STIEBEL ELTRON WWS 20 Operation And Installation

BEDIENUNG UND INSTALLATION

OPERATION AND INSTALLATION

UTILISATION ET INSTALLATION

Warmwasser-Wärmepumpe in Splitbauweise | DHW heat pump in a split design |

Chauffe-eau thermodynamique de conception split

» WWS 20

1:1

CONTENTS | SPECIAL INFORMATION

CONTENTS

SPECIAL INFORMATION

OPERATION

1. General information ��������������������������������������� 38

1.1 Safety instructions ����������������������������������������������38

1.2 Other symbols in this documentation ���������������������� 38

1.3 Information on the appliance ��������������������������������39

1.4 Units of measurement ����������������������������������������� 39

1.5 Standardised output data ������������������������������������� 39

2. Safety �������������������������������������������������������� 39

2.1 Intended use ����������������������������������������������������� 39

2.2 Incorrect use ����������������������������������������������������� 39

2.3 General safety instructions �����������������������������������39

2.4 Test symbols �����������������������������������������������������40

3. Appliance description ������������������������������������� 40

3.1 Heating the DHW cylinder ������������������������������������ 40

3.2 Appliance operation outside the application limits ������ 41

3.3 Frost protection (air as heat source) ������������������������ 41

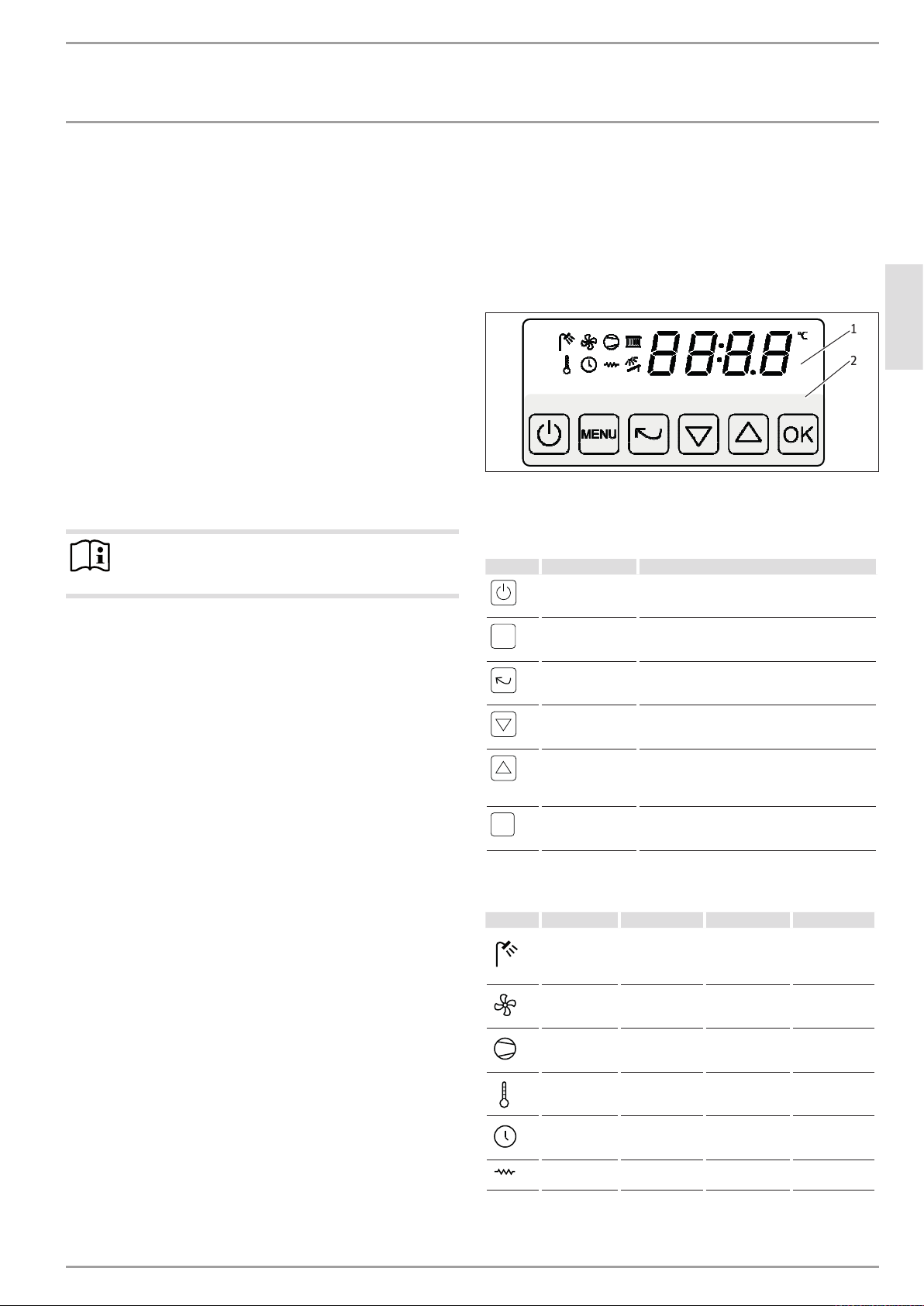

3.4 Display and control elements �������������������������������� 41

4. Menu structure ��������������������������������������������� 42

4.1 Switching on heat pump �������������������������������������� 43

4.2 Standard display ������������������������������������������������ 43

4.3 DHW heating ����������������������������������������������������� 43

4.4 Fan mode ���������������������������������������������������������44

4.5 Heat pump mode selection ����������������������������������� 45

4.6 Operation with external signal transmitter ��������������� 45

4.7 Electric heater rod ���������������������������������������������� 46

4.8 Setting the time ������������������������������������������������� 46

4.9 Parameter level �������������������������������������������������46

5. Cleaning, care and maintenance ������������������������� 47

6. Troubleshooting �������������������������������������������� 47

INSTALLATION

7. Safety �������������������������������������������������������� 49

7.1 General safety instructions ����������������������������������� 49

7.2 Instructions, standards and regulations ������������������� 49

8. Appliance description ������������������������������������� 49

8.1 Standard delivery ����������������������������������������������� 49

8.2 Accessories ������������������������������������������������������� 49

8.3 Incorrect use ����������������������������������������������������� 49

9. Preparations ������������������������������������������������ 49

9.1 Transport ��������������������������������������������������������� 49

9.2 Storage ������������������������������������������������������������50

9.3 Installation site �������������������������������������������������� 50

9.4 Heat source (air draw-off point) ����������������������������� 51

10. Installation �������������������������������������������������� 51

10.1 Wall mounting bracket installation ������������������������� 51

10.2 Siting the appliance �������������������������������������������� 52

10.3 Water connection ����������������������������������������������� 52

10.4 Condensate drain ����������������������������������������������� 54

10.5 Power supply ���������������������������������������������������� 54

10.6 Temperature sensor �������������������������������������������� 55

11. Commissioning ��������������������������������������������� 55

11.1 Initial start-up ��������������������������������������������������� 55

11.2 Recommissioning ����������������������������������������������� 56

12. Appliance shutdown ��������������������������������������� 56

13. Maintenance and cleaning �������������������������������� 56

13.1 Removing the casing ������������������������������������������� 56

13.2 Removing casing components separately ����������������� 57

13.3 Cleaning the evaporator ��������������������������������������� 57

13.4 Water treatment�������������������������������������������������57

13.5 Descaling the appliance ��������������������������������������� 57

14. Specification ������������������������������������������������ 58

14.1 Dimensions and connections ��������������������������������� 58

14.2 Hydraulic connection diagram ������������������������������� 59

14.3 Wiring diagrams ������������������������������������������������ 61

14.4 Heating output �������������������������������������������������� 65

