Page 1

Simply the Best

Installation

Operation

Functions and options

Troubleshooting

SOM 9s

Thank you for buying this product.

Read this manual carefully to get the best performance from this unit.

*49012850*

49012850

Please keep this manual carefully.

en-US/CA

Manual

SOM 9s

Page 2

SOM 9s

Contents

1 Overview ............................................................. 3

2 Installation .......................................................... 4

2.1 Mounting ....................................................................4

2.2 Electrical connection ...............................................4

2.3 Data communication / Bus ....................................6

2.4 SD card slot ..............................................................6

2.5 Overview of the systems .......................................7

2.6 System layouts ..........................................................9

3 Operation and function ................................... 69

3.1 Buttons .................................................................... 69

3.2 Selecting menu points and adjusting values ... 69

3.3 Menu structure ...................................................... 69

3.4 Indications and system monitoring display......70

3.5 Further indications ............................................... 71

4 Status menu ..................................................... 72

5 Initial commissioning ....................................... 73

General

Safety advice:

Please read the following information carefully before

installing and operating the controller. In this way damage

to the solar system caused by wrong installation will be

avoided. Please make sure that the mounting is adapted to

the characteristics of the building, that the local regulations

are respected and is conform with the technical rules.

Please pay attention to the following safety advice in order

to avoid danger and damage to people and property.

6 Functions and options ..................................... 75

6.1 Status level .............................................................. 75

6.2 Adjustment channels ............................................ 78

6.3 Overview of options and their parameters .... 94

7 User code and short menu -

Adjustment values ............................................ 96

8 Messages ........................................................... 97

9 Troubleshooting ............................................... 98

9.1 Miscellaneous ......................................................... 99

10 Accessories .................................................... 101

10.1 Sensors and measuring instruments ............... 101

10.2 Interface adapters ............................................... 101

10.3 Visualization modules ........................................102

11 Index ................................................................ 103

Subject to technical change. Errors excepted.

Instructions:

Attention should be paid to

• Valid national and local standards and regulations

• Respective valid standards and directives

Equipment to be installed and used in accordance with

the rules of the National Electrical Code (NEC) or with

Canadian Electrical Code (CEC), Part I.

These instructions are exclusively addressed to authorized

skilled personnel.

• Only qualied electricians should carry out installation and

maintenance work.

• Initial installation should be carried out by qualied personnel

Description of symbols

WARNING! Warnings are indicated with a

warning triangle!

They contain information on how

to avoid the danger described.

Signal words describe the danger that may occur, when it

is not avoided.

WARNING means that injury, possibly life-threatening

injury, can occur.

ATTE NTIO N means that damage to the appliance can

occur.

Note

Notes are indicated with an information

symbol.

Î Arrows indicate instruction steps that should be car-

ried out.

| 2

Information about the product

Proper usage

The solar controller is designed for use in solar thermal

and heating systems in compliance with the technical data

specied in these instructions.

Improper use excludes all liability claims.

Note

Strong electromagnetic elds can impair the

function of the controller.

Î Make sure the controller as well as the

system are not exposed to strong electro-

magnetic elds.

© Stiebel 11091_SOM_9s.monus.indd

Page 3

SOM 9s

1 Overview

• Extralargegraphicdisplay

• 4relayoutputs

• 7sensorinputs,

2 of them for Grundfos Direct Sensors™

• 2PWMoutputsforspeedcontrolofhighefciencypumps

• DataloggingontoSDcard

• Drainbackoption

• Time-controlledthermostatfunction

• VBus

®

• Energy-savingswitch-modepowersupply

Included:

1 x SOM 9s

1 x accessory bag

3 x screw and wall plug

8 x strain relief and screw

Additionally included in the full kit:

2 x FKP6 sensor

2 x FRP6 sensor

Note:

For more information about accessories, see

p. 101.

Note:

The SD card is not included with the controller

Technical data

Housing:

plastic, PC-ABS and PMMA

Protection type: IP 20 / EN 60 529

Protection class: I

Ambient temp.: 32 ... 104 °F

Dimensions: 204 x 170 x 47 mm

Mounting: wall mounting, also suitable for mounting into

patch panels

Display: System-Monitoring-Display for system visuali-

zation, 16-segment display, 7-segment display, 8 symbols,

control lamp (directional pad) and background illumination

Operation: 7 push buttons at the front of the housing

Functions: System controller for solar and heating sys-

tems. Functions such as: DT control, pump speed control,

Inputs:

5 inputs for Pt1000 temperature sensors, inputs for 1

Grundfos Direct Sensor™ VFS and 1 Grundfos Direct

Sensor™ RPS, 1 Impulse input V40

Outputs:

3 semiconductor relays, 1 standard relay, 2 PWM outputs

Interfaces: VBus

®

, SD card slot

Power supply:

100 ... 240 V~, 50 ... 60 Hz

Switching capacity per relay:

1 (1) A 100 ... 240 V~ (semiconductor relay)

2 (1) A 100 ... 240 V~(standard relay)

Total switching capacity: 4 A

Standby power consumption: < 1W

Mode of operation: type 1.Y

energy metering, operating hours counter for the solar

pump, evacuated tube collector function, thermostat function, vertical tank loading, priority logic, drainback option,

booster function, heat dump function, thermal disinfection

function, PWM pump control.

© Stiebel 11091_SOM_9s.monus.indd

3 |

Page 4

SOM 9s

2 Installation

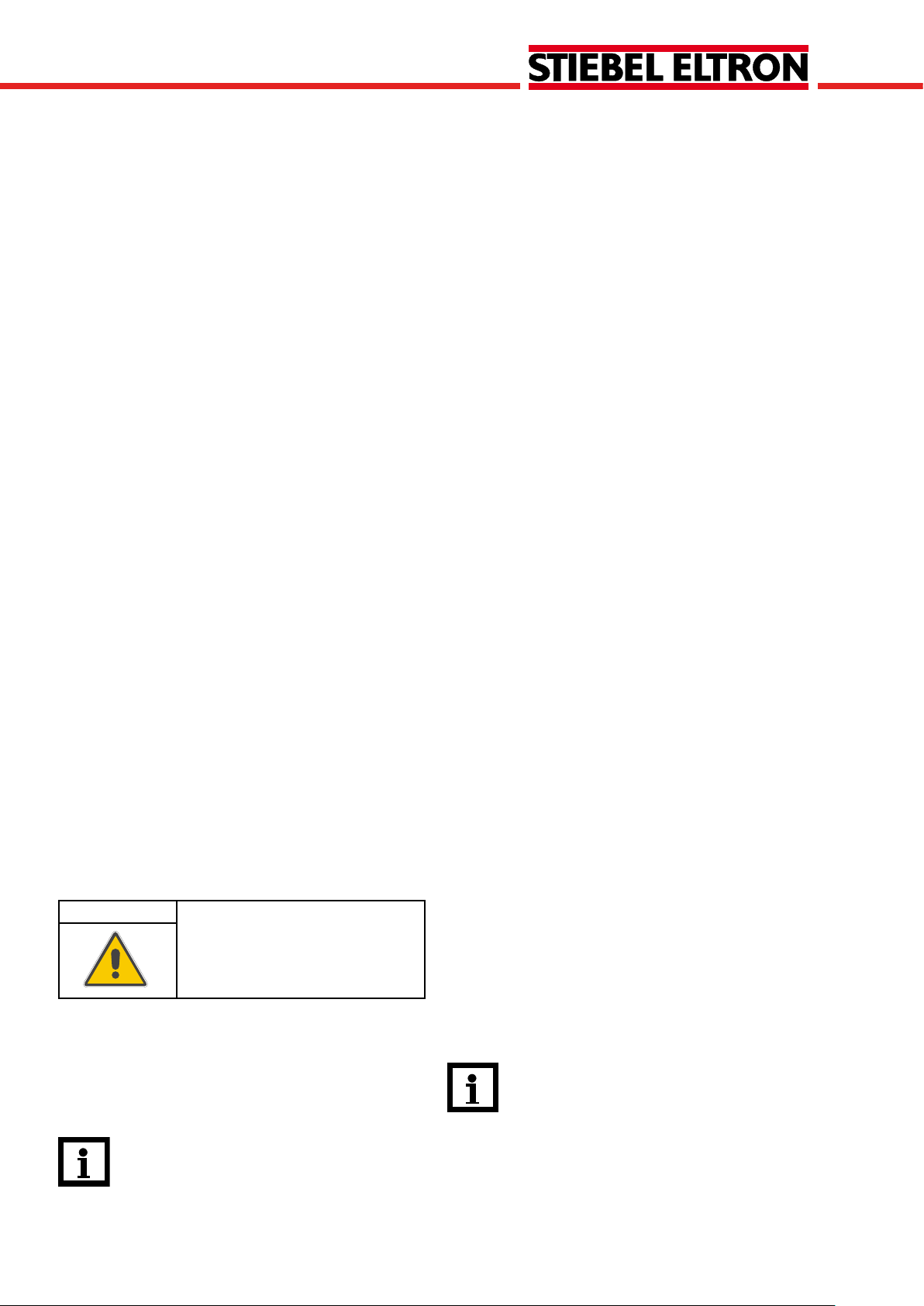

2.1 Mounting

screw

cover

upper fastening

point

lower fastening point

WARNING! Electric shock!

