OPERATION ANd INsTAllATION

BRINE | WATER HEAT PUMPs

» WPf 20

» WPf 27

» WPf 35

» WPf 40

» WPf 52

» WPf 66

» WPf 27 HT

CONTENT

SPECIAL INFORMATION _____________________________________________3

OPERATION __________________________________________________________4

1. General information �����������������������������������������4

1.1 Safety information ����������������������������������������������� 4

1.2 Other symbols in this documentation ����������������������� 4

1.3 Units of measurement ������������������������������������������ 4

1.4 Heat pump output data ����������������������������������������� 4

2. Safety ���������������������������������������������������������� 4

2.1 Correct use �������������������������������������������������������� 4

2.2 Safety instructions ����������������������������������������������� 4

2.3 CE designation ��������������������������������������������������� 4

3. Device description �������������������������������������������5

3.1 Operational characteristics ������������������������������������ 5

3.2 Function ����������������������������������������������������������� 5

4. Control ��������������������������������������������������������5

5. Maintenance and care ���������������������������������������5

6. Other problems �����������������������������������������������5

INSTALLATION _______________________________________________________6

7. Safety ���������������������������������������������������������� 6

7.1 General safety instructions ������������������������������������ 6

7.2 Instructions. standards and regulations �������������������� 6

8. Device description �������������������������������������������6

8.1 WPF 20 | 27 �������������������������������������������������������� 6

8.2 WPF 35 | 40 | 52 | 66 ��������������������������������������������� 7

8.3 WPF 27 HT ��������������������������������������������������������� 7

9. Standard delivery ��������������������������������������������8

9.1 Accessories �������������������������������������������������������� 8

10. Installation ����������������������������������������������������8

10.1 Transport ���������������������������������������������������������� 8

10.2 Positioning �������������������������������������������������������� 8

10.3 Installation of the heat pump system ������������������������ 9

10.4 Installation of the heat consumer system ������������������ 10

10.5 Fitting the casing parts ���������������������������������������� 12

10.6 Removing the casing parts ����������������������������������� 13

10.7 Power supply ���������������������������������������������������� 14

10.8 Modules ���������������������������������������������������������� 14

11. Commissioning ��������������������������������������������� 16

11.1 Operation and control ����������������������������������������� 16

12. Maintenance ������������������������������������������������ 16

13. Troubleshooting �������������������������������������������� 17

13.1 DIP switch (heat pump) ���������������������������������������� 17

13.2 DIP switch (BA) �������������������������������������������������� 17

13.3 LEDs ________________________________________________________ 17

14. Specification ������������������������������������������������ 18

14.1 Water and brine connection ���������������������������������� 18

14.2 Wiring diagrams for heat pump WPF 20 | 27 �������������� 19

14.3 Wiring diagrams for heat pump WPF WPF 35 | 40 ������� 20

14.4 Wiring diagrams for heat pump WPF WPF 52 | 66 ������� 21

14.5 Wiring diagrams for heat pump WPF WPF 27 HT �������� 22

14.6 Output diagrams WPF 20 �������������������������������������� 24

14.7 Output diagrams WPF 27 �������������������������������������� 26

14.8 Output diagrams WPF 27 HT ���������������������������������� 28

14.9 Output diagrams WPF 35 �������������������������������������� 30

14.10 Output diagrams WPF 40 �������������������������������������� 32

14.11 Output diagrams WPF 52 �������������������������������������� 34

14.12 Output diagrams WPF 66 �������������������������������������� 36

14.13 Data table �������������������������������������������������������� 38

WARRANTY

ENVIRONMENT AND RECYCLING _________________________________ 43

2 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

SPECIAL INFORMATION

SPECIAL INFORMATION

- The appliance may be used by children aged8

and up and persons with reduced physical,

sensory or mental capabilities or a lack of

experience and know-how, provided that they are

supervised or they have been instructed on how

to use the appliance safely and have understood

the resulting risks. Children must never play with

the appliance. Children must never clean the

appliance or perform user maintenance unless

they are supervised.

- Use a permanent connection to the power supply.

Ensure the appliance can be separated from the

power supply by an isolator that disconnects all

poles with at least 3mm contact separation.

- Maintain the minimum clearances to ensure

trouble-free operation of the appliance and

facilitate maintenance work.

- At the WPM II. set parameter source in the

commissioning list to "Ethylene glycol". otherwise

the frost stat would stop the heat pump at

temperatures below 7 °C.

- Maintenance work, such as checking the electrical

safety, must only be carried out by a qualified

contractor.

- We recommend an annual inspection (to establish

the system's current condition), and maintenance

by a qualified contractor if required (to return the

system to the desired condition).

- Never interrupt the power supply, even outside

the heating period. The system's active frost

protection is not guaranteed if the power supply

is interrupted.

- There is no need to shut the system down

in summer. The heat pump manager has an

automatic summer/winter changeover.

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 3

OPERATION

GENERAL INFORMATION | SAFETY

OPERATION

1. General information

The chapter entitled “Operation” is intended for appliance users

and contractors.

The chapter entitled “Installation” is intended for contractors.

Note

Read these instructions carefully before using the

appliance and retain them for future reference.

Pass on the instructions to a new user if required.

1.1 Safety information

1.1.1 Structure of safety information

KEYWORD Type of risk

Here, possible consequences are listed that may result

from non-observation of the safety information.

f Steps to prevent the risk are listed.

1.1.2 Symbols, type of risk

Symbol Type of risk

!

Injury

Electrocution

1.4 Heat pump output data

Information regarding the measuring method and interpretation of the heat pump output data provided in these

operating and installation instructions:

The output data provided in the text and diagrams of these

operating and installation instructions has been calculated

according to the standardised measuring conditions of EN14511.

Please note that these standardised measuring conditions do not

always wholly match the local on-site conditions of the individual

system user. The discrepancy may be significant, depending on

the measuring method selected, i.e. the degree of deviation of

the selected method, from the conditions stipulated in EN14511.

Further factors that may have an influence on the measured values

are the measuring equipment, the system configuration, the age

of the system and the flow rates.

It is only possible to confirm the output data provided in these

operating and installation instructions for a specific heat pump if

the measurement used for test purposes was taken under identical

conditions and parameters, i.e. in accordance with EN14511.

2. Safety

2.1 Correct use

The appliance is designed for central heating within the application

limits given in the specification.

This appliance is designed for domestic use. It can be safely

operated by untrained personnel. The appliance can also be used

in a non-domestic environment, e.g. in a small business, as long

as it is used in the same way.

Any other use beyond that described shall be deemed inappropriate.

Observation of this document is also part of the correct use of

the unit. Any changes or conversions to the appliance void any

warranty.

1.2 Other symbols in this documentation

Symbol

!

Note

Notes are bordered by horizontal lines above and below

the text. General information is identified by the symbol

shown on the left.

f This symbol indicates that you have to do something. The

action you need to take is described step by step.

Damage to the appliance and environment

f Read these texts carefully.

1.3 Units of measurement

Note

All measurements are given in mm unless stated

otherwise.

2.2 Safety instructions

Observe the following safety information and instructions.

The electrical installation and installation of the refrigerant circuit

must only be carried out by a recognised. qualified contractor or

by qualified Stiebel Eltron customer service engineers.

The recognised contractor is responsible for adherence to

all currently applicable instructions during installation and

commissioning.

Operate this device only if it is fully installed and all safety

equipment is fitted.

4 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

!

!

OPERATION

DEVICE DESCRIPTION | CONTROL | MAINTENANCE AND CARE

Danger to life through electrocution!

Never spray the device with water or other liquids.

Risk of damage!

Prior to maintenance work. isolate the device from its

power supply.

DANGER Injury

!

he appliance may be used by children aged 8 and up and

persons with reduced physical, sensory or mental capabilities or

a lack of experience provided that they are supervised or they

have been instructed on how to use the appliance safely and have

understood the resulting risks. Children must never play with the

appliance. Children must never clean the appliance or perform

user maintenance unless they are supervised.

2.3 CE designation

The CE designation shows that the device meets all the essential

requirements:

- Electrical Compatibility Directive (2004/108/EC)

- Low Voltage Directive (2006/95/EC)

- Pressure Equipment Directive (97/23/EC)

The rating plate is located at the back of the heat pump.

5. Maintenance and care

Risk of damage!

Maintenance work. such as checking the electrical

safety. must only be carried out by a qualified electrician.

Protect the equipment from dust and dirt ingress during

building work.

A damp cloth is sufficient for cleaning all plastic and sheet steel

parts. Do not use abrasive or corrosive cleaning agents!

6. Other problems

Check the fuse/circuit breaker in your fuse box. If it has blown/

tripped. replace/reset the fuse/MCB. Notify your local contractor

if the fuse/MCB blows/trips again.

If you cannot remedy the fault, notify your qualified contractor.

To facilitate and speed up your enquiry, please provide the serial

number from the type plate.

Sample type plate

*xxxxxxxxxxxxxxxxxx*

1

3. Device description

3.1 Operational characteristics

The WPF is a heating heat pump designed as brine/water heat

pump. The heat pump extracts energy from the heat source

medium. i.e. brine. at a low temperature level. This extracted

energy is then transferred to the heating water at a higher

level. enriched with the energy drawn by the compressor.

Subject to the heat source temperature. the heating water can be

heated up to a flow temperature of 60 °C.

With heat pump type WPF HT. subject to the heat source

temperature. the heating water can be heated to a flow

temperature of up to 75 °C.

A modular operation is possible with the WPF.

3.2 Function

The heat source medium (brine) enters the heat pump evaporator.

There. heat is extracted from the medium. so it exits the heat

pump at a lower temperature.

The energy made useful through the heat pump is transferred to

the heating water inside the condenser.

Then. the heating water transfers its energy to the heating circuit.

4. Control

The heat pump is exclusively controlled by the heat pump manager

WPM II. Therefore. observe the instructions in the chapter Operation

in the operating and installation instructions of the heat pump

manager WPM II.

Montageanweisung beachten! Dichtheit geprüft!

1 Number on the type plate

Made in Germany

26�03�01�1736

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 5

INSTALLATION

SAFETY | DEVICE DESCRIPTION

INSTALLATION

7. Safety

Only qualified contractors should carry out installation.

commissioning. maintenance and repair of the appliance.

7.1 General safety instructions

We guarantee trouble-free operation and operational reliability

only if the original accessories and spare parts intended for the

appliance are used.

7.2 Instructions. standards and regulations

Observe all applicable national and regional regulations and instructions.