14.5 Power consumption �������������������������������������������� 65

GUARANTEE

ENVIRONMENT AND RECYCLING

14.6 Data table �������������������������������������������������������� 66

SPECIAL INFORMATION

- The appliance may be used by children aged8

and up and persons with reduced physical, sensory or mental capabilities or a lack of experience

and know-how, provided that they are supervised

or they have been instructed on how to use the

appliance safely and have understood the resulting risks. Children must never play with the appliance. Children must never clean the appliance

or perform user maintenance unless they are

supervised.

- Observe all applicable national and regional regulations and instructions during installation.

- The appliance is not approved for outdoor

installation.

- Observe the minimum clearances (see chapter "Installation/ Preparations/ Siting the

appliance").

- Observe the requirements concerning the installation room (see chapter "Installation/ Preparations/ Installation site").

ENGLISH

www.stiebel-eltron.com WWS 20 | 37

SPECIAL INFORMATION | OPERATION

General information

- In the case of a permanent connection, the appliance must be able to be separated from the

power supply by an isolator that disconnects all

poles with at least 3mm contact separation. Contactors, mains isolators or fuses can be used for

this.

- Observe the safety measures to prevent contact

with dangerous 'live' currents.

- Observe the MCB/fuse protection required for

the appliance (see chapter "Specification/ Data

table").

- In the event of damage to the power cable this

must always be replaced by a qualified contractor

authorised by the manufacturer, using original

spare parts.

- The appliance is pressurised. During the heat-up

process, expansion water will drip from the safety

valve.

- Install a type-tested safety valve in the cold water

supply line.

- The maximum pressure in the cold water supply

line must be at least 20% below the response

pressure of the safety valve. If the maximum

pressure in the cold water supply line is higher,

install a pressure reducing valve.

- Size the drain so that water can drain off unimpeded when the safety valve is fully opened.

OPERATION

1. General information

The chapters "Special information" and "Operation" are intended

for both users and qualified contractors.

The chapter "Installation" is intended for qualified contractors.

Note

Read these instructions carefully before using the appliance and retain them for future reference.

Pass on the instructions to a new user if required.

1.1 Safety instructions

1.1.1 Structure of safety instructions

KEYWORD Type of risk

!

Here, possible consequences are listed that may result

from failure to observe the safety instructions.

Steps to prevent the risk are listed.

1.1.2 Symbols, type of risk

Symbol Type of risk

!

Injury

Electrocution

Burns

(burns, scalding)

- Fit the discharge pipe of the safety valve with

a constant downward slope and in a room free

from the risk of frost.

- The safety valve discharge aperture must remain

open to atmosphere.

1.1.3 Keywords

KEYWORD Meaning

DANGER Failure to observe this information will result in serious

WARNING Failure to observe this information may result in serious

CAUTION Failure to observe this information may result in non-seri-

injury or death.

injury or death.

ous or minor injury.

1.2 Other symbols in this documentation

Note

General information is identified by the adjacent symbol.

Read these passages carefully.

Symbol Meaning

!

Material losses

(appliance damage, consequential losses and environmental pollution)

Appliance disposal

38 | WWS 20 www.stiebel-eltron.com

OPERATION

Safety

This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

1.3 Information on the appliance

Symbol Meaning

Never cover the appliance

1.4 Units of measurement

Note

All measurements are given in mm unless stated otherwise.

1.5 Standardised output data

Explanations to determine and interpret the specified standardised

output data

Standard: EN 16147

The output data specifically mentioned in text, diagrams and

technical datasheets has been calculated according to the test

conditions of the standard shown in the heading of this section.

Generally, these standardised test conditions will not fully meet

the conditions found at the installation site of the system user.

Depending on the chosen test method and the extent to which this

method deviates from the conditions defined in the norm shown in

the heading of this section, any deviations can have a considerable

impact. Additional factors that have an influence on the test values

are the measuring equipment, the system configuration, the age

of the system and the flow rates.

