STIEBEL ELTRON WWK 220 electronic, WWK 300 electronic, WWK 300 electronic SOL Operation And Installation

OPERATION AND INSTALLATION

OBSŁUGA I INSTALACJA

DHW heat pump | Pompa ciepła do pogrzewania wody użytkowej

» WWK 220 electronic

» WWK 300 electronic

» WWK 300 electronic SOL

CONTENTS

SPECIAL INFORMATION

OPERATION

1. General information �����������������������������������������4

1.1 Safety instructions ����������������������������������������������� 4

1.2 Other symbols in this documentation ����������������������� 4

1.3 Units of measurement ������������������������������������������ 4

1.4 Standardised output data �������������������������������������� 4

2. Safety ���������������������������������������������������������� 4

2.1 Intended use ������������������������������������������������������ 4

2.2 Incorrect use ������������������������������������������������������ 5

2.3 General safety instructions ������������������������������������ 5

2.4 CE designation ��������������������������������������������������� 5

2.5 Test symbols ������������������������������������������������������ 5

3. Appliance description ���������������������������������������6

3.1 Heating the DHW cylinder ������������������������������������� 6

3.2 Appliance operation outside the application limits ������� 7

3.3 Frost protection �������������������������������������������������� 7

4. Settings �������������������������������������������������������7

4.1 Display and controls ��������������������������������������������� 7

4.2 Settings ������������������������������������������������������������ 8

4.3 Calling up fault codes ������������������������������������������� 9

4.4 Rapid heating key ����������������������������������������������� 9

4.5 Emergency shutdown ������������������������������������������ 10

5. Maintenance and care ������������������������������������� 10

6. Troubleshooting �������������������������������������������� 11

12. Shutdown ��������������������������������������������������� 19

13. Troubleshooting �������������������������������������������� 20

13.1 Fault table �������������������������������������������������������� 20

13.2 Resetting the safety pressure limiter ����������������������� 20

13.3 Resetting the high limit safety cut-out ��������������������� 20

13.4 Motor overload relay �������������������������������������������20

14. Maintenance and cleaning �������������������������������� 21

14.1 Removing the appliance cover ������������������������������� 21

14.2 Removing the casing ring ������������������������������������� 21

14.3 Cleaning the evaporator ��������������������������������������� 22

14.4 Draining the cylinder ������������������������������������������ 22

14.5 Descaling the electric emergency/booster heater ������� 22

14.6 Protective anode ������������������������������������������������ 22

14.7 Valves ������������������������������������������������������������� 22

14.8 Replacing the power cable ����������������������������������� 23

14.9 Fitting the casing ring �����������������������������������������23

14.10 Fitting the appliance cover ����������������������������������� 23

15. Specification ������������������������������������������������ 24

15.1 Dimensions and connections ��������������������������������� 24

15.2 Wiring diagram ������������������������������������������������� 27

15.3 Data table �������������������������������������������������������� 28

GUARANTEE

ENVIRONMENT AND RECYCLING

INSTALLATION

7. Safety �������������������������������������������������������� 13

7.1 General safety instructions ����������������������������������� 13

7.2 Instructions, standards and regulations ������������������� 13

8. Appliance description ������������������������������������� 13

8.1 Standard delivery ����������������������������������������������� 13

8.2 Required accessories ������������������������������������������13

8.3 Further accessories���������������������������������������������13

8.4 Incorrect use ����������������������������������������������������� 13

9. Preparations ������������������������������������������������ 13

9.1 Transport ��������������������������������������������������������� 13

9.2 Storage ������������������������������������������������������������ 14

9.3 Installation site �������������������������������������������������� 14

9.4 Siting the appliance �������������������������������������������� 15

10. Installation �������������������������������������������������� 16

10.1 Water connection ����������������������������������������������� 16

10.2 Connection of an external heat generator (only

WWK300electronicSOL) ������������������������������������� 16

10.3 Condensate drain ����������������������������������������������� 17

10.4 Power supply ���������������������������������������������������� 17

10.5 Assembling the appliance ������������������������������������ 18

11. Commissioning ��������������������������������������������� 19

11.1 Initial start-up ��������������������������������������������������� 19

11.2 Recommissioning ����������������������������������������������� 19

2 | WWK 220-300 electronic www.stiebel-eltron.com

SPECIAL INFORMATION

SPECIAL INFORMATION

- The appliance may be used by children aged8

and up and persons with reduced physical, sensory or mental capabilities or a lack of experience

and know-how, provided that they are supervised

or they have been instructed on how to use the

appliance safely and have understood the resulting risks. Children must never play with the appliance. Children must never clean the appliance

or perform user maintenance unless they are

supervised.

- Observe all applicable national and regional regulations and instructions during installation.

- The appliance is not approved for outdoor

installation.

- Observe the minimum clearances (see chapter "Installation/ Preparations/ Siting the

appliance").

- Drain the appliance as described in chapter "Installation/ Maintenance and cleaning/ Draining

the cylinder".

- Install a type-tested safety valve in the cold water

supply line.

- The maximum pressure in the cold water supply

line must be at least 20% below the response

pressure of the safety valve. If the maximum

pressure in the cold water supply line is higher,

install a pressure reducing valve.

- Size the drain so that water can drain off unimpeded when the safety valve is fully opened.

- Fit the discharge pipe of the safety valve with

a constant downward slope and in a room free

from the risk of frost.

- The safety valve discharge aperture must remain

open to atmosphere.

ENGLISH

- Observe the requirements concerning the installation room (see chapter "Specification/ Data

table").

- If the appliance is permanently connected to the

power supply, ensure that the appliance can be

separated from the power supply by an isolator

that disconnects omnipolar with at least 3mm

contact separation. Contactors, mains isolators or

fuses can be used for this.

- Observe the safety measures to prevent contact

with dangerous 'live' currents.

- Observe the MCB/fuse protection required for

the appliance (see chapter "Specification/ Data

table").

- The power cable must only be replaced (for example if damaged) with an original spare part by

a qualified contractor authorised by the manufacturer (connection typeX).

- The appliance is pressurised. During the heat-up

process, expansion water will drip from the safety

valve.

- Regularly activate the safety valve to prevent

it from becoming blocked, e.g. by limescale

deposits.

www.stiebel-eltron.com WWK 220-300 electronic | 3

OPERATION

General information

OPERATION

1. General information

The chapters "Special Information" and "Operation" are intended

for both the user and qualified contractors.

The chapter "Installation" is intended for qualified contractors.

Note

Read these instructions carefully before using the appliance and retain them for future reference.

Pass on the instructions to any new user where appropriate.

Symbol Meaning

!

This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

Material losses

(appliance damage, consequential losses and environmental pollution)

Appliance disposal

1.3 Units of measurement

Note

All measurements are given in mm unless stated otherwise.

1.1 Safety instructions

1.1.1 Layout of safety instructions

KEYWORD Type of risk

!

Here, possible consequences are listed that may result

from failure to observe the safety instructions.

Steps to prevent the risk are listed.

1.1.2 Symbols, type of risk

Symbol Type of risk

!

1.1.3 Keywords

KEYWORD Meaning

DANGER Failure to observe this information will result in serious

WARNING Failure to observe this information may result in serious

CAUTION Failure to observe this information may result in non-seri-

Injury

Electrocution

Burns

(burns, scalding)

injury or death.

injury or death.

ous or minor injury.

1.2 Other symbols in this documentation

Note

General information is identified by the adjacent symbol.

Read these texts carefully.

1.4 Standardised output data

Explanations to determine and interpret the specified standardised

output data

Standard: EN 16147

The output data specifically mentioned in text, diagrams and

technical datasheets has been determined in line with the test

conditions described in the standard shown in the heading of

this chapter.

Generally, these standardised test conditions will not fully meet

the conditions found at the installation site of the system user.

Depending on the chosen test method and the extent to which

the selected method deviates from the conditions described in the

standard shown in the heading of this chapter, any deviations can

have a considerable impact. Further factors that have an influence

on the test values are the measuring equipment, the system configuration, the age of the system and the flow rates.

A confirmation of the specified output data can only be obtained

if the conditions applicable to the relevant test match those of the

standard shown in the heading of this chapter.

2. Safety

2.1 Intended use

The appliance is intended for DHW heating within the application

limits detailed in chapter "Specification/ Data table".

The appliance is intended for domestic use, i.e. it can be used

safely by untrained persons. The appliance can also be used in a

non-domestic environment, e.g. in a small business, as long as it

is used in the same way.

Any other use beyond that described shall be deemed inappropriate. Observation of these instructions and of instructions for any

accessories used is also part of the correct use of this appliance.

4 | WWK 220-300 electronic www.stiebel-eltron.com

OPERATION

Safety

2.2 Incorrect use

The following are not permitted:

- Heating liquids other than potable water

- Operating the appliance with an empty DHW cylinder

- Operating the appliance outside the application limits (see

chapter "Specification")

- Interrupting the power supply, as without power supply the

appliance is not protected against corrosion

2.3 General safety instructions

Only qualified contractors should carry out the electrical work and

installation of this appliance. Qualified contractors are responsible

for adherence to all applicable regulations.

Operate the appliance only when fully installed and with all safety

equipment fitted.

WARNING Injury

!

The appliance may be used by children aged 8 and up and

persons with reduced physical, sensory or mental capabilities or a lack of experience and know-how, provided

that they are supervised or they have been instructed on

how to use the appliance safely and have understood

the resulting risks. Children must never play with the

appliance. Children must never clean the appliance or

perform user maintenance unless they are supervised.

CAUTION Injury

!

Never place any objects on top of the appliance. If objects

are left on the appliance, noise emissions may increase

due to resulting vibrations, and the objects could fall

and cause injury.

Material losses

!

If you disconnect the appliance from the power supply, it

is no longer protected against frost or corrosion.

Do not interrupt the power supply to the appliance.

Material losses

!

Never cover the appliance. Covering the air intake or air

discharge leads to a reduced air supply. If the air supply

is restricted, the operational reliability of the appliance

cannot be guaranteed.

Material losses

!

Only operate the appliance when the DHW cylinder has

been filled.

Material losses

!

Keep the appliance installation room free from air contaminated with oil or salt and corrosive or explosive substances.

ENGLISH

WARNING Electrocution

Contact with live components presents a threat to life.

Damage to the insulation or to individual components

may result in a threat to life.

If there is damage to the insulation, disconnect the

power supply and arrange a repair.

All work on the electrical installation must be carried

out by a qualified contractor.

WARNING Burns

The water in the DHW cylinder can be heated to temperatures in excess of 60°C. There is a risk of scalding at

outlet temperatures in excess of 43 °C.

Ensure you do not come into contact with the water

when discharged.

WARNING Burns

Touching hot components can lead to burns.

When working on hot components, always wear protective working clothing and safety gloves.