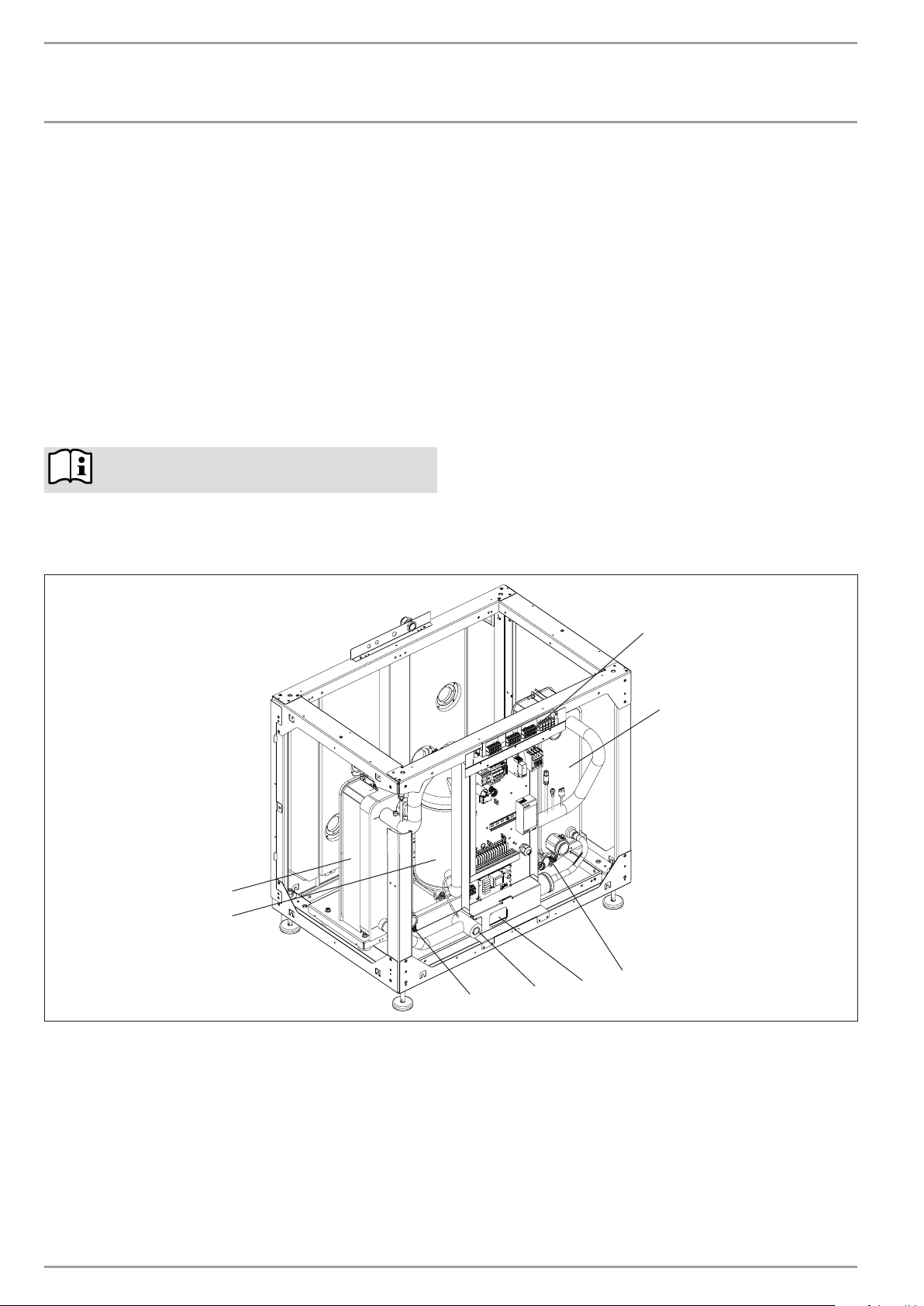

8. Device description

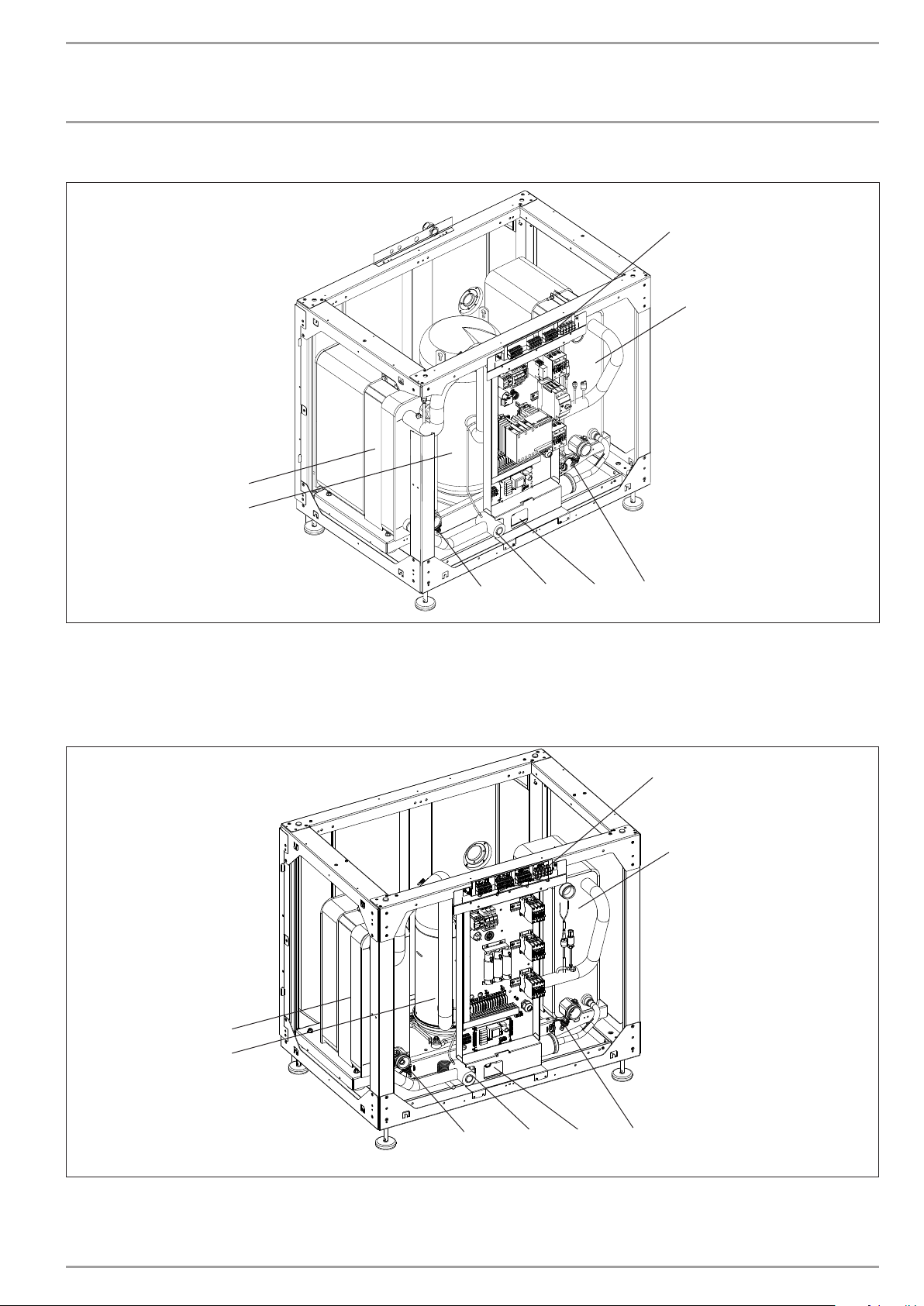

8.1 WPF 20 | 27

8

7

1

2

3

6

1 Electrical terminals

2 Condenser

3 Fill & drain valve (heating)

4 Sight glass

5 Expansion valve

6 Fill & drain valve (brine)

7 Compressor

8 Evaporator

6 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

5

4

26�03�01�1318

INSTALLATION

DEVICE DESCRIPTION

8.2 WPF 35 | 40 | 52 | 66

8

7

1

2

1 Electrical terminals

2 Condenser

3 Fill & drain valve (heating)

4 Sight glass

8.3 WPF 27 HT

8

7

6

5 Expansion valve

6 Fill & drain valve (brine)

7 Compressor

8 Evaporator

5

4

3

26�03�01�0797

1

2

6

1 Electrical terminals

2 Condenser

3 Fill & drain valve (heating)

4 Sight glass

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 7

5

5 Expansion valve

6 Fill & drain valve (brine)

7 Compressor

8 Evaporator

4

3

26�03�01�0797

INSTALLATION

Standard delivery |

INSTALLATION

9. Standard delivery

Heat pumps are delivered in two shipping units.

Designation Part no.

Standard heat pump device

Casing parts 223384

9.1 Accessories

Designation Part no.

Heat pump manager with wall mounting enclosure. WPMW II 185450

Heat pump manager as control panel mounted version. WPMS II 185451

Mixer module with wall mounting enclosure. MSMW 074012

Mixer module as control panel mounted version. MSMS 074011

Cylinder SBP 700 E 185459

Cylinder SBP 700 E SOL 185460

Kit WPVB 227760

Heating system remote control FE 7 185579

Contact sensor AVF 6 165341

Immersion sensor TF 6 165342

Heat transfer medium (concentrate) (10 litre can) 231109

Heat transfer medium (concentrate) (30 litre can) 161696

10. Installation

10.1 Transport

To protect the equipment against damage. transport it vertically

inside its packaging. Storage and transport at temperatures below

– 20 °C and in excess of + 50 °C are not permissible.

In the top of the frame are four holes for fitting lifting eyes M 12

where the equipment can be lifted.

The casing parts are delivered in a separate package. and these

are fitted to the device at the place of installation.

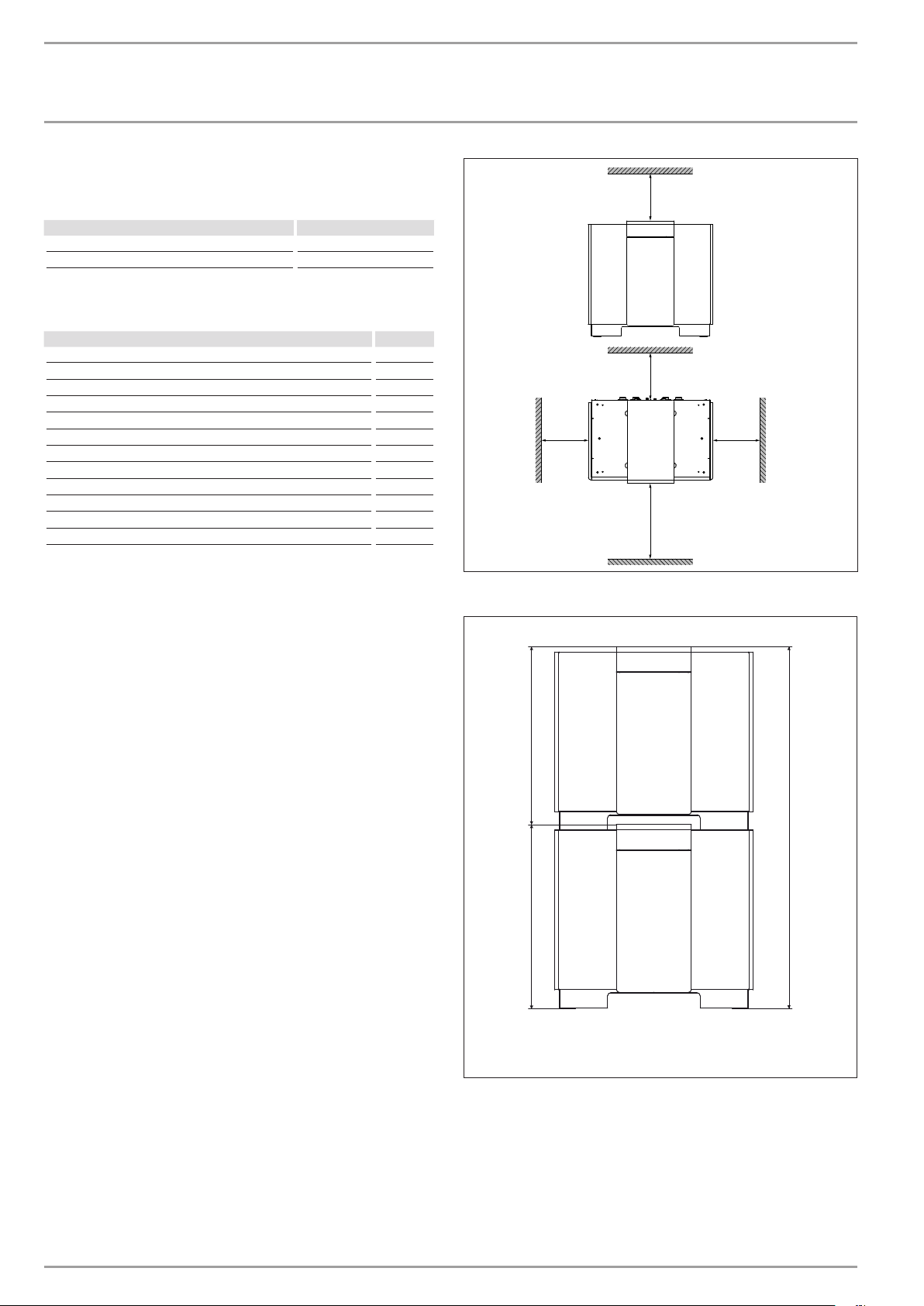

≥500

≥500

≥500

≥1000

2 heat pumps may also be stacked.

f For this, use the WPVB joining set.

