OPERATION AND INSTALLATION

Brine | water heat pump

» WPC 04

» WPC 05

» WPC 07

» WPC 10

» WPC 13

» WPC 04 cool

» WPC 05 cool

» WPC 07 cool

» WPC 10 cool

» WPC 13 cool

CONTENTS

SPECIAL INFORMATION

OPERATION

1. General information _________________________________________4

1.1 Safety instructions ����������������������������������������������� 4

1.2 Other symbols in this documentation ����������������������� 4

1.3 Units of measurement ������������������������������������������ 4

2. Safety __________________________________________________________ 4

2.1 Intended use ������������������������������������������������������ 4

2.2 General safety instructions ������������������������������������ 4

2.3 Safety instructions ����������������������������������������������� 4

2.4 Test symbols ������������������������������������������������������ 5

3. Appliance description _______________________________________5

3.1 Special features of the WPC...cool ���������������������������� 5

4. Operation _____________________________________________________6

4.1 Controls ������������������������������������������������������������ 6

4.2 Entering parameters �������������������������������������������� 7

4.3 Selecting operating modes ������������������������������������ 8

4.4 Picture symbols �������������������������������������������������� 8

5. Menu structure _______________________________________________9

5.1 INFO menu �������������������������������������������������������� 9

5.2 DIAGNOSIS menu ����������������������������������������������� 11

5.3 PROGRAMS menu ���������������������������������������������� 12

5.4 SETTINGS menu ������������������������������������������������� 14

5.5 FE7 remote control ��������������������������������������������� 21

5.6 FEK remote control ��������������������������������������������� 21

5.7 Internet Service Gateway (ISG) ������������������������������� 21

6. Maintenance and care _____________________________________ 22

7. Troubleshooting ____________________________________________ 22

7.1 Other problems ������������������������������������������������� 22

INSTALLATION

8. Safety ________________________________________________________ 23

8.1 General safety instructions ����������������������������������� 23

8.2 Instructions, standards and regulations �������������������23

9. Appliance description _____________________________________ 23

9.1 Mode of operation ���������������������������������������������� 23

9.2 Special features of the WPC...cool ��������������������������� 23

9.3 Standard delivery ����������������������������������������������� 23

9.4 Accessories �������������������������������������������������������23

10. Preparations ________________________________________________ 23

10.1 Electrical installation������������������������������������������� 24

11. Installation __________________________________________________ 24

11.1 Transport ��������������������������������������������������������� 24

11.2 Siting �������������������������������������������������������������� 26

11.3 Opening the appliance ����������������������������������������� 27

11.4 Installing the heat source system ��������������������������� 27

11.5 Heating water connection ������������������������������������� 28

11.6 Oxygen diffusion ������������������������������������������������ 28

11.7 Filling the heating system ������������������������������������ 29

11.8 Venting the heating system ����������������������������������� 29

11.9 DHW connection ������������������������������������������������ 29

11.10 DHW circulation connection ���������������������������������� 30

11.11 Operation with buffer cylinder ������������������������������� 30

11.12 Fitting the push-fit connectors ������������������������������� 30

12. Power supply _______________________________________________ 31

12.1 General ����������������������������������������������������������� 31

12.2 Power supply ���������������������������������������������������� 31

12.3 Sensor installation ���������������������������������������������� 33

12.4 FE7 remote control ��������������������������������������������� 34

12.5 FEK remote control ��������������������������������������������� 34

12.6 Uponor DEM WP module �������������������������������������� 34

12.7 Internet Service Gateway ISG �������������������������������� 34

13. Commissioning _____________________________________________ 35

13.1 Checks before commissioning�������������������������������� 35

13.2 Heating curve adjustment during commissioning �������35

13.3 COMMISSIONING menu ���������������������������������������� 36

13.4 WPM3i commissioning report �������������������������������� 39

14. Settings _____________________________________________________ 41

14.1 Standard settings ����������������������������������������������� 41

14.2 Heating and DHW programs ���������������������������������� 41

14.3 Appliance handover �������������������������������������������� 41

15. Shutting down ______________________________________________ 42

16. Troubleshooting ____________________________________________ 42

16.1 Fault display ����������������������������������������������������� 42

16.2 Fault message ��������������������������������������������������� 42

16.3 Resetting the high limit safety cut-out ��������������������� 43

16.4 Resetting the compressor high limit safety cut-out ����� 43

16.5 Fault table �������������������������������������������������������� 44

17. Maintenance ________________________________________________ 46

17.1 DHW cylinders ��������������������������������������������������� 46

18. Specification ________________________________________________ 48

18.1 Dimensions and connections ��������������������������������� 48

18.2 Wiring diagram WPC 04 | WPC 04 cool | WPC 05 | WPC

05 cool ������������������������������������������������������������50

18.3 Wiring diagram WPC 07 | WPC 07 cool | WPC 10 | WPC

10 cool | WPC 13 | WPC 13 cool������������������������������� 52

18.4 Output diagrams WPC 04 | WPC 04 cool �������������������� 54

18.5 Output diagrams WPC 05 | WPC 05 cool �������������������� 56

18.6 Output diagrams WPC 07 | WPC 07 cool �������������������� 58

18.7 Output diagrams WPC 10 | WPC 10 cool �������������������� 60

18.8 Output diagrams WPC 13 | WPC 13 cool �������������������� 62

18.9 Data table WPC... ����������������������������������������������� 64

18.10 Data table WPC...cool ������������������������������������������ 66

GUARANTEE

ENVIRONMENT AND RECYCLING

2 | WPC | WPC cool www.stiebel-eltron.com

Special information

SPECIAL INFORMATION

- The appliance may be used by children aged8

and up and persons with reduced physical, sensory or mental capabilities or a lack of experience

and know-how, provided that they are supervised

or they have been instructed on how to use the

appliance safely and have understood the resulting risks. Children must never play with the appliance. Children must never clean the appliance

or perform user maintenance unless they are

supervised.

- Use a permanent connection to the power supply.

Ensure the appliance can be separated from the

power supply by an isolator that disconnects all

poles with at least 3mm contact separation.

- Maintain the minimum clearances to ensure trouble-free operation of the appliance and facilitate

maintenance work.

- There is no need to shut the system down in

summer. The heat pump manager has an automatic summer/winter changeover.

DHW cylinders

- Regularly activate the safety valve to prevent

it from becoming blocked e.g. by limescale

deposits.

- Drain the DHW cylinder as described in the chapter "Installation/ Maintenance/ Draining the

DHW cylinder".

- Install a type-tested safety valve in the cold water

supply line. For this bear in mind that, depending

on the static pressure, you may also need a pressure reducing valve.

- The safety valve discharge aperture must remain

open to the atmosphere.

- Install the safety valve discharge pipe with a constant fall to the discharge outlet.

- In dual mode operation, return water from the

second heat generator may flow through the heat

pump. Please note that the return water temperature may be a maximum of 60°C.

- Cooling mode is only possible in conjunction with

the WPAC 1 cooling module. Set parameter COOLING to ACTIVE COOLING. The COOLING parameter

will only be shown if a FEK or FE 7 remote control

is connected. Cooling mode is only possible in

summer mode.

- The air outlet in the knurled cap of the quick-action air vent valve must not point towards the

MFG PCB. Close the quick-action air vent valve

again after venting.

- Maintenance work, such as checking the electrical safety, must only be carried out by a qualified

contractor.

- We recommend an annual inspection (to establish

the system's current condition), and maintenance

by a qualified contractor if required (to return the

system to the desired condition).

- Size the discharge outlet so that water can drain

off unimpeded when the safety valve is fully

opened.

- Never interrupt the power supply, even outside

the heating period. The system's active frost protection is not guaranteed if the power supply is

interrupted.

www.stiebel-eltron.com WPF | 3

OPERATION

General information

OPERATION

1. General information

The chapters "Special Information" and "Operation" are intended

for both the user and qualified contractors.

The chapter "Installation" is intended for qualified contractors.

Note

Read these instructions carefully before using the appliance and retain them for future reference.

Pass on the instructions to a new user if required.

1.1 Safety instructions

1.1.1 Structure of safety instructions

KEYWORD Type of risk

!

Here, possible consequences are listed that may result

from failure to observe the safety instructions.

Steps to prevent the risk are listed.

1.1.2 Symbols, type of risk

Symbol Type of risk

!

1.1.3 Keywords

KEYWORD Meaning

DANGER Failure to observe this information will result in serious

WARNING Failure to observe this information may result in serious

CAUTION Failure to observe this information may result in non-seri-

Injury

Electrocution

Burns

(burns, scalding)

injury or death.

injury or death.

ous or minor injury.

1.2 Other symbols in this documentation

Note

General information is identified by the symbol shown

on the left.

Read these texts carefully.

Symbol Meaning

!

This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

Material losses

(appliance and consequential losses, environmental pollution)

Appliance disposal

1.3 Units of measurement

Note

All measurements are given in mm unless stated otherwise.

2. Safety

2.1 Intended use

The appliance is designed for:

- heating rooms

- DHW heating

Observe the operating limits listed in chapter "Specification".

This appliance is intended for domestic use. It can be used safely

by untrained persons. The appliance can also be used in a non-domestic environment, e.g. in a small business, as long as it is used

in the same way.

Any other use beyond that described shall be deemed inappropriate. Observation of these instructions and of instructions for any

accessories used is also part of the correct use of this appliance.

2.2 General safety instructions

2.3 Safety instructions

- The electrical installation and installation of the heating circuit must only be carried out by a recognised, qualified contractor or by our customer service engineers.

- The qualified contractor is responsible for adherence to all

currently applicable instructions during installation and

commissioning.

- Operate the appliance only when fully installed and with all

safety equipment fitted.

- Protect the appliance from dust and dirt ingress during

building work.

4 | WPC | WPC cool www.stiebel-eltron.com

OPERATION

Appliance description

WARNING Injury

!

The appliance may be used by children aged 8 and up and

persons with reduced physical, sensory or mental capabilities or a lack of experience and know-how, provided

that they are supervised or they have been instructed on

how to use the appliance safely and have understood

the resulting risks. Children must never play with the

appliance. Children must never clean the appliance or

perform user maintenance unless they are supervised.

Note

Do not change any system-specific settings at the control

unit. Your contractor has set the control unit to match

the local conditions for your building and your individual

requirements. The system-specific parameters are protected by a code to prevent unintentional modifications.

The parameters that serve to adapt the appliance to your

personal requirements are not protected by a code.

CE designation

The CE designation shows that the appliance meets all essential

requirements according to the:

- Electromagnetic Compatibility Directive

- Low Voltage Directive

bled. If the DHW learning function is enabled, DHW heating will

cease and the set DHW value is overwritten with the actual DHW

temperature achieved.

The WPM3i also controls the integral electric emergency/booster

heater. No further heat generator can be switched.

3.1 Special features of the WPC...cool

An additional heat exchanger and 3-way diverter valve for changing over between heating and cooling are integrated into the

WPC...cool.

To cool the living space, the brine is pumped though the additional

heat exchanger, where heat is extracted from the heating water

to be released into the cooler zones underground.

The compressor does not run during cooling.

2.4 Test symbols

See type plate on the appliance.

3. Appliance description

The appliance is a heating heat pump suitable for operation as a

brine/water heat pump. The heat pump extracts energy from the

heat source medium at a low temperature level. This extracted

energy is then transferred to the heating water at a higher level,

augmented by the electric energy drawn by the compressor. The

heating water is heated to a flow temperature of up to 60 °C,

depending on the heat source temperature.

A heating circuit pump and a multi function assembly (MFG) with

safety assembly and 3-way diverter valve have been integrated

in the appliance for directing the flow either to the heating circuit

or the DHW circuit. To heat the DHW, the heating water that has

been heated by the heat pump is directed through an indirect coil

in the DHW cylinder, where it transfers its energy to the DHW.

The appliance is equipped with an electric emergency/booster

heater (DHC). If the dual mode point can no longer be maintained

in mono mode operation, the electric emergency/booster heater

is activated to safeguard heating operation and the provision of

high DHW temperatures. In mono energetic operation the electric

emergency/booster heater is then activated as a booster heater.

The appliance is regulated by an integral, weather-compensated

return temperature controller (WPM3i heat pump manager).

