STIEBEL ELTRON WWK 222, WWK 222 H, WWK 302, WWK 302 H Operation And Installation Manual

OPERATION AND INSTALLATION

DHW heat pump

» WWK222

» WWK222H

» WWK302

» WWK302H

2 | WWK222-302 H www.stiebel-eltron.com

CONTENTS

SPECIAL INFORMATION

OPERATION

1. General information �����������������������������������������4

1.1 Safety instructions ����������������������������������������������� 4

1.2 Other symbols in this documentation ����������������������� 4

1.3 Units of measurement ������������������������������������������ 4

2. Safety ���������������������������������������������������������� 4

2.1 Intended use ������������������������������������������������������ 4

2.2 General safety instructions ������������������������������������ 4

2.3 Test symbols ������������������������������������������������������ 5

3. Appliance description ���������������������������������������5

3.1 Heat pump operating principle ������������������������������� 6

3.2 DHW heating ������������������������������������������������������ 6

3.3 Appliance operation outside the application limits ������� 6

3.4 Frost protection �������������������������������������������������� 6

3.5 Minimum runtime and minimum pause time �������������� 7

3.6 Connection of an external signal transmitter �������������� 7

4. Settings �������������������������������������������������������7

5. Cleaning, care and maintenance ���������������������������7

6. Troubleshooting ����������������������������������������������9

INSTALLATION

7. Safety �������������������������������������������������������� 10

7.1 General safety instructions ����������������������������������� 10

7.2 Instructions, standards and regulations ������������������� 10

8. Appliance description ������������������������������������� 10

8.1 Standard delivery ����������������������������������������������� 10

8.2 Required accessories ������������������������������������������10

8.3 Further accessories��������������������������������������������� 10

8.4 Incorrect use ����������������������������������������������������� 10

9. Preparations ������������������������������������������������ 10

9.1 Transport ��������������������������������������������������������� 10

9.2 Storage ������������������������������������������������������������ 11

9.3 Installation site �������������������������������������������������� 11

9.4 Siting the appliance �������������������������������������������� 12

10. Installation �������������������������������������������������� 13

10.1 Water connection ����������������������������������������������� 13

10.2 Condensate drain ����������������������������������������������� 14

10.3 Power supply ���������������������������������������������������� 14

10.4 Assembling the appliance ������������������������������������ 17

11. Commissioning ��������������������������������������������� 18

11.1 Initial start-up ��������������������������������������������������� 18

11.2 Recommissioning ����������������������������������������������� 18

12. Shutdown ��������������������������������������������������� 18

13. Troubleshooting �������������������������������������������� 19

13.1 Resetting the safety pressure limiter ����������������������� 19

13.2 Resetting the high limit safety cut-out (only WWKH) ��� 19

13.3 Motor overload relay ������������������������������������������� 19

14. Maintenance ������������������������������������������������ 20

14.1 Removing the appliance cover ������������������������������� 20

14.2 Removing the casing ring ������������������������������������� 20

14.3 Cleaning the evaporator ��������������������������������������� 20

14.4 Draining the cylinder ������������������������������������������ 21

14.5 Descaling the electric emergency/booster heater ������� 21

14.6 Valves ������������������������������������������������������������� 21

14.7 Condensate drain ����������������������������������������������� 21

14.8 Replacing the power cable ����������������������������������� 21

14.9 Fitting the casing ring ����������������������������������������� 21

14.10 Fitting the appliance cover ����������������������������������� 21

15. Specification ������������������������������������������������ 22

15.1 Dimensions and connections ��������������������������������� 22

15.2 Wiring diagram ������������������������������������������������� 24

15.3 Data table �������������������������������������������������������� 26

WARRANTY

ENVIRONMENT AND RECYCLING

ENGLISH

www.stiebel-eltron.com WWK222-302 H | 3

SPECIAL INFORMATION

SPECIAL INFORMATION

- The appliance may be used by children aged 8

and older and persons with reduced physical,

sensory or mental capabilities or a lack of experience and know-how, provided that they are

supervised or they have been instructed on how

to use the appliance safely and have understood

the resulting risks. Children must never play with

the appliance. Children must never clean the appliance or perform user maintenance unless they

are supervised.

- Observe all applicable national and regional regulations and instructions.

- Observe the minimum clearances (see chapter "Installation/ Preparations/ Siting the

appliance").

- Observe the requirements concerning the installation room (see "Specification/ Data table").

- The connection to the power supply must be

in the form of a permanent connection. Ensure

the appliance can be separated from the power

supply by an isolator that disconnects all poles

with at least 3mm contact separation. Contactors, circuit breakers or fuses can be used for

this. This type of isolator must be installed in the

fixed electrical installation according to the wiring

rules. For Australia: Ensure that the appliance can

be separated from the power supply by a suitable

isolator. Contactors, circuit breakers or fuses can

be used for this. This type of isolator must be installed in accordance with the wiring rules.

