts are

made of fibre

reinforced rubber.

All original belts which

operate with tension

rollers actuating from

the outside have

reinforcements. The

reinforcement is

special designed for

the actual case.

Noise Manufactured

without any

special respect to

the actual case.

The original belts

are carefully

selected to give the

lowest noise

increment to the

machine during

operation.

Depending on the

function of the belt, any

of the following belt

types are itemised:

• Wrapped

• Non-friction

• Raw-edge

Page 40

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 5 Belts 5

5.3 Replacement of belts

This section describes the belt changing of belt

D. For changing other belts, see actual parts of

the belt D description.

5.3.1 Disassembly of belt D

The belt D is intended to conduct the engine

power to the front driving (HST or manual

gearbox). The belt is controled by a 3-armed

lever for the clutch function.

Dismantle the belt as follows:

1. Raise the machine by one of the alternatives

below:

• With a highjack or similar and place 4

yokes under the shafts.

• With a lifting table.

2. Remove the following:

• Belt guides (X and Y)

• Pulley (8)

• Wire (Z) with its spring and adjuster.

E

D

CB

X

Y8Z

3. Cut off the holding strap (E) for the wire.

4. Unscrew the two screws and nuts, holding

the adjustable pulley bar (F). Remove the

pulley bar with belt C.

5. Unhook and work off the belt C.

F

Page 41

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 5 Belts 6

6. Unhook the clutch spring.

7. Remove the pulley (5). Use a 15 mm and a

17 mm wrench.

Note!

Pivot and belt guide nuts; Hold the nuts

at the upper side if nessecary.

5H

8. Loosen the pivot screw (H) a couple of turns.

9. Loosen the belt guide screw (I) a couple of

turns.

10.Remove the four front axle screws (J) and

heighten the body (or lower the

transmission) about 3 cm. Preferably put a 3

cm distance (K) between the axle and the

body at both sides.

Be carefully not to damage the transmission fan. A damaged fan will increase the heating and cause gearbox

damages.

I

K

J

J

K

11.Work off the belt D.

Page 42

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 5 Belts 7

5.3.2 Inspection and measures

1. Check and lubricate all links.

• The links shall move easily and not have

any major play.

• Lubricate all pivot linkages with machine

oil.

2. Check the belts.

• The belt shall rest with its angled sides

against the pulleys. There must be a

space between belt and pulley bottom.

• The belt shall be intact. No loose parts or

cracks.

3. Check all ball bearings with respect to the

following:

• No radial play.

• The sealing shall be intact.

• No abnormal noise when rotating. Shall

rotate evenly without stop tendency.

Replace all defective parts with genuine

spare parts.

5.3.3 Assembly of belt D

Assemble all part in the reverse order.

Note the following at the assembly procedure:

1. Be carefully not to damage the fan when

fitting the belt D around the transmission

pulley (4).

5

H

2. The belt guides shall be mounted with a play

of 2-3 mm to the belt when it is stretched.

3. If the screws (H and I) cannot be tightened,

hold the respective nut at the upper side.

I

Page 43

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 5 Belts 8

4. The pulleys (5 and 7) shall be mounted with

washer etc. as illustrated. The small pulley

shall face with its prolonged part

downwards.

7

5

5. The belt guide at pulley (7) shall be centered

over the belt when the clutch is engaged.

Note!

The prolonged part of the pulley hub

shall face against the lever.

E

7

Page 44

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 5 Belts 9

6. Don´t tighten the screws to the pulley bar (F)

yet. The belt adjustment must be performed

first.

7. Perform the adjustments as described

below.

5.4 Adjustments

5.4.1 Adjustment of belt B

Adjust the tension of belt B as follows:

1. Loosen the two screws (L and M) a few

turns.

2. Tension the belt by pulling the right end of

the pulley bar (F) backwards by using a

spring scale. Pull with a force of 85 N.

3. Tighten, simultaneously as the force is

applied, the two screws (L and M).

L

F

M

L

4. Fit a new fixing strap to the PTO wire.

VARNING!

If the fixing strap is omitted, the wire

will interfere with the steering wire

and be destroyed.

85 N

M

Page 45

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 5 Belts 10

5.4.2 Adjustment of the clutch/brake,

HST

Adjust the nuts (N1 + N2) at the clutch/brake

lever to a play of 3 mm between the lock pin

and the clutch lever.