Upon opening the housing, live parts

are exposed.

Î Always disconnect the control-

ler from power supply before

opening the housing!

Note

Strong electromagnetic fields can impair the

function of the controller.

Î Make sure the controller as well as the

system are not exposed to strong electro-

magnetic elds.

The unit must only be located in dry interior rooms.

The controller must additionally be supplied from a double

pole switch with contact gap of at least 3 mm.

Please pay attention to separate routing of sensor cables

and power supply cables.

In order to mount the device to the wall, carry out the

following steps:

Î Unscrew the cross-head screw from the cover and re-

move it along with the cover from the housing

Î Mark the upper fastening point on the wall. Drill and

fasten the enclosed wall plug and screw leaving the head

protruding

Î Hang the housing from the upper fastening point and

mark the lower fastening points (centres 150 mm)

Î Insert lower wall plugs

Î Fasten the housing to the wall with the lower fastening

screws and tighten

Î Carry out the electrical wiring in accordance with the

terminal allocation, see chap. 2.2

Î Put the cover on the housing

Î Attach with the fastening screw

2.2 Electrical connection

| 4

ATTENTION! ESD damage!

Electrostatic discharge can lead to damage to electronic components!

Î Take care to discharge proper-

ly before touching the inside

ofthedevice!Todoso,touch

a grounded surface such as a

radiator or tap!

Note:

The pump speed must be set to 100 % when

auxiliary relays or valves are connected.

© Stiebel 11091_SOM_9s.monus.indd

Page 5

SOM 9s

VFS

RPS

Te mp. Sensor

Pt1000

S3

S1

S2

S4

S5

GND

1

PWM

2

PWM

T4A

100 ... 240V~

R1-R3

1 (1)A (100 ... 240)V~

2 (1)A (100 ... 240)V~

R4

L

L'

R4

V40

VBus

R3

R1

R2

N

WARNING! Electric shock!

Upon opening the housing, live parts

are exposed.

Î Always disconnect the control-

ler from power supply before

opening the housing!

The controller is supplied with power via a power supply

cable. The power supply of the device must be 100 ... 240V~

(50 ... 60 Hz).

The controller is equipped with 4 relays in total to which

loads such as a pump, a valve, etc. can be connected:

• Relays R1 ... R3 are semiconductor relays, designed for

pump speed control

Conductor R1... R3

Note:

Connecting the device to the power supply must

always be the last step of the installation!

Neutral conductor N

Ground terminal

• Relay 4 is a standard relay

Conductor R4

Neutral conductor N

Ground terminal

Depending on the product version, power supply cable and

sensor cables are already connected to the device. If that is

not the case, please proceed as follows:

Connect the temperature sensors (S1 to S5) to the

corresponding terminals with either polarity:

S1 = sensor 1 (collector sensor )

S2 = sensor 2 (e. g. tank sensor bottom)

S3 = sensor 3 (e. g. tank sensor top)

S4 = sensor 4 (e. g. tank sensor tank 2)

Note:

The connection depends on the system selected,

see chap. 2.6. “System layouts”

S5 = sensor 5 (e. g. collector sensor collector 2)

Connect the Grundfos sensors to the VFS and RPS inputs.

A V40owmeter can be connected to the terminals V40

and GND (either polarity).

The terminals marked “PWM” are control outputs for a

WARNING! Electric shock!

L' is a fused contact permanently

carrying voltage

Î Always disconnect the control-

ler from power supply before

opening the housing!

high-efciency pump (PWM1 is allocated to R1 and PWM2

is allocated to R2).

The power supply connection is at the terminals:

Neutral conductor N

Conductor L

Conductor L' (L' is not connected with the power supply

cable. L' is a fused contact permanently carrying voltage)

Note:

Ground terminal

For more details about the initial commissioning

procedure, see chap. 5, page 73.

© Stiebel 11091_SOM_9s.monus.indd

5 |

Page 6

SOM 9s

2.3 Datacommunication/Bus

The controller is equipped with the VBus® for data transfer

with and energy supply to external modules. The connection is carried out at the two terminals marked “VBus” and

GND (any polarity). One or more VBus® modules can be

connected via this data bus, such as:

• GA3 Large display module / Smart Display SD3

• AM1 Alarm module

• DL2 Datalogger

Furthermore, the controller can be connected to a PC

via the VBus

included with the SOM 9s). With the ServiceCenter Software (RSC), measured values can be read, processed and

visualized. The software allows easier function control and

adjustment of the system.

®

/USB or VBus®/LAN interface adapter (not

Note:

For more information about accessories, see

p. 101.

2.4 SD card slot

The controller is equipped with an SD card slot for storing

system data onto an SD card. The values can be opened and

visualized, e. g. in a spreadsheet programme.

Note:

Do not use an SD-HC card!

A standard SD card is not included with the SOM 9s.

For more information about using an SD card, see chap. 6.2

(page 93) “SD card“.