A confirmation of the specified output data can only be obtained

if the conditions applicable to the relevant test match those of the

standard shown in the heading of this chapter.

2. Safety

2.1 Intended use

The appliance is intended for DHW heating within the application

limits detailed in chapter "Specification/ Data table".

The appliance is intended for domestic use. It can be used safely

by untrained persons. The appliance can also be used in non-domestic environments, e.g. in small businesses, as long as it is

used in the same way.

Any other use beyond that described shall be deemed inappropriate. Observation of these instructions and of instructions for any

accessories used is also part of the correct use of this appliance.

2.2 Incorrect use

The following are not permitted:

- Heating liquids other than DHW

- Operating the appliance with an empty DHW cylinder

- Operating the appliance outside the application limits (see

chapter "Specification")

- Interrupting the power supply

2.3 General safety instructions

Only qualified contractors should carry out the electrical work and

installation of this appliance. Qualified contractors are responsible

for adherence to all applicable regulations.

The appliance should only be operated once it is fully installed

and all safety equipment has been fitted.

WARNING Injury

!

The appliance may be used by children aged 8 and up and

persons with reduced physical, sensory or mental capabilities or a lack of experience and know-how, provided

that they are supervised or they have been instructed on

how to use the appliance safely and have understood

the resulting risks. Children must never play with the

appliance. Children must never clean the appliance or

perform user maintenance unless they are supervised.

WARNING Electrocution

Contact with live components presents a threat to life.

Damage to the insulation or to individual components

may result in a threat to life.

If there is damage to the insulation, switch off the

power supply and arrange a repair.

All work on the electrical installation must be carried

out by a qualified contractor.

WARNING Burns

The water in the DHW cylinder can be heated to temperatures in excess of 60°C. There is a risk of scalding at

outlet temperatures above 43°C.

Ensure you do not come into contact with the water

when discharged.

WARNING Burns

Touching hot components can lead to burns.

When working on hot components, always wear protective working clothing and safety gloves.

The pipework connected to the DHW outlet of the appliance can reach temperatures in excess of 60°C.

WARNING Burns

The appliance is filled with refrigerant at the factory.

In the event of refrigerant escaping due to a leak, avoid

coming into contact with the refrigerant or inhaling the

released vapours. Ventilate the rooms affected.

CAUTION Injury

!

Never place any objects on top of the appliance. If objects

are left on the appliance, noise emissions may increase

due to resulting vibrations, and the objects could fall

and cause injury.

Material losses

!

If you disconnect the appliance from the power supply,

the operating status of the primary pump can no longer

be guaranteed.

Never interrupt the power supply to the appliance.

ENGLISH

www.stiebel-eltron.com WWS 20 | 39

OPERATION

Appliance description

Material losses

!

Never cover the appliance. Covering the air intake or air

discharge leads to a reduced air supply. If the air supply

is restricted, the operational reliability of the appliance

cannot be guaranteed.

Material losses

!

Only operate the appliance when the DHW cylinder has

been filled.

Material losses

!

Keep the appliance installation site and the air draw-off

point free from air contaminated with oil or salt and from

explosive or corrosive substances (e.g. chlorine, sulphur,

ammonia).

2.4 Test symbols

See type plate. The type plate is located on the side of the appliance.

3. Appliance description

The appliance is a fully wired DHW heat pump in a hydraulic split

design. When combined with an externally connected DHW cylinder, the appliance supplies DHW heating from several draw-off

points using renewable energy. Subject to the power supply and

user draw-off behaviour, the DHW cylinder is heated automatically

to the selected set temperature.

The appliance extracts heat from the ambient air at the air drawoff point. This heat is used to heat up the water in the DHW cylinder

with added electric power. The amount of electrical energy and

time required to heat-up the DHW depend on the temperature of

the air drawn in.

Note

As the heat is drawn off from the supply air, the appliance

operates with a defined cooling capacity on the exhaust

air stream. In recirculation air mode, this can then cause

a temporary cooling of the installation room.

When selecting the type and size of installation

room, ensure that energy use is compensated over a

period of 24hours and the lower application limit of

the appliance is not undershot. Please also observe

the following factors:

- Expected appliance runtime per day

- The resulting cooling energy

- Existing heat sources in the installation room

(e.g.freezer, tumble dryer, central heating)

- Heat flux from adjoining rooms

The appliance is designed for indoor installation. It can be installed

as a recirculation air appliance and thus use the existing waste

heat from other heat sources in the installation room (e.g. washing machine, freezer). Alternatively the appliance allows you to

connect an air duct to route the supply air from another room or

to remove the exhaust air from the installation room. For times

when there is no DHW demand (compressor inactive), the fan

speed can be set separately.

Note

In heat pump mode (compressor active), the fan always

operates at a fixed rated speed set at the factory (see

chapter "Specification/ Data table"), irrespective of the

fan speed set for operating without a compressor.

The appliance also extracts moisture from the ambient air, which

turns into condensate. The condensate is removed from the appliance via the condensate drain.

The appliance features an electronic control unit with LCD for setting functions and operating modes.

Depending on which hydraulic cylinder connection is selected, an

immersion heater can be connected to the appliance control unit

and controlled from there.

External signal transmitters can be integrated via the built-in

switching input, for example a photovoltaic system to increase

the percentage of on-site power or an off-peak tariff signal.

Heat pump operating principle

A closed circuit within the appliance contains refrigerant (see

chapter "Specification/ Data table"). This refrigerant evaporates

at low temperatures.

In the evaporator, which extracts heat from the air drawn in, the

refrigerant changes from a liquid into a gaseous state. A compressor draws in the gaseous refrigerant and compresses it. This

increase in pressure raises the refrigerant temperature.

