Page 1

171501128/6 02/2019

C 1.8

C 1.8 ET

C 2.0

C 2.0 ET

C 2.2

C 2.2 ET

Motosega a catena elettrica portatile

IT

ATTENZIONE: prima di usare la macchina, leggere attentamente il presente libretto.

Преносим електрически моторен верижен трион

BG

УПЪТВАНЕ ЗА УПОТРЕБА -

прочетете внимателно настоящата книжка..

Přenosná elektrická řetězová motorová pila

CS

UPOZORNĚNÍ: před použitím stroje si pozorně přečtěte tento návod k použití.

Bærbar elektrisk kædesav

DA

ADVARSEL: læs instruktionsbogen omhyggeligt igennem, før du tager denne maskine i brug.

Tragbare elektrische Kettensäge

DE

ACHTUNG: vor inbetriebnahme des geräts die gebrauchsanleitung aufmerksam lesen.

Φορητό ηλεκτρικό αλυσοπρίονο

EL

ΠΡΟΣΟΧΗ: πριν χρησιμοποιησετε το μηχανημα, διαβαστε προσεκτικα το παρον εγχειριδιο.

Portable electric chain saw

EN

WARNING: read thoroughly the instruction booklet before using the machine.

Motosierra de cadena eléctrica portátil

ES

ATENCIÓN: antes de utilizar la máquina, leer atentamente el presente manual.

Kaasaskantav elektriline kettsaag

ET

TÄHELEPANU: enne masina kasutamist lugeda tähelepanelikult antud kasutusjuhendit.

Käsin kannateltava sähkökäyttöinen moottorisaha

FI

VAROITUS: lue käyttöopas huolellisesti ennen koneen käyttöä.

Scie à chaîne électrique et portative

FR

ATTENTION: lire attentivement le manuel avant d’utiliser cette machine.

Prijenosna električna lančana pila

HR

POZOR: prije uporabe stroja, pažljivo pročitajte ovaj priručnik.

Hordozható elektromos láncfűrész

HU

FIGYELEM! a gép használata előtt olvassa el figyelmesen a jelen kézikönyvet.

Nešiojamas elektrinis grandininis pjūklas

LT

DĖMESIO: prieš naudojant įrenginį, atidžiai perskaityti šį naudotojo vadovą.

Portatīvs elektriskais ķēdes zāģis- LIETOŠANAS INSTRUKCIJA

LV

UZMANĪBU: pirms aparāta lietošanai rūpīgi izlasiet doto instrukciju.

Електрична преносна моторна пила

MK

ВНИМАНИЕ: прочитајте го внимателно ова упатство пред да ја користите машината.

Draagbare elektrische kettingzaag

NL

LET OP: vooraleer de machine te gebruiken, dient men deze handleiding aandachtig te lezen.

Bærbar elektrisk drevet kjedesag

NO

ADVARSEL: les denne bruksanvisningen nøye før du bruker maskinen.

Przenośna pilarka łańcuchowa elektryczna

PL

OSTRZEŻENIE: przed użyciem maszyny, należy uważnie przeczytać niniejszą instrukcję.

Motosserra elétrica portátil

PT

ATENÇÃO: antes de usar a máquina, leia atentamente o presente manual.

Ferăstrău electric cu lanț portabil

RO

ATENŢIE: înainte de a utiliza maşina, citiți cu atenție manualul de față.

Портативная электрическая цепная пила

RU

РУKОВОДСТВО ПО ЭKСПЛУАТАЦИИ -

пользоваться оборудованием, внимательно прочтите зто руководство по зксплуатации.

Prenosna električna verižna žaga

SL

POZOR: preden uporabite stroj, pazljivo preberite priročnik z navodili.

Eldriven bärbar kedjesåg

SV

VARNING: läs igenom hela detta häfte innan du använder maskinen.

Elektrikli taşınabilir zincirli testere

TR

DİKKAT: makıneyı kullanmadan önce talımatlar ıçeren kilavuzu dıkkatle okuyun.

- BRUGSANVISNING

- OPERATOR’S MANUAL

- MANUAL DE INSTRUÇÕES

- BRUKSANVISNING

-

MANUALE DI ISTRUZIONI

ВНИМАНИЕ: преди да използвате машината

-

NÁVOD K POUŽITÍ

- GEBRAUCHSANWEISUNG

- ΟΔΗΓΙΕΣ ΧΡΗΣΠΣ

-

MANUAL DE INSTRUCCIONES

- KASUTUSJUHEND

-

-

MANUEL D’UTILISATION

-

PRIRUČNIK ZA UPORABU

- HASZNÁLATI UTASÍTÁS

-

NAUDOJIMO INSTRUKCIJOS

-

УПАТСТВА ЗА УПОТРЕБА

-

GEBRUIKERSHANDLEIDING

- INSTRUKSJONSBOK

-

INSTRUKCJE OBSŁUGI

-

MANUAL DE INSTRUCŢIUNI

ВНИМАНИЕ: прежде чем

- PRIROČNIK ZA UPORABO

- KULLANIM KILAVUZU

KÄYTTÖOHJEET

Page 2

Page 3

i

ITALIANO - Istruzioni Originali ...................................................................................................

БЪЛГАРСКИ - Превод на оригиналните инструкции ................................................................

ČESKY - Překlad původního návodu k používání .........................................................................

DANSK - Oversættelse af den originale brugsanvisning ..............................................................

DEUTSCH - Übersetzung der Originalbetriebsanleitung ..............................................................

ΕΛΛΗΝΙΚΑ - Μετάφραση του πρωτοτύπου των οδηγιών χρήσης

ENGLISH - Translation of the original instruction ..........................................................................

ESPAÑOL - Traducción del Manual Original ................................................................................

EESTI - Algupärase kasutusjuhendi tõlge .....................................................................................

SUOMI - Alkuperäisten ohjeiden käännös ....................................................................................

FRANÇAIS - Traduction de la notice originale ..............................................................................

HRVATSKI - Prijevod originalnih uputa .........................................................................................

MAGYAR - Eredeti használati utasítás fordítása ...........................................................................

LIETUVIŠKAI - Originalių instrukcijų vertimas ...............................................................................

LATVIEŠU - Instrukciju tulkojums no oriģinālvalodas ....................................................................

МАКЕДОНСКИ -Превод на оригиналните упатства ................................................................

NEDERLANDS - Vertaling van de oorspronkelijke gebruiksaanwijzing

NORSK - Oversettelse av orginal bruksanvisning .........................................................................

POLSKI - Tłumaczenie instrukcji oryginalnej ................................................................................

PORTUGUÊS - Tradução do manual original ...............................................................................

ROMÂN - Traducerea manualului fabricantului ............................................................................

РУССКИЙ - Перевод оригинальных инструкций .....................................................................

SLOVENŠČINA - Prevod izvirnih navodil ......................................................................................

SVENSKA - Översättning av bruksanvisning i original ..................................................................

TÜRKÇE - Orijinal Talimatların Tercümesi ....................................................................................

...................................................

...................................................

IT

BG

CS

DA

DE

EL

EN

ES

ET

FI

FR

HR

HU

LT

LV

MK

NL

NO

PL

PT

RO

RU

SL

SV

TR

Page 4

ii

1 1A

2 1513

11a 11

3

5

4

4

2

3

3

5A

12

11

6 6A

1

1a

12

1

7

11

5

4

2

3

6 7

Page 5

16 17

iii

50 mm

50 mm

18A 18B 18C

18D 19 20

21

< 0,5 mm

Page 6

INTRODUCTION 1

Dear Customer,

thank you for choosing one of our products. We hope that you will be completely satised with this machine

and that it fully meets your expectations. This manual has been compiled in order to provide you with all

the information you need to get acquainted with the machine and use it safely and eciently. Don’t forget

that it is an integral part of the machine, so keep it handy so that it can be consulted when necessary, and

pass it on to a further user if you resell or loan the machine.

Your new machine has been designed and manufactured in pursuance with current regulations, and is

safe and reliable if used in compliance with the instructions provided in this manual (proper use). Using the

machine in any other way, or non-compliance with the safety specications relative to use, maintenance

and repair is considered “improper use” which will invalidate the warranty, relieve the manufacturer from

all liabilities, and the user will consequently be liable for all and any damage or injury to himself or others.

For this electric tool, the company provides the end user - independently from the retailer‘s obligations

resulting from the purchasing contract - with the following warranties:

The warranty period is 24 months beginning from the hand-over of the device which has to be proved by

the original purchasing document. For commercial use and use for rent, the warranty period is reduced

to 12 months. Wearing parts and defects caused by the use of not tting accessories, repair with parts

that are no original parts of the manufacturer, use of force, strokes and breaking as well as mischievous

overloading of the motor are excluded from this warranty. Warranty replacement does only include defective parts, not complete devices. Warranty repair shall exclusively be carried out by authorized service

partners or by the company‘s customer service. In the case of any intervention of not authorized personnel,

the warranty will be held void.

All postage or delivery costs as well as any other subsequent expenses will be borne by the customer.

EN

Since we regular improve our products, you may nd slight dierences between your machine and the descriptions contained in this manual. Modications can be made to the machine without notice and without

the obligation to update the manual, although the essential safety and function characteristics will remain

unaltered. In case of any doubts, please contact your dealer. And now enjoy your work!