| 6

© Stiebel 11091_SOM_9s.monus.indd

Page 7

SOM 9s

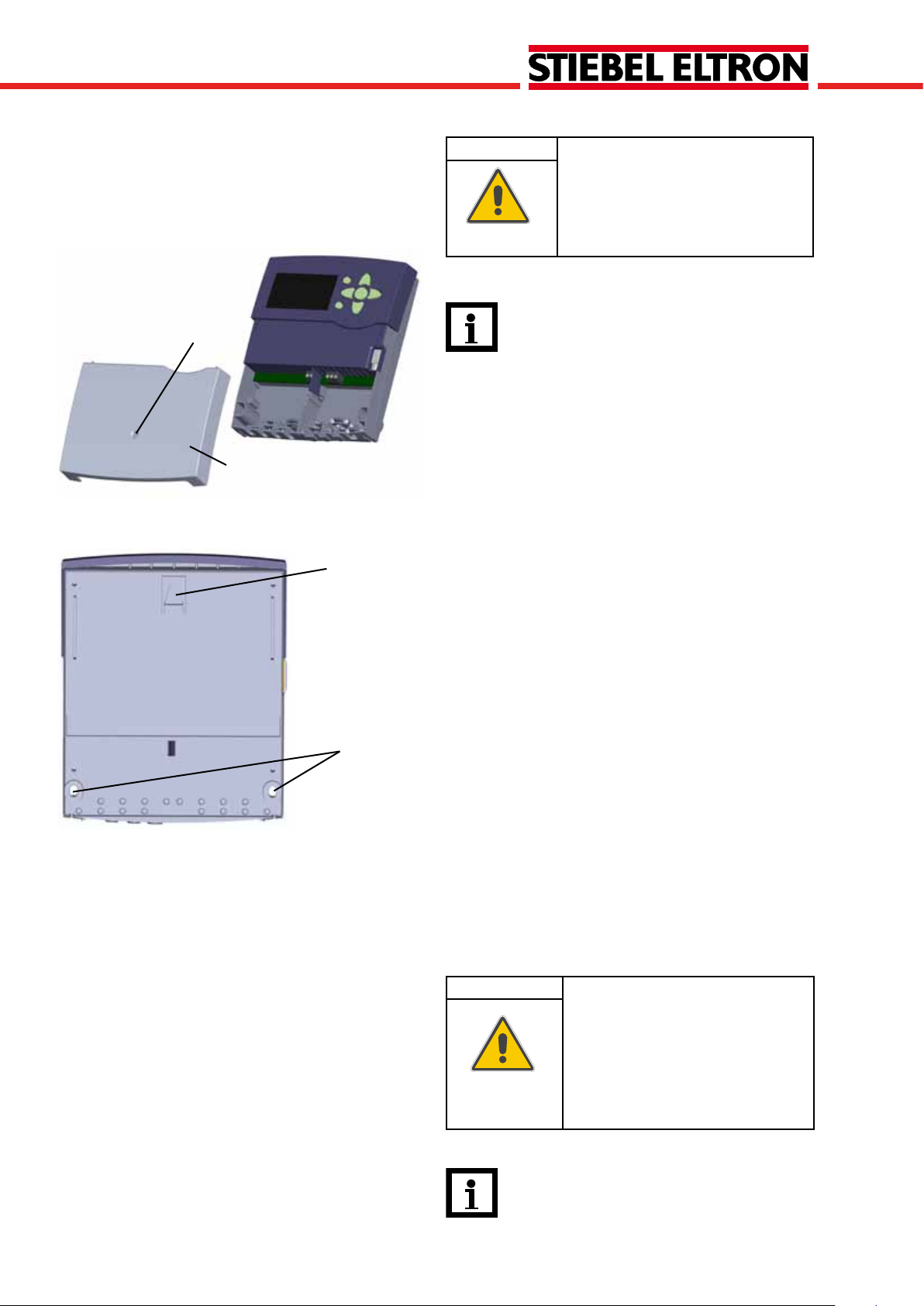

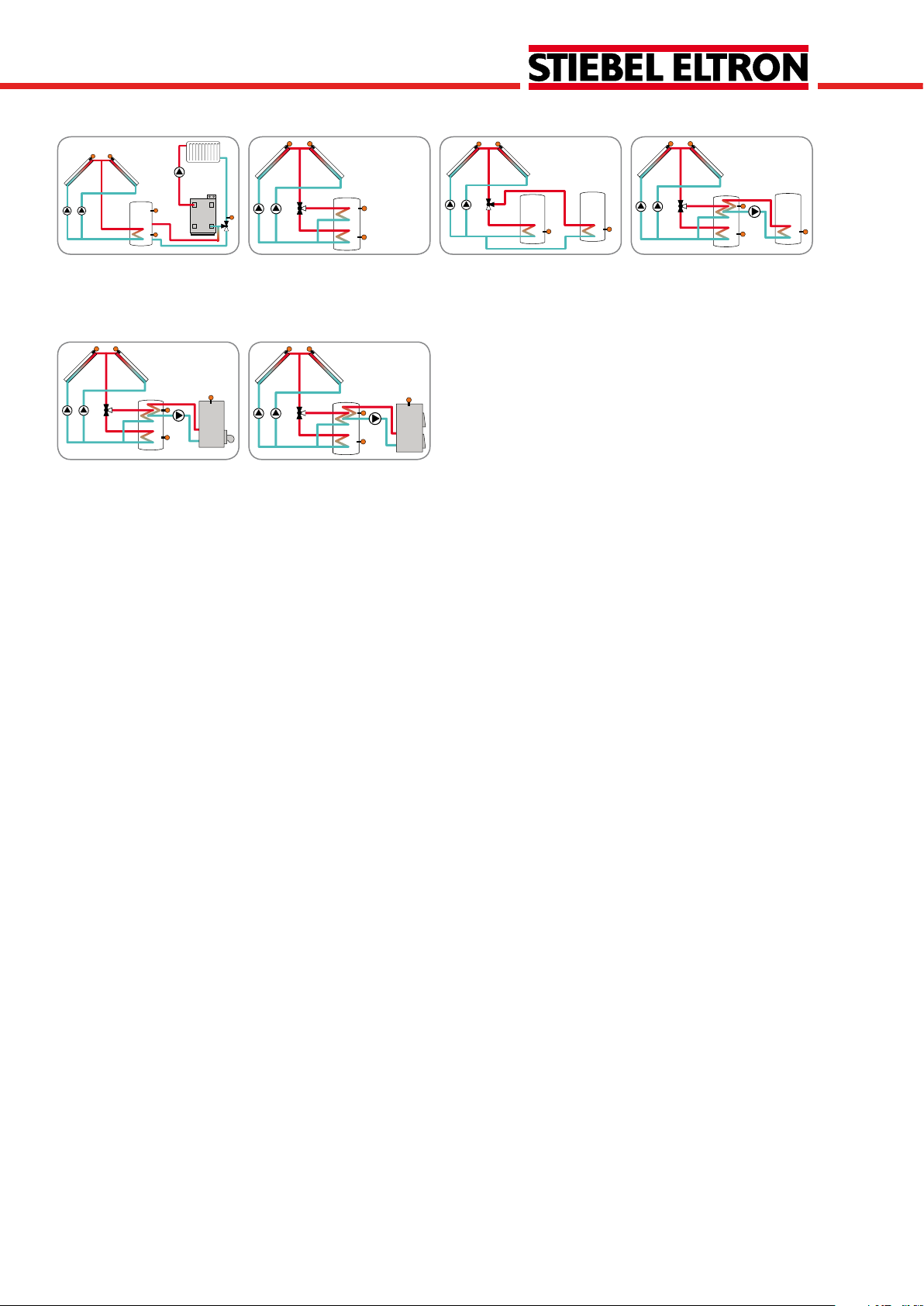

2.5 Overview of the systems

1 2 3 4

Standard solar system with 1

tank (page 9)

Solar system with 2 tanks and

heat exchange (page 11)

Solar system with 1 tank and

backup heating (page 13)

Solar system with 1 tank and

3-port valve for vertical tank

loading (page 15)

5 6 7 8

2-tank system with valve

logic, 1 pump, 3 sensors and

3-port valve (page 17)

2-tank solar system with

pump logic (page 19)

Solar system with east-/west

collectors (page 21)

Solar system with 1 tank and

backup heating with solid fuel

boiler (page23)

9 10 11 12

Solar system with 1 tank and

heating circuit return preheating (page 25

Solar system with 1 tank, heating circuit return preheating and thermostatic backup

heating (page 27)

Solar system with vertical

tank loading and heat exchange control (page 29)

Solar system with vertical

tank loading and thermostatic

backup heating (page 31)

13 14 15 16

Solar system with vertical

tank loading and backup

heating with solid fuel boiler

(page 33)

Solar system with vertical

tank loading and return preheating (page 35)

Solar system with vertical

tank loading and backup

heating with heating backup

(page 37)

2-tank solar system with

valve logic and heat exchange

control (page 40)

17 18 19 20

2-tank solar system with

pump logic and heat exchange control (page 42)

© Stiebel 11091_SOM_9s.monus.indd

Solar system with east-/west

collectors and heat exchange

control (page 45)

Solar system with east-/west

collectors and thermostatic

backup heating (page 47)

Solar system with east-/west

collectors, thermostatic

backup heating and return

preheating (page 49)

7 |

Page 8

SOM 9s

21 22 23 24

Solar system with east-/west

collectors and heating circuit

return preheating (page 51)

Solar system with vertical

tank loading and east-/west

collectors (page 53)

25 26

Solar system with east-/

west collectors, vertical tank

loading and and thermostatic

backup heating (page 62)

Solar system with east-/west

collectors, vertical tank loading and backup heating with

solid fuel boiler (page 65)

Solar system with east-/west

collectors and 2 tanks (valve

logic) (page 56)

Solar system with east-/

west collectors, vertical tank

loading and heat exchange

(page 59)

| 8

© Stiebel 11091_SOM_9s.monus.indd

Page 9

SOM 9s

Temp.Sensor

Pt1000

L

R3

R2

R1

GND

S1

S2

S3

S4

S5

VBus

PWM 1

PWM 2

N

R4

V40

L'

VFS

RPS

out in

2.6 System layouts

System 1

Standard solar system with 1 tank

The controller calculates the temperature difference between collector sensor S1 and tank sensor S2. If the difference is larger than or identical to the adjusted switch-on

S1

temperature difference, the pump (R1) will be switched on

and the tank will be loaded until the switch-off temperature

difference or the maximum tank temperature is reached.

R1

S2

Relay Description

R1 Solar pump

R2 optional:

R3

R4

Thermal disinfection

Booster pump

Parallel relay

Heat dump

Change to Description Page

9 |

Sensor/Terminal

S1 TCOL Temperature collector

S2 TSTB Temperature tank bottom

S3 Optional sensor for measurement

S4

Designation Description

purposes or options

S5

VFS

RPS

V40

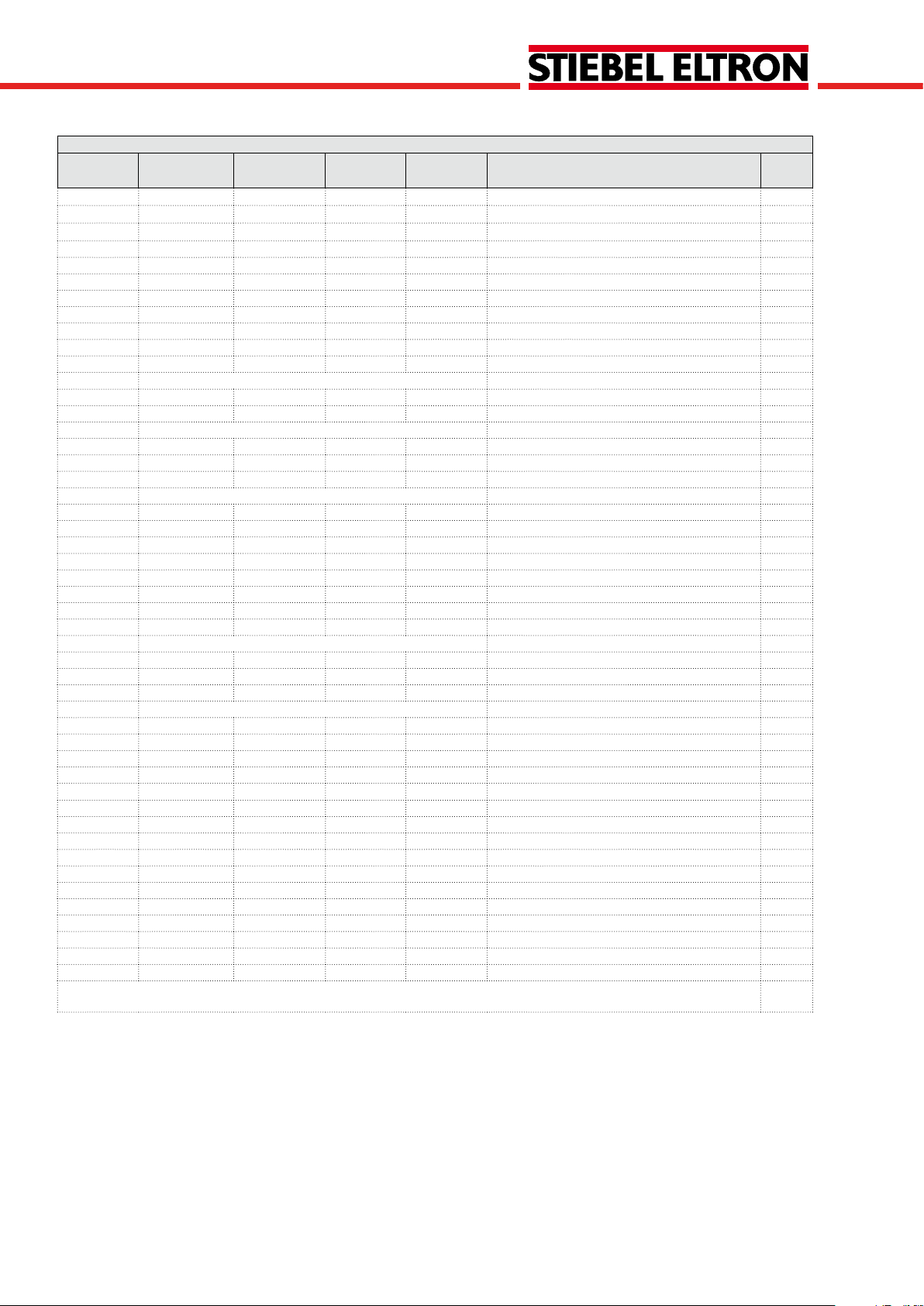

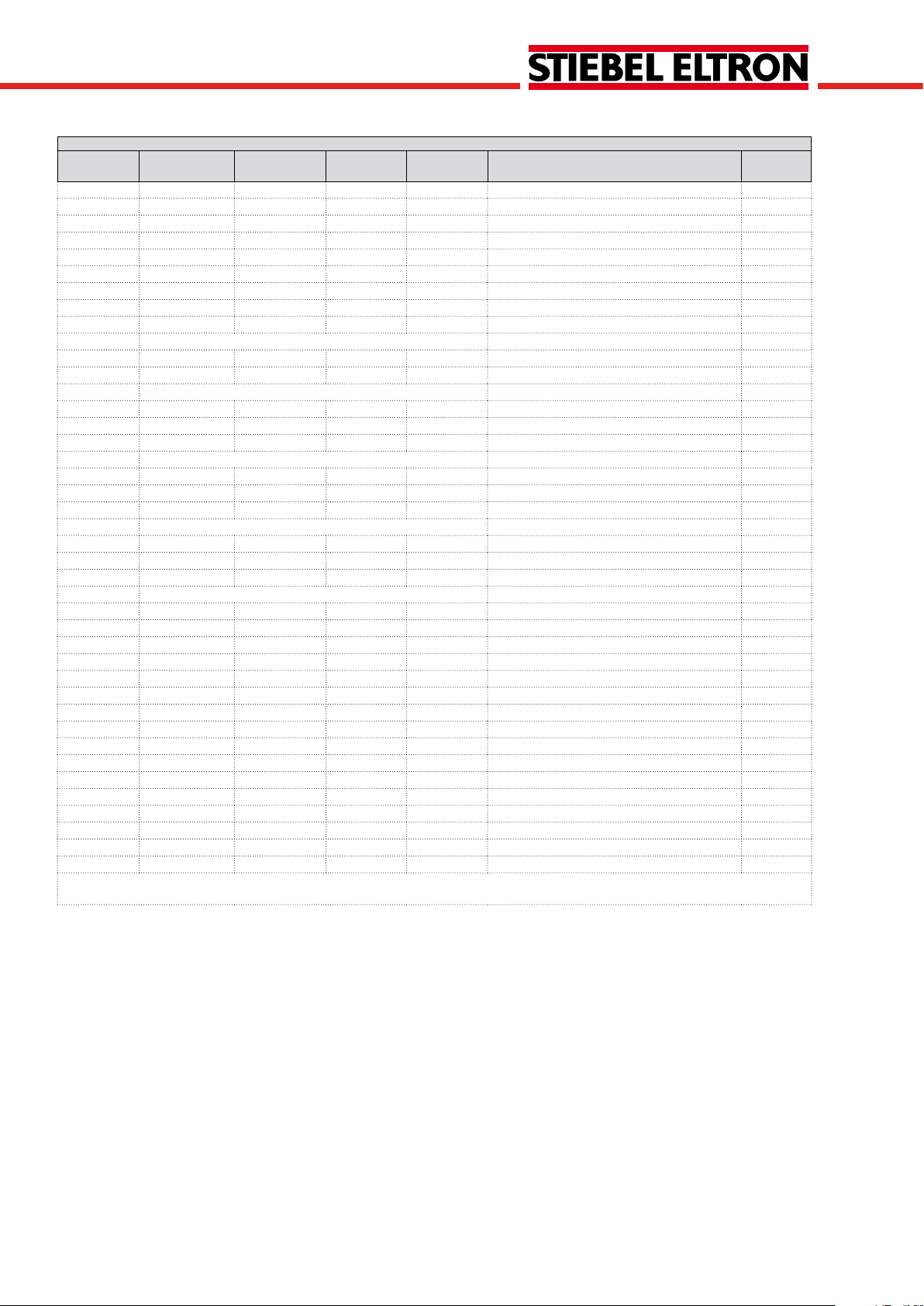

Adjustment channels

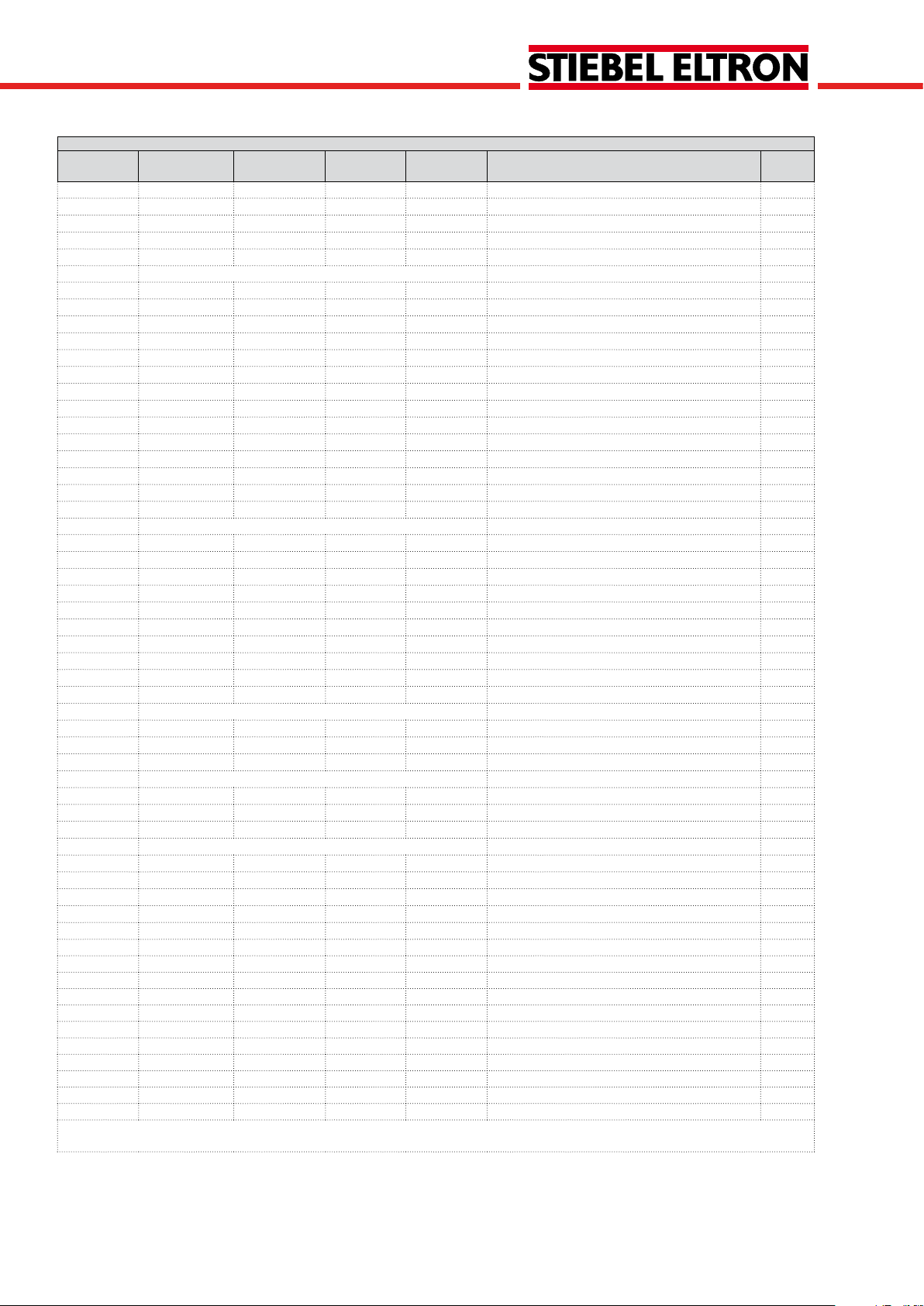

Channel Sub channel 1 Sub channel 2 Factory

setting

ARR 1 System 78

LOAD > Loading

DT O 12 °R Switch-on temperature difference 78

DT F 8 °R Switch-off temperature difference 78

DT S 20 °R Set temperature difference 78

RIS 4 °R Rise 78

S MAX 140 °F Tank maximum limitation 78

SMAXS 2 Sensor tank max 79

COL > Collector

CEM 270 °F Collector emergency temperature 80

OCCO** OFF Option collector cooling 80

CMAX 230 °F Maximum collector temperature 80

OCMI OFF Option collector minimum limitation 80

© Stiebel 11091_SOM_9s.monus.indd

CMIN 50 °F Minimum collector temperature 80

Page 10

SOM 9s

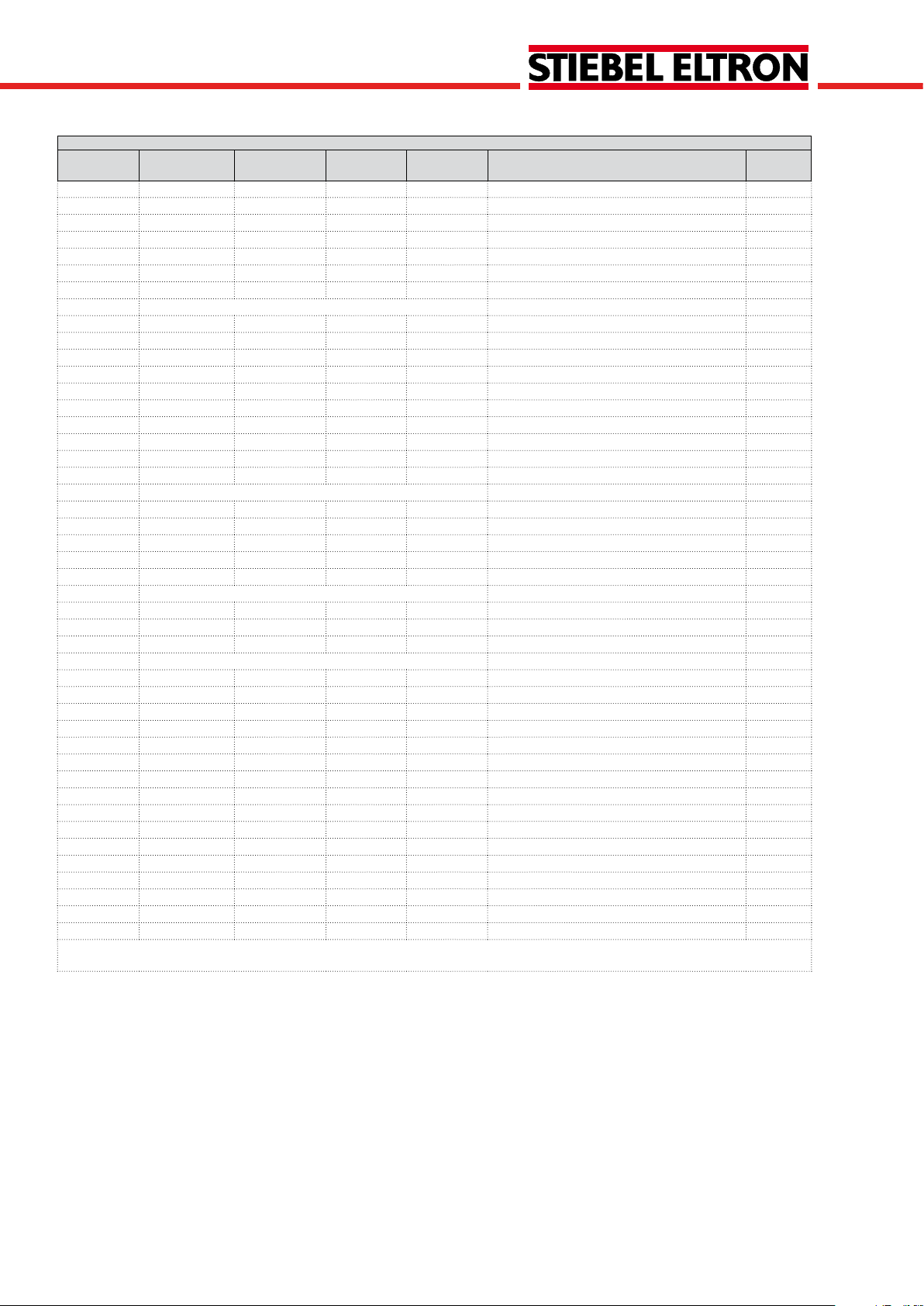

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

OTCO OFF Option evacuated tube collector function 81

TCST 07:00 Evacuated tube collector starting time 81

TCEN 19:00 Evacuated tube collector ending time 81

TCRU 30 s Evacuated tube collector runtime 81

