Page 1

1www.stiebel-eltron.CoM

Hot wat e r rene w a b les a i r c ondit ion i n g room He at i n g

»ISSUE 2009

TEchnIcal GUIdE

hEaT pUmpS

Page 2

Design/engineeRing anD installation

Issue March 2009

Reprinting or duplication, even partially, only with our express permission.

STIEBEL ELTRON, D-37601 Holzminden

Legal note:

In spite of the care taken in the production of this brochure, no guarantee can be given regarding the accuracy of its contents.

Information concerning equipment levels and specification are subject to modification. The equipment features described in this

brochure are not stated as agreed properties of our products. Due to our policy of ongoing improvement, some features may have

subsequently been changed or even removed. Our advisors will be happy to consult with you regarding the currently applicable

equipment features. Pictorial illustrations in this brochure only represent application examples. The illustrations also contain

installation components, accessories and special equipment, which is not part of the standard delivery.

Page 3

3WWW.STIEBEL-ELTRON.COM

Heat pumps protect our energy reserves 6

How does a heat pump work? 7

Energy sources for heat pumps 8

Heat pump operating modes 10

The right heat pump for every application 11

This is could be your solution 12

Energy Savings Order EnEV [Germany] 13

Cost calculation to VDI 2067 21

Terminology and descriptions 23

Summary of formulae 24

System design 25

Regulations and guidelines/directives 26

Heating load calculation 28

Flow temperatures of heating surfaces 29

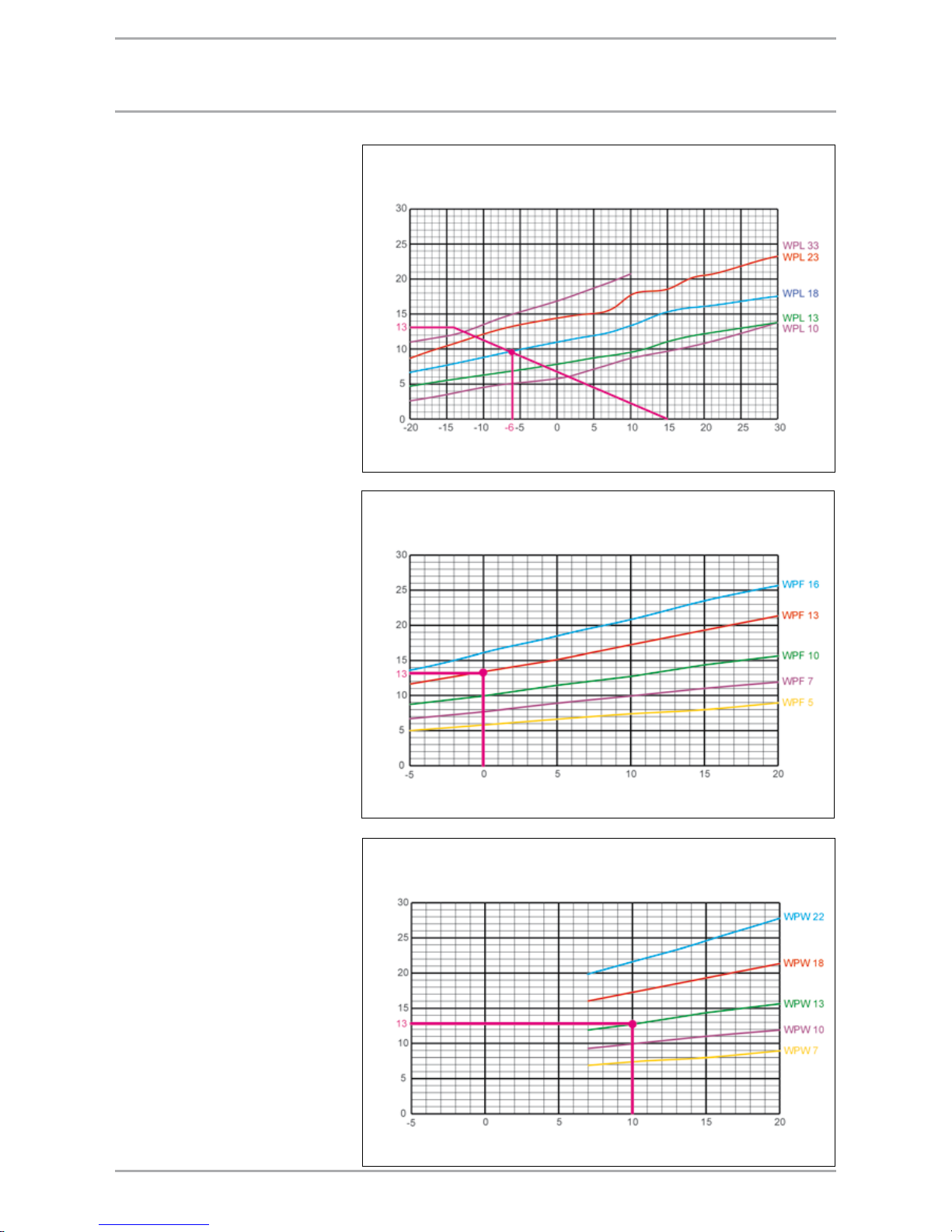

Sizing of heat pumps 30

Power supply and tariffs 32

Integration into the heating system 33

Heat pumps with buffer cylinder 34

Heat pumps without buffer cylinder 35

DHW heating with heat pumps 36

Freshwater station 38

Modernisation of older buildings 39

Cooling with the heat pump system 40

Cooling load calculation 41

Heat sinks for cooling operation 43

Cooling capacity 44

Distribution system for cooling operation 45

Cooling capacity, underfloor heating system 46

Cooling capacity, fan convectors 47

Cooling capacity, cassettes 48

Passive cooling with the WPC cool heat pump 49

Passive cooling with the WPF...E heat pump 50

Passive cooling with the WPF heat pump 51

Active cooling with the WPC heat pump 52

Active cooling with the WPF heat pump 53

Active cooling with the WPL heat pump 54

Air | water heat pump; external installation 55

Condensate connection 58

Air | water heat pump - internal installation 59

Air routing 60

Condensate connection 61

Checklist 62

Air | water heat pumps 63

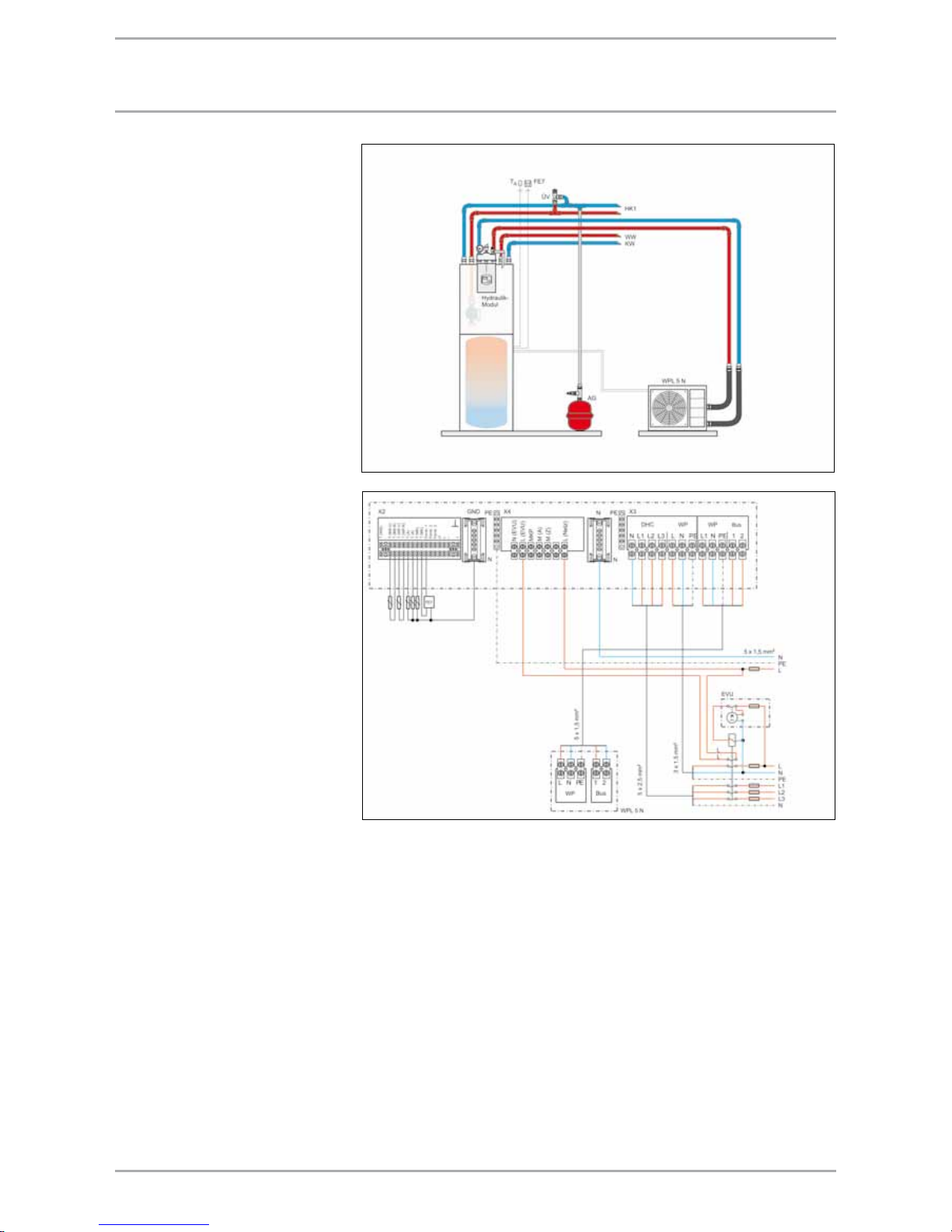

Air | water heat pump WPL 5 N 64

Connection WPL 5 N 66

Connection WPL 5 N 67

Air | water heat pump WPL 10 68

Output details WPL 10 70

External installation WPL 10 71

Internal installation WPL 10 72

Heating system connection WPL 10. 76

Power supply WPL 10. 77

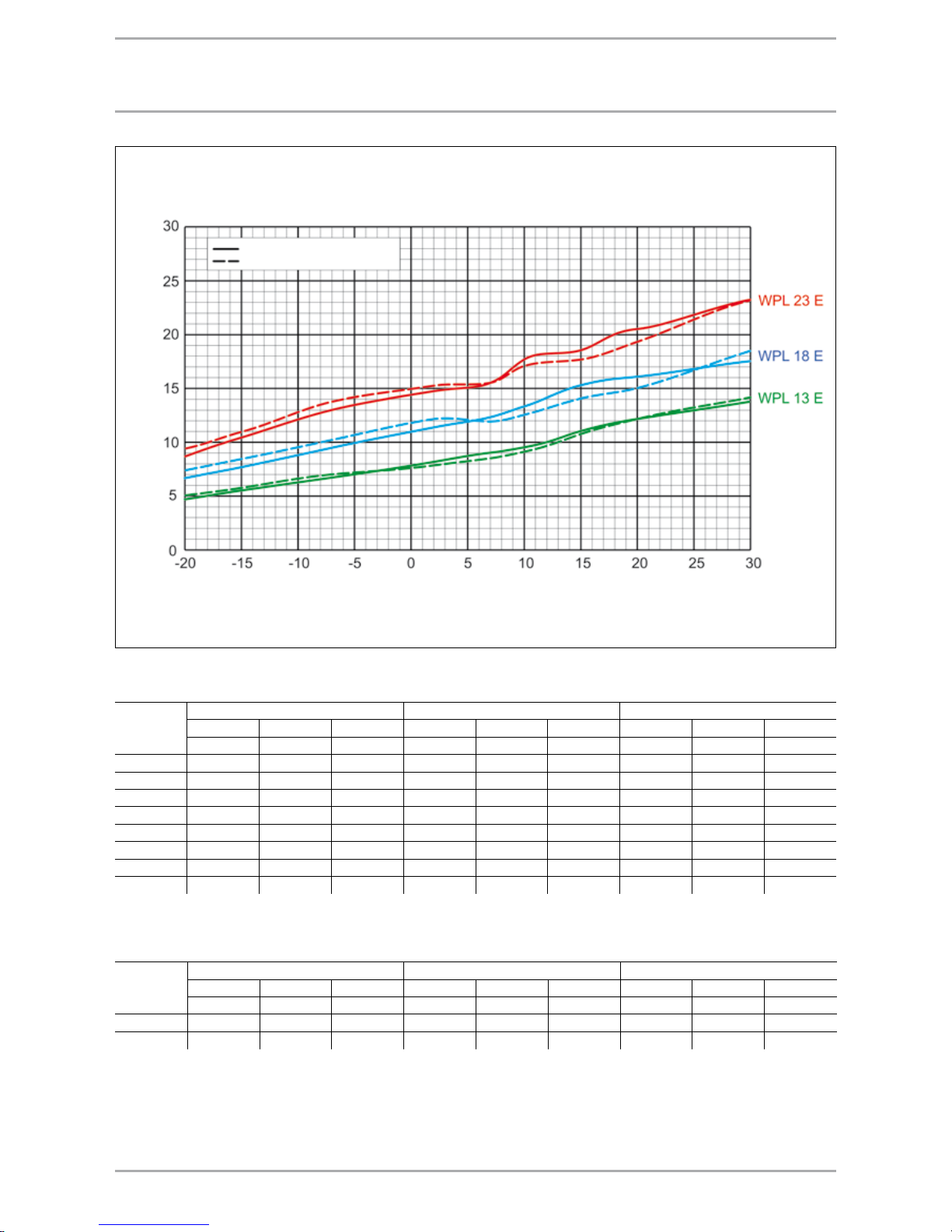

Air | water heat pumps WPL 13/18/23 E/cool 78

Output details WPL 13/18/23 E/cool. 80

External installation WPL 13/18/23 E/cool 82

Internal installation WPL 13/18/23 E/cool 83

Air routing of WPL 13/18/23 E for internal installations 87

Heating system connection WPL 13/18/23 E/cool 88

Power supply WPL 13/18/23 E/cool 89

Air | water heat pump WPL 33 90

inDex

Page 4

4 WWW.STIEBEL-ELTRON.COM

inDex

Output details WPL 33 92

External installation WPL 33 93

Internal installation WPL 33 94

Heating system connection WPL 33. 95

Power supply WPL 33. 96

Air | water heat pump WPL 14 HT 98

Output details WPL 14 HT 100

Internal installation WPL 14 HT 102

Heating system connection WPL 14 HT 104

Power supply WPL 14 HT 105

Air | water heat pump WPL 20/26 AZ 106

Installation WPL 20/26 AZ 108

Connection WPL 20/26 AZ 109

Notes 110

Geothermal collector 111

Sizing tables, geothermal collectors 115

Geothermal probe 117

Sizing tables, geothermal probes 121

Heat transfer medium 122

Checklist 123

Brine | water heat pumps 125

Brine | water heat pumps WPC 5/7/10/13 (cool) 126

Output details WPC 5/7/10/13 128

Installation WPC 5/7/10/13 130

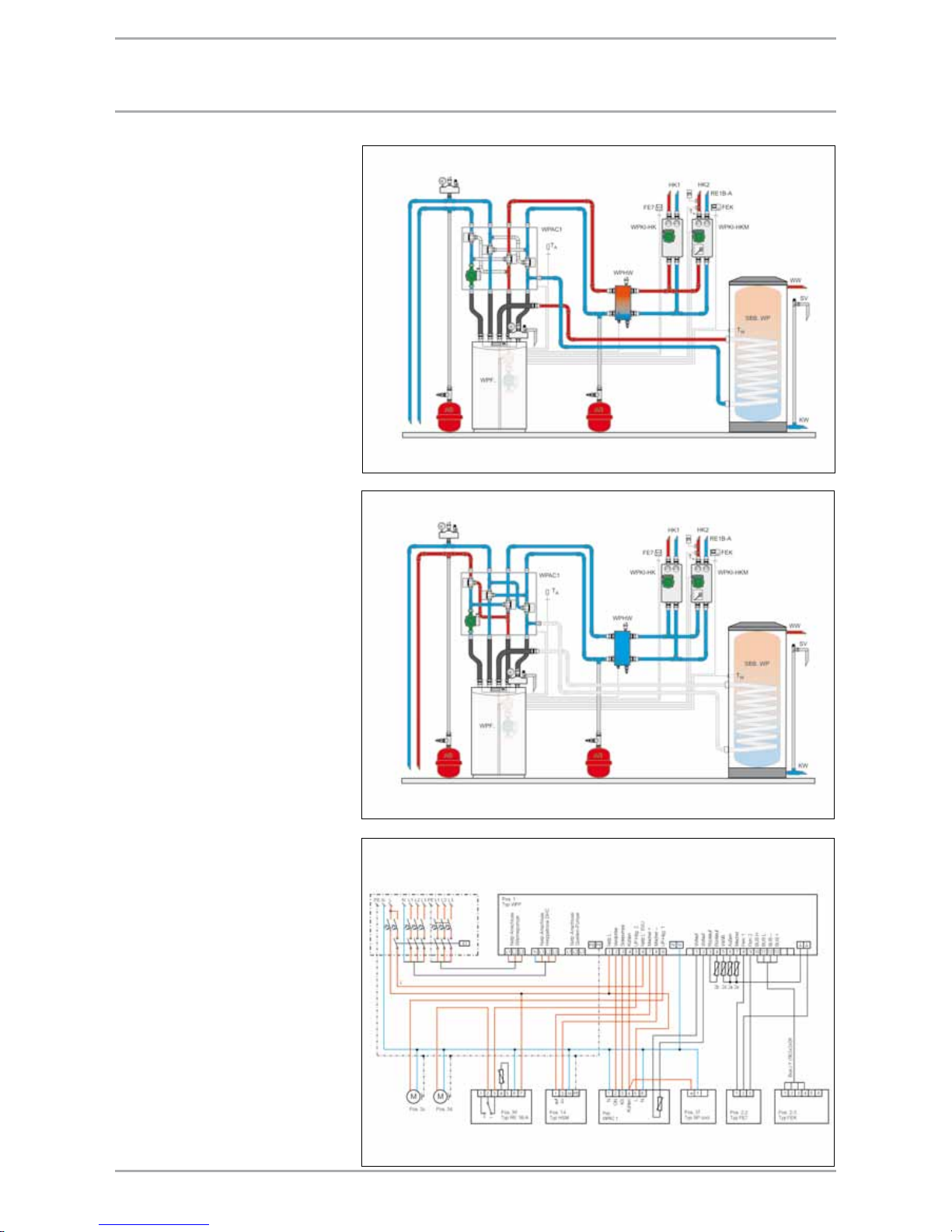

Heating system connection WPC 5/7/10/13 131

Brine | water heat pump WPF 5/7/10/13/16 E/cool 132

Output details WPF 5/7/10/13/16 E/cool 134

Installation WPF 5/7/10/13/16 E/cool 136

Heating system connection WPF 5/7/10/13/16 E/cool 137

Brine | water heat pumps WPF 5/7/10/13/16 138

Output details WPF 5/7/10/13/16 140

Installation WPF 5/7/10/13/16 142

Heating system connection WPF 5/7/10/13/16 143

Brine | water heat pumps WPF 10/13/16 M 144

Output details WPF 10/13/16 M 146

Installation WPF 10/13/16 M 148

Heating system connection WPF 10/13/16 M 149

Power supply WPF 10/13/16 M (SET) 151

Brine | water heat pumps WPF 20/27/40/52/66 152

Output details WPF 20/27/40/52/66 154

Internal installation WPF 20/27/40/52/66 156

External installation WPF 20/27/40/52/66 157

Heating system connection WPF 20/27/40/52/66 158

Power supply WPF 20/27/40/52/66 160

Well installation 161

Assessing the water quality 164

Well installation with brine | water heat pumps 165

Checklist 166

Water | water heat pumps 167

Water | water heat pumps WPW 7/10/13/18 168

Output details WPW 7/10/13/18 170

Installation WPW 7/10/13/18 172

Heating system connection WPW 7/10/13/18 173

Water | water heat pumps WPW 13/18/22 M 174

Output details WPW 13/18/22 M 176

Installation WPW 10/13/16 M 178

Heating system connection WPW 10/13/16 M 179

Power supply WPW 13/18/22 M (SET) 181

Accessories for heating heat pumps 183

Heat pump manager 184

Page 5

5WWW.STIEBEL-ELTRON.COM

Mixer, swimming pool module 186

Remote control unit and sensors 188

Communication 189

Heat meter 191

Underfloor heating control system 192

Low loss header 193

Buffer cylinder SBP 100 Komfort 194

Compact installation for SBP 100 Komfort 195

Buffer cylinder SBP 200 E, SBP 200 E cool 196

Buffer cylinder SBP 400 E, SBP 400 E cool 197

Buffer cylinder SBP 700 E, SBP 700 E SOL 198

Compact installations for SBP 200/400/700 199

Buffer cylinder SBP 1000 E, SBP 1000 E SOL, SBP 1000 E cool 200

Buffer cylinder SBP 1500 E, SBP 1500 E SOL, SBP 1500 E cool 201

Thermal insulation for SBP 1000/1500 E cool 202

Circulation pumps 203

Pump assemblies 206

Pressure hoses 207

Threaded immersion heater BGC 209

Brine kit 210

Brine circuit pumps 212

Brine manifold, heat transfer medium 213

Expansion vessel, antifreeze tester, brine pressure switch 214

Convector heater module LWM 250 215

Cooling module 217

Air hoses and connections 218

Duct silencer, silencer, condensate pump 219

DHW cylinder SBB 301/302 WP 220

DHW cylinder SBB 401/501 WP SOL 221

DHW cylinder SBB 751/1001 222

DHW cylinder SBB 751/1001 SOL 223

DHW cylinder SBS 800/1000/1500 224

DHW cylinder SBS 800/1000/1500 SOL 225

Thermal insulation; DHW cylinder 226

Freshwater station 227

Plate-type heat exchanger 228

Convector replacement 229

Standard circuits 230

DHW heat pumps 247

Hot water out of "thin air" 248

WWK 300 249

Special accessories WWK 300..SOL 252

Installation WWK 300..SOL 253

Installation WWK 300..SOL 254

WWP 300 255

Installation WWP 300 258

Installation WWP 300 259

inDex

Page 6

6 WWW.STIEBEL-ELTRON.COM

HEat pUmpS protEct oUr EnErgy rESErvES

Advanced heat pumps save energy

and reduce emissions

Heat is a fundamental human

need. Many people today not only

consider economy when they think

of heating, but also consider the

environmental impact. That both can

be combined effectively is shown by

the development of the heat pump.

This utilises the energy held in the

air, water and under ground. This it

converts into useful heating energy.

The positive aspect of this type of

"harvesting" available heat is that you

can draw deep without damaging the

environment.

The heat pump is regulated subject

to the outside temperature. This

control unit safeguards the selected

set temperature. As a result, the heat

pump achieves an excellent quotient

of "harvested" heat to expended

primary energy. To put it into figures:

Each kWh electrical energy spent

generates up to 5 kWh available

energy, subject to the respective heat

source, i.e. from the air, from the

groundwater and the ground of your

own property. The compact design

requires little space and ensures

an easy installation. The lowest

installation effort secures the air

|water heat pump the top prize for

easy installation. With internal and

external versions, it can yield heat

for domestic heating from outside

air down to a temperature of –20°C.