TABLE OF CONTENTS

1. Identication of the main components ........................................ 2

2. Symbols ..................................................................................... 3

3. Safety warnings .......................................................................... 4

4. Machine assembly ..................................................................... 6

5. Preparing to work ....................................................................... 7

6. How to start - Stop the engine .................................................... 8

7. Using the machine ..................................................................... 9

8. Maintenance and storage ......................................................... 13

9. Troubleshooting ....................................................................... 13

10. Accessories ............................................................................. 14

Page 7

2 IDENTIFICATION OF MAIN COMPONENTS

1314 16

8

3

2

21

10.1

10.2 10.3

10.10

10.8

10.9

10.5

10.6

10.7

10.11

10.12

Made in Cina

Electric Chainsaw

V

Hz

W

EN

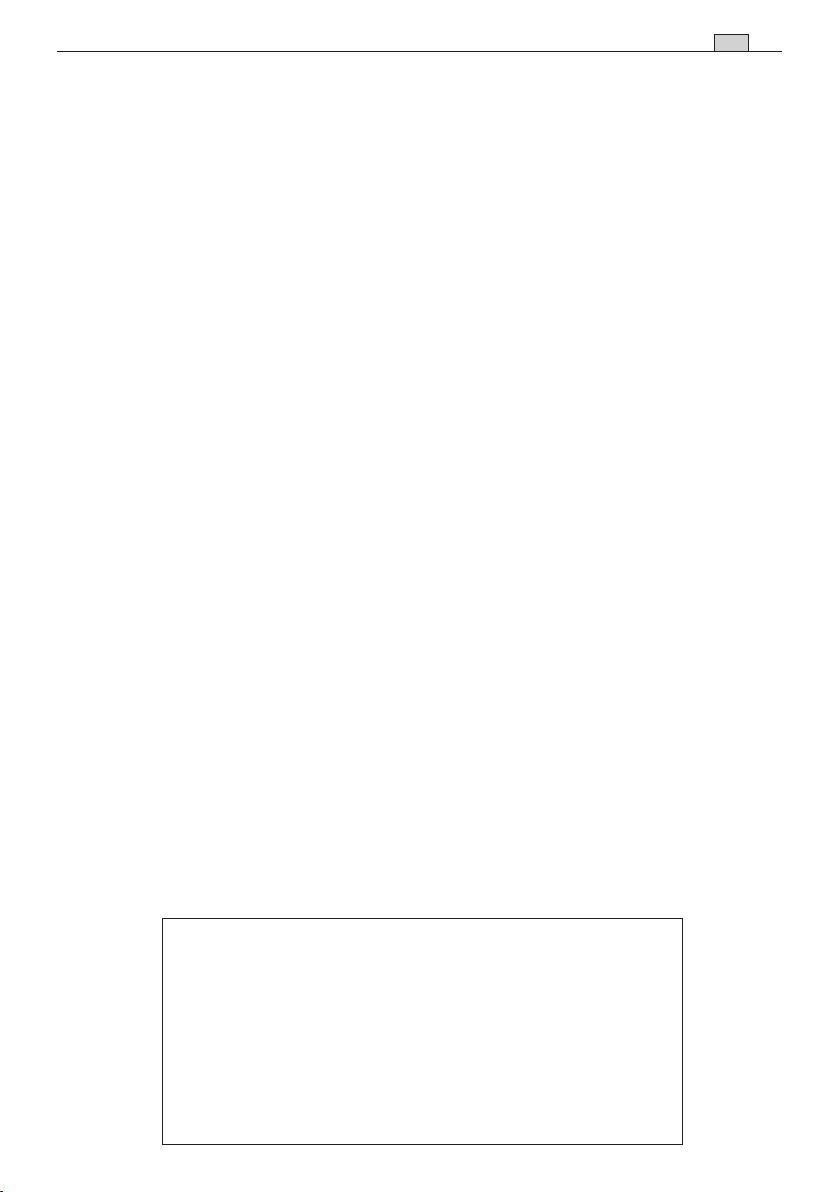

1. IDENTIFICATION OF MAIN COMPONENTS

MAIN COMPONENTS

1. Power unit

2. Spiked bumper

3. Front hand guard

4. Front handgrip

1

5

5. Rear handgrip

6. Chain catcher

7. Bar

8. Chain

9. Bar cover

10. Identication plate

11. Power cable

12. Extension lead

(not supplied)

11

CONTROLS AND FILLING POINTS

13. Trigger switch

14. Safety button

15. Reset button (Only for C 2.2 E/ET

SE 2216 / 2216 Q - A 220 EQ)

16. Extension lead connection

21. Chain oil tank cap

22. Chain oil gauge

IDENTIFICATION PLATE

10.1) Conformity marking in accordance

with Directive 2006/42/EC

10.2) Name and address of the manufacturer

10.3) Acoustic output level LWA in

accordance with directive 2000/14/EC

10.5) Machine model

10.6) Serial number

10.7) Year of manufacture

10.8) Power supply frequency and voltage

10.9) Engine power

10.10) Dual insulation

10.11) Article Code

10.12) Maximum permitted length of the bar.

Do not use longer bars.

4

9

7

C 1.8 ET - SE 1814 Q - SE 2014 Q

6

22

10

12

C 2.0 ET - SE 2016 Q - C 2.2 ET

SE 2216 Q - XC 120 Q - CP 2.0 Q - A 220 EQ

15

The example of the conformity declaration is

found in the penultimate page of the manual.

Do not dispose of electrical equipment together with household waste material. In observance of European Directive

2012/19/UE on waste electrical and electronic e quip ment and its implementation in accordance with national law, electric

equipment that have rea ched the end of their life must be collected se pa rately and returned to an environmentally compatible recycling facility. If electrical appliances are disposed of in landlls or dumps, hazardous substances can leak into the groundwater and get into the foodchain, damaging your health and well-being. For further information on the disposal of this product,

contact your dealer or a dome s tic waste collection Service.

Page 8

IDENTIFICATION OF MAIN COMPONENTS / SYMBOLS 3

Maximum noise and vibration levels [1] Model

A 180 E

C 1.8 E • C 1.8

ET SE 1814

SE 1814 Q

SE 2014

SE 2014 Q

A 200 E • XC 120 Q

CP 2.0 Q

C 2.0 E • C 2.0 ET

SE 2016

SE 2016 Q

EN

A 220 EQ

C 2.2 E • C 2.2 ET

SE 2216

SE 2216 Q

Operator ear noise pressure level dB(A) 94.3 95.1 95.1 96.1

– Measurement uncertainty dB(A) 3 3 3 3

Measured acoustic output level dB(A) 104,6 104,5 104,5 104,8

– Measurement uncertainty dB(A) 2,4 2,4 2,4 2,4

Sound power level guaranteed dB(A) 107 107 107 107

Vibration level m/sec24.686 4.916 4.916 5.285

– Measurement uncertainty m/sec

2

1.5 1.5 1.5 1.5

TECHNICAL SPECIFICATIONS

Voltage V~ 230 - 240 230 - 240 230 - 240 230 - 240

Power frequency Hz 50 50 50 50

Overload protection A 16 16 16 16

Motor power W 1800 2000 2000 2200

Bar length cm 35 35 40 40

Cutting length cm 33.5 33.5 38.5 38.5

Chain speed m/sec 14 14 14 14

Weight kg 5.00 5.05 5.30 5.42

Oil ml 130 130 130 130

[1]

Notice:

The vibration value indicated was determined with a standardized tool and can be used to make comparisons with other electric equipment

as well as temporary estimates of the load through the vibrations.

WARNING!

The vibration value may vary according to the usage of the machine and its tted equipment, and be higher than the one indicated. Safety

measures must be established to protect the user and must be based on the load estimate generated by the vibrations in real usage conditions.

In this regard, all the operational cycle phases must be taken into consideration, such as switching o or idle running.

2. SYMBOLS

21 73 4 6 85

1) If you are using the machine every day in normal conditions, you can be exposed to a noise

level of 85 dB (A) or higher. Wear safety glasses

and hearing protection.

2) Warning!

3) Read the instruction manual before using the

machine.

4) Do not leave the machine in the rain (or in

damp con ditions).

EXPLANATORY SYMBOLS

ON THE MACHINE

(if present)

11) Direction in which the chain is mounted

12) Chain brake

13) Direction in which the chain runs

11 12 13 14 15

5) Wear strong working gloves.

6) Unplug the chain-saw immediately if the ca ble

(or extension lead) is cut or damaged.

7) Beware of kickback! Kickback is the rapid and

uncontrollable backward motion of the machine in

the direction of the operator.

8) Hold the machine fast with both hands to control the machine and reduce the risk of kickback.

14) Chain oil tank

15) Chain tension

Page 9

4 SAFETY WARNINGS

EN

3. SAFETY WARNINGS

HOW TO READ THE MANUAL

Certain paragraphs in the manual contain particularly signicant

information and are marked with various levels of highlighting

with the following meaning:

NOTE

or

IMPORTANT

tion on what has already been said, in the aim to prevent damage to the machine.

WARNING!

risk of injury to oneself or others.

DANGER!

risk of serious injury or death to oneself or o thers.

GENERAL POWER TOOL SAFETY WARNINGS

WARNING!

instructions. Failure to follow the warnings and instructions may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool.

1) Work area safety

a) Keep work area clean and well lit. Dirty or cluttered areas

invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of ammable liquids, gases

or dust. Power tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodied plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces,

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use. Use of a cord suitable

These give details or further informa-

Non-observance will result in the

Non-observance will result in the

Read all safety warnings and all

for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoid-

able, use a residual current device (RCD) protected

supply. Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the inuence of drugs,

alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

b) Wear protective clothing. Always wear protective gog-

gles. Using personal protective equipment such as dust

mask, non-skid safety shoes, safety helmets or hearing protectors will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in

the «o»-position before connecting to power source,

picking up or carrying the tool. Carrying power tools with

your nger on the switch or energising power tools that have

the switch «ON» invites accidents.

d) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct po wer tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it

on and o. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source before mak-

ing any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the

risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power tools

are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or bind-

ing of moving parts, breakage of parts and any other

condition that may aect the power tool’s operation.

If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power

tools.

f) Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

g) Use the power tool, accessories and tool bits etc. in

Page 10

SAFETY WARNINGS 5

accordance with these instructions, taking into account

the working conditions and the work to be performed.

Use of the power tool for operations dierent from those

intended could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a qualied repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

CHAIN SAW SAFETY WARNINGS:

• Keep all parts of the body away from the saw chain

when the chain saw is operating. Before you start the

chain saw, make sure the saw chain is not contacting

anything. A moment of inattention while operating chain saws

may cause entanglement of your clothing or body with the

saw chain.