That requires electrical energy. The energy (motor heat) is not lost,

but reaches the downstream condenser together with the compressed refrigerant (plate heat exchanger). There, the refrigerant

indirectly transfers heat to the passing DHW. An expansion valve

then reduces the still prevalent pressure and the cycle starts again.

The appliance is fitted with a DHW primary pump at the factory.

Material losses

!

The internal primary pump should be started periodically

(every 20hours for 3seconds) to prevent it seizing up.

Never interrupt the power supply to the appliance.

To switch off the appliance (standby mode), keep the

power button pressed for approx. 2seconds.

Note

When the intake air temperature drops, the appliance

output is reduced and the heat-up time is extended.

40 | WWS 20 www.stiebel-eltron.com

3.1 Heating the DHW cylinder

A temperature sensor captures the amount of heat in the DHW

cylinder. The water in the DHW cylinder is heated up if the amount

of heat is lower than that required to achieve the set temperature.

OPERATION

Appliance description

3.2 Appliance operation outside the application

limits

3.2.1 Ambient temperatures below the application limit

At temperatures below the lower application limit, hoar frost may

form on the evaporator depending on the air humidity and water

temperature.

Temperature sensor F3 captures and monitors the evaporator

temperature. If the evaporator temperature falls below 0°C for

longer than 120minutes, the evaporator will defrost. This defrosting raises the evaporator temperature again.

Defrosting is registered as successful if the evaporator temperature rises to >6°C within 20minutes. If defrosting is unsuccessful,

two more attempts will be made. If these attempts are still unsuccessful, the heat pump will be switched off and the error message

Er47 will appear on the display.

To guarantee fault-free operation of the appliance, make sure

you operate the appliance within its application limits (see

chapter "Specification/ Data table").

Note

Heat-up times are longer while the evaporator is defrosting.

3.4 Display and control elements

The appliance is equipped with an integral digital controller. You

can use the controller display and control elements to call up and

set the appliance data.

3.4.1 Display

The display consists of a display and programming unit.

1

2

1 Display unit

2 Programming unit

Keys

Button Designation Description

Power button Put the appliance into standby mode or restart

it

ENGLISH

D0000045887

3.2.2 Ambient temperatures above the application limit

The safety equipment switches the appliance off if the upper application limit is exceeded. Following a cooling time of several

minutes the appliance is switched back on automatically. The appliance is switched off again if the intake air temperature rises

back above the permissible temperature value.

To guarantee fault-free operation of the appliance, make sure

you operate the appliance within its application limits (see

chapter "Specification/ Data table").

3.3 Frost protection (air as heat source)

If the intake air temperature is too low, the error message Er57

will appear on the display.

If an immersion heater is installed in the DHW cylinder, it can

continue DHW heating while the fault remains. This requires heat

pump mode to be disabled.

MENU

OK

Menu key

Back button

Down button Scroll through the menu, adjust values,

Up button

OK button

Calling up the controller menu

Return to the previous menu

display the set DHW value

Scroll through the menu, adjust values,

display the optional temperature sensor in the

DHW cylinder (only when display sensor F2 is

connected)

Save settings,

select submenus,

acknowledge error messages

Symbols

Symbol Meaning bright dimmed flashes

DHW heating

Fan mode Fan mode active Fan mode

Compressor Compressor

Setting the

temperature

DHW heating

active

active

Setting the temperature

DHW heating according to time

program

switched off -

Compressor

switched off

-

Pasteurisation

function active

Maintenance

(every 2500

hours run)