The WPM3i also regulates the DHW heating to the required temperature. If either the high pressure sensor or the hot gas limiter

of the heat pump responds during DHW heating, then DHW heating

will automatically be completed by an integral electric emergency/

booster heater, subject to the DHW learning function being disa-

www.stiebel-eltron.com WPC | WPC cool | 5

OPERATION

Operation

4. Operation

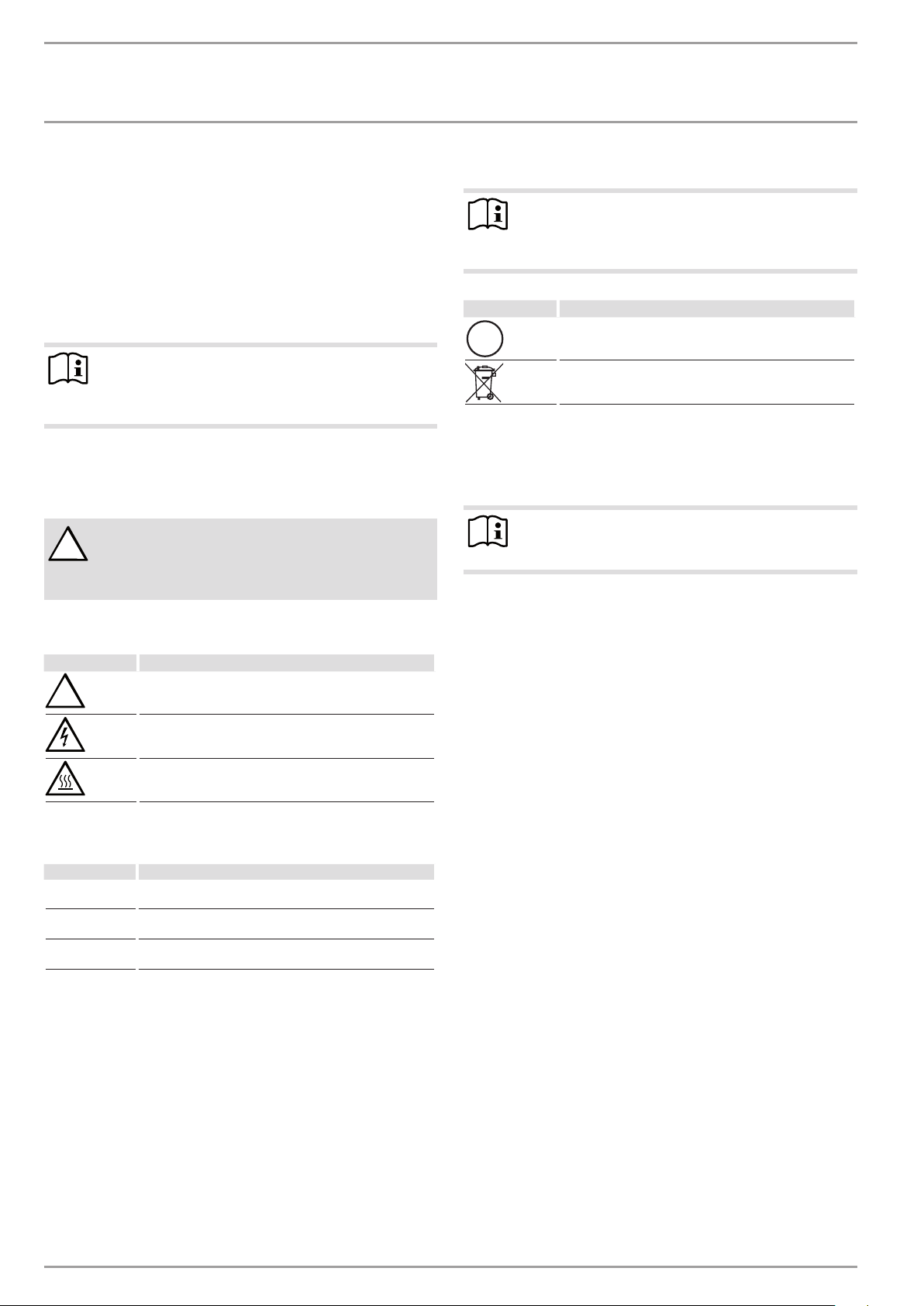

4.1 Controls

WEDNESDAY 12.JUN 13 10: 23 TIME

OUTSIDE TEMPERATURE

1

2

3

1 Display

2 MENU key

3 Scroll wheel

4 OK key

You control the system with the programming unit of the heat

pump manager. Use the scroll wheel and the MENU and OK keys

to navigate through the menu structure.

ACTUAL DHW TEMP

ACTUAL RETURN TEMP

ECO MODE

27. 0 °C

35.0 °C

28.0 °C

4

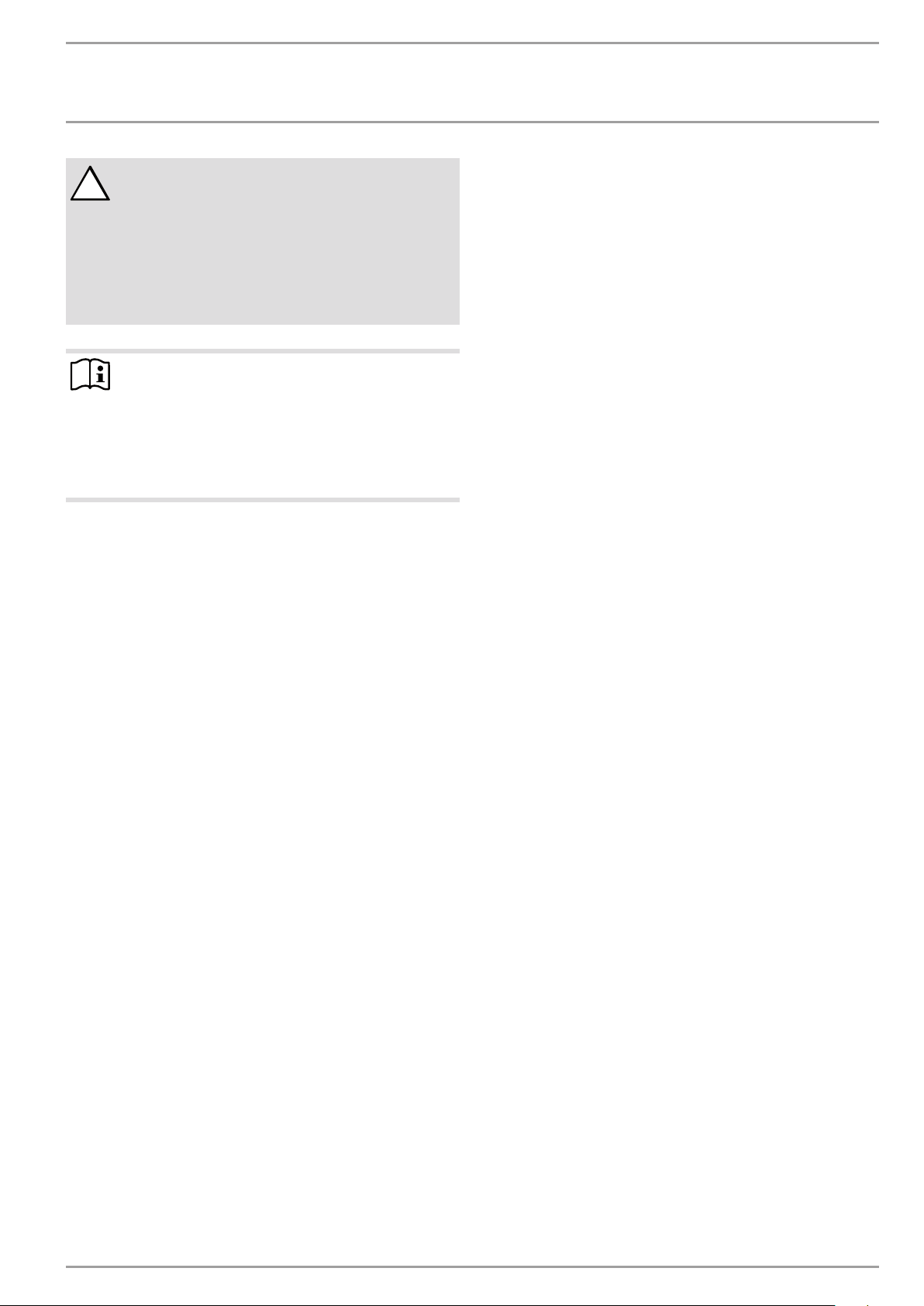

Activation

If the scroll wheel and keys/fields are not used for 5minutes,

the programming unit is locked.

WEDNESDAY 12.JUN 13 10:23 TIME

OUTSIDE TEMPERATURE

To activate please

ACTUAL DHW TEMP

ACTUAL RETURN TEMP

press MENU for 3 s.

27. 0 ° C

35.0 °C

28.0 °C

.

ECO MODE

Press MENU for 3 seconds to activate the programming unit.

Selection indicator

26�04�01�0309

An indicator shows the current position within the menu structure

at all times. The currently selected menu item is indicated by a

dark background. The current menu level is indicated at the top

of the display.

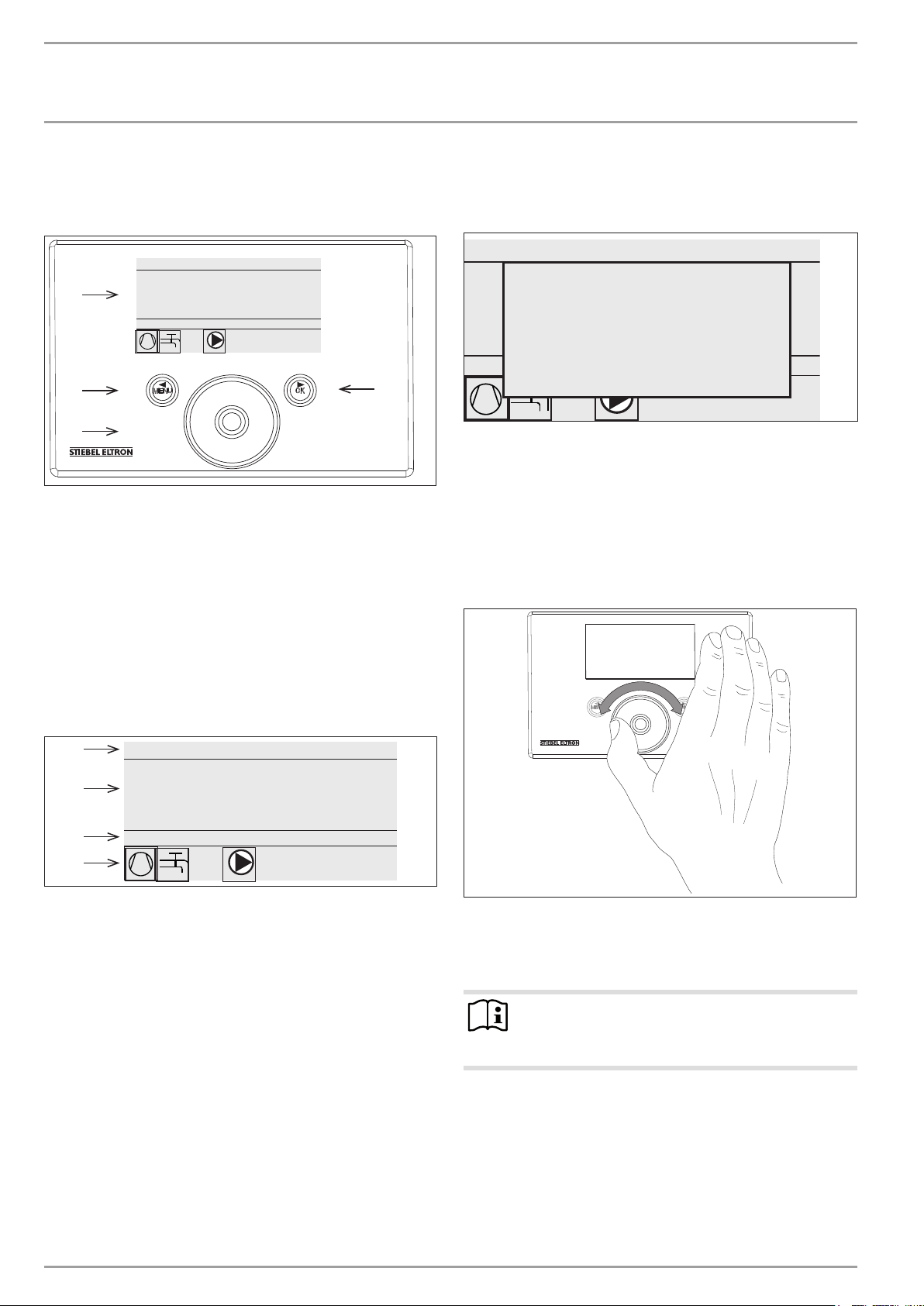

4.1.2 Scroll wheel

26�04�01�0292

4.1.1 Display

The programming unit display shows the current state of the system and provides messages and information.

Start screen

1

2

3

4

1 Date and time

2 Temperature display

3 Operating mode

4 System status picture symbols

The start screen is divided into four sections. The top field displays

the date and time. The field below displays the outside temperature along with the actual DHW temperature and the actual return

temperature. The third section is for selecting and displaying the

operating modes. In the fourth section, picture symbols indicate

the current system state.