- Observe the safety measures to prevent contact

with dangerous 'live' currents.

- Observe the MCB/fuse protection required for

the appliance (see chapter "Specification/ Data

table").

- If the power cable is faulty, replace it with a new

one. The power cable must only be replaced (for

example if damaged) by a qualified contractor.

- The appliance is pressurised. During the heat-up

process, expansion water will drip from the safety

valve.

- Activate any valves at least once every 6months

to prevent blockages, e.g. by limescale deposits.

- Drain the appliance as described in "Installation/ Maintenance and cleaning/ Draining the

cylinder".

- A T&P valve or a safety valve (cold water expansion control valve) must be installed. Observe all

applicable national and regional regulations and

instructions.

- The maximum pressure in the cold water supply

line must be at least 20% below the response

pressure of the lowest pressure rated valve installed, otherwise a pressure reduction valve will

be required. If this is the case, install a pressure

reduction valve in the cold water feed. The pressure reducing valve must be set to 440kPa if a

safety valve is installed; otherwise to 550kPa.

- Fit the discharge pipe of the safety valve with

a constant downward slope and in a room free

from the risk of frost.

- Size the drain so that water can drain off unimpeded when the safety valve is fully opened.

- The safety valve discharge aperture must remain

open to atmosphere.

OPERATION

General information

4 | WWK222-302 H www.stiebel-eltron.com

OPERATION

1. General information

The chapters "Special Information" and "Operation" are intended

for both the user and qualified contractors.

The chapter "Installation" is intended for qualified contractors.

Note

Read these instructions carefully before using the appliance and retain them for future reference.

Pass on the instructions to any new user where appropriate.

1.1 Safety instructions

1.1.1 Structure of safety instructions

!

KEYWORD Type of risk

Here, possible consequences are listed that may result

from failure to observe the safety instructions.

Steps to prevent the risk are listed.

1.1.2 Symbols, type of risk

Symbol Type of risk

Injury

Electrocution

Burns

(burns, scalding)

1.1.3 Keywords

KEYWORD Meaning

DANGER Failure to observe this information will result in serious

injury or death.

WARNING Failure to observe this information may result in serious

injury or death.

CAUTION Failure to observe this information may result in non-seri-

ous or minor injury.

1.2 Other symbols in this documentation

Note

General information is identified by the adjacent symbol.

Read these texts carefully.

Symbol Meaning

Material losses

(appliance damage, consequential losses and environmental pollution)

Appliance disposal

This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

1.3 Units of measurement

Note

All measurements are given in mm unless stated otherwise.

2. Safety

2.1 Intended use

The purpose of this appliance is to heat domestic hot water within

the application limits stated in the chapter "Specification / data

table".

This appliance is intended for domestic use. It can be used safely

by untrained persons. The appliance can also be used in a non-domestic environment, e.g.in a small business, as long as it is used

in the same way.

Any other use beyond that described shall be deemed inappropriate. Observation of these instructions and of instructions for any

accessories used is also part of the correct use of this appliance.

2.2 General safety instructions

Operate the appliance only when fully installed and with all safety

equipment fitted.

!

WARNING Injury

The appliance may be used by children aged 8 and older

and persons with reduced physical, sensory or mental

capabilities or a lack of experience and know-how, provided that they are supervised or they have been instructed on how to use the appliance safely and have

understood the resulting risks. Children must never play

with the appliance. Children must never clean the appliance or perform user maintenance unless they are

supervised.

WARNING Electrocution

Contact with live components presents a threat to life.

Damage to the cable insulation or to individual components may result in a risk to life.

If there is damage to the insulation, switch off the

power supply and arrange a repair.

All work on the electrical installation must be carried

out by a qualified contractor.

!

!

OPERATION

Appliance description

ENGLISH

www.stiebel-eltron.com WWK222-302 H | 5

WARNING Burns

The water in the DHW cylinder can be heated to temperatures in excess of 60°C. There is a risk of scalding at

outlet temperatures in excess of 43 °C.

Ensure you do not come into contact with the water

when discharged.

WARNING Burns

Touching hot components can lead to burns.

When working on hot components, always wear

protective working clothing and safety gloves.

The pipework connected to the DHW outlet of the appliance can reach temperatures in excess of 60°C.

WARNING Burns

The appliance is filled with refrigerant at the factory.

In the event of refrigerant escaping due to a leak, avoid

coming into contact with the refrigerant or inhaling the

released vapours. Ventilate the rooms affected.

WARNING Electrocution

Never operate the appliance when the casing is open or

without a cover.

!

CAUTION Injury

If objects are left on the appliance, noise emissions may

increase due to resulting vibrations, and the objects

could fall and cause injury.

Never place any objects on top of the appliance.

!