Future purchasing decisions will

increasingly favour products with

sound environmental credentials. Heat

pumps from STIEBEL ELTRON already

enable the basic premise of heating

an apartment or entire houses with

environmentally responsible and costeffective methods to be achieved.

Future-proof solutions from

STIEBEL ELTRON

Over the last 30 years, STIEBEL ELTRON

has invested a lot of time and energy

in the development of its heat pumps.

This has created a reliable, standard

technology that delivers every

conceivable convenience. Our range

of heat pumps satisfies the most

divers requirements in the heating

technology sector - conveniently and

economically. Our heat pumps are

part of the extensive range of systems

by STIEBEL ELTRON, the predominant

aim of which is to translate our high

quality standards into future-proof,

alternative technologies. As one of

the most important manufacturers of

products in the heating, ventilation,

air conditioning and domestic hot

water equipment sector, we feel a

great sense of responsibility for our

environment. For that reason will we

continue to adhere to our commitment

to this sector.

Exclusive technology -

hot water included.

Hot water and cosy ambience are

our business. You can safeguard

your domestic hot water supply with

DHW cylinders from STIEBEL ELTRON.

Or have you ever considered

separating your hot water heating

from your existing heating system?

For larger DHW demand you

could, for example in commercial

operations, use STIEBEL ELTRON

heat pumps exclusively for heating

your domestic hot water, irrespective

of whether you want to provide a

centralised or decentralised supply.

At STIEBEL ELTRON, a complete range

of energy-efficient electric appliances

awaits you.

26_0 3_01_0358

Page 7

7WWW.STIEBEL-ELTRON.COM

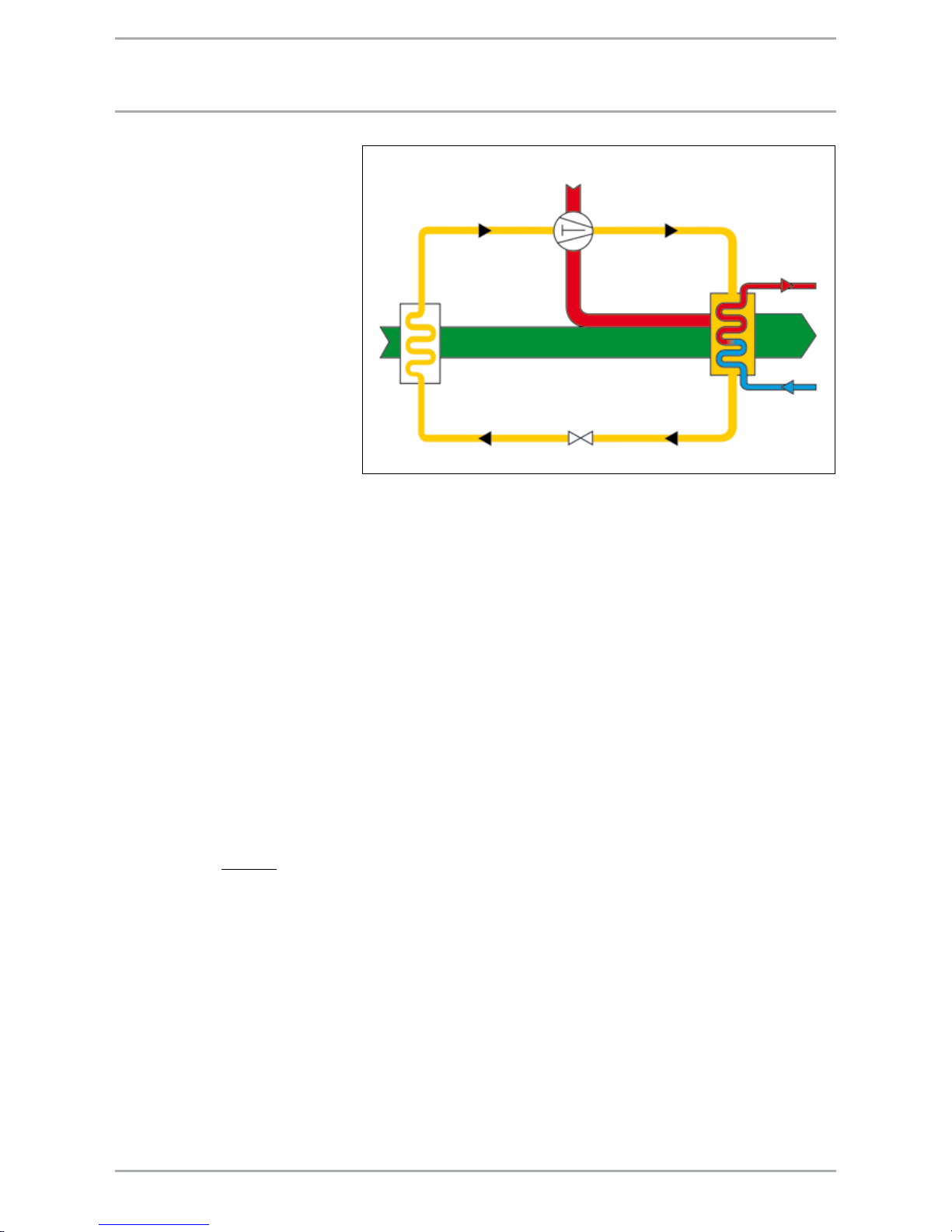

Heat pump principle

The most important contribution to

the heat pump function is made by

the refrigerant (in the following also

referred to as "process medium"). This

evaporates at the lowest temperatures.

If you route outside air or water to a

heat exchanger (evaporator), in which

the process medium circulates, then

that refrigerant extracts the required

evaporation heat from the heat source

and changes from a liquid into a

gaseous state. During this process,

the heat source cools down by a few

degrees. A compressor draws the

process medium in and compresses

it. The increase in pressure also raises

the temperature; in other words,

the process medium is "pumped"

to a higher temperature level. That

requires electrical energy. As the

compressor is of the suction gascooled design, the energy (motor

heat) is not lost, but reaches the

downstream condenser together with

the compressed process medium.

Here, the process medium transfers

its absorbed energy to the circulating

system of the hot water heating

system by being returned into the

liquid state again. An expansion valve

reduces the still prevalent pressure

and the circular process starts again.

Heat pump coefficient of performance

The coefficient of performance

ε

HP

is equal to the quotient of heating

output Q

HP

and electrical power

consumption P

HP

in accordance with

the following equation

It provides a factor, by which yield

exceeds expenditure. The coefficient

of performance is subject to the

temperature of the heat source

and that of the heat consumer. The

higher the heat source temperature

and the lower the heat consumer

temperature, the higher the coefficient

of performance. It relates, as current

value, always to a specific operating

condition.

How doES a HEat pUmp work?

ε

HP

=

Q

HP

P

HP

Main layout of a heat pump refrigeration circuit

Compressor

Inlet line

Gaseous process medium

low pressure

Pressure line

Gaseous process medium

high pressure

Liquid line

Liquid process medium

high pressure

Injection line

Liquid process medium

low pressure

Expansion valve

Flow

Return

Evaporator

Heating

energy

Environmental

energy

Page 8

8 WWW.STIEBEL-ELTRON.COM

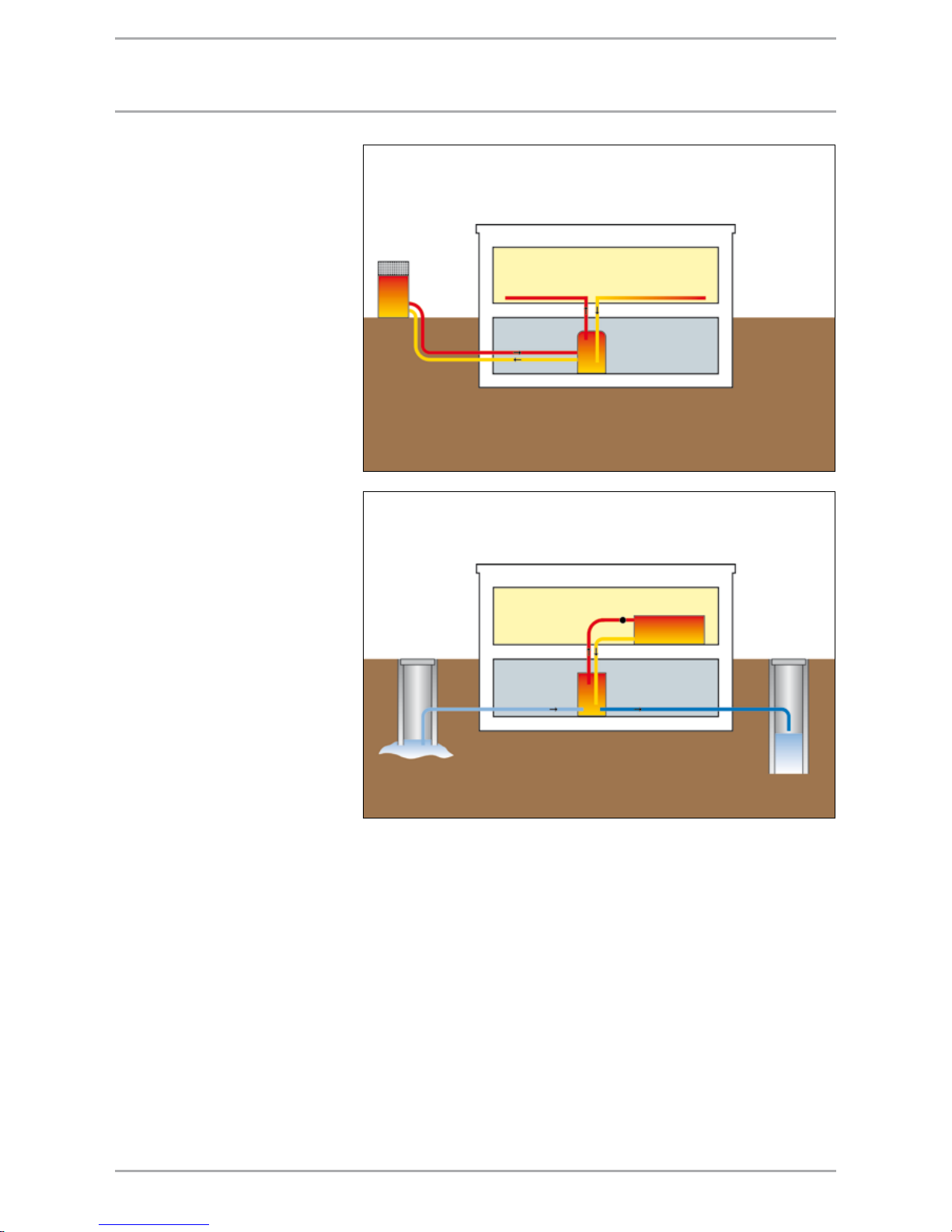

Heat source air

Air heated by the sun is universally

available. Even at temperatures as low

as –20 °C, heat pumps yield sufficient

heat from the outside air. However, air

as heat source has the disadvantage

that it is coldest when the highest

heat demand arises. Although it is

still possible to extract heat from air

as cold as –20 °C, the heat pump

coefficient of performance is, however,

regressive in line with the outside

temperature. It is for that reason,

that in most cases a combination

with a second heat source is required

that boosts the heating system,

particularly during the colder season.

One particular benefit is the ease of

installation of air|water heat pumps,

as no extensive ground work or well

drilling is required.

Heat source water

Groundwater is a good store of solar

energy. Even on the coldest days in

winter, temperatures of +7 °C to +12

°C are achieved - and this is where

its advantage lies. The near constant

temperature level of this heat source

enables the heat pump to achieve a

favourable coefficient of performance

all the year round. Regrettably,

groundwater of adequate quality is

not universally available. Where it is

available, its utilisation is certainly

worthwhile. The use of groundwater

requires the approval of your local

water board [check local regulations].

Utilising this heat source requires the

drilling of a delivery and return well.

Your local water board will advise you

about the possibility of utilising these

waterways.

EnErgy SoUrcES for HEat pUmpS

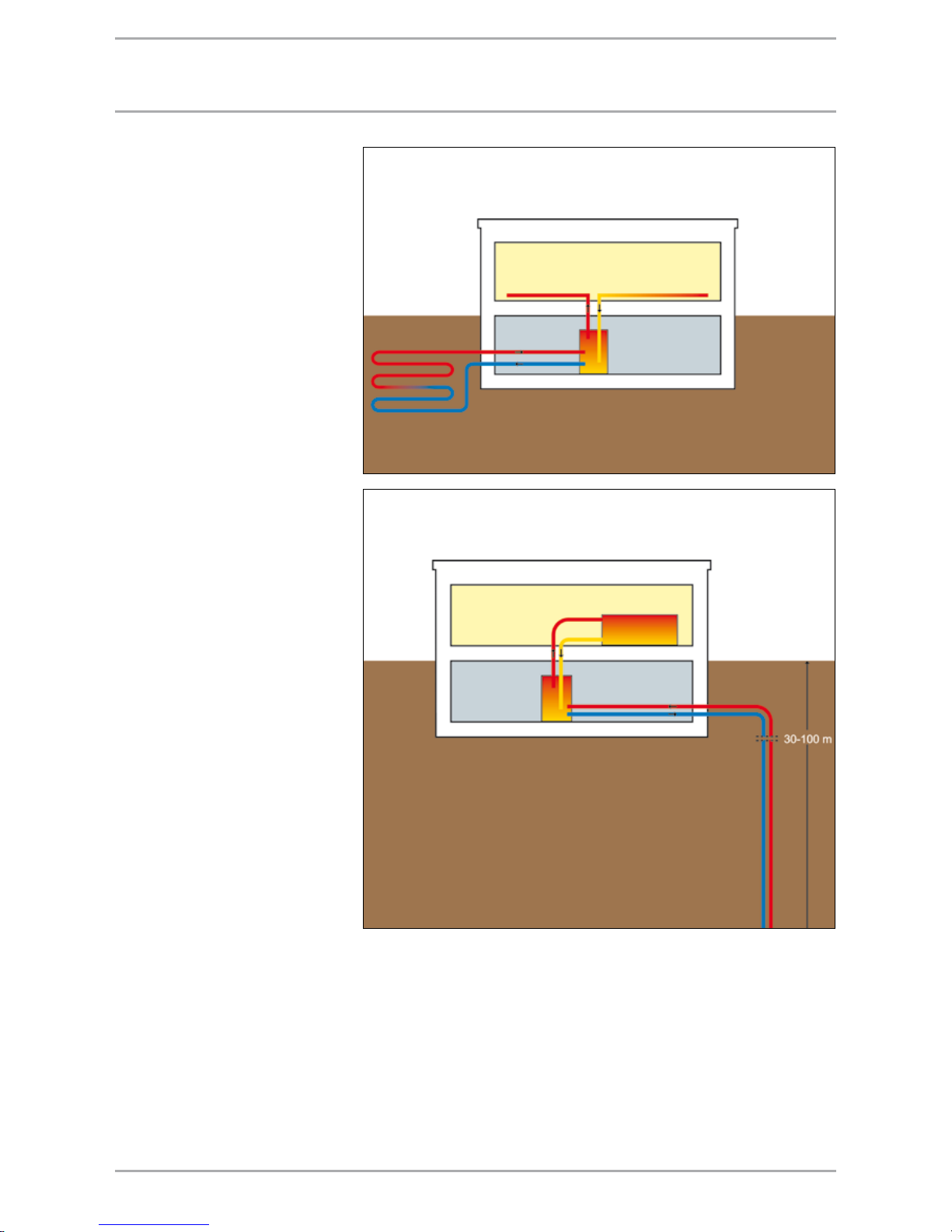

Main layout of an air source heat pump system

Main layout a groundwater heat pump system

Page 9

9WWW.STIEBEL-ELTRON.COM

EnErgy SoUrcES for HEat pUmpS

Heat source ground with geothermal

collector

At a depth of 1.2 to 1.5 m, the ground

remains warm enough, even on

colder days, to enable an economical

heat pump operation. However, this

requires the availability of a property

large enough to accommodate a

pipe system for collecting the heat

from the ground. In dry, sandy soil,

the collector can extract between 10

and 15 W/m² and up to 40 W/m² in

ground that carries groundwater.

An environmentally-friendly brine

mixture that cannot freeze and which

transports the yielded energy to

the heat pump evaporator courses

through the pipes. As a rule of thumb,

you would need approximately

two to three times as much ground

area as area to be heated. If your

property is large enough, you have an

inexhaustible reserve of energy and

ideal conditions for a STIEBEL ELTRON

brine |water heat pump.

Heat source ground with geothermal

probe

Geothermal probes that are set up

to 100 metres deep into the ground

by specialist drilling contractors,

require less space. Geothermal probes

comprise a probe foot and endless,

vertical probe pipes made from

plastic. As with geothermal collectors,

a brine mixture that extracts heat from

the ground circulates through the

plastic pipework. The extraction rate is

subject to the ground characteristics,

and generally lies between 30 and

100 W per metre geothermal probe.

Subject to heat pump and ground

conditions, several geothermal probes

can be linked up in a single system.

These systems must be notified to and

possibly approved by your local water

board.

Main layout geothermal probe heat source system

Main layout geothermal collector heat pump system

Page 10

10 WWW.STIEBEL-ELTRON.COM

Operating modes

For the different types of heat pump

operation, the heating technology

world uses the following terminology:

Mono-mode

The heat pump is the sole provider

of heating in the building. This

operating mode is suitable for all

low temperature heating systems up

to +60 °C flow temperature.

Mono-energetic

The heating system uses no second

form of energy. The air | water heat

pump operates down to an outside air

temperature of –20 °C. Upon demand,

an electric booster heater is started at

very low outside air temperatures.

HEat pUmp opEratIng modES

Dual-mode - alternative

Down to a fixed outside temperature

(e.g. 0 °C), the heat pump delivers

the entire heating energy. When the

temperature falls below that value,

the heat pump switches itself OFF

and the second heat source takes over

the heating operation. This operating

mode is suitable for all heating

systems up to 90 °C.

Dual-mode - parallel

Down to a certain outside

temperature, the heat pump alone

delivers the required heating energy.

A second heat source starts at low

temperatures. However, contrary

to the dual-mode alternative

operation, the heat pump proportion

of the annual output is higher.

This operating mode is suitable

for underfloor heating systems

and radiators up to +60°C flow

temperature.

Dual-mode - partially parallel

Down to a certain outside

temperature, the heat pump alone

delivers the required heating energy.

The second heat source starts, if the

temperature falls below that value. The

heat pump is stopped if the heat pump

flow temperature is inadequate. The

second heat source supplies the entire

heating output. This operating mode is

suitable for all heating systems above

60 °C flow temperature.

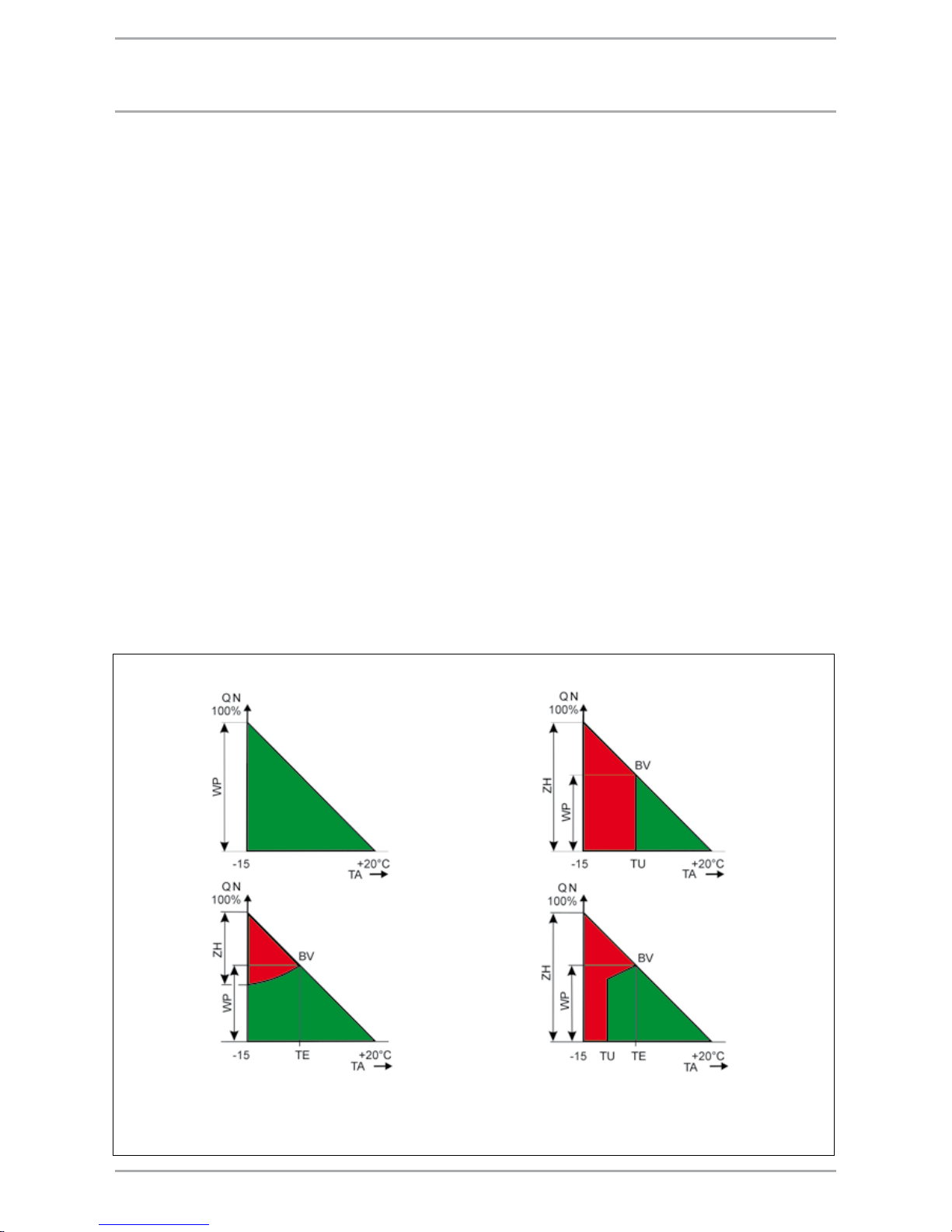

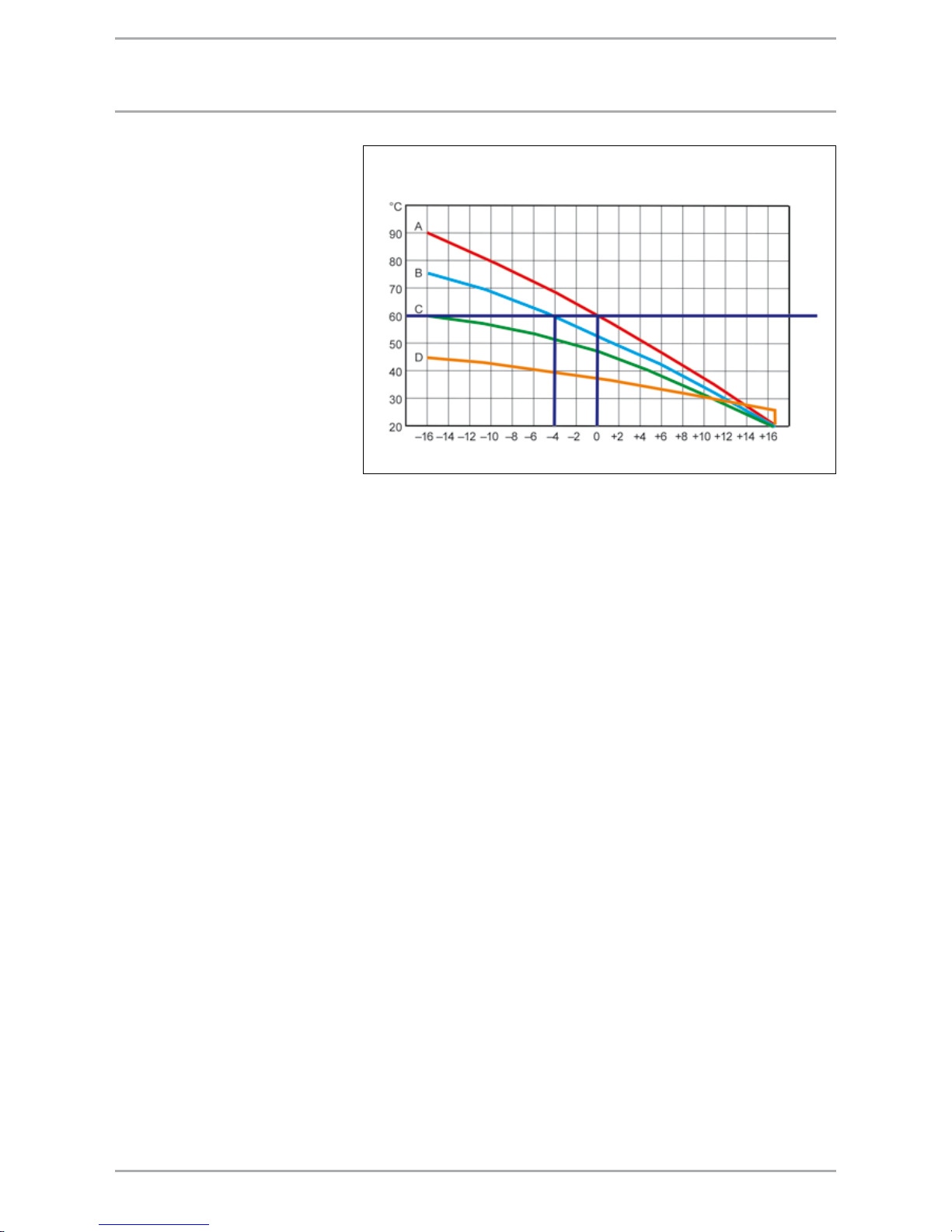

Illustration of the possible operating modes of a heat pump system

mono-mode dual-mode -

alternative

dual-mode partially

parallel

dual-mode - parallel,

mono-energetic

Heat distribution system tv < 60 °C Heat distribution system tv > 60 °C

HP = Heat pump

QN = Heating load

TU = Changeover point

BV = Dual-mode point

ZH = Booster heater

TE = Booster heater start

Page 11

11WWW.STIEBEL-ELTRON.COM

tHE rIgHt HEat pUmp for EvEry applIcatIon

For the use of a water | water heat

pump, groundwater of sufficient

volume and quality must be

available at an economical depth.