After the adjustment, tighten the nuts (N1 +

N2).

5.4.3 Adjustment of the clutch, Man

Note!

Manual machines shall have 0 mm play

at the clutch rod (Q).

If the clutch not disengage the engine rotation

properly, it will be very difficult to change gears.

In that case, adjust the clutch as follows:

1. Hold the clutch rod (Q) with a polygrip and

loosen the rear nut (O2) until the clutch rod

(Q) is completely loose. Now, the belt

stretching will perform the stop for the clutch

arm (P). I.e the belt is max stretched by the

spring.

2. Screw the rear nut (O2) slowly forward until

the clutch arm (P) begin to move. Then

screw the nut one more turn. If nessecary,

move the front nut (O1) forwards.

N1 N2

O1 O2

3 mm

Q

P

0 mm

3. Lock by screwing the forward nut (O1)

backwards and tighten against the lever

loop. Hold the clutch rod (Q) with a polygrip

when tightening the nut.

Page 46

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 6 Control wires 1

6 Control Wires

Contents in this chapter

6.1 Description.................................2

6.2 Cable holders.............................2

6.3 PTO wire.....................................3

6.3.1 Dismantling.............................3

6.3.2 Checks ...................................3

6.3.3 Assembly................................3

6.3.4 Adjustment .............................3

6.4 Throttle wire .............................. 4

6.4.1 Dismantling ............................ 4

6.4.2 Assembly ............................... 4

6.4.3 Adjustment............................. 4

General

All the manoeuvring functions are collected around the operator.

All mechanical control movements from the operator to the respective device on the ma-

chine are conducted by wires or rods.

This chapter gives a brief description about the wires and information about how to re-

place and adjust the wires.

This chapter is valid for the actual machines where the actual system occur.

Page 47

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 6 Control wires 2

6.1 Description

All wires consist of a wire and a conduit. In the

wire ends one part, the wire or the conduit, is

fastened to the body and the other part to a lever. The levers are connected to the operator

control and to the controlled device. I.e. the

throttle wire, etc.

Wires can only transfer traction forces. The return forces for the wires are maintained by return springs.

To transfer higher forces and both pushing

and traction forces, rods are used, i.e. brakes,

etc.

Maintenance of wires:

Drop a little engine oil or lubricating spray in

the ends of the control wires two or three times

a year.

6.2 Cable holders

Warning!

It is essential that all cable holders

are fitted properly. If not, there is

risk of abnormal wear, short circuit

and fire.

All wires, electrical cables and other conductors are fitted to the chassis with cable holders. Always, after removal or replacement of

wires, new cable holders shall be fitted in places where they were original mounted.

Loose wires and cables cause unneseccary

wear of components which finally result in

electrical short circuit, paint removal and damages of plastic covers etc.

Page 48

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 6 Control wires 3

6.3 PTO wire

6.3.1 Dismantling

1. Lift the machine, either with a lifting table or

by highjack and pallets.

2. Open the engine casing.

3. Unscrew the cable adjustments, upper (A)

and lower (B).

4. Cut the holding strap (C) and unhook the

wire.

6.3.2 Checks

Check the brake shoe (D) for wear. If nessecary replace it.

A

D

6.3.3 Assembly

1. Apply a couple of oil at the wire ends while

moving it in its conduit.

2. Assemble in the reverse order.

Warning!

If the wire is loose, it will interfere with

the steering wire. It is therefore especially important that it is locked with a

new holding strap correctly.

3. Replace the holding strap (C).

4. Adjust the wire. See below.

6.3.4 Adjustment

1. Set the cable adjustments, upper (A) and

lower (B) in their middle positions.

2. Adjust about the same amount at both

adjustments until the lever have a play of

3-3,5 cm.

B

C

3-3,5 cm

3. Lock the adjustment nuts.

Page 49

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 6 Control wires 4

6.4 Throttle wire

6.4.1 Dismantling

1. Open the engine casing.

2. Loosen the wire conduit at the engine and

at the throttle lever. At machines with the

throttle lever in the front panel, remove the

upper casing for acess to the lever. See

section 2.

Note!

.It is not nessecary to cut the holding

strap (A).