Material losses

At the factory, the appliance is fitted with rechargeable

batteries that ensure the power supply to the impressed

current anode in the case of a power failure.

To enable the impressed current anode to provide protection against corrosion, the power supply to the appliance must not be interrupted for more than 16 hours if

the DHW cylinder is filled with water and the anode is

not connected separately to a continuous power supply

source.

If regular interruptions to the power supply are not anticipated, the batteries will require no maintenance.

Every three years, you must replace the batteries for the

impressed current anode in the following cases:

- The impressed current anode is not connected separately to a continuous power supply source and

a switching contact regularly interrupts the power

supply to the appliance.

- The security of supply is inadequate.

Neglecting to do this puts the appliance at risk of damage.

Never use batteries that cannot be charged. Only nickel-metal hydride (Ni-MH) rechargeable batteries are

permissible.

Batteries may be damaged in the appliance. Without a

power supply, the impressed current anode and the cylinder would not be protected against corrosion.

!

Material losses

Ensure that the appliance, the water pipes and safety

valves are free from any risk of frost. If you disconnect the

appliance from the power supply, it is no longer protected

against frost.

!

Material losses

Never cover the appliance. Covering the air intake or air

discharge leads to a reduced air supply. If the air supply

is restricted, the operational reliability of the appliance

cannot be guaranteed.

!

Material losses

Only operate the appliance when the DHW cylinder has

been filled. If the DHW cylinder is empty, safety equipment switches off the appliance.

!

Material losses

Heating liquids other than potable water is not permitted.

!

Material losses

Keep the appliance installation site free from air contaminated with oil or salt (chloride) and corrosive or explosive substances. Avoid contaminating the installation site

with dust, hairspray or substances containing chlorine

or ammonia.

!

Material losses

Operating the appliance outside the application limits

(see "Specification/ Data table") is not permitted. The

appliance may be damaged if operated continuously outside the application limits.

Note

The appliance is pressurised. During the heat-up process,

expansion water will drip from the safety valve.

If water continues to drip when heating is complet-

ed, inform your qualified contractor.

2.3 Test symbols

See type plate on the appliance.

3. Appliance description

This appliance enables DHW to be supplied efficiently to several

draw-off points using renewable energy. The appliance extracts

heat from the ambient air. This heat is used to heat up the water

in the DHW cylinder with added electric power. The amount of

electrical energy and time required to heat up the DHW depend

on the temperature of the air drawn in. When the air inlet temperature drops, the appliance output is reduced and the heat-up

time is extended.

Subject to the power supply and user draw-off behaviour, the

water is heated automatically to the selected set temperature. The

appliance heats up the water to a temperature which is selected

at the factory.

OPERATION

Appliance description

6 | WWK222-302 H www.stiebel-eltron.com

In the case of indoor installation, the air inside the installation

room can be cooled by 1°C to 3°C through heat extraction. The

appliance also extracts moisture from the air, which turns into

condensate. The condensate is removed from the appliance via

the condensate drain.

When a hot water draw-off point is opened, the hot DHW is pushed

out of the appliance by the inflow of cold water.

The heat pump drive unit is located in the upper section of the

appliance. The DHW cylinder is located in the lower section of the

appliance. To protect against corrosion, the DHW cylinder is coated

internally with special enamel and is additionally equipped with

an impressed current anode.

3.1 Heat pump operating principle

A closed circuit within the appliance contains refrigerant (see

"Specification/ Data table"). This refrigerant evaporates at low

temperatures. In the evaporator, which extracts heat from the

air drawn in, the refrigerant changes from a liquid into a gaseous state. A compressor draws in the gaseous refrigerant and

compresses it. This increase in pressure raises the refrigerant

temperature. That requires electrical energy.

The energy (motor heat) is not lost, but reaches the downstream

condenser together with the compressed refrigerant. There, the

refrigerant transfers heat to the DHW cylinder. An expansion valve

then reduces the still prevalent pressure and the cyclical process

starts again.