-

Electric heater

Setting the

time

rod

Setting the time -

Immersion

heater active

Immersion heater switched off

Time needs resetting

-

www.stiebel-eltron.com WWS 20 | 41

OPERATION

Menu structure

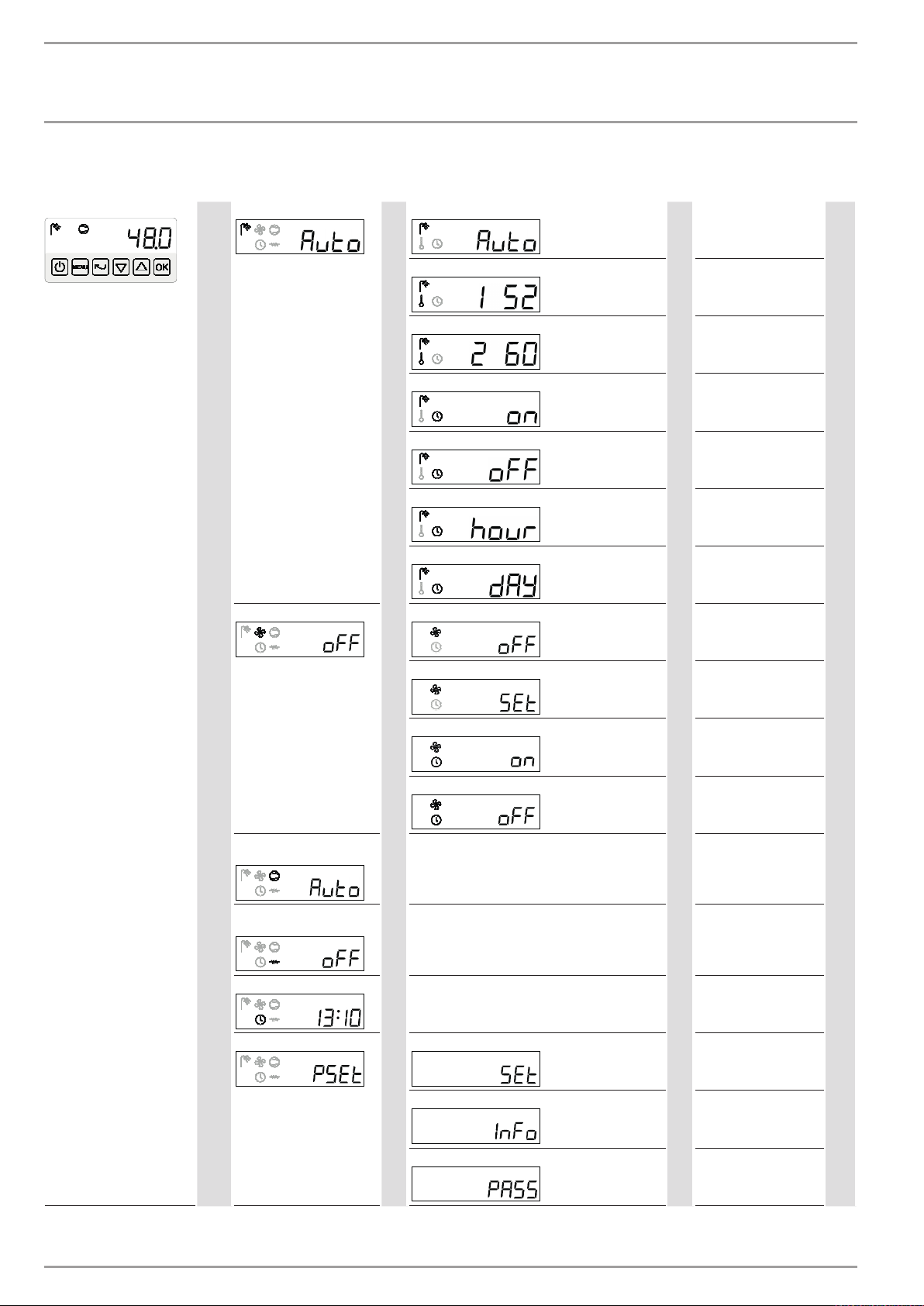

4. Menu structure

Standard display (chapter 4.2)

DHW heating (chapter 4.3)

MENU

▲Fan mode (chapter 4.4)

DHW mode selection (chapter 4.3.1)

OK

Set DHW value (chapter 4.3.2)

▲

Set pasteurisation value (chapter 4.3.3)

▲

DHW start time (chapter 4.3.1)

▲

DHW stop time (chapter 4.3.1)

▲

Pasteurisation function start time (chapter 4.3.3)

▲

Pasteurisation function time interval (chapter 4.3.3)

▲

Fan mode selection (chapter 4.4)

OK

Auto* = Automatic mode

OK

FASt = Quick heat-up

0...60

OK

(52*)

0...60*

OK

00:00*...23:59

OK

00:00...23:59*

OK

00:00*...23:59

OK

0*...14

OK

(0 = Pasteurisation function disabled)

oFF* = Fan switched off

OK

on = Continuous mode

Auto = Automatic mode

▲▼

▲▼

▲▼

▲▼

▲▼

▲▼

▲▼

▲▼

Heat pump mode selection

▲

(chapter 4.5)

Immersion heater mode se-

▲

lection (chapter 4.7)

Time (chapter 4.8)

▲

▲Parameter level (chapter 4.9)

Fan speed (chapter 4.4)

▲

Fan start time (chapter 4.4)

▲

Fan stop time (chapter 4.4)

▲

OK

OK

OK

Parameter setting (chapter 4.9.1)

OK

Call up operating data (chapter 4.9.2)

▲

→

→

→

1...9*

OK

00:00*...23:59

OK

00:00...23:59*

OK

oFF = Compressor

switched off

Auto* = Automatic mode

dEFr = Manual defrosting

oFF* = Immersion heater

switched off

Auto = Automatic mode

00:00...23:59

▲▼

▲▼

▲▼

▲▼

▲▼

▲▼

▲Enter password

11 /34

* Factory setting

42 | WWS 20 www.stiebel-eltron.com

OPERATION

Menu structure

MENU Menu key

OK OK button

▲ Up button

▼ Down button

Press the Back button to go from one menu level to the high-

er menu level.

4.1 Switching on heat pump

Keep the power button pressed for 2seconds.

The standard display appears.