You have ideal conditions for a

mono-mode operation, if this heat

source is available to you.

The utilisation of a brine | water

heat pump requires the availability

of property without buildings that

can be used for a geothermal

collector. The property should

be at least two to three times

the area to be heated. These

systems can be operated in monomode in conjunction with a low

temperature heating system.

We help before you start

Take an overview first; our table will

assist you in that. A good analysis,

from the building and heating

technology point of view is crucial.

In new build, generally all kinds of

heat sources can be utilised, i.e. air,

groundwater or ground. You judge

which is the optimum one for you

using the following criteria.

Using an air | water heat pump is

always possible, as the heat source

air is available anywhere. It is

suitable for dual-mode and monoenergetic operation.

Larger systems can be realised by

connecting several heat pumps

together. The electric and hydraulic

connection of brine | water or

water | water heat pumps is easily

achieved with the appropriate

accessories.

Central heating

Specific heat demand 50

W/m² living space, low

temperature heating

system, max. flow

temperature +60 °C

(desirable is +35 °C)

Heat source

Groundwater

exploration via a well

system

Operating mode

mono-mode

Heat pump size subject to

m

2

heated living space

up to 120 m2WPW 7

up to 180 m²

WPW 10

up to 220 m²

WPW 13

up to 300 m²

WPW 18

up to 420 m²

WPW 22 M

up to 440 m²

WPW 26 SET

up to 520 m²

WPW 31 SET

up to 600 m²

WPW 36 SET

up to 720 m²

WPW 40 SET

up to 840 m²

WPW 44 SET

Operating mode

mono-mode

Heat pump size subject to

m

2

heated living space

up to 100 m2WPF/C 5

up to 140 m²

WPF/C 7

up to 180 m²

WPF/C 10

up to 240 m²

WPF/C 13

up to 300 m²

WPF 16

up to 360 m²

WPF 20 SET

up to 420 m²

WPF 23 SET

up to 480 m²

WPF 26 SET

up to 540 m²

WPF 29 SET

up to 600 m²

WPF 32 SET

up to 380 m²

WPF 20

up to 500 m²

WPF 27

up to 800 m²

WPF 40

up t 950 m²

WPF 52

up to 1100 m²

WPF 66

Operating mode

mono-energetic dualmode point -5 °C outside

temperature

Heat pump size subject to

m

2

heated living space

up to 160 m2WPF/C 5

up to 200 m²

WPF/C 7

up to 280 m²

WPF/C 10

up to 340 m²

WPF/C 13

up to 420 m²

WPF 16

up to 520 m²

WPF 20 SET

up to 640 m²

WPF 23 SET

up to 700 m²

WPF 26 SET

up to 760 m²

WPF 29 SET

up to 840 m²

WPF 32 SET

up to 600 m²

WPF 20

up to 760 m²

WPF 27

up to 1200 m²

WPF 40

up to 1560 m²

WPF 52

up to 1880 m²

WPF 66

Operating mode

mono-energetic dualmode point -5 °C outside

temperature

Heat pump size subject to

m

2

heated living space

up to 80 m² WPL 5 N

up to 120 m2WPL 10

up to 180 m²

WPL 13

up to 220 m²

WPL 18

up to 300 m²

WPL 23

up to 360 m²

WPL 33

Operating mode

mono-mode

Heat pump size subject to

m

2

heated living space

up to 200 m2WPL 14 HT

Heat source

Ground

geothermal collectors -

geothermal probe

Heat source

Air

universally available

Page 12

12 WWW.STIEBEL-ELTRON.COM

tHIS coUld bE yoUr SolUtIon

General information

Naturally, all compact heat pumps

from STIEBEL ELTRON can be installed

in all new and existing heating

systems. In many cases, a monomode operation is feasible, so that

no additional, conventional heating

system and associated additional

investment is required, even on

those few exceptionally cold days

of the year. When deciding on the

potential Part of this is of a heat

pump, the heat distribution system

too, and in particular the required

flow temperature, must be given due

consideration. Generally speaking,

low temperature and conventional

heating systems (radiators) can

be supplied by heat pumps. When

developing new systems, allow for

low temperature heating systems with

max. flow temperatures of +55°C.

Existing systems with conventional

heat distribution too can generally be

combined with heat pumps without

requiring major changes. Generally,

such heating systems are designed for

maximum flow temperature of 90 °C.

However, most are oversized making

substantially lower flow temperatures

sufficient on account of subsequently

installed thermal insulation of the

building.

Heat pumps not only provide

heating but also produce hot water

economically.

All STIEBEL ELTRON heating heat

pumps also generate domestic hot

water, e.g. with special accessories,

such as the compact installation

and DHW cylinders. The heat pump

manager provides the automatic

changeover between central heating

and DHW heating operation.

Matching solutions for every

application

For many years, STIEBEL ELTRON

has been producing heat pumps

for all applications. Part of this is

an extensive installation accessory

range, e.g. buffer cylinders, pressure

hoses and control equipment. These

enable an easy and consequently

cost-effective installation. In the

following, two examples of heat pump

installations are shown. Naturally,

alternative installation options are

also feasible.

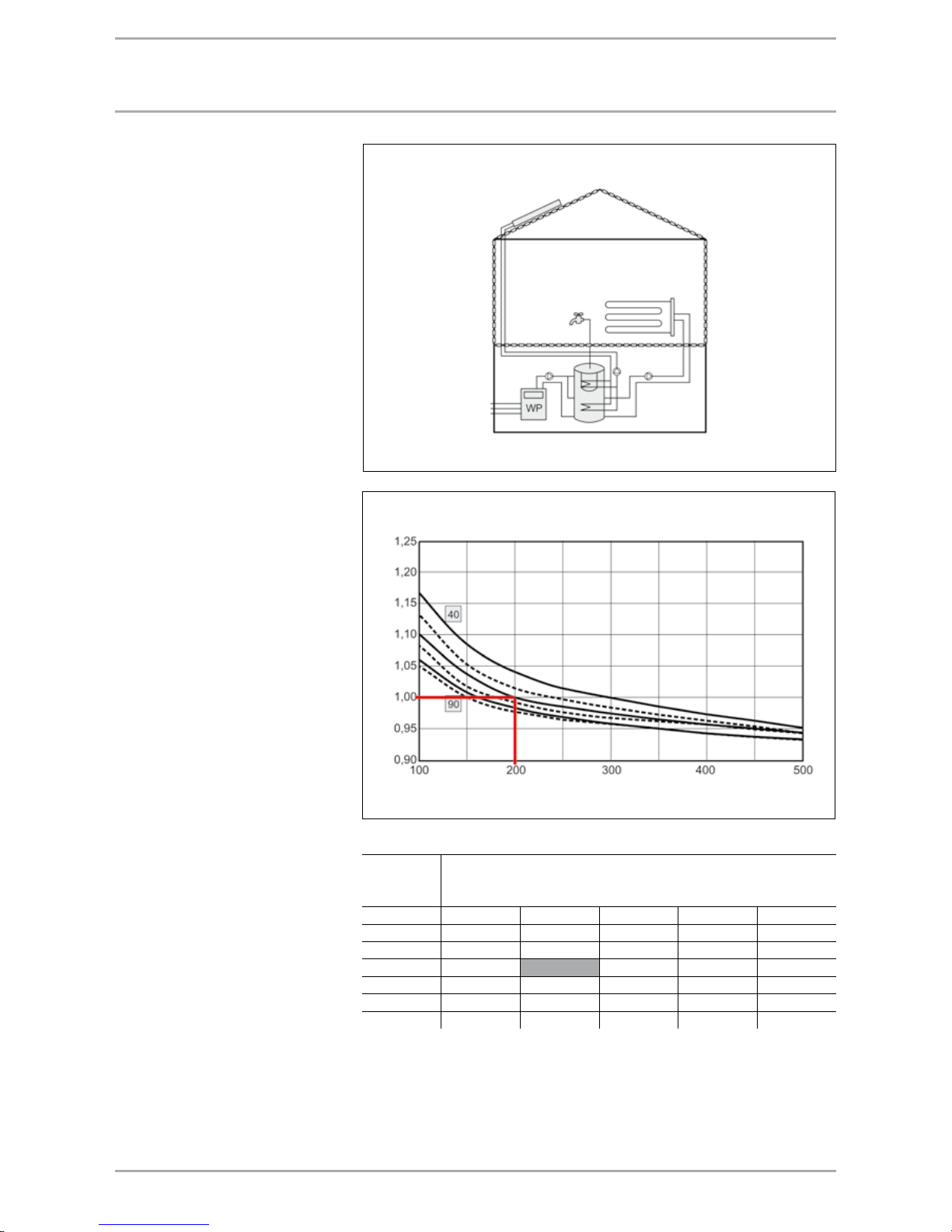

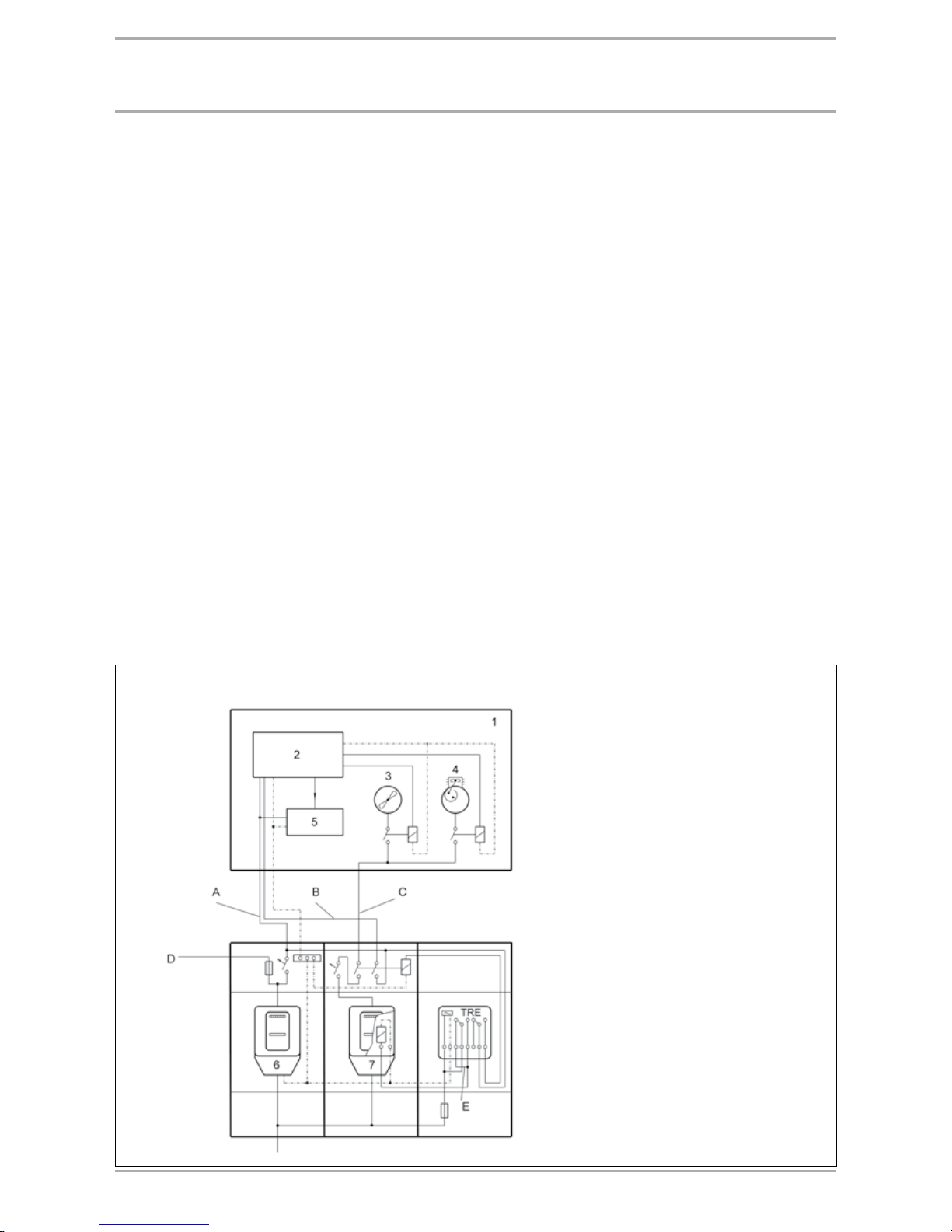

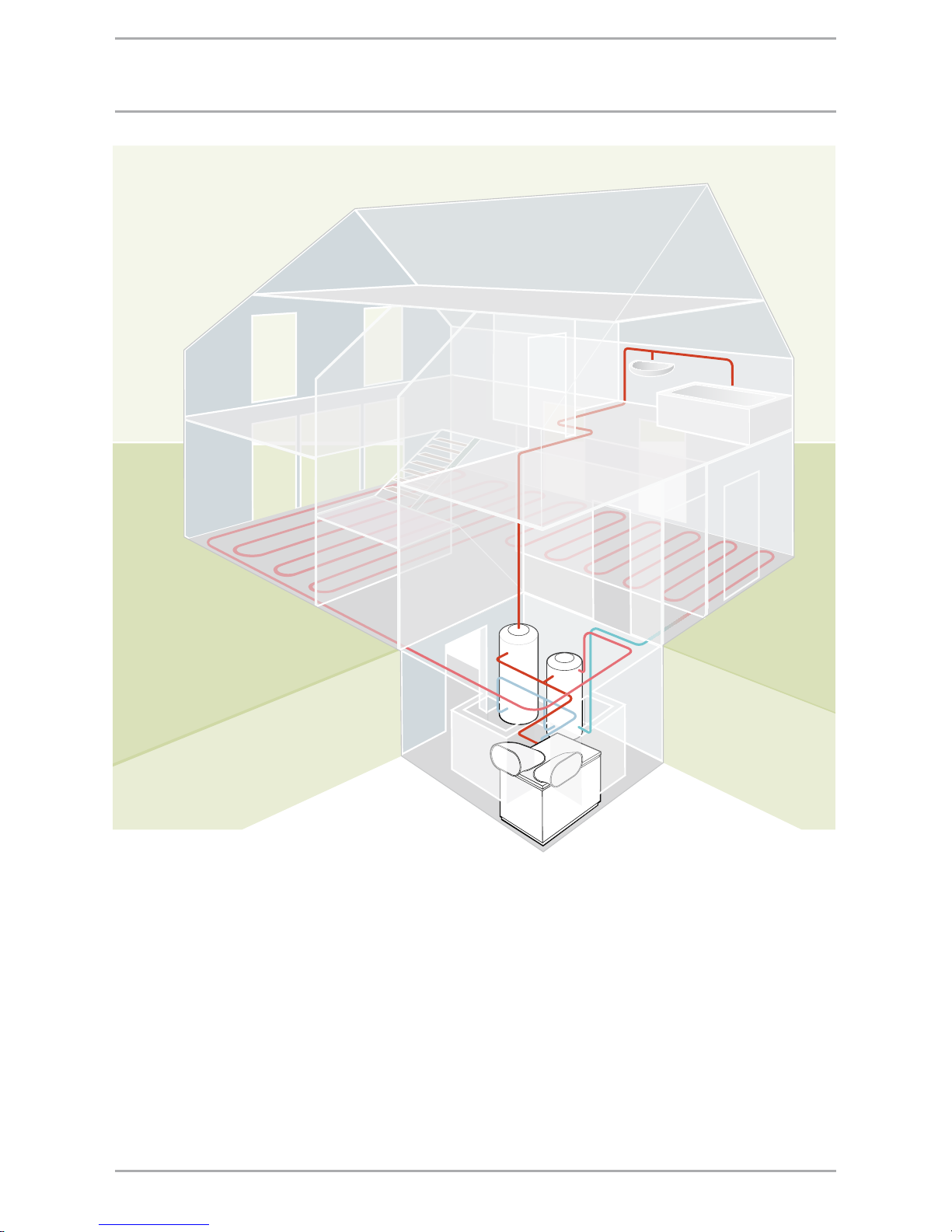

Design example 1

Water|water heat pump

Operating mode: mono-mode

Mono-mode operation is only feasible

in conjunction with a low temperature

heating system (maximum flow

temperature +60 °C). At a specific

heat demand of 50 Watt/m², suitable

heat pumps offer themselves from the

heating system sizes listed in the table

on page 11.

Important information:

A water analysis is part of the first

design phase.

Two results from that analysis are

relevant to the engineering of the

system: free chlorine and chloride.

Iron and manganese content.

Construct the heat pump system in

accordance with the regulations of

your local water board.

The system can be installed

subject to the availability of

groundwater of adequate quantity

and quality.

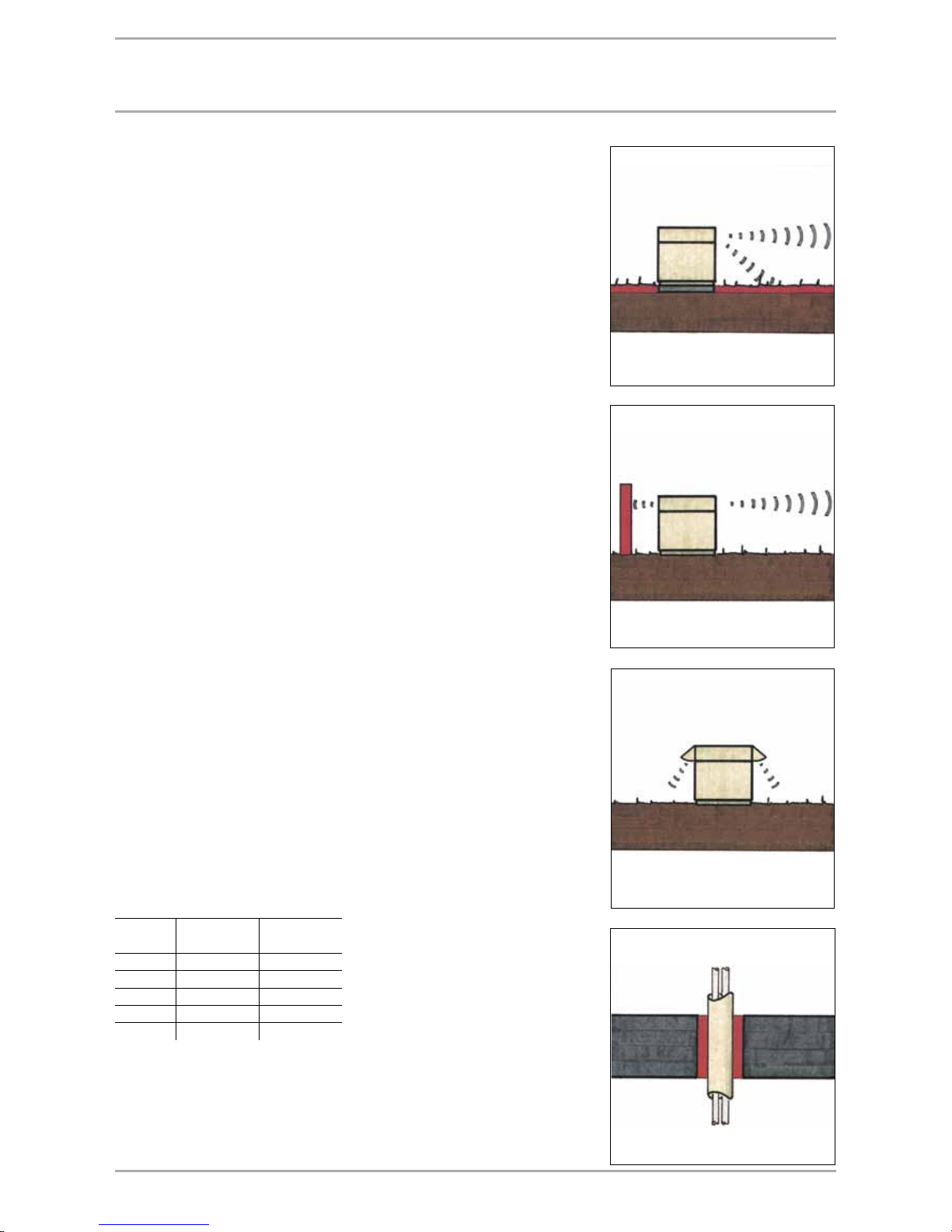

Design example 2

Air|water heat pump without

additional boiler

The mono-energetic air | water heat

pump WPL from STIEBEL ELTRON. As

the description suggest, the heating

system requires no second form of

energy. This heat pump operates with

outside air temperatures down to –20

°C where the outside air provides the

heat source. Between –5 °C and –20

°C, the heating water is additionally

heated by a small electric booster

heater integrated into the heat pump.