3.2 DHW heating

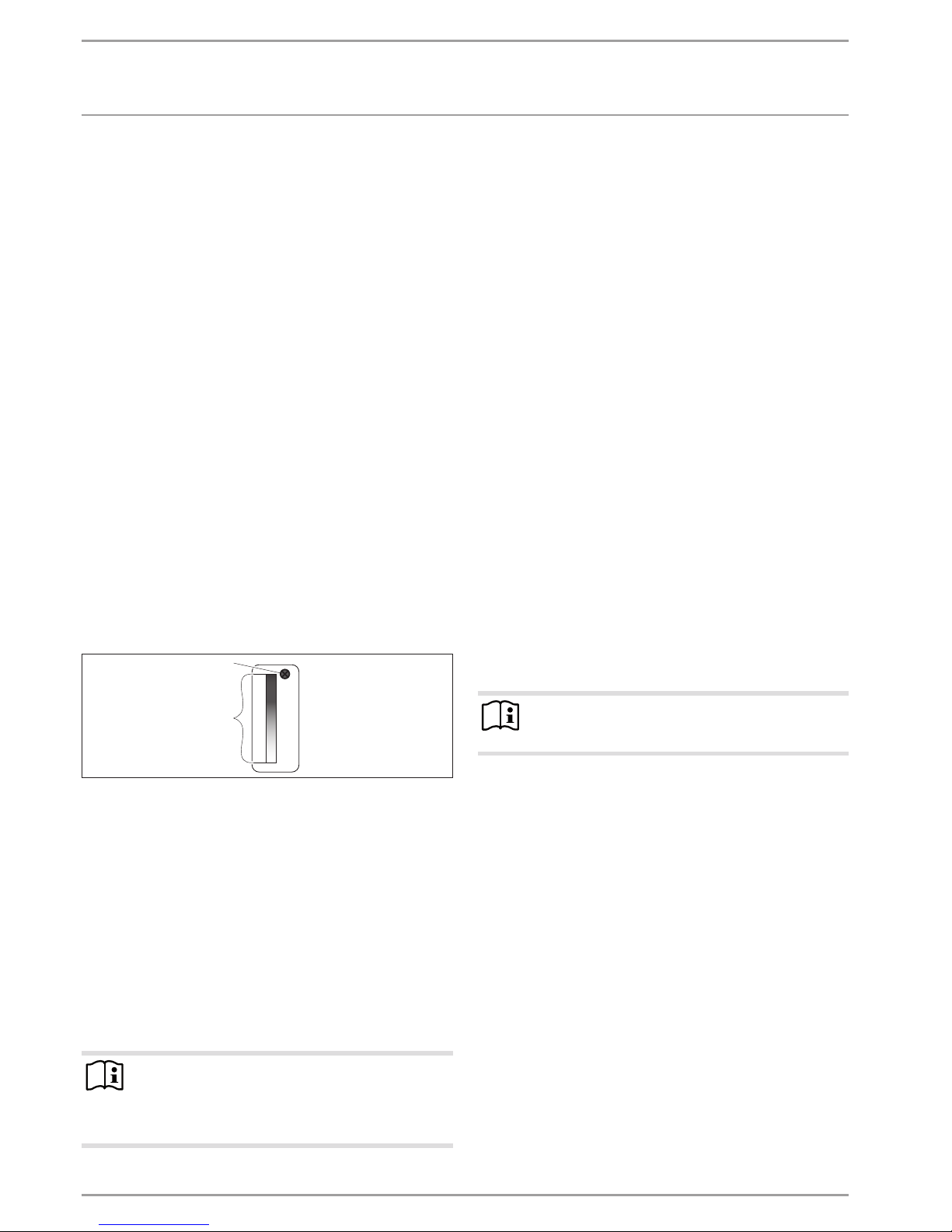

2

1

D0000050335

1 Cylinder top sensor

2 Integral sensor

The appliance is equipped with two temperature sensors.

- The cylinder top sensor captures the water temperature in

the upper section of the cylinder.

- The integral sensor is a temperature sensor affixed over the

entire cylinder height. The integral sensor determines the

average cylinder temperature.

The appliance control unit uses the average cylinder temperature

captured by the integral sensor. DHW heating is started when

the average cylinder temperature has fallen below the set temperature.

DHW is normally heated by the heat pump of the appliance (see

chapter "Specification/ Data table").

Note

If the appliance has been isolated from the power supply

during operation, the compressor will only restart after

the pressure inside the refrigerant circuit has been equalised. Pressure compensation can take several minutes.

WWK222H|WWK302H: Electric emergency/booster heater

When the temperature in the upper section of the DHW cylinder

drops 10K below the selected set temperature, the appliance

automatically switches on the electric emergency/booster heater.

When the temperature in the upper section of the DHW cylinder

rises 2K above the selected set temperature, the appliance switches off the electric emergency/booster heater.

3.3 Appliance operation outside the application

limits

3.3.1 Ambient temperatures below the application limit

Outside the application limits, the appliance disables the compressor operation. This could lead to reduced DHW convenience.

If the appliance has an electric emergency/booster heater, this

will be enabled if a demand for heating up the water exists and

the lower application limit is underrun.

Low ambient temperatures may result in the formation of hoar

frost on the evaporator depending on the air humidity and water

temperature.

Active defrost feature

The appliance is equipped with active hot gas defrosting, which

allows quick defrosting of the evaporator when needed. During

defrosting, the appliance fan is disabled and the compressor continues to run. A solenoid valve routes the hot gas directly to the

evaporator. While this is happening, the condenser is disabled by

another solenoid valve.

In contrast to conventional defrosting methods, the appliance

guarantees that defrosting takes place only when needed.

Note

Heat-up times are longer while the evaporator is defrosting.