The pipework connected to the DHW outlet of the appliance can reach temperatures in excess of 60°C.

WARNING BURNS

The appliance is filled with refrigerant at the factory.

In the event of refrigerant escaping due to a leak, avoid

coming into contact with the refrigerant or inhaling the

released vapours. Ventilate the rooms affected.

2.4 CE designation

The CE designation shows that the appliance meets all essential

requirements according to the:

- Electromagnetic Compatibility Directive

- Low Voltage Directive

2.5 Test symbols

See type plate on the appliance.

www.stiebel-eltron.com WWK 220-300 electronic | 5

OPERATION

1

Appliance description

3. Appliance description

The appliance is designed for indoor installation. The appliance

operates in recirculation air mode and does not require outdoor

air. The appliance extracts heat from the ambient air. This heat is

used to heat up the water in the DHW cylinder with added electric

power. The amount of electric energy and time required to heat-up

the DHW depend on the temperature of the induced air.

This heat extraction results in a drop in the ambient temperature inside the installation room by between 1°Cand3°C. The

appliance also extracts moisture from the air, which turns into

condensate. The condensate is removed from the appliance via

the condensate drain.

When a hot water draw-off point is opened, the hot DHW is pushed

out of the appliance by the inflow of cold water.

To protect against corrosion, the DHW cylinder is coated internally with special enamel and is additionally equipped with an

impressed current anode.

The electronic control unit makes energy saving adjustments easier. Subject to the power supply and your usage pattern, the water

is heated up automatically to the set temperature.

Heat pump operating principle

A closed circuit within the appliance contains refrigerant (see

"Specification/ Data table"). This refrigerant evaporates at low

temperatures.

In the evaporator, which extracts heat from the air, the refrigerant

changes from a liquid into a gaseous state. A compressor draws

in the gaseous refrigerant and compresses it. This increase in

pressure raises the refrigerant temperature.

That requires electrical energy. The energy (motor heat) is not

lost, but reaches the downstream condenser together with the

compressed refrigerant. There, the refrigerant indirectly transfers

heat to the DHW cylinder. An expansion valve then reduces the

still prevalent pressure and the cycle starts again.

Material losses

!

If you disconnect the appliance from the power supply, it

is no longer protected against frost or corrosion.

Do not interrupt the power supply to the appliance.

Note

Following an interruption of the power supply, the

compressor operation remains blocked for at least one

minute. The PCB delays electronic starting by a minute,

during which the appliance goes through its initialising

process.

If the compressor subsequently fails to start, it may be

blocked by additional safety devices (Klixon and high

pressure switch). This block should lift after 1 to 10minutes.

After the power supply has been re-established, the appliance continues to operate with the parameters that

were selected before the power supply was interrupted.

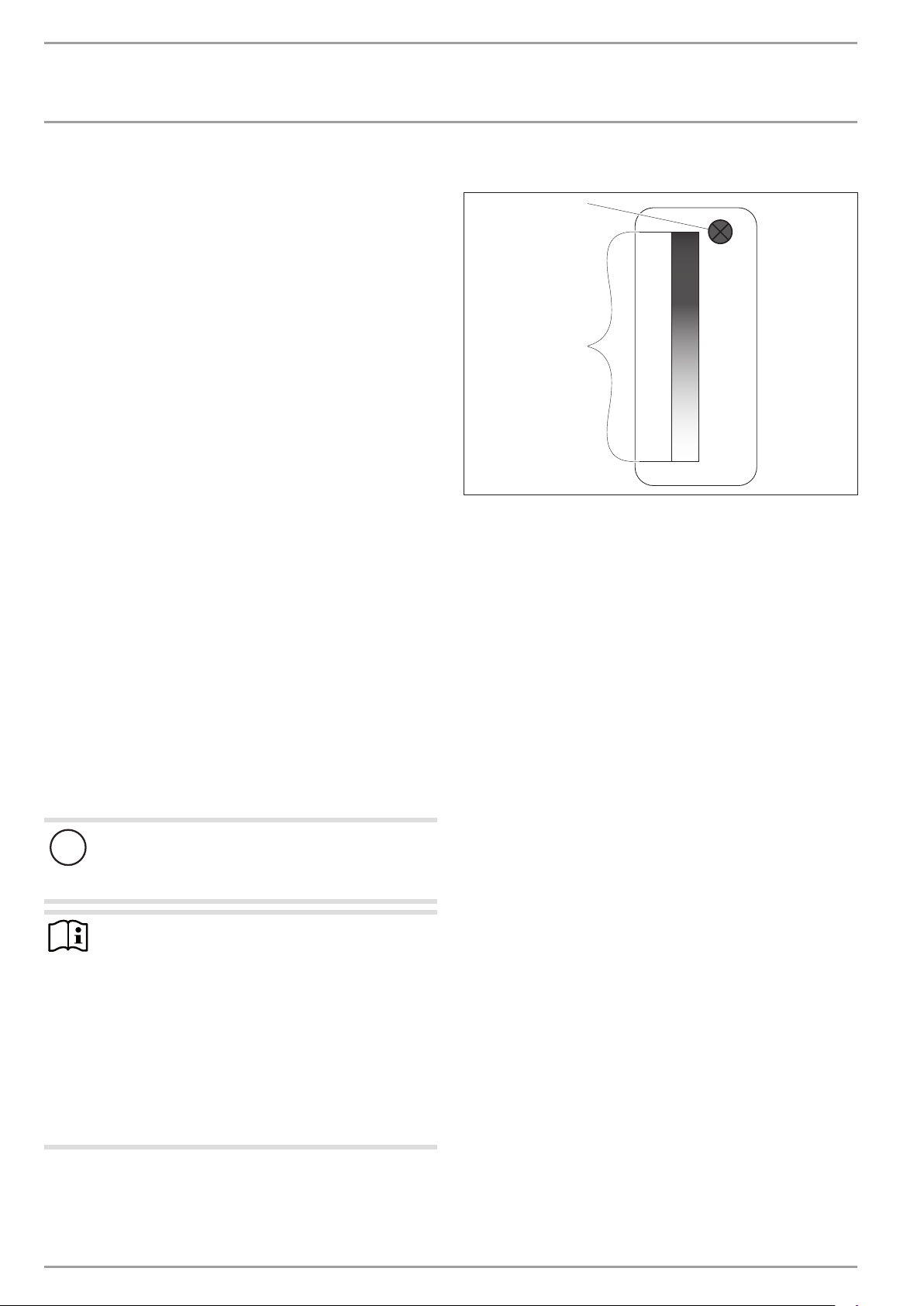

3.1 Heating the DHW cylinder

2

D0000050335

1 Domed sensor

2 Integral sensor

The appliance is equipped with two temperature sensors.

- The domed sensor captures the water temperature in the

upper section of the cylinder.

- The integral sensor is a temperature sensor affixed over the

entire cylinder height. The integral sensor determines the

average cylinder temperature.

The appliance display indicates the temperature in the upper section of the cylinder. The appliance control unit operates with the

average cylinder temperature.

The appliance may well start to heat even though the display

would indicate that it has reached the set temperature. In this

case the deviation of the average cylinder temperature from the

set value is greater than the start hysteresis.

For information on the heat-up time, see chapter "Specification".

The calculation of the available amount of mixed water is based

on the average cylinder temperature. The amount of mixed water

is only calculated if the water temperature in the upper section of

the cylinder is higher than 40 °C.

DHW is normally heated by the heat pump of the appliance within

the application limits (see chapter "Specification/ Data table").

Electric emergency/booster heater

Heat pump operation will be interrupted if the application limits are exceeded or undershot in heat pump mode. The electric

emergency/booster heater takes over the DHW heating with the

selected set temperature. Once the appliance is back within the

application limits, the electric emergency/booster heater switches

off and DHW heating continues with the heat pump.

In emergencies you can start the electric emergency/booster heater should the appliance have developed a fault and the fault code

is higher than 256. See chapter "Operation/ Rapid heating key/

Emergency heating mode".

In the event of an unexpectedly high hot water demand, the emergency/booster heater can be activated with the rapid heating key

in addition to the heat pump. See chapter "Operation/ Rapid

heating key/ Rapid/comfort heating".

6 | WWK 220-300 electronic www.stiebel-eltron.com

OPERATION

Settings

WWK300electronicSOL: Connection of an external heat

generator

Material losses

!

Even if an external heat generator is connected, do not

disconnect the appliance from the power supply as otherwise it is not protected against frost and corrosion. The

power supply must not be interrupted even in winter,

when it is possible that DHW heating is only being provided via the external heat generator.

The appliance is equipped with an integral smooth tube heat exchanger to which an external heat generator can be connected

(e.g. a solar thermal system or central heating system). The DHW

cylinder has sensor wells available for this in various positions.

Once during commissioning, the qualified contractor must match

the controls between the appliance and the external heat generator.

3.2 Appliance operation outside the application

limits

3.2.1 Ambient temperatures below the application limit

At temperatures below the lower application limit hoar frost may

form on the evaporator depending on the air humidity and water

temperature. If hoar frost forms on the evaporator, the hoar frost

temperature monitor switches the heat pump compressor off. The

compressor switches on automatically once the evaporator has

defrosted.

To guarantee fault-free operation of the appliance, make sure

you operate the appliance within its application limits (see

chapter "Specification/ Data table").

Note

Heat-up times are longer while the evaporator is defrosting.

3.2.2 Ambient temperatures above the application limit

The safety equipment switches the appliance off if the upper application limit is exceeded. Following a cooling time of several

minutes the appliance is switched back on automatically. The

appliance is switched off again if the ambient temperature rises

above the permissible temperature value again.

To guarantee fault-free operation of the appliance, make sure

you operate the appliance within its application limits (see

chapter "Specification/ Data table").

3.3 Frost protection

The appliance activates the frost protection function if the integral

sensor in the DHW cylinder captures a temperature below 10°C.

The appliance then heats the water by means of the heat pump

and the electric emergency/booster heater. The heat pump and

electric emergency/booster heater switch off when the temperature captured by the integral sensor reaches 18°C.