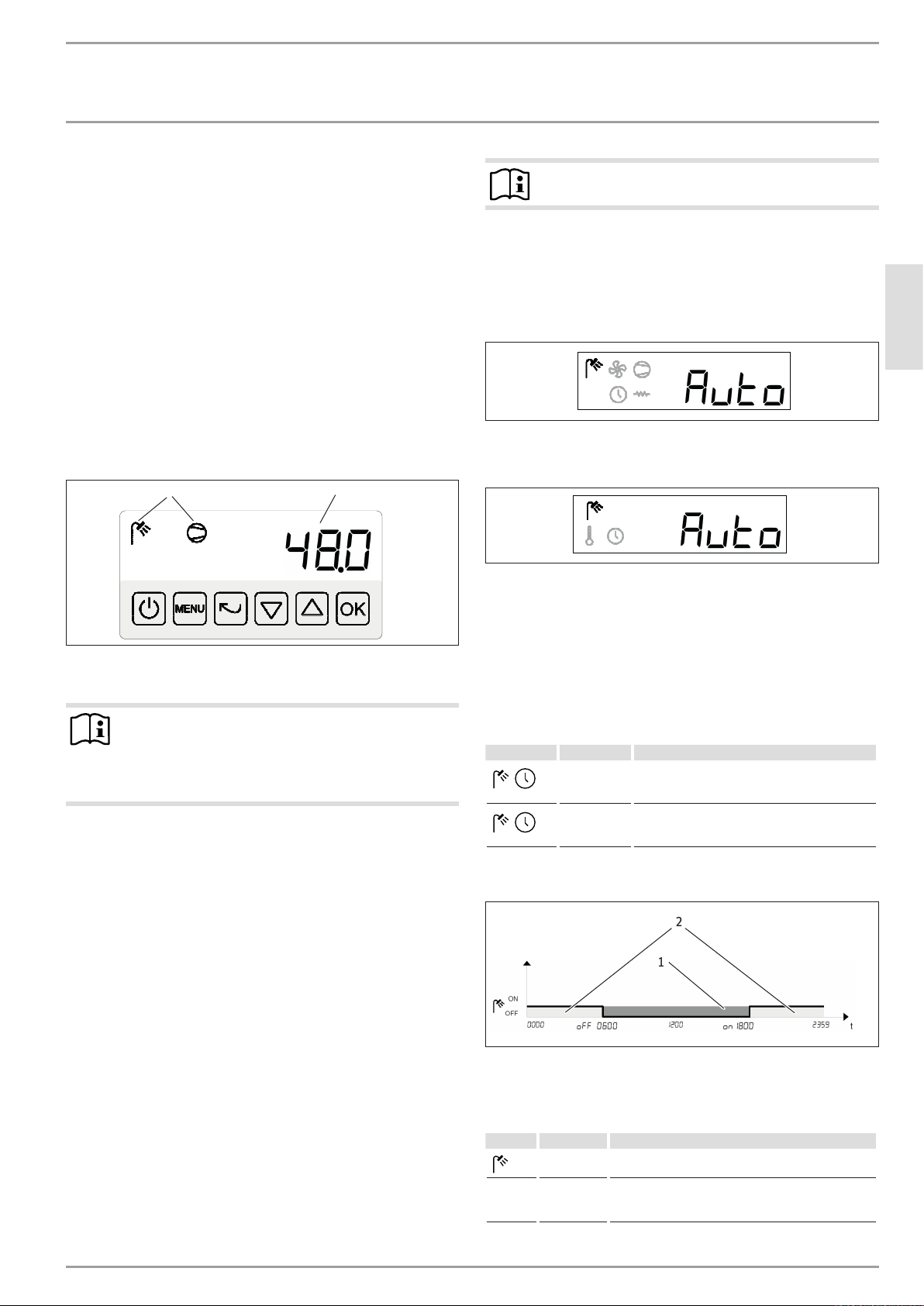

4.2 Standard display

When you are not navigating through the menu structure, the

standard display will be shown. The standard display shows the

actual temperature inside the DHW cylinder (control sensor F1)

and the current operating state of the appliance.

1

1 Operating state

2 Temperature inside the DHW cylinder

2

Note

Automatic mode is the default factory setting.

DHW heating mode setting

You are in the standard display.

Press the Menu button.

The DHW heating submenu appears.

Press the OK button.

The DHW mode selection submenu appears.

Press the OK button.

The operating mode flashes.

Set the required operating mode using the Up/Down buttons.

D0000045843

Confirm your entry with the OK button.

Keep pressing the Back button to return to the standard

display.

ENGLISH

D0000045844

D0000045845

Note

While you are in the standard display, the Up and Down

buttons function like short-cut buttons to call up the current set DHW value and, if display sensorF2 is connected,

the current actual temperature in the DHW cylinder.

4.3 DHW heating

The water in the DHW cylinder is heated up if:

- There is a current demand for domestic hot water

- DHW heating is not blocked by the time program

There is a current demand for domestic hot water when the water

temperature in the DHW cylinder is 5K lower than the selected

set DHW value.

4.3.1 DHW mode selection

The appliance features two different operating modes for DHW

heating:

- Automatic mode

- Quick heat-up

In automatic mode, DHW heating is controlled via an individually

adjustable time program. The DHW is heated using all the heat

sources which are enabled for automatic mode (see chapter "Parameter level/ Parameter setting").

In quick heat-up mode, the water is heated immediately to the

selected set DHW value, irrespective of automatic mode. Once the

selected set DHW value has been reached, the appliance switches

back to automatic mode.

Automatic mode time program setting

Symbol Parameter Description

on

off

DHW start time:

The time when DHW heating is enabled (factory

setting = 00:00)

DHW stop time:

The time when DHW heating is blocked (factory

setting = 23:59)