3.3.2 Ambient temperatures above the application limit

Outside the application limits, the appliance disables the compressor operation. This could lead to reduced DHW convenience.

If the appliance has an electric emergency/booster heater, this

will be enabled if a demand for heating up the water exists and

the lower application limit is underrun.

3.4 Frost protection

The appliance activates the frost protection function if the integral

sensor in the DHW cylinder captures a temperature below 10°C.

The appliance then heats the water by means of the heat pump

and the electric emergency/booster heater. The heat pump and

electric emergency/booster heater switch off when the temperature captured by the integral sensor reaches 18°C.

OPERATION

Settings

ENGLISH

www.stiebel-eltron.com WWK222-302 H | 7

3.5 Minimum runtime and minimum pause time

!

Material losses

When operating with external switching devices that can

interrupt the power supply to the appliance, such as time

switches, energy management systems or home automation systems, observe the following conditions:

- The minimum ON time is 60 minutes.

- The minimum pause time following a shutdown is

20 minutes.

- The appliance should not be switched on/off more

than 10 times per day.

- The breaking capacity of the switching element must

meet the fuse rating requirements (see chapter

“Specification/ Data table”).

!

Material losses

If you disconnect the appliance from the power supply, it

is no longer protected against frost.

!

Material losses

At the factory, the appliance is fitted with rechargeable

batteries that ensure power supply to the impressed current anode in the case of a power failure.

To enable the impressed current anode to provide protection against corrosion, the power supply to the appliance must not be interrupted for more than 16 hours if

the DHW cylinder is filled with water and the annode is

not connected separately to a continuous power supply

source.

If regular interruptions to the power supply are not anticipated, the batteries will require no maintenance.

Every three years, you must replace the batteries for the

impressed current anode in the following cases:

- The impressed current anode is not connected separately to a continuous power supply source and

a switching contact regularly interrupts the power

supply to the appliance.

- The security of supply is inadequate.

Neglecting to do this puts the appliance at risk of damage.

Never use batteries that cannot be charged. Only nickel-metal hydride (Ni-MH) rechargeable batteries are

permissible.

Batteries may be damaged in the appliance. Without a

power supply, the impressed current anode and the cylinder would not be protected against corrosion.

3.6 Connection of an external signal transmitter

Note

This type of connection must only be carried out by a

qualified electrician.

External signal transmitters can be integrated via the built-in contact input, e.g. a PV system to make use of solar power generated

on site.

The appliance has a second set temperature preselected at the factory. This is activated in the event of an external switching signal.

Set temperature2 takes priority over the standard set temperature

while there is an external switching signal.

Following a one-off activation (signal is present for at least 1minute), set temperature2 applies for at least 20minutes and is ranked

higher than set temperature1.

The qualified contractor can use software to change set temperature2 with an accessory available from us.

4. Settings

Adjustments are not necessary. The DHW temperature has been

set at the factory.

Emergency shutdown

In the event of an emergency, carry out the following steps:

Disconnect the appliance from the mains at the MCB/fuse in

the fuse box.

Shut off the cold water supply.

5. Cleaning, care and maintenance

WARNING Electrocution

- Only clean the exterior of the appliance.

- Never open the appliance.

- Do not insert objects through the grills into the inte-

rior of the appliance.

- Never spray the appliance with water.

- Never spray water into the appliance.

!

WARNING Injury

Maintenance work, such as checking electrical safety,

must only be carried out by a qualified contractor.

Appliance

components

Care and maintenance t ips

Casing Use a damp cloth to clean the casing sections. Never use

abrasive or corrosive cleaning agents.

Air intake

grille/ air discharge grille

Clean the air intake grille and air discharge grille every six

months. Cobwebs or other kinds of contamination could obstruct the air supply to the appliance.

DHW cylinder

The DHW cylinder is equipped with a maintenance-free

impressed current anode to safeguard it against corrosion.

The power supply must not be interrupted for more than 16

hours while the DHW cylinder is filled with water to enable

the impressed current anode to provide protection against

corrosion.

Electric emergency/booster

heater

Have the electric emergency/booster heater descaled from

time to time. This will ex tend the service life of the electric

emergency/booster heater.

Safety equipment

Activate any valves at least once every 6months to prevent

blockages, e.g. by limescale deposits.

Evaporator Have the evaporator checked regularly by a qualified contrac-

tor.

Condensate

drain

Undo the condensate drain. Check that the condensate drain

is clear and remove any dirt from the condensate drain connection.

OPERATION

Cleaning, care and maintenance

8 | WWK222-302 H www.stiebel-eltron.com

Protective anode and battery replacement

The appliance is equipped with a maintenance-free, impressed

current anode that protects the tank from corrosion while it is

supplied with power. At the factory, the appliance is fitted with

rechargeable batteries that ensure the power supply to the impressed current anode in the case of a power failure. The power

supply may be interrupted for up to 16 hours.