4. Settings

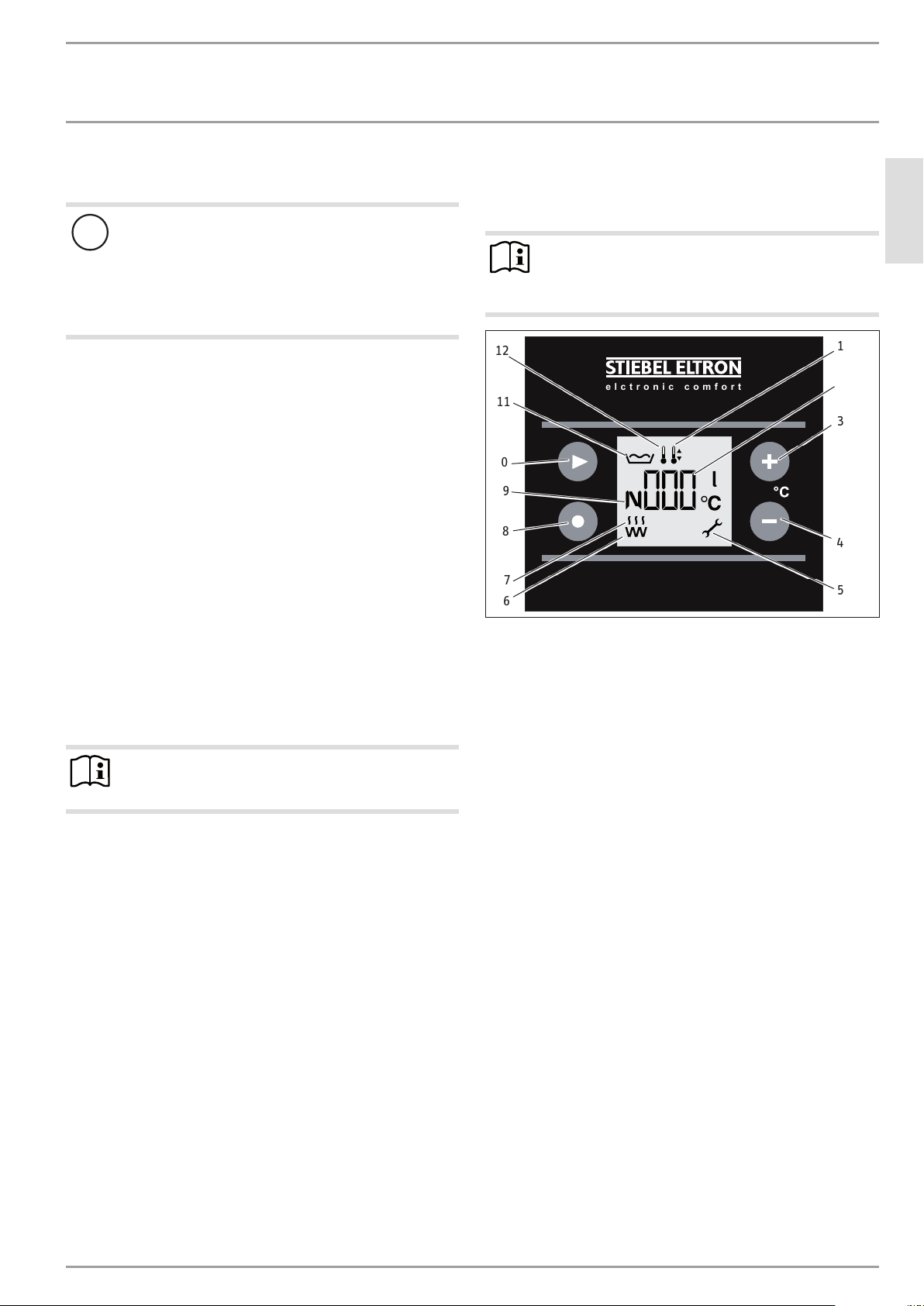

4.1 Display and controls

Note

15seconds after every adjustment, the appliance automatically reverts to the standard display (amount of

mixed water) and saves the set value.

12

elctronic comfort

11

10

9

8

7

6

1 Set temperature symbol

2 Amount of amount of mixed waterdisplay (l|40°C)/

Actual temperature display, upper cylinder section/

Set temperature1display

Display, set temperature 2 /

Fault code display

3 Plus key

4 Minus key

5 Service/fault symbol

6 Electric emergency/booster heater symbol

7 Heat pump symbol

8 Rapid heating key

9 Set temperature2 symbol

10 Menu key

11 Amount of amount of mixed watersymbol

12 Actual temperature symbol

The "electric emergency/booster heater" and "heat pump" symbols are displayed when there is a demand for these appliance

components. The display of these symbols does not necessarily

mean that the electric emergency/booster heater and the heat

pump are running.

Example: The appliance is in rapid/comfort heating mode. The

electric emergency/booster heater switches off when the temperature in the upper cylinder section has reached 65°C. The heat

pump has not yet heated the lower section to 65°C and the rapid/

comfort heating function has therefore not been terminated yet.

The electric emergency/booster heater symbol is displayed until

the rapid/comfort heating function has been terminated.

1

2

3

4

5

ENGLISH

26�03�13�0006�

www.stiebel-eltron.com WWK 220-300 electronic | 7

OPERATION

Settings

Service/fault symbol

Note

Notify your contractor if the service/fault symbol appears

on the display. Continuous illumination of the symbol

indicates that the fault is not preventing appliance operation.

A flashing service/fault symbol indicates that the water is

not being heated and that it is essential you notify your

contractor.

Switching the appliance to emergency mode is a special

case. The heat pump and the electric emergency/booster heater will then heat the water despite the flashing

service/fault symbol.

4.2 Settings

In standard display mode, the display shows amount of mixed

water.

Note

15seconds after every adjustment, the appliance automatically switches back to standard display and saves

the set value.

With the menu key, you call up all information and setting options in sequence.

The relevant symbol appears.

4.2.2 Actual temperature display

4.2.3 Set temperature1

Note

For reasons of hygiene, never set the DHW temperature

lower than 50°C.

The set temperature1 is the DHW temperature to which the appliance regulates if no external signal transmitter is connected and

active. Set temperature1 is set to 55°C at the factory.

In the mixed water menu, press the

menu key once to get to the actual temperature menu.

The actual temperature symbol appears.

The current actual temperature is shown.

The actual temperature indicates the

temperature in the upper section of the

DHW cylinder and therefore largely corresponds to the outlet temperature.

In the actual temperature menu, press

the menu key once to get to the menu

for set temperature1.

The set temperature1 symbol appears.

Adjust set temperature1 from 20 to 65°C

using the plus and minus keys.

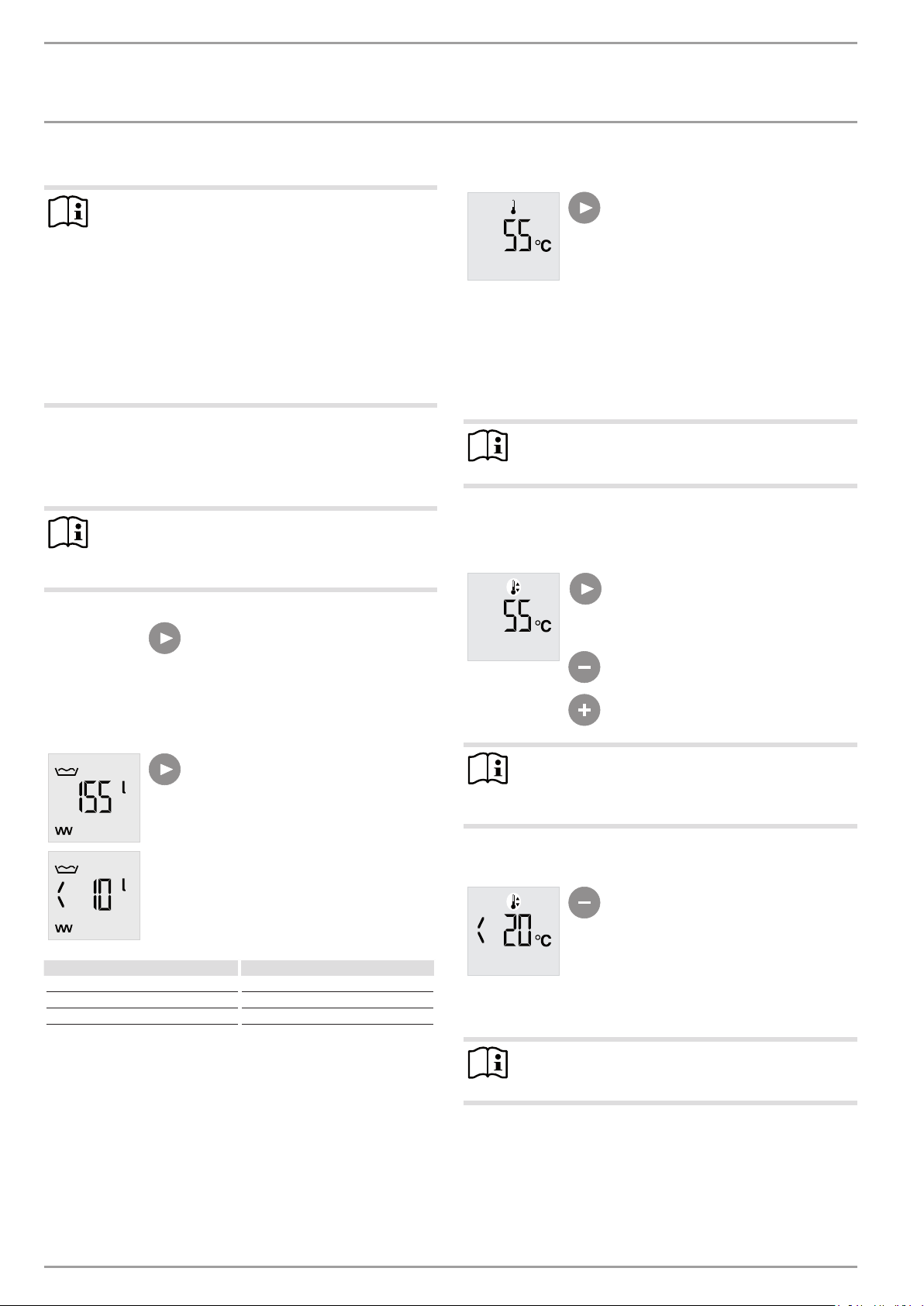

4.2.1 Amount of mixed water display (standard display)

DHW demand for Mixed water volume at 40°C

Bath 120-150 l

Shower 30-50 l

Hand washing 2-5 l

The amount of mixed water that can be achieved depends on the

cylinder size and the selected set temperature.

The currently available amount of mixed

water at 40°C and at 15°C cold water

temperature is shown.

If there is currently less than 10l mixed

water available, "<10l" is shown.

Note

Another way to adjust set temperature1 is to press the

plus or minus key when in standard display (amount of

mixed water).

Frost protection

Only frost protection remains active if

you set the set temperature with the

minus key to less than 20°C.

4.2.4 Solltemperatur2

Note

For reasons of hygiene, never set the DHW temperature

lower than 50°C.

Set temperature2 is the DHW temperature to which the appliance

regulates if an external signal transmitter is connected and active.

8 | WWK 220-300 electronic www.stiebel-eltron.com

OPERATION

A

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 t [min]

Settings

In the set temperature1 menu, press the

menu key once to get to the menu for set

temperature2.

The "set temperature2" symbol appears.

The display of set temperature2 is denoted with an "N".

Adjust set temperature2 to between 20

and 65°C using the plus and minus keys.

