OPERATION AND INSTALLAT ION

Heat pump manager

» WPM 3

MITTWO CH 12.JUN 13

10:23 UHR

AUSSENTEMP ERATUR

WW-IS TTEMPERATUR

27,0 °C

35,0 °C

28,0 °C

RÜCKLAUFI STTEMPERATUR

ECO-BET RIEB

2 | WPM 3 www.stiebel-eltron.com

CONTENTS

OPERATION

1. General information _________________________________________3

1.1 Safety instructions ����������������������������������������������� 3

1.2 Other symbols in this documentation ����������������������� 3

1.3 Units of measurement ������������������������������������������ 3

2. Safety __________________________________________________________ 3

2.1 Intended use ������������������������������������������������������ 3

2.2 Safety instructions ����������������������������������������������� 3

2.3 Test symbols ������������������������������������������������������ 3

3. Appliance description _______________________________________4

3.1 Heat pump types ������������������������������������������������� 4

3.2 Accessories �������������������������������������������������������� 5

4. Operation _____________________________________________________6

4.1 Controls ������������������������������������������������������������ 6

4.2 Entering parameters �������������������������������������������� 7

4.3 Selecting operating modes ������������������������������������ 8

4.4 Picture symbols �������������������������������������������������� 9

5. Menu structure _______________________________________________9

5.1 INFO menu ������������������������������������������������������� 10

5.2 DIAGNOSIS menu �����������������������������������������������12

5.3 PROGRAMS menu ���������������������������������������������� 13

5.4 SETTINGS menu ������������������������������������������������� 16

6. Fault message ______________________________________________ 27

7. Maintenance and care _____________________________________ 27

INSTALLATION

8. Safety ________________________________________________________ 28

8.1 General safety instructions ����������������������������������� 28

8.2 Instructions, standards and regulations ������������������� 28

9. Standard delivery __________________________________________ 28

9.1 WPMW 3 (wall mounting) ������������������������������������� 28

9.2 WPMS 3 (control panel mounting) �������������������������� 28

10. Installation __________________________________________________ 28

10.1 Wall mounting WPMW 3���������������������������������������28

10.2 Control panel mounting WPMS 3 ���������������������������� 28

10.3 Programming unit ���������������������������������������������� 28

10.4 Electrical connection ������������������������������������������� 30

10.5 Sensor installation ���������������������������������������������� 33

10.6 FE7 remote control ��������������������������������������������� 34

10.7 FEK remote control ��������������������������������������������� 34

10.8 Internet Service Gateway ISG �������������������������������� 35

11. Commissioning _____________________________________________ 35

11.1 COMMISSIONING menu ���������������������������������������� 36

11.2 Setting parameters ��������������������������������������������� 40

12. Settings _____________________________________________________ 44

12.1 Standard settings ����������������������������������������������� 44

12.2 Settings made ��������������������������������������������������� 44

12.3 Appliance handover �������������������������������������������� 44

13. Troubleshooting ____________________________________________ 45

13.1 Fault display ����������������������������������������������������� 45

13.2 Fault list ����������������������������������������������������������46

13.3 Fault message – sensor break ������������������������������� 53

13.4 Heat pump-specific or hardware faults �������������������� 53

14. Specification ________________________________________________ 54

14.1 Details on energy consumption ������������������������������ 54

14.2 Data table �������������������������������������������������������� 54

GUARANTEE

ENVIRONMENT AND RECYCLING

OPERATION

General information

www.stiebel-eltron.com WPM 3| 3

OPERATION

1. General information

The chapter "Operation" is intended for appliance users and qualified contractors.

The chapter "Installation" is intended for qualified contractors.

Note

Read these instructions carefully before using the appliance and retain them for future reference.

Pass on the instructions to a new user if required.

1.1 Safety instructions

1.1.1 Structure of safety instructions

!

KEYWORD Type of risk

Here, possible consequences are listed that may result

from failure to observe the safety instructions.

Steps to prevent the risk are listed.

1.1.2 Symbols, type of risk

Symbol Type of risk

Injury

Electrocution

1.1.3 Keywords

KEYWORD Meaning

DANGER Failure to observe this information will result in serious

injury or death.

WARNING Failure to observe this information may result in serious

injury or death.

CAUTION Failure to observe this information may result in non-seri-

ous or minor injury.

1.2 Other symbols in this documentation

Note

General information is identified by the symbol shown

on the left.

Read these texts carefully.

Symbol Meaning

Material losses

(appliance damage, consequential losses and environmental pollution)

Appliance disposal

This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

1.3 Units of measurement

Note

All measurements are given in mm unless stated otherwise.

2. Safety

2.1 Intended use

Observe the operating limits listed in chapter "Specification".

This appliance is intended for domestic use. It can be used safely

by untrained persons. The appliance can also be used in a non-domestic environment, e.g. in a small business, as long as it is used

in the same way.

Any other use beyond that described shall be deemed inappropriate. Observation of these instructions and of instructions for any

accessories used is also part of the correct use of this appliance.

2.2 Safety instructions

- The electrical installation and installation of the heating circuit must only be carried out by a recognised, qualified contractor or by our customer support engineers.

- The qualified contractor is responsible for adherence to all

currently applicable instructions during installation and

commissioning.

- Operate the appliance only when fully installed and with all

safety equipment fitted.

- Protect the appliance from dust and dirt ingress during

building work.

!

WARNING Injury

The appliance may be used by children aged 8 and up and

persons with reduced physical, sensory or mental capabilities or a lack of experience and know-how, provided

that they are supervised or they have been instructed on

how to use the appliance safely and have understood

the resulting risks. Children must never play with the

appliance. Children must never clean the appliance or

perform user maintenance unless they are supervised.

Note

Do not change any system-specific settings at the control

unit. Your contractor has set the control unit to match

the local conditions for your building and your individual

requirements. The system-specific parameters are protected by a code to prevent unintentional modifications.

The parameters that serve to adapt the appliance to your

personal requirements are not protected by a code.

2.3 Test symbols

See type plate on the appliance.

!

!

OPERATION

Appliance description

4 | WPM 3 www.stiebel-eltron.com

3. Appliance description

The second generation heat pump manager, also referred to as

WPM3, is responsible for the processes that control and regulate

all our heat pumps.

Connected heat pumps are controlled via the digital BUS connection that handles the bi-directional data exchange

Cascade control

Up to 6output stages can be controlled for heat generation.

The maximum permitted configuration for cascade control is subject to the type of heat pump you are using.

- 6 single compressor heat pumps

- 3 dual compressor heat pumps with identical compressors

- From the third connected heat pump upwards, an MSM must

be used to control the buffer charging pumps

Function overview

- The 4-wire data BUS enables rapid installation and system

extension using the MSM mixer module

- Control of a second heat source for DHW and heating

- 9 temperature inputs as set/actual value display

- Demand-dependent control of 7 different circulation pumps

- Input of the system and heat pump frost protection limits

- At least 10 h power reserve for the clock

- Automatic pump kick control

- Reset option

- Stored fault list with precise fault code indication on the display, including date and time

- Fast and precise fault diagnosis with system analysis, incl.

temperature scanning of heat pump and peripherals without

additional equipment.

- Default settings for time switch programs for all heating and

DHW circuits

- Solar differential controller

3.1 Heat pump types

Note

Heat pump type 5/5* cannot be connected directly to the heat pump manager.

Use an indoor unit with integral WPM 3 heat pump manager for these heat pumps.

The description of individual functions varies between the different heat pump types. The types of heat pump are therefore identified

in this document as HP type 1 to 5 and 1* to 5*.

Heat pumps with second internal heat source

HP type 1 HP type 2 HP type 3 HP type 4 HP type 5

WPL 13, 18, 23 cool WPL 10 A / I / IK WPL 15 A(C)S WPL 33 HT WPL 08, 12, 16 S Trend

WPL 13, 18, 23 E WPL 33 WPL 20 A(C) WPL 33, HT (S) WPL 22, 28 Trend

WPL 13, 20 basic WPL 25 A(S)

WPL 13, 20 A basic WPL 25 AC(S)

WPL 13, 18 S basic WPL 07, 09, 17 ACS classic

WPL 10 AC WPL 19 I(K), WPL 24 I(K)

WPL 10 ACS

Heat pumps with second external heat source

HP type 1* HP type 2* HP type 3* HP type 4* HP type 5*

WPL 13, 18, 23 cool WPF-M 10, 13, 16 WPL 15 A(C)S WPL 33 HT WPL 08, 12, 16 S Trend

WPL 13, 18, 23 E WPW-M 13, 18, 22 WPL 20 A(C) WPL 33, HT (S) WPL 22, 28 Trend

WPL 13, 20 basic WPF 20, 27, 35, 40, 52, 66 WPL 25 A(S)

WPL 13, 20 A basic WPF 27 HT WPL 25 AC(S)

WPL 13, 18 S basic WPL 10 A / I / IK WPL 07, 09, 17 ACS classic

WPL 10 AC WPL 33 WPL 19 I(K), WPL 24 I(K)