WEDNESDAY 12.JUN 13 10:23 TIME

OUTSIDE TEMPERATURE

ACTUAL DHW TEMP

ACTUAL RETURN TEMP

ECO MODE

27.0 °C

35.0 °C

28.0 °C

26�04�01�0292

The scroll wheel consists of a touch-sensitive sensor. To the left

and right of it there is one key each. All required appliance functions are controlled and checked with the scroll wheel and the

keys.

Note Sensor responsiveness

Wearing gloves, wet hands or a damp programming unit

impede the recognition of your touch and the execution

of the action you require.

26�04�01�0329

Your contractor can set the sensitivity to touch using the TOUCH

SENSITIVITY parameter under MAIN MENU / COMMISSIONING.

6 | WPC | WPC cool www.stiebel-eltron.com

OPERATION

Operation

Circular movement

Move one finger clockwise over the scroll wheel to move the indicator downwards or to the right in the list, depending on how the

menu options are arranged. An anti-clockwise rotation moves the

selection indicator to the left or upwards in the list.

Alongside navigation within the menu structure, the scroll wheel

is also used to set parameters. Clockwise rotation increases the

values. Anti-clockwise rotation decreases values.

4.1.3 Keys

Note

Press the keys only briefly to initiate the required action.

If a key is touched for too long, the programming unit

does not respond.

MENU key

The MENU key has two functions:

- On the start screen, touch the MENU key to navigate to the

first of the 5 menu structure levels.

- Touching the MENU key while in the menu structure will return you to the previous menu level.

Example 1

Adjusting the set room temperature.

MAIN MENU

SETTINGS

+

21.7

21

-

To enter set temperatures, a number surrounded by a circle appears on the display. This indicates that you can change the value

by turning the scroll wheel.

Example 2

Setting the time and date.

MAIN MENU

SETTINGS

HEATING CIRCUIT 1

HEATING HC1

°C SET ROOM TEMP COMFORT

TIME / DATE

GENERAL

SET ROOM TEMP CO

SET CLOCK

26�04�01�0347

OK key

The OK key has four functions:

- On the start screen, touching the OK key will activate the

required operating mode previously selected with the scroll

wheel.

- Within the menu structure, touching the OK key confirms the

selected menu option and takes you to the next lower menu

level.

- If you are already at parameter level, touching the OK key

saves the currently set parameter.

- At every menu level, you will see the entry BACK. Selecting

BACK takes you to the next higher menu level.

If there is no user action for more than five minutes, no rotation

and neither

display automatically jumps back to the start screen.

Any recent parameter changes which had not yet been confirmed

with OK are lost. The parameters retain the values previously

saved.

4.1.4 Contractor access

MENU nor OK are pressed, the programming unit

Note

Some menu options are protected by a code and can only

be viewed and adjusted by a qualified contractor.

15.

DAY MONTH YEAR Hour Minute

On activation, the selection indicator is over the position MONTH.

Confirm with OK. Set the current month with the scroll wheel and

confirm with OK. A calendar page is displayed. Move the indicated

field to the required day using the scroll wheel and confirm with

OK. The new value is saved when you confirm with OK. Set the

year, hours and minutes the same way.

09 08:23

Jun

13

26�04�01�0296

4.2 Entering parameters

Parameters are changed by rotating the scroll wheel. To save the

new value, touch OK.

If you want to cancel the entry, touch

tains the previously saved value.

www.stiebel-eltron.com WPC | WPC cool | 7

MENU. The parameter re-

OPERATION

Operation

4.3 Selecting operating modes

When activating the start screen, the current operating mode is

displayed. If you want to select another operating mode, turn the

scroll wheel. This takes you through the list of possible operating

modes. The current choice (list entry) is shown in the shaded

selection field.

Note

To change the appliance to this new operating mode,

confirm with OK.

WEDNESDAY 12.JUN 13 10:23 TIME

OUTSIDE TEMPERATURE

ACTUAL DHW TEMP

ACTUAL RETURN TEMP

ECO MODE

Since navigation to a new operating mode is always made from the

currently enabled mode, you may need to move in an anti-clockwise direction. All operating modes, apart from DHW mode, apply

to both central heating and DHW.

Standby mode

Frost protection is activated for heating and DHW mode. The set

DHW value is fixed at 10°C, the set heating flow value is calculated

based on a set room value of 5°C.

Application: During prolonged periods of absence, e.g. holidays.

27. 0 ° C

35.0 °C

28.0 °C

DHW mode

DHW heating according to time switch program. If a time program

is active, the water inside the DHW cylinder is heated to the set

comfort temperature. At all other times, the water is heated to

the set ECO temperature. Frost protection is activated for heating

operation.

Application: The heating season has ended; only DHW should be

provided (summer mode).

Emergency mode

In this operating mode, the heat pump is blocked. The BH stages

(electric booster stages) of the emergency/booster heater heat

according to the selected time program for heating and DHW operation.

Inform your contractor immediately.

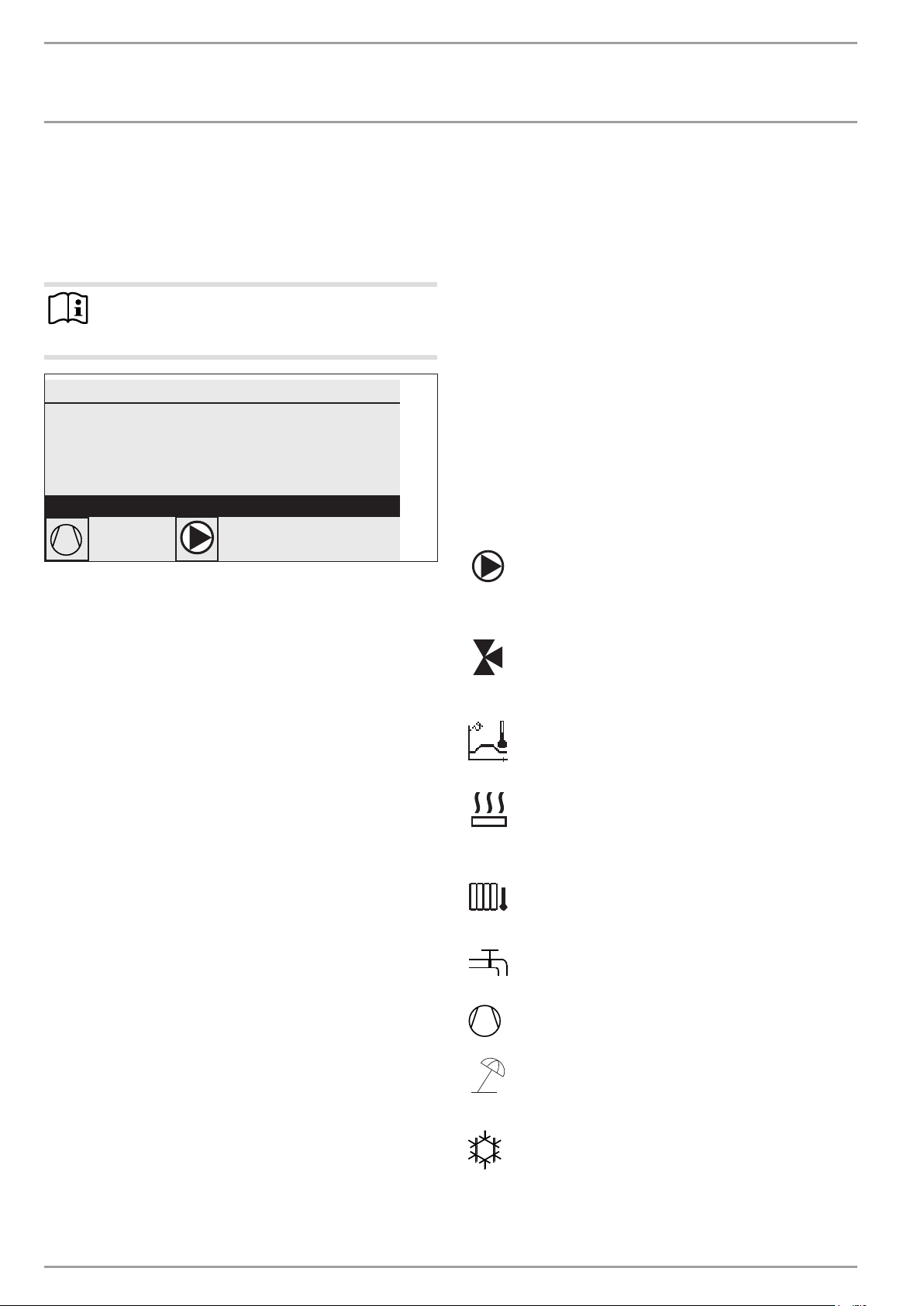

4.4 Picture symbols

At the lower edge of the display, symbols provide information

about the current appliance operating status.

26�04�01�0292

Heating circuit pump

The pump symbol is displayed when a heating circuit

pump is running.

Mixer circuit pump

The mixer symbol is displayed when a mixer circuit pump

is running.

Heat-up program

This symbol is displayed when the heat-up program is

running.

Programmed operation

Heating in line with the time switch program (applies to heating

circuits1 and2). Changeover between Comfort temperature and

ECO temperature.

DHW heating in line with the time switch program; changeover

between Comfort temperature and ECO temperature.

The remote control is only active in this operating mode.

Application: When DHW and central heating are required.

Comfort mode

The heating circuit (HC) is constantly held at the comfort temperature (HC1 and HC2). DHW heating according to time switch

program.

Application: Low energy houses without setback mode.

ECO mode

The heating circuit is constantly held at the ECO temperature (applicable to HC1 and HC2). DHW heating according to time switch

program.

Application: During weekends away.

Electric emergency/booster heater

The electric emergency/booster heater has started up.

This occurs, for example, when the outside temperature

has fallen below the dual mode point.

Heating

The heating symbol is displayed when the appliance is

in heating mode.

DHW heating

This symbol indicates that the heat pump is heating DHW.

Compressor

The symbol is displayed when the compressor is running.

Summer mode

The symbol is displayed when the appliance is in summer

mode.

Cooling

The symbol is displayed when the appliance is in cooling

mode.

8 | WPC | WPC cool www.stiebel-eltron.com

OPERATION

Menu structure

5. Menu structure

After activating the programming unit, you can use the scroll

wheel to select other operating modes, or you can use the menu

key to jump to a level from which you can navigate to a specific

appliance parameter.