4.3 Calling up fault codes

In the set temperature2 menu, press the

menu key once to get to the fault code

menu. A fault code will appear if a fault

has occurred. This menu remains inactive if no fault has occurred.

See chapter "Troubleshooting/ Fault codes".

ENGLISH

4.4 Rapid heating key

Operation with external signal transmitter (230 V input)

As standard, the appliances feature the ability to allocate a specific, individual set DHW temperature (set temperature2) to a

connected external signal transmitter, such as a PV system or a

low tariff transmitter.

This set temperature2 is activated when a phase (LF signal) is

present at terminal X0/2 (see chapter "Connection types"). While

activated, set temperature2 replaces the standard set DHW temperature ("set temperature1").

If set temperature2 has been activated by the external signal

transmitter, this set temperature will then be active for at least

20minutes. If the signal remains active after those 20minutes

have passed, the compressor will run until the LF signal ends. If

not, the selected set temperature1 is activated again.

When the relevant set DHW temperature has been reached, the

compressor switches off and remains off for a minimum idle time

of 20minutes.

The following diagram illustrates the connections by means of a

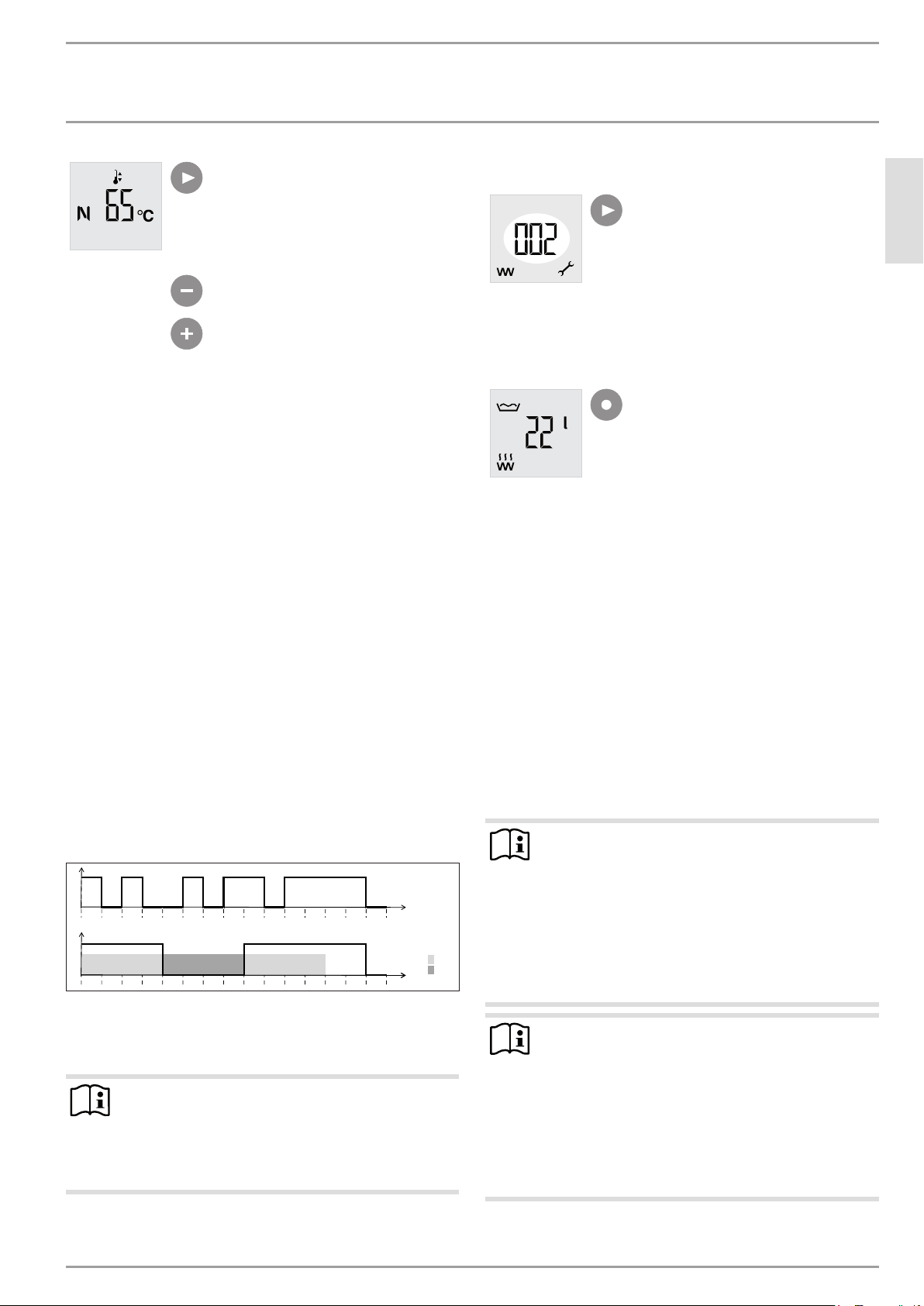

sample signal sequence of an external signal transmitter.

Example:

- DHW temperature = 55°C

- Set temperature 1 = 50°C

- Set temperature 2 = 65°C

1

0

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 t [min]

B

1

0 2

A LF signal

B Compressor

1 20 min. minimum runtime, set temperature 2

2 20 min. minimum compressor idle time

Note

An LF signal must be active for at least 60seconds, before the control unit responds to it. This will for example

prevent a brief burst of sunshine from triggering a heatup process, which due to a lack of further insolation can

then not be supplied with PV power generated on site.

1

4.4.1 Rapid/comfort heating

Normally, the rapid heating key is used to activate the rapid/comfort heating function, which enables you to cover an unexpectedly high DHW demand without changing any of the appliance's

standard settings.

If rapid/comfort heating is activated manually by pressing the relevant key, the heat pump and the electric emergency/booster heater

will start in parallel, irrespective of the selected set temperature,

and will remain active until the DHW temperature in the cylinder

has reached 65°C. To save energy, the electric emergency/booster

heater switches off early, as soon as a temperature of 65°C has

been achieved in the upper cylinder section (rapid heating).

The rapid/comfort heating function remains active until a temperature of 65°C has been achieved in the entire DHW cylinder

(comfort heating). The appliance then automatically switches back

to the previously set parameters.

Note

The electric emergency/booster heater and heat pump

symbols are displayed until the rapid/comfort heating

function has terminated.

During rapid/comfort heating, the electric emergency/

booster heater symbol is displayed until the heat pump

has heated the entire cylinder to 65°C and the function

is terminated. The electric emergency/booster heater al-

D0000034613

ready switches off when the 65°C has been achieved in

the upper cylinder section.

Note

If the rapid/comfort heating has been activated unintentionally, you can cancel the function by lowering the set

temperature.

Hold down the minus key, until you hear a clicking

noise caused by the heat pump and emergency/

booster heater switching off. At the same time, the

set temperature also jumps back to the value that

was selected before rapid/comfort heating was activated.

Press the rapid heating key.

The heat pump and electric emergency/

booster heater symbols appear.

www.stiebel-eltron.com WWK 220-300 electronic | 9

OPERATION

Maintenance and care

4.4.2 Emergency mode

If the appliance is faulty, you can use the emergency mode to

activate the electric emergency/booster heater.

The compressor shuts down if, following a DHW demand, no temperature increase is captured for 6 hours (24 intervals of 15minutes each, during which the temperature increase is <0.25°C respectively). The fault key flashes on the display and a fault code

indicates that the appliance is not heating the water.

In such an event you can activate emergency mode by pressing the rapid heating key. After the rapid heating key has been

pressed, the indicated fault code increases by a value of 256, as

the fault codes are added together (see fault code table in chapter

"Troubleshooting"). The fault key continues to flash. The electric

emergency/booster heater is activated.

The current set temperature (set temperature1 or set temperature2) is ignored. In emergency mode, the appliance operates

with a fixed set temperature of 40°C. Following a one-off activation of the function via the rapid heating key, this function remains

active for 7days.

Following 7days of emergency operation the electric emergency/

booster heater is deactivated. The fault code shown on the display

decreases by 256.

If you press the rapid heating key again within the 7days of emergency operation, the 7-day runtime for emergency mode will start

afresh from that point.

If the 7-day runtime for emergency mode has passed, you can

restart emergency operation for a further 7days by pressing the

rapid heating key.

Pressing the rapid heating key only activates emergency mode if

a fault with fault code8 occurred previously. In standard mode

pressing the rapid heating key only triggers a one-off heating of

the DHW cylinder.

Emergency mode is no longer active after an interruption of the

power supply. The appliance tries to heat with the heat pump

again. Fault code8 is only set after 6hours. Only then can emergency mode be manually activated again via the rapid heating key.

4.5 Emergency shutdown

In the event of an emergency, carry out the following steps:

Interrupt the power supply by unplugging the appliance from

the mains or by tripping the MCB.

Shut off the cold water supply.

Immediately notify a qualified contractor, as the appliance

is not protected against corrosion while the power supply is

interrupted.

5. Maintenance and care

WARNING Electrocution

Only clean the exterior of the appliance.

Never open the appliance.

Do not insert objects through the grille into the interior

of the appliance.

Never spray the appliance with water.

Never spray water into the appliance.

WARNING Injury

!

Maintenance work, such as checking the electrical safety, must only be carried out by a qualified contractor.

Appliance components

Casing Use a damp cloth to clean the casing sections. Never

Air intake grille / air

discharge grille

DHW cylinder

Electric emergency/

booster heater

Appliance Have the safety assembly and the evaporator checked

Condensate drain Undo the condensate drain. Check that the condensate

Care and maintenance t ips

use abrasive or corrosive cleaning agents.

Clean the air intake grille and air discharge grille

every six months. Cobwebs or other kinds of contamination can restrict the air supply to the appliance.

The DHW cylinder is equipped with a maintenance-free impressed current anode to safeguard

it against corrosion. The power supply must not be

interrupted while the appliance is filled with water to

enable the impressed current anode to provide protection. Otherwise there is a risk of corrosion.

Have the electric emergency/booster heater descaled

from time to time. This will extend the service life of

the electric emergency/booster heater.

regularly by a qualified contractor.

drain is clear and remove any dirt from the condensate drain connection of the appliance.

10 | WWK 220-300 electronic www.stiebel-eltron.com

OPERATION

Troubleshooting

6. Troubleshooting

Problem Cause Remedy

No hot water is

available.

The appliance is

not heating the

DHW cylinder

although the heat

pump symbol is

illuminated.

The safety valve

of the cold water

supply line is dripping.

The condensate

drain drips.

The room temperature drops too

low.

Service/fault symbol is continuously

illuminated.

No power at the appliance.

A fuse/MCB in the fuse

box has blown/responded.

The air intake or air discharge of the appliance is

blocked.