WPL 10 ACS

WPL 34, 47, 57

OPERATION

Appliance description

www.stiebel-eltron.com WPM 3| 5

3.2 Accessories

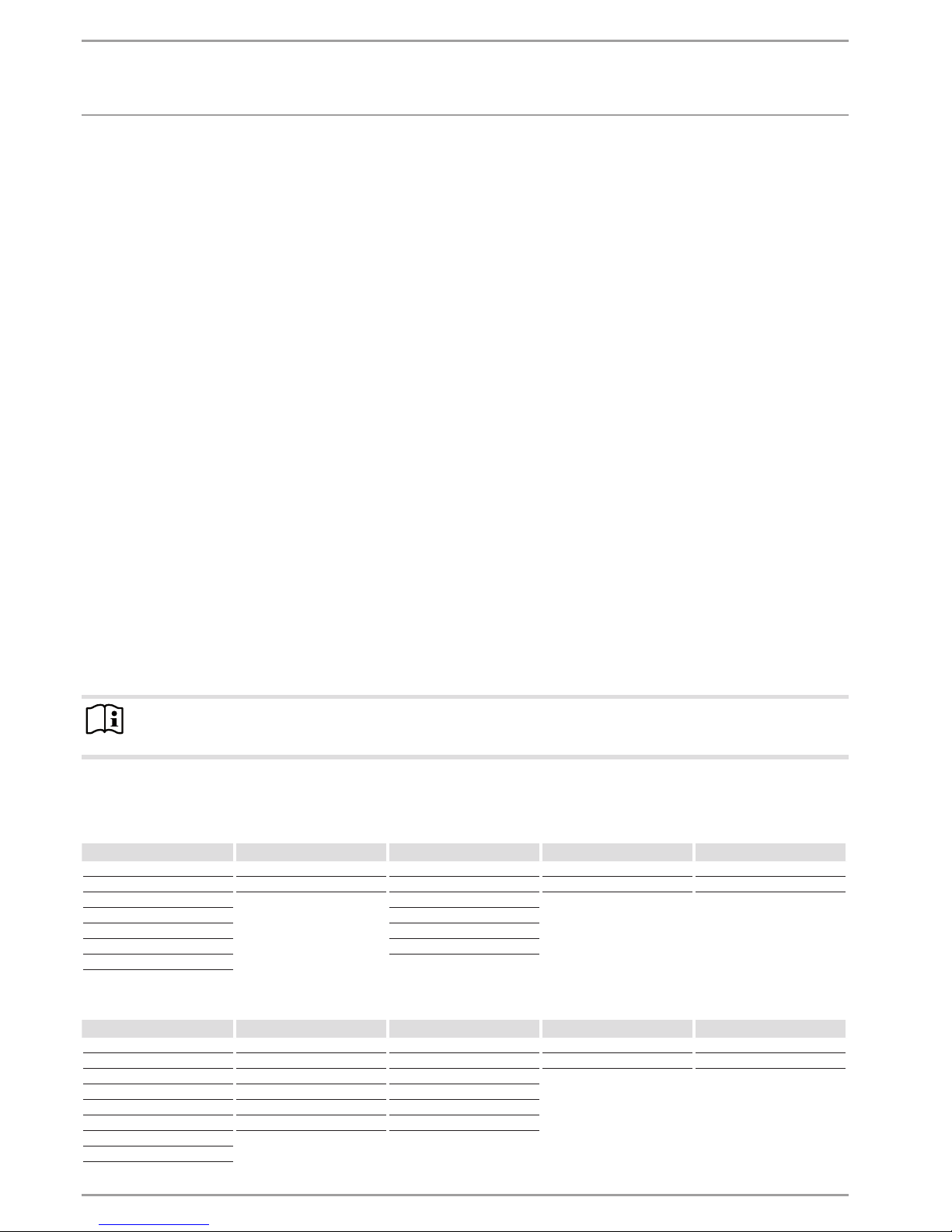

FE7 remote control

PIC00000609

The FE7 remote control allows you to:

- Change the set room temperature for heating by ±5°C, for

heating circuit1 or heating circuit2.

- Change the operating mode.

The FE7 remote control features the following controls:

- Rotary selector for changing the set room temperature

- Rotary selector with the following positions

-

Automatic mode

-

Constant setback mode

-

Constant day mode

Note

The remote control is only effective in the automatic mode

of the heat pump manager.

FEK remote control

PIC00000704

The FEK remote control allows you to:

- Change the set room temperature for heating by ±5°C, for

heating circuit1 or heating circuit2.

- Change the operating mode.

The device features the following controls:

- Rotary selector for changing the set room temperature

- “Away” button

- “Info” button

- Button for selecting the following operating modes:

-

Standby mode

-

Automatic mode

-

Constant day mode

-

Constant setback mode

Note

If the FEK is pre-selected for a specific heating circuit,

the heating curve, room temperature and heating program parameters are not shown at the WPM3 heat pump

manager.

Internet Service Gateway (ISG)

PIC00001002

The Internet Service Gateway (ISG) is an Ethernet gateway in a

wall mounting enclosure and is connected into the LAN (local

area network).

It enables the convenient operation, adjustment and checking of

heat pump system data via the browser of a computer, laptop or

tablet in the local home network.

If required by the customer, appliance data can be automatically

transmitted to the appliance manufacturer’s Servicewelt portal

via the internet.

Via services, you can access additional options such as system

operation on the go with a smartphone as well as remote setting

of parameters and remote diagnosis, etc.

You can find the current services on our homepage.

Mixer module MSMW

PIC00000599

The MSM is an extension module for the WPM 3 which makes

additional functions available.

The MSM can also be used as an independent mixer control. In

this case, an outside temperature sensor has to be connected to

the MSM as it cannot communicate with the WPM.

The MSM is operated in the same way as the WPM II.

MSMS 3 mixer and swimming pool module

PIC00005250

The MSM is a control panel module for the WPMS3 which makes

additional functions available. The module does not have its own

programming unit; it is operated via the WPM3. The menus are

extended accordingly.