≥500

D0000019260

10.2 Positioning

10.2.1 General

Level the device horizontally by adjusting the equipment feet.

To prevent the heat pump from being damaged by frost in case

of external installation. fit and electrically connect the contact

sensor AVF 6 into the heating return as frost protection. Electrical

connection and sensor installation. see chapter "Power supply".

f Observe the minimum clearances.

2269

1154 1115

D0000020355

8 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

INSTALLATION

INSTALLATION

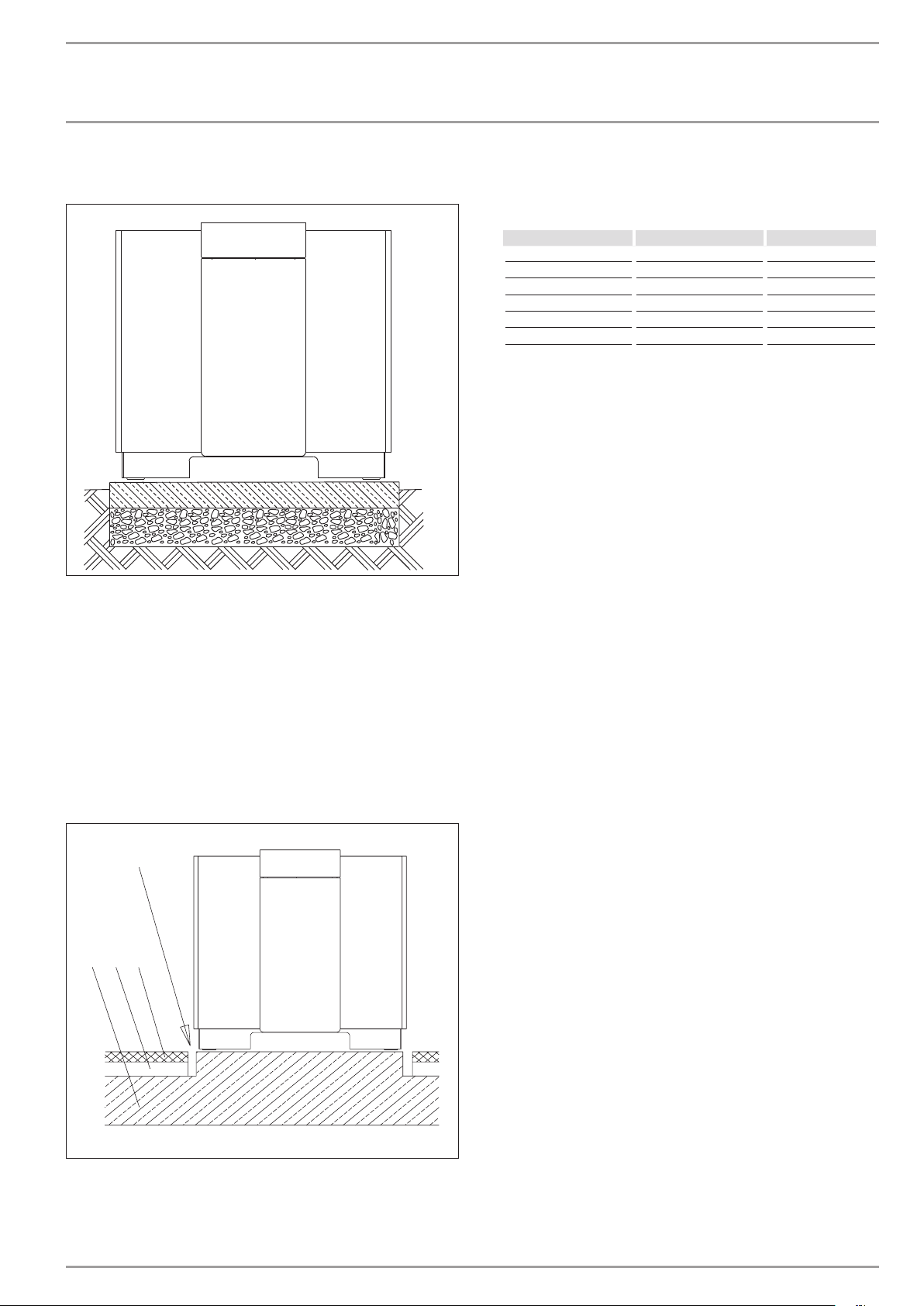

10.2.2 External installation

We recommend foundations as base for the device.

Route all supply lines inside a conduit that is free from frost

(protective pipe).

Protect the connection area at the back panel against all weather

and solar influences.

10.2.3 Internal installation

The room where the WPF is to be installed must meet the following

conditions:

- Load-bearing floor. For the weight of the WPF. see

"Specification".

- For a quiet heat pump operation on floating screeds. recess

the screed and the anti-vibration insulation around the

installation location

of the heat pump.

4

1

3

2

- The room must not be subject to a risk of explosions arising

from dust. gases or vapours. Never allow the floor area

and the volume of the installation room to be less than the

minimum values listed in the table.

Typ Volume Floor area

WPF 20 14 m³ 5 m²

WPF 27 | WPF 27 HT 16 m³ 7 m²

WPF 35 23 m³ 9 m²

WPF 40 23 m³ 9 m²

WPF 52 28 m³ 11 m²

WPF 66 33 m³ 13 m²

- When installing the WPF in a boiler room together with

other heating equipment ensure. that the operation of other

heating equipment will not be impaired.

10.2.4 Sound emission.

Never install the heat pump immediately below or adjacent to

bedrooms. Insulate pipes through walls and ceilings against

structure-borne noise transmission.

10.3 Installation of the heat pump system

26�03�01�0803

The layout of the connection material on the soruce side has to

be done according to the evaporator and condensator materials

(Technical Datas) to avoide corrosion.

Design the heat source system for the brine/water heat pump in

accordance with Stiebel Eltron technical guides.

Permitted brine:

- Heat transfer medium as concentrate on an ethylene glycol

base, part no: 231109

- Heat transfer medium as concentrate on an ethylene glycol

base, part no: 161696

10.3.1 Circulation pump and required flow rate

Use a circulation pump with compound-filled windings to supply

the brine. to prevent an earth short circuit through condensation

in the electrical part of the pump (cold water version).

Size the circulation pump in accordance with the system-specific

conditions. i.e. nominal flow rate and pressure drop must be taken

into consideration (see "Specification").

An adequate flow rate must be safeguarded at every possible

brine temperature. i.e.:

Size the nominal flow rate at brine temperature 0 °C with a

tolerance of + 10 %.

10.3.2 Connection and filling with brine

Prior to connecting the heat pump. check the heat source circuit

for possible leaks. and flush thoroughly.

Calculate the volume of the heat source circuit. You can obtain the

brine volume inside the heat pump from the "Specification" table.

The overall volume equals that of the required amount of brine

that should be mixed from undiluted ethylene glycol and water.

The chloride content of the water must not exceed 300 ppm.

C26�03�01�0802

1 Concrete ceiling

2 Impact sound insulation

3 Floating screed

4 Recess

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 9

INSTALLATION

INSTALLATION

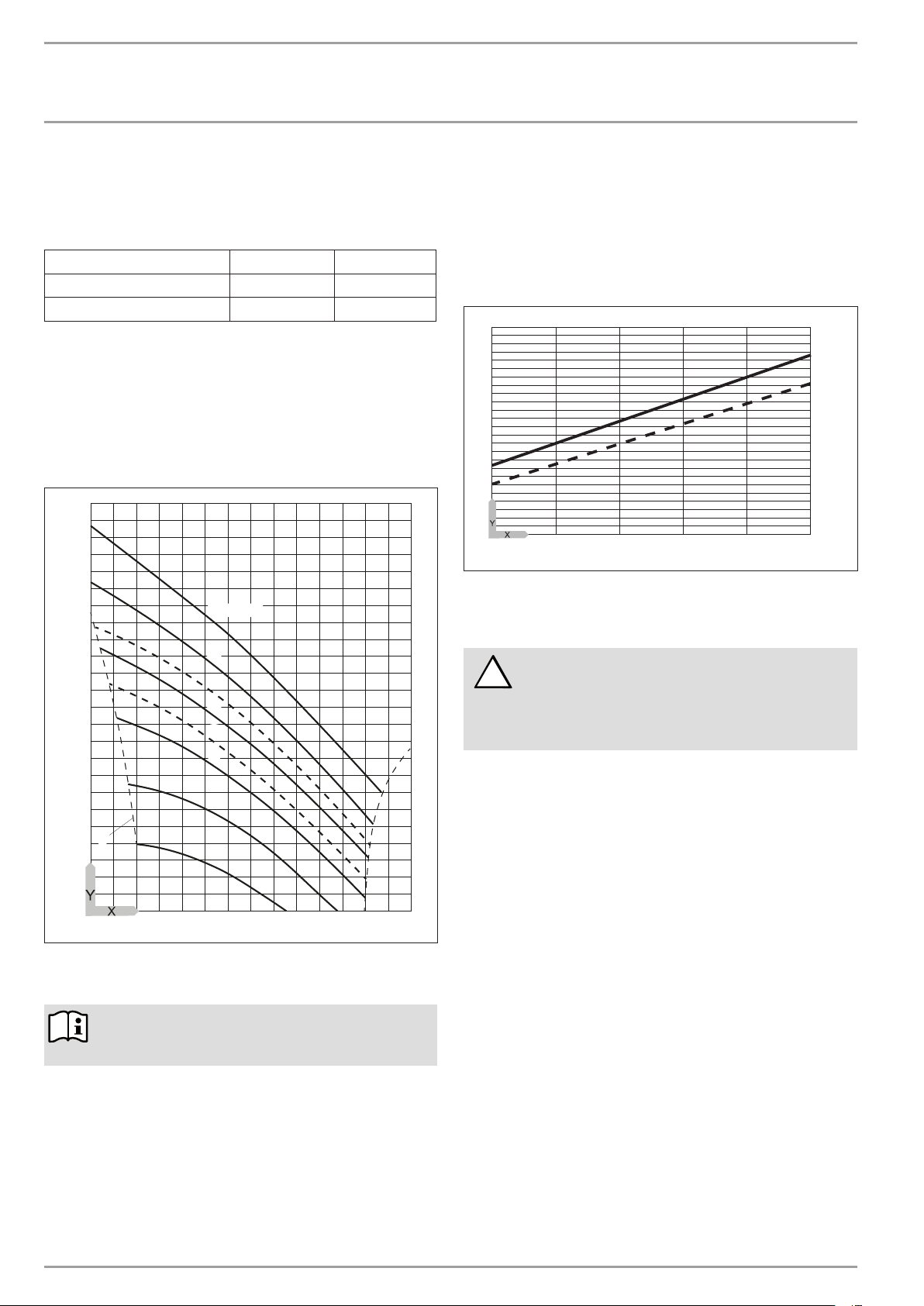

Mixing ratio

The brine concentration varies when using a ground collector or

a geothermal probe as a heat source.