• Always hold the chain saw with your right hand on

the rear handle and your left hand on the front handle.

Holding the chain saw with a reversed hand conguration

increases the risk of personal injury and should never be done.

• Wear safety glasses and hearing protection. Further

protective equipment for head, hands, legs and feet is

recommended. Adequate protective clothing will reduce

personal injury by ying debris or accidental contact with the

saw chain.

• Do not operate a chain saw in a tree. Operation of a chain

saw while up in a tree may result in personal injury.

• Always keep proper footing and operate the chain saw

only when standing on xed, secure and level surface.

Slippery or unstable surfaces such as ladders may cause a

loss of balance or control of the chain saw.

• When cutting a limb that is under tension be alert for

spring back. When the tension in the wood bres is released

the spring loaded limb may strike the operator and/or throw

the chain saw out of control.

• Use extreme caution when cutting brush and saplings.

The slender material may catch the saw chain and be whipped

toward you or pull you o balance.

• Carry the chain saw by the front handle with the chain

saw switched o and away from your body. When transporting or storing the chain saw always t the guide

bar cover. Proper handling of the chain saw will reduce the

likelihood of accidental contact with the moving saw chain.

• Follow instructions for lubricating, chain tensioning and

changing accessories. Improperly tensioned or lubricated

chain may either break or increase the chance for kickback.

• Keep handles dry, clean, and free from oil and grease.

Greasy, oily handles are slippery causing loss of control.

• Cut wood only. Do not use chain saw for purposes not

intended. For example: do not use chain saw for cutting

plastic, masonry or non-wood building materials. Use

of the chain saw for operations dierent than intended could

result in a hazardous situation.

CAUSES AND OPERATOR PREVENTION

OF KICKBACK:

Kickback may occur when the nose or tip of the guide bar

touches an object, or when the wood closes in and pinches the

saw chain in the cut.

Tip contact in some cases may cause a sudden reverse reac-

tion, kicking the guide bar up and back towards the operator.

Pinching the saw chain along the top of the guide bar may push

the guide bar rapidly back towards the operator.

Either of these reactions may cause you to loose control of the

saw which could result in serious personal injury. Do not rely

exclusively upon the safety devices built into your saw.

As a chain saw user, you should take several steps to keep your

cutting jobs free from accident or injury.

Kickback is the result of tool misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below:

• Maintain a rm grip, with thumbs and ngers encirc-

ling the chain saw handles, with both hands on the saw

and position your body and arm to allow you to resist

kickback forces. Kickback forces can be controlled by the

operator, if proper precautions are taken. Do not let go of

the chain saw.

• Do not overreach and do not cut above shoulder height.

This helps prevent unintended tip contact and enables better

control of the chain saw in unexpected situations.

• Only use replacement bars and chains specied by the

manufacturer. Incorrect replacement bars and chains may

cause chain breakage and/or kickback.

• Follow the manufacturer’s sharpening and maintenance

instructions for the saw chain. Decreasing the depth gauge

height can lead to increased kickback.

• Techniques for using the electric chain-saw

Always observe the safety regulations and use the most suitable

sawing techniques (see chapter 7 for instructions and examples).

Arrange the power cable so that it does not get tangled in

branches or other obstacles.

• Safe carrying of the saw

Whenever the machine is to be handled or transported you

must:

– turn o the engine, wait for the chain to stop and unplug the

machine from the mains;

– mount the bar cover;

– only hold the machine using the handgrips and position the

bar in the opposite direction to that used during operation.

When using a vehicle to transport the machine, position it so that

it can cause no danger to persons and fasten it rmly.

• Recommendation for the rst-time users

Before felling or delimbing for the rst time, make sure:

– you have been specically trained to use this type of equip-

ment;

– you have carefully read the safety regulations and user in-

structions contained in this manual;

– you practise rst on logs on the ground or attached to trestles,

in order to get familiar with the machine and the most suitable

cutting techniques.

EN

Page 11

6 MACHINE ASSEMBLY

EN

4. MACHINE ASSEMBLY

PACKAGING CONTENTS

The packaging contains:

– power unit,

– bar,

– chain,

– bar cover,

– bag containing equipment and documents.

IMPORTANT

the bar and chain dismantled and the oil tank

empty.

The machine is supplied with

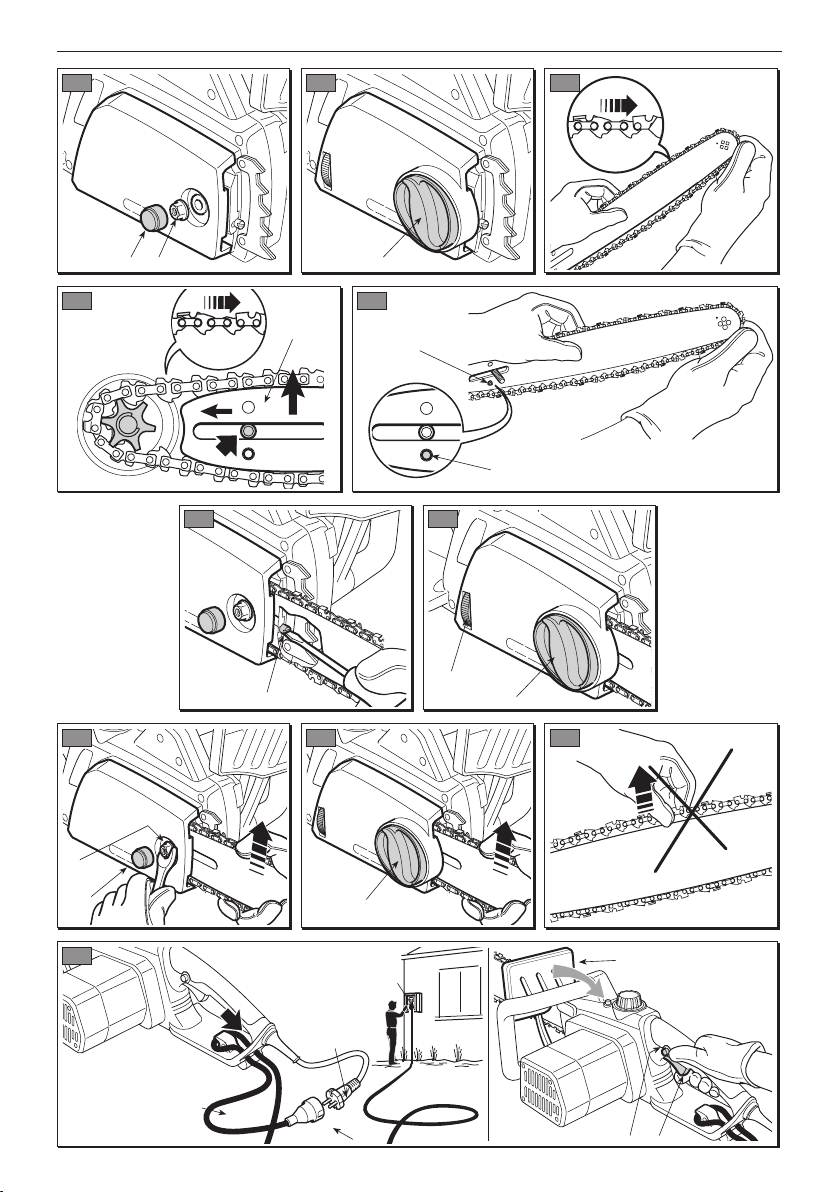

– Mount the bar (2) by inserting the stud bolt in

the groove and push it towards the back of the

machine body and wind the chain around the

drive sprocket (Fig. 3).

– Check that the chain tension adjuster pin (3) is

tted properly in the hole on the bar (Fig. 4); if

it isn’t, turn the chain tension adjuster screw (4)

using a screwdriver until the pin is comple tely

inserted (Fig. 5).

– Fit the guard back on without tightening the nut

(1).

WARNING! Unpacking and complet-

ing the assembly should be done on a at and

sta ble surface, with enough space for ma

chi ne handling and its packaging, always

making use of suitable equipment.

Disposal of the packaging should be done in

ac cordance with the local regulations in for ce.

BAR AND CHAIN MOUNTING

WARNING! Always wear heavy-duty

gloves when handling the bar and chain.

Mount the bar and chain very carefully so as

not to impair the safety and eciency of the

m achine. If in doubt, contact your dealer.

Before tting the bar, make sure the chain brake is

not engaged; this is done by pulling the front hand

guard right back towards the body of the machine.

WARNING! Make sure the machine is

not plugged into the mains socket.

• MACHINES WITH STANDARD

CHAIN TENSION ADJUSTER

– Remove the rubber protection (1a), unscrew the

nut (1) and remove the guard to get to the drive

sprocket and the point where the bar is tted

(Fig. 1).

– Mount the chain in the right direction on the bar.

If the tip of the bar has a nose sprocket, make

sure the drive links are correctly inserted in the

sprocket rims (Fig. 2).

– Turn the chain tension adjuster screw (4) to ad-

just the chain tension (Fig. 5).

– Raise the bar and tighten the guard nut (1)

securely using the supplied wrench, then replace the rubber protection (1a) (Fig. 6).

• MACHINES WITH QUICK CHAIN TENSION

ADJUSTER

– Unscrew the handle (11) and remove the

guard to get to the drive sprocket and the point

where the bar is tted (Fig. 1a).

– Mount the chain in the right direction on the bar.

If the tip of the bar has a nose sprocket, make

sure the drive links are correctly inserted in the

sprocket rims (Fig. 2).

– Mount the bar (2) by inserting the stud bolt in

the groove and push it towards the back of the

machine body and wind the chain around the

drive sprocket (Fig. 3).

– Fit the guard back on without tightening the han-

dle (11). Check that the chain tension adjuster

pin (3) is tted properly in the hole on the bar

(Fig. 4); if it isn’t, turn the chain tension adjuster

ring-nut (12) until the pin is completely inserted

(Fig. 5a).