The ambient temperature

exceeds the upper application limit (see chapter

"Specification/ Data

table"). The appliance

safety equipment has

responded and the appliance has switched off

automatically.

The ambient temperature

falls below the lower application limit (see chapter "Specification/ Data

table"). The evaporator is

currently being defrosted.

The blocking time for

compressor has not

yet elapsed. Once the

compressor has been

switched off, it will only

be switched back on

again after the 20minute

compressor blocking time

has elapsed.

These units are under

water mains pressure.

During the heat-up process, expansion water will

drip from the safety valve.

The surface temperature

of the evaporator is lower

than the dew point temperature of the ambient

air. Condensate forms.

See chapter "Fault codes".

Check that the appliance

is connected to the power

supply.

Check whether the fuses/

MCBs in your fuse box have

blown/responded. If required,

disconnect the appliance from

the power supply and replace

the fuses/reset the MCBs.

Contact your contractor if the

fuse blows again after the

appliance is connected to the

power supply.

Check the air intake grille

and air discharge grille for

contamination. Remove any

contamination (see chapter

"Maintenance and care").

Wait for the appliance to cool

down. Call a qualified contractor if the appliance does

not switch back on automatically.

Wait until the appliance

switches back on automatically.

Notify a qualified contractor if

water continues to drip when

heating is completed.

The amount of condensate

depends on the air humidity

level.

Operation of the appliance can

cause the room temperature

to fall by 1 to 3°C. If the room

temperature falls by more

than 5°C, check the room size

(see chapter "Specification/

Data table"). Increasing the

room size by opening a door

to another room will remedy

this.

Notify a qualified contractor.

Problem Cause Remedy

Service/fault symbol flashes and

the water does not

heat up.

The "heat pump"

symbol is illuminated but the

compressor is not

running. The fan is

running.

The "heat pump"

symbol is flashing.

The "electric emergency/booster

heater" symbol is

flashing.

See chapter "Fault codes".

The appliance is in defrost

mode.

There is a heat demand,

but the compressor is

blocked.

A temperature controller has switched off the

"electric emergency/

booster heater" during

quick heat-up.

It is imperative that you notify

a qualified contractor.

No action required.

No action required. The

compressor switches itself

on automatically after the

compressor blocking time

has elapsed. The compressor

blocking time lasts 20minutes

once the compressor has been

switched off. The symbol stops

flashing automatically.

No action required. The appliance continues the quick

heat-up process using the

heat pump. The symbol stops

flashing when the controller

releases the "electric emergency/booster heater". The

symbol goes out when the

temperature throughout the

DHW cylinder reaches the set

temperature of 65°C.

ENGLISH

www.stiebel-eltron.com WWK 220-300 electronic | 11

OPERATION

Troubleshooting

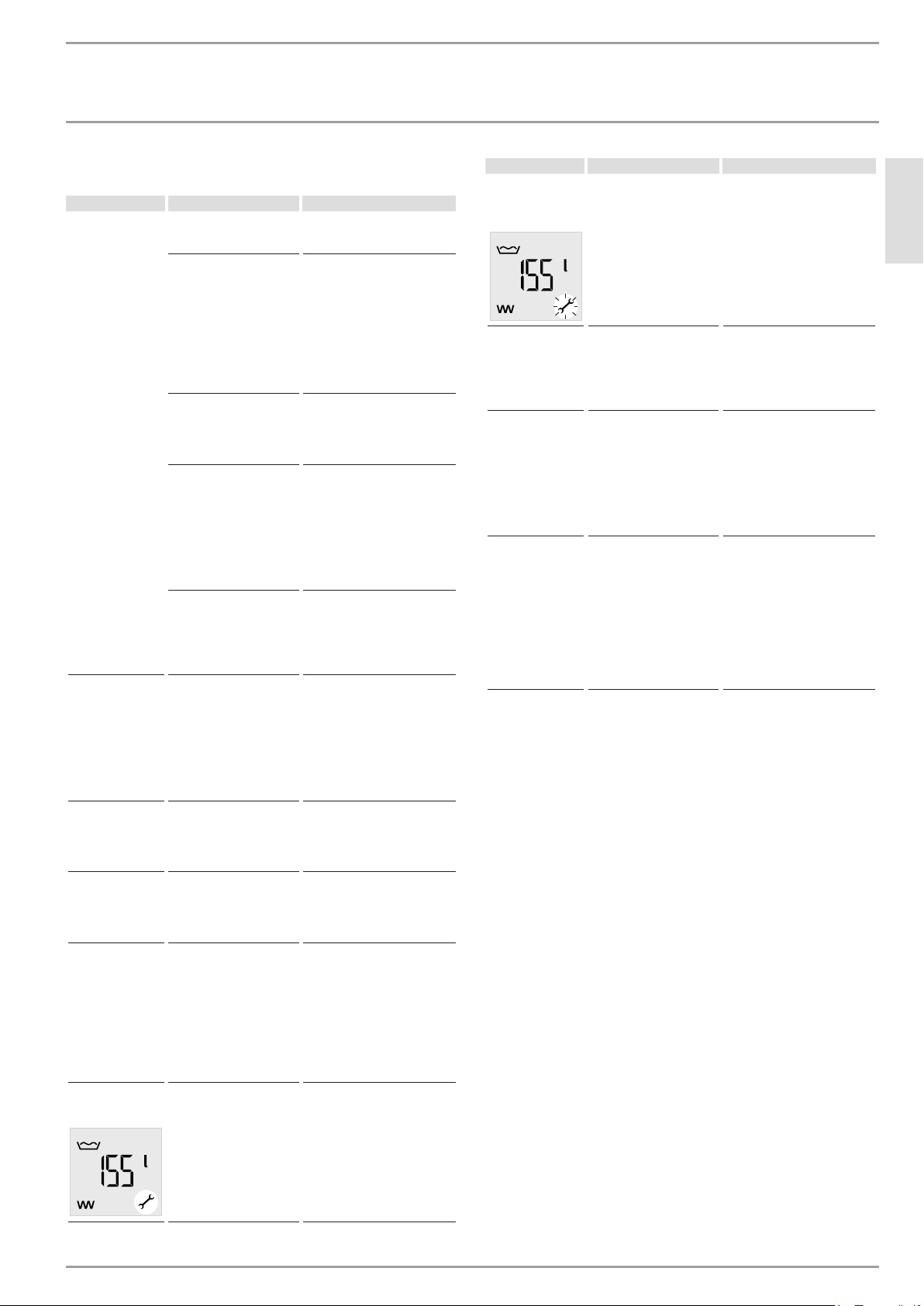

Fault code

If the service/fault symbol is flashing or continuously illuminated

on the display, you can call up a fault code.

Repeatedly press the menu key until the

fault code is shown following set temperature2.

Fault code appears

Fault

code

0 No fault

2

4

6

8

16

32

128

256

Service/

fault

symbol

continuously illuminated

continuously illuminated

flashes Dome sensor and integral

flashes

continuously illuminated

flashes

continuously illuminated

flashes Manually activated emergency

Fault description Remedy

Dome sensor faulty. The actual

temperature display switches

over to the integral sensor. The

appliance continues to deliver

heat. The amount of mixed

water shown is always less

than 10 litres.

Integral sensor faulty. In the

event of a faulty integral sensor, the integral sensor is set

to the dome sensor value and

amount of mixed water is calculated using this value. The

appliance continues to deliver

heat.

sensor faulty. The appliance no

longer delivers heat.

The appliance has ascertained

that the DHW cylinder has not

been heated for 13 hours, despite there being a demand.

Short circuit impressed current

anode / protective anode faulty

The appliance is operating with

an empty cylinder or the appliance is not delivering heat.

The anode current is interrupted. The appliance does not

heat up.

No communication between

controller and programming

unit. The most recently selected

set values are active.

mode (only electric emergency/

booster heater active).

You can continue to

use the appliance by

activating emergency

mode. See chapter

"Emergency mode".

Immediately notify a

qualified contractor,

as the appliance is not

protected against corrosion if the impressed

current anode is faulty.

Fill the appliance. The

fault code disappears

and the appliance

starts.

The contractor needs

to check the impressed

current anode and the

wiring.

See chapter "Appliance

description/ Emergency mo de".

Application scenarios for emergency mode

If the appliance shows fault code8, you can manually activate

emergency mode. If a different fault occurred previously, but did

not cause the appliance to switch off, the display may show a fault

code that is the result of several faults added together.

Listed below are the fault codes which will allow you to activate

emergency mode.

Fault code displayed

8 8

10 Fault code 8 + fault code 2

12 8+4

24 8+16

26 8+2+16

28 8+4+16

138 8+2+128

140 8+4+128

152 8+16+1 28

154 8+2+16+128

156 8+4+16+128

When the appliance is operating in emergency mode, the fault

code shown is increased by 256.

Notifying a qualified contractor

If you cannot remedy the fault, notify your qualified contractor. To

facilitate and speed up your request, provide the serial number

from the type plate (000000-0000-00000). The type plate can be

found on the left, above the "DHW outlet" connection.

Sample type plate

1

000000-0000-000000

D0000035352

1 Number on the type plate

If several faults occur, the fault codes are added up.

Example: If both the dome sensor and integral sensor are faulty,

the display shows fault code6(=2+4).

12 | WWK 220-300 electronic www.stiebel-eltron.com

INSTALLATION

Safety

INSTALLATION

7. Safety

Only a qualified contractor should carry out the installation, commissioning, maintenance and repair of the appliance.

7.1 General safety instructions

We guarantee trouble-free function and operational reliability only

if original accessories and spare parts intended for the appliance

are used.

7.2 Instructions, standards and regulations

Note

Observe all applicable national and regional regulations

and instructions.

Take note of the appliance type plate and chapter "Specification".

8. Appliance description

The heat pump drive unit is located in the upper section of the

appliance. The DHW cylinder is located in the lower section of

the appliance.

9. Preparations

9.1 Transport

CAUTION Injury

!

Take note of the weight of the appliance.

Use suitable transport aids (e.g. a sack truck) and

enough personnel for transportation.

Material losses

!

The appliance has a high centre of gravity and low overturning moment.

Safeguard the appliance against falling over.

Only set the appliance down on an even base.

Material losses

!

The appliance casing is not designed to withstand strong

forces. Incorrect handling can lead to material losses of

considerable extent.

Observe the information on the packaging.

Only remove the packaging shortly before the installation.

Do not unpack the appliance until it has arrived in the installation

room.

Leave the appliance in its packaging and on the pallet. This enables brief horizontal transport and provides places to hold onto

during transport.

ENGLISH

8.1 Standard delivery

The following are delivered with the appliance:

- Condensate drain bend

- 2 pipe connectors with plastic union nuts and gaskets for the

"cold water inlet" and "DHW outlet" connections.

8.2 Required accessories

Various safety assemblies are available that need to be selected

subject to the static pressure. These type-tested safety assemblies

protect the appliance against unacceptable excess pressure.

