STIEBEL ELTRON SBP 200 E, SBP 700 E, SPB 400 E, SBP 700 E SOL Operating And Installation Instructions

268941

SBP 200 E, SPB 400 E, SBP 700 E, SBP 700 E SOL with WPKI 5

Operating and installation instructions

SBP 200 E / WPKI 5

1. Operating instructions 3

1.1 Cylinder description 3

1.2 Special accessories 3

1.3 Essential special accessories

1.4 Operating and installation instructions 3

2. Installation instructions 3

2.1 Cylinder construction 3

2.2 Regulations 3

2.3 Place of installation 3

2.4 Cylinder casing assembly/removal 3

2.5 Immersion heater installation 5

2.6 WPKl 3 installation 5

2.7 Commissioning 5

2.8 Maintenance 5

26_03_01_0222

2

7

6

5

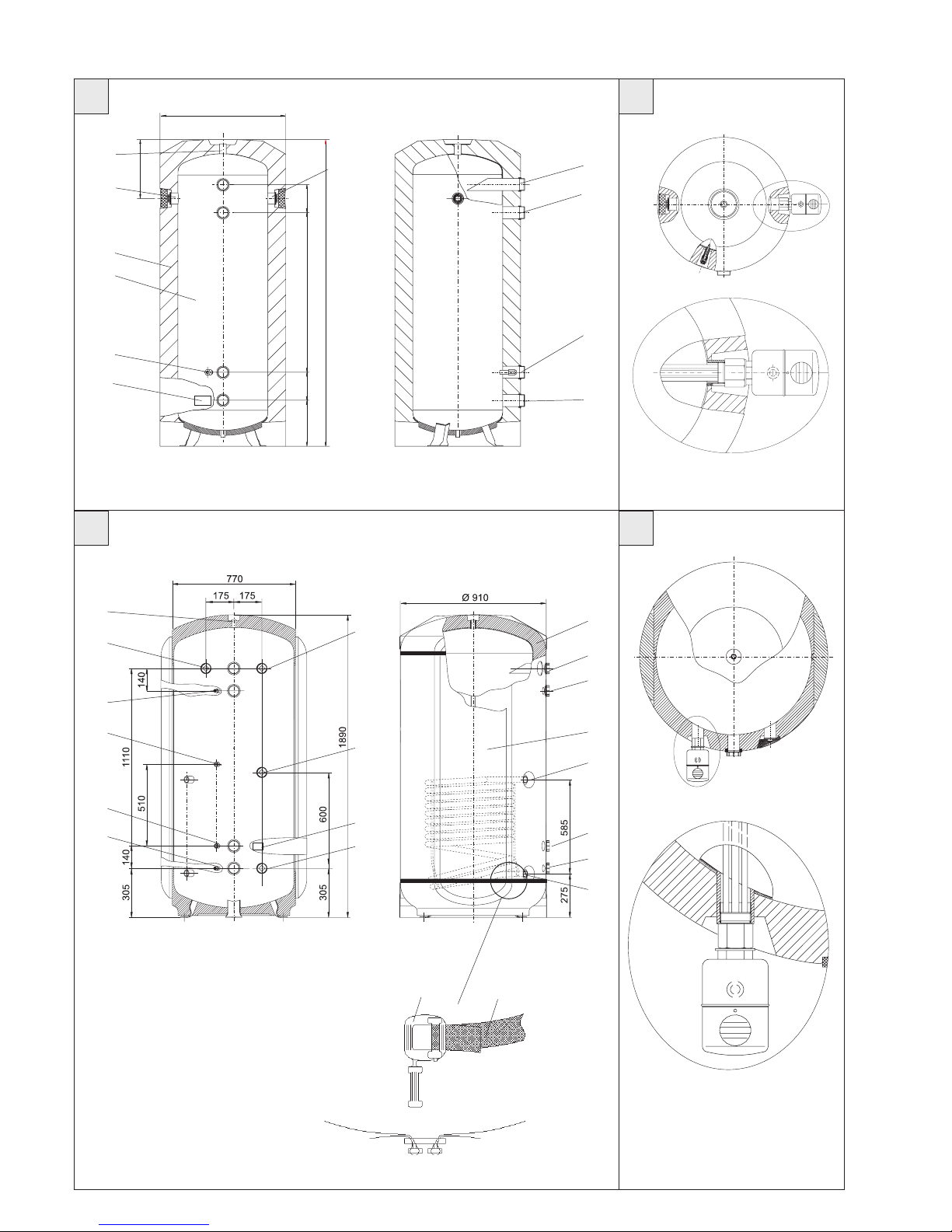

SBP 200 E (SBP 400)

18 17

1

2

9

8

3

4

10

Dimensions in mm

1

2

10

8

14

10

11

11

7

6

5

4

Dimensions in mm

SBP 700 E / SBP 700 E SOL

10

9

13

12

16

15

15

A

B

C

D

C26_03_01_0225

26_03_01_0227

230

140

800

1535

140

295

Ø 630

(1710)

(925)

(250)

(320)

(Ø 750)

C26_03_01_0229

26_03_01_0225

C26_03_01_0225

3

2. Installation instructions for contractors

1. Instructions for users and contractors

SBP 200 E Part no: 18 54 58

SBP 700 E Part no: 18 54 59

SBP 400 E Part no: 22 08 24

SBP 700 E SOL Part no: 18 54 60

1.1 Cylinder description

The sealed freestanding cylinder (with a volume of 200 or 700 litres) acts as buffer cylinder

for heat pumps.