The mixing ratio can be found in the table below.

Ethylene glycol Water

Geothermal probe 25% 75%

Geothermal collector 33% 67%

After filling the system with brine and prior to commissioning.

open the fill & drain valve until brine runs out of it. No water must

remain in the pipe run to the fill & drain valve.

10.3.3 Check the brine concentration:

f Determine the density of the ethylene glycol/water mixture,

e.g. with a hydrometer.

Using the actual density and temperature, you can check the actual

concentration in the diagram.

1,10

1,09

1,08

1,07

1,06

1,05

1,04

1,03

1,02

1,01

A

1,00

0,99

0,98

-20 0 20 40 60 80 100

50 Vol.-%

40

33

30

25

20

10

0

X Temperature [°C]

Y Density [g/cm³]

A Frost protection [°C]

Note

The quoted details refer to ethylene glycol (see

"Specification").

10.3.4 Checking the flow rate (during heat pump

commissioning)

Check the flow and return temperatures of the heat source. For

this. determine the temperature differential by measuring the

temperature under the thermal insulation on both flow and return

pipes of the heat pump.

The diagram shows the temperature spread at the nominal flow

rate.

6

5

4

3

2

1

-5 0 5 10 15 20

Y Temperature differential

X Source inlet temperature

1 Brine = heating flow 35 °C

2 Brine = heating flow 50 °C

Risk of damage!

At the WPM II. set parameter source in the commissioning

!

list to "Ethylene glycol". otherwise the frost stat would

stop the heat pump at temperatures below 7 °C. The

source inlet temperature can be checked on the display

of the WPM II under the Info Temp. system parameter.

10.4 Installation of the heat consumer system

The layout of the connection material on the heating side has to

be done according to the evaporator and condensator materials

(Technical Datas) to avoide corrosion.

Implement the heat consumer system (heating circuit) in

accordance with current technical rules. For safety equipment in

heating systems. consult the DIN EN 12828.

Ensure the correct connection of the heating flow and return.

26�03�01�1914

Protect the heating water lines against frost and moisture (only

in case of external installation). Protect flow and return lines

in external installations with an adequate amount of thermal

insulation against frost and by routing them inside a conduit

against moisture

Maintain the required insulation thickness in accordance with the

Heating System Order [or local regulations].

The integral frost protection control (inside the heat pump). that

automatically starts the circulation pump in the heat pump circuit

at + 8 °C and thereby safeguards circulation in all water-bearing

components. offers additional frost protection. The heat pump is

started automatically no later than when the temperature inside

the buffer cylinder drops below + 5 °C.

Prior to connecting the heat pump. check the heating system for

leaks. flush it thoroughly. fill and carefully vent it.

.

1

2

84�03�01�0017

10 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

INSTALLATION

INSTALLATION

10.4.1 Oxygen diffusion

Risk of damage

In underfloor heating systems. avoid open heating

!

systems or the installation of steel pipes in conjunction

with plastic pipes that are permeable to oxygen.

Steel components. such as radiators and pipes. can corrode if

plastic underfloor heating system pipes. which are permeable to

oxygen. are used.

The products of corrosion. e.g. rusty sludge. can settle inside the

heat pump condenser and result in a lower output by reducing

the cross-section. or in a shutdown being activated by the high

pressure limiter.

10.4.2 Filling the heating system

Water quality

A fill water analysis must be available prior to charging the system.

This may, for example, be requested from the relevant water

supply utility.

Material losses

!

To avoid damage as a result of scaling, it may be necessary

to soften or desalinate the fill water. The fill water limits

specified in chapter "Specification / Data table" must

always be observed.

f Recheck these limits 8-12 weeks after

commissioning and as part of annual system

maintenance.

10.4.6 Second external heat source

For dual-mode heating systems. always connect the heat pump

into the return of the second heat source (e.g. oil fired boiler).

High heating water temperature: In dual-mode heating systems.

the return water from the second heat source can flow through

the heat pump. immediately after it has been switched off. with

a max. temperature of 60 °C. The temperature may be 70 °C no

earlier than ten minutes after the heat pump has been shut down.

10.4.7 Heat meter

Observe the additional pressure drop when installing heat meters

on the heating side. The sieves inside the heat meters are easily

blocked by dirt particles in the heating circuit. further increasing

the pressure drop.

Note

With conductivity of >1000μS/cm, desalination treatment

is recommended in order to avoid corrosion.

Note

Suitable appliances for water softening and desalinating,

as well as for charging and flushing heating systems, can

be obtained via trade suppliers.

Note

If you treat the fill water with inhibitors or additives, the

same limits as for desalination apply.

10.4.3 Buffer cylinder

A buffer cylinder is recommended to ensure a trouble-free heat

pump operation. The buffer cylinder provides hydraulic separation

of the volume flow in the heat pump circuit and the heating circuit.

The flow rate in the heat pump remains constant if. for example.

the flow rate in the heating circuit is reduced by thermostatic

valves.

10.4.4 Circulation pump (cylinder primary pump)

When using a buffer cylinder. observe the pressure drop of the

evaporator. of the connecting lines. bends. valves etc. in sizing the

circulation pump to be installed.

10.4.5 Circulation pump (heating circuit pump)

Where no buffer cylinder is used. size the circulation pump

on the heating side taking the condenser pressure drop into

consideration. The flow rate at DT = 10 K (see "Specification") of

the heat pump must be assured under all operating conditions of

the heating system through the installation of an overflow valve.

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 11

INSTALLATION

INSTALLATION

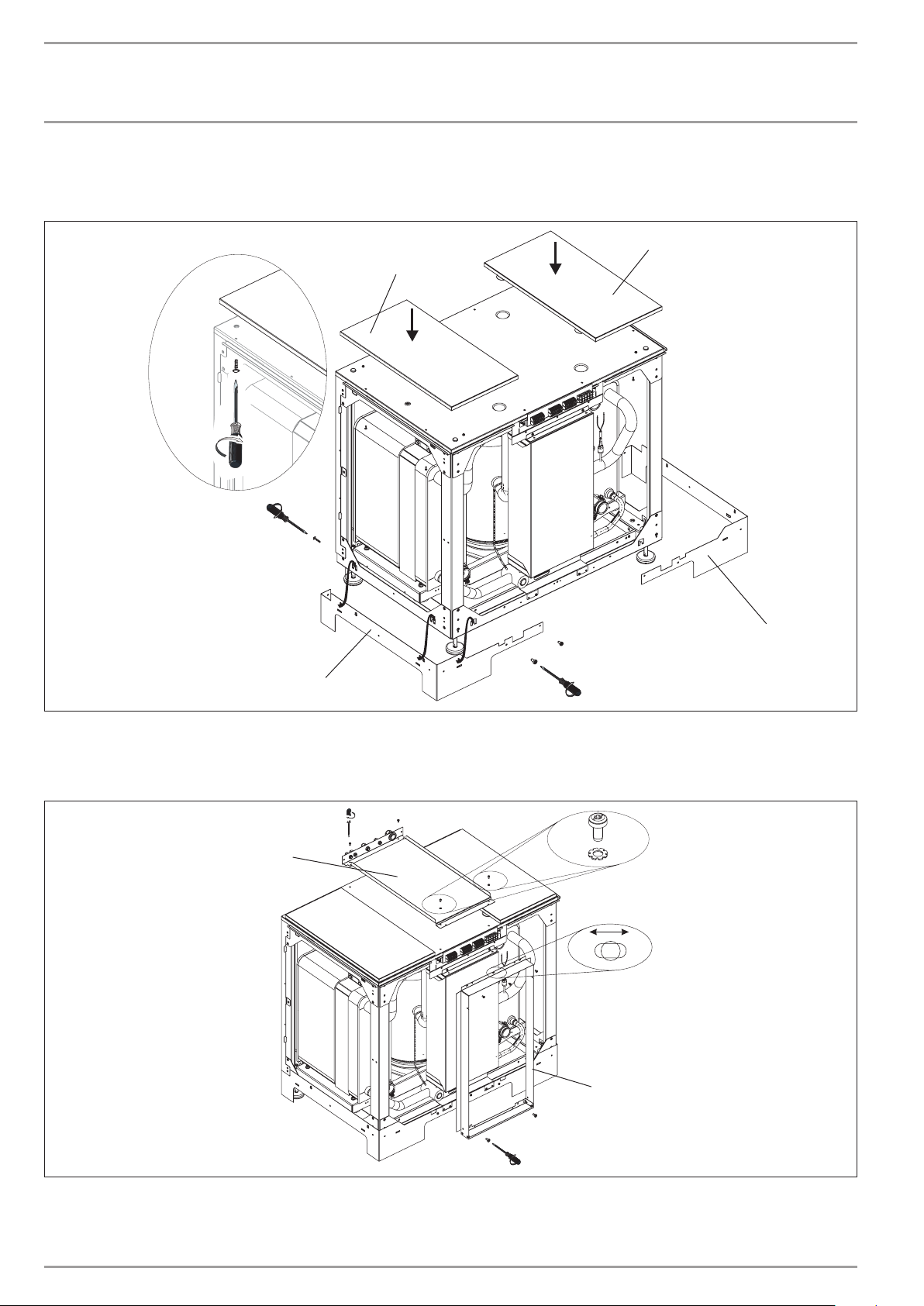

10.5 Fitting the casing parts

Fitting the plinth facia and control panel frame

2

1.

3.2.

1

2

1

C26�03�01�0791

f Hook the plinth facia 1 into the device frame and secure each with three screws

f Position the covers 2 and secure each with two screws to the sides.

Fitting the side covers

1

2

C26�03�01�0792

f Fix the guard plate 1 with four screws. The both in the front with the toothed locked washer.

f Secure the control panel frame 2 with five screws.