8.3 Further accessories

– Condensate pump (if the condensate cannot be drained off with

a naturally occurring fall)

8.4 Incorrect use

The following are not permitted:

- Operating the appliance when the casing is open

- Filling the appliance with a refrigerant other than the one

detailed in chapter "Specification/ Data table"

Observe the list of requirements regarding the installation room

and non-permissible installation sites (see chapter "Installation

site").

Vehicular transport

Material losses

!

The appliance must generally be stored and transported

vertically.

The appliance may be transported horizontally for brief periods,

over a maximum distance of 100miles and on made-up roads.

Strong shocks are not permissible.

Material losses

!

If transported horizontally, the appliance must always be

laid on the shaded side of the box.

The appliance must not remain in a horizontal position

for more than 24hours.

If the appliance was transported horizontally, leave it to

rest in a vertical position for at least one hour before

commissioning.

Observe the information on the packaging.

www.stiebel-eltron.com WWK 220-300 electronic | 13

INSTALLATION

Preparations

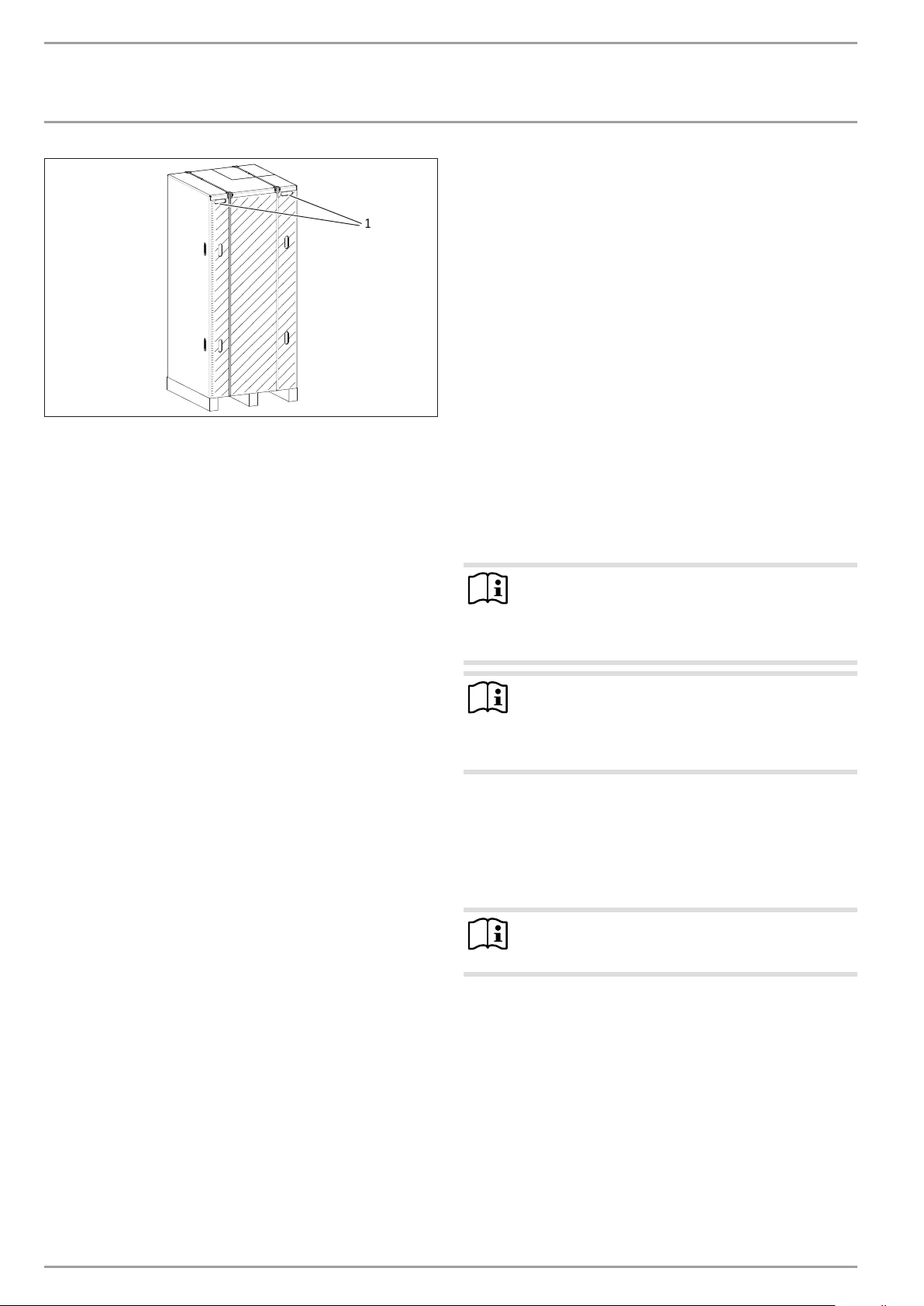

1

1 Recessed grips

Transport from vehicle to installation room

The cardboard box has reinforced recessed grips along the top.

You can use these recessed grips, as well as the pallet at the lower

end, to carry the appliance into the installation room. Take note

of the weight of the appliance and ensure a sufficient number of

personnel is available for handling the appliance.

9.2 Storage

If it is necessary to store the appliance for a prolonged period

before installation, observe the following information:

- Only store the appliance in a vertical position. Never store

the appliance horizontally.

- Store the appliance in a location that is dry and largely

dust-free.

- Protect the appliance from coming into contact with corrosive

substances.

- Ensure the appliance is not subjected to shocks or vibrations.

- Always leave sufficient space to provide access for installation, maintenance and cleaning. Observe the required

minimum clearances (see chapter "Preparations/ Siting the

appliance").

- Ensure the operation of other equipment in the installation

room is not impaired.

- To keep the duct lengths as short as possible, we recommend

installing the appliance close to the kitchen or bathroom.

- To prevent adverse effects from operating noise, never install

the appliance close to bedrooms.

The following installation sites are not permissible, due to risk of

appliance damage:

- Locations where the air is contaminated with oil or grease

D0000034797

- Saline environments

- Environments with thermal water

- Areas in proximity to high frequency machines

- Places where the air contains ammonia (e.g.sewage works)

- Places where the air contains chlorine (e.g.swimming pools)

- Generally places where the air is strongly contaminated, e.g.

due to dust, or contains aggressive substances

Note

The performance data indicated for this appliance has

been determined in line with the relevant standard, that

is at an intake temperature of 15°C. Below 15°C the

efficiency of the appliance decreases.

Note

You can improve the efficiency of the appliance by utilising the waste heat from other appliances to heat the DHW

cylinder, e.g. boilers, tumble dryers or freezers.

9.3 Installation site

The appliance is not approved for outdoor installation.

Further requirements regarding the installation room and appli-

ance positioning, to prevent appliance damage:

- The installation site must be free from flammable, highly

combustible gases and substances, as well as high levels of

dust.

- The installation room must be free from the risk of frost.

- The intake temperature of the appliance must be within the

permissible application limits (see chapter "Specification/

Data table").

- The floor of the installation room must be level and have

sufficient load bearing capacity. Take note of the weight of

the appliance with a full DHW cylinder (see "Specification/

Data table"). A floor with insufficient load bearing capacity is

in danger of collapse. If the appliance is not evenly balanced,

there may be a risk of appliance damage.

- The size of the installation room must correspond to the application limits of the appliance (see chapter "Specification/

Data table").

- Observe the safety clearances and protection zones.

Sound emissions

The sound emissions are louder on the air intake and air discharge

sides of the appliance than on the closed sides.

Never direct the air intake or air discharge towards

noise-sensitive rooms of the house, e.g. bedrooms.

Note

For details on sounds emissions, see chapter "Specification/ Data table".

14 | WWK 220-300 electronic www.stiebel-eltron.com

INSTALLATION

≥100

≥350

≥400

≥400

≥500

Preparations

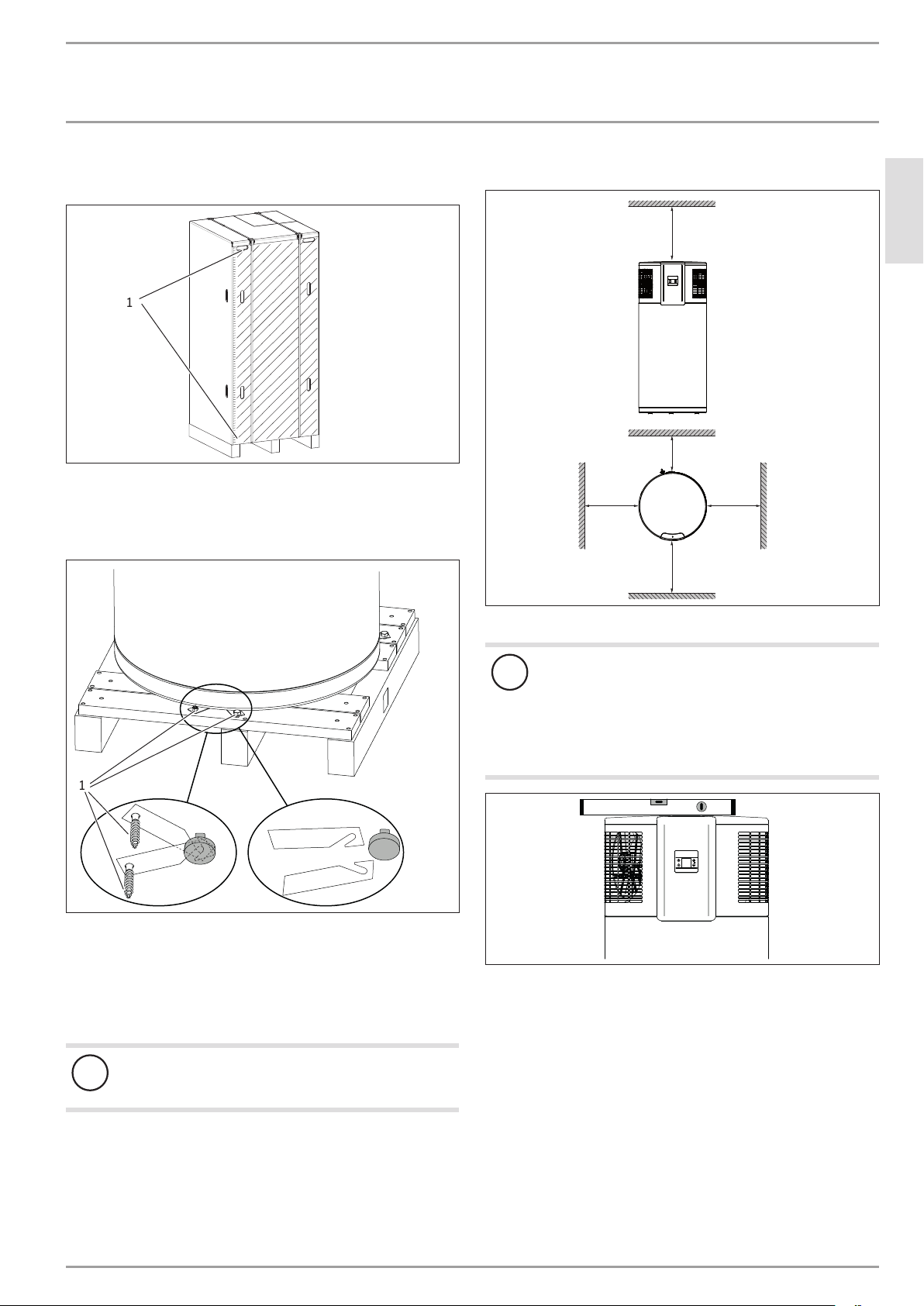

9.4 Siting the appliance

Carefully undo the cardboard packaging at the clips.