STIEBEL ELTRON offers the air | water

heat pump WPL in different versions,

from 10 to 30 kW heating output. This

produces adequate heating for small

to large houses with a living space of

up to approx. 500 m².

Installation information:

The unrestricted air flow through

the inlet and discharge apertures

must be assured at all times.

A thermal "short circuit" between

the inlet and discharge apertures

must be prevented. The direction

of the air flow should be in line

with the main wind direction,

where possible. An installation

in a corner is advisable when

selecting an internal installation.

Design the air ducts as directly and

as short as possible.

Maintain as small a clearance as

possible between heat pump and

house to keep pipe runs short.

Select the installation location so

that no noise pollution is caused,

even though these appliances are

extremely quiet.

The heat pump by necessity

creates condensate that must be

drained off in a suitable manner.

For internal installations via a

drain, possibly with a condensate

pump.

Page 13

13WWW.STIEBEL-ELTRON.COM

EnErgy SavIngS ordEr EnEv [gErmany]

Energy Savings Order

The EU Energy Performance of

Buildings Directive obliged Member

States to translate measures regarding

energy and CO

2

reductions by

2006 into their national laws. The

EnEV 2002/2004 already laid down

requirements for new buildings and

introduced the energy performance

certificate. Adhering to the required

limits meets the energy-technical

requirements for new residential

properties to obtain planning

permission [in Germany]. The

EnEV 2007 introduces the energy

performance certificate for existing

residential buildings as well as for

non-residential buildings. The energy

performance certificate details the

energy-technical quality of a building

and retains its validity for ten years.

EnEV for residential properties

Calculation of the primary energy

demand Q

P

Energy requirements made of

residential buildings and the system

technology employed are considered in

unison. This global approach enables

an overall statement appertaining

the building envelope and the

system technology to be established

and is based on the primary energy

which allows losses during energy

generation and transmission to be

taken into consideration. To calculate

the annual primary energy demand Q

P

and the system expenditure of energy

value e

P

, the annual heat demand

Q

h

of the building and the available

surface area A

N

must be known. The

system expenditure of energy value

e

P

, which has no dimension and

which relates to the primary energy

for heating, ventilation and DHW,

enables the assessment of the entire

system technology. Furthermore,

this parameter forms the basis for

calculating the annual primary energy

demand Q

P

of a building, and describes

the system efficiency. The lower the

system expenditure of energy value,

the greater the scope for the building

envelope, i.e. the physical building

characteristics. This highlights the

importance of the cooperation between

all engineers and all those involved in

the process.

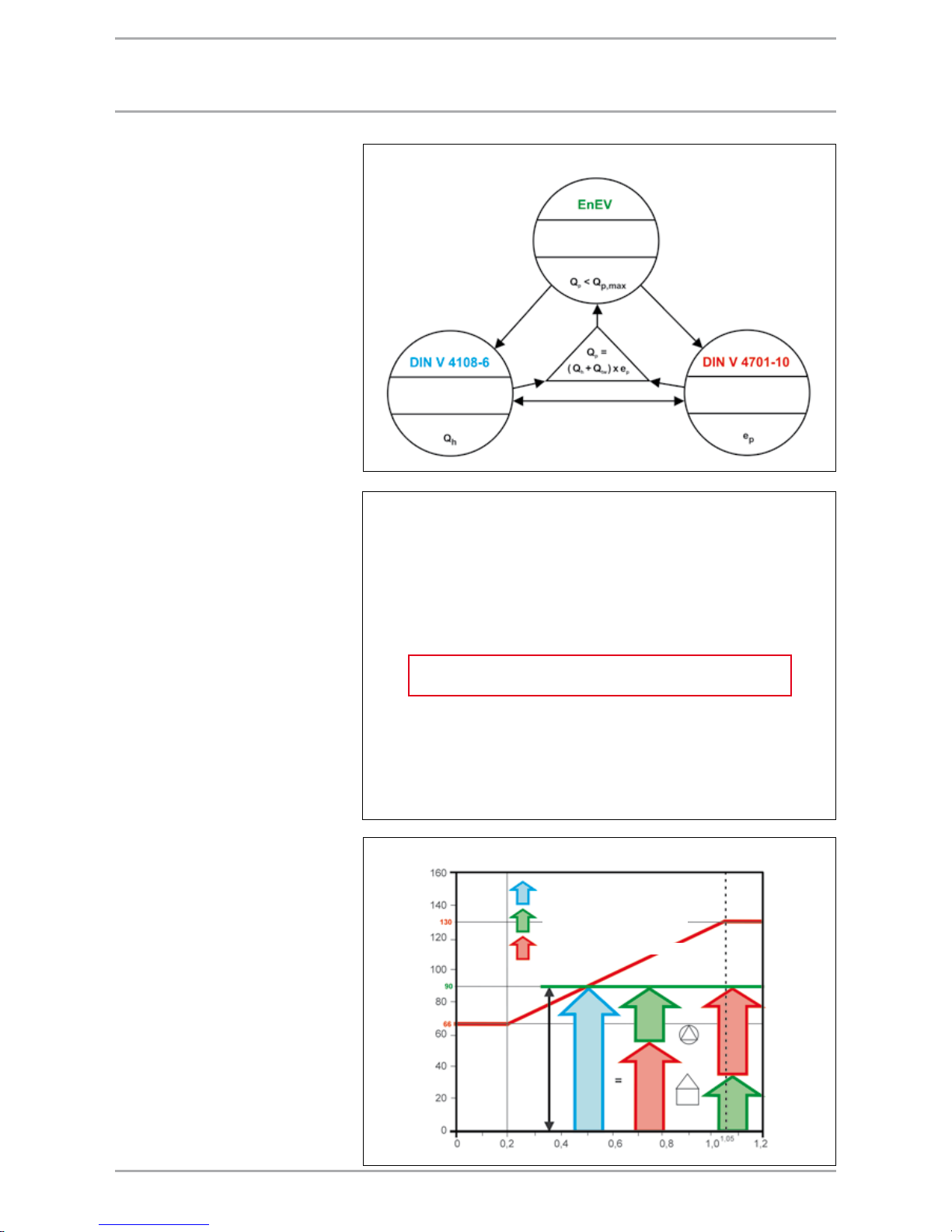

Calculation of the primary energy demand

Effects of standards

Optional compensations between the building and the system

Total energy demand

Energy efficient version

Energy inefficient version

Ratio external surface area / volume (1/m)

Q

p,max

= permissible annual energy demand (kWh/

(m² p.a.)) relative to the area of available space

Energy savings

calculation

System engineering

calculations

Calculating the structural

physical parameters

Max. annual energy demand

Annual heat demand

System expenditure of energy value

Primary energy

demand

Heating energy

demand

DHW

demand

System expenditure

of energy value

* (QtW fixed value 12.5 kWh/m² p.a. acc. to EnEV)

QP = ( Qh + QtW* ) x e

P

( )

= + x

Building

System

Page 14

14 WWW.STIEBEL-ELTRON.COM

EnErgy SavIngS ordEr EnEv [gErmany]

Outline DIN V 18599

Part 1 General statement procedure, terminology,

zoning and assessing fuel types

Part 2 Demand for useable energy for heating and cooling building zones

Part 3 Demand of useable energy for air treatment with energy

Part 4 Useable energy and net energy demand for lighting

Part 5 Net energy demand of heating systems

Part 6 Net energy demand of domestic ventilation systems

and air heating systems for residential buildings

Part 7 Net energy demand for air handling and air conditioning systems

for non-residential buildings

Part 8 Useable energy and net energy demand for DHW heating systems

Part 9 Net and primary energy demand of CHP systems

Part 10 Utilisation framework conditions, climate data

Supplement 1

Examples

System description - reference system technology

Central Low temperature boilers

heating Pressure-jet boilers

Natural gas

Installation outside the thermal envelope

System temperature 55/45 °C

Hydraulically balanced

Twin-pipe heating system

Distribution lines - unheated area

Riser and connection lines, internal

Dp constant

Pump sized in accordance with demand

WWB Common heat generation with the heating system

(central) Indirectly heated cylinder

Installation outside the thermal envelope

with DHW circulation

Dp constant

Pump sized in accordance with demand

Compensation options

The better the equipment performs,

the lower the requirement for thermal

insulation of the building envelope.

The EnEV opens up interesting

compensation options. The optimum

use of primary energy is ensured

by systems such as heat pumps or

domestic ventilation systems with heat

recovery.

System technology

It is generally recommended to

calculate the heat source expenditure

of energy value in accordance

with the detailed procedure in DIN

4701-10 applying manufacturer's

details. Subject to heat source,

performance factors are applied at

different operating conditions that

can sometimes vary significantly from

standard values. This also applies to

the expenditure as a result of losses

and auxiliary energy, for example

caused by components such as

cylinders and auxiliary drives. STIEBEL

ELTRON offers you a calculation

service or the calculation basics and

software free of charge on CD ROM.

EnEV for non-residential buildings

As part of the EnEV 2007 update,

applicable from the 1st October

2007, the EU Energy Performance of

Buildings Directive" for the statement

of non-residential buildings was

adopted in the form of the extensive

standard DIN V 18599 that determines

the calculations principles.

DIN V 18599 - Energy assessment of

buildings

Contrary to the calculation for

residential buildings to DIN 4108

part 6 and DIN 4701 part 10, the

DIN V 18599 provides a statement

not only for the energy demand for

heating, DHW heating and domestic

ventilation, but also for cooling and

lighting. It comprises 10 parts that

are linked through cross-references.

The essential difference when

considering non-residential buildings

is the assessment of the respective

utilisation profile. The primary energy

demands are no longer simply

dependent on the area and volume

covered by the building envelope,

but additionally relate to different

room temperatures, lighting, air

changes, times of utilisation, density

of occupation and the internal heating

loads. A further update of the EnEV

2007 (scheduled for 1 January 2009)

envisages replacement of the currently

applicable method of calculation for

residential buildings through that

specified in the DIN V 18599.

The reference building procedure

To determine the permissible annual

primary energy demand of a nonresidential building, a reference

building is determined that in

geometry, net floor area, orientation

and utilisation profile matches the

building to be assessed perfectly.

The energy quality of the building

envelope of the reference building

is specified in the EnEV via default

transmission heat transfer coefficient

HT ‘. System technology is also

specified for the reference building

covering heating, DHW heating, air

conditioning, air handling technology

and lighting. For this reference

building, in the first instance the

permissible annual primary energy

demand is determined. Then the

actual value is determined applying

the actual building characteristics

and system technology. To meet the

requirements of the EnEV the existing

annual primary energy demand must

be below the maximum permissible

value of the reference building. Heat

pumps are particularly suitable heat

sources for heating and DHW heating,

as they deliver a more favourable

primary energy statement than the

reference system technology. This

enables the EnEV requirements

to be met quite easily, given a

corresponding quality of the building

envelope.

Page 15

15WWW.STIEBEL-ELTRON.COM

The DIN V 18599 provides a

segregation of the overall building

into various zones, since diverse

areas within the building are used for

various purposes and these require

different conditioning. A zone includes

those rooms within a building that

demand similar parameters on

account of their use (temperature,

ventilation, illumination, internal

loads, daylight provision, technical

equipment) with similar framework

conditions. Every zone has one of

33 programmed utilisation profiles

applied to it (e.g. office, hotel room,

kitchen, toilet, transit areas). The

energy demand for heating and

cooling must be defined separately

for each conditioned zone. Up to

a proportion of 3% of the overall

available floor area, living space may

be appropriately assigned to different

zones than those to which they should

be designated, as long as the internal

loads are not substantially different.

To simplify the calculation process it is

permissible to determine the annual

primary energy demand in accordance

with a single zone model for the

following types of building: Schools,

kindergartens, office buildings, hotels

(without internal swimming pool),

pubs and commercial premises.

However, different framework

conditions must still be applied.

Main areas of use and passages must

account for at least one third of the

total area; the building must only be

equipped with a central system used

to provide DHW and central heating

and must not be cooled. Illumination

must largely correspond to the

reference lighting technology.

The calculations according to DIN V

18599 are extensive and can, because

of the interactions that occur can

only be resolved by iterative means,

only be done with computer-aided

support. STIEBEL ELTRON offers

software solutions for this calculation.

This enables complex calculations

to be carried out, and even includes

manufacturer's data. In this

connection, our specialist department

offers support in all areas concerning

the Energy Savings Order 2007.

EnErgy SavIngS ordEr EnEv [gErmany]

Primary energy demand for non-residential buildings

Primary energy

demand = heating + cooling + steam + DHW + light + auxiliary energy

QP = Q

P.h

+ Q

P.c +

Q

P.m

+ Q

P.w +

Q

P.l +

Q

P.aux

Page 16

16 WWW.STIEBEL-ELTRON.COM

ExpEndItUrE of EnErgy valUES of HEat pUmpS

EnEV – calculation to DIN V 4701-10

The EnEV provides three possible

certification processes:

Diagram process

Tabular process

Detailed process

For the detailed certification process,

verification can be provided using

standard values or manufacturer's

details. Generally, the certification

process with standard values is

sufficient for heat pumps, since their

high efficiency level allows results to

fall below the required expenditure of

energy value.

Where better expenditure of energy

values are demanded by more

stringent subsidy stipulations, e.g.

KFW 40 or KFW 60, these may possibly

be achieved with verification based on

the manufacturer's details.

IT programs or the calculation process

of the EnEV should be applied where

manufacturer's details are to be used.

For calculating the ep figure, STIEBEL

ELTRON offers the software "Energy

efficiency in residential buildings".

Where the certification utilises the

tabular process, draw the expenditure

of energy value eg from the

DIN V 4701-10 according to "Table

C3-4c expenditure of energy value eg

and drive auxiliary energy qg, HE for

heat pumps with electric drive".

Electrically operated heating heat pumps

The heat generation expenditure of energy value is calculated using the annual

performance factor in accordance with the following equation:

e

H,g

= 1 : β

HP

e

H,g

= Expenditure of energy value for the heat pump

β

HP

= Seasonal performance factor of the heat pump, calculated subject to

type of heat pump

Brine|water heat pumps

The seasonal performance factor of brine | water heat pumps is calculated in

accordance with the following equation:

β

HP

= εN x Fϑ x F

∆ϑ

βHP = Annual performance factor of heat pump

ε

N

= Coefficient of performance to EN 14511 at B0/W35

F

ϑ

= Correction factor to table 5.3.7

F

∆ϑ

= Correction factor to table 5.3.8

Water|water heat pumps

The annual performance factor of water|water heat pumps is calculated in

accordance with the following equation:

β

HP

= εN x Fϑ x F

∆ϑ

βHP = Annual performance factor of heat pump

ε

N

= Coefficient of performance to EN 14511 at W10/W35

F

ϑ

= Correction factor to table 5.3.7

F

∆ϑ

= Correction factor to table 5.3.8

Air|water heat pumps

The annual performance factor of air|water heat pumps is calculated in

accordance with the following equation:

βHP = (ε

N

(A-7/W35)

x Fϑ + ε

N

(A2/W35)

x F

ϑ2

+ ε

N

(A10/W35)