TCIN 30 min Evacuated tube collector standstill interval 81

OCFR OFF Option collector frost protection 82

CFR O 40 °F Antifreeze temperature collector on 82

CFR F 42 °F Antifreeze temperature collector off 82

LLOGI > Loading logic

ODB > OFF Drainback option 84

OOVRU* OFF Overrun option 84

COOL > Cooling functions

OSYC** OFF System cooling 85

OSTC OFF Tank cooling 85

OHDP** OFF Heat dump 85

PUMP > Pump speed

PUMP1 OnOF Speed variant pump 1 79

PUMP2 OnOF Speed variant pump 2 79

PUMP3 OnOF Speed variant pump 3 79

MAN > Manual mode

MAN1 Auto Manual mode 1 88

MAN2 Auto Manual mode 2 88

MAN3 Auto Manual mode 3 88

MAN4 Auto Manual mode 4 88

BLPR >

OTDIS > OFF Thermal disinfection option 89

OPARR > OFF Parallel relay option 90

OHQM > OFF Energy metering option 90

GFDS > OFF Registration Grundfos sensors 90

PRS* > OFF Pressure monitoring option 92

DATE > OFF Enter date 92

LANG > En Language 93

UNIT > °F Unit 92

OSDC > SD card option 93

CODE 0000 User code 96

RESET OFF Factory setting

* This channel is only available if the Grundfos sensors have been registered in the GFDS channel.

** are blocked against each other

setting

OFF Blocking protection 88

Change to Description Page

| 10

© Stiebel 11091_SOM_9s.monus.indd

Page 11

SOM 9s

R4

R1

S4

S3

S2

S1

Temp.Sensor

Pt1000

L

R3

R2

R1

GND

S1

S2

S3

S4

S5

VBus

PWM 1

PWM 2

N

R4

V40

L'