12 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

INSTALLATION

INSTALLATION

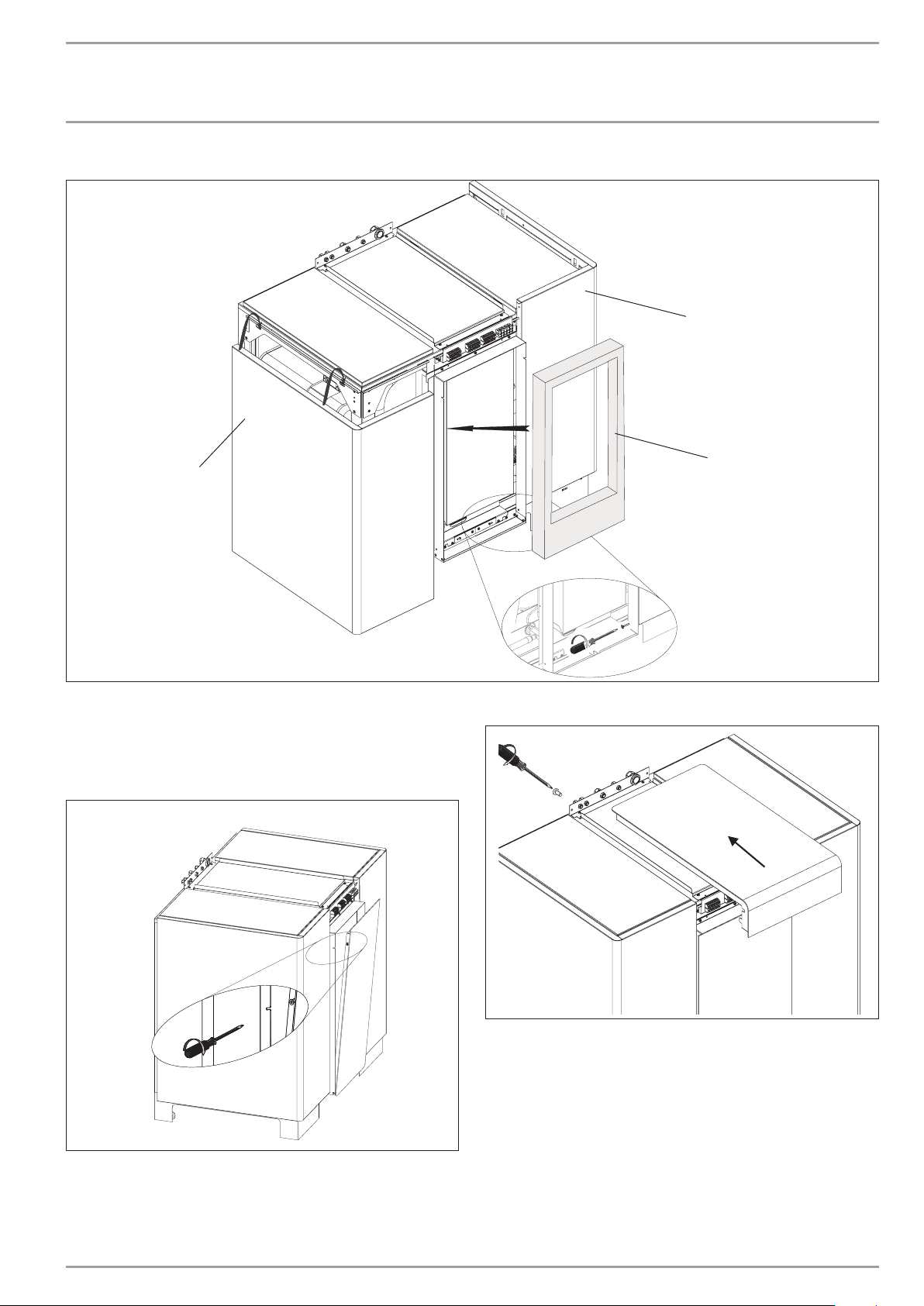

Fitting the side panels

1

1

2

f Hook the side panels 1 from the top into the slots and hooks

provided and secure with one screw each at the bottom of

the control panel frame.

f Install sound insulation 2 in the control panel frame

Fit front panel

C26�03�01�0793

Fit centre cover

C26�03�01�0794

f Position the cover at the front of the device and push it back;

then secure it with two screws.

f Make the power supply before the centre cover and front

panel are fitted.

C26�03�01�0795

10.6 Removing the casing parts

f Hook the bottom of the front panel into the control panel

frame. pivot it towards the frame and secure with one screw

on each side.

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 13

The casing parts are removed in reverse order.

INSTALLATION

INSTALLATION

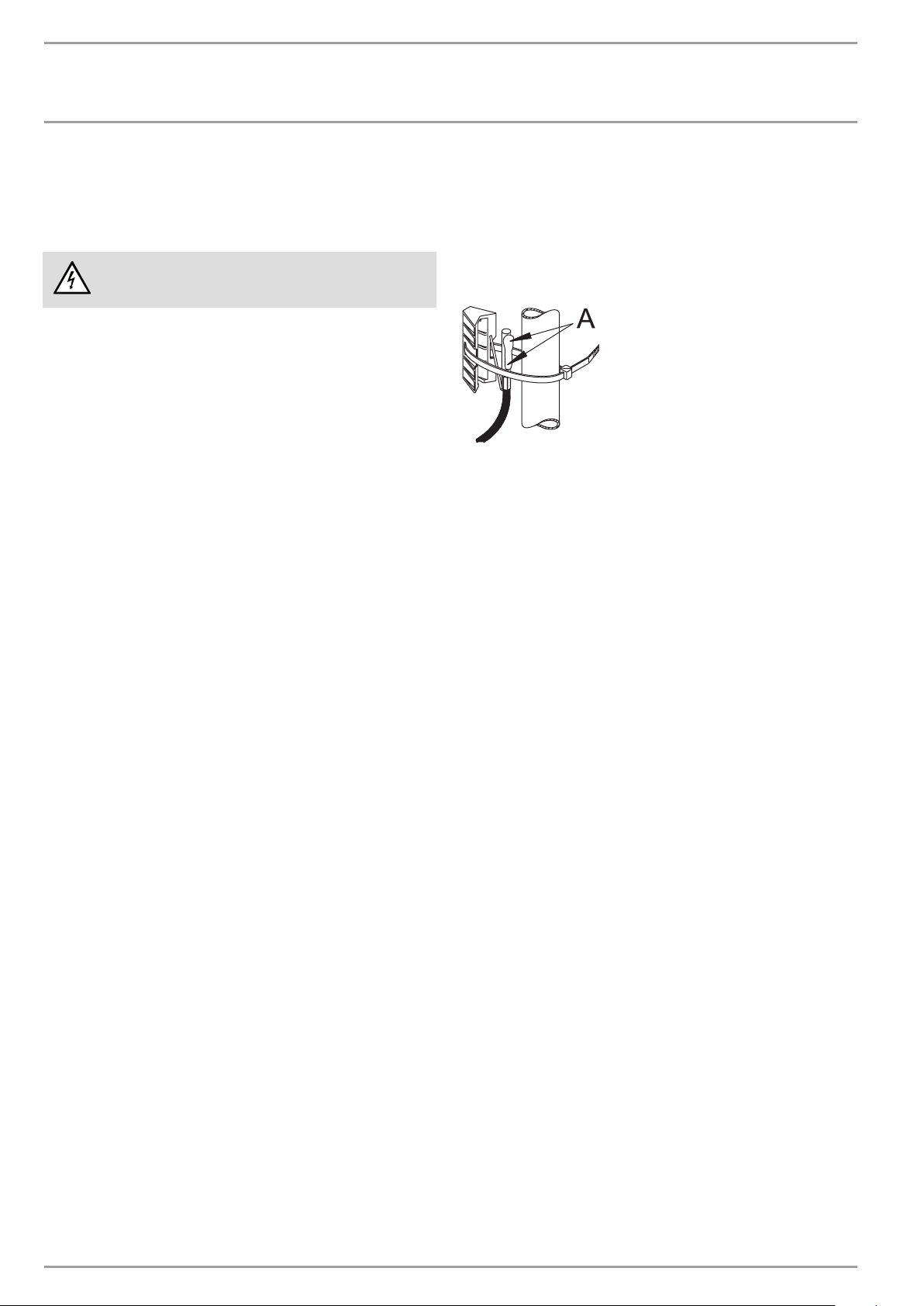

10.7 Power supply

Notify your local power supply utility of the electrical connection.

Only qualified electricians must carry out the installation in

accordance with these instructions.

Danger to life through electrocution!

Before any work. isolate the equipment from the power

supply at the control panel.

Observe VDE 0100 [or local regulations] and the regulations of your

local power supply utility.

The heat pump must be able to be separated from the mains power

supply by an additional isolator. that disconnects all poles with at

least 3 mm contact separation. For this purpose. use contactors.

main isolators. fuses. etc. on site.

The terminals are located above the control panel. Remove the lid

to enable the equipment to be connected.

The following are connected at the terminals:

- the power supply of the IWS heat pump control unit

- the compressor power supply

- the brine pump power supply

- the BUS cable (J-Y (St) 2x2x0.8)

Ensure that High. Low and Ground are correctly connected.

- the enable signal for the stand-alone operation at terminal

X4/2. For this. remove the jumper between X4/L and X4/2.

The IWS (integral heat pump controller) is a PCB that is fitted as

standard into the heat pump control panel. The IWS controls the

contactors of the compressors and the starting current limiter.

receives the signal inputs for high pressure. low pressure and

central faults and contains the BUS interface to the WPM II.

Use appropriate cables in accordance with local regulations

for all connections. For this. observe the Electrical details in

"Specification" and the Electrical connection diagram.

Check the strain relief function.

Observe the operating instructions for the WPM II heat pump

manager.

Connect the circulation pump for the heat consumers in accordance

with the electrical connection diagram

documentation.

In case of external installation. use only weather-proof

connecting cables to VDE 0100 [or local regulations]. As a

minimum requirement. use cables with rubber sheathing with

the identification 60245 IEC 57. Route all lines inside a conduit

(protective pipe).

or the engineering

To prevent the heat pump from being damaged by frost in case of

external installation or when installing it in a room that is not free

from the risk of frost. fit and electrically connect the contact sensor

AVF 6 at the heating-return. The contact sensor is electrically

connected at terminals X2/4 and X2/5.

The heating circuit pumps are started when the heating-return

temperature falls to +8 °C. The reverse switching hysteresis is 4 K.

Sensor installation:

f Thoroughly clean the pipe.

f Apply heat conducting paste A.

f Secure the sensor with a tie.

STAND-ALONE operation

In emergencies. this heat pump can also operate without the heat

pump manager (see troubleshooting).

Route all connecting cables and sensor leads through the apertures

in the back panel.

10.8 Modules

When using a modular approach. connect the individual heat

pumps via terminal BUS 1. 2. 3. Ensure that High. Low and Ground

are correctly connected at the WPM II as well as at the heat pump.

14 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

Störung

INSTALLATION

INSTALLATION

Power supply WPF 20. WPF 27. WPF 35, WPF 40. WPF 52. WPF 66. WPF 27 HT

WPM II

BUS / Fühler

X2

X2 LV terminal

1 BUS High H

2 BUS Low L

3 BUS Ground

4 & 5 Temperature sensor B6

X3 Power supply

Heat pump (compressor)

L1. L2. L3. N. PE

X4 Control terminal

Power supply: L. N. PE

Control input:

Ext. control. STAND-ALONE operation

ON. compressor output signal

Fault message. output signal

X5 Power supply

Brine pump

L1. L2. L3. N. PE

~230V 50Hz

X4

3/N/PE

~400V 50Hz

X5

3/N/PE

~400V 50Hz

X3

26�03�01�0796

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 15

!

!

INSTALLATION

COMMISSIONING

| MAINTENANCE

11. Commissioning

Only approved contractors may commission this equipment and

instruct the owner in its use.

Commission the WPF in accordance with these installation

instructions and the operating and installation instructions of the

heat pump manager WPM II. Our customer service can assist in

the commissioning. which is chargeable.

Where this heat pump is used in an installation that is intended

for commercial use. the rules of the relevant Health & Safety at

Work Act may come into play. For further details. check your local

authorising body. The function of the device. including those of

any safety equipment fitted is tested at the factory.

After commissioning. the installer should complete the

commissioning report contained in these instructions.

Check the following prior to commissioning:

Heating system

- Was the heating system filled to the correct pressure. and

was the quick-acting air vent valve opened?

Temperature sensor

- Were the outside temperature and the return temperature

sensor (in conjunction with a buffer cylinder) correctly

positioned and connected?

Power supply

- Was the mains power supply properly connected?

Please note:

!

The compressor in the appliance can only turn in one

direction. If the appliance is not connected correctly. the

compressor remains in operation for 30 seconds then

switches off.

Drain the liquid contained inside the evaporator via the fill & drain

valve that becomes accessible after removing the r.h. side panel.

12. Maintenance

Danger to life through electrocution!

Before any work. isolate the equipment from the power

supply at the control panel.

Risk of damage!