If the power supply is regularly interrupted by a switching contact or the security of supply is inadequate, the batteries of the

impressed current anode must be replaced every three years. Neglecting to do this puts the appliance at risk of damage. If regular

interruptions in the power supply are not anticipated and there

is security of supply, no maintenance of the batteries is required

and the appliance is maintenance-free in this regard.

!

Material losses

Never use batteries that cannot be charged. Only rechargeable batteries are permissible.

Batteries may be damaged in the appliance. Without a

power supply, the impressed current anode and the cylinder would not be protected against corrosion.

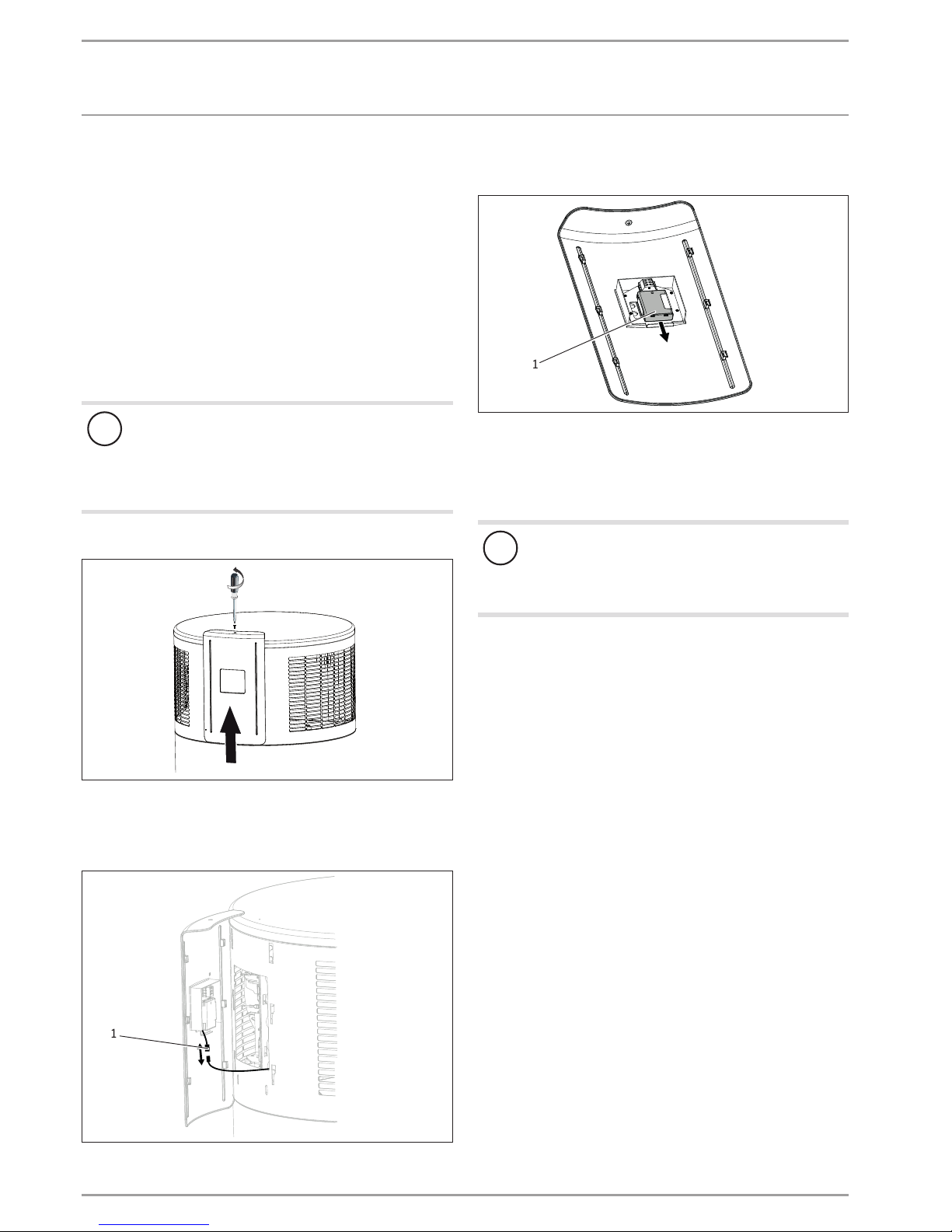

The rechargeable batteries are secured at the back of the fascia.

D0000040621

Undo the screw securing the fascia.

Carefully remove the fascia so that the cables running from

the batteries to the impressed current anode in the appliance

are not pulled out.

D0000051618

1

1 Plug-in connection

Undo the plug-in connection by pressing the connection lock

on both sides.

D0000051617

1

1 Battery compartment

Pull the battery compartment down to remove it from the

retainer.

Open the battery compartment using a screwdriver.