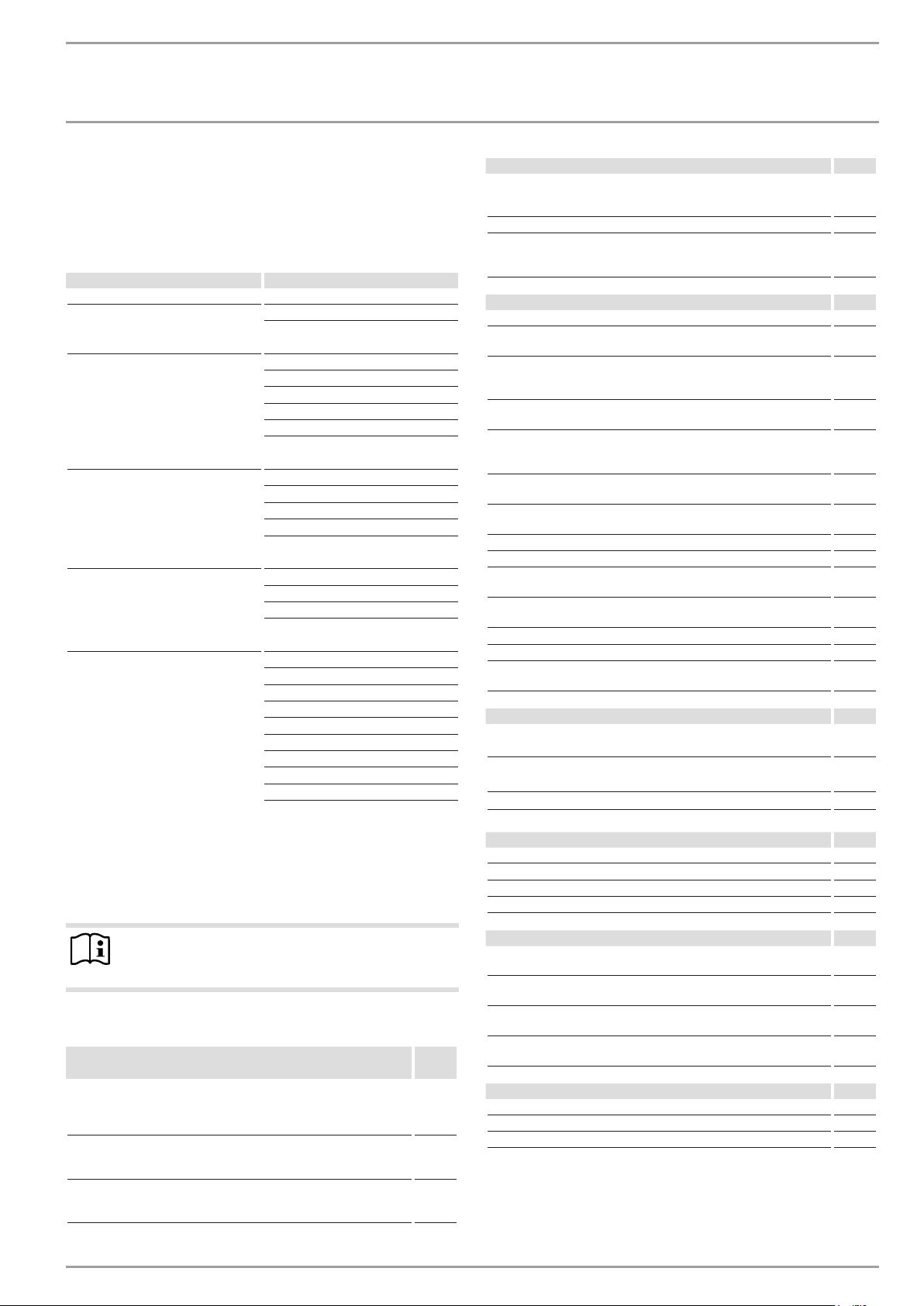

Level 1 Level 2

INFO SYSTEM

HEAT PUMP

DIAGNOSIS SYSTEM STATUS

HEAT PUMP STATUS

SYSTEM

INTERNAL CALCULATION

FAULT LIST

RELAY TEST SYSTEM

PROGRAMS HEATING PROGRAM

DHW PROGRAM

PARTY PROGRAM

HOLIDAY PROGRAM

HEAT-UP PROGRAM

SETTINGS GENERAL

HEATING

DHW

COOLING

COMMISSIONING ENTER CODE

LANGUAGE

SOURCE

HEATING

DHW

COMPRESSOR

EMERGENCY OPR

HEAT PUMP RESET

FAULT LIST RESET

SYSTEM RESET

Level 3

SET TEMPERATURE FEK

Set room temperature for heating circuit 1 or heating circuit 2

(is only displayed if the FE7 remote control is connected)

REL HUMIDITY %

DEW POINT TEMPERATURE

Dew point temperature (is only displayed if the FEK remote control is

connected)

HEAT ING

OUTSIDE TEMPERATURE °C

ACTUAL TEMPERATURE HC 1

Actual heating circuit temperature, heating circuit 1

SET TEMPERATURE HC 1

Set heating circuit temperature, heating circuit 1 (HC1). With fixed

value control, the set fixed temperature is displayed.

ACTUAL TEMPERATURE HC 2

Actual heating circuit temperature, heating circuit 2

SET TEMPERATURE HC 2

Set heating circuit temperature, heating circuit 1 (HC1). With fixed

value control, the set fixed temperature is displayed.

ACTUAL FLOW TEMPERATURE HP

Actual heat pump flow temperature

ACTUAL FLOW TEMPERATURE BH

Actual flow temperature of electric emergency/booster heater

ACTUAL RETURN TEMP °C

SET FIXED TEMPERATURE °C

ACTUAL BUFFER TEMPERATURE

Actual buffer cylinder temperature

SET BUFFER TEMPERATURE

Set buffer cylinder temperature

HEATING PRES bar

FLOW RAT E l/min

SYST FROST PRO

System frost protection temperature

DHW

ACTUAL TEMPERATURE

ACTUAL DHW TEMPERATURE

SET TEMPERATURE

SET DHW TEMPERATURE

FLOW RAT E l/min

°C

°C

°C

°C

°C

°C

°C

°C

°C

°C

°C

°C

°C

5.1 INFO menu

In the INFO menu you can check comparisons of set and actual

values for temperatures, flow rates and pressures of the heating

system and the heat pump.

Note

Please note that actual and set values can only be displayed if the appropriate sensors are connected.

5.1.1 INFO SYSTEM

Level 3

ROOM TEMPERATURE

ACTUAL TEMPERATURE FE7

Actual room temperature for heating circuit 1 (HC1) or heating circuit

2 (HC2)

(is only displayed if the FE7 remote control is connected)

SET TEMPERATURE FE7

Set room temperature for heating circuit 1 or heating circuit 2

(is only displayed if the FE7 remote control is connected)

ACTUAL TEMPERATURE FEK

Actual room temperature for heating circuit 1 or heating circuit 2

(is only displayed if the FEK remote control is connected)

°C

°C

°C

COOLING

ACTUAL TEMPERATURE FAN °C

SET TEMPERATURE FAN °C

ACTUAL TEMPERATURE AREA °C

SET TEMPERATURE AREA °C

ELECTR IC REHEAT ING

DUAL MODE TEMP HEATING

Heating dual mode point

APPLICATION LIMIT HEATING

Heating application limit

DUAL MODE TEMP DHW

DHW dual mode point

APPLICATION LIMIT DHW

DHW application limit

SOURCE

SOURCE TEMPERATURE °C

SOURCE TEMPERATURE MIN °C

SOURCE PRESSURE bar

°C

°C

°C

°C

www.stiebel-eltron.com WPC | WPC cool | 9

OPERATION

Menu structure

5.1.2 INFO HEAT PUMP

Level 3

PROCESS DATA

HOT GAS TEMPERATURE

Compressor outlet temperature

HIGH PRESSURE bar

LOW PRESSURE bar

AMOUNT OF HEAT

COMPRESSOR HEATING DAY

Amount of compressor heat generated in heating mode since 00:00

h of current day, in kWh.

COMPRESSOR HEATING TOTAL

Total amount of compressor heat generated in heating mode, in

MWh.

COMPRESSOR DHW DAY

Amount of compressor heat generated in DHW mode since 00:00 h

of current day, in kWh.

COMPRESSOR DHW TOTAL

Total amount of compressor heat generated in DHW mode, in MWh.

BH HEATING TOTAL

Total amount of heat generated by the electric emergency/booster

heater in heating mode, in MWh.

BH DHW TOTAL

Total amount of heat generated by the electric emergency/booster

heater in DHW mode, in MWh.

°C

kWh

MWh

kWh

MWh

MWh

MWh

POWER CONSUMPTION

COMPRESSOR HEATING DAY

Electrical output of compressor in heating mode since 0:00 h today.

COMPRESSOR HEATING TOTAL

otal electrical output of compressor in heating mode.

COMPRESSOR DHW DAY

Electrical output of compressor in DHW mode since 0:00 h today.

COMPRESSOR DHW TOTAL

Total electrical output of compressor in DHW mode

RUNTIMES in hours

HEATING COMPRESSOR 1

Runtime of compressor 1 in heating mode.

DHW COMPRESSOR 1

Runtime of compressor 1 in DHW mode.

COOLING COMPRESSOR 1

Runtime of compressor 1 in cooling mode.

BH 1

Runtime of electric emergency/booster heater in booster stage 1.

BH 2

Runtime of electric emergency/booster heater in booster stage 2.

BH 1/2

Runtime of electric emergency/booster heater in booster stages 1

and 2.

kWh

MWh

kWh

MWh

Hours

Hours

Hours

Hours

Hours

Hours

10 | WPC | WPC cool www.stiebel-eltron.com

OPERATION

Menu structure

5.2 DIAGNOSIS menu

For heating system and heat pump troubleshooting and analysis,

you can query all important process data and bus subscribers

under DIAGNOSIS and carry out a relay test.

Note

The menu item RELAY TEST SYSTEM is protected by a

code and can only be accessed by a qualified contractor.

Level 2 Level 3 Level 4

SYSTEM STATUS BUFFER CHARGING PUMP

DHW VALVE

HTG CIRC PUMP

MIXER PUMP

MIXER OPEN

MIXER CLOSED

SOURCE PUMP

COOLING MODE

POWER BLOCKED

HEAT PUMP STATUS REM IDLE TIME in minutes

COMPRESSOR

BH 1

BH 2

SYSTEM BUS SUBSCRIBER SUBSCRIBER

SOFTWARE NO.

HEAT PUMP TYPE HEAT PUMP

5.2.1 Fault list

The fault list provides an overview of the faults most recently

registered by the appliance. The fault list contains up to 20 fault

messages. The display, however, can show only 2. Turn the scroll

wheel to access the other entries in the fault list.

MAIN MENUDIAGNOSIS

FAULT LIST 1/1

01. SENSOR BREAK E 71

10:26 14.JUN 13

02. MIN SRCE TEMP

17:45 25. JUN 13

5.2.2 Fault message

If the appliance registers a fault, this is clearly displayed with the

message shown below.

TUESDAY 14.JUN 13 16:27 TIME

!

FAULT

SENSOR BREAK E 71

INTERNAL CALCULATION INTERVAL

LIVE STAGES

FAULT LIST See fault table

RELAY TEST SYSTEM BUFFER CHARGING PUMP

DHW VALVE

HTG CIRC PUMP

MIXER PUMP

MIXER OPEN

MIXER CLOSED

BH 1

BH 2

BH 3

SOURCE PUMP

COOLING MODE

DRAIN HYD MFG

COMFORT MODE

If more than one fault occurs, the most recent fault is always

shown. Notify your qualified contractor.

5.2.3 Relay test

All relay outputs of the controller can be individually switched

from here.

www.stiebel-eltron.com WPC | WPC cool | 11

OPERATION

Menu structure

5.3 PROGRAMS menu

All set times for heating, DHW, holiday and party modes can be

adjusted here, in addition, the heat-up program can be started.

Level 2 Level 3 Level 4

HEATING PROGRAM HEAT CIRCUIT 1

HEAT CIRCUIT 2

DHW PROGRAM

PARTY PROGRAM HOURS

HOLIDAY PROGRAM HOLS BEGINNING

HOLIDAYS ENDING

HEAT-UP PROGRAM ON / OFF LOW END TEMPERA-

TURE

TEMP. RISE PERIOD

MAXIMUM TEMPERA-

TURE

MAX TEMPERATURE

DURAT ION

RISE PER DAY

5.3.1 HEATING PROGRAM

In the menu item HEATING PROGRAM you can determine when

and how often the appliance heats to the set comfort values for

heating circuit1 and heating circuit2. At all other times, the appliance heats to the set ECO value. You can adjust the set values under

menu item SETTINGS / HEATING / HEAT CIRCUIT1 or HEAT CIRCUIT2. Below is an explanation of how to define a time program.

First, select the days on which you want to enable the HEATING

function:

MAIN MENU

PROGRAMS

HEATING PROGRAM

HEAT CIRCUIT 1

MONDAY

07:00 - 20:00

- -:- - - - -:- -

- -:- - - - -:- -

In this example, only one switching time pair has so far been

programmed. For switching time pairs 2 and 3, short dashes are

displayed instead of times. These switching time pairs are still

empty. Select one of the free switching time pairs with OK to reach

the level where you can set the associated start and end time.

Pressing OK brings up the display shown below. Set the required

time with the scroll wheel.

MAIN MENU

PROGRAMS

HEATING PROGRAM

- -:- -

Start

Times can be entered in intervals of 15 minutes. You can set 16:30

or 16:45 h, but not 16:37 h. Confirm your entry with OK.

HEAT CIRCUIT 1

H H

- -:- -

End

26�04�01�0299

26�04�01�0302

MAIN MENU

PROGRAMS

HEATING PROGRAM

HEAT CIRCUIT 1

+

Monday

Mon

-

You can set your heating system as follows:

- For each individual day of the week (Monday - Sunday)

- Monday to Friday (Mon - Fri)

- Saturday and Sunday (Sat - Sun)

- The whole week (Mon - Sun)

Monday is initially offered.

Turn the scroll wheel to select another day or group of days.

Confirm your selection with OK.

You can now set three switching time pairs. The three switching

time pairs are shown on the display, to the right of the clock. A

switching time pair comprises the start time and end point, at

which the appliance returns to its previous state.

Periods around midnight

Assume, for example, you want heating mode to be enabled from

22:00 h for four hours every Wednesday evening. This means the

period does not expire until the next day, Thursday, at 02:00 h.

Since the day ends at 00:00, two switching time pairs are necessary

for the required program. First, program the period 22:00 to 00:00

h for Wednesday, then 00:00 to 02:00 h for Thursday.

5.3.2 DHW PROGRAM

26�04�01�0301

In the menu item DHW PROGRAM you can determine the times

during which DHW heating with the set comfort value should take

place. At all other times, DHW is heated to the set ECO value. You

can select the set values under menu item SETTINGS/DHW/DHW

TEMPERATURES.