Check the refrigerant circuit of the heat pump WPF 20,

27, 35, 40, 52, 66 annually for tightness in accordance

with EU Directive 842/2006.

Document tightness tests in the service record.

If heat meters are installed. frequently clean their sieves. which

block easily.

When the heat pump operation is impaired (high pressure limiter

responds) through deposits of corrosion by-products (rust sludge)

inside the condenser. only dissolving them by means of solvents

used by our customer service will remove this problem.

Risk of damage!

Never change the factory setting of the rotary selector

on the overcurrent circuit breaker

Factory setting

WPF 52 35 A

WPF 66 45 A

A permanently set overcurrent circuit breaker is installed inside

the compressor of the WPF 20. 27 and 40.

In this case the heat pump manager displays the fault message

"no output". Two phases should then be interchanged to alter the

direction of rotation.

When everything has been implemented correctly. the system

can be heated to its maximum operating temperature and vented

once again.

Risk of damage!

Observe the maximum system temperature in underfloor

!

heating systems.

11.1 Operation and control

A WPM II heat pump manager is required to operate the heat

pump. It regulates the entire heating system. All necessary

adjustments prior and during operation are made on this device.

Only qualified contractors must make adjustments listed in the

commissioning report of the WPM II heat pump manager.

Risk of damage!

The system does not need to be shut down during summer.

!

as the WPM II implements an automatic summer/winter

changeover. If the system is. nevertheless. to be shut

down. set the WPM II to standby. That way the safety

functions that protect the system remain enabled (e.g.

frost protection).

Drain the water side of the equipment. if the heat pump is taken

out of use at a location subject to a risk of frost or if it is installed

externally.

16 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

INSTALLATION

BA

!

TROUBLESHOOTING

13. Troubleshooting

Checking the IWS settings

1

2

1 LEDs

2 DIP switch (BA)

3 Reset button

4 DIP switch (heat pump)

The control panel with the "Internal heat pump controller" (IWS II)

becomes accessible after removing the front hood. The following

list the adjustments of the IWS II required for the WPF:

13.1 DIP switch (heat pump)

The DIP switch (heat pump) enables the pre-selection of the

various compressor systems. Subject to the system heat pump

type. for the WPF this was set to 12 at the factory.

If the WPF is to be operated as a module with another WPF. this

setting (heat pump) remains at 12.

f Please check whether the DIP switch (heat pump) is set

correctly.

3

4

temperature sensor at sensor terminals X2/4 and X2/5. The

sensor must be connected to the heating return (chapter Device

description). The operating mode is indicated by the green LED

on the right.

Risk of damage!

For STAND-ALONE operation. remove the jumper

between X4/1 and X4/2.

13.3 LEDs

Red LED:

The LED flashes when a heat pump fault occurs once. The system

will be shut down.

The red LED illuminates steady if more than 5 heat pump faults

occur within 2 hours. The system will be shut down permanently.

If the red LED is flashing or illuminated steadily, voltage of 230V

is present at the fault output (terminal X4/3).

To delete the faults from the IWS II. select Reset WP and reset

by pressing PRG on the IWS II. The internal counter will then be

26�03�01�0661

returned to zero.

Heat pump faults displayed by the LED: High pressure fault / low

pressure fault. central fault message and hardware faults at the

IWS II (see fault list).

Green centre LED: Flashes during the initialisation and becomes

steady after the BUS address has been allocated. Communication

to the WPM II is only then established. This is only relevant for the

WPF. if the control unit is replaced. otherwise the unit is initialised

at the factory.

Green r.h. LED: Illuminates steady if STAND-ALONE operation has

been selected.

Reset button

In case of incorrect initialisation. see chapter 5.4.1 in the operating

and installation instructions of the WPM II.

The correct position of the slide switch can also be checked on

control level 3 on the WPM II. The display should indicate a C under

parameter "Type IWS".

13.2 DIP switch (BA)

Switches 1, 2 and 3 have no relevance to the WPF.

Position switch 4

Switch ON : STAND-ALONE operation

STAND-ALONE operation is only possible if a heat pump type has

been allocated to the WPM II under parameter IWS TYPE.

Should the WPM II heat pump manager develop a fault. the heat

pump can be operated in STAND-ALONE mode in an emergency.

In this operating mode. there is no communication with the WPM

II. The heat pump regulates to a fixed temperature: it starts up at

50 °C and shuts down at 55 °C. For this. 230 V must be applied to

terminal X4/2. and a contact sensor AVF 6 connected as a return

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 17

f01

INSTALLATION

SPECIFICATION

14. Specification

14.1 Water and brine connection

e01

860

b01

1150

1250

WPF 20 WPF 27 WPF 35 WPF 40 WPF 52 WPF 66 WPF 27 HT

b01 Entry electrical cables

e01 Heating flow Male thread G 2 G 2 G 2 G 2 G 2 G 2 G 2

e02 Heating return Male thread G 2 G 2 G 2 G 2 G 2 G 2 G 2

f01 Heat source flow Male thread G 2 G 2 G 2 G 2 G 2 G 2 G 2

f02 Heat source return Male thread G 2 G 2 G 2 G 2 G 2 G 2 G 2

e02

900

772

f02

340

470

360

480

600

720

D0000016833.ai

18 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

8

X2

K1

A2

A1

6

7

Q1

2

1

6

5

4

3

L

1 1

2

1

s u B

Hei ß gas

12

10

9

8

7

H

Einfrierschutz

3

HD/ND

Solepumpe

N

5

4

3

2

1

3

4

5

L

M1

M

3

X3

X5

A2

9

10

1 1

12

13

X1

F ü r e l h

2

1

L1

L2 L3

N

K4

6

4

2

1 3 5

K1

6

4

2

1 3 5

14

L

N

X4

euetS.txE

r .

1/N /PE AC 50Hz 230V

F2

> p

2

3/N/PE AC 50Hz 400V

3/N/PE AC 50Hz 400V

3 2 1

4

5

X23

X34

N3

X23

X29

X33

X30

2 1

1

X24

X24

C

T1

S

T2

R

T3

L1

L2 L3

N

K4

A1

A2

Q1

A2

A1

Q1

2

4

6

5

3

1

L3

L2

L1

T1

T2

T3

A1

A2

T <

E2

1

2

3

Anschluss Solepumpe

L

H

Kleinspannung

BUS

B6

B6

N O

F9

Z2

6

4

2

1 3 5

br ws sw

br ws sw

3

4

5

2

1

X35

6

P

I

P

I

P3

P1

1

1

2

2

12-18V

X28

B5

3

rungötS

INSTALLATION

SPECIFICATION

14.2 Wiring diagrams for heat pump WPF 20 | 27

heater

X24 Power supply earth screw

X28 Plug-in connector terminal strip

X29 Plug-in connector IWS II 12-PIN

X30 Plug-in connector IWS II 3-PIN

X33 Plug-in connector IWS II 5-PIN

X34 Plug-in connector terminal strip - oil sump

X35 Plug-in connector IWS II 6-PIN

Z2 Supressor elemen

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 19

N3 Temp. controller - oil sump heater

P1 High pressure transducer

P3 Low pressure transducer

Q1 Softstart contactor

X1 Terminals

X2 LV terminal

X3 Heat pump - mains

X4 Control voltage terminals

X5 Brine pump terminals

X23 Power supply earth terminal block

not free from the risk of frost)

26�03�01�0853�d

A2 Integral heat pump controller IWS II

B5 Hot gas temperature sensor

B6 Frost sensor (only for ext. inst. or inst. in a room

E2 Oil sump heater

F2 High pressure limiter

F9 Solar pump MCB

K1 Safety contactor

K4 Brine pump contactor

M1 Compressor motor

INSTALLATION

SPECIFICATION

14.3 Wiring diagrams for heat pump WPF WPF 35 | 40

X23

N

L2 L3

3/N/PE AC 50Hz 400V

L1

X3

N

L2 L3

3/N/PE AC 50Hz 400V

L1

Anschluss Solepumpe

X5

2

P1

P

I

1

2

P

I

1

P3

1 3 5

1 3 5

br ws sw

1 3 5

X28

K1

F9

Z2

K4

6

4

2

br ws sw

6

4

2

12-18V

6

4

2

1 3 5

K2

2

4

6

L3

5

L2

3

L1

1

Q1

A1

23

A2

24

T3

6

T2

4

T1

2

A2

K2

A1

Drossel

Z1

X24

R

T3

S

T2

M

3

C

T1

M1

4

1

X1

X30 Plug-in connector IWS II 3-PIN

X33 Plug-in connector IWS II 5-PIN

X34 Plug-in connector terminal strip - oil sump heater

X35 Plug-in connector IWS II 6-PIN

Z1 Supressor elemen

Z2 Supressor elemen

B6

5

4

B6

3 2 1

L

BUS

H

Kleinspannung

X2

B5

X35

A2

1

X29

X1

2

1

Z1/schräg links

Z1/schräg rechts

X23

6

4

5

3

2

1

3

A2

4

4

Q1

5

A2

5

A1

6

K4

Q1

6

7

A1

7

8

N

L

2

3

X33

HD/ND

Solepumpe

9

8

9

10

4

5

3

2

10

1 1

Hei ß gas

1 1

12

N3

X34

Einfrierschutz

12

13

14

T <

3

2

1

1

F ü r e l h

X30

A1

2

1

3

H

L

s u B

P1 High pressure transducer

P3 Low pressure transducer

Q1 Softstart contactor

X1 Terminals

X2 LV terminal

X3 Heat pump - mains

X4 Control voltage terminals

X5 Brine pump terminals

X23 Power supply earth terminal block

X24 Power supply earth screw

X28 Plug-in connector terminal strip

X29 Plug-in connector IWS II 12-PIN

K1

A2

F2

X4

1

E2

> p

2

3

2 1

L

N

törungS

e u e t S . t x E r .

N O

1/N /PE AC 50Hz 230V

X24

not free from the risk of frost)

26�03�01�0806�d

A2 Integral heat pump controller IWS II

B5 Hot gas temperature sensor

B6 Frost sensor (only for ext. inst. or inst. in a room

E2 Oil sump heater

F2 High pressure limiter

F9 Solar pump MCB

K1 Safety contactor

K2 Compressor contactor

K4 Brine pump contactor

M1 Compressor motor

N3 Temp. controller - oil sump heater

20 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

8

X2

K1

A2

A1

6

7

Q1

2

1

6

5

4

3

L

1 1

2

1

s u B

Hei ß gas

12

10

9

8

7

H

Einfrierschutz

3

HD/ND

Solepumpe

N

5

4

3

2

1

3

4

5

L

X3

X5

A2

9

10

1 1

12

13

X1

F ü r e l h

2

1

L1

L2 L3

N

K4

6

4

2

1 3 5

K1

6

4

2

1 3 5

14

L

N

X4

euetS.txE r.