Replace the batteries (NiMH, type AAA, ≥800mAh).

!

Material losses

Make sure that the batteries are properly inserted the

right way round, because otherwise there will be no

corrosion protection in the event of interruptions in the

power supply.

Close the battery compartment using a screwdriver.

Push the battery compartment into the retainer.

Reconnect it to the appliance with the plug-in connection.

OPERATION

Troubleshooting

ENGLISH

www.stiebel-eltron.com WWK222-302 H | 9

6. Troubleshooting

Problem Cause

Remedy

No hot water

is available.

No power at the appliance. Check that the appliance is con-

nected to the power supply.

A fuse/MCB in the fuse box

has blown/responded.

Check whether the fuses/MCBs

in your fuse box have blown/

responded. Contact a qualified

contractor if the fuse blows or

the MCB responds again after

the appliance is connected to the

power supply.

The air intake or air discharge

of the appliance is blocked.

Check the air intake grille and

air discharge grille for contamination. Remove any contamination (see chapter "Maintenance

and care").

Outside the application limits, the appliance blocks the

compressor. This could lead to

reduced DHW convenience.

No action required. The appliance will then restart the compressor automatically.

The DHW cylinder is not completely full.

The appliance restarts automatically when the DHW cylinder has

been filled.

Due to a previous high demand for hot water, the unit

has not had the chance to

fully recover.

No action required. Allow the

unit to continue operating normally until the heating cycle is

completed.

The safety pressure limiter

has responded 5 times in

5hours.

Notify a qualified contractor who

will reset the safety pressure

limiter.

A safety valve

is dripping.

These units are under water

mains pressure. During the

heat-up process, expansion

water will drip from a safet y

valve.

If water continues to drip when

heating is completed, please inform your qualified contractor.

The condensate drain

drips.

The surface temperature of

the evaporator is lower than

the dew point temperature of

the ambient air. Condensate

forms.

This is expected and no action

is required. The amount of

condensate depends on the air

humidity level.

For indoor installations the

room temperature drops

too low.

Operation of the appliance can

cause the room temperature to

fall by 1 to 3°C. If the room temperature falls by more than 5°C,

check the room size (see chapter

"Specification/Data table").

Increasing the room size by

opening a door to another room

will remedy this.