3. Remove the wire.

A

6.4.2 Assembly

1. Apply a couple of oil at the wire ends while

moving it in its conduit.

2. Assemble in the reverse order.

3. Thread the wire through the holding strap

(A) and at machines with the throttle lever in

the front panel, through the holes (B).

4. Adjust the wire. See below.

6.4.3 Adjustment

1. Adjust the wire conduits at the ends until

the throttle lever can reach its end positions.

2. Fasten the conduit clamps.

3. Check the following:

• Function of the choke position

• Full throttle position

B

If nessecary repeat the adjustment procedure.

Page 50

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 1

7 Electrical System

Contents in this chapter

7.1 Description.................................2

7.2 Trouble Shooting ......................3

7.3 Repair and replacements..........16

7.3.1 Replacement of switches ....... 16

7.3.2 Replacement of switch knob .. 16

7.3.3 Connections ........................... 16

General

Each machine has its own electrical system, configurated to fit the purpose and demand of

the actual machine. The electrical system has two main duties, to maintain the machine

safety and to make the different functions easy to handle.

The main part of this chapter consists of trouble shooting of the electrical system to isolate

faults and to give information about corrective measures. The electrical system is also

described. There are also given instructions about general repair and replacement

procedures.

Page 51

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 2

7.1 Description

The electrical components are connected with cables, integrated in a complete insulated

harness, which is unique for each machine model. Thus the cables are protected against

wear, contaminations and other stresses. The cables are connected to the actual

components with tab or screw connectors and in some cases with multi-contact connectors.

The electrical system contains several safety circuits. Therefore actual levers and pedals

are provided with micro switches. The micro switches are shown in the figure below. The

signals from the micro switches are used to interlock the actual circuit in case of a forbidden

manoeuvre attempt. Some manual switches and relays have also built in interlocks, related

to the safety system.

The wiring diagrams are presented separately in the respective spare parts manual. To

achieve a complete understanding of the electrical system for a certain machine, read also

the actual wiring diagram.

All current consumption circuits except the start circuit are protected by 1-3 fuses,

depending on the machine model.

Microswitch under the seat

Microswitch under the

control panel

Microswitch at the

brake pedal lever

Page 52

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 3

7.2 Trouble Shooting

Warning!

Do not wear rings, metallic bracelet, chain round the neck or similar metal

objects when working with the electrical system. It can cause short-circuit,

burns and fire.

This section describes the trouble shooting procedures in absence of an electrical function.

It also describes the correction measures in each actual case. When following the trouble

shooting schedules, it is provided that the following states are fulfilled:

• All fuses are checked and, if necessary replaced.

• The battery shall be charged.

• The requirements for the actual measure shall be fulfilled. E.g. if it is advised to perform a

start attempt, the operator shall sit down on the seat, press the brake pedal and the

power take off shall be in disengaged position.

When following the trouble shooting shedules, it is in normal cases assumed that

conductors and connectors to conductors are OK. However, in some cases, after a long

period of use or in case of mechanical damages, the cables at the articulating point can be

damaged. The circuit diagrams are presented in the respective spare parts manual.

The following operation faults for models 2002-2007 are described.