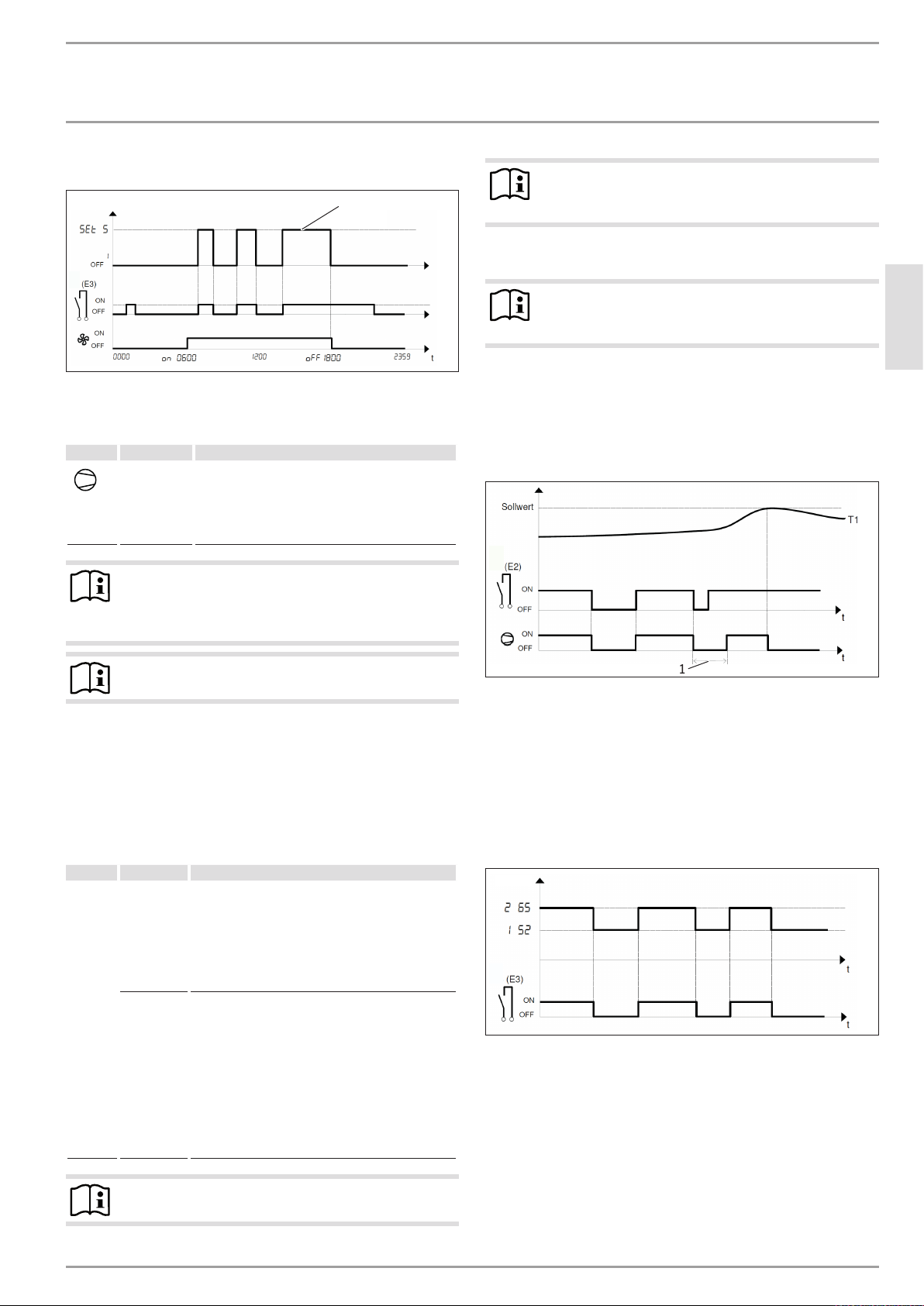

Example: DHW heating is blocked between 06:00-18:00

2

1

1 DHW heating enabled

2 DHW heating blocked

Quick heat-up activation and setting

Symbol Parameter Description

FASt Once-only quick heat-up starts as soon as "FASt" is

PSEt

└ SEt

b03

set.

Select the heat source for quick heat-up

0 = Heat pump only (factory setting)

1 = Heat pump and immersion heater

D0000045896

www.stiebel-eltron.com WWS 20 | 43

OPERATION

Menu structure

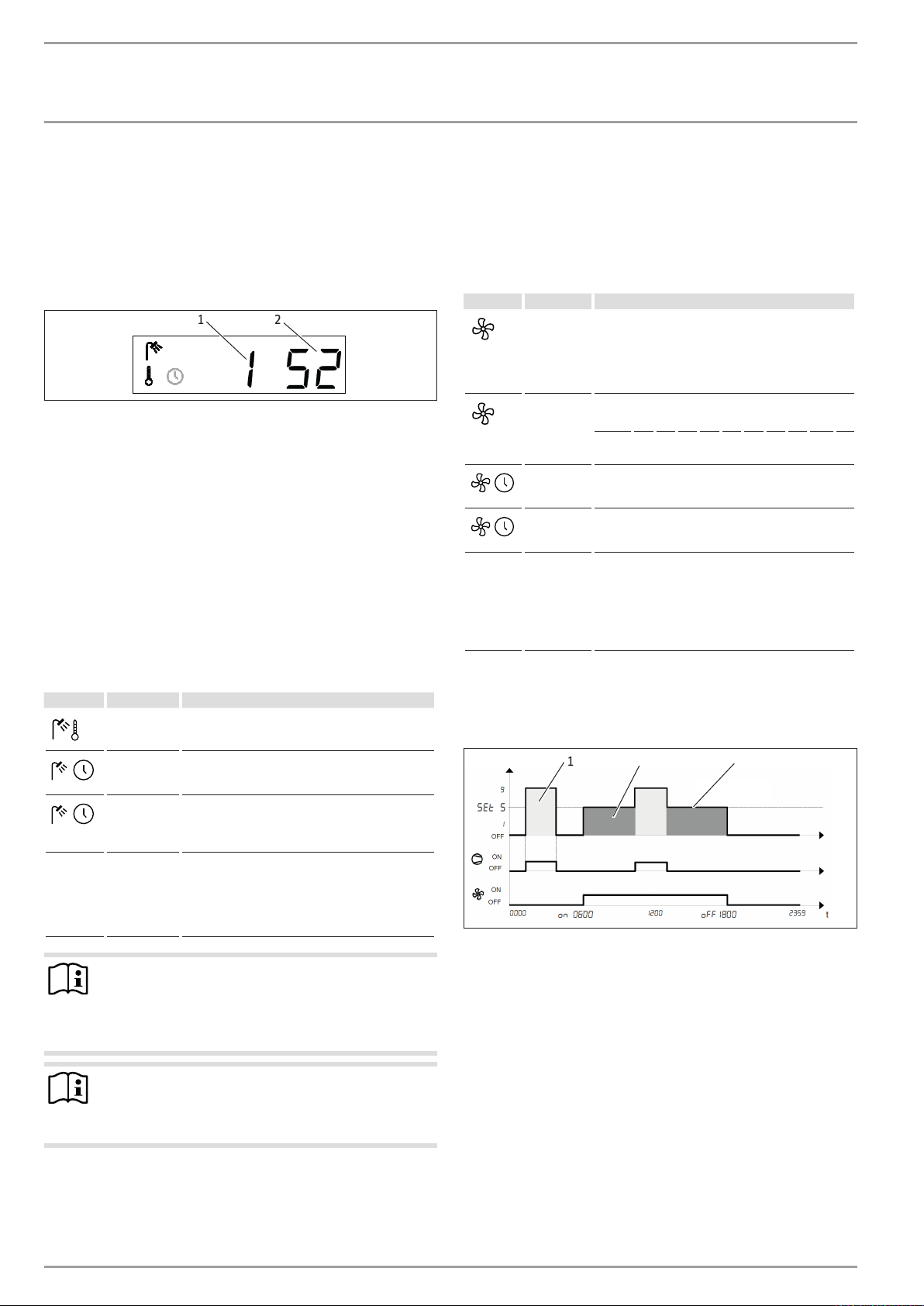

4.3.2 DHW value setting

You are in the standard display.