x F

ϑ10

) x F

∆ϑ

βHP = Annual performance factor of heat pump

ε

N

= Coefficient of performance to EN 14511 at A-7/W35

ε

N

= Coefficient of performance to EN 14511 at A2/W35

ε

N

= Coefficient of performance to EN 14511 at A10/W35

F

ϑ-7

= Correction factor to table 5.3.10

F

ϑ2

= Correction factor to table 5.3.10

F

ϑ10

= Correction factor to table 5.3.10

F

∆ϑ

= Correction factor to table 5.3.8

Page 17

17WWW.STIEBEL-ELTRON.COM

ExpEndItUrE of EnErgy valUES of HEat pUmpS

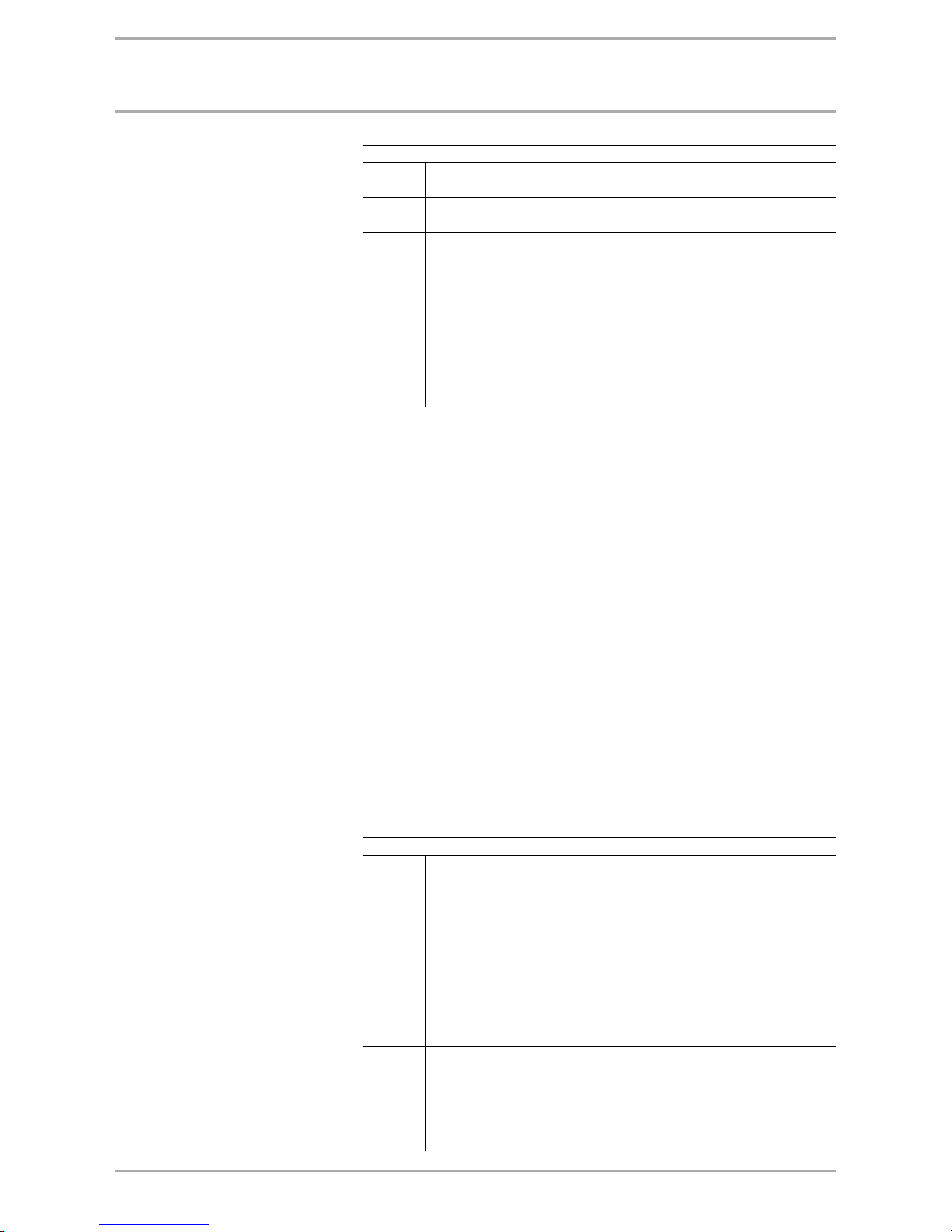

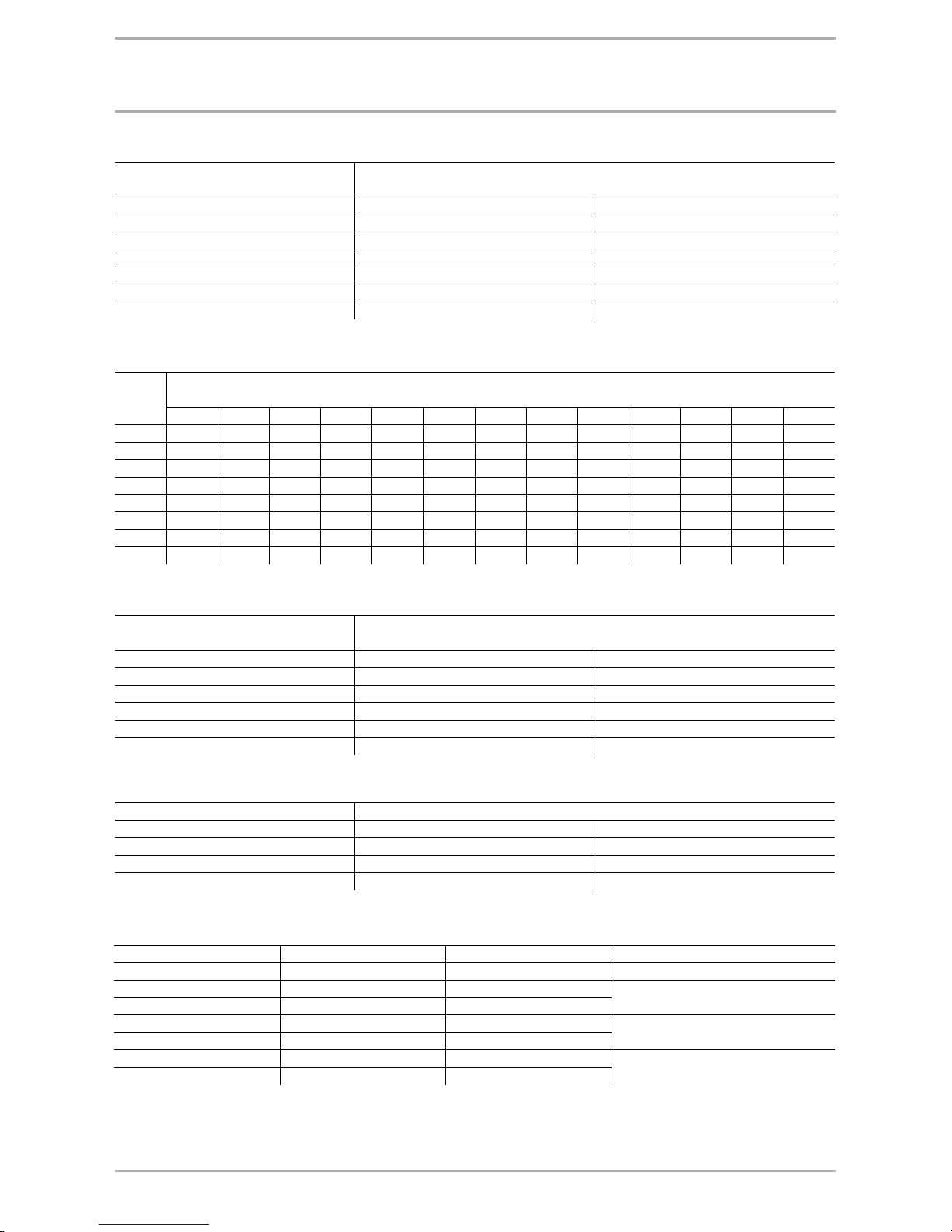

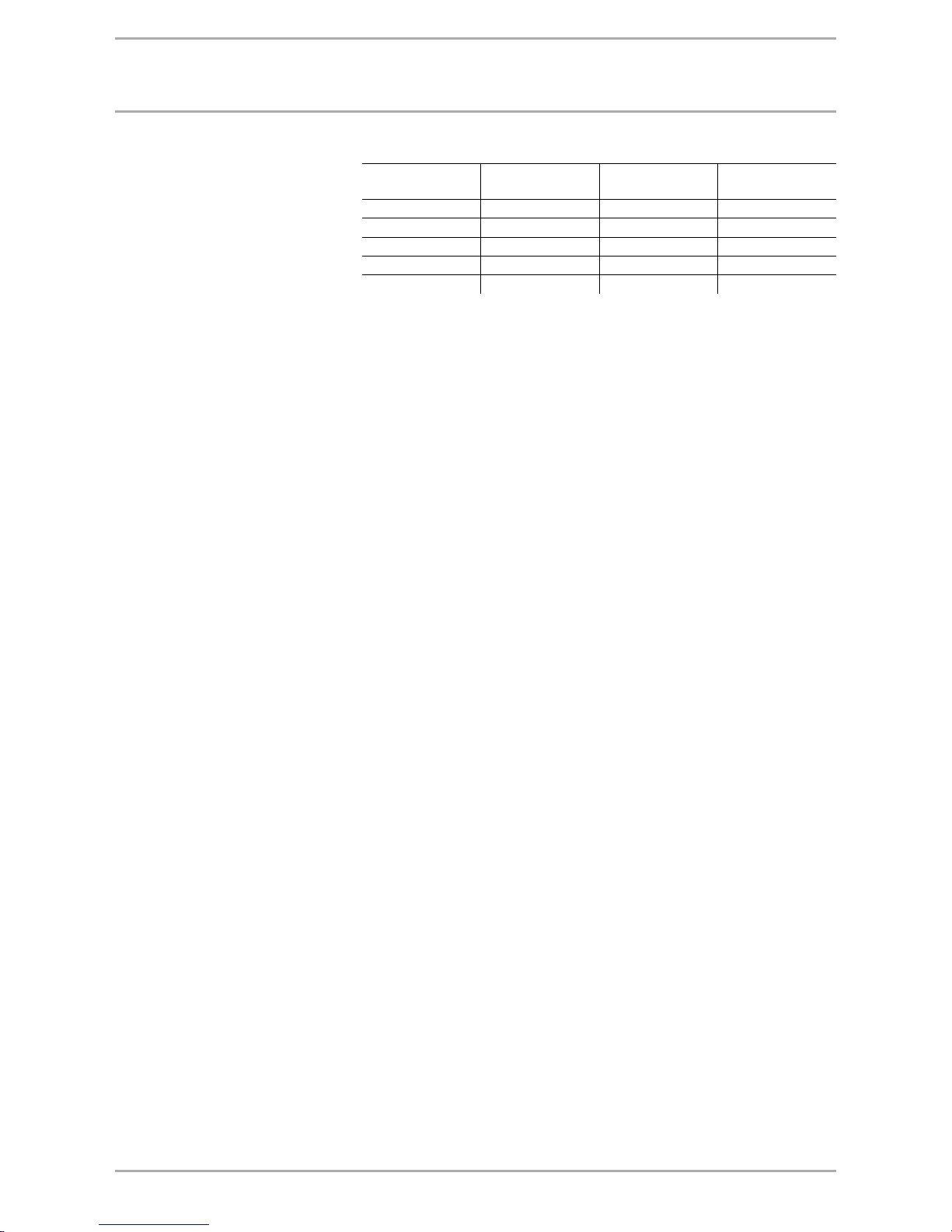

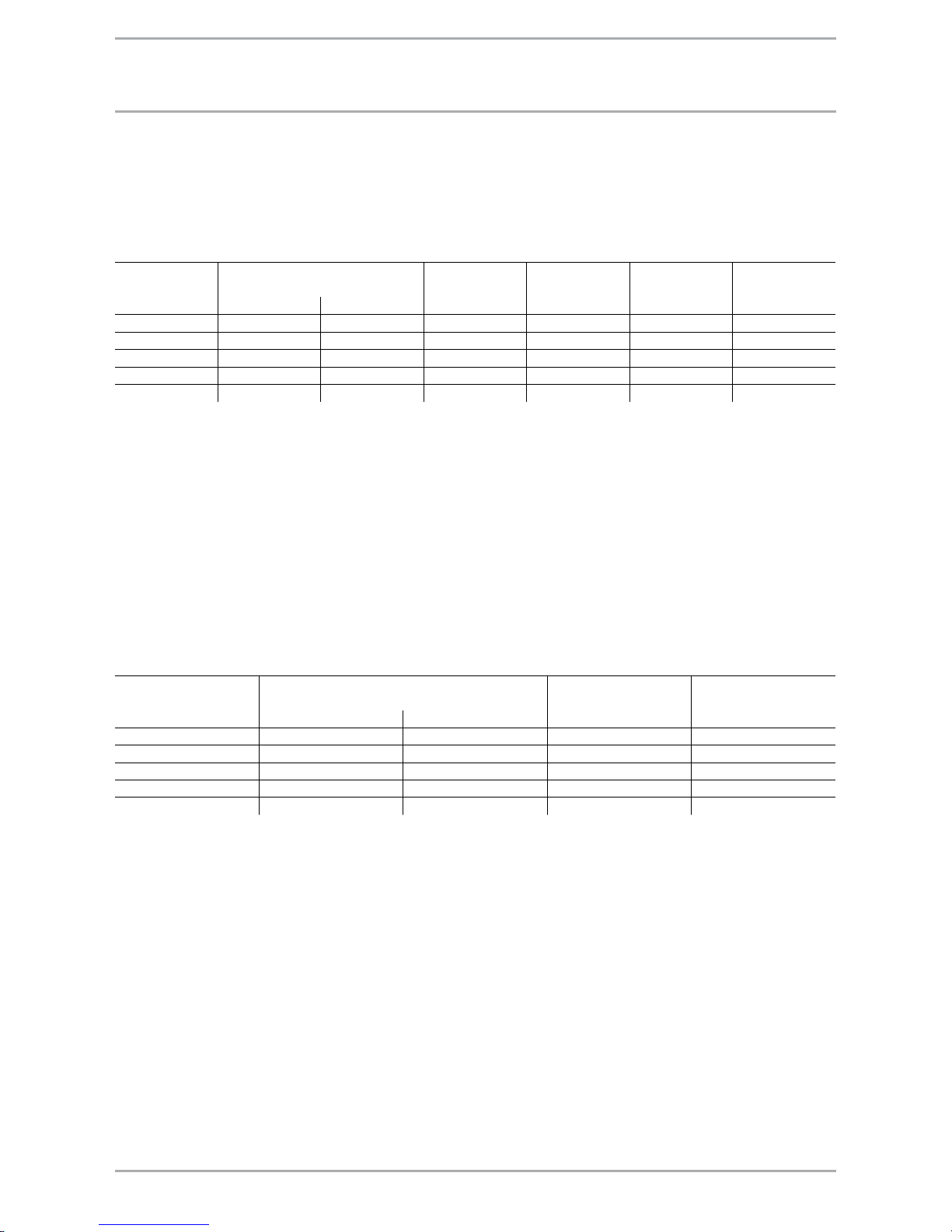

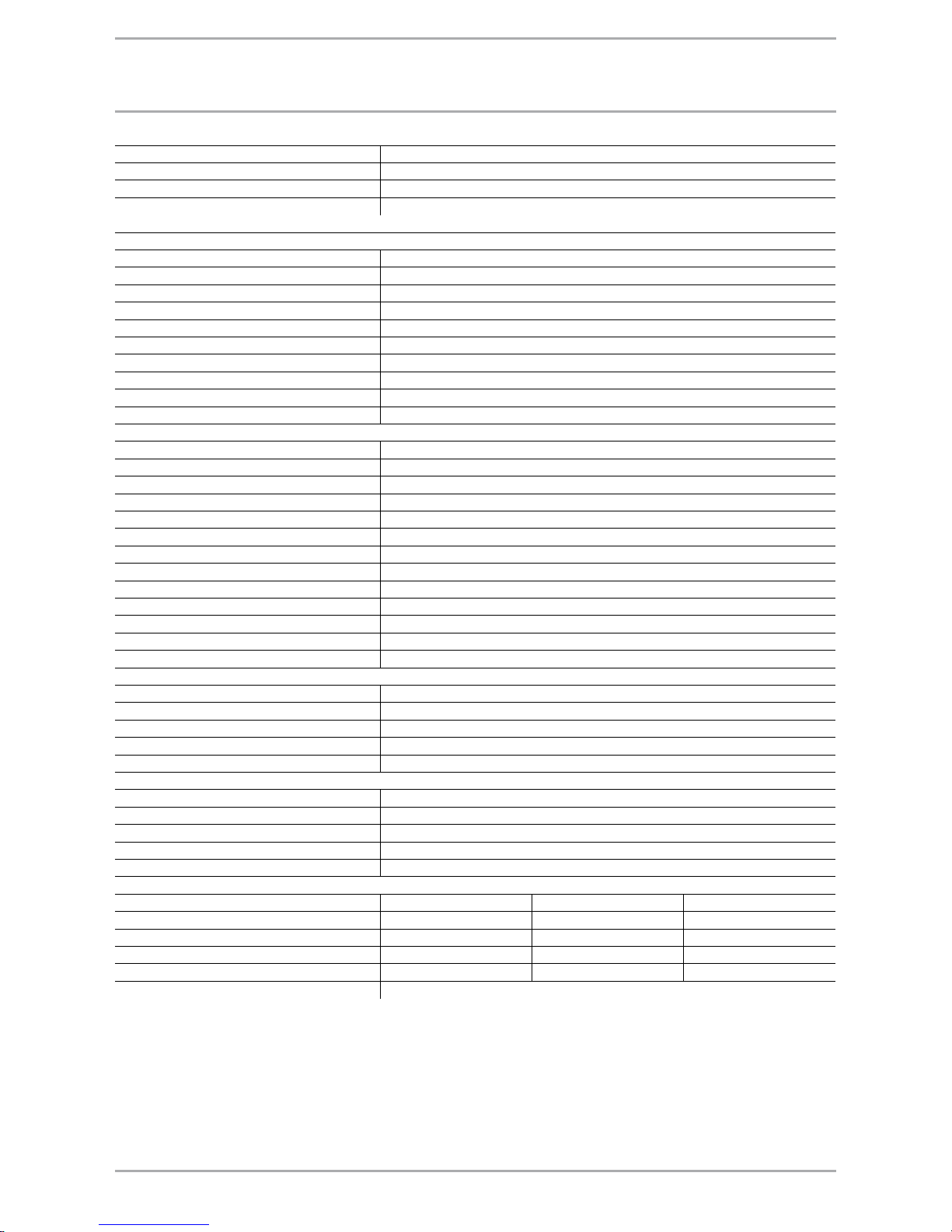

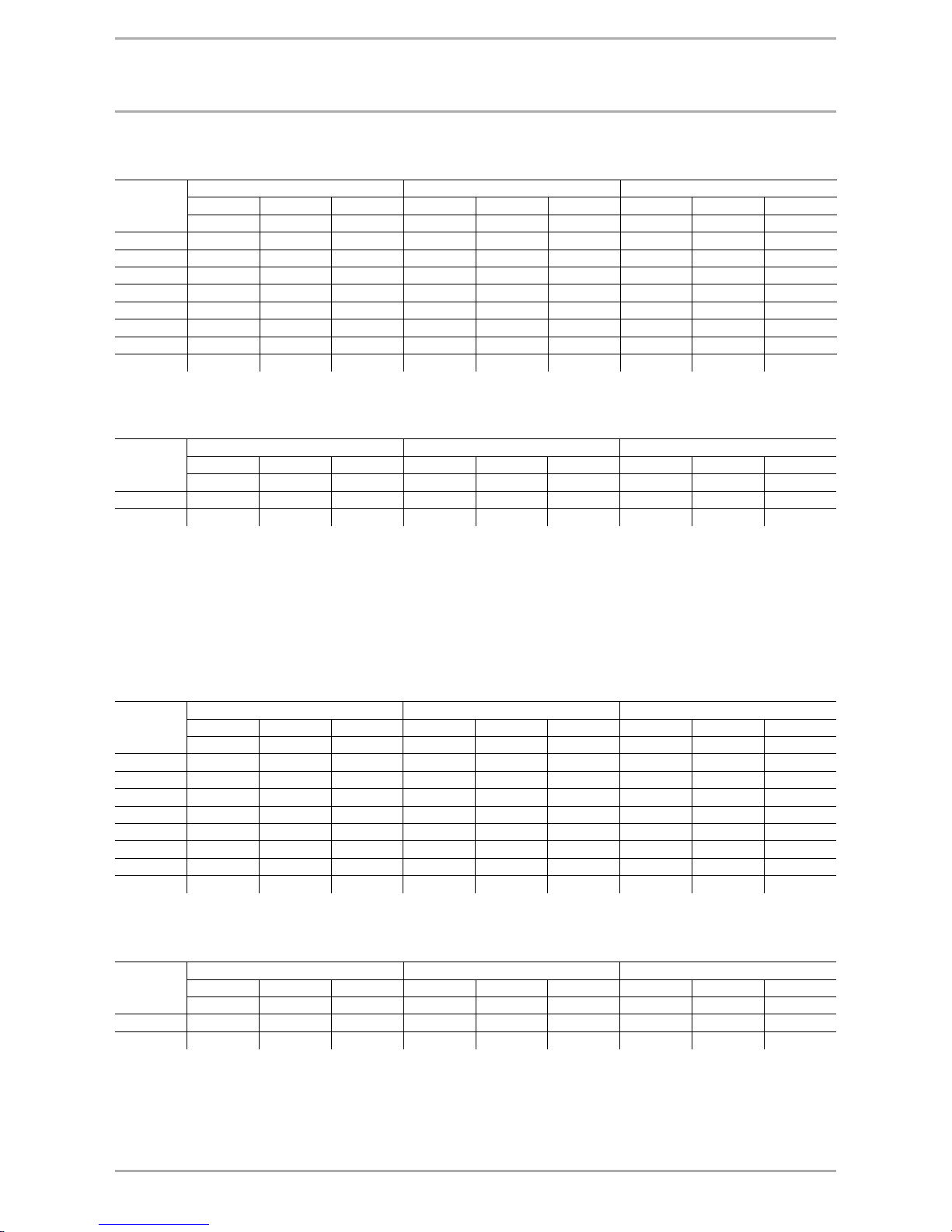

Table 5.3.8 - Correction factors FDϑ for deviating temperature differentials at the condenser

Operation

DϑB

(K)

Temperature differential at the test bed DϑM (K) DIN EN 255

3 4 5 6 7 8 9 10 11 12 13 14 15

3 1.000 0.990 0.980 0.969 0.959 0.949 0.939 0.928 0.918 0.908 0.898 0.887 0.877

4 1.010 1.000 0.990 0.980 0.969 0.959 0.949 0.939 0.928 0.918 0.908 0.898 0.887

5 1.020 1.010 1.000 0.990 0.980 0.969 0.959 0.949 0.939 0.928 0.918 0.908 0.898

6 1.031 1.020 1.010 1.000 0.990 0.980 0.969 0.959 0.949 0.939 0.928 0.918 0.908

7 1.041 1.031 1.020 1.010 1.000 0.990 0.980 0.969 0.959 0.949 0.939 0.928 0.918

8 1.051 1.041 1.031 1.020 1.010 1.000 0.990 0.980 0.969 0.959 0.949 0.939 0.928

9 1.061 1.051 1.041 1.031 1.020 1.010 1.000 0.990 0.980 0.969 0.959 0.949 0.939

10 1.072 1.061 1.051 1.041 1.031 1.020 1.100 1.000 0.990 0.980 0.969 0.959 0.949

Table 5.3.7 - Correction factor Fϑ for brine | water heat pumps

Minimum brine temperature at the

evaporator inlet (°C)

Heating circuit design temperature

35°C / 28°C 55 °C / 45 °C

2 1.113 0.917

1 1.100 0.904

0 1.087 0.890

–1 1.074 0.877

–2 1.062 0.864

–3 1.051 0.852

Table 5.3.9 - Correction factor Fϑ for water | water heat pumps

Minimum water temperature at the

evaporator inlet (°C)

Heating circuit design temperature

35°C / 28°C 55 °C / 45 °C

12 1.106 0.892

11 1.087 0.873

10 1.068 0.853

9 1.049 0.834

8 1.030 0.815

Table 5.3.10 - Correction factor Fϑ for air | water heat pumps

Outside air inlet (°C) Heating circuit design temperature

35°C / 28°C 55 °C / 45 °C

–7 0.103 0.080

+2 0.903 0.745

+10 0.061 0.053

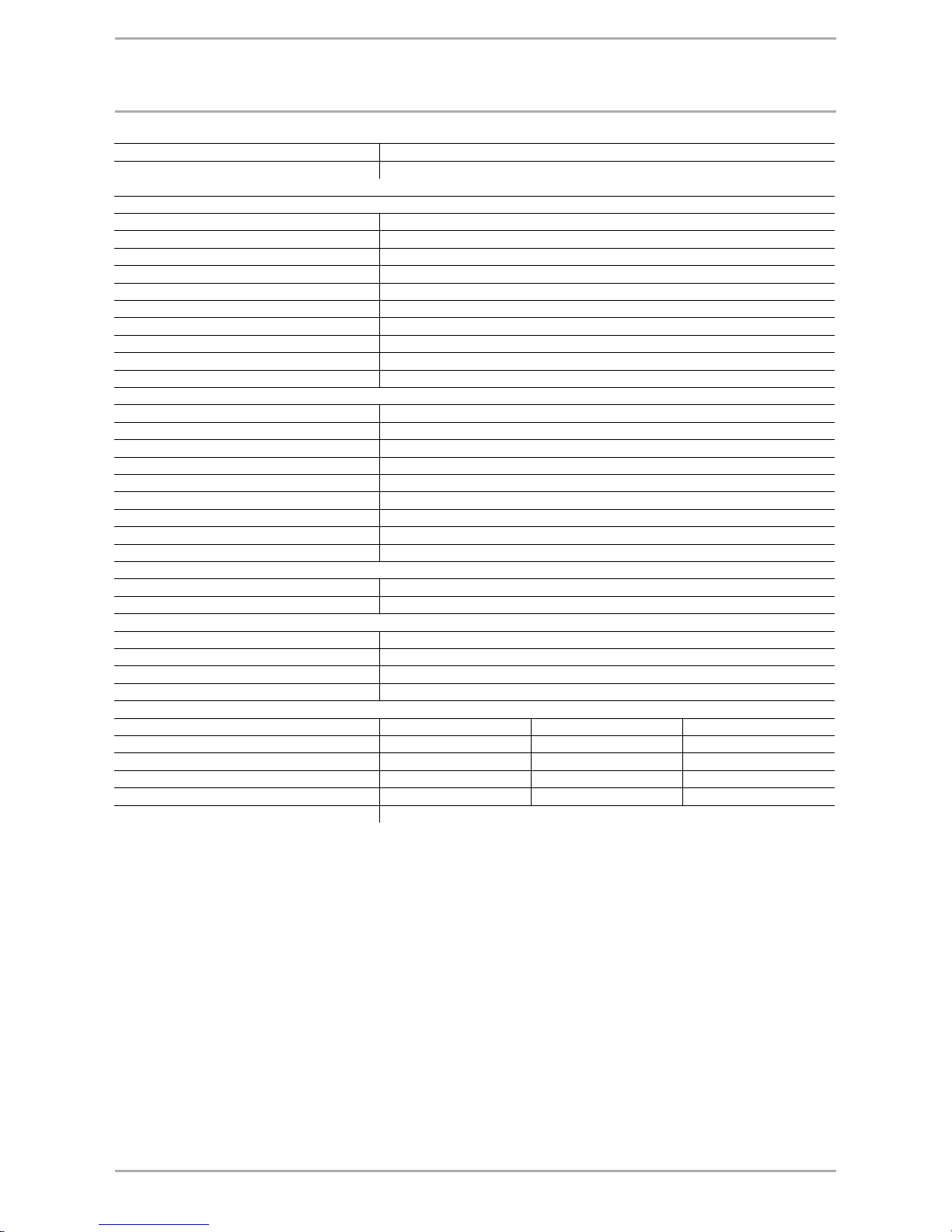

Table C3-4c - Expenditure of energy value eg and auxiliary drive energy qgHE for electric heat pumps

Electric heat pump Heating circuit temperature Expenditure of energy value Auxiliary energy

e

g qgHE (kWh/m² p.a.)