1

1 Cardboard packaging clips

The appliance is secured to the pallet with metal brackets and

screws. The metal brackets are hooked on to the feet underneath

the floor plate of the appliance.

Minimum clearances

ENGLISH

D0000034797

D0000020783

1

1.

1 Metal bracket fixing screw

Remove the fixing screws of the metal brackets from the

pallet.

Push the metal brackets a little towards the cylinder centre to

unhook them from the appliance feet.

Pull the metal brackets out from underneath the appliance.

Material losses

!

Take note of the appliance's weight and centre of gravity.

2.

Maintain the minimum clearances.

Material losses

!

The appliance must be positioned vertically to avoid

damage.

The feet under the floor plate of the appliance are

height-adjustable.

Level the appliance horizontally using the height-ad-

justable feet.

D0000034798

D0000034806

Slightly tip the appliance and carefully roll the appliance off

the pallet.

Position the appliance in the final installation site.

www.stiebel-eltron.com WWK 220-300 electronic | 15

INSTALLATION

Installation

10. Installation

WARNING Injury

!

Incorrect installation can lead to serious injury or material losses.

Before any work, ensure sufficient clearances for the

installation.

Handle sharp-edged components carefully.

10.1 Water connection

Material losses

!

Carry out all water connection and installation work in

accordance with regulations.

The following material combinations are approved for metal pipework installations:

Cold waterInlet DHW outlet

Copper pipe Copper pipe

Steel pipe Steel pipe or copper pipe

Thoroughly flush the pipework before connecting the ap-

pliance. Foreign bodies, such as welding pearls, rust, sand

or sealant can impair the operational reliability of the

appliance.

Safety valve

The appliance is a sealed unvented DHW cylinder. Provide the

appliance with a pressure relief valve.

Install a type-tested safety valve in the cold water supply

line. The response pressure of the safety valve must be below

or equal to the permissible operating pressure of the DHW

cylinder.

The safety valve protects the appliance against unacceptable excess pressure. The diameter of the cold water supply line must be

no greater than the diameter of the safety valve.

Ensure that the expansion water escaping from the safety

valve can drip into a drain, e.g. a tank or funnel.

Ensure the drain cannot be shut off.

Size the drain so that water can drain off unimpeded when

the safety valve is fully opened.

Ensure that the discharge pipe of the safety valve is open to

atmosphere.

Fit the discharge pipe of the safety valve with a constant

downward slope and in a room free from the risk of frost.

Pressure reducing valve

The maximum pressure in the cold water supply line must be at

least 20% below the response pressure of the safety valve. If the

maximum pressure in the cold water supply line is higher, install

a pressure reducing valve.

Material losses

!

To protect the connections against corrosion the water

connection must be made with flat gaskets. The use of

hemp on connections is not permissible.

The plastic union nuts included in the standard delivery

serve to prevent and insulate against cathodic scaling due

to highly conductive water.

Material losses

!

Too much torque can destroy the plastic union nuts. This

leads to a risk of appliance damage.

Never exceed a torque of 25Nm when using the gasket

supplied as standard. Keep to the permissible torque.

Using the gaskets and plastic union nuts provided, connect

the flanged copper pipes included in the standard delivery to

the "cold water inlet" and "DHW outlet" connections.

Check the gasket and plastic union nut for leaks.

Drain valve

Install a suitable drain valve at the lowest point in the cold

water inlet line.

DHW circulation

The heat losses incurred in the DHW circulation line and the electrical power consumption of the circulation pump reduce the efficiency of the system. The cooled water in the circulation line mixes

with the cylinder content. Where possible, avoid installing a DHW

circulation line. Where that is not possible, the DHW circulation

pump must be controlled thermally or by time switch.

Thermal insulation

Insulate the DHW line against heat loss in accordance with

locally applicable regulations.

10.2 Connection of an external heat generator (only

WWK300electronicSOL)

Material losses

!

Even if an external heat generator is connected, do not

disconnect the appliance from the power supply as otherwise it is not protected against frost and corrosion. The

power supply must not be interrupted even in winter,

when it is possible that DHW heating is only being provided via the external heat generator.

16 | WWK 220-300 electronic www.stiebel-eltron.com

INSTALLATION

Installation

Material losses

!

The integration of an external heat generator via the "heat

source flow" connection must not result in the application

limits being exceeded (see chapter "Specification/ Data

table").

The connected external heat generator cannot be controlled by the appliance. The external heat generator

must be controlled externally. The possibility of exceeding the maximum permissible DHW temperature in the

cylinder (as given in chapter "Specification/ Data table")

must be prevented.

Material losses

!

Carry out all installation work in accordance with regulations. In Germany, to comply with heating system regulations, an external heat generator must be connected with

a diaphragm expansion vessel and a safety valve between

the external heat generator and the DHW cylinder.

External heat generators may only be connected with DHW priority

control. As part of this, the cylinder temperature must be captured

with an electronic temperature sensor with safety low voltage.

The DHW cylinder of the appliance allows the temperature sensor

to be positioned at one of two different heights in the cylinder.

Using the sensor well in the upper third of the cylinder enables

later DHW heating through the external heat generator than the

lower sensor position.

10.4 Power supply

WARNING Electrocution

Carry out all electrical connection and installation work

in accordance with national and regional regulations.

WARNING Electrocution

If the appliance is permanently connected to the power

supply, ensure that the appliance can be separated from

the power supply by an isolator that disconnects omnipolar with at least 3mm contact separation. Contactors,

mains isolators or fuses can be used for this.

WARNING Electrocution

Observe the safety measures to prevent contact

with dangerous 'live' currents.

WARNING Electrocution

Coming into contact with 'live' components presents a

threat to life. Disconnect the appliance from the power

supply before carrying out work on the control panel.

Prevent the power supply from being switched on while

you are working on the system.

WARNING Electrocution

Insufficient earthing can lead to electrocution. Ensure

the appliance is earthed according to locally applicable

requirements.

ENGLISH

10.3 Condensate drain

Install a condensate drain hose in order to remove the condensate

which forms.

Connect the condensate drain bend included in the standard

delivery to the "condensate drain" connection.

Connect a condensate drain hose to the condensate drain

bend.

Material losses

!

Ensure condensate cannot back up.

Use a condensate drain hose with a diameter great-

er than the diameter of the condensate drain bend.

Ensure the condensate drain hose is not kinked.

Route the condensate drain hose with a continuous

fall.

The condensate drain must be open to atmosphere.

Use a suitable condensate pump if there is insufficient fall.

Observe the building characteristics.

WARNING Electrocution

The power cable must only be replaced (for example

if damaged) with an original spare part by a qualified

contractor authorised by the manufacturer (connection

typeX).

Material losses

!

The specified voltage must match the mains voltage. Observe the type plate.

Material losses

!

Never connect the appliance to the power supply before

the DHW cylinder is filled.

The appliance is delivered with a power cable with mains plug.