Press the Menu button.

The DHW heating submenu appears.

Press the Up button.

The set DHW value submenu appears.

1 2

1 Set DHW value display (set value1)

2 Current set DHW value

Press the OK button to confirm your selection.

The set DHW value flashes.

Set the required DHW value using the Up/Down buttons.

Confirm your entry with the OK button.

Keep pressing the Back button to return to the standard

display.

4.3.3 Pasteurisation function

The pasteurisation function is used to meet hygiene requirements. It is implemented using the heat pump and other active

heat sources. The DHW cylinder is heated periodically to the set

pasteurisation value (set value2).

Symbol Parameter Description

2 60

hour

Set pasteurisation value: Set temperature in the

DHW cylinder for the pasteurisation function (factory setting = 60°C)

Pasteurisation function start time

(factory setting = 00:00)

4.4 Fan mode

The fan can be switched on irrespective of the heat pump mode.

For this fan mode, you can set the fan speed and a time program.

Alternatively, the fan can be switched on and off via an external

switching input.

Fan mode setting

Symbol Parameter Description

D0000045846

(factory setting = 9)

PSEt

└ SEt

* The fan stage data is based on a freely blowing appliance

Example switching diagram:

Auto

SEt

on

oFF

A04

Fan mode selection

oFF = Fan switched off (factory setting)

on = Fan operating at rated speed, compressor

active

Auto = Automatic mode (fan operating via separate

time program)

Fan speed (automatic mode)

Stage* 0 1 2 3 4 5 6 7 8 9

% 0 45 60 71 81 89 94 98 99 100

Fan start time (automatic mode)

(factory setting = 00:00)

Fan stop time (automatic mode)

(factory setting = 23:59)

Function of switching input E3

0 = No function (factory setting)

3 = External fan control:

K3 open = Fan switched off, no DHW demand

K3 closed = Fan operates at set speed

with no external air routing lines.

1 3

2

PSEt

└ SEt

dAY

b02

Pasteurisation function time interval: The time

interval during which the pasteurisation function

is periodically implemented

(factory setting = 0)

Maximum pasteurisation function heat-up time: If

the set pasteurisation value is not achieved within

the time set here, the heat-up process is terminated (see chapter "Parameter level/ Parameter

setting").

(factory setting = 4.0h)

Note

The pasteurisation function may be influenced by the

DHW heating time program.

Set the pasteurisation function start time in the peri-

od where DHW heating is enabled.

Note

If the power supply has been interrupted, e.g. following a

power failure, the selected heat-up time can be extended

up to 6hours.

D0000045897

1 Compressor active (light grey)

2 Fan operating at rated speed

3 Compressor switched off (dark grey)

4 Fan in automatic mode, independently of compressor

5 Fan stage curve

4.4.1 External fan control

Alternatively, the fan can be switched on and off from an external

control unit via switching input E3 (see chapter "Junction box").

To do this, fan mode selection must be set to "Auto". The time

program for fan mode takes priority over the external fan control,

so switching inputE3 is active only while fan mode is enabled.

44 | WWS 20 www.stiebel-eltron.com

OPERATION

Menu structure

Example switching diagram:

1 Fan speed curve

4.5 Heat pump mode selection

Symbol Parameter Description

Auto

Heat pump mode selection

oFF = Compressor switched off

Auto = Automatic mode (according to the period

DHW heating is enabled)

defr = Manual defrosting of the compressor

(factory setting = Auto)

Note

When the heat pump compressor is switched off, the fan

operates in automatic mode. The heat pump does not

provide any DHW heating.

Note

1

An external shutdown takes priority over increasing the

set value.

4.6.1 Power supply utility shutdown

Note

Shutting down the heat pump power supply utility has

no effect on ventilation.

D0000045898

The heat pump shuts down automatically when:

ENGLISH

- Switching input E2 is open

- The set value for DHW temperature has been reached

The display shows the word StOP.

Example switching diagram:

Note

The heat pump is set to automatic mode at the factory.

4.6 Operation with external signal transmitter

You can switch off the heat pump or set it to a higher set value

using floating switching inputsE2 and E3 (see chapter "Junction

box").

You can configure E2 and E3 via the "Parameter setting" submenu

as follows:

Symbol Parameter Description

PSEt

└ SEt

A03

A04

Function of switching input E2

0 = No function (factory setting)

1 = Power supply utility shutdown:

K2 open = Heat pump (and immersion heater)

switched off

K2 closed = Heat pump is running

Function of switching input E3

0 = No function (factory setting)

1 = Power supply utility shutdown:

K2 open = Heat pump (and immersion heater)

switched off

K2 closed = Heat pump is running

2 = Smart Grid function:

K3 open = DHW set value is delivered

K3 closed = Pasteurisation set value is delivered

1

T1 Temperature in the DHW cylinder (sensor F1)

1 Minimum compressor idle time (20min)

4.6.2 Set value increase

If you have your own photovoltaic system, you can increase the

delivered set value via switching input E3 when you have a low

electricity tariff. This will then deliver the pasteurisation set value

(2) instead of the DHW set value (1).

Example switching diagram:

D0000045900

D0000045901

Note

The compressor has a minimum idle time of 20minutes.

www.stiebel-eltron.com WWS 20 | 45