You can set your DHW heating as follows:

- For each individual day of the week (Monday - Sunday)

- Monday to Friday (Mon - Fri)

- Saturday and Sunday (Sat - Sun)

- The whole week (Mon - Sun)

You can set three switching time pairs for each of these options.

Exception: If you want to heat DHW from 22:00 h until 06:00 h the

following day you will need two switching time pairs.

Example:

12 | WPC | WPC cool www.stiebel-eltron.com

OPERATION

Menu structure

You would like to heat DHW twice daily, from 22:00 h until 06:00 h

the following day, and then from 08:00 h until 09:00 h.

As the day begins at 00:00 h, programming for this example must

again start at 00:00 h.

- The first switching time pair runs from 00:00 h until 06:00 h.

- The second switching time pair runs from 08:00 h until 09:00

h.

- The third switching time pair runs from 22:00 h until 24:00 h.

5.3.3 PARTY PROGRAM

In the party program you can extend the comfort mode for heating

by a few hours.

5.3.4 HOLIDAY PROGRAM

In the holiday program, the heat pump system runs in ECO mode

and frost protection for DHW heating is enabled.

For both the start and end of the holiday, enter the year, month

and day. The start time is 0:00 h on the first day of the holiday. The

end time is 24:00 h on the day the holiday ends. After the holiday

period has expired, the heat pump system switches back to the

previous heating and DHW program.

5.3.5 HEAT-UP PROGRAM

Note

The menu item HEAT-UP PROGRAM is protected by a

code and can only be accessed and set by a qualified

contractor.

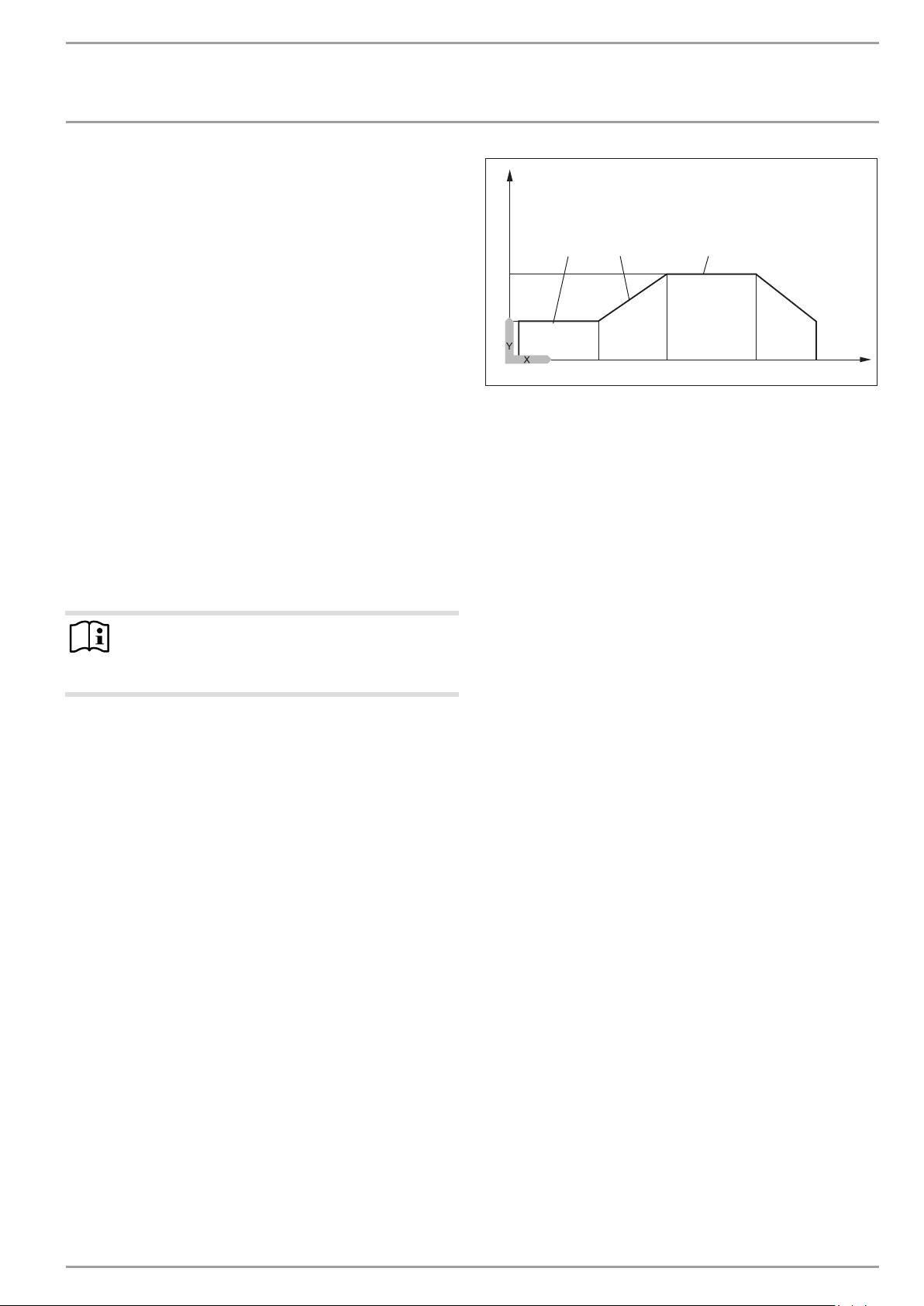

3

1

2

6

Y Temperature

X Time

1 Maximum temperature

2 Low end temperature

3 Low end temperature duration

4 Increase K/day

5 Maximum temperature duration

6 Start

7 End

Please note that only the mixer circuit pump is running when

operating with 2 heating circuits.

If only direct heating circuit 1 is operational, the return sensor is

again used for control. As the actual temperature inside the buffer

cylinder is higher at the heating flow, this configuration results in

5 K being deducted from the set heat-up program values (low end

and maximum temperatures).

4 5

7

84�03�01�0038

Heat-up program for underfloor heating systems

Never use the heat pump for drying screed, as this places an

excessive demand on the heat source and may cause it to be

damaged. Use the electric emergency/booster heater for the

heat-up program. For this, set LOWERAPPLIMITHEATING and

DUALMODETEMPHEATING parameters to 30°C and start the

heat-up program.

Emergency mode cannot be enabled in the heat-up program.

There are a total of 6 parameters for the heat-up program. These

6 parameters can be adjusted in sequence as soon as the heat-up

program is activated. The program is started with the HEAT-UP

PROGRAM parameter and with the setting ON. The system then

heats to the selected low end temperature. The low end temperature is held for the set period (parameter TEMPRISEPERIOD).

After expiry of this period, the system heats to the maximum low

end temperature (parameter MAXIMUMTEMPERATURE) using an

increase K/day (parameter RISEPER DAY) and holds this maximum temperature for the selected time (parameter MAXTEMPERATURE DURATION). The system subsequently returns to the

low end temperature using the same steps as for heat-up. This

concludes the heat-up program. As soon as 2 heating circuits

are operational, both will be operated in line with the heat-up

program (operation with buffer cylinder and mixer circuit). Direct

heating circuit1 (buffer circuit with return sensor) adopts the

set values of the heat-up program. Since this is regulated via the

return sensor, the actual temperature inside the buffer cylinder is

higher at the heating flow. The mixer (heating circuit 2) regulates

the temperature back down to the set values selected in the heatup program (low end temperature and maximum temperature).

The summer logic is disabled whilst the heat-up program runs.

www.stiebel-eltron.com WPC | WPC cool | 13

OPERATION

Menu structure

5.4 SETTINGS menu

Here you can select all system-specific parameters for heating, cooling and DHW modes as well as general settings such as the time.

Note

Some menu options are protected by a code and can only be viewed and adjusted by a qualified contractor.