OPERATION

Operation

6 | WPM 3 www.stiebel-eltron.com

4. Operation

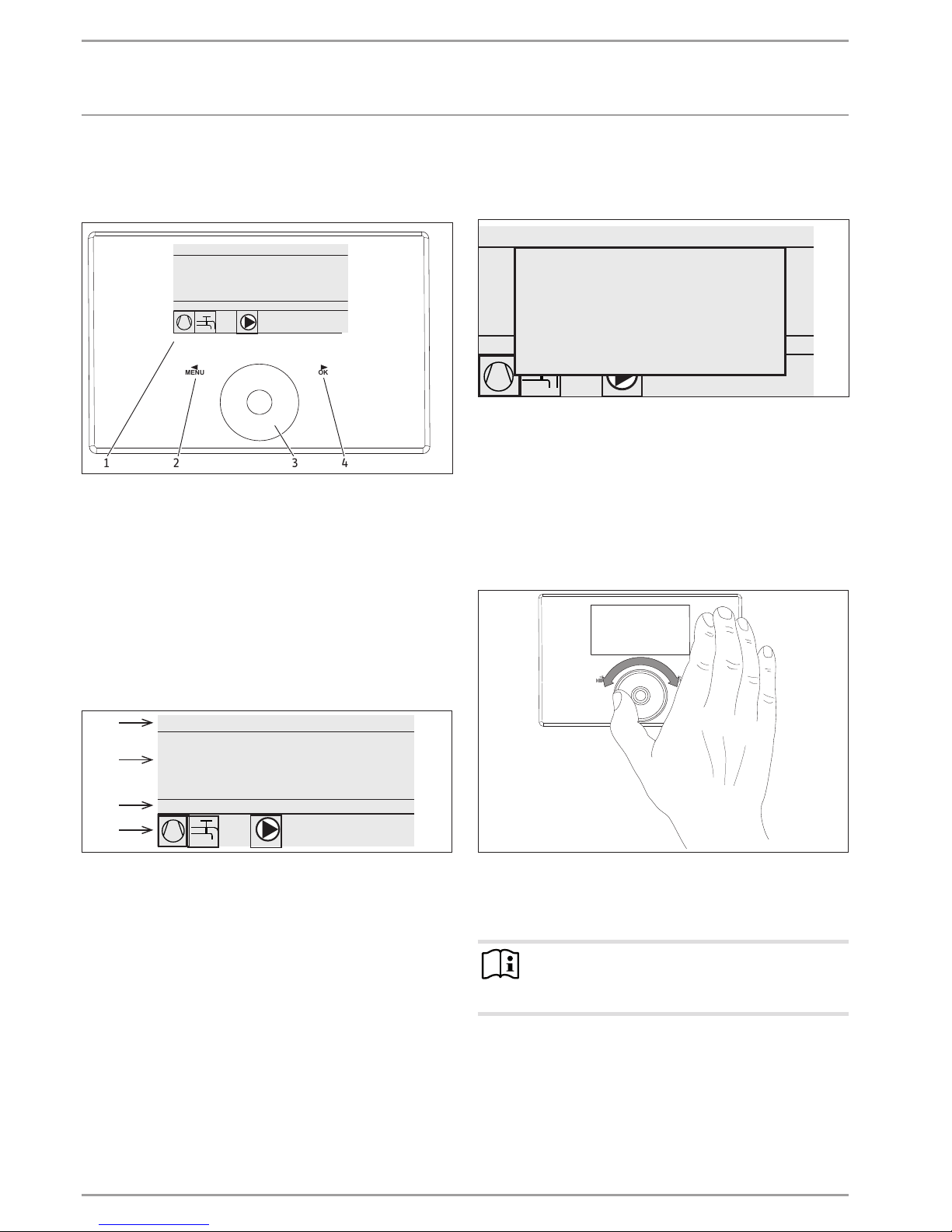

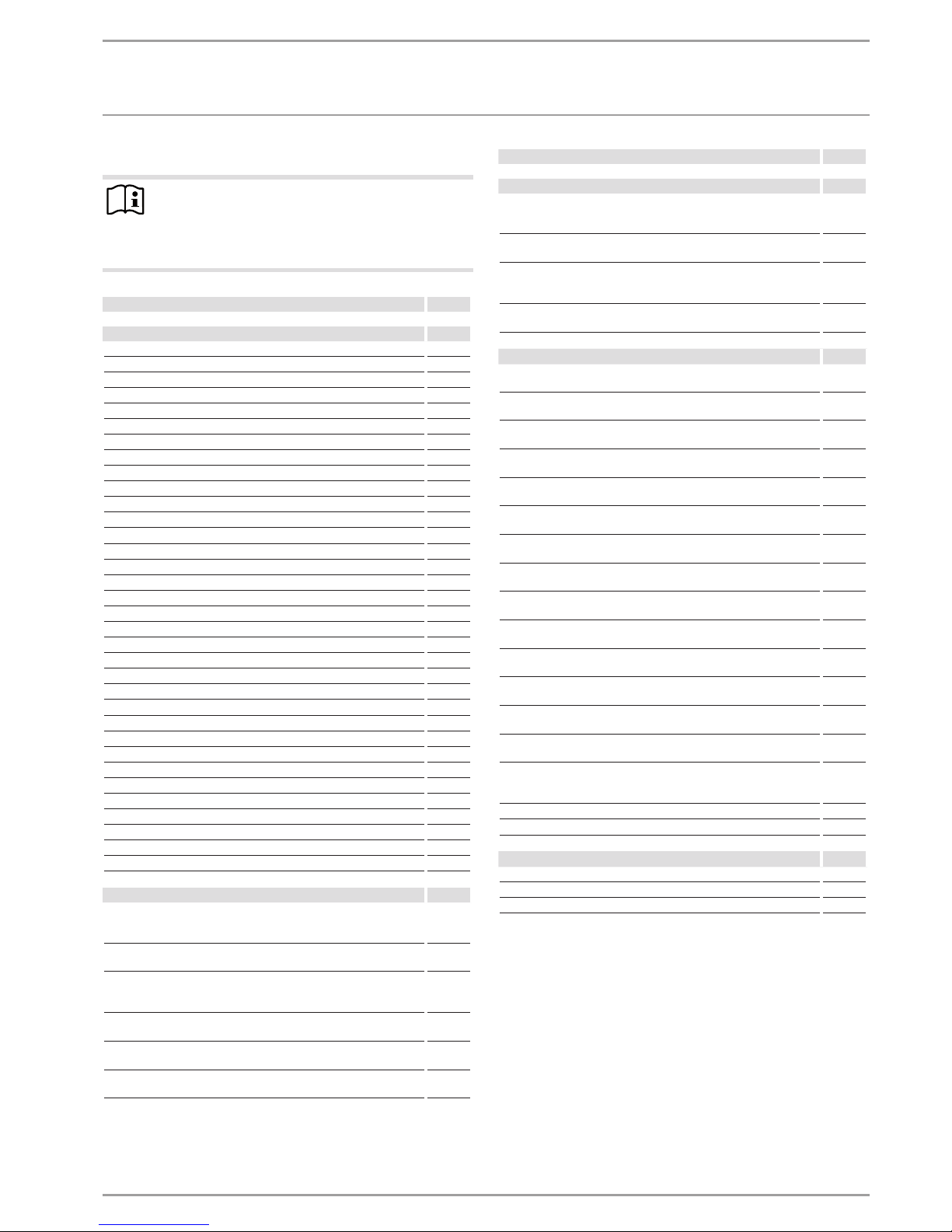

4.1 Controls

OKMENU

D0000064711

WEDNESDAY 12JUN 13 10:23 TIME

OUTSIDE TEMPERATURE

ACTUAL WW TEMPERATURE

27. 0 °C

35.0 °C

28.0 °C

ACTUAL RETURN TEMPERATURE

ECO MODE

1 32 4

1 Display

2 MENU key

3 Scroll wheel

4 OK key

You control the system with the programming unit of the heat

pump manager. Use the scroll wheel and the MENU and OK keys

to navigate through the menu structure.

4.1.1 Display

The programming unit display shows the current system status

and provides messages and information.

Start screen

WEDNESDAY 12JUN 14 10:23 TIME

OUTSIDE TEMPERATURE

ACTUAL WW TEMPERATURE

27.0 °C

35.0 °C

28.0 °C

ACTUAL RETURN TEMPERATURE

ECO MODE

26�04�01�0292

1

2

3

4

1 Date and time

2 Temperature display

3 Operating mode

4 System status picture symbols

The start screen is divided into four sections. The top field displays

the date and time. The field below displays the outside temperature along with the actual DHW temperature and the actual return

temperature. The third section is for selecting and displaying the

operating modes. In the fourth section, picture symbols indicate

the current system status.

Activating

If the scroll wheel and keys are not used for 5minutes, the programming unit is locked.

WEDNESDAY 12JUN 14 10:23 TIME

OUTSIDE TEMPERATURE

ACTUAL WW TEMPERATURE

27.0 °C

35.0 °C

28.0 °C

ACTUAL RETURN TEMPERATURE

ECO MODE

To activate please

press MENU

for 3 seconds.

26�04�01�0292

Press MENU for three seconds to activate the programming

unit.

Selection indicator

A selection indicator shows the current position within the menu

structure at all times. The currently selected menu item is indicated by a dark background. The current menu level is indicated

at the top of the display.

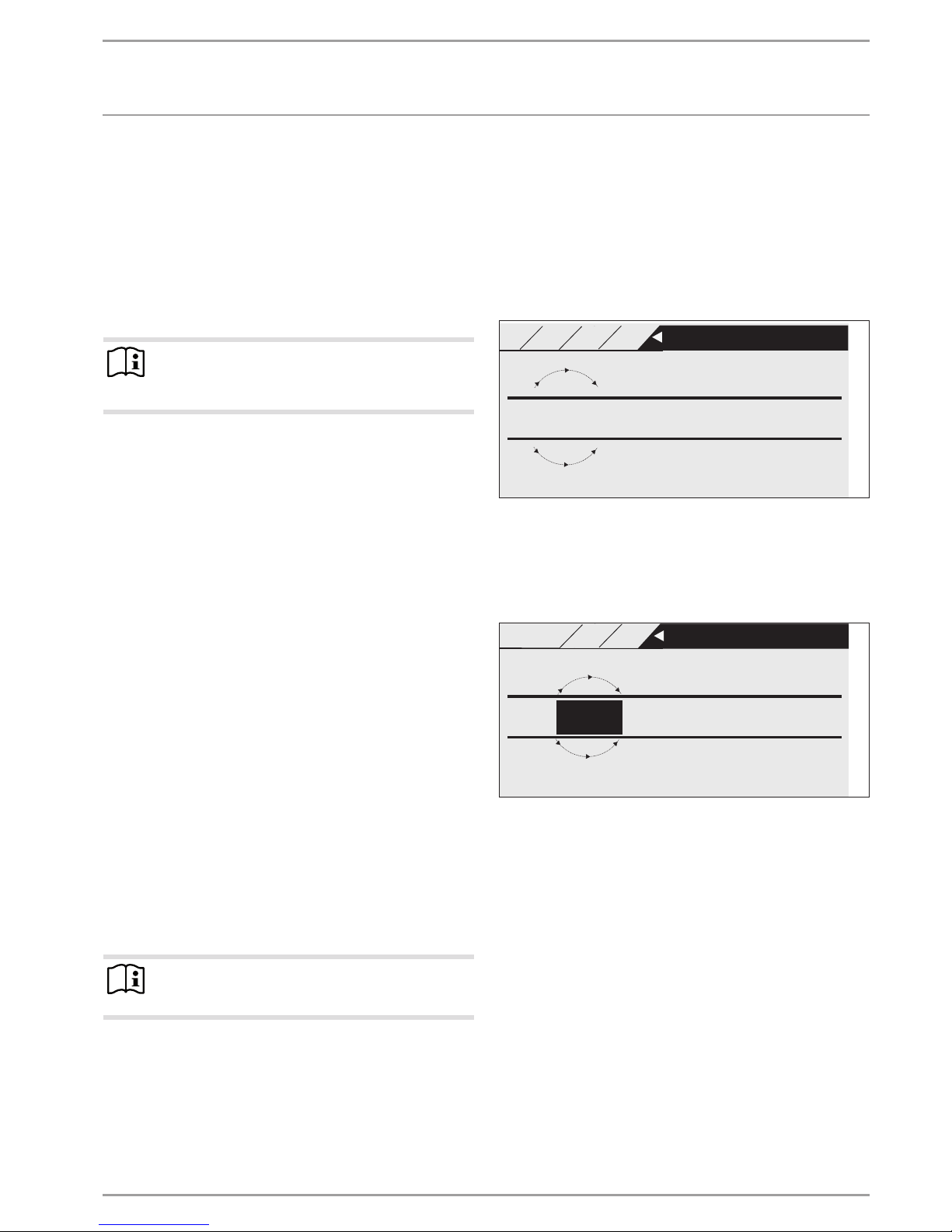

4.1.2 Touch wheel

D0000064710

The scroll wheel consists of a touch-sensitive sensor. There is a

key to the left and another to the right of it. All required appliance

functions are controlled and checked with the scroll wheel and

the keys.

Note Sensor responsiveness

If you have gloves on, have wet hands or the programming unit is damp, this impedes the recognition of your

touch and the execution of the action you require.

Your contractor can set the sensitivity to touch under SETTINGS/

GENERAL using the TOUCH SENSITIVITY parameter.

OPERATION

Operation

www.stiebel-eltron.com WPM 3| 7

Circular movement

Move one finger clockwise over the scroll wheel to move the selection indicator downwards or to the right in the list, depending

on how the menu items are arranged. Scrolling anti-clockwise

moves the selection indicator to the left or upwards in the list.

Alongside navigation within the menu structure, the scroll wheel

is also used to set parameters. Scrolling clockwise increases the

values. Scrolling anti-clockwise decreases the values.

4.1.3 Keys

Note

Press the keys only briefly to initiate the required action.

If a key is touched for too long, the programming unit

does not respond.

MENU key

The MENU key has two functions:

- On the start screen, touch the MENU key to navigate to the

first of the 5 menu structure levels.

- Touching the MENU key while in the menu structure will return you to the previous menu level.

OK key

The OK key has four functions:

- On the start screen, touching the OK key will activate the

required operating mode previously selected with the scroll

wheel.

- Within the menu structure, touching the OK key confirms the

selected menu item and takes you to the next lower menu

level.

- If you are already at parameter level, touching the OK key

saves the currently set parameter.

- At every menu level, you will see the entry BACK. Selecting

BACK takes you to the next higher menu level.

If there is no user action for more than five minutes, no scrolling

and neither

MENU nor OK are pressed, the programming unit

display automatically reverts to the start screen.

Any recent parameter changes which had not yet been confirmed

with OK are lost. The parameters retain the values previously

saved.

4.1.4 Contractor access

Note

Some menu items are protected by a code and can only

be accessed and adjusted by a qualified contractor.