– Turn the ring-nut (12) to obtain the desired chain

tension level (Fig. 5a).

– Raise the bar and tighten the handle (11)

securely (Fig. 6a).

Page 12

PREPARING TO WORK 7

EN

5. PREPARING TO WORK

1. CHECKING THE MACHINE

• MACHINES WITH QUICK CHAIN TENSION

ADJUSTER

WARNING! Make sure the machine is

not plugged into the mains socket.

Before starting work please:

– check that the mains frequency and voltage is

the same as the rating data on the “identication

plate” (see chap. 1 - 10.8);

– ccheck that all the screws on the machine and

the bar are tightly fastened;

– check that the chain is tensioned correctly,

sharp and there are no signs of any damage;

– check that handgrips and protection devices

are clean and dry, correctly mounted and well

fastened to the machine;

– check that the chain brake is working eciently;

– check that the trigger switch and the safety

button should move freely without forcing and

return automatically and rapidly back to their

neutral position;

– check that the trigger switch must remain locked

until the safety button is pressed;

– make sure the cooling air vents are not clog ged

up with sawdust or debris;

– check that the power cable and extension lead

are not damaged;

– check that the chain’s oil level is not below the

«MIN» level mark and top up to 1 cm from the

rim of the ller if necessary.

2. CHECKING THE CHAIN TENSION

WARNING! Make sure the machine is

not plugged into the mains socket.

– Loosen the handle (11). (Fig. 5a).

– Turn the ring-nut (12) to obtain the desired chain

tension level (Fig. 5a).

– Raise the bar and tighten the handle (11)

securely (Fig. 6a).

The tension is correct when the drive links do not

slip out of the chain guides if you hold the chain in

the middle of the bar (Fig. 7).

Loosen the brake by pressing both the switch

and the safety button. Using a screwdriver, run

the chain along the guides to check that it moves

smoothly.

3. CHECKING THE CHAIN BRAKE

This machine is equipped with a double braking

system that intervenes in two situations:

a) When the switch lever is released, a brake

is automatically activated that slows and stops

chain movement, in order to prevent the risk of

injury should the chain continue to turn after it

has been switched o.

b) In the event of a kickback while working,

following an irregular contact of the tip of the

bar, with a brusque upward movement that

causes the hand to strike the front guard. In

this case, the brake blocks chain movement

and must be released manually in order to disengage it.

• MACHINES WITH STANDARD

CHAIN TENSION ADJUSTER

– Loosen the guard nut, using the wrench (Fig. 5).

– Turn the chain tension adjuster screw (4) to ad-

just the chain tension (Fig. 5).

– Raise the bar and tighten the guard nut securely

using the wrench (Fig. 6).

The tension is correct when the drive links do not

slip out of the chain guides if you hold the chain in

the middle of the bar (Fig. 7).

Loosen the brake by pressing both the switch

and the safety button. Using a screwdriver, run

the chain along the guides to check that it moves

smoothly.

This brake can be operated manually by pushing

the front guard forward. To release the brake, pull

the front guard towards the handgrip until you hear

a click.

To check that the brake works eciently, proceed

as follows:

– Start the engine by holding the front handgrip

and push the front hand guard forwards with

your thumb (towards the bar).

– When the brake is engaged, release the trigger

switch.

The chain must stop as soon as the brake is engaged.

Page 13

8 PREPARING TO WORK / STARTING - STOPPING THE ENGINE

EN

WARNING! Do not use the machine if

the chain brake does not function correctly

and have it inspected by your dealer.

4. CHAIN LUBRICANT

IMPORTANT

adhe sive oil for chain-saws. Do not use oil con-

taining impurities, to avoid clogging the tank lter

and permanently damaging the oiler.

Only use chain-saw oil or

– Always handle and connect electric cables

in dry conditions.

– Keep electric sockets or cables away from

wet and damp areas (e.g. puddles or wet

ground).

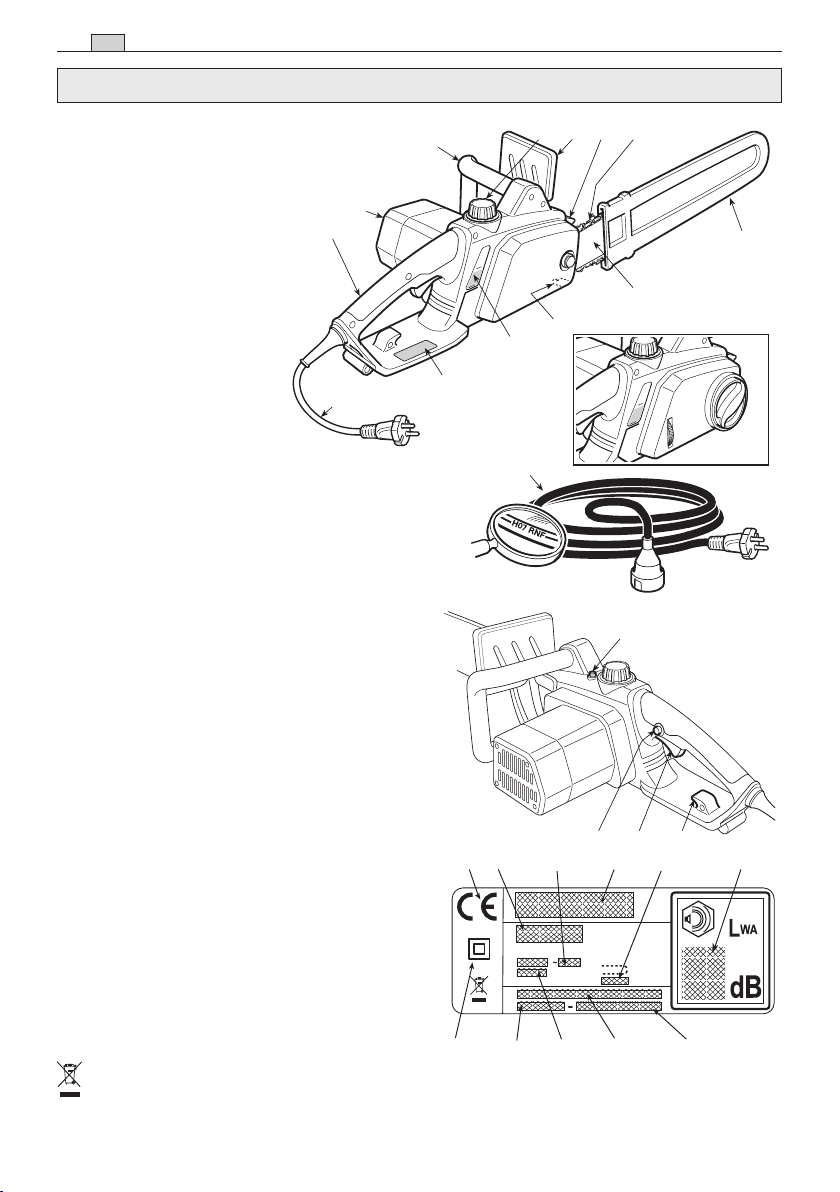

The quality of the extension leads must be no less

than H07RN-F or H07VV-F, with a minimum section of 1.5 mm2 and a recommended maximum

length of 30 m.

To avoid overheating, do not keep the extension

lead rolled up during use.

IMPORTANT

bio-degradable. The use of mineral oil or engine oil

can have a serious impact on the environment.

It is essential that you use good quality oil to lubricate the cutting parts eectively.

Used or poor quality oil does not guarantee good

lubrication and reduces the duration of the chain

and bar.

IMPORTANT

the oil level should be checked and topped up to

1 cm from the rim of the ller. The oil level must not

drop below the «MIN» level mark.

5. ELECTRICAL CONNECTIONS

DANGER! Electricity and moisture

are not compatible.

The chain lubricating oil is

Before each machine use,

DANGER! The permanent connec-

tion of any electrical equipment to the mains

of a building must be installed by a qualied

electrician in conformity with the regulations

in force. Incorrect wiring can cause serious

injury and even death.

DANGER! Supply power to the ma-

chine using a dierential switch (RCD Residual Current Device) with a tripping current of

max. 30 mA.

IMPORTANT

tages:

– make sure that the electric system’s overall ca-

pacity is adequate;

– connect the machine to a mains socket with suf-

cient amperage;

– avoid simultaneous use of other electrical ap-

pliances with high power consumption.

6. HOW TO START - STOP THE ENGINE

STARTING THE ENGINE (Fig. 12)

Before starting the engine:

– Fasten the extension lead (1) to the cable clamp

on the rear handgrip.

– FIRST connect the power cable plug (2) to the

extension lead (3) and THEN plug the extension

lead into the mains socket (4).

– Take o the bar cover.

– Make sure the bar is not touching the ground or

any other object

3. Press the safety button (6) and then the switch

(7).

NOTE

switch, the safety button is also released and the

engine stops.

WARNING! The chain may take one

second to come to a stop after the engine is

switched o.

STOPPING THE ENGINE

To prevent power supply ou-

When you release the

To start the engine (Fig. 12):

1. Disengage the chain brake (5) by pulling the

front hand guard towards the front handgrip.

2. Hold the chain-saw rmly with both hands.

To stop the engine:

– Release the switch (7).

– FIRST unplug the extension lead (3) from the

mains socket (4) and THEN disconnect the

power cable (2) of the machine from the extension lead (3).

Page 14

USING THE MACHINE 9

EN

7. USING THE MACHINE

WARNING! For personal safety and

that of others:

1) Do not use the machine without reading

the instructions carefully. Become acquainted with the controls and the proper

use of the machine. Learn how to stop the

engine quickly.

2) Only use the machine for the purpose for

which it was designed, that is for “felling,

bucking and delimbing trees with dimensions

suitable for the length of the bar” or wooden

objects with the same characteristics. Any

other use, such as using accessories not

specied in this manual, may be hazardous

and also damage the machine. Examples

of improper use may include, but are not

limited to:

– trimming hedges;

– intaglio carving;

– sectioning pallets, crates and various

packing materials;

– sectioning furniture or other materials

with nails, screws or other metal com-

ponents;

– butchering meat;

– using the machine to lift, move or split

objects;

– using the machine while fastened to xed

supports.