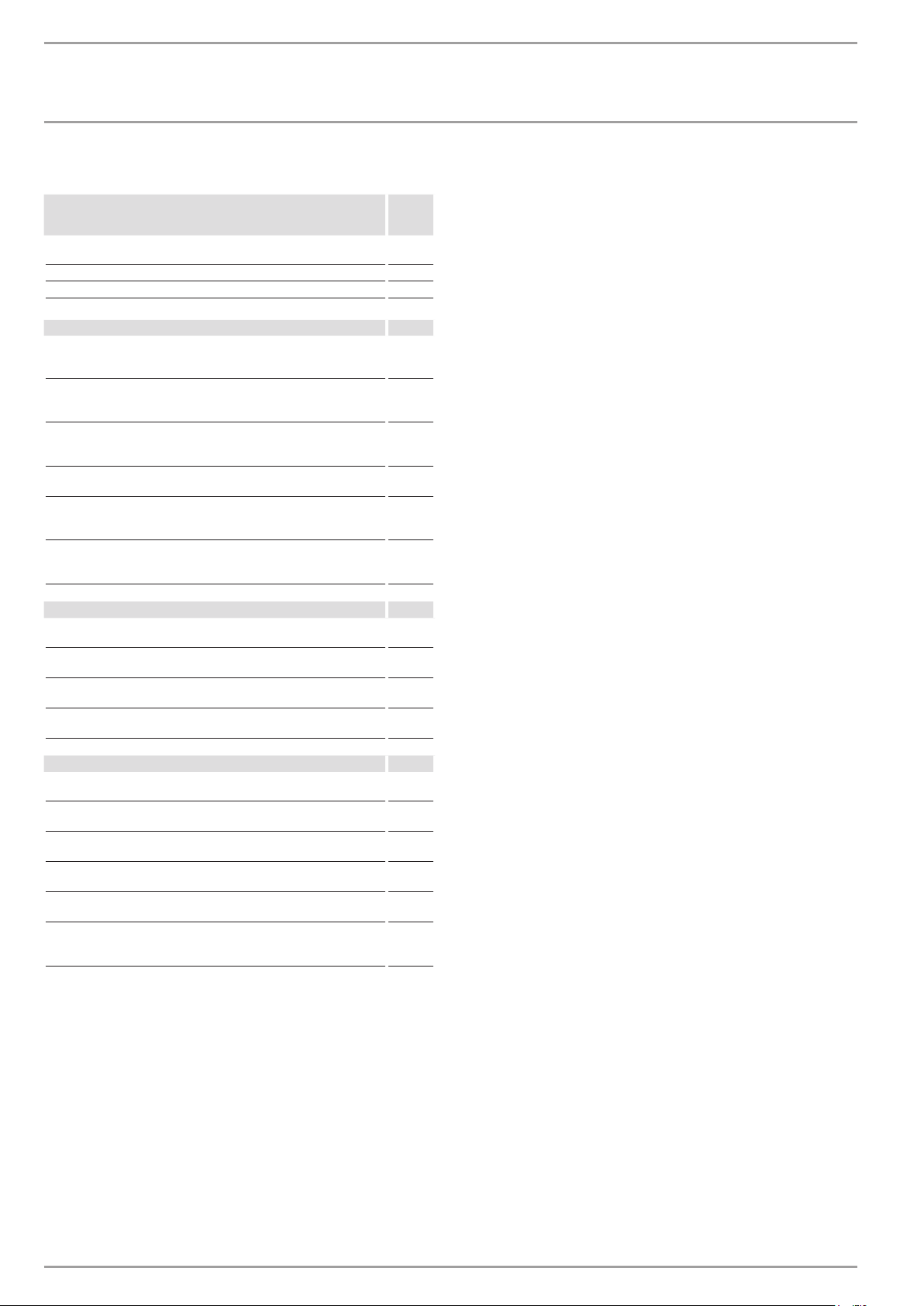

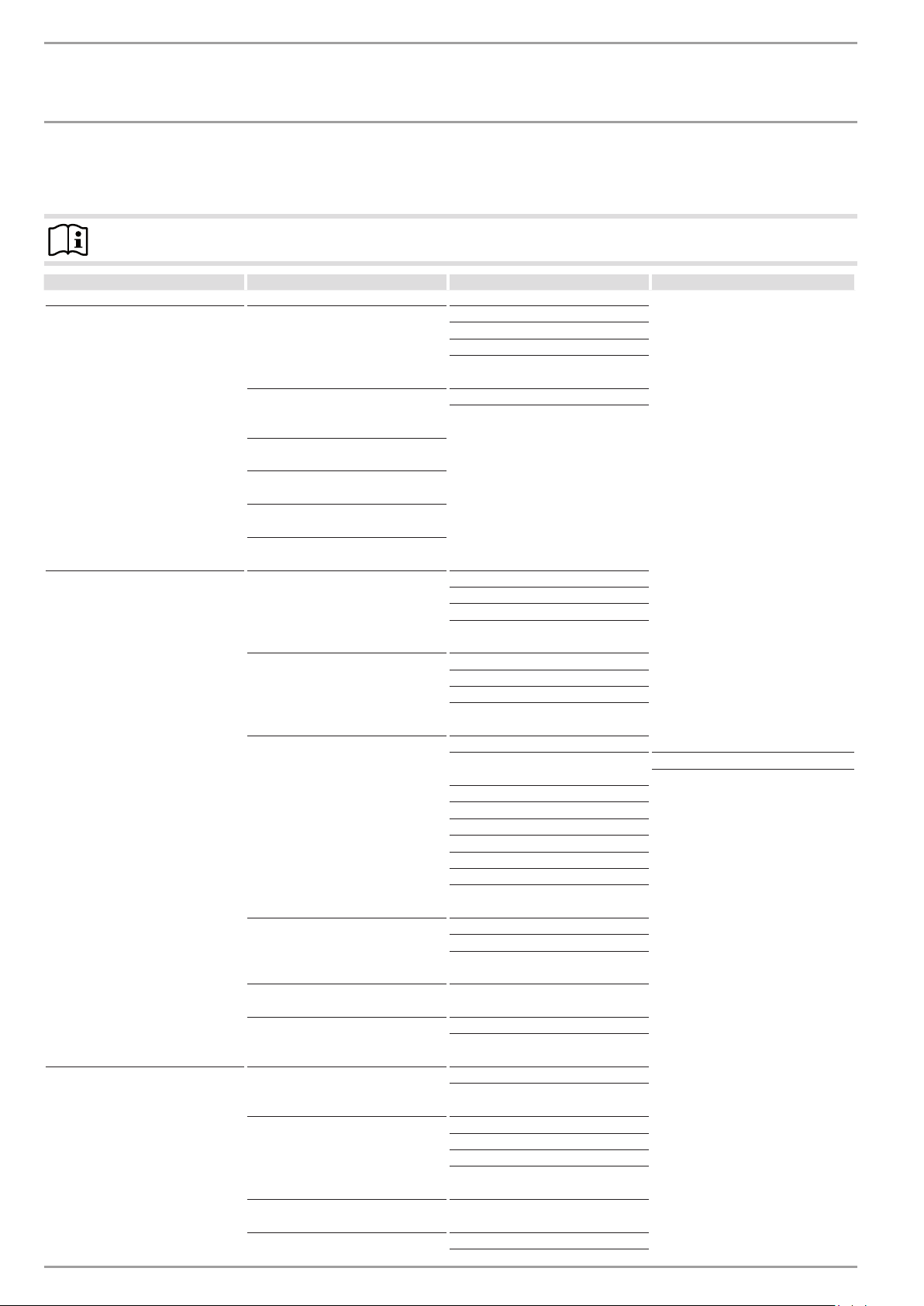

Level 2 Level 3 Level 4 Level 5

GENERAL TIME / DATE TIME

YEAR

MONTH

DAY

SETTING SUMMER TIME DAY BEGINNING

DAY ENDING

CONTRAST

BRIGHTNESS

TOUCH SENSITIVITY

TOUCH ACCELERATION

HEATING HEAT CIRCUIT 1 SET ROOM TEMP COMFORT

SET ROOM TEMP ECO

HEATING CURVE RISE

HEATING CURVE

HEAT CIRCUIT 2 SET ROOM TEMP COMFORT

SET ROOM TEMP ECO

HEATING CURVE RISE

HEATING CURVE

STANDARD SETTING BUFFER OPERAT

SUMMER MODE OUTSIDE TEMPERATURE

MAXIMUM RETURN TEMP

MAXIMUM FLOW TEMP

MIXER DYNAMICS

MAXIMUM MIXER TEMPERATURE

FIXED VALUE OPERATION

HEATING CIRCUIT OPTIMAL

FROST PROTECT

REMOTE CONTROL FE7 HEATING CIRC PRESELECTION

ROOM INFLUENCE

ROOM CORRECTION

PUMPCYCLES ON / OFF

BUILDING HEAT BUFFER

ELECTRIC REHEATING DUAL MODE TEMP HEATING

LOWER APP LIMIT HEATING

DHW DHW TEMPERATURES SET DHW TEMP COMFORT

SET DHW TEMP ECO

STANDARD SETTING DHW HYSTERESIS

DHW LEARNING FUNCTION

DHW CORRECTION

COMBI CYLINDER

PASTEURISATION ON / OFF

ELECTRIC REHEATING DUAL MODE TEMP DHW

LOWER APP LIMIT DHW

14 | WPC | WPC cool www.stiebel-eltron.com

OPERATION

Menu structure

COOLING COOLING ON / OFF

COOLING MODE PASSIVE COOLING / ACTIVE COOLING

ACTIVE COOLING AREA COOLING SET FLOW TEMPERATURE

FAN COOLING SET FLOW TEMPERATURE

PASSIV E COOLING AREA COOLING SET FLOW TEMPERATURE

FAN COOLING SET FLOW TEMPERATURE

FLOW TEMP HYSTERESIS

SET ROOM TEMPERATURE

DYNAMIC

FLOW TEMP HYSTERESIS

SET ROOM TEMPERATURE

DYNAMIC

FLOW TEMP HYSTERESIS

SET ROOM TEMPERATURE

FLOW TEMP HYSTERESIS

SET ROOM TEMPERATURE

5.4.1 GENERAL

TIME / DATE

Here you can set the time, year, month and day.

SETTING SUMMER TIME

Here you can adjust the settings for summer time.

Summer time is factory set to begin on 25March and to end on

25October.

CONTRAST

Here you can adjust the display contrast.

BRIGHTNESS

Here you can adjust the display brightness.

TOUCHSENSITIVITY and TOUCH ACCELERATION

A code is required for this adjustment.

5.4.2 HEATING

HEAT CIRCUIT 1 and HEAT CIRCUIT 2

SET ROOM TEMP COMFORT and SET ROOM TEMP ECO

Here you can select the set room temperatures for comfort mode

and ECO mode as well as the heating curve rise for heating circuit1

and heating circuit2.

Changing the set room temperature results in a parallel shift of

the heating curve.

As soon as the FE7 remote control has been connected and allocated to heating circuit 1, the actual room temperature can also

be scanned.

As soon as the FE7 or FEK remote control has been connected

and allocated to heating circuit2, the actual room temperature

can also be scanned.

The display HEAT CIRCUIT2 only appears if the mixer flow sensor

for heating circuit2 has been connected.

HEATING CURVE RISE

The menu item HEATING CURVE RISE enables you to set one heating curve each for heating circuits1 and 2.

Note: Your contractor will have set a building and system-specific

optimum heating curve for every heating circuit. For heating circuit 1 the curve relates to the heat pump return temperature, for

heating circuit 2 to the mixer flow temperature.

When you adjust the heating curve on the heat pump manager, the

calculated set return or flow temperature, subject to the outside

temperature and the set room temperature, will be shown at the

top of the display.

As soon as you have preselected a temperature in menu SETTINGS

/ HEATING / STANDARD SETTING under parameter FIXED VALUE

OPERATION, heating curve 1 is hidden from view and the display

showsSETFIXED TEMPERATURE with the relevant temperature.