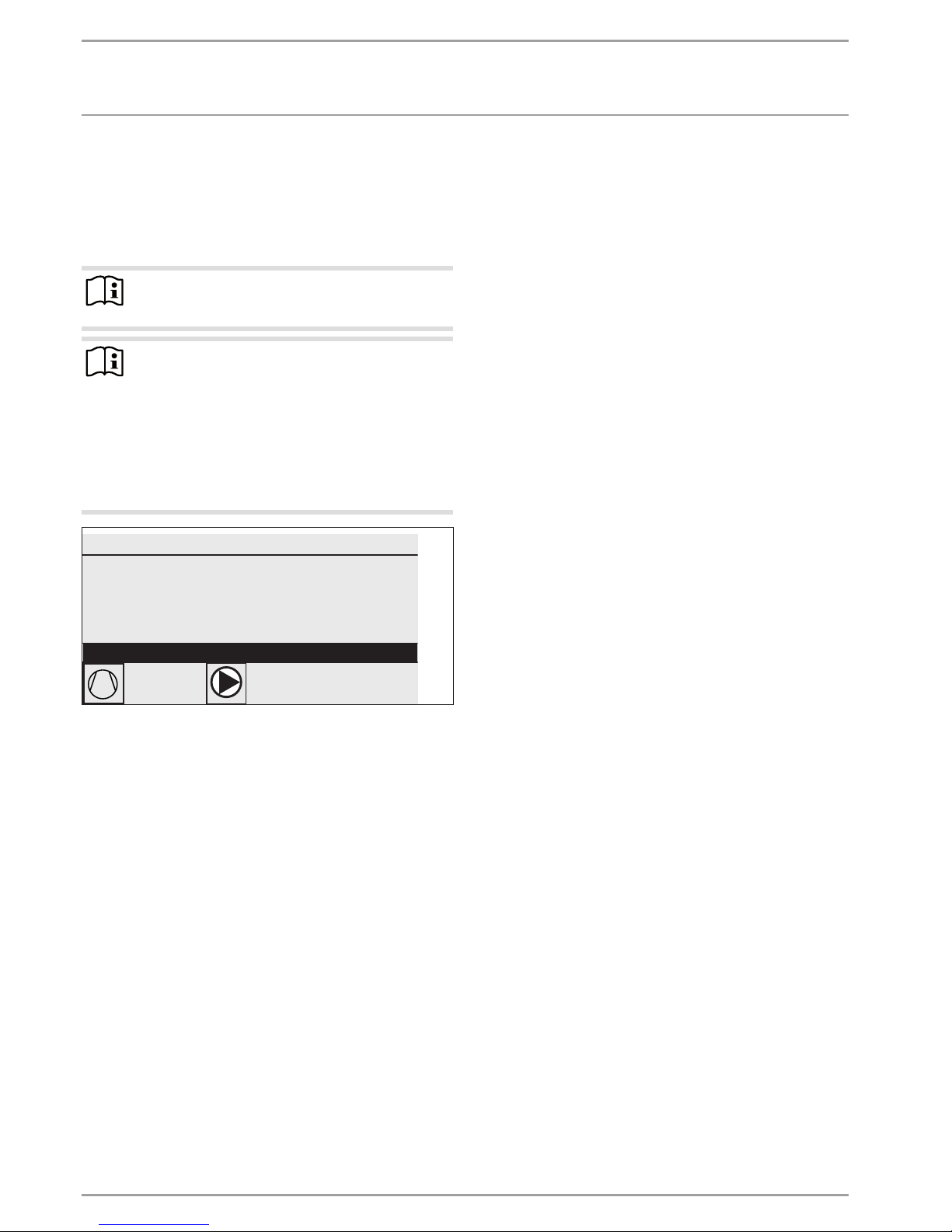

4.2 Entering parameters

Parameters are changed by scrolling with the scroll wheel. To save

the new value, touch OK.

If you want to cancel the entry, touch

MENU. The parameter re-

tains the previously saved value.

Example 1

Adjusting the set room temperature.

+

21.7

-

MAIN MENU

SETTINGS

°C SET ROOM TEMP COMFORT

26�04�01�0347

HEATI NG HK1

HEATING CIRCUIT 1

SET ROOM TEMP CO

21

To enter set temperatures, a number surrounded by a circle appears on the display. This indicates that you can change the value

by scrolling with the scroll wheel.

Example 2

Setting the time and date.

15.

09 08:23

DAY MONTH YEAR Hour Minute

Jun

26�04�01�0296

MAIN MENU

SETTINGS

GENERAL

TIME / DATE

SET CLOCK

14

On activation, the selection indicator is over the position MONTH.

Confirm with OK. Set the current month with the scroll wheel and

confirm with OK. A calendar page is displayed. Move the indicated

field to the required day using the scroll wheel and confirm with

OK. The new value is saved when you confirm with OK. Set the

year, hours and minutes the same way.

OPERATION

Operation

8 | WPM 3 www.stiebel-eltron.com

4.3 Selecting operating modes

When the start screen is activated, the current operating mode

is displayed. If you want to select another operating mode, scroll

with the scroll wheel. This takes you through the list of possible

operating modes. The current choice (list entry) is shown in the

shaded selection field.

Note

To change the appliance to this new operating mode,

confirm with OK.

Note

If the selection field shows “POWER-OFF” behind the operating mode, then the heat pump will not heat or cool

during the blocking time.

The compressor and the internal electric reheating stages are switched off. If a buffer cylinder is installed, the

heating circuit pumps will continue running.

One external heat source can be configured for the blocking time (see chapter “SETTINGS / HEATING / EXTERNAL

HEAT SOURCE / BLOCKING TIME EVU”).

WEDNESDAY 12JUN 14 10:23 TIME

OUTSIDE TEMPERATURE

ACTUAL WW TEMPERATURE

27.0 °C

35.0 °C

28.0 °C

ACTUAL RETURN TEMPERATURE

26�04�01�0292

ECO MODE

Since navigation to a new operating mode is always made from the

currently enabled mode, you may need to scroll in an anti-clockwise direction. All operating modes, apart from DHW mode, apply

to both heating and DHW.

Standby mode

Frost protection is activated for heating and DHW mode. The set

DHW value is fixed at 10°C, the set heating flow value is calculated

based on a set room value of 5°C.

Application: During prolonged periods of absence, e.g. holidays.

Programmed operation

Heating according to the time switch program (applies to heating circuit1 and heating circuit2). Changeover between comfort

temperature and ECO temperature.

DHW heating according to the time switch program; changeover

between comfort temperature and ECO temperature.

The remote control is only effective in this operating mode.

Application: When DHW and heating are required.

Comfort mode

The heating circuit (HC) is constantly held at the comfort temperature (HC1 and HC2). DHW heating according to time switch

program.

Application: Low energy houses without setback mode.

ECO mode

The heating circuit is constantly held at the ECO temperature (applicable to HC1 and HC2). DHW heating according to time switch

program.

Application: During weekends away.

DHW mode

DHW heating according to time switch program. If a time program

is active, the water inside the DHW cylinder is heated to the set

comfort temperature. At all other times, the water is heated to

the set ECO temperature. Frost protection is activated for heating

mode.

Application: The heating season has ended; only DHW should be

provided (summer mode).

Emergency operation

This setting activates the emergency operation.

In heat pumps with an integral 2nd heat source, the NHZ stages (electric reheating stages) of the electric emergency/booster

heater take over DHW and central heating irrespective of the dual

mode changeover point.

For heat pumps with an external 2nd heat source, the external

heat source for DHW or central heating must be set to ON under

SETTINGS / HEATING or DHW. Only then can the operating mode

be selected. The external heat source then takes over operation

for the DHW or central heating function, irrespective of the dual

mode changeover point.