A buffer cylinder is recommended to ensure

trouble-free heat pump operation. It acts as

a bridge during electricity supply shutdown

periods and as separator between the volume

flow in the heat pump and that in heating

circuits.

Features of the SBP 700 E SOL

The cylinder SBP 700 E SOL is also fitted with

a heat exchanger for boosting the DHW with

solar energy.

1.2 Special accessories

WPKI 5 Part no: 22 08 30

The compact installation heat pump set

WPKl 3 is designed especially for use with

buffer cylinders SBP 200 E, SBP 400 and

SBP 700 E (SOL). Clear and simple connection

of buffer cylinder SBP to heat pumps WPL.

WPKI 6 Part no: 22 08 31

The compact heat pump set WPKl 4 is desi

gned especially for use with buffer cylinders

SBP 200 E and SBP 700 E (SOL). Clear and sim

ple connection of buffer cylinder SBP to heat

pumps WPF.

Inserts Part no: 00 37 11

For close fitting pipe connection of the buffer

cylinder without heat pump compact installati

on WPKl 3. This set comprises 4 inserts,

4 gaskets and 4 union nuts G 2”.

Thermally insulated pressure hoses

G 1¼” x 1 m (DN 25) Part no: 07 44 15

G 1¼” x 2 m (DN 25) Part no: 07 44 16

G 1¼” x 5 m (DN 25) Part no: 07 44 17

G 1¼” x 1 m (DN 32) Part no: 07 44 14

G 1¼” x 2 m (DN 32) Part no: 18 20 19

G 1¼” x 5 m (DN 32) Part no: 18 20 20

1.3 Essential special

accessories

UP 25-60-180 Part no: 07 43 25

UP 25-80-180 Part no: 07 43 16

For further accessories, see the design docu

-

mentation.

1.4 Operating and installation instructions

Observe the operating and installation instructions of the components for each relevant

system.

Keep these operating instructions

in a safe place and pass them on to

any new user, should the equipment change

hands. Let your contractor check their content in conjunction before commencing any

maintenance or repair work

To prevent damage and contaminati-

on, we recommend that the cylinder

casing is removed for transportation and

installation (see 2.3).

Do not use a barrel clamp!

2.1 Cylinder construction

(A, B, E)

1 Ventilation connectors R ¾” and

combined

temperature and pressure relief valve

2 PUR foam thermal insulation

3 Steel container

4 G 2” flow connector, heat pump compact

installation

5 G 2” heating flow connector

6 G 2” heating return connector

7 G 2” return connector, heat pump compact

installation

8 G ½” connector with protective pipe for HP

return temperature sensor

9 Type plate (on the protective cover)

10 G 1½” connectors, for electric immersion

heater

11 G ½” connector, sealed with plug

12 G 1” flow connector, HE solar

(only SBP 700 E SOL)

13 G 1” return connector, HE solar

(only SBP 700 E SOL)

14 G ½” connector with protective sleeve for

temperature sensor (only SBP 700 E SOL)

15 G 1½” connector for additional heat source

16 PUR foam body, thermal insulation segment

17 Retaining strap

18 Buckle

19 Plastic casing

20 Plastic lid

21 Plastic plinth cover

2.2 Regulations

• Installation and commissioning, as well

as the maintenance of this equipment,

must only be carried out by an authori-

sed qualified contractor in accordance

with these instructions.

• Optimum function and safe operation

can only be assured when using original,

specialised accessories and spare parts

intended for this equipment.

2.3 Place of installation

The installation location should be safe from

frost. If the system is not in use at times when

frost is likely, drain the cylinder and the whole

system connected to it, to prevent damage.

Ensure that the floor at the installation loca

tion is a load bearing surface, which must be

level and even.

Secure the cylinder feet firmly to the floor to

prevent tipping.

Minimum ceiling height:

1.80 m for SBP 200 E,

2.00 m for SBP 400 E and

2.10 m for SBP 700 E.

2.4 Cylinder casing

assembly / removal

The cylinder casing is fitted in the delivered

condition. It can be removed if necessary.

Removal (E):

1. Removing the plastic lid (20)

2. Removing the plastic plinth cover (21)

3. Removing the plastic casing (19)

Installation in reverse order.

Fit the cylinder casing before installation work begins on the immersion

heater.

Features of the SBP 700 E and

the SPB 700 E SOL (B)

The two polyurethane foam segments, attached to both sides of the cylinder, can be

removed to ensure safe transportation of the

cylinder through narrow passages and door-

SBP 200 E SBP 400 E SBP 700 E SBP 700 E SOL

Weight: empty:

full

kgkg56

256

82

482

145

845

176

876

Height of unit when tilted:

mm 1650 1800 2000 2000

Permissible operating pressure MPa (bar) 0,3 (3) 0,3 (3) 0,3 (3) 0,3 (3)

Loading...

Loading...