3) Keep in mind that the operator or user is

re sponsible for accidents or hazards occurring to other people or their property.

4) Always wear suitable clothing when using

the machine. Your dealer can provide

you with all the information on the most

suitable accident-prevention devices to

guarantee your safety. Wear anti-vibration

gloves. All the above-mentioned precautions do not however guarantee the prevention of certain risks – i.e. Raynaud’s

phenomenon or Carpal tunnel syndrome.

For operators who use this machine for

prolonged periods, it is therefore recommended to have periodic check-ups on the

hands and ngers.

If any of the above mentioned symptoms

should appear, please contact a physician

immediately.

5) Mow only in daylight or good articial light.

6) Take utmost care when working near me-

tal fences

7) Keep the chain away from the electric ca-

ble. Use the cable clamp to prevent the

extension lead from disconnecting accidentally. Make sure it is connected to the

socket without being forced. Never touch

a live electric cable if it is poorly insulated.

If the extension lead gets damaged during

use, do not touch the cable and unplug the

extension lead immediately.

8) Take care not to hit the bar hard against

foreign objects or ying debris caused by

the movement of the chain.

9) Stop the engine and unplug the machine

from the mains:

– whenever you leave the machine un-

attended;

– before cleaning, checking or servicing

the machine;

– after striking a foreign object. Inspect

the machine for any damage and make

repairs before restarting it again;

– if the machine begins to abnormally vi-

brate (Immediate look for the cause of

the vibrations and take for necessary

controls at a Specialised Centre).

– when the machine is not in use.

IMPORTANT

incorrectly used electric chain-saw may disturb

others and have a serious impact on the environment.

To respect people and the environment:

– Avoid using the machine in environments or at

times of the day when it may disturb others.

– Scrupulously comply with local regulations and

provisions for the disposal of waste materials

after sawing.

– Scrupulously comply with local regulations and

provisions for the disposal of oils, damaged

parts or any elements which have a strong impact on the environment.

– A certain amount of chain lubricating oil is re le-

ased into the environment when the machine is

running, so only use biodegradable oils made

specically for this use.

– To avoid the risk of re, do not leave the ma

chi ne with the engine hot on leaves or dry grass.

WARNING! It takes specic training to

use the machine for felling and delimbing.

Always remember that an

Page 15

10 USING THE MACHINE

EN

1. CHECKS DURING WORK

• Checking the chain tension

The chain tends to stretch gradually as you work,

so you need to check its tension frequently.

IMPORTANT

(or after replacing the chain), it must be checked

more frequently due to settling of the chain.

WARNING! Never work with the chain

loose, as it can be hazardous if the chain slips

out of its guides.

To adjust the chain tension, follow the instructions

in Chapter 5.2.

During the rst period of use

2. DIRECTIONS FOR USE AND CUTTING

TECHNIQUES

Before felling or delimbing for the rst time, practise sawing logs on the ground or on trestles, so

that you can get familiar with the machine and the

most suitable sawing techniques.

WARNING! Always hold the machine

with both hands when sawing.

WARNING! Stop the engine im me dia

tely if the chain stops during sawing. Be wa re

of kickback, which can occur if the bar contacts an obstacle.

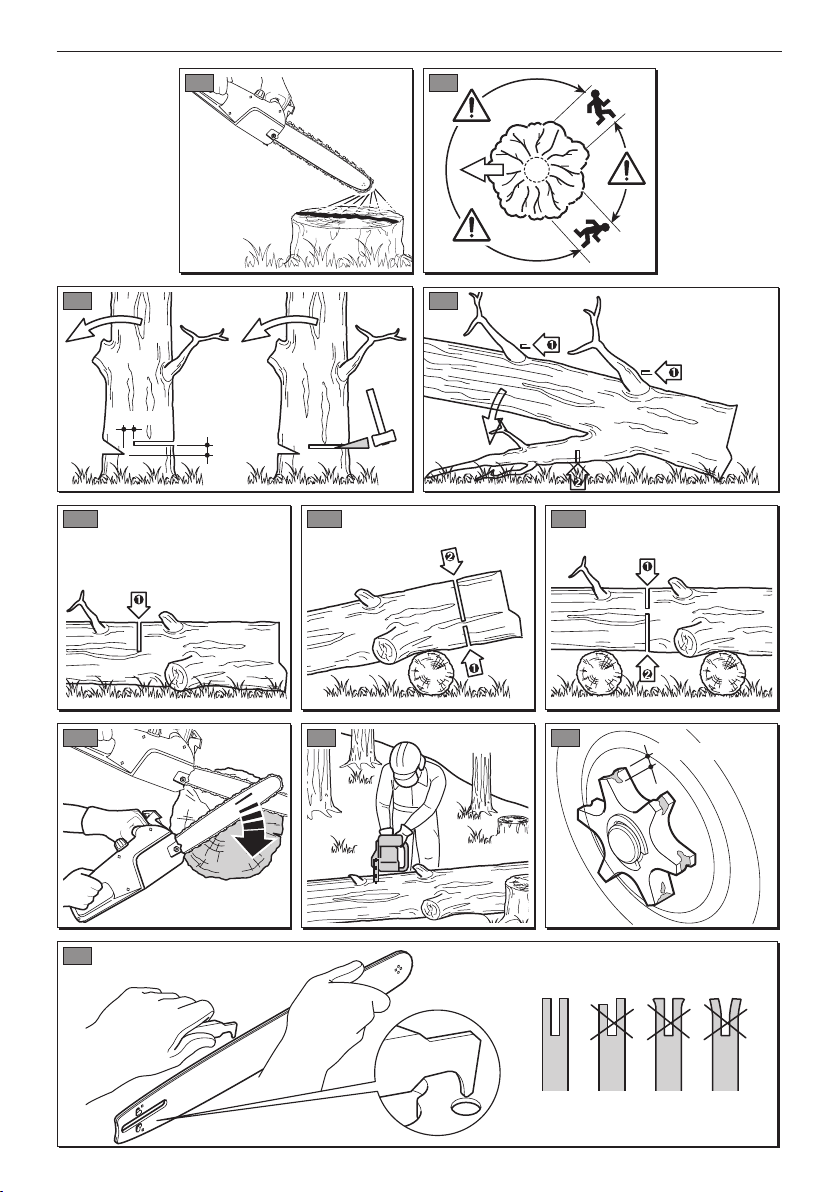

• Felling a tree

• Checking the oil delivery

IMPORTANT

out lubrication! You can check the oil level in the

tank through the transparent gauge. Make sure

you ll up the oil tank every time you use the ma

chine.

WARNING! Make sure the bar and the

chain are in place when you check the oil delivery.

Start the engine and check if the chain oil is de li vered as shown in the gure (Fig. 13).

• Shutdown whilst working (Only for

C 2.2 E/ET – SE 2216 / 2216 Q - A 220 EQ)

Your chain saw is designed with an overload

protection with circuit breaker. If the chain saw is

clogged (e.g. blocking of the cutting means, chain

teeth jammed, overload cutting) during the cutting

operation, the overload circuit breaker will cut the

mains power supply automatically to protect your

chain saw.

IMPORTANT

activated when the cutting current is over 35-40A,

and it can be reset manually by pressing the reset

button (1.15) 30 seconds after it has cooled completely.

Never use the machine with-

The circuit breaker will be

– When bucking and felling operations are being

performed by two or more persons at the sa me

time, the felling operations should be separated

from the bucking operation by a distance of at

least twice the height of the tree being felled.

Trees should not be felled in a man ner that

would endanger any person, stri ke any utility

line or cause any property damage. If the tree

does make contact with any u ti lity line, the company should be notied im mediately.

– The chain saw operator should keep on the up-

hill side of the terrain as the tree is likely to roll

or slide downhill after it is felled.

– An escape path should be planned and clea-

red as necessary before cuts are started. The

e scape path should extend back and diagonally

to the rear of the expected line of fall as illustrated in Figure 15.

– Before felling is started, consider the natural

lean of the tree, the location of larger branches

and the wind direction to judge which way the

tree will fall.

– Remove dirt, stones, loose bark, nails, staples

and wire from the tree.

• Notching undercut

Make the notch 1/3 the diameter of the tree, perpendicular to the direction of falls as illustrated in

Figure 16.

Make the lower horizontal notching cut rst.

his will help to avoid pinching either the saw chain

or the guide bar when the second notch is being

made.

Page 16

USING THE MACHINE 11

• Felling back cut

– Make the felling back cut at least 50 mm higher

than the horizontal notching cut as illustrated

in Figure 16. Keep the felling back cut parallel

to the horizontal notching cut. Make the felling back cut so enough wood is left to act as

a hinge. The hinge wood keeps the tree from

twisting and falling in the wrong direction. Do not

cut through the hinge.

– As the felling gets close to the hinge, the tree

should begin to fall. If there is any chance that

the tree may not fall in desired direction or it may

rock back and bind the saw chain, stop cutting

before the felling back cut is complete and use

wedges of wood, plastic or aluminium to open

the cut and drop the tree along the desired line

of fall.

– When the tree begins to fall remove the chain

saw from the cut, stop the motor, put the chain

saw down, then use the retreat path planned.

Be alert for overhead limbs falling and watch

your footing.

• Limbing a tree

Limbing is removing the branches from a fallen

tree. When limbing leave larger lower limbs to support the log o the ground. Remove the small limbs

in one cut as illustrated in Figure 17. Bran ches

under tension should be cut from the bottom up to

avoid binding the chain saw.

– When the log is supported on both ends, as

illustrated in Figure 18C, cut 1/3 the diameter

from the top (overbuck). Then make the nished

cut by underbucking the lower 2/3 to meet the

rst cut.

– It is easier to saw a log using the spiked bum per

(Figure 18D).