OPERATION

Menu structure

www.stiebel-eltron.com WPM 3| 9

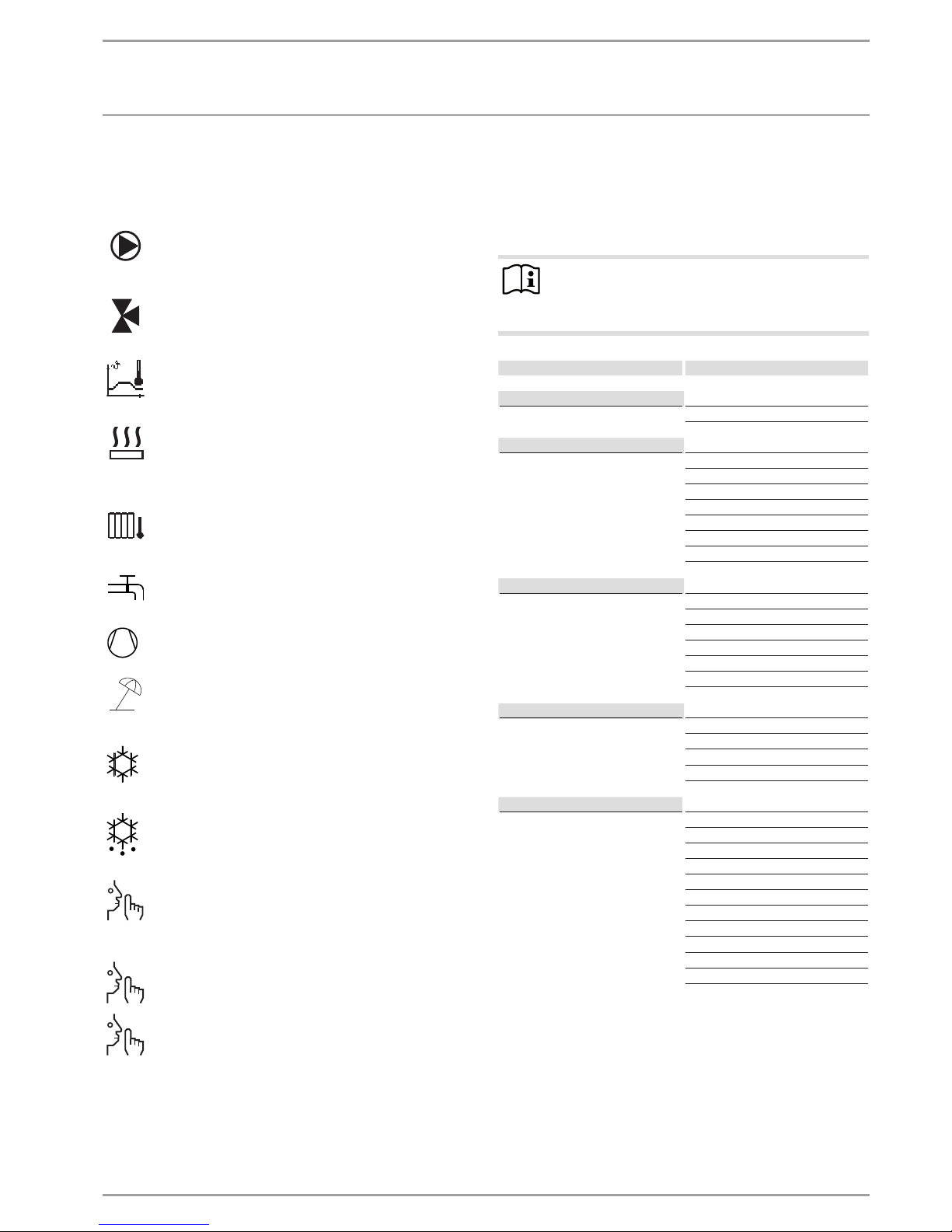

4.4 Picture symbols

At the lower edge of the display, symbols provide information

about the current operating status of the heat pump.

Heating circuit pump

The pump symbol is displayed when a heating circuit

pump is running.

Mixer circuit pump

The mixer symbol is displayed when a mixer circuit pump

is running.

Heat-up program

This symbol is displayed when the heat-up program is

running.

Electric emergency/booster heater

The electric emergency/booster heater has started up.

This occurs, for example, when the outside temperature

has fallen below the dual mode point.

Heating

The heating symbol is displayed when the heat pump is

in heating mode.

DHW heating

This symbol indicates that the heat pump is heating DHW.

Compressor

The symbol is displayed when the compressor is running.

Summer mode

The symbol is displayed when the heat pump is in summer mode.

Cooling

The symbol is displayed when the heat pump is in cooling

mode.

Defrost

The symbol is displayed when the heat pump is in defrost

mode.

Silent mode

Reduced noise mode

Silent mode is enabled. The associated time programs

determine activation of the fan or compressor throttle.

1

Silent mode 1

The fan and / or compressor run with reduced output.

2

Silent mode 2

Compressor and fan are stopped. Heat source 2 takes

over heating.

Note: This operating mode can result in higher operating

costs.

5. Menu structure

After activating the programming unit, you can use the touch

wheel to select alternative operating modes or use the menu key

to jump to a level from which you can navigate to a specific appliance parameter.

Note

Not all appliance parameters and values are displayed

in the different menus, depending on which heat pump

type is connected.

Level 1 Level 2

INFO SYSTEM

HEAT PUMP 1-6

DIAGNOSIS SYSTEM STATUS

HEAT PUMP STATUS 1-6

HEAT PUMP ANALYSIS 1-6

SYSTEM

INTERNAL CALCULATION

FAULT LIST

RELAY TEST SYSTEM

RELAY TEST HEAT PUMP 1-6

PROGRAMS HEATING PROGRAM

DHW PROGRAM

PARTY PROGRAM

HOLIDAY PROGRAM

HEAT-UP PROGRAM

SILENT PROGRAM 1

SILENT PROGRAM 2

SETTINGS GENERAL

HEATING

DHW

COOLING

SOLAR

COMMISSIONING ENTER CODE

LANGUAGE

SOURCE

HEATING

DHW

COMPRESSOR

SILENT MODE

EMERGENCY OPERATION

HEAT PUMP RESET

FAULT LIST RESET

SYSTEM RESET

SENSOR CALIBRATION

OPERATION

Menu structure

10 | WPM 3 www.stiebel-eltron.com

5.1 INFO menu

In the INFO menu you can compare the set and actual values for

temperatures, flow rates and pressures of the heating system and

the heat pump.

Note

Please note that actual and set values can only be displayed if the appropriate sensors are connected.

5.1.1 INFO SYSTEM

Level 3

ROOM TEMPERATURE

ACTUAL TEMPERATURE FE7

Actual room temperature for heating circuit 1 (HC1) or heating circuit 2 (HC2)

(is only displayed if the FE7 remote control is connected)

°C

SET TEMPERATURE FE7

Set room temperature for heating circuit 1 (HC1) or heating circuit

2 (HC2)

(only displayed if the FE7 remote control is connected)

°C

ACTUAL TEMPERATURE FEK

Actual room temperature for heating circuit 1 or heating circuit 2

(is only displayed if the FEK remote control is connected)

°C

SET TEMPERATURE FEK

Set room temperature for heating circuit 1 or heating circuit 2

(is only displayed if the FE7 remote control is connected)

°C

RELATIVE HUMIDITY %

DEW POINT TEMPERATURE

Dew point temperature (is only displayed if the FEK remote control

is connected)

°C

HEAT ING

OUTSIDE TEMPERATURE °C

ACTUAL TEMPERATURE HK 1

Actual heating circuit temperature, heating circuit 1

°C

SET TEMPERATURE HK 1

Set heating circuit temperature, heating circuit 1 (HC1). With fixed

value control, the fixed temperature is displayed.

°C

ACTUAL TEMPERATURE HK 2

Actual heating circuit temperature, heating circuit 2

°C

SET TEMPERATURE HK 2

Set heating circuit temperature, heating circuit 1 (HK1). With fixed

value control, the fixed temperature is displayed.

°C

ACTUAL FLOW TEMPERATURE HP

Actual heat pump flow temperature

°C

ACTUAL FLOW TEMPERATURE NHZ

Reheating stages, actual flow temperature

°C

ACTUAL RETURN TEMPERATURE WP °C

SET FIXED TEMPERATURE °C

ACTUAL BUFFER TEMPERATURE

Actual buffer cylinder temperature

°C

SET BUFFER TEMPERATURE

Set buffer cylinder temperature

°C

HEATING PRESSURE bar

FLOW R ATE l/min

SYSTEM FROST PROTECTION °C

DHW

ACTUAL TEMPERATURE

Actual DHW temperature

°C

SET TEMPERATURE

Set DHW temperature

°C

FLOW R ATE l/min

Level 3

COOLING

ACTUAL TEMPERATURE FAN °C

SET TEMPERATURE FAN °C

ACTUAL TEMPERATURE AREA °C

SET TEMPERATURE AREA °C

SOLAR

COLLECTOR TEMPERATURE °C

CYLINDER TEMPERATURE °C

RUNTIME Hours

EXTERNAL HEAT SOURCE

ACTUAL TEMPERATURE °C

SET TEMPERATURE °C

DUAL MODE TEMP HZG

Heating dual mode point

°C

APPLICATION LIMIT HZG

Heating application limit

°C

DUAL MODE TEMP DHW

DHW dual mode point

°C

APPLICATION LIMIT DHW

DHW application limit

°C

RUNTIME Hours

ELECTR IC REHEAT ING

DUAL MODE TEMP HZG

Heating dual mode point

°C

APPLICATION LIMIT HZG

Heating application limit

°C

DUAL MODE TEMP DHW

DHW dual mode point

°C

APPLICATION LIMIT DHW

DHW application limit

°C

SOURCE

SOURCE TEMPERATURE °C

MIN SOURCE TEMPERATURE °C

OPERATION

Menu structure

www.stiebel-eltron.com WPM 3| 11

5.1.2 INFO HEAT PUMP 1-6

Note

The power consumption is calculated on the basis of refrigerant circuit pressure. This calculation is inappropriate for billing purposes. Together with the amount of heat

it is used for a rough energy statement.

Level 3

PROCESS DATA

RETURN TEMPERATURE °C

FLOW TEMPERATURE °C

FROST PROTECTION TEMP °C

OUTSIDE TEMPERATURE °C

EXHAUST AIR TEMPERATURE °C

EVAPOR ATOR TEMPER AT UR E °C

RECUPERATOR TEMPERATURE °C

COMP SUCTION GAS TEMP °C

COMP SUCTION GAS TEMP ND °C

COMP SUCTION GAS TEMP HD °C

INTERMEDIATE INJ TEMP °C

HOT GAS TEMPERATURE °C

CONDENSER TEMPERATURE °C

OIL SUMP TEMPERATURE °C

LOW PRESSURE bar

MEAN PRESSURE bar

HIGH PRESSURE bar

DIFF PRESSURE VOLT INPUT V

DIFFERENTIAL PRESSURE mbar

WP WATER FLOW RATE l/min

INVERTER CURRENT ND A

INVERTER CURRENT HD A

INVERTER CURRENT A

INVERTER VOLTAGE V

SPEED ND Hz

SET SPEED ND Hz

SPEED HD Hz

SET SPEED HD Hz

ACTUAL COMPRESSOR SPEED Hz

SET COMPRESSOR SPEED Hz

REL FAN RATE %

ACTUAL FAN SPEED Hz

SET FAN SPEED Hz

EVAPORATOR INLET TEMP. °C

AMOUNT OF HEAT

VD HEATING DAY

Amount of compressor heat generated in heating mode since 00:00

of the current day.

kWh

VD HEATING TOTAL

Total amount of compressor heat generated in heating mode.

MWh

VD DHW DAY

Amount of compressor heat generated in DHW mode since 00:00 of

the current day.

kWh

VD DHW TOTAL

Total amount of compressor heat generated in DHW mode.

MWh

NHZ HEATING TOTAL

Total amount of booster heat generated in heating mode.

MWh

NHZ DHW TOTAL

Total amount of booster heat generated in DHW mode.

MWh

Level 3

POWER CONSUMP TION

VD HEATING DAY

Amount of electric compressor output in heating mode since 00:00

of the current day.

kWh

VD HEATING TOTAL

Total amount of electric compressor output in heating mode.