Water/Water 55 °C / 45 °C 0.23

3.2 x A

N

-0.1

35°C / 28°C 0.19

Ground/Water 55 °C / 45 °C 0.27

1.9 x A

N

-0.1

35°C / 28°C 0.23

Air/Water 55 °C / 45 °C 0.37

0

35°C / 28°C 0.30

Page 18

18 WWW.STIEBEL-ELTRON.COM

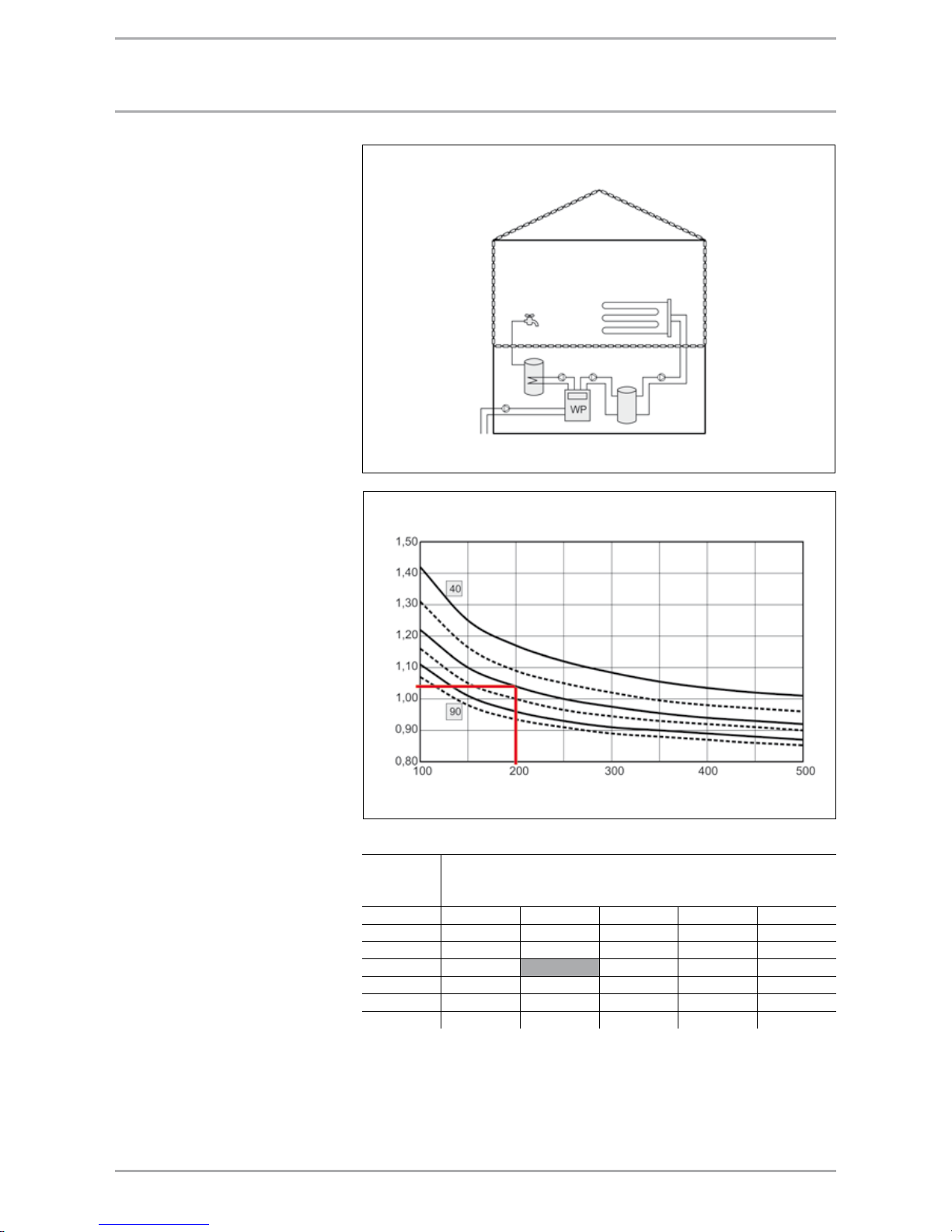

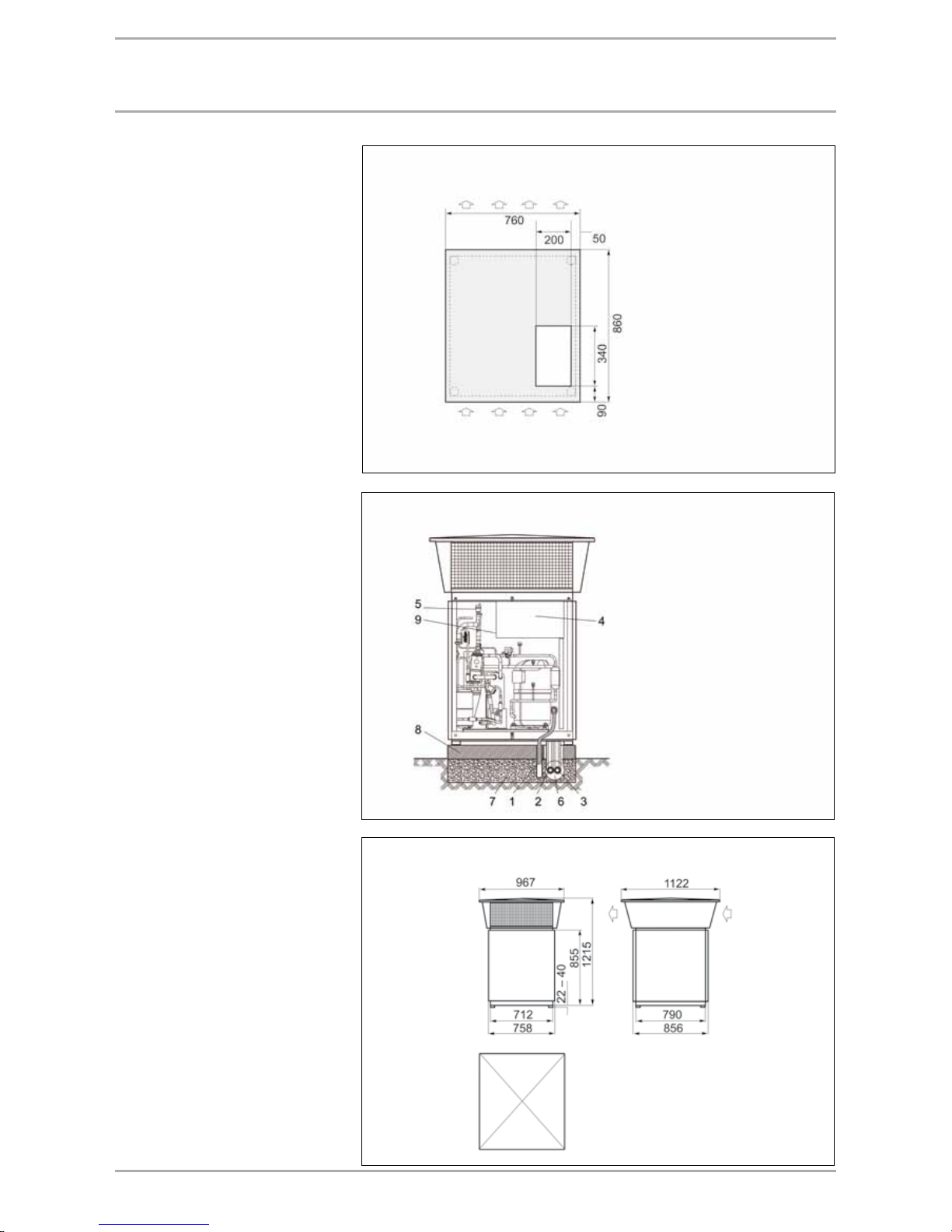

ExamplE 1: brInE | watEr HEat pUmp

Diagram system expenditure of energy value e

p

System description

Brine | water heat pump WPF with 100

litre buffer cylinder and 300 litre DHW

cylinder

DHW heating

Centralised provision; no DHW

circulation; distribution outside the

thermal envelope; indirectly heated

cylinder; installation outside the

thermal envelope; heating heat pump

brine|water powered by electricity.

Ventilation

No mechanical ventilation.

Central heating

Integral heating surface (e.g.

underfloor heating system); individual

room regulation with two-point

controller, switching differential

Xp=2 K; heating system design 35/28

°C; centralised system; horizontal

distribution outside the thermal

envelope, lines running internally;

regulated pump; buffer cylinder

installed; installation outside the

thermal envelope; heating heat pump

brine | water powered by electricity.

Example:

Annual heat demand

60 kWh/m² p.a.

Heated living space 200 m²

Result:

System expenditure of energy value =

1.04

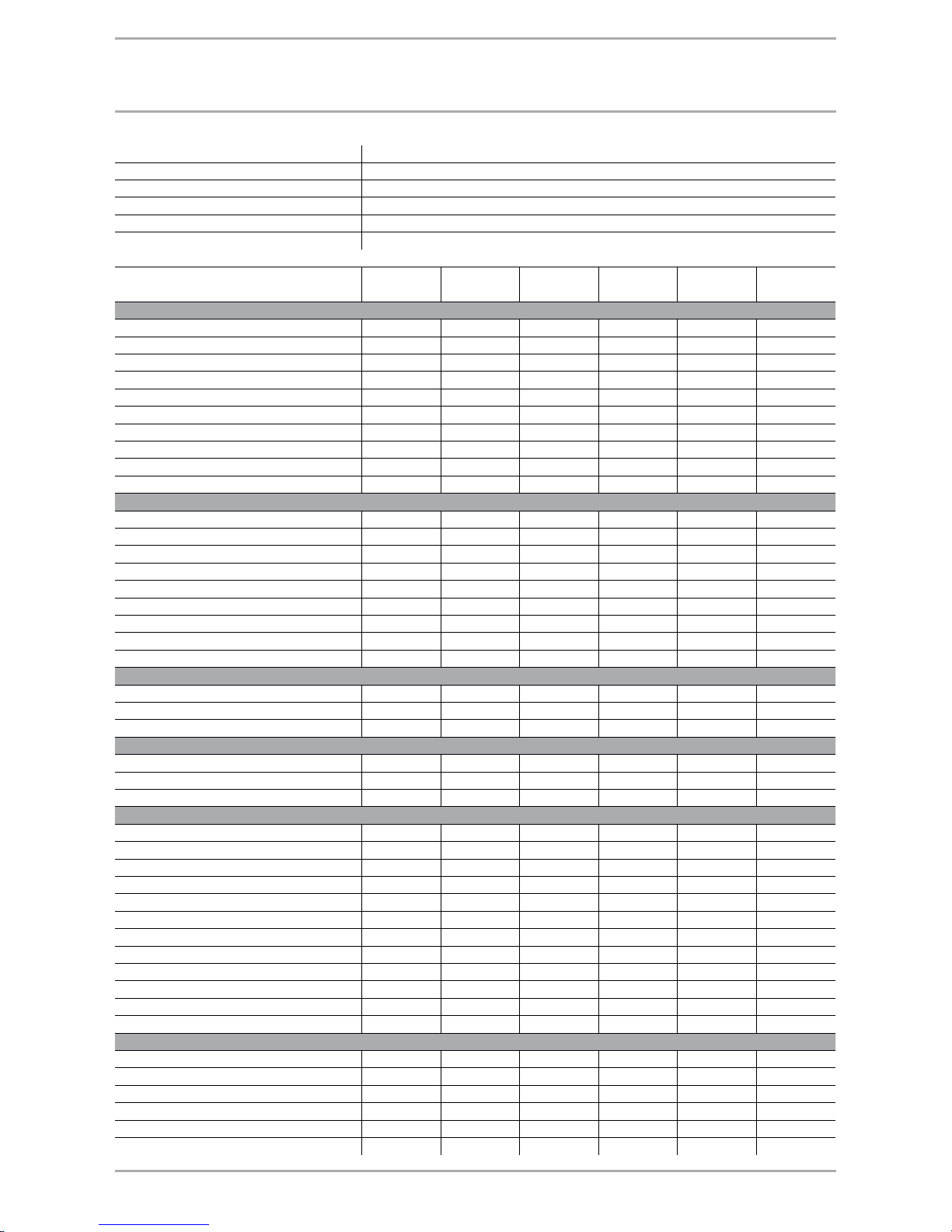

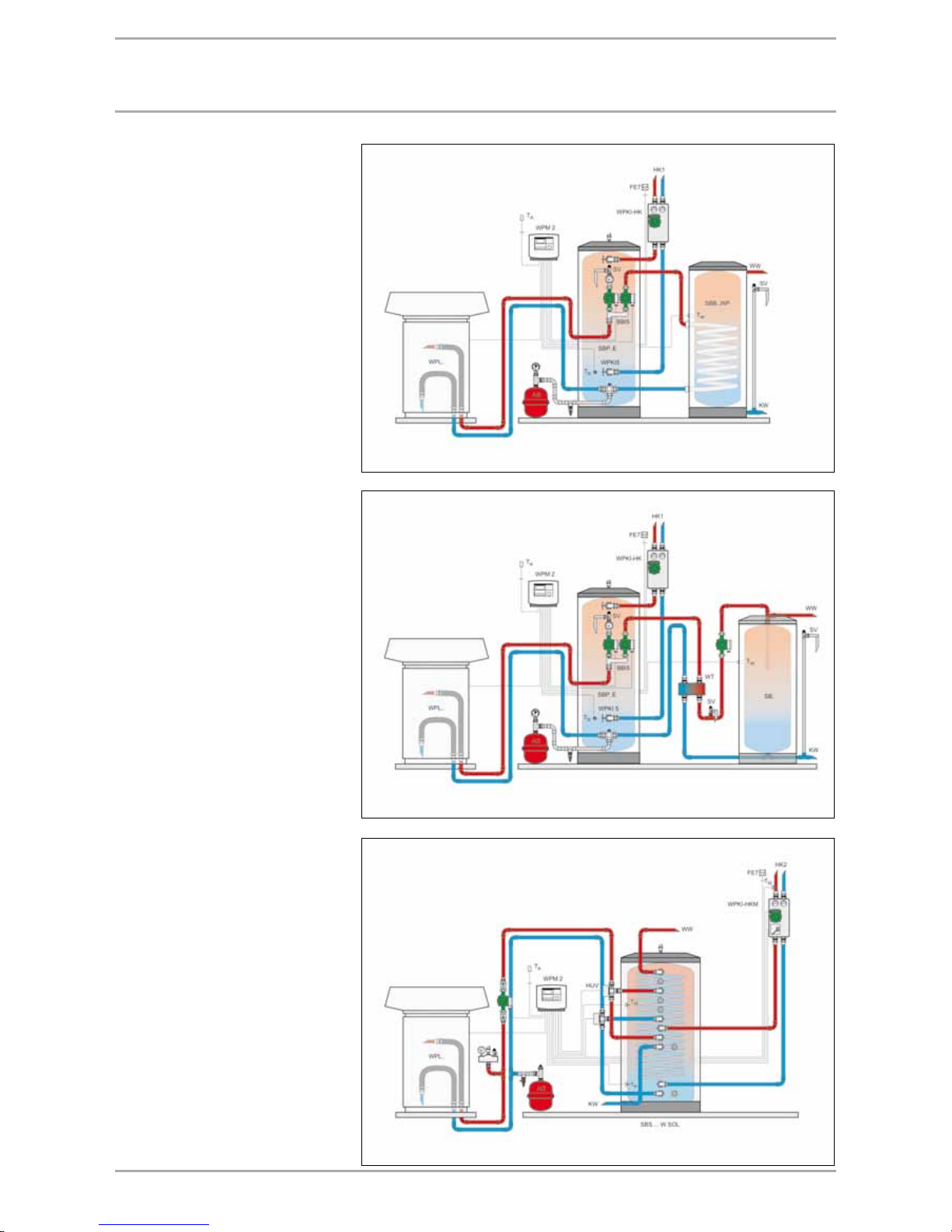

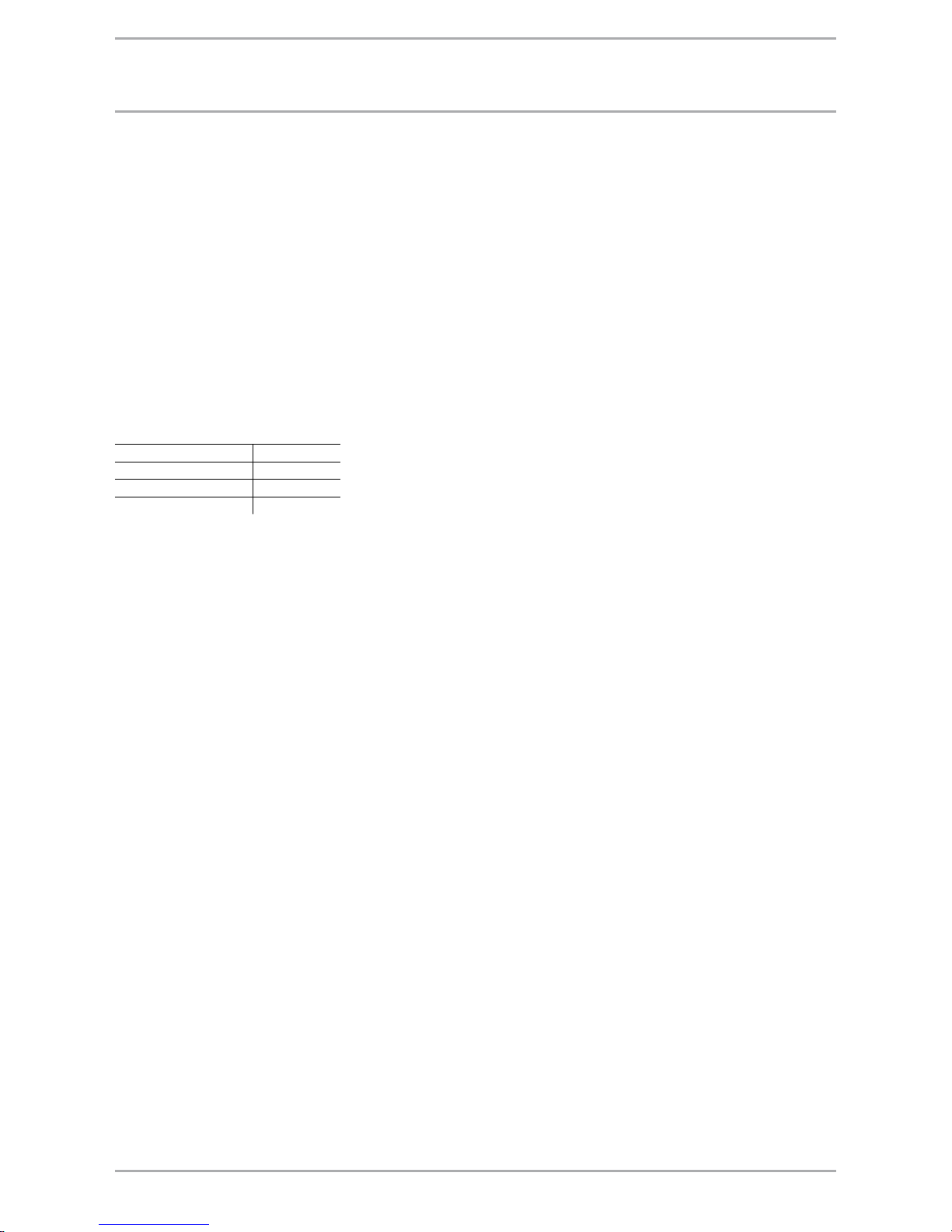

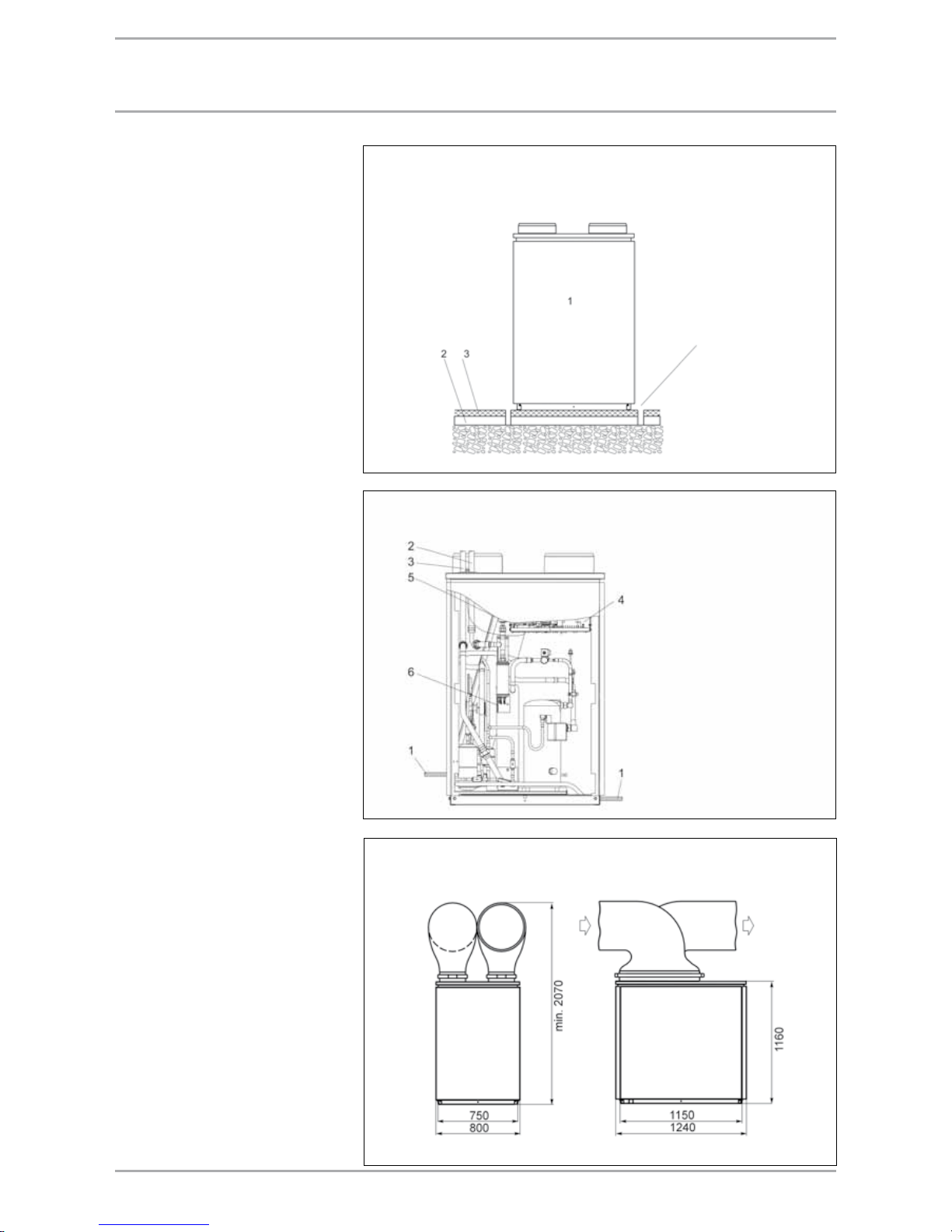

System layout

Diagram system expenditure of energy value e

p

Annual

heating

demand

Heated available area in A

N

in m²

kWh/m² p.a. 100 200 300 400 500

40 1.42 1.17 1.08 1.04 1.01

50 1.31 1.09 1.02 0.98 0.96

60 1.22 1.04 0.98 0.95 0.92

70 1.16 1.00 0.94 0.93 0.90

80 1.11 0.96 0.91 0.89 0.87

90 1.07 0.94 0.89 0.87 0.86

Underfloor heating

system

Ground

Heated available area in AN in m²

System expenditure of energy value e

p

Page 19

19WWW.STIEBEL-ELTRON.COM

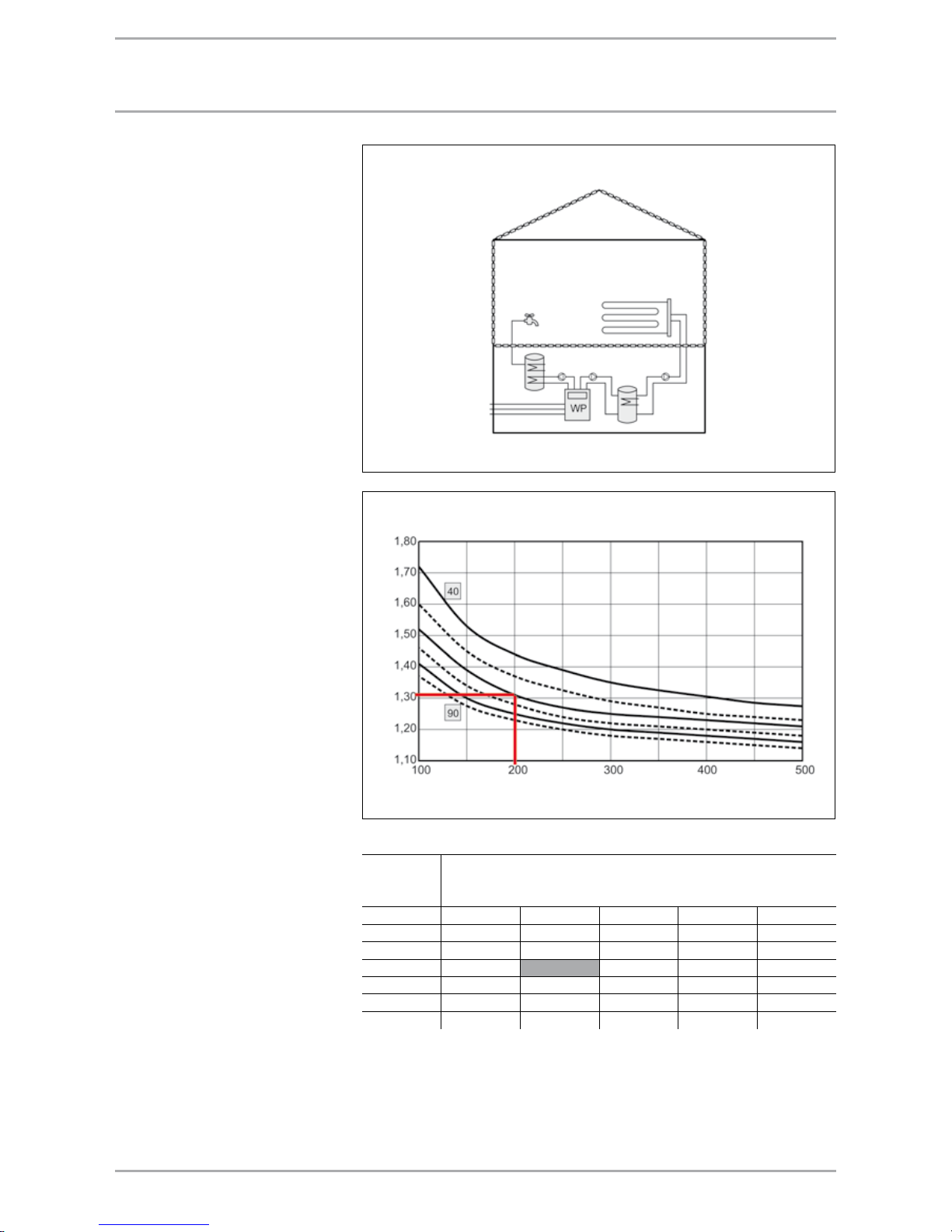

ExamplE 2: aIr | watEr HEat pUmp

Diagram system expenditure of energy value e

p

System description

Air | water heat pump WPL with 200

litre buffer cylinder and 300 litre DHW

cylinder

DHW heating

Centralised provision; no DHW

circulation; distribution outside the

thermal envelope; indirectly heated

cylinder; installation outside the

thermal envelope; heating heat pump

brine | water powered by electricity;

peak load: Electric heater rod.