• Dig the spiked bumper into the log and use it

as a pivot. Cut with an arched motion to make

the bar penetrate the wood.

• Repeat several times if necessary, changing

the point where you plant the spiked bum per.

– When bucking on a slope always stand on the

uphill side of the log, as illustrated in Figure 19.

When “cutting through”, to maintain complete

control release the cutting pressure near the

end of the cut without relaxing your grip on the

chain saw handles. Don’t let the chain contact

the ground.

After completing the cut, wait for the saw chain to

stop before you move the chain saw. Al ways stop

the motor before moving from tree to tree.

3. END OF OPERATIONS

When you have nished your work:

EN

WARNING! Be careful of where the

bran ches are lying on the ground, the risk of

them being under tension, the direction the

branch may go during cutting and the risk of

the tree being unstable after the branch has

been cut.

• Bucking a log

Bucking is cutting a log into lengths. It is important

to make sure your footing is rm and your weight is

evenly distributed on both feet. When possible, the

log should be raised and supported by the use of

limbs, logs or chocks. Follow the simple directions

for easy cutting.

– When the log is supported along its entire length

as illustrated in Figure 18A, it is cut from the top

(overbuck).

– When the log is supported on one end, as illus-

trated in Figure 18B, cut 1/3 the diameter from

the underside (underbuck). Then make the

nished cut by overbucking to meet the rst cut.

– Switch off the engine as indicated above

(Chap. 6).

– Wait for the chain to stop and allow the machine

to cool.

– Remove any traces of sawdust or oil deposits

from the chain.

– If there is excessive dirt or resin build-up, dis-

assemble the chain and place it in a container

with a specic cleanser. Then rinse it with clean

water and treat it with a suitable anticorrosive

spray, before reassembling on the machine.

– Fit the bar cover before reassembling the ma-

chine.

WARNING! Allow the engine to cool

be f ore storing in any enclosure.

To reduce re hazards, clean the machine

thoroughly to get rid of any sawdust, branches,

leaves or excess grease, never leave contain-

ers with the cut debris inside the storage area.

Page 17

12 MAINTENANCE AND STORAGE

EN

8. MAINTENANCE AND STORAGE

WARNING! For your safety and that of

others:

Regularly check the condition of the chain catcher

and replace it if it gets damaged.

– Correct maintenance is essential to main-

tain the original eciency and safety of the

machine over time.

– Keep all nuts, bolts and screws tight to be

sure the equipment is in safe working condition.

– Never use the machine with worn or dam-

aged parts. Damaged parts are to be replaced and never repaired.

– Only use original spare parts. Parts that are

not of the same quality can seriously damage the equipment and compromise safety.

WARNING! During maintenance oper-

ations:

– Unplug the machine from the mains.

– Use protective gloves when handling the

bar and chain.

– Keep the bar protection devices on, except

when intervening directly on the bar or the

chain.

– Never dispose of oils or other polluting ma-

te rials in unauthorised places.

1. ENGINE COOLING

To avoid overheating and damage to the engine,

always keep the cooling air vents clean and free

of sawdust and debris.

2. CHAIN BRAKE

5. NUTS AND SCREWS

Periodically check that all the nuts and screws are

securely tightened and the handgrips are tightly

fastened.

6. SHARPENING THE CHAIN

WARNING! To ensure that the chain-

saw works safely and eciently, it is essential

that the cutting components are well-sharpened. Any work on the chain and bar requires

specic skills and special tools in order to do

the work properly. For safety purposes, we

recommend you contact your Dealer.

Sharpening is necessary when:

• The sawdust looks like dust.

• Cutting becomes more dicult.

• The cut is not straight.

• Vibrations increase.

A specialized centre will sharpen the chain using

the right tools to ensure minimum removal of material and even sharpness on all the cutting edges.

Replace the chain whenever:

– The length of the cutting edges reduces to 5

mm or less;

– There is too much play between the links and

the rivets.

Regularly check the eciency of the chain brake.

3. CHAIN SPROCKET (Fig. 20)

Regularly check the condition of the sprocket and

replace it when wear exceeds 0.5 mm.

Do not mount a new chain with a worn sprocket

or vice-versa.

4. CHAIN CATCHER

This is an important safety device that restrains the

chain if it breaks or degrooves.

7. EMPTYING AND FLUSHING

THE OIL TANK

(Only if organic oil is used for the chain)

The use of some types of organic oil may cause

deposits or fouling after a certain period of use.

If this happens, before leaving the machine unused for a long period of time:

– disassemble the chain and the bar;

– empty the oil tank;

– pour a specic liquid cleanser in the tank, to

about half the maximum level;

Page 18

MAINTENANCE AND STORAGE 13

– close the tank cap and operate the machine until

all the cleanser runs out.

9. ELECTRIC CABLES

EN

Remember to ll with oil, before using the machine

again.

8. BAR MAINTENANCE (Fig. 21)

To avoid asymmetrical wear on the bar, make sure

it is turned over periodically.

To keep the bar in perfect working order, proceed

as follows:

– Grease the bearings on the nose sprocket (if

pre sent) with the syringe.

– Clean the bar groove with the scraper.

– Clean the lubrication holes.

– With a at le, remove burr from the edges and

level o the guides.

Replace the bar whenever:

– the groove is not as deep as the height of the

drive links (which must never touch the bottom);

– the inside of the guide is worn enough to make

the chain lean to one side.

WARNING! Check the condition of the

electric cables regularly and replace them if

they are worn or their insulation looks damaged.

If the machine’s power cable is damaged, it can

only be replaced with an original spare part by your

dealer or an authorised service centre.

10. EXTRAORDINARY MAINTENANCE

All maintenance operations not foreseen in this

ma nual must be performed exclusively by your

dealer.

All and any operations performed in unauthori sed

centres or by unqualied persons will totally invalidate the warranty.

11. STORAGE

The machine must be stored in a dry place away

from the elements and with the bar cover correctly

tted.

9. TROUBLESHOOTING

IMPORTANT

mation in this Manual provides good machine notions and the guide allows you to identify and face

the most common operating situations. For any

other diculty or problem, please contact an Authorised Service Centre.

• The machine does not start:

– make sure there is current in the socket;

– check that the power cable and extension lead

are intact.

• The chain does not turn:

– make sure that the front guard is positioned fa-

cing backwards.

Carefully reading the infor-

• The oil does not ow:

– make sure there is oil in the tank and ush it if

necessary ( 8.7).

• Sparks form:

– contact your Dealer for an inspection of the mo-

tor and brushes.

Page 19

14 ACCESSORIES

EN

10. ACCESSORIES

The table contains a list of all possible combinations between bar and chain, indicating those

which may be used on each machine, marked with

the symbol “ ”.

WARNING! In consideration that the

selection, application and usage of bar and

Bar and chain combinations

Pitch BAR CHAIN Model

Inches

Length

Inches / cm

3/8” 14” / 35 cm 0,050” / 1,3 mm

3/8” 14” / 35 cm 0,050” / 1,3 mm

3/8” 16” / 40 cm 0,050” / 1,3 mm

3/8” 16” / 40 cm 0,050” / 1,3 mm

3/8” 16” / 40 cm 0,050” / 1,3 mm

Groove

width

Inches / mm Code Code

Oregon

140SDEA041

Oregon

140SDEA041

Oregon

160SDEA041

Oregon

160SDEA041

Oregon

160SDEA041

chain are actions made solely by the user, the

latter assumes responsibility for damages of

any kind due to such actions. When in doubt

or if lacking knowledge of the specicity of

each bar or chain, contact your retailer or spe-

cialised gardening centre.

C 1.8 E • C 1.8 ET

Oregon

91PJ052X

Oregon

91P052X

Oregon

91P057X

Oregon

91VG057X

Oregon

91PX057X

C 2.0 E • C 2.0 ET

C 2.2 E • C 2.2 ET

Page 20

DICHIARAZIONE CE DI CONFORMITÁ

(Istruzioni Originali)

(Direttiva Macchine 2006/42/CE, Allegato II, parte A)

1. La Società: STIGA S.p.A. – Via del Lavoro, 6 – 31033 Castelfranco Veneto (TV) – Italy

2. Dichiara sotto la propria responsabilità, che la macchina: Motosega a catena elettrica portatile,

abbattimento / sezionamento / sramatura di alberi

a) Tipo / Modello Base

C 1.8 E, C 1.8 ET, C 2.0 E, C 2.0 ET, C 2.2 E, C 2.2 ET

b) Mese/ Anno di costruzione

c) Matricola

d) Motore

elettrico

3. É conforme alle specifiche delle direttive:

• MD: 2006/42/EC

e) Ente Certificatore N°0123 – TÜV SÜD Product service GmbH

Ridlerstraβe 65, 80339 München - Germany

f) Esame CE del tipo: M6A 18 01 01414 054

• OND: 2000/14/EC, ANNEX V

D. Lgs. 262/2002, ANNEX V (Italy)

e) Ente Certificatore: /

• EMCD: 2014/30/EU

• RoHS II: 2011/65/EU

4. Riferimento alle Norme armonizzate:

EN 60745-1:2009/A11:2010

EN 55014-1:2017

EN 60745-2-13:2009/A1:2010

EN 50581:2012

EN 55014-2:2015

EN 61000-3-2:2014

EN 61000-3-11:2000

C 1.8 E

C 1.8 ET

C 2.0 E

C 2.0 ET

C 2.2 E

C 2.2 ET

g) Livello di potenza sonora misurato

105

105

105

d(B)A

h) Livello di potenza sonora garantito

107

107

107

d(B)A

k) Potenza installata

1,8

2,0

2,2

kW

n) Persona autorizzata a costituire il FascicoloTecnico: STIGA S.p.A.