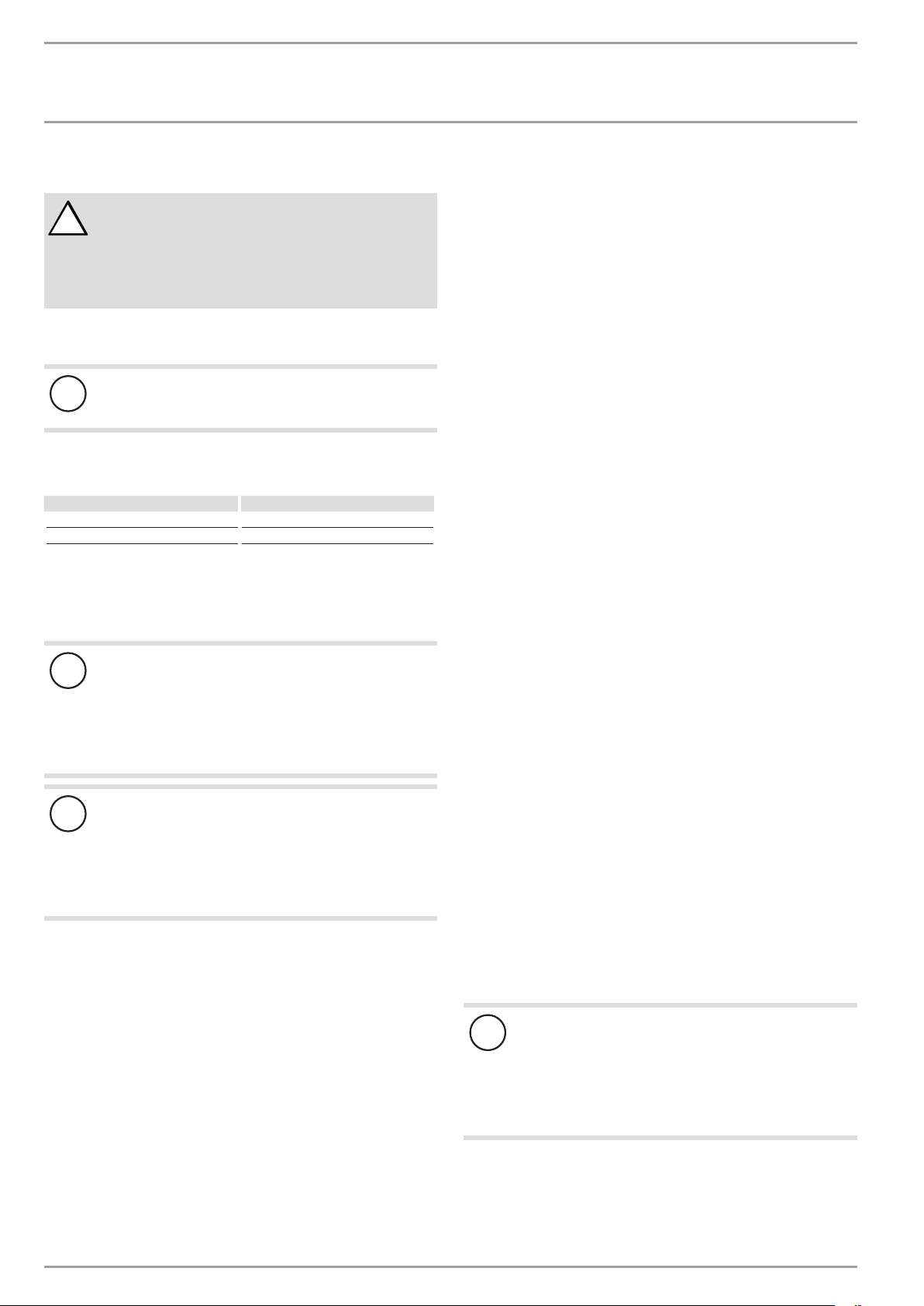

10.4.1 Standard connection without external signal transmitter

X0

PE

PE

N

N

L

L

2

1

D0000034487

www.stiebel-eltron.com WWK 220-300 electronic | 17

INSTALLATION

Installation

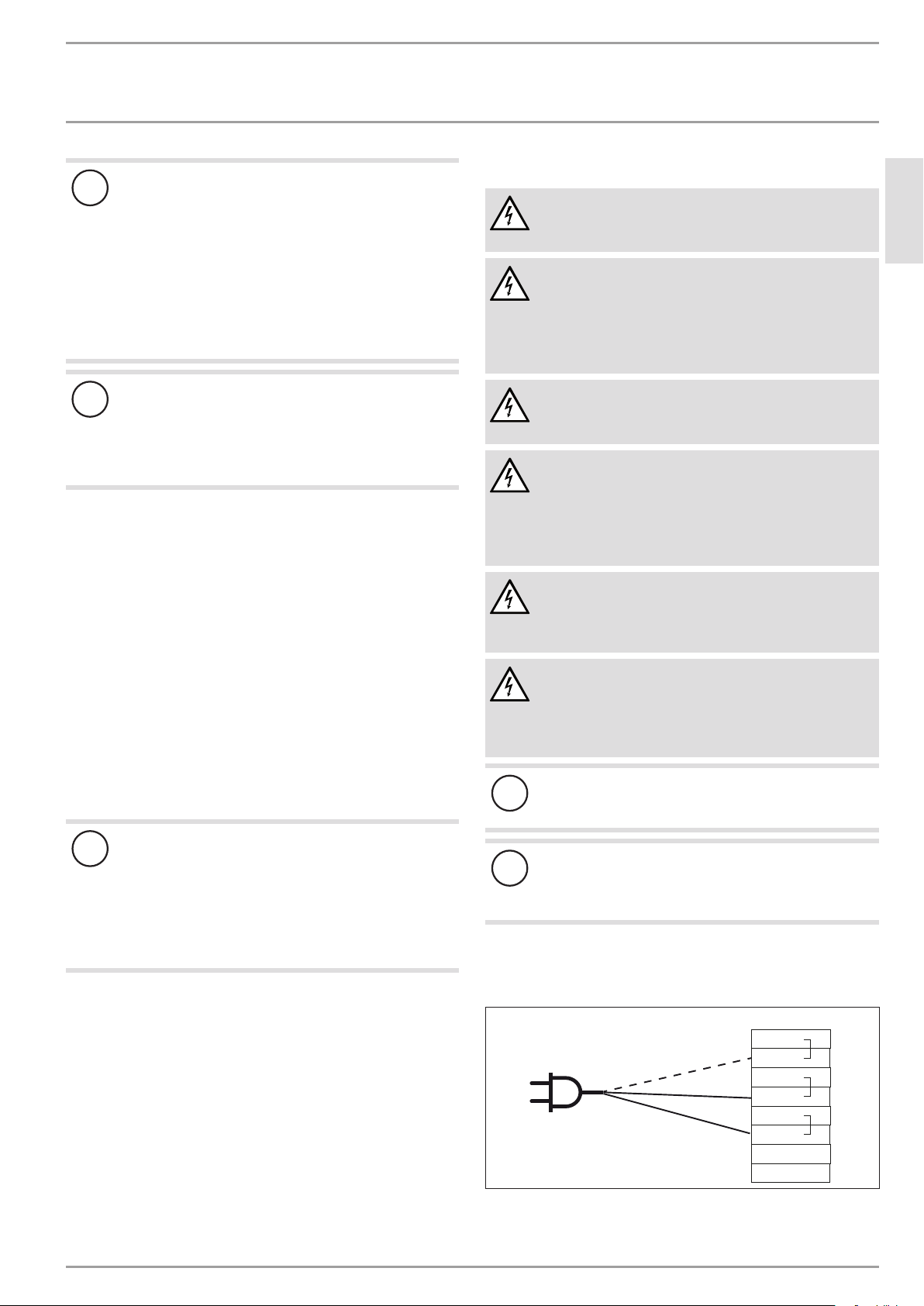

10.4.2 Connection with external signal transmitter

An external signal transmitter for switching a separate set DHW

temperature (set temperature2) can be connected to terminal

X0/2.

In the delivered condition, terminal X0/2 is not assigned. If this

terminal is connected to 230V, the appliance activates set temperature2.

Following a one-off activation (signal is present for at least one

minute), set temperature2 applies for at least 20minutes and is

ranked higher than set temperature1.

WARNING Electrocution

If the 230V signal of an external signal transmitter is

to be connected to terminal X0/2, do not connect the

appliance to the power supply with the factory fitted

power cable and standard plug.

Instead connect the appliance to the power supply permanently. Never interchange L1 and N.

Note

Never wire up terminal X0/1.

Example 1: Power-OFF signal with own 230V phase

X0

PE

PE

N

L1

PE

N

N

L

L

2

1

1

1 Inverter (floating contact)

The inverter power feed is located at a central distribution point

(e.g. in the main fuse box).

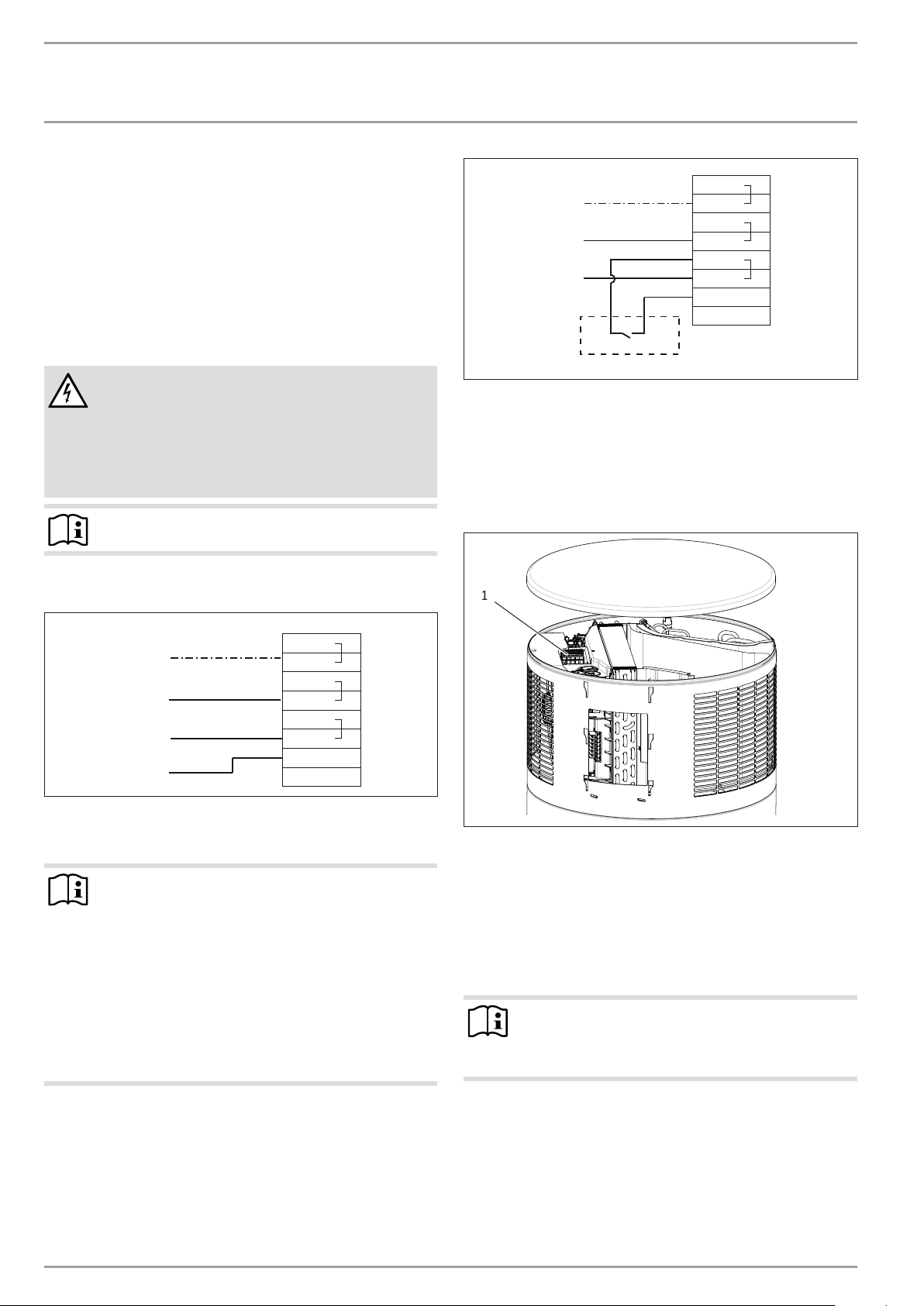

Connection to terminal block X0

Remove the appliance cover (see chapter "Cleaning and

maintenance/ Removing the appliance cover").

1

D0000034590

X0

PE

N

L1

L1, L2 oder L3

EVU:

Example 2: Photovoltaic signal via on-site relay and phase

routed outside the appliance

Note

The relay in the inverter must meet the following requirements:

- Potential-free relay (240VAC / 24VDC, 1A) with

N/O contact

- Adherence to safety regulations and standards for

safety extra low voltage

- The switching output must be programmed so that

the relay closes or opens if certain limits are exceeded or undershot (inverter output level).

If necessary, check with the inverter manufacturer whether the product meets the stated criteria.

PE

PE

N

N

L

L

2

1

D0000034589

1 Terminal X0

Prepare the leads for connection to X0 in such a manner, that

each lead terminating at X0 has a wire ferrule.

Route leads through the strain relief.

Connect the leads to X0 (see chapter "Connection with exter-

nal signal transmitter").

10.5 Assembling the appliance

Note

Refit the appliance cover after completing your work. See

chapter "Maintenance and cleaning/ Fitting the appliance

cover").

D0000034803

18 | WWK 220-300 electronic www.stiebel-eltron.com

Loading...

Loading...