Paragraph Page

7.2.1 The starter does not rotate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

7.2.2 The starter rotate, but the motor does not start . . . . . . . . . . . . . .8

7.2.3 The battery runs repeatedly empty . . . . . . . . . . . . . . . . . . . . . . .10

7.2.4 The motor does not stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

7.2.5 Electric cutting height adjustment . . . . . . . . . . . . . . . . . . . . . . . .12

7.2.6 The PTO clutch does not engage . . . . . . . . . . . . . . . . . . . . . . . . 12

7.2.7 The motor can be started without the brake pedal is pressed . .13

7.2.8 The motor can be started with the mover deck activated . . . . . . 13

7.2.9 The motor can be started with a gear activated . . . . . . . . . . . . . 13

7.2.10 The motor does not stop when the operator leaves

the seat and the mover deck is activated . . . . . . . . . . . . . . . . . .14

7.2.11 The PTO clutch does not disengage when the operator

leaves the seat and the mover deck is activated . . . . . . . . . . . . .14

7.2.12 The motor does not stop after a few minutes

when the shut off valve cable is disconnected . . . . . . . . . . . . . .15

Page 53

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 4

7.2.13 The starter does not rotate

Ready Man, Villa 12r

B70

Page 54

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 5

Villa Comfort, Villa Elit

B50

Page 55

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 6

Ready HST, Villa 14 HST, Villa 16 HST

B71 89

Page 56

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 7

Villa de Lux, Villa Royal

B53 62

Page 57

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 8

7.2.14 The starter rotate, but the motor does not start

Ready Man, Villa 12, Villa Comfort, Villa Elit 14

B50 70

Ready HST, Villa 14 HST, Villa 16 HST

D71 89

Page 58

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 9

Villa de Lux, Villa Royal

D53 62

Page 59

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 10

7.2.15 The battery runs repeatedly empty

Ready Man, Ready HST, Villa 12, Villa 14 HST, Villa 16 HST, Villa Comfort, Villa Elit 14

A50 70 71 89

Villa de Lux

A62

Page 60

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 11

Villa Royal

A53

7.2.16 The motor does not stop

All machines

C alla

Page 61

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 12

7.2.17 Electric cutting height adjustment

G53

Page 62

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 13

7.2.18 The PTO clutch does not engage

Villa de Lux, Villa Royal

K53 62

PTO clutch characteristic

Due to high temperature and magnetic stress, the PTO clutch, after a long term

of use, can show up instability in the internal components. This can result in that

the clutch works properly when it is cold, but sometimes (not always) failures

after warming up.

Therefore, to be sure to isolate the fault, the PTO clutch must be checked in

both cold and warm condition; particular in warm condition.

Page 63

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 14

7.2.19 The motor can be started without the brake pedal is pressed

All machines except machines with manual gearboxex

H_Alla11

7.2.20 The motor can be started with the mover deck activated

All machines with mechanic PTO

H_ABDE12

7.2.21 The motor can be started with a gear activated

Machines with manual gearboxes

H_B13

Page 64

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 15

7.2.22 The motor does not stop when the operator leaves the seat and

the mover deck is activated

All machines with mechanic PTO

I_all14

7.2.23 The PTO clutch does not disengage when the operator leaves the

seat and the mover deck is activated

All machines with electric PTO clutch

I_CF15

7.2.24 The motor does not stop after a few minutes when the shut off

valve cable is disconnected

All machines with electric shut off valve in the fuel system

J_EDFC17

Page 65

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 16

7.3 Repair and replacements

Warning

Do not wear rings, metallic bracelet,

chain round the neck or similar metal objects when working with the

electrical system. It can cause shortcircuit, burns and fire.

7.3.1 Replacement of switches

All switches are pressed into place in their

rectangular holes at the control panel. To

change a switch proceed as follows:

1. Remove the actual cover to get access to

the switch.

2. Press the fixation pig at the connector and

pull the connector from the switch.

See the figure.

Some connectors have 2 pigs.

3. Press the fixation tongues on both sides of

the switch against the switch. Use a

screwdriver or similar and work up the

switch.

See the figure.

7.3.2 Replacement of switch knob

To replace the switch knob, there is a special

tool available. Regarding reference number,

see the spare parts list

Remove the knob by pushing in the tool

backwards and press until the knob jumps

up.

The knob is easily assembled by pressing it

down in its hole in the switch.

7.3.3 Connections

The machine is equipped with three kinds of

connectors:

• Fixed connectors in plastic holders.

• Tab connectors

• Screw connectors

All connectors shall be kept free from

contamination, corrosion and damp.

Page 66

Edition Manual Chapter Page

2008-05-19 Workshop Manual, Stiga Villa/Ready 7 Electrical System 17

Fixed connectors in plastic holders

To remove the connectors from the plastic

holder, put a small screwdriver behind the

connector, hold the cable and pull out the

connector.

See the figure.

Tab connectors

To restore tab connectors if bad crimp forces

occur, e.g. after a long time of use, the

connector can be pinched by a pliers.

See the figure.

Screw connectors

When cables shall be connected into screw

connectors, the cable shall be stripped off 5

mm only. No metallic conductor is allowed to

be exposed outside the terminal.

Warning!

Exposed conductors can cause

short-circuit and fire.

Page 67

STIGA S.p.A - Via del Lavoro, 6 - 31033 Castelfranco Veneto (TV) - Italien

www.stiga.com

Loading...

Loading...