Via del Lavoro, 6

31033 Castelfranco Veneto (TV) - Italia

o) Castelfranco V.to, 28.03.2018 Senior VP R&D & Engineering

Maurizio Tursini

171513532_11

FR (Traduction de la notice originale)

Déclaration CE de Conformité

(Directive Machines 2006/42/CE, Annexe II, partie

A)

1. La Société

2. Déclare sous sa propre responsabilité que la

machine : Scie à chaîne électrique et portative /

abattage/tronçonnage/ébranchage d’arbres

a) Type / Modèle de Base

b) Mois / Année de construction

c) Série

d) Moteur: électrique

3. Est conforme aux prescriptions des

directives :

e) Organisme de certification

f) Examen CE du Type

4. Renvoi aux Normes harmonisées

g) Niveau de puissance sonore mesuré

h) Niveau de puissance sonore garanti

k) Puissance installée

n) Personne habilitée à établir le Dossier

Technique :

o) Lieu et Date

EN (Translation of the original instruction)

DE (Übersetzung der Originalbetriebsanleitung)

NL (

Vertaling v an de oorspro nkelijke gebru iksaanwijzing )

EG-verklaring van overeenstemming

(Richtlijn Machines 2006/42/CE, Bijlag e II, deel A)

1. Het bedrijf

2. Verklaart onder zijn eigen

verantwoordelijkheid dat de machine: Draagb are

elektrische kettingzaag /

vellen/snijden/snoeien van bomen

a) Type / Basismodel

b) Maand / Bouwjaar

c) Serienummer

d) Motor: elektrisch

3. Voldoet aan de specificaties van de richtlijnen:

e) Certificatie-instituut

f) EG-onderzoek van het Type

4. Verwijzing naar de Geh armoniseerde normen

g) Gemeten niveau van g eluidsvermogen

h) Gegarandeerd niveau van geluidsvermogen

k) Geïnstalleerd vermogen

n) Bevoegd persoon voor het opstellen van het

Technisch Dossier

o) Plaats en Datum

Traducción del Manual Original)

Tradução do manual original)

EL (

Μετάφραση του πρωτοτύπου των οδ ηγιών

χρήσης)

EK-Δήλωση συμμόρφωσης

(Οδηγία Μηχανών 2006/42/CE, Παράρτημα II,

μέρος A)

1. Η Εταιρία

2. Δηλώνει υπεύθυνα ότι η μηχανή: Φορητό

ηλεκτρικό αλυσοπρίονο

/Κατάρριψη/κατατομή/κοπή κλαδιών δέντρων

a) Τύπος / Βασικό Μοντέλο

b) Μήνας / Έτος κατασκευής

c) Αριθμός μητρώ ου

d) Κινητήρας: ηλεκτρικό

3. Συμμορφώνεται με τις προδιαγραφές της

οδηγίας:

e) Οργανισμός πιστοποίησης

f) Εξέταση CE του Τύπου

4. Αναφορά στους Κανονισμούς εναρμόνισης

g) Στάθμη μέτρησης ακουστικής ισχύος

h) Στάθμη εγγυημένης ακουστικής ισχύος

k) Εγκαταστημένη ισχύς

n) Εξουσιοδοτημένο άτομο για την κατάρτιση

του Τεχνικού Φυλλαδίου:

o) Τόπος και Χρόνος

TR (Orijinal Talimatların Tercümesi)

MK (Превод на оригиналните упатства )

EXAMPLE

Page 21

NO (

Oversettelse av orginal bruksanvisning)

EF- Samsvarserklæring

(Maskindirektiv 2006/42/EF, Vedlegg II, del A)

1. Firmaet

2. Erklærer på eget ansvar at maskinen: Bærbar

elektrisk drevet kjedesag /

Nedfelling/kutt/kvisting av trær

a) Type / Modell

b) Måned / Byggeår

c) Serienummer

d) Motor: elektrisk

3. Oppfyller kravene i direktivene:

e) Sertifiseringsorgan

f) EF-typeprøving

4. Henvisning til harmoniserte standarder

g) Målt lydeffektnivå

h) Garantert lydeffektnivå

k) Installert effekt

n) Person som har fullmakt til å utferdige teknisk

dokumentasjon:

o) Sted og dato

SV (

Översättning av bruksanvisning i original)

EG-försäkran om överensstämmelse

(Maskindirektiv 2006/42//EG, bilaga II, de la)

1. Företaget

2. Försäkrar på eget ansvar att ma Eldriven

bärbar kedjesåg /

Fällning/kapning/grenklippning av träd

skinen :

a) Typ / Basmodell

b) Månad / Tillverkningsår

c) Serienummer

d) Motor: elektrisk

3. Överensstämmer med föreskrifterna i

direktivet

e) Intygsorgan_Anmält organ

f) EG typgodkännande

4. Referens till harmoniserade standarder

g) Uppmätt ljudeffektnivå

h) Garanterad ljudeffektnivå

k) Installerad effekt

n) Auktoriserad person för upprättandet av den

tekniska dokumentationen:

o) Ort och datum

DA (

Oversættelse af den originale brugsanvisning)

EF-overensstemmelseserklæring

(Maskindirektiv 2006/42/EF, bilag II, del A)

1. Firmaet

2. Erklærer på eget ansvar, at maskinen:

Fældning af træer/udskæring af

stykker/opskæring af grene

a) Type / Model

b) Måned / Konstruktionsår

c) Serienummer

d) Motor: elektrisk

3. Er i overensstemmelse med specifikationerne

ifølge direktiverne:

e) Certificeringsorgan

f) EF-typeafprøvning

4. Henvisning til harmoniserede standarder

g) Målt lydeffektniveau

h) Garanteret lydeffektniveau

k) Installeret effekt

n) Person, der har bemyndigelse til at udarbejde

det tekniske dossier:

o) Sted og dato

FI (Al kuperäisten ohjeiden käännös)

EY-VAATIMUSTENMUKAISUUSVAKUUTUS

(Konedirektiivi 2006/42/EY, Liite II, osa A)

1. Yritys

2. Vakuuttaa omalla vastuullaan, että kone: Käsin

kannateltava sähkökäyttöinen moottorisaha /

Puiden kaataminen/pilkkominen/karsinta

a) Tyyppi / Perusmalli

b) Kuukausi /Valmistusvuosi

c) Sarjanumero

d) Moottori: sähköinen

3. On yhdenmukainen seuraavien direktiivien

asettamien vaatimusten kanssa:

e) Sertifiointiyritys

f) EY-tyyppitarkastus

4. Viittaus harmonisoituihin standardeihin

g) Mitattu äänitehotaso

h) Taattu äänitehotaso

k) Asennettu teho

n) Teknisten asiakirjojen laatimiseen valtuutettu

henkilö:

o) Paikka ja päivämäärä

CS (Překlad původního návodu k používání)

ES – Prohlášení o shodě

(Směrnice o Strojních zařízeních 2006/42/ES,

Příloha II, část A)

1. Společnost

2. Prohlašuje na vlastní odpovědnost, že stroj:

Přenosná elektrická řetězová motorová pila /

Kácení/rozřezávání/odvětvování stromů

a) Typ / Základní model

b) Měsíc / Rok výroby

c) Výrobní číslo

d) Motor: elektrický

3. Je ve shodě s nařízeními směrnic:

e) Certifikační orgán

f) ES zkouška Typu

4. Odkazy na Harmonizované normy

g) Naměřená úroveň akustického výkonu

h) Zaručená úroveň akustického výkonu

k) Instalovaný výkon

n) Osoba autorizovaná pro vytvoření

Technického spisu:

o) Místo a Datum

PL (Tłumaczenie instrukcji oryginalnej)

Deklaracja zgodności WE

(Dyrektywa maszynowa 2006/42/WE, Załącznik II,

część A)

1. Spółka

2. Oświadcza na własną odpowiedzialność, że

maszyna: Przenośna pilarka łańcuchowa

elektryczna /

Ścinanie, obalanie/przerzynanie/okrzesywanie

drzew

a) Typ / Model podstawowy

b) Miesiąc / Rok produkcji

c) Numer seryjny

d) Silnik: elektryczny

3. Spełnia podstawowe wymogi następujących

Dyrektyw:

e) Jednostka certyfikująca

f) Badanie typu WE

4. Odniesienie do Norm zharmonizowanych

g) Zmierzony poziom mocy akustycznej

h) Gwarantowany poziom mocy akustycznej

k) Moc zainstalowana

n) Osoba upoważniona do zredagowania

Dokumentacji technicznej:

o) Miejscowość i data

HU

(Eredeti használati utasítás fordítása)

EK-megfelelőségi nyilatkozata

(2006/42/EK gépirányelv, II. melléklet "A" rész)

1. Alulírott Vállalat

2. Felelősségének teljes tudatában kijelenti, hogy

az alábbi gép: Hordozható elektromos láncfűrész

/ Fák kidöntése/darabolása/gallyazása

a) Típus / Alaptípus

b) Hónap / Gyártás éve

c) Gyártási szám

d) Motor: elektromos

3. Megfelel az alábbi irányelvek előírásainak:

e) Tanúsító szerv

f) CE vizsgálat típusa

4. Hivatkozás a harmonizált szabványokra

g) Mért zajteljesítmény szint

h) Garantált zajteljesítmény szint

k) Beépített teljesítmény

n) Műszaki Dosszié szerkesztésére

felhatalmazott személy:

o) Helye és ideje

RU

(Перевод оригинальных инструкций)

Декларация соответствия норм ам ЕС

(Директивао машинном оборудовании

2006/42/ЕС, Приложение II, часть A)

1. Предприятие

2. Заявляет под собственную

ответственность, что машина: Портативная

электрическая цепная пила /

Валка/разделка/обрезка ветвей деревьев

a) Тип / Базовая модель

b) Месяц /Год изготовления

c) Паспорт

d) Двигатель: электрический

3. Соответствует требованиям следующих

директив:

e) Сертифицирующийорган

f) Испытание ЕС типовогообразца

4. Ссылки на гармонизированные нормы

g) Измеренный уровень звуковоймощности

h) Гарантируемый уровень звуковой

мощности

k) Установленная мощность

n) Лицо, уполномоченное на подготовку

технической документации:

o) Место и дата

HR

(Prijevod originalnih uputa)