MWh

VD DHW DAY

Amount of electric compressor output in DHW mode since 00:00 of

the current day.

kWh

VD DHW TOTAL

Total amount of electric compressor output in DHW mode.

MWh

RUNT IME

VD HEATING

Runtime of compressor in heating mode.

Hours

VD 1 HEATING

Runtime of compressor 1 in heating mode.

Hours

VD 2 HEATING

Runtime of compressor 2 in heating mode.

Hours

VD 1/2 HEATING

Runtime of compressor 1 and 2 in heating mode.

Hours

VD DHW

Runtime of compressor in DHW mode.

Hours

VD 1 DHW

Runtime of compressor 1 in DHW mode.

Hours

VD 2 DHW

Runtime of compressor 2 in DHW mode.

Hours

VD 1/2 DHW

Runtime of compressor 1 and 2 in DHW mode.

Hours

VD COOLING

Runtime of compressor in cooling mode.

Hours

VD DEFROST

Runtime of compressor in defrost mode.

Hours

VD 1 DEFROST

Runtime of compressor 1 in defrost mode.

Hours

VD 2 DEFROST

Runtime of compressor 2 in defrost mode.

Hours

NHZ 1

Runtime of electric emergency/booster heater in booster stage 1.

Hours

NHZ 2

Runtime of electric emergency/booster heater in booster stage 2.

Hours

NHZ 1/2

Runtime of electric emergency/booster heater in booster stages 1

and 2.

Hours

DEFROST TIME Minutes

DEFROST STARTS

STAR TS

COMPRESSOR

COMPRESSOR 1

COMPRESSOR 2

OPERATION

Menu structure

12 | WPM 3 www.stiebel-eltron.com

5.2 DIAGNOSIS menu

For heating system and heat pump troubleshooting and analysis,

you can call up all important process data and BUS subscribers

under DIAGNOSIS and carry out a relay test.

Note

Menu item RELAY TEST SYSTEM is protected by a code

and can only be accessed by a qualified contractor.

Level 2 Level 3

SYSTEM S TATUS

BUFFER CHARGING PUMP

DHW VALVE

HEATING CIRCUIT PUMP

MIXER PUMP

MIXER OPEN

MIXER CLOSE

SOURCE PUMP

COOLING MODE

BUFFER CHARGING PUMP 1

BUFFER CHARGING PUMP 2

BUFFER CHARGING PUMP 3 - 6

DHW CHARGING PUMP

HEAT SOURCE 2

DHW CIRCULATION PUMP

SOLAR CIRCUIT PUMP

NHZ 1

NHZ 2

NHZ 1/2

POWER-OFF

HEAT PUMP STATUS 1 - 6

REMAINING IDLE TIME

COMPRESSOR

COMPRESSOR ND

COMPRESSOR HD

COMPRESSOR 1

COMPRESSOR 2

NHZ 1

NHZ 2

NHZ 1/2

DEFROST VALVE

PRESSURE COMPENSATION

OIL COMPENSATION

OIL SUMP

FAN

RIBBON HEATER

EXTERNAL COMPRESSOR ON

EXTERNAL FAULT

HD LIMITER

HD/TEMPERATURE MONITOR

DEFROST SIGNAL

CENTRAL INPUT

INVERTER POWER SUPPLY

FAULT

FORCED HEATING

COOLING MODE

HEAT PUMP ANALYSIS 1-6

SET SUPERHEATING

ACTUAL SUPERHEATING V

CONTROL DEVIATION

P FACTOR

I FACTOR

D FACTOR

PRE-CTRL OPENING EXV

Level 2 Level 3

OPENING EXV

SET SUPERHTG SG V HD

ACTUAL SUPERHTG SG V HD

P FACTOR V-HD

I FACTOR V-HD

D FACTOR V-HD

SET SUPERHEATING SG V-ZE

ACTUAL SUPERHEATING SG V-ZE

P FACTOR V-ZE

I FACTOR V-ZE

D FACTOR V-ZE

V OPENING DEGREE EXV ZE

OPENING EXV ZE

SUPERCOOLING COND

ACTUAL SUPERHEATING REK

INTERMEDIATE INJ PRESSURE

ACTUAL SUPERHEATING ZE

AMBIENT TEMP. INVERTER

TEMP. INV. COMPRESSOR

TEMPERATURE INV. FAN

MOTOR CURRENT

BYPASS VALVE OPENING LVL

SYSTEM

BUS SUBSCRIBER

HEAT PUMP TYPE

INTERNAL CALCULATION

INTERVAL

LIVE STAGES

FAULT L IST

RELAY TEST SYSTEM

DHW CIRCULATION PUMP

BUFFER CHARGING PUMP 1

BUFFER CHARGING PUMP 2

DHW CHARGING PUMP

HEATING CIRCUIT PUMP

HEAT SOURCE 2

WE 2 MIN OUTPUT

WE 2 MAX OUTPUT

MIXER OPEN

MIXER CLOSE

MIXER PUMP

SOURCE PUMP

SOLAR CIRCUIT PUMP

COOLING MODE

DRAIN HYD

NHZ 1

NHZ 2

NHZ 3

RELAY TEST HEAT PUMP 1-6

DEFROST

FAN

NHZ 1

NHZ 2

OIL SUMP

COMPRESSOR

STEPPER MOTOR PHASE 1

STEPPER MOTOR PHASE 2

STEPPER MOTOR PHASE 3

STEPPER MOTOR PHASE 4

STEPPER MOTOR PHASE 1 ZE

STEPPER MOTOR PHASE 2 ZE

STEPPER MOTOR PHASE 3 ZE

STEPPER MOTOR PHASE 4 ZE

OPERATION

Menu structure

www.stiebel-eltron.com WPM 3| 13

Level 2 Level 3

RIBBON HEATER

EXTERNAL COMPRESSOR ON

EXTERNAL FAULT

EX VALVE CENTRE POSITION

5.2.1 Fault list

The fault list provides an overview of the faults most recently

registered by the appliance. The fault list contains up to 20 fault

messages. The display, however, can show only 2. Scroll with the

scroll wheel to access the other entries in the fault list.

MAIN MENUDIAGNOSIS

FAULT L IST 1/1

01. SENSOR BREAK E 71

10:26 14 JUN 14

02. MIN SOURCE

17:45 25 JUN 13

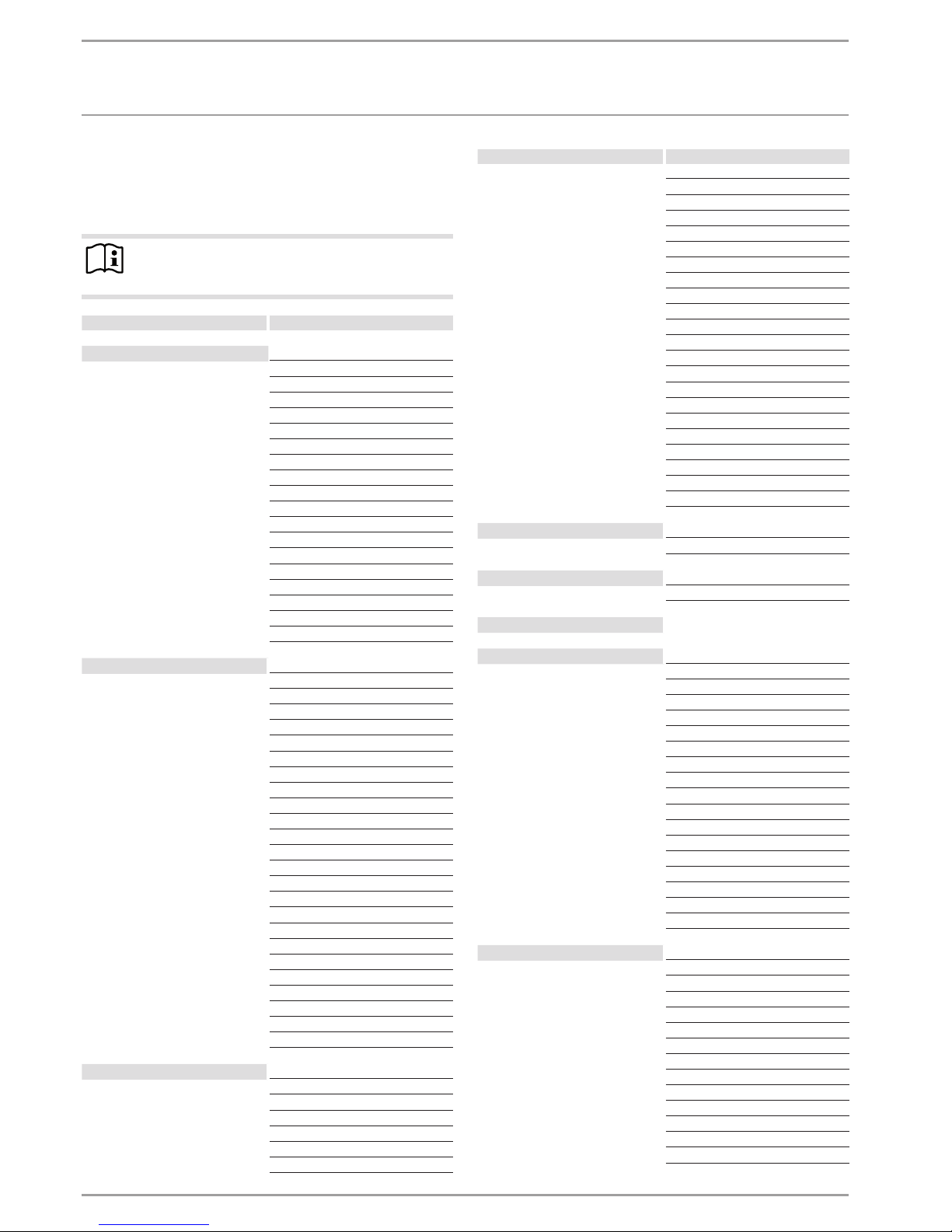

5.2.2 Fault message

If the appliance registers a fault, this is clearly displayed with the

message shown below.