1/N /PE AC 50Hz 230V

F2

> p

2

3/N/PE AC 50Hz 400V

3/N/PE AC 50Hz 400V

3 2 1

4

5

X23

X34

N3

X23

X29

X33

X30

21

1

X24

L1

L2 L3

N

K4

A1

A2

Q1

A2

A1

T <

E2

1

2

3

Anschluss Solepumpe

L

H

Kleinspannung

BUS

B6

B6

NO

F9

Z2

6

4

2

1 3 5

br ws sw

br ws sw

3

4

5

2

1

X35

6

P

I

P

I

P3

P1

1

1

2

2

12-18V

X28

B5

M1

M

3

6

4

2

1 3 5

X24

C

T1

S

T2

R

T3

A2

A1

K2

Q1

2

4

6

5

3

1

L3

L2

L1

T1

T2

T3

K2

23

24

A1

A2

X1

1

4

Drossel

Z1

Z1/schräg rechts

Z1/schräg links

F8

5

3

1

2

4

6

T1

T2

F7

> u

M2

M1

3

Störung

INSTALLATION

SPECIFICATION

14.4 Wiring diagrams for heat pump WPF WPF 52 | 66

X30 Plug-in connector IWS II 3-PIN

X33 Plug-in connector IWS II 5-PIN

heater

X34 Plug-in connector terminal strip - oil sump

X35 Plug-in connector IWS II 6-PIN

Z1 Supressor elemen

Z2 Supressor elemen

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 21

N3 Temp. controller - oil sump heater

P1 High pressure transducer

P3 Low pressure transducer

Q1 Softstart contactor

X1 Terminals

X2 LV terminal

X3 Heat pump - mains

X4 Control voltage terminals

X5 Brine pump terminals

26�03�01�0780�c

A2 Integral heat pump controller IWS II

not free from the risk of frost)

B5 Hot gas temperature sensor

B6 Frost sensor (only for ext. inst. or inst. in a room

E2 Oil sump heater

F2 High pressure limiter

F7 Protective motor switch. internal

F8 Protective motor switch. external

F9 Solar pump MCB

X23 Power supply earth terminal block

X24 Power supply earth screw

X28 Plug-in connector terminal strip

X29 Plug-in connector IWS II 12-PIN

K1 Safety contactor

K2 Compressor contactor

K4 Brine pump contactor

M1 Compressor motor

INSTALLATION

8

X2

K1.1

A2

A1

6

7

K2

2

1

6

5

4

3

L

1 1

2

1

s u B

Hei ß gas

12

10

9

8

7

H

Einfrierschutz

3

HD/ND

Solepumpe

N

5

4

3

2

1

3

4

5

L

X3

X5

A2

9

10

1 1

12

13

X1

F ü r e l h

2

1

L1

L2 L3

N

K4

6

4

2

1 3 5

K1.1

6

4

2

1 3 5

14

L

N

X4

euetS.txE r.

1/N /PE AC 50Hz 230V

F2

> p

2

3/N/PE AC 50Hz 400V

3/N/PE AC 50Hz 400V

3 2 1

4

5

X23

X34

N3

X23

X29

X33

X30

21

1

X24

L1

L2 L3

N

K4

A1

A2

K2

A2

A1

T <

E2

1

2

3

Anschluss Solepumpe

L

H

Kleinspannung

BUS

B6

B6

NO

F9

Z3

6

4

2

1 3 5

sw ws br

sw ws br

3

4

5

2

1

X35

6

P

I

P

I

P3

P1

1

1

2

2

12-18V

X28

B5

M1

M

3

6

4

2

1 3 5

X24

C

T1

S

T2

R

T3

K1

T1

T2

F7

> υ

M2

M1

6

4

2

1 3 5

K2

K1

K1

A2

A1

R1

R2

R3

3

Störung

SPECIFICATION

14.5 Wiring diagrams for heat pump WPF WPF 27 HT

heater

X28 Plug-in connector terminal strip

X29 Plug-in connector IWS II 12-PIN

X30 Plug-in connector IWS II 3-PIN

X33 Plug-in connector IWS II 5-PIN

X34 Plug-in connector terminal strip - oil sump

X35 Plug-in connector IWS II 6-PIN

Z3 Supressor elemen

22 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

N3 Temp. controller - oil sump heater

P1 High pressure transducer

P3 Low pressure transducer

R1 Sart-Resistor

R2 Sart-Resistor

R3 Sart-Resistor

X1 Terminals

X2 LV terminal

X3 Heat pump - mains

X4 Control voltage terminals

X5 Brine pump terminals

X23 Power supply earth terminal block

X24 Power supply earth screw

26�03�01�1435�b

A2 Integral heat pump controller IWS II

room not free from the risk of frost)

B5 Hot gas temperature sensor

B6 Frost sensor (only for ext. inst. or inst. in a

E2 Oil sump heater

F2 High pressure limiter

F7 Protective motor switch. internal

F9 Solar pump MCB

K1 Relay. resitor bridge

K1.1 Safety contactor

K2 Compressor contactor

K4 Brine pump contactor

M1 Compressor motor

INSTALLATION

SPECIFICATION

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 23

INSTALLATION

1

2

3

4

1

2

3

4

SPECIFICATION

14.6 Output diagrams WPF 20

Key to output diagrams

Y Heating output [kW] / power consumption [kW] / coefficient of performance e [-]

X Inlet temperature of the WQA medium [°C]

1 Flow temperature 35 °C

2 Flow temperature 45 °C

3 Flow temperature 55 °C

4 Flow temperature 60 °C

Heating output

37

35

33

31

29

27

25

23

21

19

17

-5 0 5 10 15 20

Power consumption

9,0

8,5

8,0

7,5

7,0

6,5

D0000021913

6,0

5,5

5,0

4,5

4,0

-5 0 5 10 15 20

24 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

D0000021913

1

2

3

4

INSTALLATION

SPECIFICATION

COP

8

7

6

5

4

3

2

1

0

-5 0 5 10 15 20

D0000021913

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 25

INSTALLATION

1

2

3

4

1

2

3

4

SPECIFICATION

14.7 Output diagrams WPF 27

Key to output diagrams

Y Heating output [kW] / power consumption [kW] / coefficient of performance e [-]

X Inlet temperature of the WQA medium [°C]

1 Flow temperature 35 °C

2 Flow temperature 45 °C

3 Flow temperature 55 °C

4 Flow temperature 60 °C

Heating output

53

48

43

38

33

28

23

-5 0 5 10 15 20

Power consumption

12

11

10

9

8

7

D0000021913

6

5

-5 0 5 10 15 20

26 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

D0000021913

1

2

3

4

INSTALLATION

SPECIFICATION

COP

8

7

6

5

4

3

2

1

0

-5 0 5 10 15 20

D0000021913

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 27

INSTALLATION

35

45

55

65

75

35

45

55

65

75

SPECIFICATION

14.8 Output diagrams WPF 27 HT

Key to output diagrams

Y Heating output [kW] / power consumption [kW] / coefficient of performance e [-]

X Inlet temperature of the WQA medium [°C]

1 Flow temperature 35 °C

2 Flow temperature 45 °C

3 Flow temperature 55 °C

4 Flow temperature 60 °C

Heating output

42

37

32

27

22

17

-5 0 5 10 15 20

Power consumption

15

14

13

12

11

10

9

8

D0000021913

7

6

5

-5 0 5 10 15 20

28 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

D0000021913

35

45

55

65

75

INSTALLATION

SPECIFICATION

COP

8

7

6

5

4

3

2

1

0

-5 0 5 10 15 20

D0000021913

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 29

1

2

3

4

1

2

3

4

INSTALLATION

SPECIFICATION

14.9 Output diagrams WPF 35

Key to output diagrams

Y Heating output [kW] / power consumption [kW] / coefficient of performance e [-]

X Inlet temperature of the WQA medium [°C]

1 Flow temperature 35 °C

2 Flow temperature 45 °C

3 Flow temperature 55 °C

4 Flow temperature 60 °C

Heating output

62

57

52

47

42

37

32

27

-5 0 5 10 15 20

Power consumption

16

15

14

13

12

11

D0000021913

10

9

8

7

-5 0 5 10 15 20

30 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

D0000021913

1

2

3

4

INSTALLATION

SPECIFICATION

COP

8

7

6

5

4

3

2

1

0

-5 0 5 10 15 20

D0000021913

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 31

1

2

3

4

1

2

3

4

INSTALLATION

SPECIFICATION

14.10 Output diagrams WPF 40

Key to output diagrams

Y Heating output [kW] / power consumption [kW] / coefficient of performance e [-]

X Inlet temperature of the WQA medium [°C]

1 Flow temperature 35 °C

2 Flow temperature 45 °C

3 Flow temperature 55 °C

4 Flow temperature 60 °C

Heating output

74

69

64

59

54

49

44

39

34

-5 0 5 10 15 20

Power consumption

17

16

15

14

13

12

D0000021913

11

10

9

8

-5 0 5 10 15 20

32 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

D0000021913

1

2

3

4

INSTALLATION

SPECIFICATION

COP

8

7

6

5

4

3

2

1

0

-5 0 5 10 15 20

D0000021913

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 33

1

2

3

4

1

2

3

4

INSTALLATION

SPECIFICATION

14.11 Output diagrams WPF 52

Key to output diagrams

Y Heating output [kW] / power consumption [kW] / coefficient of performance e [-]

X Inlet temperature of the WQA medium [°C]

1 Flow temperature 35 °C

2 Flow temperature 45 °C

3 Flow temperature 55 °C

4 Flow temperature 60 °C

Power consumption

95

90

85

80

75

70

65

60

55

50

45

-5 0 5 10 15 20

Leistungsaufnahme

21

20

19

18

17

16

D0000021913

15

14

13

12

11

-5 0 5 10 15 20

34 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

D0000021913

1

2

3

4

INSTALLATION

SPECIFICATION

COP

8

7

6

5

4

3

2

1

0

-5 0 5 10 15 20

D0000021913

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 35

1

2

3

4

1

2

3

4

INSTALLATION

SPECIFICATION

14.12 Output diagrams WPF 66

Key to output diagrams

Y Heating output [kW] / power consumption [kW] / coefficient of performance e [-]

X Inlet temperature of the WQA medium [°C]

1 Flow temperature 35 °C

2 Flow temperature 45 °C

3 Flow temperature 55 °C

4 Flow temperature 60 °C

Heating output

113

103

93

83

73

63

53

-5 0 5 10 15 20

Power consumption

29

27

25

23

21

D0000021913

19

17

15

13

-5 0 5 10 15 20

36 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

D0000021913

1

2

3

4

INSTALLATION

SPECIFICATION

COP

8

7

6

5

4

3

2

1

0

-5 0 5 10 15 20

D0000021913

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 37

INSTALLATION

SPECIFICATION

14.13 Data table

Output details apply to new appliances with clean heat exchangers.