EK Izjava o sukladnosti

(Direktiva 2006/42/EZ o strojevima, dodatak II,

dio A)

1. Tvrtka:

2. pod vlastitom odgovornošću izjavljuje da je

stroj: Prijenosna električna lančana pila /

Obaranje/prerezivanje/obrezivanje stabala

a) Vrsta / Osnovni model

b) Mjesec / Godina proizvodnje

c) Matični broj

d) Motor: električni

3. sukladan s temeljnim zahtjevima direktiva:

e) Certifikacijsko tijelo

f) Tipsko ispitivanje EZ

4. Primijenjene su slijedeće harmonizirane

norme:

g) Izmjerena razina zvučne snage

h) Zajamčena razina zvučne snage

k) Instalirana snaga

n) Osoba ovlaštena za pravljenje Tehničke

datoteke:

o) Mjesto i datum

SL (

Prevod izvirnih navodil)

ES izjava o skladnosti

(Direktiva 2006/42/ES) , priloga II, del A)

1. Družba

2. pod lastno odgovornostjo izjavlja, da je stroj:

Prenosna električna verižna žaga,

Podiranje/rezanje/odstranjevanje vej

a) Tip / osnovni model

b) Mesec /Leto izdelave

c) Serijska številka

d) Motor: električen

3. Skladen je z določili direktiv :

e) Ustanova, ki izda potrdilo

f) ES pregled tipa

4. Sklicevanje na usklajene predpise

g) Izmerjen nivo zvočne moči

h) Zagotovljen nivo zvočne moči

k) Instalirana moč

n) Oseba, pooblaščena za sestavo tehnične

knjižice:

o) Kraj in datum

BS (

Prijevod originalnih uputa)

EZ izjava o sukladnosti

(Direktiva o mašinama 2006/42/EZ, Prilog II, deo

A)

1. Firma

2. Daje izjavu pod vlastitom odgovornošću da je

mašina: Ručna električna lančana motorna pila,

Obaranje i sječa drveća/rezanje grana

a) Tip / Osnovni model

b) Mjesec / Godina proizvodnje

c) Serijski broj

d) Motor: električno

3. sukladna s osnovnim zahtjevima direktive:

e) Certifikaciono tijelo

f) EZ ispitivanje tipa

4. Pozivanje na usklađene norme

g) Izmjereni nivo zvučne snage

h) Garantovani nivo zvučne snage

k) Instalisana snaga

n) Osoba ovlaštena za izradu tehničke brošure:

o) Mjesto i datum

SK (

Preklad pôvodného návodu na použitie)

ES vyhlásenie o zhode

(Smernica o Strojných zariadeniach 2006/42/ES,

Príloha II, časť A)

1. Spoločnosť

2. Vyhlasuje na vlastnú zodpovednosť, že stroj:

Prenosná elektrická reťazová motorová píla,

Stínanie/rozrezávanie/odvetvovanie stromov

a) Typ / Základný model

b) Mesiac / Rok výroby

c) Výrobné číslo

d) Motor:

elektrický

3. Je v zhode s nariadeniami smerníc:

e) Certifikačný orgán

f) Skúška typu ES

4. Odkaz na Harmonizované normy

g) Nameraná úroveň akustického výkonu

h) Zaručená úroveň akustického výkonu

k) Inštalovaný výkon

n) Osoba autorizovaná na vytvorenie

Technického spisu:

o) Miesto a Dátum

RO (Traducerea manualului fabricantului)

CE -Declaratie de Conformitate

(Directiva Maşini 2006/42/CE, Anexa II, partea A)

1. Societatea

2. Declară pe propria răspundere că maşina:

Ferăstrău electric cu lanț portabil,

Doborâre/secţionare/tăierea ramurilor de copaci

a) Tip / Model de bază

b) Luna /Anul de fabricație

c) Număr de serie

d) Motor: electric

3. Este în conformitate cu specificaţiile

directivelor:

e) Organism de certificare

f) Examinare CE de Tip

4. Referinţă la Standardele armonizate

g) Nivel de putere sonoră măsurat

h) Nivel de putere sonoră garantat

k) Putere instalată

n) Persoană autorizată să întocmească Dosarul

Tehnic

o) Locul şi Data

LT (Originalių instrukcijų vertimas)

EB atitikties deklaracija

(Mašinų direktyva 2006/42/CE, Priedas II, dalis A)

1. Bendrovė

2. Prisiima atsakomybę, kad įrenginys:

Nešiojamas elektrinis grandininis pjūklas,

Medžių kirtimas/pjaustymas/genėjimas

a) Tipas / Bazinis Modelis

b) Mėnuo / Pagaminimo metai

c) Serijos numeris

d) Variklis: elektrinė

3. Atitinka direktyvose pateiktas specifikacijas:

e) Sertifikavimo įstaiga

f) CE tipo tyrimas

4. Nuoroda į suderintas Normas

g) Išmatuotas garso galios lygis

h) Užtikrinamas garso galios lygis

k) Instaliuota galia

n) Autorizuotas asmuo sudaryti Techninę

Dokumentaciją:

o) Vieta ir Data

LV (Instrukciju tu lkojums no oriģinālvalodas)

EK atbilstības deklarācija

(Direktīva 2006/42/EK par mašīnām, pielikums II,

daļa A)

1. Uzņēmums

2. Uzņemoties par to pilnu atbildību, paziņo, ka

mašīna: Portatīvs elektriskais ķēdes zāģis,

Koku gāšana/zāģēšana/atzarošana

a) Tips / Bāzes modelis

b) Mēnesis / Ražošanas gads

c) Sērijas numurs

d) Motors: elektriskais

3. Atbilst šādu direktīvu prasībām:

e) Sertifikācijas iestāde

f) CE tipveida pārbaude

4. Atsauce uz harmonizētiem standartiem

g) Izmērītais skaņas intensitātes līmenis

h) Garantētais skaņas intensitātes līmenis

k) Uzstādītā jauda

n) Pilnvarotais darbinieks, kas sagatavoja

tehnisko dokumentāciju:

o) Vieta un datums

SR

(Prevod originalnih uputstvaI)

EC deklaracija o usaglašenosti

(Direktiva o mašinama 2006/42/EC, Prilog II, deo

A)

1. Preduzeće

2. Daje izjavu pod vlastitom odgovornošću da je

mašina: Ručna električna lančana motorna

testera,

Obaranje i seča drveća/rezanje grana

a) Tip / Osnovni model

b) Mesec /Godina proizvodnje

c) Serijski broj

d) Motor: električni

3. u skladu s osnovnim zahtevima direktiva:

e) Sertifikaciono telo

f) EC ispitivanje tipa:

4. Pozivanje na usklađene norme

g) Izmereni nivo zvučne snage

h) Garantovani nivo zvučne snage

k) Instalisana snaga

n) Osoba ovlašćena za sastavljanje tehničke

brošure

o) Mesto i datum

BG

(Превод на оригиналните инструкции)

ЕО декларация за съответствие

(Директива Машини 2006/42/ЕО, Приложение

II, част А)

1. Дружеството

2. На собствена отговорност декларира, че

машината: Преносим електрически моторен

верижен трион,

Сеч/нарязване на трупи/окастряне клоните на

дървета

а) Вид / Базисен модел

б) Месец / година на производство

в) Сериен номер

г) Мотор: електрически

3. Е в съответствие със спецификата на

директивите:

д) Сертифициращ орган

е) ЕО изследване на вида

4. Базирано на хармонизираните норми

ж) Ниво на измерена акустична мощност

и) Гарантирано ниво на акустична мощност

л) Инсталирана мощност

р) Лице, упълномощено да състави

Техническата Документация:

o) Място и дата

ET

(Algupärase kasutusjuhendi tõlge)

EÜ vastavusdeklaratsioon

(Masinadirektiiv 2006/42/EÜ, Lisa II, osa A)

1. Firma

2. Kinnitab omal vastutusel, et masin:

Kaasaskantav elektriline,

Puude langetamine/järkamine/laasimine

a) Tüüp / Põhimudel

b) Kuu aega / Tootmisaasta

c) Matrikkel

d) Mootor: elektriline

3. Vastab direktiivide nõuetele:

e) Kinnitav asutus

f) EÜ tüübihindamine

4. Viide ühtlustatud standarditele

g) Mõõdetud helivõimsuse tase

h) Garanteeritud helivõimsuse tase

k) Installeeritud võimsus

n) Tehnilise Lehe autoriseeritud koostaja:

o) Koht ja Kuupäev

FR (Traduction de la notice originale)

Déclaration CE de Conformité

(Directive Machines 2006/42/CE, Annexe II, partie

A)

1. La Société

2. Déclare sous sa propre responsabilité que la

machine : Sci e à chaîne électrique et portative /

abattage/tronçonnage/ébranchage d’arbres

a) Type / Modèle de Base

b) Mois /Année de construction

c) Série

d) Moteur: électrique

3. Est conforme aux prescriptions des

directives :

e) Organisme de certification

f) Examen CE du Type

4. Renvoi aux Normes harmonisées

g) Niveau de puissance sonore mesuré

h) Niveau de puissance sonore garanti

k) Puissance installée

n) Personne habilitée à établir le Dossier

Technique :

o) Lieu et Date

EN (Translation of the original instruction)

EC Declaration of Conformity

(Machine Directive 2006/42/EC, Annex II, part A)

1. The Company

2. Herby declares under its own responsibility

that the machine: Portable electric chain saw /

felling, bucking, delimbing trees

a) Type / Base Model

b) Month / Year of manufacture

c) Serial number

d) Motor: electric

3. Conforms to directive specifications:

e) Certifying body

f) EC examination of Type

4. Reference to harmonised Standards

g) Sound power level measured

h) Sound power level guaranteed

k) Power installed

n) Person authorised to create the Technical

Folder:

o) Place and Date

DE (Übersetzung der Originalbetriebsanleitung)