COMFORT MODE

!

FAULT

SENSOR BREAK E 71

TUESDAY 14JUN 14 16:27 TIME

If more than one fault occurs, the most recent fault is always

shown. Notify your qualified contractor.

5.2.3 Relay test

All relay outputs of the controller and heat pump can be individually switched from here.

5.3 PROGRAMS menu

All times for the heating, DHW, holiday and party modes can be

adjusted here. In addition, the heat-up program can be started.

Level 2 Level 3

HEAT ING PRO GRAM

HEATING CIRCUIT 1

HEATING CIRCUIT 2

DHW PROGR AM

PART Y PROGRAM

HOURS

HOL IDAY PROGRAM

HOLIDAYS BEGINNING

HOLIDAYS ENDING

HEAT-UP PRO GR AM

LOW END TEMPERATURE

DURATION BASE TEMP

MAXIMUM TEMPERATURE

MAX TEMPERATURE DURATION

RISE PER DAY

SILENT PROGR AM 1

SILENT PROGR AM 2

5.3.1 HEATING PROGRAM

In menu item HEATING PROGRAM you can determine when and

how often the appliance heats to the set comfort values for heating

circuit1 and heating circuit2. At all other times, the appliance

heats to the set ECO value. You can adjust the set values under

menu item SETTINGS / HEATING / HEATING CIRCUIT1 or HEATING CIRCUIT2. Below is an explanation of how to define a time

program.

First, select the days on which you want to enable the HEATING

function:

+

-

26�04�01�0301

Monday

Mon

MAIN MENU

PROGRAMS

HEATING PROGRAM

HEATING CIRCUIT 1

You can set your heating system as follows:

- For each individual day of the week (Monday - Sunday)

- Monday to Friday (Mon - Fri)

- Saturday and Sunday (Sat - Sun)

- the whole week (Mon - Sun)

Monday is initially offered.

Scroll with the scroll wheel to select another day or group of

days.

Confirm your selection with OK.

You can now set three switching time pairs. The three switching

time pairs are shown on the display, to the right of the clock. A

OPERATION

Menu structure

14 | WPM 3 www.stiebel-eltron.com

switching time pair comprises the start time and end point, at

which the appliance returns to its previous state.

07:00 - 20:00

- -:- - - - -:- -

- -:- - - - -:- -

26�04�01�0299

MONDAY

MAIN MENU

PROGRAMS

HEATING PROGRAM

HEATING CIRCUIT 1

In this example, only one switching time pair has so far been

programmed. For switching time pairs 2 and 3, short dashes are

displayed instead of times. These switching time pairs are still

empty. Select one of the free switching time pairs with OK to reach

the area where you can set the associated start and end time.

Pressing OK brings up the display shown below. Set the required

time with the scroll wheel.

End

- -:- -

- -:- -

TIME TIME

Start

26�04�01�0302

MAIN MENU

PROGRAMS

HEATING PROGRAM

HEATING CIRCUIT 1

Times can be entered in intervals of 15 minutes. You can set 16:30

or 16:45 h, but not 16:37 h. Confirm your entry with OK.

Periods around midnight

Assume, for example, you want heating mode to be enabled from

22:00 h for four hours every Wednesday evening. This means the

period does not expire until the next day, Thursday, at 02:00 h.

However, since the day ends at 00:00h, two switching time pairs

are necessary for the required program. First, program the period

22:00 to 00:00 h for Wednesday, then 00:00 to 02:00 h for Thursday.

5.3.2 DHW PROGRAM

In menu item DHW PROGRAM you can determine the times during

which DHW heating to the set comfort value should take place.

At all other times, DHW is heated to the set ECO value. You can

adjust the set values under menu item SETTINGS / DHW / DHW

TEMPERATURES. The DHW circulation output is also switched in

line with the times programmed here.

You can set your DHW heating as follows:

- For each individual day of the week (Monday - Sunday)

- Monday to Friday (Mon - Fri)

- Saturday and Sunday (Sat - Sun)

- the whole week (Mon - Sun)

You can set three switching time pairs for each of these options.

Exception: If you want to heat DHW from 22:00 h until 06:00 h the

following day you will need two switching time pairs.

Example:

You would like to heat DHW twice daily, e.g. from 22:00 h until

06:00 h the following day, and then from 08:00 h until 09:00 h.

As the day begins at 00:00 h, programming for this example must

again start at 00:00 h.

- The first switching time pair runs from 00:00 h until 06:00 h.

- The second switching time pair runs from 08:00 h until

09:00h.

- The third switching time pair runs from 22:00 h until 24:00 h.

5.3.3 PARTY PROGRAM

In the party program you can extend the comfort mode for heating

by a few hours.

5.3.4 HOLIDAY PROGRAM

In the holiday program, the heat pump system runs in ECO mode

and frost protection for DHW heating is enabled.

For both the start and end of the holiday, enter the year, month

and day. The start time is 0:00h on the first day of the holiday. The

end time is 24:00h on the day the holiday ends. After the holiday

period has expired, the heat pump system switches back to the

previous heating and DHW program.

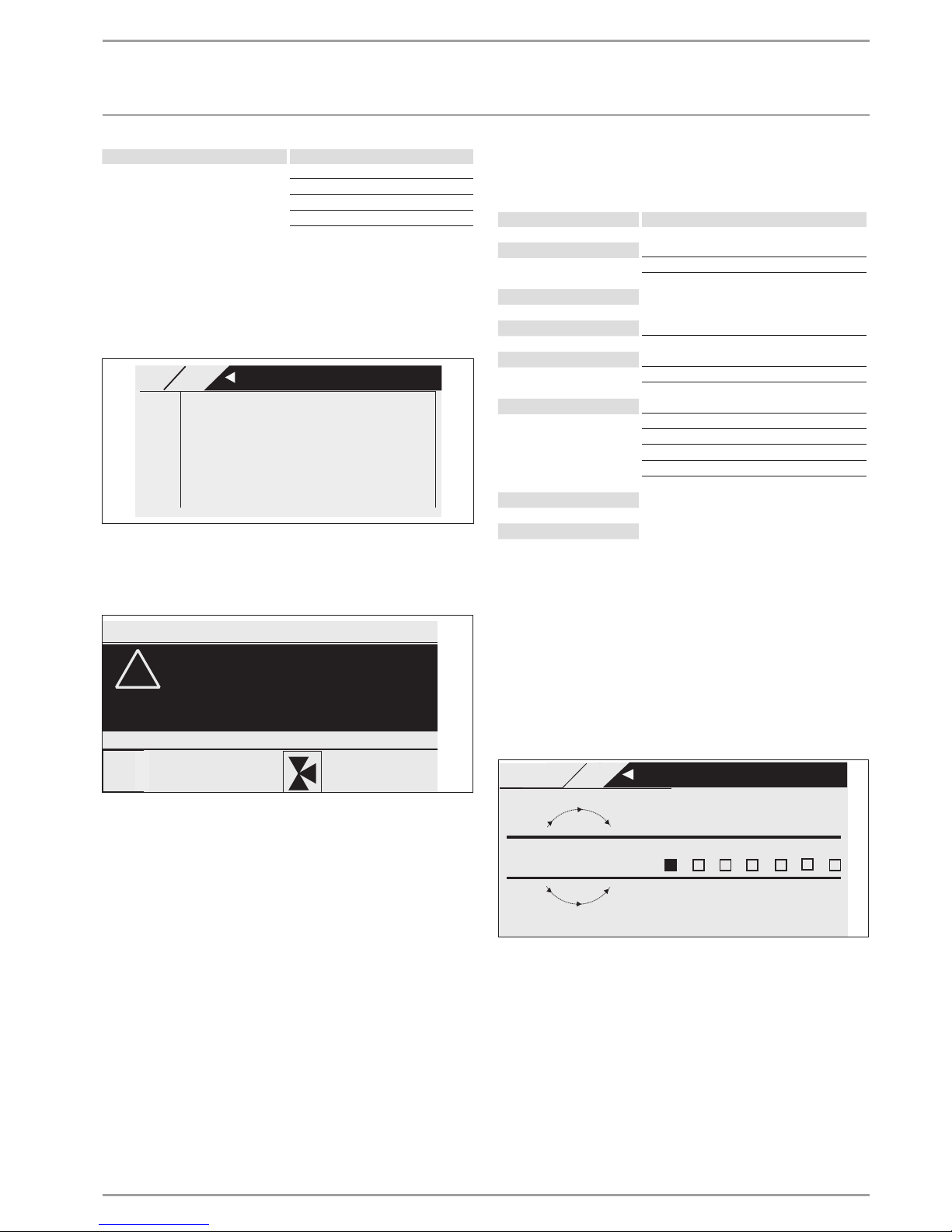

5.3.5 HEAT-UP PROGRAM

Note

Menu item HEAT-UP PROGRAM is protected by a code

and can only be accessed and adjusted by a qualified

contractor.

Heat-up program for underfloor heating systems

Use the heat-up program to dry your screed with a defined temperature profile. To prevent damage to the appliance and/or the

installation, observe the following differences between air | water

heat pumps (WPL) and brine | water heat pumps (WPF):

- WPL: Where return temperatures are < 25°C, the heat-up

program / screed drying must be carried out via the emergency/booster heater. The process must not be carried out

via the heat pump – such low system temperatures during

the defrost cycle mean that the appliance may not be protected from frost during the defrost cycle. If the return temperature rises > 25°C the heat pump can take over screed drying.

For this, set parameter “LOWER APP LIMIT HZG” to -20°C.

- WPF: The heat-up program / screed drying must be carried

out via the emergency/booster heater. Never use the heat

pump to perform screed drying as this would place too high

a demand on the heat source and could damage it.

If you use the heat-up program, input the following settings at

the heat pump manager:

First set parameter “LOWER APP LIMIT HZG” to 30°C.