Ventilation

No mechanical ventilation.

Central heating

Integral heating surface (e.g.

underfloor heating system);

individual room regulation with

two-point controller, switching

differential Xp=2 K; heating system

design 35/28°C; centralised system;

horizontal distribution outside the

thermal envelope, lines running

internally; regulated pump; buffer

cylinder installed; installation outside

the thermal envelope; heating

heat pump air | water powered by

electricity. Electric heater rod.

Example:

Annual heat demand

60 kWh/m² p.a.

Heated living space 200 m²

Result:

System expenditure of energy value =

1.31

System layout

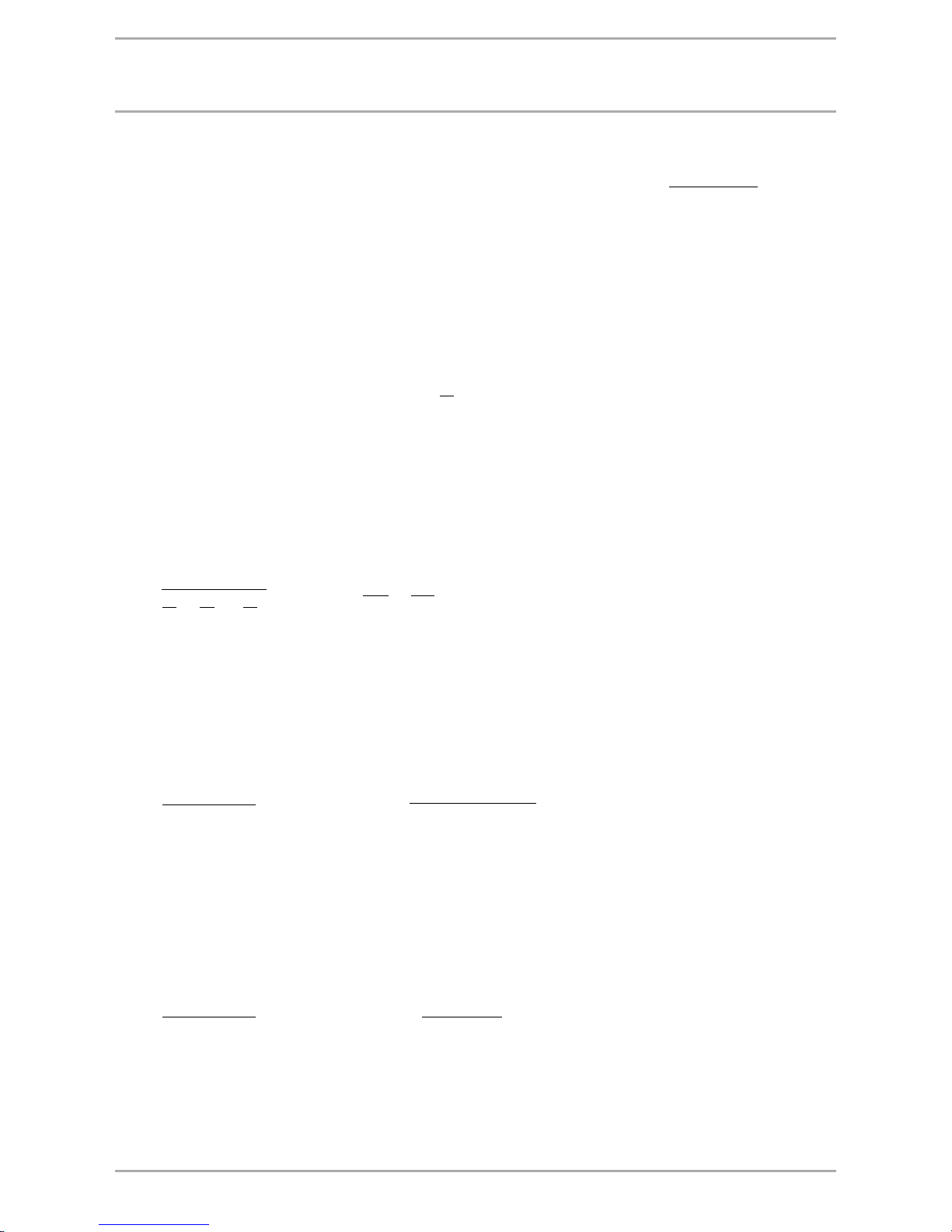

Diagram system expenditure of energy value e

p

Annual

heating

demand

Heated available area in A

N

in m²

kWh/m² p.a. 100 200 300 400 500

40 1.72 1.44 1.35 1.30 1.27

50 1.60 1.37 1.29 1.25 0.23

60 1.52 1.31 1.25 1.23 1.20

70 1.46 1.28 1.22 1.20 1.17

80 1.41 1.25 1.20 1.18 1.16

90 1.37 1.23 1.18 1.16 1.14

Underfloor heating

system

Air

Heated available area in AN in m²

System expenditure of energy value e

p

Page 20

20 WWW.STIEBEL-ELTRON.COM

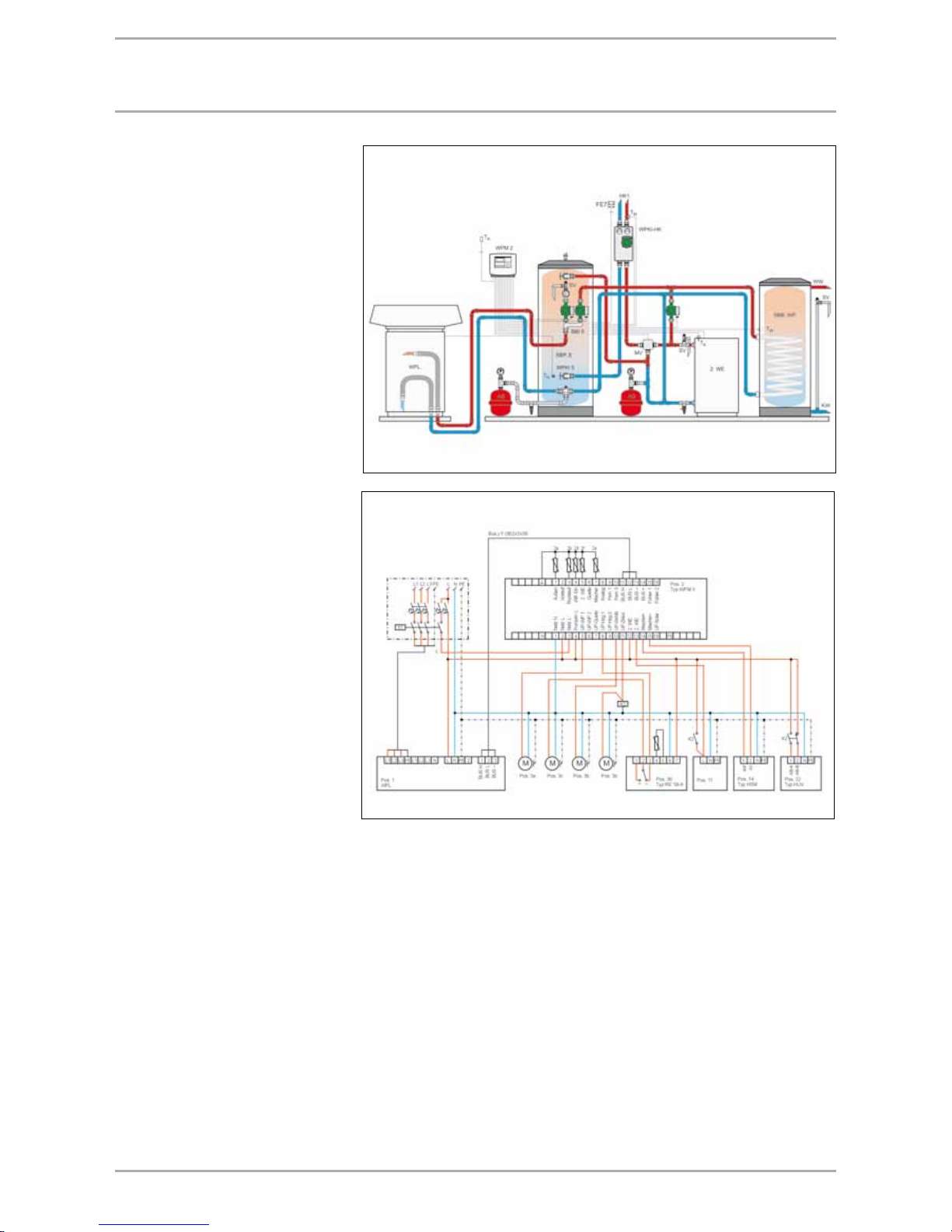

ExamplE 3: aIr | watEr HEat pUmp wItH Solar

Diagram system expenditure of energy value e

p

System description

Air | water heat pump WPL with 200

litre buffer cylinder and 300 litre DHW

cylinder

DHW heating

Centralised provision; no DHW

circulation; distribution outside the

thermal envelope; indirectly heated

dual-mode cylinder; installation

outside the thermal envelope; heating

heat pump air|water powered by

electricity; peak load: Electric heater

rod; with solar DHW heating.

Ventilation

No mechanical ventilation.

Central heating

Integral heating surface (e.g.

underfloor heating system);

individual room regulation with

two-point controller, switching

differential Xp=2 K; heating system

design 35/28°C; centralised system;

horizontal distribution outside the

thermal envelope, lines running

internally; regulated pump; buffer

cylinder installed; installation outside

the thermal envelope; heating

heat pump air | water powered by

electricity. Electric heater rod.

Example:

Annual heat demand

60 kWh/m² p.a.

Heated living space 200 m²

Result:

System expenditure of energy value =

1.00

System layout

Diagram system expenditure of energy value e

p

Annual

heating energy

demand

Heated available area in AN in m²

kWh/m² p.a. 100 200 300 400 500

40 1.17 1.04 1.00 0.97 0.95

50 1.13 1.02 0.98 0.96 0.94

60 1.10 1.00 0.97 0.95 0.94

70 1.08 0.99 0.97 0.95 0.94

80 1.06 0.98 0.96 0.94 0.93

90 1.05 0.98 0.96 0.94 0.93

Underfloor heating

system

Air

SOLAR

Heated available area in AN in m²

System expenditure of energy value e

p

Page 21

21WWW.STIEBEL-ELTRON.COM

coSt calcUlatIon to vdI 2067

Cost calculation

Calculation in accordance with VDI

2067

To establish the total costs, carry out

the following calculations.

Hours run at full utilisation

VDI 2067 sheet 1 to 6

The hours at full utilisation are

required for calculating the annual

heat demand. The calculation is based

on the number of heating days during

the heating season, the average

building temperature, the average

outside temperature and the lowest

outside temperature.

Energy costs

VDI 2067 sheet 1 to 6

The energy costs result from the

energy consumption, the energy price

and the standing charges.

Operating costs

VDI 2067 sheet 1, table A2

Costs for maintenance, cleaning and

chimney sweeping.

Capital costs

VDI 2067 sheet 1, table A8

Interest and repayments of system

costs.

Maintenance

VDI 2067 sheet 1, table A2

The maintenance costs are calculated

as a percentage of the system costs.

Annuity calculation

The VDI 2067 uses the annuity

method. Part 6 is responsible for

calculations in connection with

heat pumps. The annuity factor

determines the uniform payments in

connection with an investment that

are due annually. The annuity method

provides a dynamic investment

calculation that converts the payments

received and made into equal annual

contributions (annuities). Primarily,

the annuity method is used in the

investment and finance sector. In

addition, it is used in cost calculation

regarding long-term decisions, such

as the selection of processes or

whether to manufacture in-house or

use outside suppliers.

Amortisation calculation

An investment is viable if, with the

given interest rate, an average annual

surplus can be achieved that is greater

or equal to zero. Using the cash

value and the cash value factor the

amortisation can be calculated.

Cash value

The value of one or several capital

sums due in future within the

reference time. The cash value or

present value is the current value of

future receipts or payments resulting

from discounting. The cash value (K0)

is determined when regular equal

payments are made:

a = periodically due retroactive

payments (interest).

Cash value factor

The discounting total factor (cash

value factor, interest cash value

factor, discounting total factor,

capitalisation factor) is one of the

financial-mathematical factors. It

applies interest to the segments g of

a series of payments, taking the rate

of interest and compound interest

into consideration, and adds the cash

values together.

Page 22

22 WWW.STIEBEL-ELTRON.COM

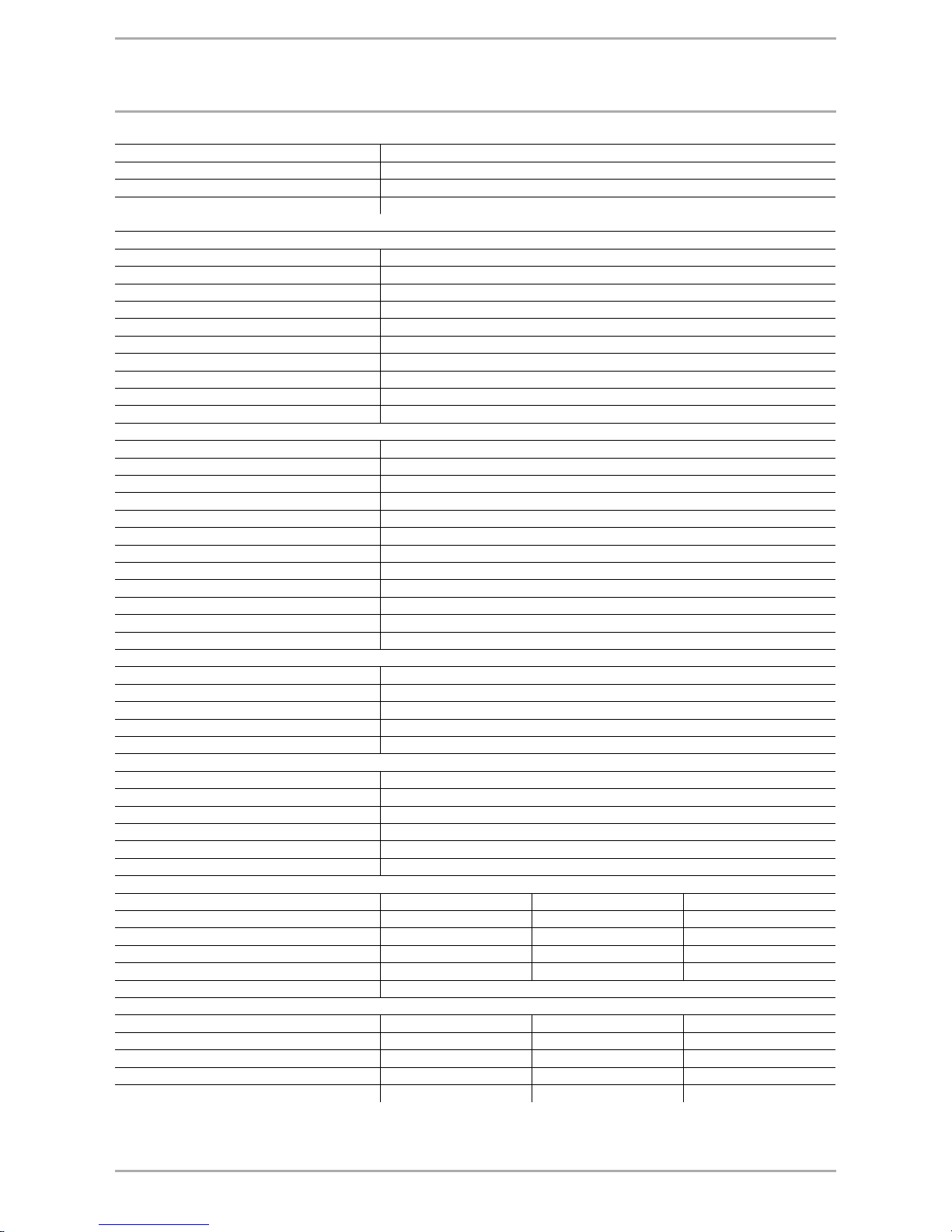

Building heating load 7.0 kW

Hours run at full utilisation 1744

Specific heat demand 50 W/m² (underfloor heating system 35/28 °C)

Number of occupants 4

Energy consumption DHW 2.00 kWh/person/day

Amortisation 0.0963 annuity table (depreciation 15 years with 5% interest)

Air | water heat

pump

Brine | water

heat pump

Water | water

heat pump

Oil heating with

solar

Gas condensing

with solar

Wood heating

(pellets)

1. System details

Energy price heating Ct/kWh 13.00 13.00 13.00 7.50 7.00 4.80

Domestic energy price Ct/kWh 18.00 18.00 18.00 18.00 18.00 18.00

Standing charge p.a. Euro 60.00 60.00 60.00 170.00

Efficiency distribution 0.98 0.98 0.98 0.98 0.98 0.98

Heat source efficiency 1.00 1.00 1.00 0.90 0.99 0.90

DHW efficiency 1.00 1.00 1.00 0.80 0.80 0.80

Annual performance factor 3.60 4.40 4.70

Heating coverage 0.98 1.00 1.00

DHW coverage 0.95 1.00 1.00

Coverage solar heating/DHW 5% 5%

2. Investment

Heat source complete Euro 10.000.00 9.000.00 7.200.00 3.000.00 4.000.00 10.000.00

Heating system with DHW Euro 4.800.00 4.800.00 4.800.00 4.800.00 4.800.00 4.800.00

Installation costs Euro 2.400.00 2.400.00 2.400.00 2.400.00 2.400.00 2.400.00

Electrical installation Euro 1.050.00 1.050.00 1.050.00 350.00 350.00 350.00

Solar thermal system Euro 4.600.00 4.600.00

Oil tank/storage room and gas connection

Euro 2.000.00 1.300.00

Chimney Euro 2.000.00 2.000.00 2.000.00

Heat source system Euro 7.000.00 5.000.00

Total Euro 18.250.00 24.250.00 20.450.00 19.150.00 19.450.00 21.550.00

3. Capital costs

Capital costs Euro 1.758.00 2.336.00 1.970.00 1.845.00 1.874.00 2.076.00

Maintenance Euro 183.00 243.00 205.00 192.00 195.00 216.00

Total Euro 1.941.00 2.579.00 2.175.00 2.037.00 2.069.00 2.292.00

4. Operational costs

Maintenance Euro 150.00 150.00 250.00

Chimney sweep Euro 70.00 70.00 70.00

Total Euro 220.00 220.00 320.00

5. Costs of consumption

Central heating

Annual energy demand kWh 12.208 12.208 12.208 12.208 12.208 12.208

Energy consumption, heating kWh 3.391 2.831 2.650 13.149 11.954 13.841

Energy consumption, booster heater

kWh 249

Annual auxiliary energy demand kWh 200 400 400 200 200 200

DHW

Annual energy demand kWh 2.920 2.920 2.920 2.920 2.920 2.920

Energy consumption DHW kWh 771 664 621 1.825 1.825 3.650

Energy consumption, booster heater

kWh 146

SOLAR

Energy yield kWh 2.070 2.070

Energy consumption solar kWh 160 160

Results

Total energy consumption kWh/p.a. 4.757 3.895 3.672 15.334 14.139 17.691

Emissions CO

2

in total kg/p.a. 3.235 2.648 2.497 4.928 3.690 245

System energy costs Euro/p.a. 688.00 586.00 558.00 1.187.80 1.199.80 875.00

Total system costs Euro/p.a. 2.629.00 3.165.00 2.733.00 3.444.80 3.488.80 3.487.00

Primary energy factor 2.7 2.7 2.7 1.1 1.1 0.2

Primary energy demand kWh/p.a. 12.843 10.516 9.914 16.868 15.553 3.538

ExamplE: coSt calcUlatIon to vdI 2067

Page 23

23WWW.STIEBEL-ELTRON.COM

Defrosting

Removal of a frost or ice coating

from the evaporator of the air|water

heat pump by supplying heat.

STIEBEL ELTRON heat pumps are

defrosted on demand through the

refrigerant circuit.

Process medium

Special term for refrigerant in heat

pump systems.

Dual-mode temperature

Outside temperature, which dictates

when a second heat source is started.

Enthalpy

According to its definition, it is

the sum of internal energy and

displacement work. The specific

enthalpy (kJ/kg) is used for all

calculations.

Expansion appliance

Component of the heat pump between

the condenser and the evaporator for

reducing the condensation pressure to

the evaporation pressure that equates

to the evaporation temperature. In

addition the expansion valve regulates

the injection volume of the process

medium, subject to the evaporator

load.

Fill level

The mass of the process medium

inside the heat pump.

Heating output

The heating output is the available

heat produced by the heat pump.

lg p, h-diagram

Graphic representation of the thermodynamic properties of process media

(enthalpy h, pressure p).

Annual performance factor

Quotient of heat and compressor drive

work over a definite period.

Annual expenditure of energy

The annual expenditure of energy

is the flip-side of the annual

performance factor.

Cooling capacity

Heat flow extracted by the heat pump

evaporator.

Refrigerant

Material with a low boiling point,

which is evaporated by heat

absorption and re-liquefied through

heat transfer in a circular process.

Circular process

Constantly repeating changes in

condition of a process medium by

adding and extracting energy in a

sealed system.

Coefficient of performance (COP)

Factor comprising the heating output

and the compressor drive rating.

The COP can only be quoted as an

actual value at a defined operating

condition. The heating load is always

greater than the compressor drive

rating; hence the COP is always > 1.

Equation symbol: ε

Rated consumption (compressor)

The maximum power consumption

of the heat pump during constant

operation under defined conditions.

It is decisive only for the power

connection to the supply network and

is given on the manufacturer's type

plate.

Standard efficiency

Quotient derived from the used and

related expended work or heat.

Evaporator

Heat exchanger of a heat pump, in

which the thermal flow is extracted

through condensation of the heat

source process medium.

Compressor

Machine for the mechanical

transportation and compression of

vapours and gases. Differentiation

according to the type of construction.

Condenser

Heat exchanger of a heat pump where

the thermal flow is transferred to a

heat transfer medium by condensing a

process medium.