www.stiebel-eltron.com WPC | WPC cool | 15

OPERATION

Menu structure

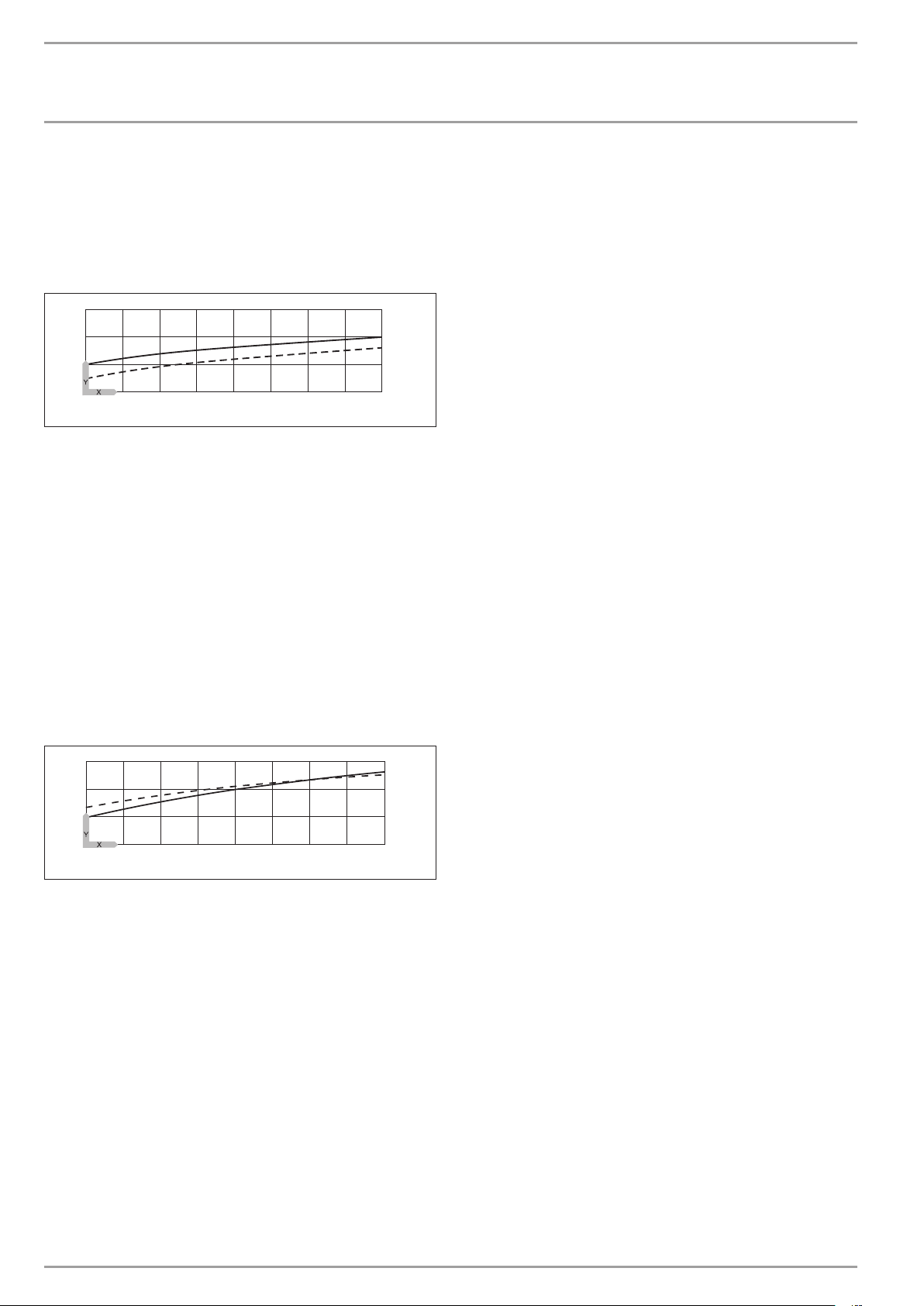

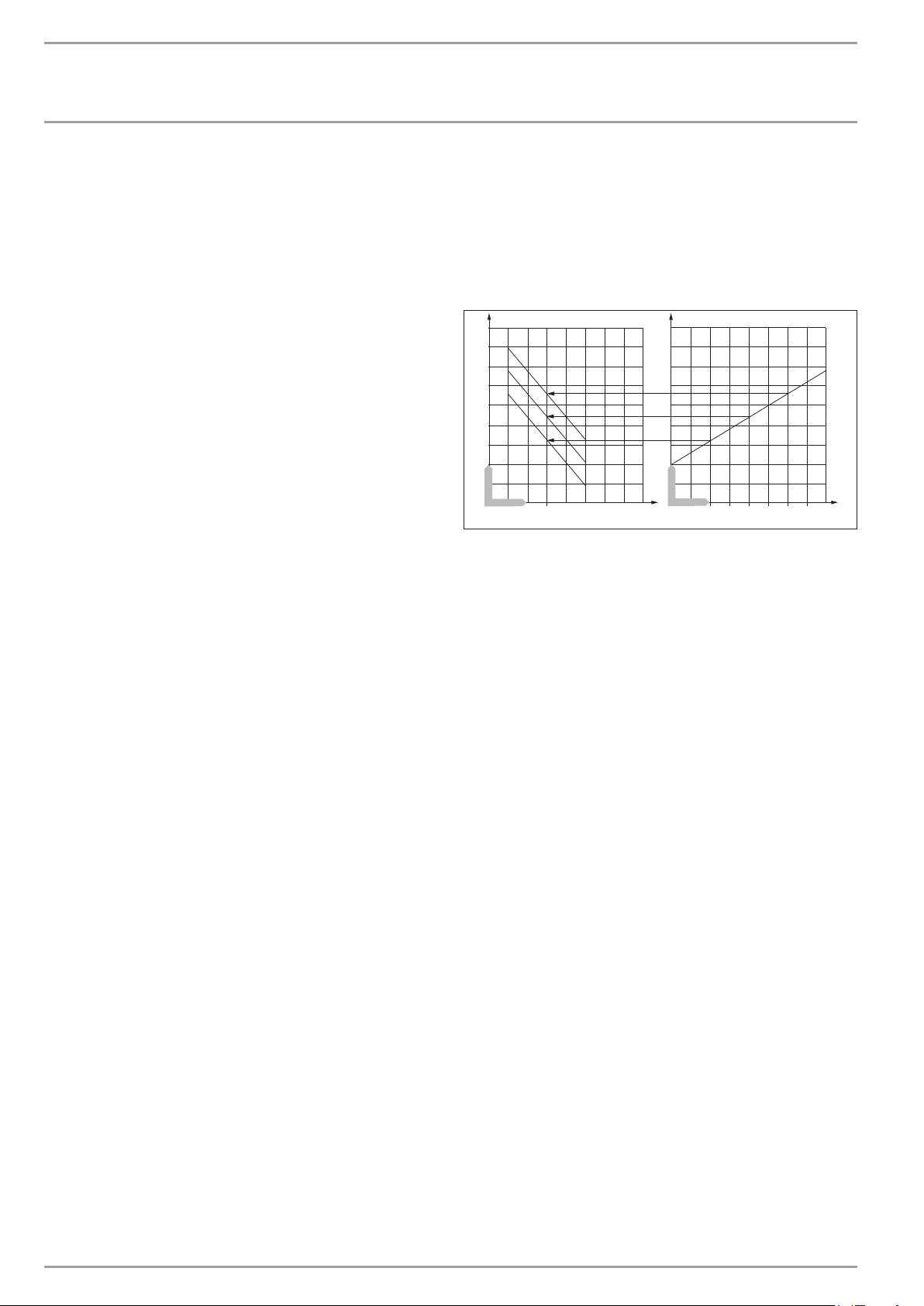

HEATING CURVE

Adjustment of programmed changeover between Comfort and

ECO mode

The figure shows the diagram with the set heating curve relating

to a set room temperature for comfort mode. The second, dashed

line relates to a set room temperature for ECO mode.

60

40

20

0

20 15 10 5 0 -5 -10 -15 -20

1

2

Y Return / flow temperature [°C]

X Outside temperature [°C]

1 Comfort mode

2 ECO mode

Adapting a heating curve

Example:

With heating systems, the temperature in a building during the

transitional periods (spring and autumn) is too low when outside

temperatures are between 5 °C and 15°C, despite open radiator

valves, but is OK at outside temperatures ≤ 0°C. This problem can

be remedied with a parallel shift and a simultaneous reduction

of the heating curve.

Heating curve 1.0 was initially adjusted relative to a set room temperature of 20 °C. The dotted line indicates the modified heating

curve at 0.83 and a modified set room temperature of 23.2°C.

60

40

20

0

20 15 10 5 0 -5 -10 -15 -20

Y Return / flow temperature [°C]

X Outside temperature [°C]

STANDARD SETTING

BUFFER OPERAT

When using a buffer cylinder, set this parameter to ON.

SUMMER MODE

Parameter SUMMER MODE enables you to define the point at

which the heating system is to switch to summer mode. Summer

mode can be switched on or off. There are 2 adjustable parameters

for this function.

- Parameter OUTSIDE TEMPERATURE:

Outside temperature adjustable from 10 °C to 30 °C

26�03�01�1915

- Parameter BUILDING HEAT BUFFER

This parameter lets you choose whether an average outside temperature should be determined, according to the type of building.

You can choose from 3 settings.

Setting "1": Minor insulation towards outside temperatures (averaging over a 24 h period), e.g.for timber construction with rapid

heat transfer.

Setting "2": Moderate insulation towards outside temperatures

(averaging over a 48 h period), e.g. brick construction with thermal

insulation and average heat transfer.

Setting "3": Strong insulation towards outside temperatures (averaging over a 72 h period). House with slow heat transfer.

If the determined outside temperature is ≥ than the selected outside temperature, both heating circuits (if installed) enter summer

mode; reverse hysteresis –1 K.

With fixed-value control, summer mode is disabled for heating

circuit 1.

MAXIMUM RETURN TEMP

Setting range 20 °C to 55 °C.

If the temperature at the return sensor reaches this set value dur-

26�03�01�1916+

ing heating operation, the heat pump is immediately switched

off. This safety function prevents the high pressure switch from

responding. No fault message is issued when this value is reached.

During DHW operation the return temperature is not scanned.

MAXIMUM FLOW TEMP

Maximum heat pump flow temperature for central heating

Setting range 20 °C to 65°C.

This setting limits the flow temperature of the heat pump and the

electric emergency/booster heater in heating mode.

MIXER DYNAMICS

Mixer runtime

Setting range 60 to 240

You can use this setting to adapt the mixer characteristics. The

setting 60 to 240 means 6 K to 24 K control deviation.

16 | WPC | WPC cool www.stiebel-eltron.com

OPERATION

Menu structure

The scan rate is 10 s and the minimum on time for the mixer is

0.5 s. The mixer does not respond in the dead zone of ±1 K from

the set value.

Example for the setting 100 = 10 K

The control deviation (set mixer temperature – actual mixer temperature) is 5K. The mixer opens for 5 s, then pauses for 5 s and

starts again.

The control deviation (set mixer temperature – actual mixer temperature) is 7.5 K. The mixer opens for 7.5 s, then pauses for 2.5

s and starts again.

The smaller the control deviation, the shorter the mixer on time

and the longer the pauses.

A reduction of the MIXER DYNAMIC value with the control deviation unchanged increases the on duration and reduces pauses.

Example for setting 100 and a current control deviation of 5 K.

5 K of 10 K = 50% = on duration

Example: Control deviation

1

± 1 K

HEATING CIRCUIT OPTIMAL

When an Uponor DEM-WP module is connected, the heating curve

is dynamically optimised for the heat demand of individual rooms.

This involves modifying the preset heating curve by up to 50%

of its original value.

The parameter HEATINGCIRCUITOPTIMAL is only displayed when

the buffer operation parameter is set to "OFF" and neither a mixer

sensor nor an FE7 remote control are connected.

The parameter HEATINGCIRCUITOPTIMAL can be set to "ON" or

"OFF". The default value is "OFF".

This parameter may only be set to "ON" when an Uponor DEM WP

module is connected.

This function is only active in comfort mode, ECO mode and programmed operation.

FROST PROTECT

To protect the heating system from frost, start the heating circuit

pumps at the selected frost protection temperature; the reverse

hysteresis is 1K.

2

4

3

1 Setting 100 = control deviation 10 K

2 Control deviation 5 K

3 Control deviation in K

4 On time in %

MAXIMUM MIXER TEMPERATURE

Setting range 20 °C to 90°C.

This setting limits the flow temperature of the mixer circuit. For

example, if a higher set flow temperature is calculated from the

mixer circuit data, the max. set mixer flow temperature will be

used to control and regulate to this value.

FIXED VALUE OPERATION

The heat pump return is regulated to the set fixed value. The

switching time program will then be ignored. The various positions of the program selector will then only affect the mixer circuit

(if installed). When the program selector is set to standby and a

fixed temperature has been selected the frost protection is activated and the compressor is switched off. Summer logic remains

disabled with fixed temperature control. This means that the heating circuit pump is not switched off for the direct heating circuit.

26�03�01�1067

www.stiebel-eltron.com WPC | WPC cool | 17

OPERATION

Menu structure

REMOTE CONTROL FE7

This menu item is only displayed when the FE7 remote control is

connected.

HEATING CIRC PRESELECTION

The FE7 remote control can be selected for both heating circuits.

This parameter lets you choose which heating circuit the remote

control is to act on. Depending on the remote control preselection,

the actual room temperature can be checked under INFO / SYSTEM

/ ROOM TEMPERATURE.

ROOM INFLUENCE

Standard setting 5 adjustable from ---- via 0 to 20 Dashes (----)

in the display:

With the FE7 remote control connected, the room temperature

sensor only serves to record and display the actual room temperature; it has no influence on the actual control. The remote control

can be used to adjust the room temperature for heating circuit 1

or 2 by ± 5 °C in automatic mode only. This set value adjustment

applies to the current heating time, not to the setback time.

At the same time, the setting "0 to 20" serves to control the room

temperature-dependent night setback. This means that the heating circuit pump is switched off at the point of changeover from the

heating into the setback phase. It remains off until the actual room

temperature falls below the set room temperature. After this, the

system continues to regulate in weather-compensated mode.

If you want the room temperature to be taken into account, set

the room temperature sensor influence to a value > 0. The room

sensor influence has the same effect as the outside temperature

sensor has on the return temperature, except that the effect is 1

to 20 times greater, depending on the factor set.

- Room temperature-dependent return / flow temperature

with weather compensation

With this type of control, a control cascade is formed from both

weather-compensated and room temperature dependent return/

flow temperature control. This means that the weather-compensated return/flow temperature control sets a default return/flow

temperature that is corrected by the overriding room temperature

control in accordance with the following formula:

∆ϕ

= (ϕ

R

RSOLL

− ϕ

RIST

) * S * K

Because a substantial proportion of the control is already handled by the weather-compensated control, the room temperature

sensor compensation factor K can be set lower than with pure

room temperature control (K=20). The figure indicates the control

method with the set factor K=10 (room influence) and a heating

curve S=1.2.

- Room temperature control with weather-compensation

This type of control offers two main benefits:

Incorrectly set heating curves are corrected by the room sensor

influence K; whilst the smaller factor K means the control unit

works in a more stable manner.

However, observe the following for all control units with room

temperature sensor influence:

- The room temperature sensor must capture the room temperature accurately.

- Open doors and windows greatly affect the control result.

- All radiator valves in the lead room must be fully open at all

times.

- The temperature inside the lead room affects the entire heating circuit.

If you want the room temperature to be taken into account, set the

room temperature sensor influence to a value > 0.

90

80

70

1

60

1

50

1

40

30

20

10

Y

0

X 1

20

1917 18 21 22 23 24 25

3

4

5

Y

X 2

10

15

20

2

-10

-5

0

5

-20

-15

Y Flow temperature [°C]

X 1 Room temperature [°C]

X 2 Outside temperature [°C]

1 Room temperature sensor influence at K = 10 and S = 1.2

and control deviation +/- 2 K

2 Heating curve S = 1.2

3 Weather-compensated set flow temperature at ϕA = - 10

°C

4 Weather-compensated set flow temperature at ϕA = 0 °C

5 Weather-compensated set flow temperature at ϕA = + 10

°C

ROOM CORRECTION

You can use this parameter to calibrate the measured room temperature.