There are a total of 6 parameters that serve to determine the temperatures and periods for the heat-up program. These 6 parameters can be adjusted in sequence as soon as the heat-up program

is activated. The program is started with the HEAT-UP PROGRAM

parameter and the setting ON. Please note that depending on the

system temperature it may take some time to reach the required

low end temperature.

OPERATION

Menu structure

www.stiebel-eltron.com WPM 3| 15

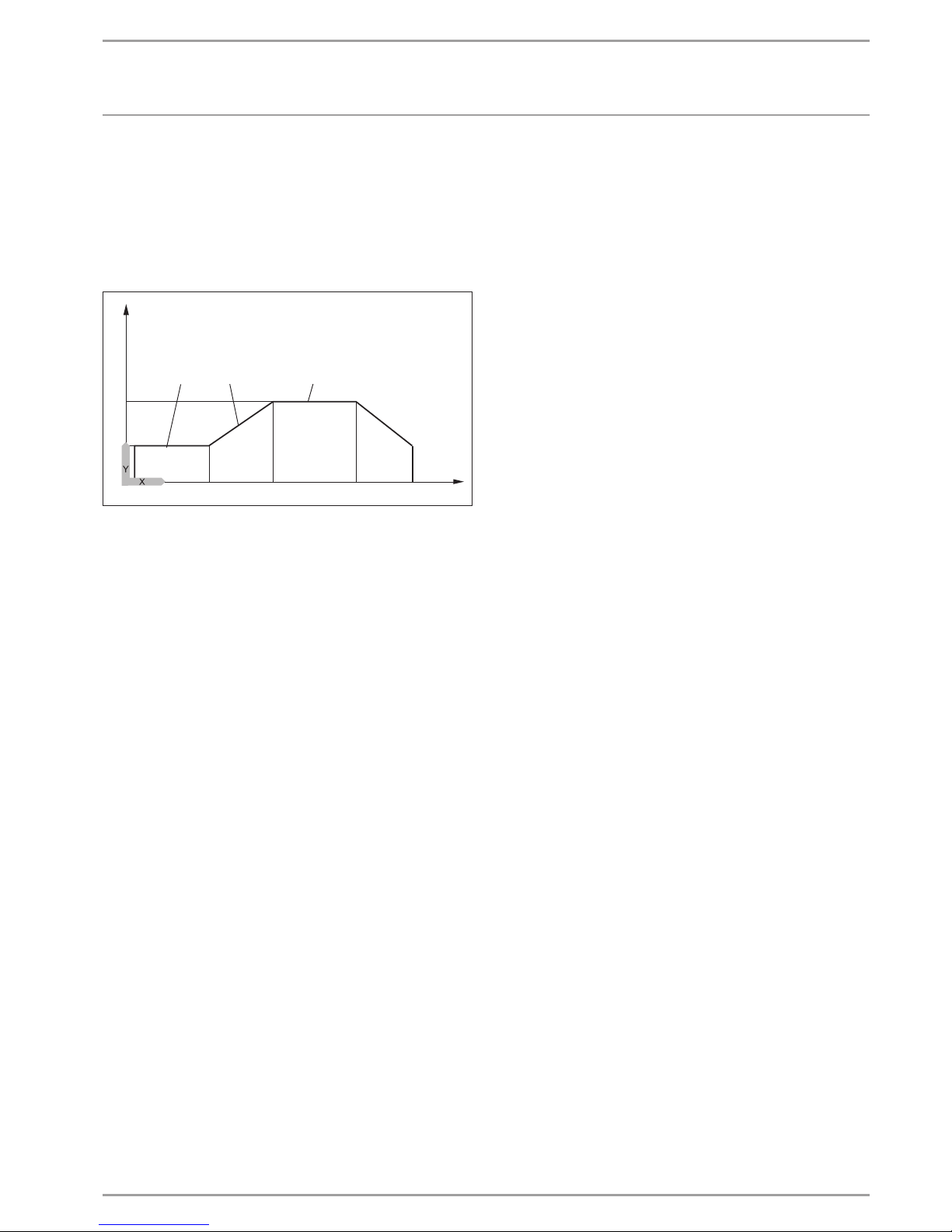

The low end temperature (parameter LOW END TEMPERATURE)

is held for the selected time (parameter DURATION BASE TEMP).

After expiry of this period, the system heats to the maximum low

end temperature (parameter MAXIMUMTEMPERATURE) using

an increase K/day (parameter RISEPERDAY) and holds this maximum temperature for the selected time (parameter MAXTEMPERATURE DURATION). The system subsequently returns to the

low end temperature using the same steps as for heat-up.

1

7

4 5

3

2

84�03�01�0038

6

Y Temperature

X Time

1 Maximum temperature

2 Low end temperature

3 Low end temperature duration

4 Increase K/day

5 Max temperature duration

6 Start

7 End

If a heating buffer cylinder has been integrated into the system,

the temperature in the buffer cylinder is controlled solely via the

return sensor (fitted at the base of the buffer cylinder). If only the

direct heating circuit 1 is operational, the set values are reduced

by 5K to even out temperature differences in the buffer cylinder.

If 2 heating circuits are operational (second heating circuit is for

underfloor heating system), the mixer in heating circuit 2 regulates

down to the selected set values. The pump for heating circuit 1

is not controlled.

During the heat-up program the appliance often reaches maximum output. For this reason, energy consumption and noise levels

are comparatively high during screed drying.

After the heat-up process all modified parameters must be reset

to their standard values or system values.

Emergency operation is not possible while the heat-up program

is active.

5.3.6 SILENT PROGRAM 1

For HP types 1/1* (not for WPL 34/47) and 4/4*, the fan speed is

reduced. This reduces the sound level emitted by the heat pump.

For HP types 3/3* and 5/5*, both the fan speed and the compressor

output can be reduced. Both options can be set independently of

one another.

5.3.7 SILENT PROGRAM 2

In this program, the air source heat pump is switched off for the

entire set period and only the internal or external secondary heat

generator is used for heating.

PLEASE NOTE: This program may result in high electricity bills.

OPERATION

Menu structure

16 | WPM 3 www.stiebel-eltron.com

5.4 SETTINGS menu

Here you can set all system-specific parameters for heating, cooling and DHW modes as well as general settings such as the time.

Note

Some menu items are protected by a code and can only be accessed and adjusted by a qualified contractor.

Note

Not all appliance parameters are displayed in the different menus, depending on which heat pump type is connected.

Level 2 Level 3 Level 4 Level 5

GENERAL

TIME / DATE TIME

YEAR

MONTH

DAY

SET SUMMER TIME DAY BEGINNING

DAY ENDING

CONTRAST

BRIGHTNESS

TOUCH SENSITIVITY

TOUCH ACCELERATION

HEAT ING

HEATING CIRCUIT 1 COMFORT TEMPERATURE

ECO TEMPERATURE

MINIMUM TEMPERATURE

ROOM INFLUENCE

HEATING CURVE RISE

HEATING CURVE VIEW

HEATING CIRCUIT 2 COMFORT TEMPERATURE

ECO TEMPERATURE

MINIMUM TEMPERATURE

MAXIMUM TEMPERATURE

MIXER DYNAMICS

ROOM INFLUENCE

HEATING CURVE RISE

HEATING CURVE VIEW

STANDARD SETTING BUFFER OPERATION

SUMMER MODE OUTSIDE TEMPERATURE

BUILDING HEAT BUFFER

FLOW PROP HEATING CIRC

MAXIMUM RETURN TEMP

MAXIMUM FLOW TEMPERATURE

FIXED VALUE OPERATION

HEATING CIRCUIT OPTIMAL

FROST PROTECTION

REMOTE CONTROL FE7 HEATING CIRC PRESELECTION

ROOM INFLUENCE

ROOM CORRECTION

PUMP CYCLES

EXTERNAL HEAT SOURCE THREADED IMMERSION HEATER

BOILER

HZG PWM

HEATING CURVE GAP

OPERATION

Menu structure

www.stiebel-eltron.com WPM 3| 17

Level 2 Level 3 Level 4 Level 5

SET BOILER TEMPERATURE

BLOCKING TIME EVU

LOWER APP LIMIT HZG

DUAL MODE TEMP HZG

HZG PWM

ELECTRIC REHEATING LOWER APP LIMIT HZG

DUAL MODE TEMP HZG

NUMBER OF STAGES

DEL AY

DHW

DHW TEMPERATURES COMFORT TEMPERATURE

ECO TEMPERATURE

STANDARD SETTING DHW MODE PRIORITY OPERATION

PARALLEL OPERATION

PARTIAL PRIORITY

DHW HYSTERESIS

DHW STAGES

AUTOMATIC DHW CONTROL OUTSIDE TEMPERATURE

WW LEARNING FUNCTION

COMBI CYLINDER

WW OUTPUT WP WW OUTPUT SUMMER

WW OUTPUT WINTER

MAXIMUM FLOW TEMPERATURE

PASTEURISATION

ELECTRIC REHEATING DUAL MODE TEMP WW

LOWER APP LIMIT WW

EXTERNAL HEAT SOURCE SUPPORTED

ALONE

INDEPENDENT

DUAL MODE TEMP WW

LOWER APP LIMIT WW

WW PWM

COOLING

COOLING

COOLING MODE PA SSIVE COOLING

ACTIVE COOLING

STANDARD SETTING COOLING STAGES

COOLING LIMIT

COOLING CAPACITY

ACTIVE COOLING AREA COOLING SET FLOW TEMPERATURE

FLOW TEMP HYSTERESIS

SET ROOM TEMPERATURE

DYNAMICS ACTIVE

DYNAMICS PASSIVE

FAN COOLING SET FLOW TEMPERATURE

FLOW TEMP HYSTERESIS

SET ROOM TEMPERATURE

DYNAMICS ACTIVE

DYNAMICS PASSIVE

PASSIV E COOLING AREA COOLING SET FLOW TEMPERATURE

FLOW TEMP HYSTERESIS

SET ROOM TEMPERATURE

DYNAMICS PASSIVE

FAN COOLING SET FLOW TEMPERATURE

Loading...

Loading...