Heat pump

Machine that absorbs a thermal flow

at a low temperature (cold side) and

transfers it through energy supplied

at a higher temperature (hot side).

When using the "cold side" we refer

to refrigerators, when using the "hot

side" we refer to heat pumps.

Heat pump system

Total system, comprising a heat source

and a heat pump system.

Compact heat pump system

Fully-wired appliance, where the

complete refrigerant circuit, incl.

safety and control equipment, has

been manufactured and tested.

Heat source

Medium, from which the heat pump

extracts energy.

Heat utilisation system

Equipment for heat transfer to the

heating system.

Heat source system (WQA)

Equipment for the extraction of

energy from a heat source and the

transportation of the heat transfer

medium between the heat source

and the "cold side" of the heat pump,

including all auxiliary equipment.

Heat transfer medium

Liquid or gaseous medium (e.g. water

or air), with which heat is transported.

Auxiliary energy

Energy required for the operation of

auxiliary equipment.

Off-periods

In Germany, heat pumps can be

stopped, subject to your tariff, by the

power supply utility for 3 x 2 hours

daily.

tErmInology and dEScrIptIonS

Page 24

24 WWW.STIEBEL-ELTRON.COM

SUmmary of formUlaE

Heat amount

Q = m

x c x (t

2

– t1)

Q = Heat amount Wh

m = Water volume kg

c = Specific heat Wh/kgK

1 163 Wh/kgK

t

1

= Cold water temperature °C

t

2

= DHW temperature °C

Heating output

Q = A

x k x ∆ϑ

Q = Heating output W

A = Surface m²

k = Heat transition coefficient

W/m²K

∆ϑ = Temperature differential K

k value

1 + d + 1

αi λ α

a

1

k =

k = k value W/m²K

α

i

= Heat transfer

coefficient, internal W/m²K

α

a

= Heat transfer coefficient,

external W/m²K

λ = Thermal conductivity W/mK

Connected load

P =

m

x c x (t

2

- t1)

T x η

P = Connected load W

m = Water volume kg

c = Specific heat Wh/kgK

t

1

= Cold water temperature °C

t

2

= DHW temperature °C

D = Heat-up times h

η = Efficiency

Heat-up time T

D =

m x c x (t2 - t1)

P

x η

D = Heat-up time h

m = Water volume kg

c = Specific heat Wh/kgK

t

1

= Cold water temperature °C

t

2

= DHW temperature °C

P = Connected load W

η = Efficiency

Pressure drop calculation

∆p = L

x R + Z

∆p = Pressure differential Pa

R = Tubes frictional resistance

L = Pipe length (m)

Z = Pressure drop from the

individual resistances Pa

Individual resistances

Z = Σz x x v

2

ς

2

z = Resistance coefficient

ς = Density

v = Flow velocity (m/s)

Z can be taken from the total z and the

velocity in the pipework in the tables.

Duct work curve

∆p

1

∆p

2

V

1

V

2

)

2

=

∆p1 = Pressure differential Pa

∆p

2

= Pressure differential Pa

V

1

= Air flow rate m³/h

V

2

= Air flow rate m³/h

Mixed water temperature

(m1 x t1) + (m2 x t2)

t

m

=

(m

1

+ m2)

tm = Mixed water temperature °C

t

1

= Cold water temperature °C

t

2

= DHW temperature °C

m

1

= Cold water volume kg

m

2

= DHW volume kg

Mixed water volume

m2 x (t2 - t1)

m

m

=

t

m

- t

1

mm = Mixed water volume kg

m

1

= Cold water volume kg

m

2

= DHW volume kg

t

m

= Mixed water temperature °C

t

1

= Cold water temperature °C

t

2

= DHW temperature °C

DHW volume

mm x (tm - t1)

m

2

=

t

2

- t

1

mm = Mixed water volume kg

m

1

= Cold water volume kg

m

2

= DHW volume kg

t

m

= Mixed water temperature °C

t

1

= Cold water temperature °C

t

2

= DHW temperature °C

Approximate heating load according

to oil consumption

Q

N

= Ba x h x Hu / b

VH

QN = Heating load (kW)

B

a

= Annual oil consumption (l)

Average consumption over the

last five years, minus 75 litres

of oil per person for DHW

heating.

h = Seasonal efficiency [to DIN]

(h = 0.7)

H

u

= Calorific value of fuel oil

(10 kWh/l)

b

VH

= Hours run at full utilisation

(average value 1800 h/p.a.)

Q

N

= Ba / 250

(

Page 25

25WWW.STIEBEL-ELTRON.COM

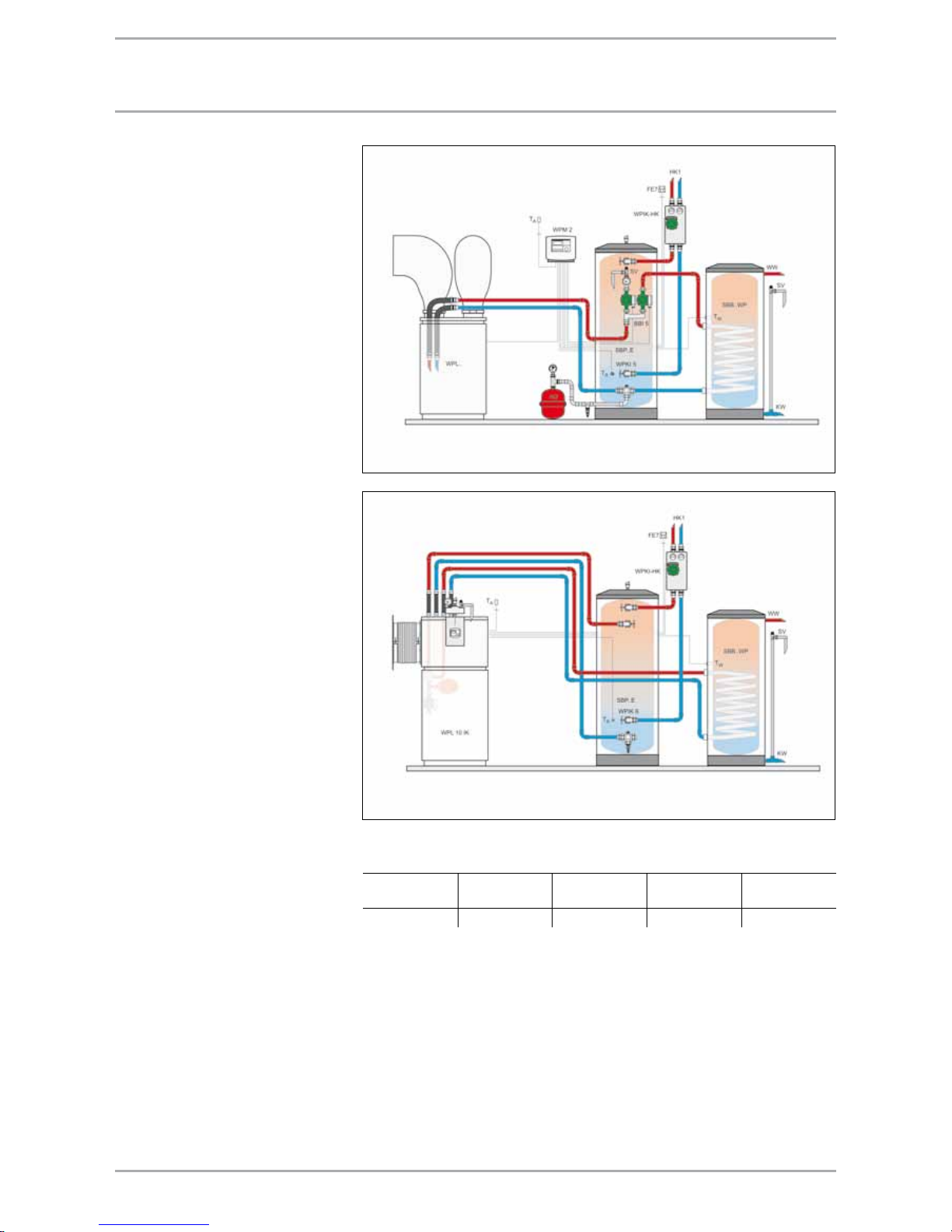

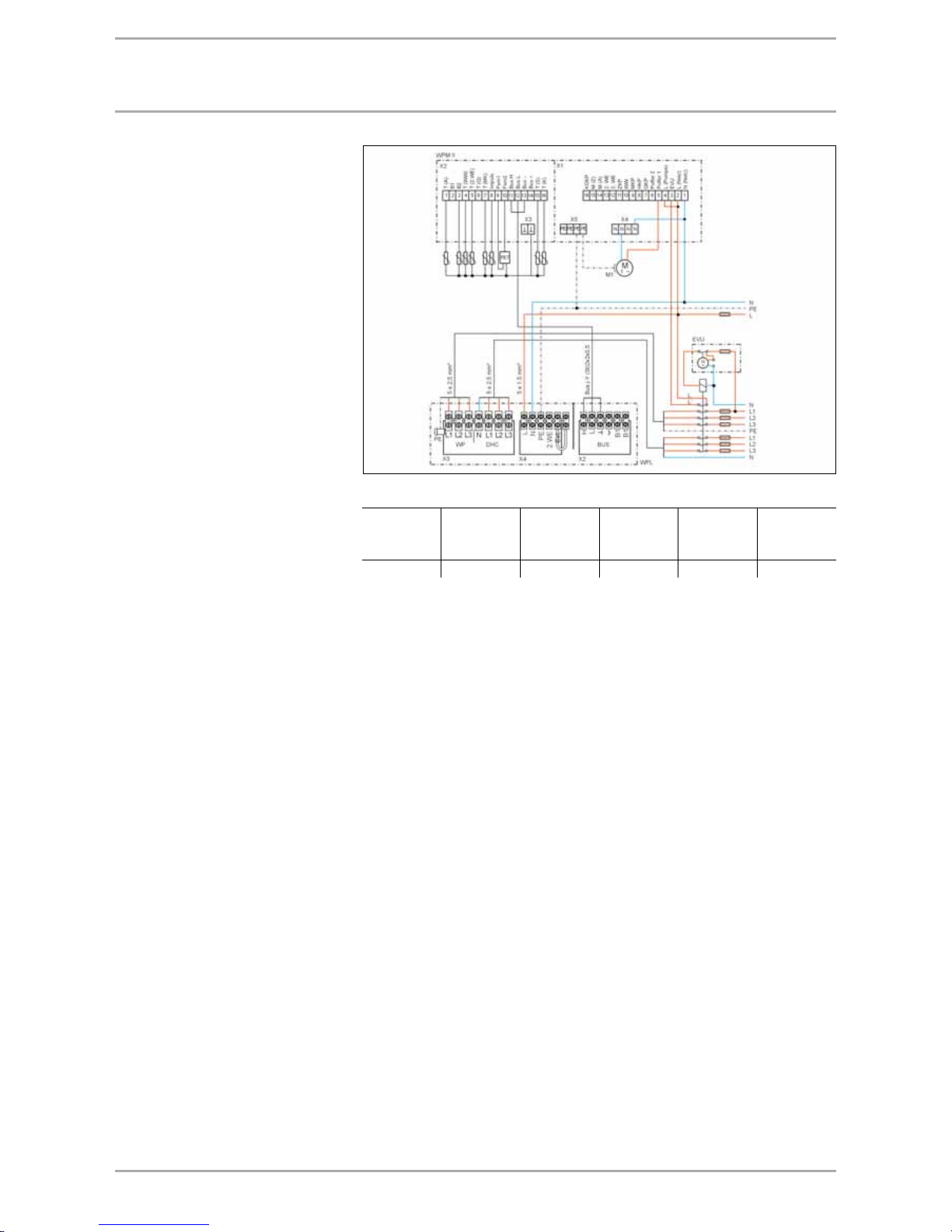

SyStEm dESIgn

Design information

To size heat pump systems accurately,

the following points regarding the

building to be heated or cooled must

be known:

Calculation of heating load to

DIN EN 12831

Calculation of the cooling load to

VDI 2078

Determination of the heating

surface temperature

New build: Determine the

maximum flow temperature

Older building: Determine the

maximum flow temperature

Determine or select the most

favourable heat source

Determine the operating mode of

the heat pump according to the

heating system

Size the heat pump according to

heat demand and operating mode

Power connection conditions and

requirements for the heat pump

control unit

Connection of the heat pump to

the heating system

DHW heating with the heating heat

pump

General regulations and

guidelines/directives

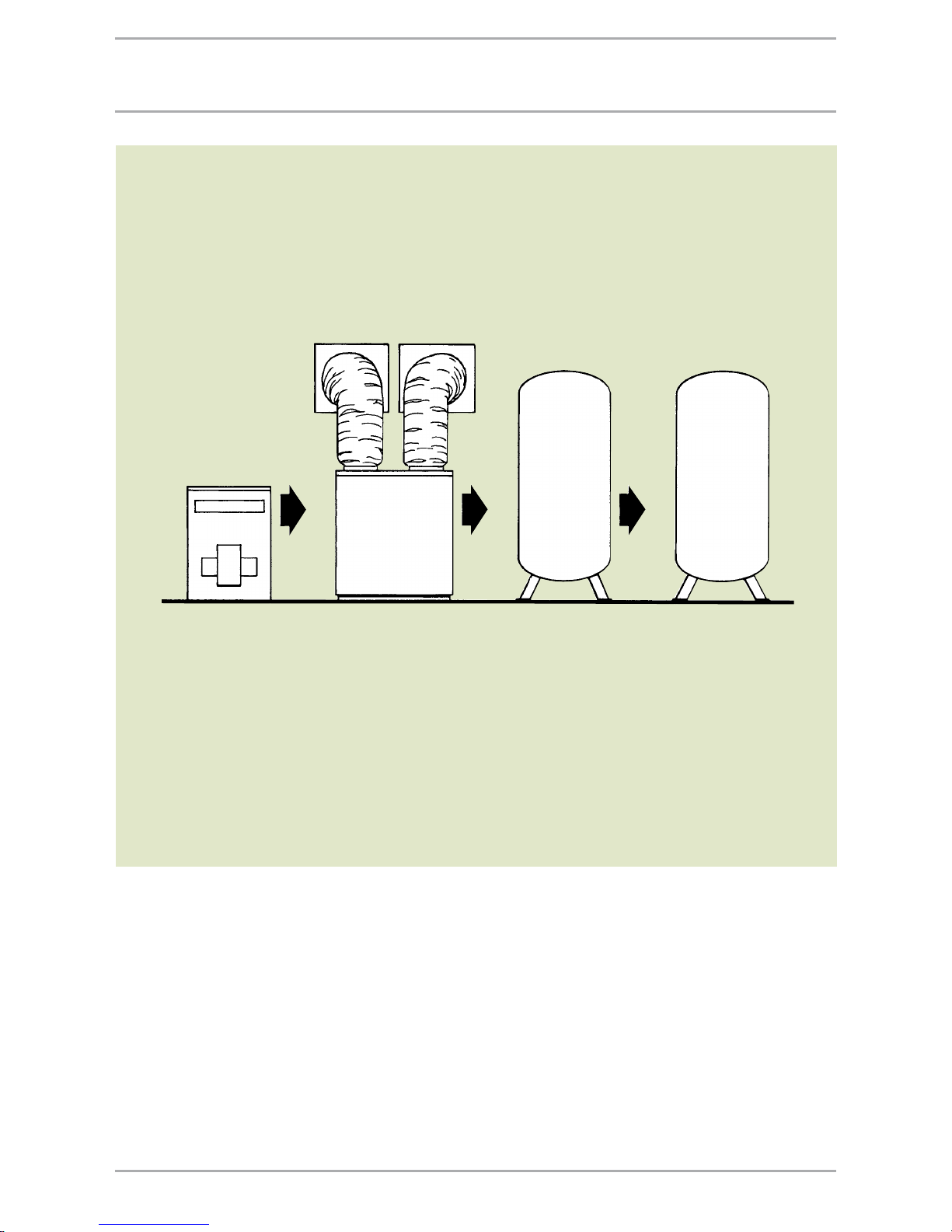

Existing system Heat pump Buffer cylinder DHW heating

Page 26

26 WWW.STIEBEL-ELTRON.COM

rEgUlatIonS and gUIdElInES/dIrEctIvES

The positioning, installation,

adjustment and commissioning of

heat pump systems must only be

carried out by qualified personnel,

giving due consideration to the

operating and installation instructions.

Only a qualified person authorised by

the relevant electricity supply utility

may carry out the heat pump power

connection, giving due consideration

to the relevant wiring regulations and

the conditions applied by the power

supply utility. The installer should also

make the relevant application to the

power supply utility.

Observe the following acts, standards,

regulations and orders during the

installation and operation of heat

pump heating systems in Germany:

Outside Germany, observe all

regulations and guidelines/directives

that may apply to your specific

country.

General conditions:

Building Regulations and others

Observe all relevant local and national

standards since heat pumps represent

"structural systems" in accordance

with the state building regulations

[Germany]. Therefore check with the

local Building Regulations authority

regarding applicable regulations prior

to the installation of a heat pump. The

building owner may need to notify

the relevant authority of the system

installation after the heat pump

installation has been completed. This

notification should be accompanied

by a manufacturer's declaration

that the intended installation will

comply with the requirements

of the building regulations

[Germany]. The requirement for

a permit in accordance with the

"Wasserhaushaltsgesetz" remains

unaffected by this exemption.

Special laws governing the utilisation

of various heat sources

The utilisation of heat latent in the

environment may, be subject to legal

regulations that are designed to

ensure that other private and public

concerns are not impeded, and

that these measures will not exert

dangerous environmental influences.

Groundwater as heat source

The extraction of groundwater

as heat source for a heat pump

and the reintroduction of the

cooled groundwater is regulated

by paragraph 3 sect. 1 no. 6 and

paragraph 3 sect. 1 no. 5 of the

"Wasserhaushaltsgesetzes (WHG)"

[Germany] and is subject to a permit.

The ground is the source of thermal

energy

The extraction of heat by

pipework buried under ground

that are filled with a means for

transporting heat, generally requires

notification to the water board or

a permit. If the ground collector

is in contact with groundwater,

a duty to obtain a permit may be

determined in accordance with

the "Wasserhaushaltsgesetz".

However, this case has not been

finally regulated. It is, nevertheless,

recommended that discussions are

held prior to commencement with the

relevant water authority (see chapter

"Heat source system").

Heat source

The utilisation of the outside air

as heat source with regard to the

entitlement to cool the outside air is

not subject to statutory regulations.

However, observe the technical

instructions regarding protection

against noise emissions [TA-Lärm in

Germany, or local regulations] from

evaporators. The expelled chilled

air may result in a nuisance for

neighbours (LBO sect.18).

Federal Immission Protection Act

(BImSchG) and TA-Lärm [Germany].

Heat pumps are "Systems" in the

sense of the Federal Immissions

Protection Act. The BlmSchG

differentiates between systems

subject to permit (paras. 44, 22) and

systems requiring no permit. Systems

requiring permits are listed finally

in the fourth BImSchV. Heat pumps

of any kind are not listed here. For

that reason, heat pumps are subject

to para. 22 to 25 BlmSchG, i.e. they

must be installed and operated in

such a way that avoidable nuisance is

limited to a minimum. Regarding the

noise emitted by heat pump systems,

observe the technical instructions

appertaining to the protection

against noise as per TA-Lärm [or

local regulations]. For living areas,

the sound pressure levels in the

table LS-Lärm that are subject to the

surrounding development have been

set as emission values.

TA-Lärm (VDI 2058).

The following sound pressure levels at

the neighbours' windows must not be

exceeded:

In commercial residential areas

day 60 dB(A)

night 45 dB(A)

In general residential areas

day 55 dB(A)

night 40 dB(A)

In exclusively residential areas

day 50 dB(A)

night 35 dB(A)

Page 27

27WWW.STIEBEL-ELTRON.COM

rEgUlatIonS and gUIdElInES/dIrEctIvES

DIN standards

– DIN EN 12831 Heating systems in

buildings – procedure to calculate

the standard heating load.

– DIN 4108 Thermal insulation and

energy saving in buildings.

– DIN 4109 Sound insulation in

buildings.

– DIN 8901 Refrigerating systems

and heat pumps – protection of

the ground, groundwater and

surface water – technical safety,

environmental requirements and

test.

– DIN 4701-10 Energy assessment of

heating and air handling system:

Heating, DHW heating, ventilation.

VDI guidelines

– VDI 2067 Efficiency of technical

building systems.

– VDI 2068 Measuring/monitoring

and control equipment in heating

systems with water as heat transfer

medium.

– VDI 2715 Noise reduction in hot

water heating systems.

– VDI 4640-2 Thermal utilisation of

the ground – ground source heat

pump systems.

– VDI 4650 (Draft) Heat pump

calculations. Abridged procedure for

calculating the annual expenditure

of energy values of heat pump

systems.

– VDI 2078 Cooling load calculation

for air conditioned rooms.

Regulations regarding the water side

– DIN EN 806 Technical rules for DHW

installations.

– DIN 4708-1 Central DHW heating

systems – part 1: Terminology and

calculation principles.

– DIN EN 378 Refrigeration systems

and heat pumps – technical safety

and environmental requirements.

– DIN EN 14511-1 to 4 Air handling

units, chillers and heat pumps with

electrically operated compressors

for central heating and cooling –

part 1: Terminology, part 2: Test

conditions, part 3: Test procedures,

part 4: Requirements.

– DIN EN 12828 Heating systems in

buildings - Designing hot water

heating systems.

– TRD 721 Safety equipment to

prevent excess pressure; safety

valves for steam boilers category II.

– DVGW Code of Practice W 101

Guideline for protected potable

water areas, part 1: Protected

groundwater areas.

– DVGW Code of practice W501

Potable water heating and routing

systems - technical measures for the

reduction of the growth of legionella

bacteria – engineering, installing,

operating and modernising potable

water installations.

Regulations regarding the power side

– VDE 0100 Regulations for the

installation of HV systems up to

1000 V.

– VDE 0105 Regulations for the

operation of three-phase systems.

– VDE 0700 Safety of electrical

equipment for domestic use and

similar purposes.

Accident prevention instructions

by the governing body of the trade

associations

– BGV D4 Accident prevention

instructions; refrigerating

equipment, heat pumps and cooling

facilities.

Additional standards and regulations

for dual-mode heat pump systems.

Observe the following acts, standards,

regulations and orders during

the installation of an additional

combustion system for solid, liquid or

gaseous fuels:

Combustion Order [or local/national

equivalent]

– Feu Vo part II, para. 4, sect. 2, sect.

4

– DIN EN 267 Oil combustion system

– technical rules - oil combustion

installation (TRÖ) - test.

Safety principles

– DIN 4787 Oil atomisation burners,

terminology, technical safety

requirements, testing, identification.

– DIN EN 12285-1 Factory-produced

steel tanks – part 1: Horizontal

single or twin-wall cylindrical tanks

for the subterranean storage of

combustible and non-combustible

liquids that represent a risk to

groundwater.

– DIN EN 12285-2 Factory-produced

steel tanks – part 2: Horizontal

single or twin-wall cylindrical tanks

for the above-ground storage of

combustible and non-combustible

liquids that represent a risk to

groundwater.

– DIN 6618-1 Vertical steel containers

(tanks), single wall, for above-

ground storage of combustible

and non-combustible liquids that

represent a risk to groundwater.

– DIN 6619-1 Vertical steel

containers (tanks), single wall, for