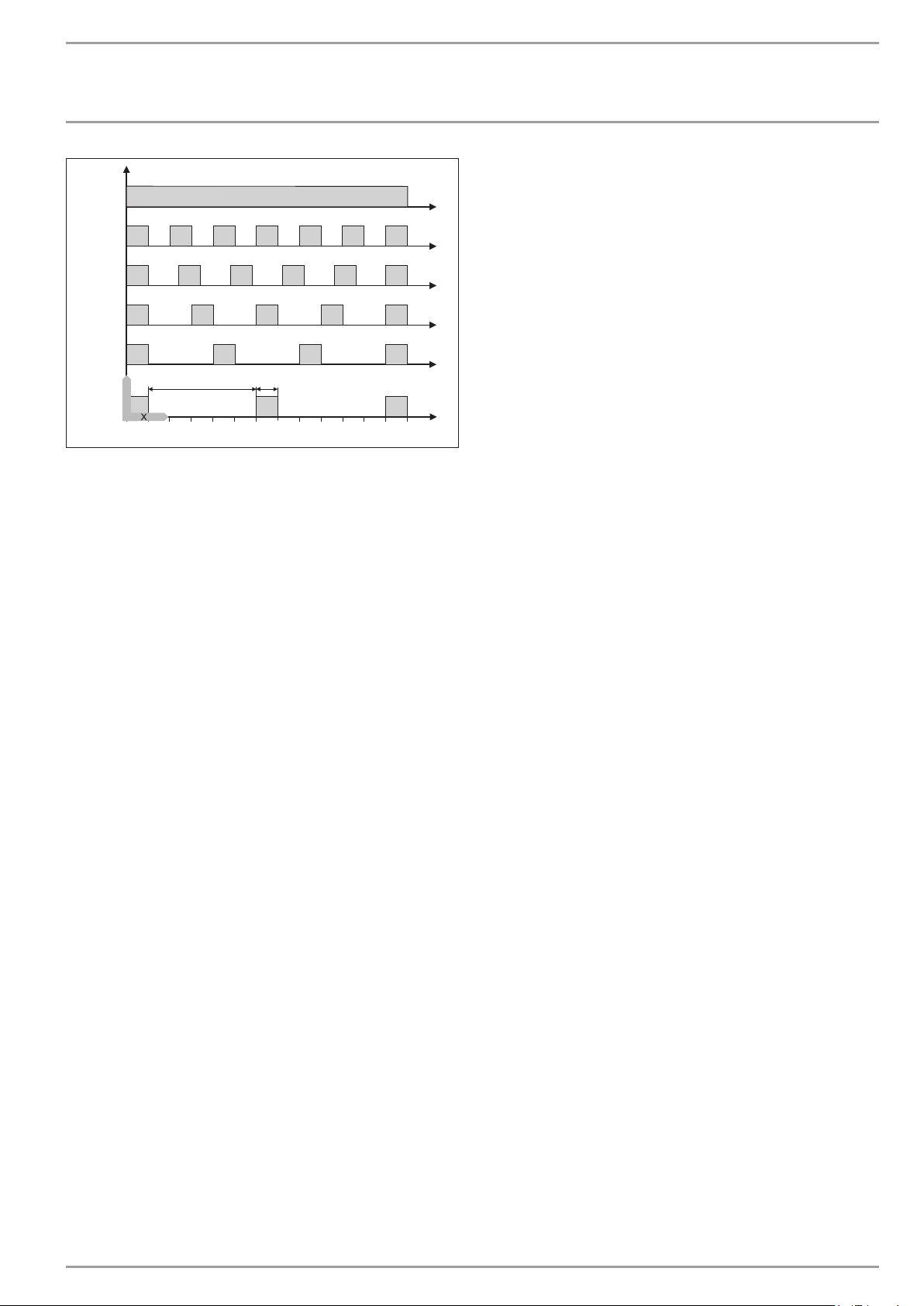

PUMPCYCLES

- Heating circuit pump control

The PUMP CYCLES parameter only applies to the direct heating

circuit1, i.e. for heating circuit pump 1.

This parameter can be switched ON or OFF. In the OFF position,

the heating circuit pump will not cycle. It will operate constantly.

It is only switched off in summer mode.

As soon as you set the parameter to ON, the heating circuit pump

will be switched in line with a fixed temperature curve for the

outside temperature.

The heating circuit pump start pulse is always 5minutes.

The heating circuit pump for heating circuit 1 always starts with

each heat pump start. The pump runs on for 5 minutes after the

heat pump has been shut down. This is where the start-up duration is brought to bear, e.g.at an outside temperature of 5°C, the

pump starts 3 times per hour for 5minutes respectively.

26�03�01�1917

18 | WPC | WPC cool www.stiebel-eltron.com

OPERATION

Menu structure

5.4.3 DHW

< -10

-10

-5

0

5

Y

10

0 10 20 30 40 50 60

1

2

Y Outside temperature in °C

X Time in minutes

1 Pause

2 Pump run time

- Pump kick

To prevent the pumps seizing up, for example over summer, the

pumps are switched on for 10 seconds after every 24 hour period

of inactivity. This applies to all pumps.

- Heating circuit pump control with FE7 / FEK remote control

connected

In conjunction with the FE7 or FEK remote control, the switching

condition

ϕ

ACTUAL room

>ϕ

SET room

+ 1K

causes the respective heating circuit pump to be switched off,

while the mixer moves to CLOSE. This only applies if the room

sensor influence is set to K > 0. Reverse switching is subject to

the following condition:

ϕ

ACTUAL room

>ϕ

SET room

The summer mode is also effective for the respective heating circuit when operating with a FE7 or FEK remote control.

DHW TEMPERATURES

SET DHW TEMP COMFORT and SET DHW TEMP ECO

Here you can select the set DHW temperatures for Comfort and

ECO mode.

STANDARD SETTING

DHW HYSTERESIS

This is where you determine the switching hysteresis for DHW

heating.

- Starting DHW heating at the set DHW temperature minus the

84�03�01�0039

hysteresis value.

DHW LEARNING FUNCTION

Setting OFF

When heating DHW, the system automatically adjusts itself to the

required DHW temperature (self-learning function).

The electric emergency/booster heater will be added as a booster

stage as soon as the heat pump is shut down in DHW mode via

the HP sensor or via the hot gas temperature limit (130 °C). If the

flow temperature of 70°C is achieved in this operating mode,

DHW heating will be terminated, and the set DHW temperature is

overwritten with the actual DHW temperature.

Setting ON

As soon as the heat pump is shut down in DHW mode via the HP

sensor or the hot gas temperature limit (130 °C), DHW heating is

terminated and the set DHW temperature will be overwritten with

the current actual DHW temperature. This operating mode saves

energy, as DHW is exclusively heated by heat pump.

DHW CORRECTION

The DHW temperature is measured in the bottom third of the

cylinder. The DHW outlet temperature is approx.3K higher than

the measured temperature. This deviation is corrected and can be

calibrated if necessary.

ELECTRIC REHEATING

DUAL MODE TEMP HEATING

Dual mode temperature of the heat pump for heating operation

COMBI CYLINDER

As soon as you set the parameter to ON, the heating circuit pumps

are switched off during DHW heating.

(Only in conjunction with the SBS instantaneous water cylinder)

Below this outside temperature, the electric emergency/booster

heater is switched on for heating operation, subject to load.

LOWER APP LIMIT HEATING

Heat pump application limit

PASTEURISATION

The DHW cylinder is heated daily at 01:00 h to 60 °C if pasteurisation has been enabled. Pasteurisation only takes place when the

electric emergency/booster heater is connected.

The heat pump is switched off if the outside temperature drops

below the selected lower application limit for heating.

The electric emergency/booster heater alone provides central

heating.

www.stiebel-eltron.com WPC | WPC cool | 19

OPERATION

Menu structure

ELECTRIC REHEATING

DUAL MODE TEMP DHW

Dual mode temperature of the heat pump for DHW heating.

Below this outside temperature, the electric emergency/booster

heater is switched on for DHW heating, subject to load.

LOWER APP LIMIT DHW

Lower application limit of the heat pump for DHW heating.

The heat pump is switched off at outside temperatures below the

selected lower DHW application limit.

The electric emergency/booster heater alone provides DHW heating.

5.4.4 COOLING

The appliance is designed for DHW and central heating. Passive

cooling is possible in conjunction with the WPC cool. In the delivered condition, the COOLING parameter is set to OFF. Active

cooling mode is only possible in conjunction with the WPAC 2

cooling module.

COOLING

On / OFF

COOLING MODE

PASSIVE COOLING / ACTIVE COOLING

ACTIVE COOLING

AREA COOLING

- FLOW TEMPERATURE

- FLOW TEMP HYSTERESIS

- SET ROOM TEMPERATURE

- DYNAMIC

FAN COOLING

- FLOW TEMPERATURE

- FLOW TEMP HYSTERESIS

- SET ROOM TEMPERATURE

- DYNAMIC

PASSIVE COOLING

AREA COOLING

- FLOW TEMPERATURE

- FLOW TEMP HYSTERESIS

- SET ROOM TEMPERATURE

FAN COOLING

- FLOW TEMPERATURE

- FLOW TEMP HYSTERESIS

- SET ROOM TEMPERATURE

Appliance and system damage

!

You must not enable the COOLING parameter without a

cooling module.

WPC 04 - 16 with WPAC 2 cooling module

Appliance and system damage

!

Set the COOLING parameter to ACTIVE COOLING.

Note

The COOLING parameter will only be shown if an FEK or

FE7 remote control is connected. Cooling mode is only

possible in summer mode.

The WPC with the WPAC 2 cools in 2 stages:

Stage 1 (source pump)

Heat is extracted from the heating circuit and is passed to the

heat source system.

Stage 2 (source pump + compressor)

In addition, the refrigerant circuit extracts heat from the heating

circuit and transfers it to the heat source system.

DHW heating

DHW heating always has priority. As long as the actual temperature has not dropped below the set flow or room temperature, active cooling continues even during DHW heating, and any extracted

heat is transferred to the DHW. If there is no cooling demand, DHW

is conventionally heated via the heat source system.

Cooling mode with the FE7

The FE7 remote control is not equipped with dew point monitoring. It can therefore only be used in conjunction with fan convectors with condensate drain. The cooling mode parameter must

be set to FAN.

Cooling mode with the FEK

The FEK remote control is equipped with dew point monitoring,

and can therefore be used with area heating systems (e.g. underfloor/wall heating systems, etc.). The COOLING parameter must be

set to AREA COOLING. The set flow temperature is compared with

the captured dew point temperature, so the actual temperature

never drops below the dew point. When using fan convectors

with the FEK remote control, set the COOLING parameter to FAN

COOLING.

In the COOLINGparameter, you can select the following cooling

modes for the FE7 and the FEK:

- Room temperature

Cooling mode starts when the selected room temperature is

exceeded (output COOLING=230 V).

Cooling mode is stopped when the actual room temperature

drops 2K below the set temperature. (output COOLING=0 V)

20 | WPC | WPC cool www.stiebel-eltron.com

OPERATION

Menu structure

- Flow temperature and hysteresis

Cooling mode is regulated via the selected flow temperature.

The brine pump starts at:

[Flow temperature + hysteresis]

Brine pump off when the actual temperature drops below the

flow temperature.

The [flow temperature+hysteresis] should be at least 3 K <

room temperature. Lower flow temperatures cause a more

rapid cooling of the room.

On the setting AREA COOLING, as soon as the determined

dew point temperature is + 2 K higher than the set flow temperature, that temperature will be overridden with the dew

point temperature and acts as control variable. The brine

pump starts at [entered or newly determined flow temperature + hysteresis].

If the actual flow temperature drops below the entered or

newly determined flow temperature, the source pump stops

and cooling mode is terminated. The cooling signal remains

active.

- Dynamic

The Dynamic can be adjusted from 1 to 10. It describes the

delay and changeover between passive cooling and active

cooling, whereby active cooling is started sooner, the smaller

the value.

5.5 FE7 remote control

5.6 FEK remote control

The FEK remote control allows you to:

- Change the set room temperature for heating in heating circuit1 or2 by ±5°C.

- Change the operating mode.

The FEK features the following controls:

- Rotary selector for changing the set room temperature

- "Away" button

- "Info" button

- Button for selecting the following operating modes:

-

Standby mode

-

Automatic mode

-

Constant day mode

-

Constant setback mode

PIC00000704

The FE7 remote control allows you to:

- Change the set room temperature for heating in heating circuit1 or2 by ±5°C.

- Change the operating mode.

The FE7 remote control features the following controls:

- Rotary selector for changing the set room temperature

- Rotary selector with the following positions

-

Automatic mode

-

Constant setback mode

-

Constant day mode

Note

The remote control is only active in the automatic mode

of the heat pump manager.

Note

If the FEK is preselected for a specific heating circuit,

the heating curve, room temperature and heating program parameters are not shown at the WPM3i heat pump

manager.

PIC00000609

5.7 Internet Service Gateway (ISG)

The Internet Service Gateway (ISG) is an Ethernet gateway in a

wall mounted casing and is connected into the LAN (local area

network).

It enables the convenient operation, adjustment and checking of

heat pump system data via the browser of a computer, laptop or

tablet in the local home network.

If required by the customer, appliance data can be automatically

transmitted to the appliance manufacturer's SERVICEWELT portal

via the internet.

Via SERVICES you can access additional options such as system

operation on the go with a smartphone as well as remote setting

of parameters and remote diagnosis, etc.

You can find the current services on our homepage.

PIC00001002

www.stiebel-eltron.com WPC | WPC cool | 21

OPERATION

Maintenance and care

6. Maintenance and care

Appliance and system damage

!

Maintenance work, such as checking the electrical safety,

must only be carried out by a qualified contractor.

A damp cloth is sufficient for cleaning all plastic and sheet metal

parts. Never use abrasive or corrosive cleaning agents.

We recommend an annual inspection (to establish the system's

current condition), and maintenance by a qualified contractor if

required (to return the system to the desired condition).

7. Troubleshooting

Fault Cause

There is no hot water or

the heating system stays

cold.

The fuse/MCB has blown/

responded.

Remedy

Check the fuses/MCBs in

your fuse box.

7.1 Other problems

If you cannot remedy the fault, notify your qualified contractor.

To facilitate and speed up your enquiry, please provide the serial

number from the type plate. The type plate is located at the front

top, on the right or left hand side of the casing.

Sample type plate

1

Montageanweisung beachten! Dichtheit geprüft!

1 Number on the type plate

*xxxxxxxxxxxxxxxxxx*

Made in Germany

26�03�01�1570

22 | WPC | WPC cool www.stiebel-eltron.com

Loading...

Loading...