WPF 20 WPF 27 WPF 27 HT WPF 35 WPF 40 WPF 52 WPF 66

233003 233004 233009 233005 233006 233007 233008

Outputs to EN 14511

Output at B0/W35 (EN 14511) kW 21.5 29.69 27.41 38.04 43.1 55.83 67.10

Power consumptions to EN 14511

Power consumption at B0/W35 (EN 14511) kW 4.61 6.12 6.32 7.96 9.23 11.61 14.71

Coeff icients of performance to EN 14511

Coeff icient of performance at B0/W35 (EN 14511) 4.66 4.85 4.34 4.78 4.67 4.81 4.56

Sound data

Sound power level (EN 12102) dB(A) 54.6 55 55 56 57.9 58 61.5

Sound pressure level at 1 m distance in a free

field

Sound pressure level at 5 m distance in a free

field

Application limits

Min. installation room volume m³ 14 16 24 20 23 27 33

Max. permissible pressure MPa 0.6 0.6 0.6 0.6 0.6 0.6 0.6

Min. application limit on the heating side °C 15 15 15 15 15 15 15

Max. application limit on the heating side °C 60 60 75 60 60 60 60

Heat source application limit (min.) °C -5 -5 -5 -5 -5 -5 -5

Heat source application limit (max.) °C 20 20 20 20 20 20 20

[Wasserhärte] °dH ≤3 ≤3 ≤3 ≤3 ≤3 ≤3 ≤3

[pH-Wert (mit Aluminiumverbindungen)] [mg/l] 8.0-8.5 8.0-8.5 8.0-8.5 8.0-8.5 8.0-8.5 8.0-8.5 8.0-8.5

[pH-Wert (ohne Aluminiumverbindungen)] [mg/l] 8.0-10.0 8.0-10.0 8.0-10.0 8.0-10.0 8.0-10.0 8.0-10.0 8.0-10.0

[Chlorid] [mg/l] <30 <30 <30 <30 <30 <30 <30

[Leitfähigkeit (Enthärten)] [μS/cm] <1000 <1000 <1000 <1000 <1000 <1000 <1000

[Leitfähigkeit (Entsalzen)] [μS/cm] 20-100 20-100 20-100 20-10 0 20-10 0 20 -100 20-100

[Sauerstoff 8-12 Wochen nach Befüllung (Ent-

härten)]

[Sauerstoff 8-12 Wochen nach Befüllung (Ent-

salzen)]

Electrical details

Frequency Hz 50 50 50 50 50 50 50

Control circuit fuse A 1x B 16 1 x B 16 1 x B 16 1 x B 16 1 x B 16 1 x B 16 1 x B 16

Fuse - compressor A 3 x C 35 3 x C 35 3 x C 35 3 x C35 3 x C 35 3 x C 50 3 x C 50

Control phases 1/N/PE 1/N/PE 1/N/PE 1/N/PE 1/N/PE 1/N/PE 1/N/PE

Compressor phases 3/PE 3/PE 3/PE 3/PE 3/PE 3/PE 3/PE

Rated control voltage V 230 230 230 230 230 230 230

Rated compressor voltage V 400 400 400 400 400 400 400

Current (with/without softstarter) A 55/- 60/- 90/- 60/- 60/- 65/- 80/Operating current max. A 15 19 23.3 23.5 30 32 41

Max. phase angle cos(phi) 0.83 0.83 0.82 0.79 0.87 0.88

Versions

Refrigerant R410 A R410 A R134a R410 A R410 A R410 A R410 A

Refrigerant capacity kg 5.99 7.2 5.99 10.0 10 12 14.5

Compressor oil Emkarate RL

Condenser material 1.4401/Cu 1.4401/Cu 1.4401/Cu 1.4401/Cu 1.4401/Cu 1.4401/Cu 1.4401/Cu

Evaporator material 1.4401/Cu 1.4401/Cu 1.4401/Cu 1.4401/Cu 1.4401/Cu 1.4401/Cu 1.4401/Cu

IP-Rating IP34 D IP34 D IP34 D IP34 D IP34 D IP34 D IP34 D

Dimensions

Height mm 1154 1154 1154 1154 1154 1154 1154

Width mm 1242 1242 1242 1242 1242 1242 1242

Depth mm 860 860 860 860 860 860 860

Weights

Weight kg 345 367 409 391 415 539 655

Connections

Connection on the heating system side G 2 G 2 G 2 G 2 G 2 G 2 G 2

Connection on the heat source side G 2 G 2 G 2 G 2 G 2 G 2 G 2

Connecting cable mm

Values

permissible refrigerant pressure MPa 4.3 4.3 2.4 4.3 4.3 4.3 4.3

Brine volume l 11.2 13 13 16.6 16.6 20.2 23.8

dB(A) 47 47 47 48 49.9 50 53.5

dB(A) 33 33 33 34 35.9 36 39.5

[mg/l] <0.02 <0.02 <0.02 <0.02 <0.02 <0.02 <0.02

[mg/l] <0.1 <0.1 <0.1 <0.1 <0.1 <0.1 <0.1

32 3MAF

2

Emkarate RL

32 3MAF

5 x 6.0 5 x 6.0 5 x 6.0 5 x 6.0 5 x 6.0 5 x 10.0 5 x 10.0

Emkarate RL

32 3MAF

Emkarate RL

32 3MAF

Emkarate RL

32 3MAF

Emkarate RL

32 3MAF

Emkarate RL

32 3MAF

38 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

INSTALLATION

SPECIFICATION

WPF 20 WPF 27 WPF 27 HT WPF 35 WPF 40 WPF 52 WPF 66

Pressure differential on the heat source side hPa 150 140 140 160 160 150 160

Pressure differential, central heating side hPa 60 52 52 80 80 60 80

Flow rate, heat source side m³/h 5 7 6.75 8.8 10.5 13 16.1

Rated heating flow rate m³/h 2.65 3.65 3.29 4.48 5.3 6.86 8.26

Heating flow rate (min.) m³/h 1.85 2.56 2.3 3.14 3.71 4.81 5.78

Heating flow rate (EN 14511) at A7/W35, B0/W35

and 5 K

m³/h 3.7 5.12 4.61 6.5 7.42 9.61 11.56

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 39

NOTES

40 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

NOTES

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 41

NOTES

42 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

WARRANTY

ENVIRONMENT AND RECYCLING

Warranty

The warranty conditions of our German companies do not

apply to appliances acquired outside of Germany. In countries

where our subsidiaries sell our products, it is increasingly the

case that warranties can only be issued by those subsidiaries.

Such warranties are only granted if the subsidiary has issued

its own terms of warranty. No other warranty will be granted.

We shall not provide any warranty for appliances acquired in

countries where we have no subsidiary to sell our products.

This will not aect warranties issued by any importers.

Environment and recycling

We would ask you to help protect the environment. After use,

dispose of the various materials in accordance with national

regulations.

KYOTO | R410A

This device is filled with refrigerant R410A.

Refrigerant R410A is a CFC greenhouse gas mentioned in the Kyoto

protocol with a global greenhouse potential (GWP) = 1925.

Never release refrigerant R410A to atmosphere.

WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 43

g

y

Deutschland

STIEBEL ELTRON GmbH & Co. KG

Dr.-Stiebel-Straße 33 | 37603 Holzminden

Tel. 05531 702-0 | Fax 05531 702-480

info@stiebel-eltron.de

www.stiebel-eltron.de

Australia

STIEBEL ELTRON Australia Pty. Ltd.

4/8 Rocklea Drive | Port Melbourne VIC 3207

Tel. 03 9645-1833 | Fax 03 9645-4366

info@stiebel.com.au

www.stiebel.com.au

Austria

STIEBEL ELTRON Ges.m.b.H.

Eferdinger Str. 73 | 4600 Wels

Tel. 07242 47367-0 | Fax 07242 47367-42

info@stiebel-eltron.at

www.stiebel-eltron.at

Belgium

STIEBEL ELTRON bvba/sprl

't Hofveld 6 - D1 | 1702 Groot-Bijgaarden

Tel. 02 42322-22 | Fax 02 42322-12

info@stiebel-eltron.be

www.stiebel-eltron.be

China

Stiebel Eltron (Guangzhou) Technology

Development Co., Ltd.

Rm 102, F1, Yingbin-Yihao Mansion, No. 1

Yingbin Road

Panyu District | 511431 Guangzhou

Tel. 020 61952996 | Fax 020 61952990

info@stiebeleltron.cn

www.stiebeleltron.cn

Czech Republic

STIEBEL ELTRON spol. s r.o.

K Hájům 946 | 155 00 Praha 5 - Stodůlky

Tel. 251116-111 | Fax 235512-122

info@stiebel-eltron.cz

www.stiebel-eltron.cz

Denmark

Pettinaroli A/S

Mandal Allé 21 | 5500 Middelfart

Tel. 06341 666-6 | Fax 06341 666-0

info@stiebel-eltron.dk

www.stiebel-eltron.dk

Finland

STIEBEL ELTRON OY

Kapinakuja 1 | 04600 Mäntsälä

Tel. 020 720-9988

info@stiebel-eltron.fi

www.stiebel-eltron.fi

Verkauf Tel. 05531 702-110 | Fax 05531 702-95108 | info-center@stiebel-eltron.de

Kundendienst Tel. 05531 702-111 | Fax 05531 702-95890 | kundendienst@stiebel-eltron.de

Ersatzteilverkauf Tel. 05531 702-120 | Fax 05531 702-95335 | ersatzteile@stiebel-eltron.de

France

STIEBEL ELTRON SAS

7-9, rue des Selliers

B.P 85107 | 57073 Metz-Cédex 3

Tel. 0387 7438-88 | Fax 0387 7468-26

info@stiebel-eltron.fr

www.stiebel-eltron.fr

Hungary

STIEBEL ELTRON Kft.

Gyár u. 2 | 2040 Budaörs

Tel. 01 250-6055 | Fax 01 368-8097

info@stiebel-eltron.hu

www.stiebel-eltron.hu

Japan

NIHON STIEBEL Co. Ltd.

Kowa Kawasaki Nishiguchi Building 8F

66-2 Horikawa-Cho

Saiwai-Ku | 212-0013 Kawasaki

Tel. 044 540-3200 | Fax 044 540-3210

info@nihonstiebel.co.jp

www.nihonstiebel.co.jp

Netherlands

STIEBEL ELTRON Nederland B.V.

Daviottenweg 36 | 5222 BH 's-Hertogenbosch

Tel. 073 623-0000 | Fax 073 623-1141

info@stiebel-eltron.nl

www.stiebel-eltron.nl

Poland

STIEBEL ELTRON Polska Sp. z o.o.

ul. Działkowa 2 | 02-234 Warszawa

Tel. 022 60920-30 | Fax 022 60920-29

stiebel@stiebel-eltron.pl

www.stiebel-eltron.pl

Russia

STIEBEL ELTRON LLC RUSSIA

Urzhumskaya street 4,

building 2 | 129343 Moscow

Tel. 0495 7753889 | Fax 0495 7753887

info@stiebel-eltron.ru

www.stiebel-eltron.ru

Slovakia

TATRAMAT - ohrievače vody, s.r.o.

Hlavná 1 | 058 01 Poprad

Tel. 052 7127-125 | Fax 052 7127-148

info@stiebel-eltron.sk

www.stiebel-eltron.sk

Switzerland

STIEBEL ELTRON AG

Industrie West

Gass 8 | 5242 Lupfig

Tel. 056 4640-500 | Fax 056 4640-501

info@stiebel-eltron.ch

www.stiebel-eltron.ch

Thailand

STIEBEL ELTRON Asia Ltd.

469 Moo 2 Tambol Klong-Jik

Amphur Bangpa-In | 13160 Ayutthaya

Tel. 035 220088 | Fax 035 221188

info@stiebeleltronasia.com

www.stiebeleltronasia.com

United Kingdom and Ireland

STIEBEL ELTRON UK Ltd.

Unit 12 Stadium Court

Stadium Road | CH62 3RP Bromborough

Tel. 0151 346-2300 | Fax 0151 334-2913

info@stiebel-eltron.co.uk

www.stiebel-eltron.co.uk

United States of America

STIEBEL ELTRON, Inc.

17 West Street | 01088 West Hatfield MA

Tel. 0413 247-3380 | Fax 0413 247-3369

info@stiebel-eltron-usa.com

www.stiebel-eltron-usa.com

4<AMHCMN=iaggaj>

Irrtum und technische Änderungen vorbehalten! | Subject to errors and technical changes! | Sous réserve

d‘erreurs et de modifications techniques! | Onder voorbehoud van ver

Salvo error o modificación técnica! | Excepto erro ou alteração técnica | Zastrzeżone zmian

ewentualne błędy | Omyly a technické změny jsou vyhrazeny! | A muszaki változtatások és tévedések jogát

fenntartjuk! |

technické zmeny sú vyhradené! Stand 8870

Отсутствие ошибок не гарантируется. Возможны технические изменения.

issingen en technische wijzigingen! |

techniczne i

| Chyby a

A 280660-37738-8870

B 280643-37738-8870

Loading...

Loading...