Notifying a qualified contractor

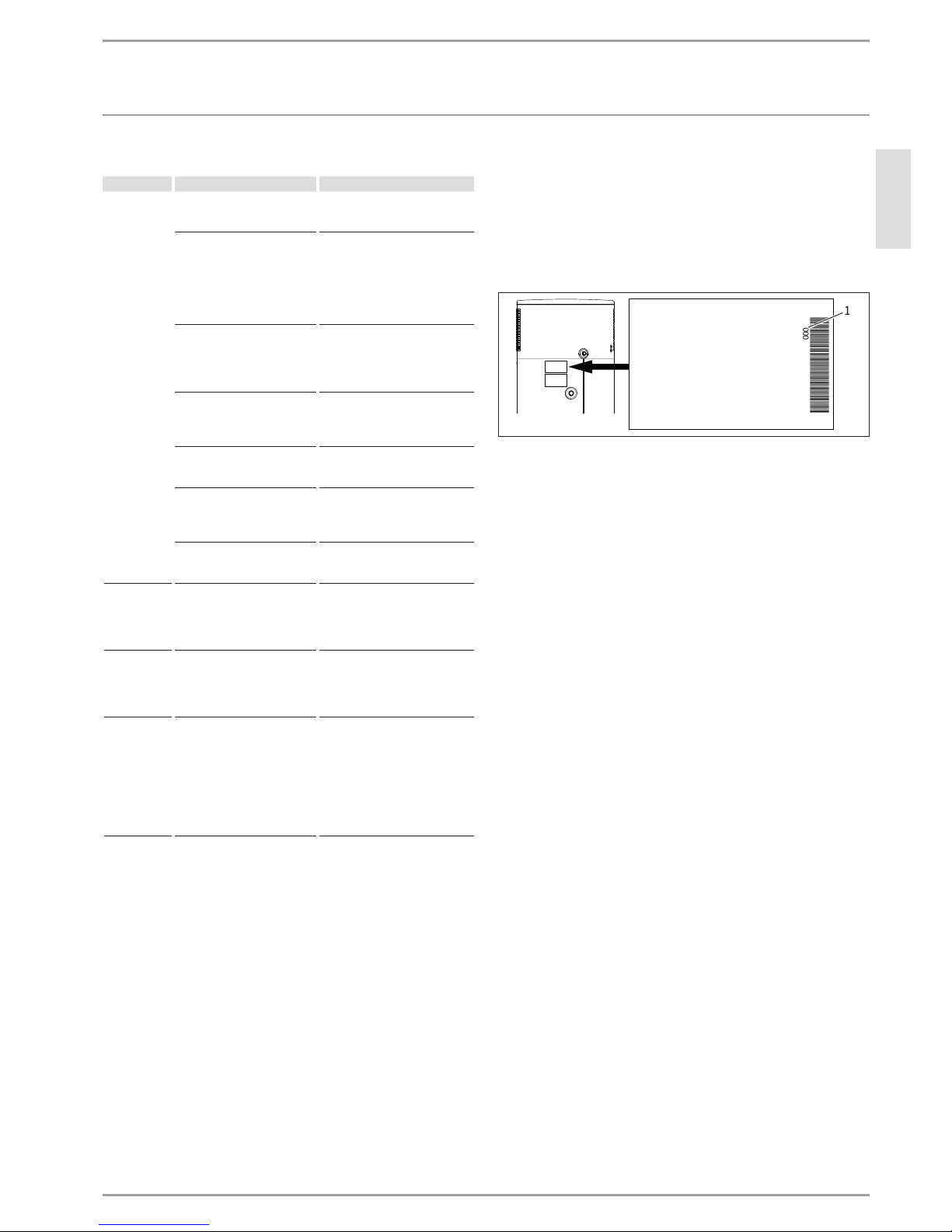

If you cannot remedy the fault, notify your qualified contractor. In

Australia direct notify us (1800153351). To facilitate and speed up

your request, provide the number from the type plate (0000000000-000000). The type plate can be found on the left, above the

DHW outlet connection.

Sample type plate

000000-0000-000000

D0000035352

1

1 Number on the type plate

10 | WWK222-302 H www.stiebel-eltron.com

INSTALLATION

Safety

INSTALLATION

7. Safety

Only a qualified contractor should carry out installation, commissioning, maintenance and repair of the appliance.

7.1 General safety instructions

We guarantee trouble-free function and operational reliability only

if original accessories and spare parts intended for the appliance

are used.

7.2 Instructions, standards and regulations

Note

Observe all applicable national and regional regulations

and instructions.

Take note of the appliance type plate and chapter "Specification".

8. Appliance description

The heat pump drive unit is located in the upper section of the

appliance. The DHW cylinder is located in the lower section of

the appliance.

8.1 Standard delivery

The following are delivered with the appliance:

- Condensate drain bend

- 2 straight pipe adapters G1 to G3/4 (use subject to type of

installation, see chapter "Preparations/ Siting the appliance/

Minimum clearances") comprising a flanged pipe, a gasket

and a union nut

- 2 135° pipe adapters G1 to G3/4 union nut (use subject to

type of installation, see chapter "Preparations/ Siting the appliance/ Minimum clearances")

8.2 Required accessories

Various safety assemblies are available that need to be selected

subject to the static pressure. These type-tested safety assemblies

protect the appliance against unacceptable excess pressure.

8.3 Further accessories

- Condensate pump (if the condensate cannot be drained off

with a naturally occurring fall)

8.4 Incorrect use

The following are not permitted:

- Operating the appliance when the casing is open

- Filling the appliance with a refrigerant other than the one

detailed in chapter "Specification/ Data table"

- Heating liquids other than potable water

Observe the list of requirements regarding the installation room

and non-permissible installation sites (see chapter "Installation

site").

9. Preparations

9.1 Transpor t

!

CAUTION Injury

Observe the weight of the appliance.

Use suitable transport aids (e.g. a pallet trolley) and

enough personnel for transportation.

!

Material losses

The appliance has a high centre of gravity and low overturning moment.

Safeguard the appliance against falling over.

Only set the appliance down on an even base.

!

Material losses

The appliance casing is not designed to withstand strong

forces. Incorrect handling can lead to material losses of

considerable extent.

Observe the information on the packaging.

Only remove the packaging shortly before the installation.

Where possible, do not unpack the appliance until it has arrived

in the installation room.

For transport and handling leave the appliance in its packaging

and on the pallet. This enables brief horizontal transport and provides places to hold on to during transport.

If the appliance has to be unpacked before transportation, we

recommend using a pallet trolley. Pad the contact surfaces to avoid

damaging the appliance. Secure the appliance to the pallet trolley

using a strap. Pad between the strap and the appliance and avoid

overtightening the strap. Where stair wells are narrow, you can

carry the appliance by the handles on the pallet trolley and the

foot of the appliance.

Vehicular transport

!

Material losses

The appliance must generally be stored and transported

vertically.

A transport lock fitted at the factory to the refrigerant circuit

area inside the appliance enables relatively short transportation

horizontally over a maximum distance of 160km of paved roads.

Strong shocks are not permissible.

!

Material losses

If transported horizontally, the appliance must always be

laid on the shaded side of the box.

The appliance must not remain in a horizontal position

for more than 24hours.

If the appliance was transported horizontally, leave it to

rest in a vertical position for at least one hour before

commissioning.

Observe the information on the packaging.

Loading...

Loading...