VFS

RPS

out in

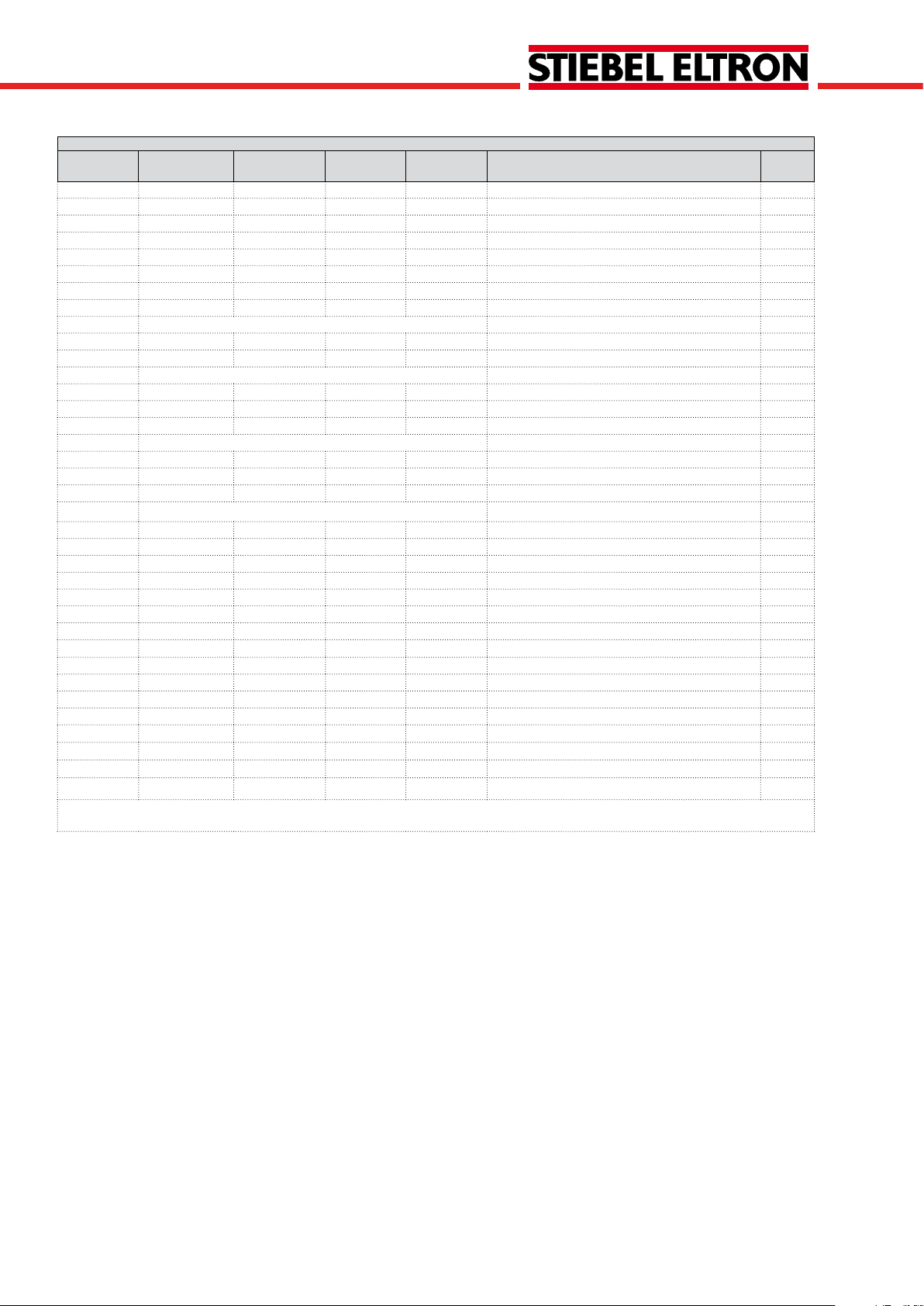

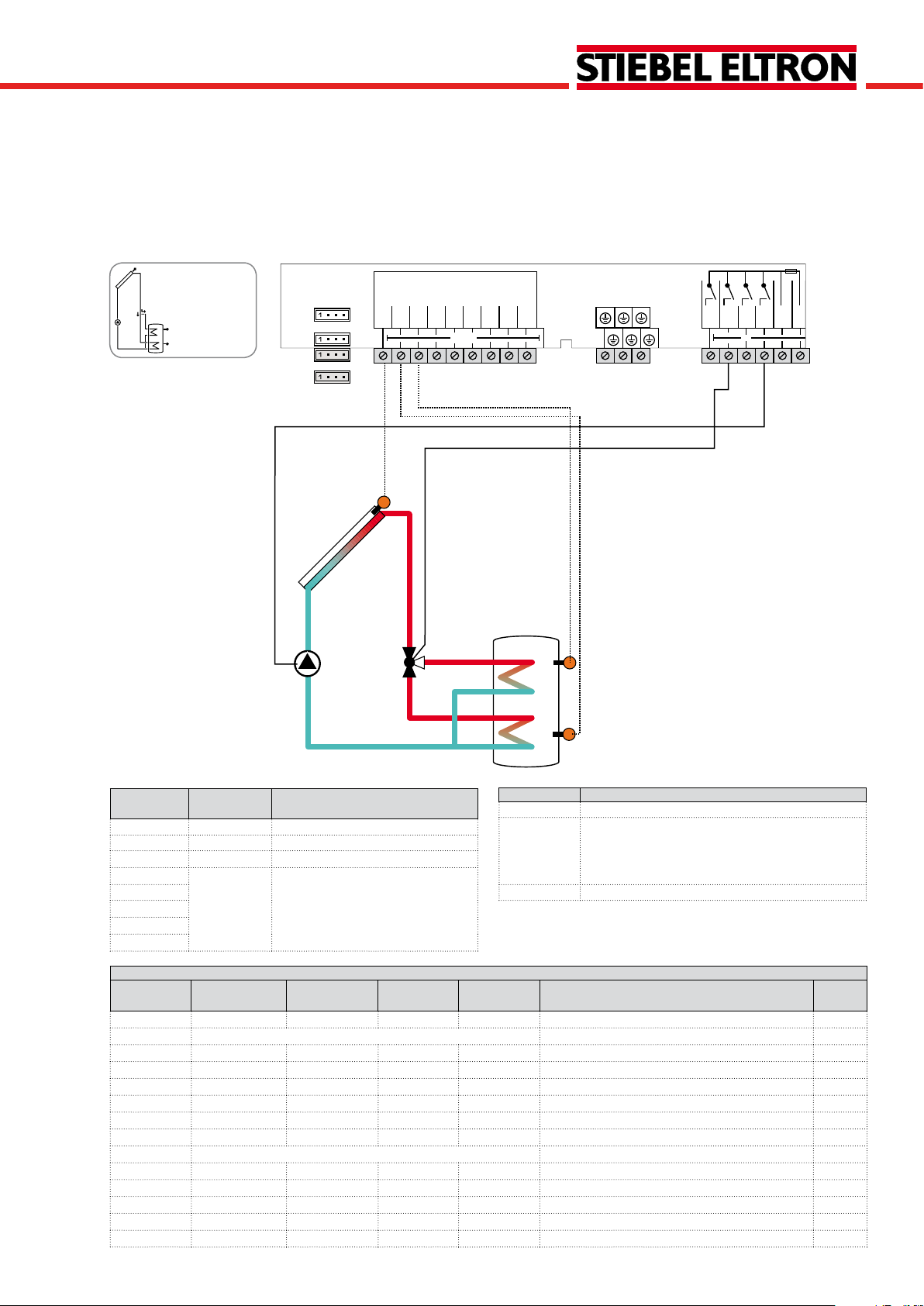

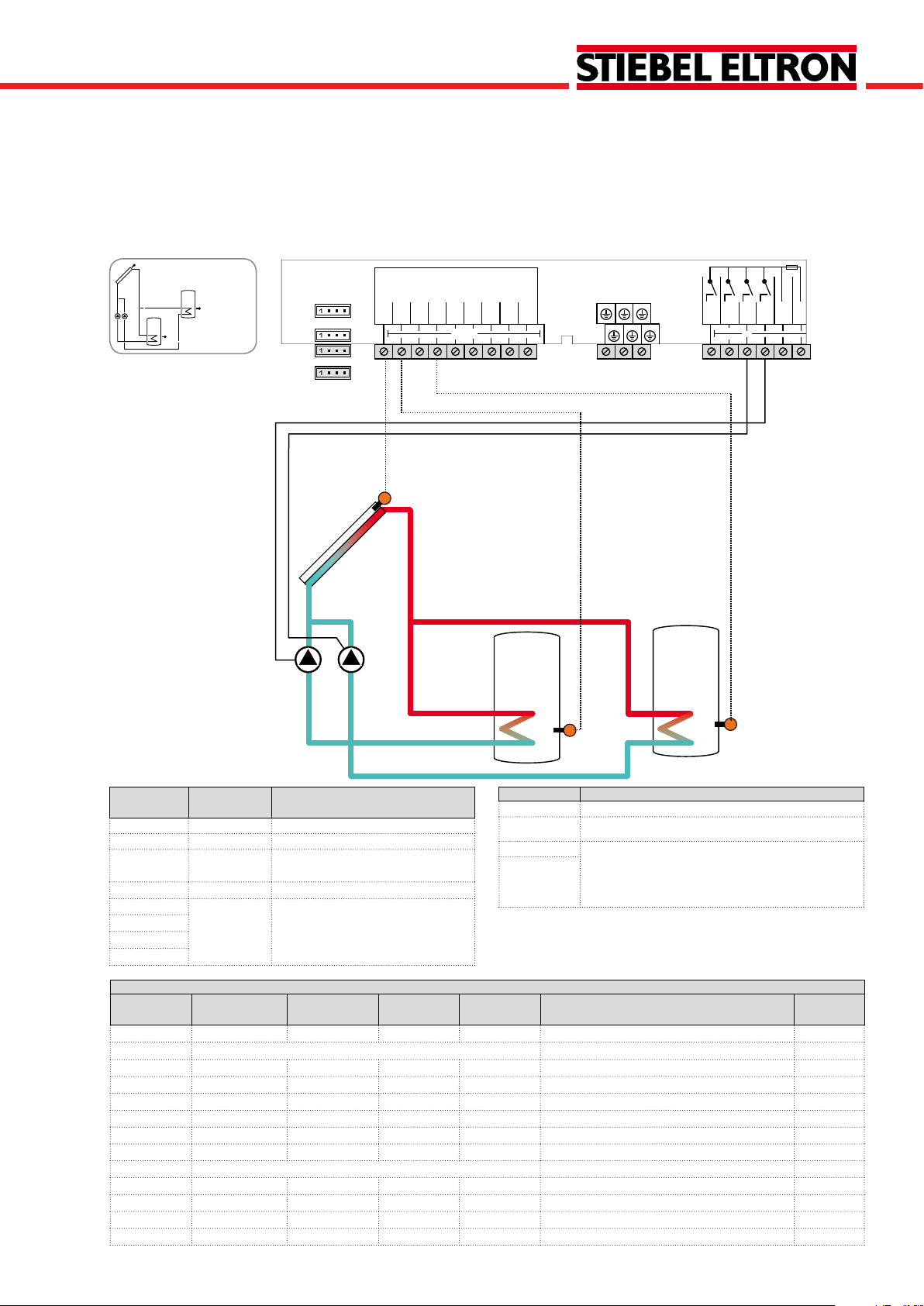

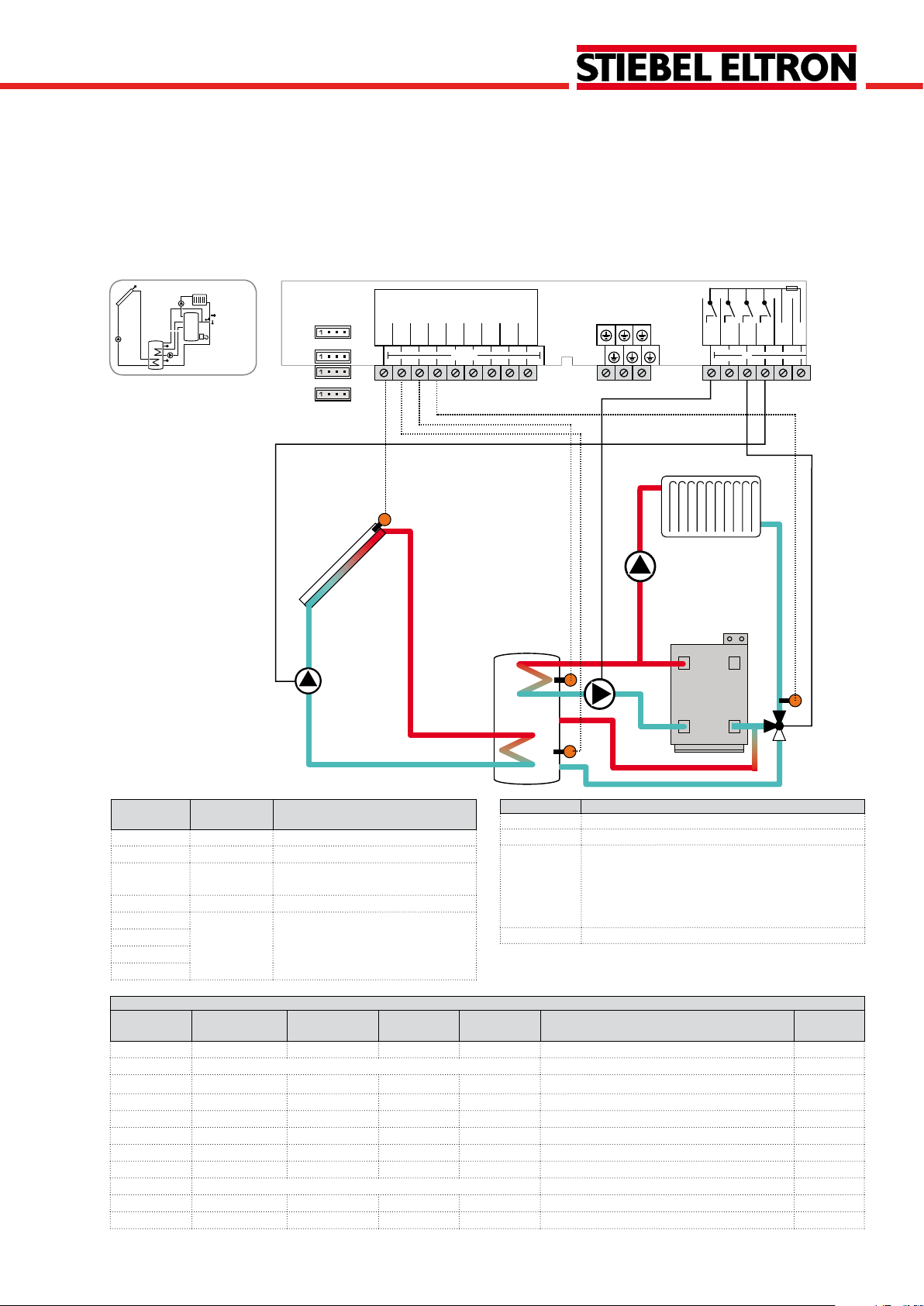

System 2

Solar system with 2 tanks and heat exchange

The controller calculates the temperature difference between collector sensor S1 and tank sensor S2. If the difference is larger than or identical to the adjusted switch-on

temperature difference, the pump (R1) will be switched on

and the tank will be loaded until the switch-off temperature

difference or the maximum tank temperature is reached.

Heat exchange between S3 and S4 is possible.

Sensor/Terminal

S1 TCOL Temperature collector

S2 TST1B Temperature tank 1 bottom

S3 TST1T Temperature tank 1 top

S4 TST2B Temperature tank 2 top

S5 Optional sensor for measurement

VFS

RPS

Designation Description

purposes or options

Relay Description

R1 Solar pump

R2 Heat exchange pump

R3 optional:

R4

Thermal disinfection

Booster pump

Parallel relay

Heat dump

V40

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

Change to Description Page

setting

ARR 1 2 System 78

LOAD > Loading

DT O 12 °R Switch-on temperature difference 78

DT F 8 °R Switch-off temperature difference 78

DT S 20 °R Set temperature difference 78

RIS 4 °R Rise 78

S MAX 140 °F Tank maximum limitation 79

SMAXS 2 Sensor tank max 79

COL > Collector

CEM 270 °F Collector emergency temperature 80

OCCO** OFF Option collector cooling 80

CMAX 230 °F Maximum collector temperature 80

OCMI OFF Option collector minimum limitation 80

© Stiebel 11091_SOM_9s.monus.indd

CMIN 50 °F Minimum collector temperature 80

11 |

Page 12

SOM 9s

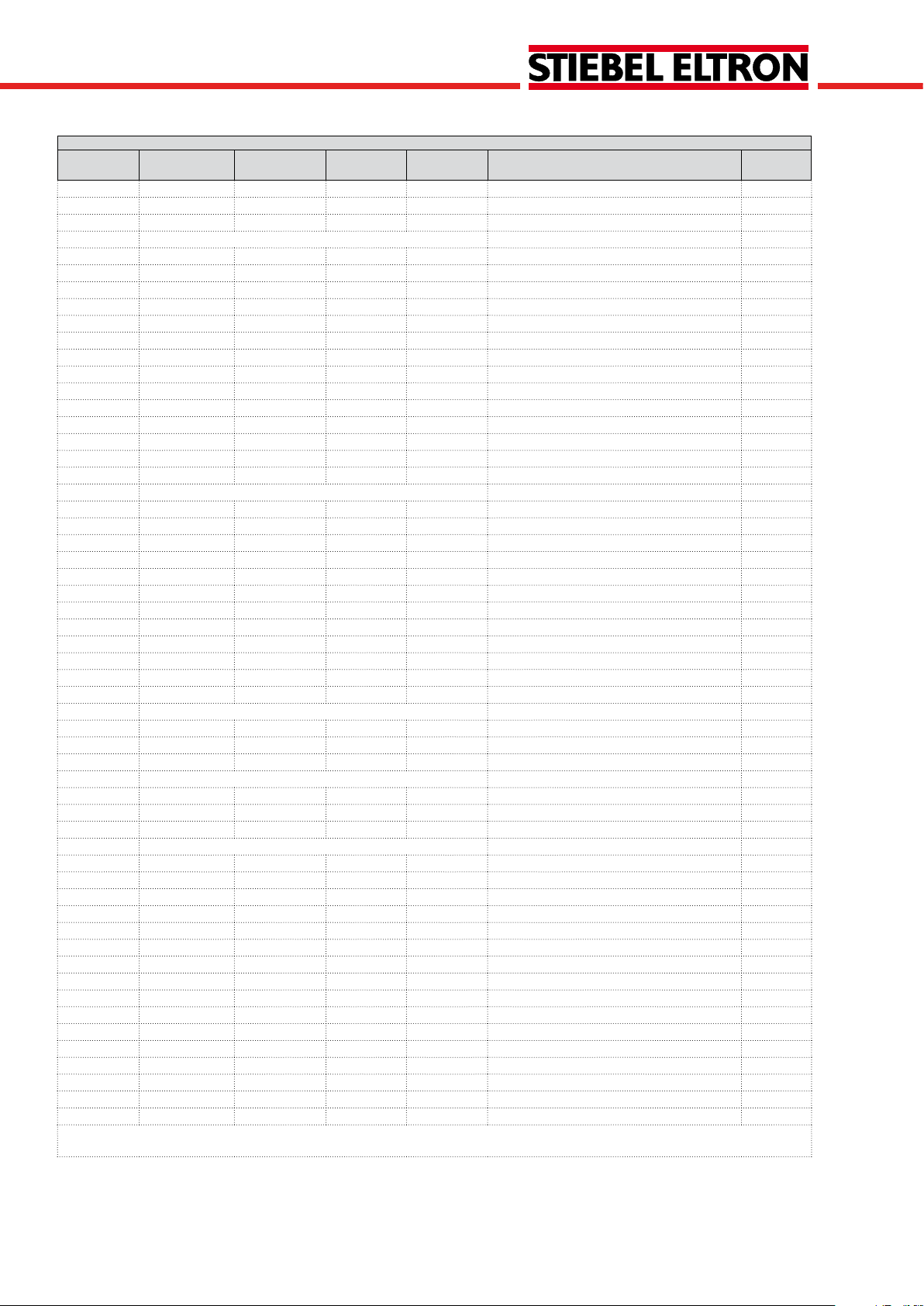

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

OTCO OFF Option evacuated tube collector function 81

TCST 07:00 Evacuated tube collector starting time 81

TCEN 19:00 Evacuated tube collector ending time 81

TCRU 30 s Evacuated tube collector runtime 81

TCIN 30 min Evacuated tube collector standstill interval 81

OCFR OFF Option collector frost protection 82

CFR O 40 °F Antifreeze temperature collector on 82

CFR F 42 °F Antifreeze temperature collector off 82

LLOGI > Loading logic

ODB > OFF Drainback option 84

OOVRU* OFF Overrun option 84

COOL > Cooling functions

OSYC** OFF System cooling 85

OSTC OFF Tank cooling 85

OHDP** OFF Heat dump 85

DT3 > Heat exchange

DT3O 12 °R Switch-on difference 86

DT3F 8 °R Switch-off difference 86

DT3S 20 °R Set difference 86

RIS3 4 °R Rise 86

MAX3O 140 °F Switch-on temperature (maximum limitation) 86

MAX3F 136 °F Switch-off temperature (maximum limitation) 86

MIN3O 40 °F Switch-on temperature (minimum limitation) 86

MIN3F 50 °F Switch-off temperature (minimum limitation) 86

S2DT3 4 Reference sensor heat sink 86

PUMP > Pump speed

PUMP1 OnOF Speed variant pump 1 79

PUMP2 OnOF Speed variant pump 2 79

PUMP3 OnOF Speed variant pump 3 79

MAN > Manual mode

MAN1 Auto Manual mode 1 88

MAN2 Auto Manual mode 2 88

MAN3 Auto Manual mode 3 88

MAN4 Auto Manual mode 4 88

BLPR >

OTDIS > OFF Thermal disinfection option 89

OPARR > OFF Parallel relay option 90

OHQM > OFF Energy metering option 90

GFDS > OFF Registration Grundfos sensors 90

PRS* > OFF Pressure monitoring option 92

DATE> OFF Enter date 92

LANG > En Language 93

UNIT > °F Unit 92

OSDC > SD card option 93

CODE 0000 User code 96

RESET OFF Factory setting

* This channel is only available if the Grundfos sensors have been registered in the GFDS channel.

** are blocked against each other

setting

OFF Blocking protection 88

Change to Description Page

| 12

© Stiebel 11091_SOM_9s.monus.indd

Page 13

SOM 9s

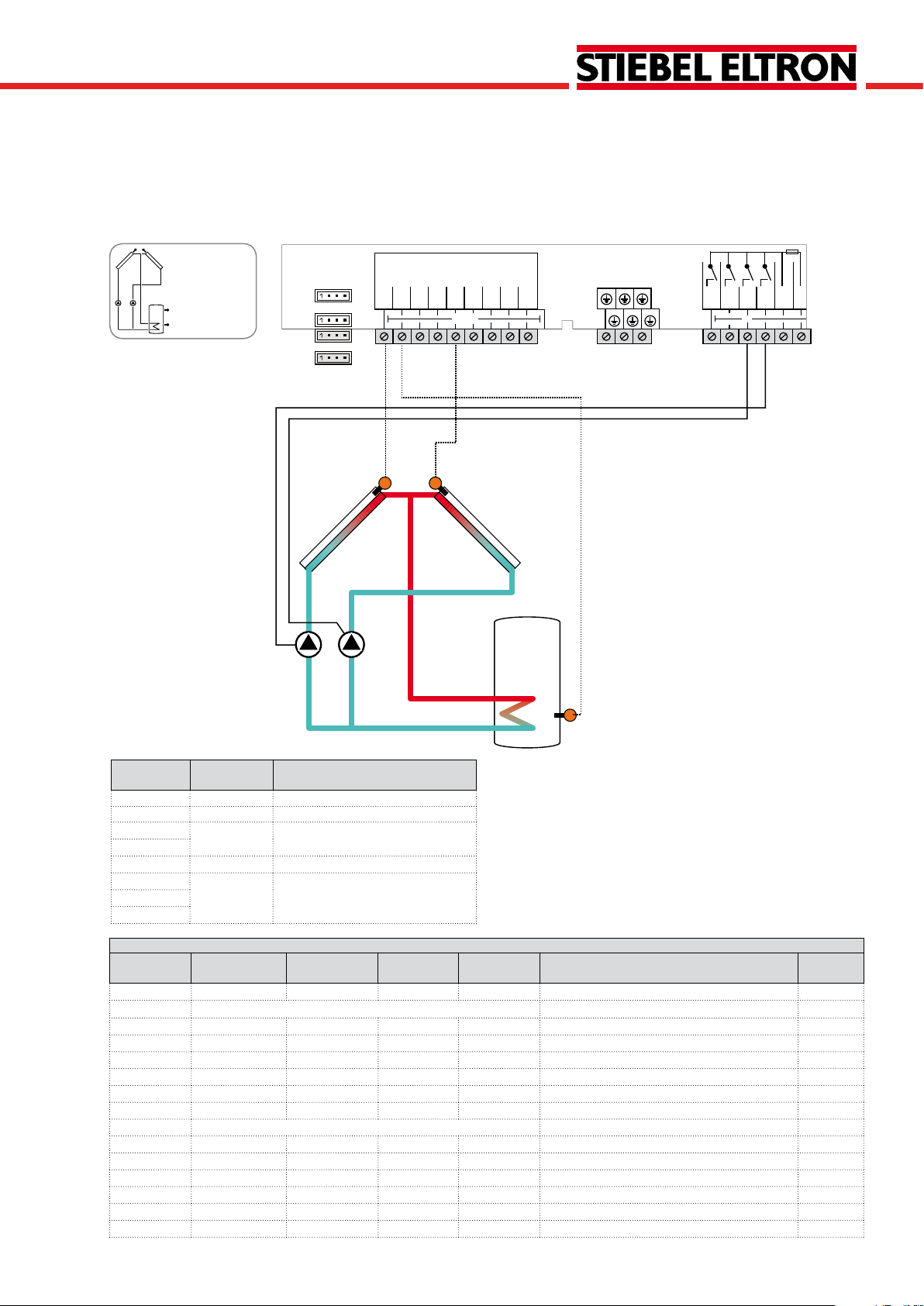

System 3

Solar system with 1 tank and backup heating

The controller calculates the temperature difference between collector sensor S1 and tank sensor S2. If the difference is larger than or identical to the adjusted switch-on

temperature difference, the pump (R1) will be switched on

and the tank will be loaded until the switch-off temperature

difference or the maximum tank temperature is reached.

Domestic hot water backup heating (R4) can be carried out

with a thermostat function (S3). If the value at S3 reaches

the switch-on temperature for the backup heating, the relay

is energized. If the value exceeds the switch-off temperature

for the backup heating, the relay is switched off again.

R1

VFS

RPS

Te mp. Sensor

Pt1000

S1

S2

S3

S1

S4

S5

GND

out in

PWM 1

PWM 2

L

V40

VBus

S3

R4

R4

L'

R1

R3

R2

N

S2

Sensor/Terminal

S1 TCOL Temperature collector

S2 TSTB Temperature tank bottom

S3 TSTT Temperature tank top

S4 Optional sensor for measurement

S5

VFS

RPS

V40

Adjustment channels

Channel Sub channel 1 Sub channel 2

ARR 1 3 System 78

LOAD > Loading

COL > Collector

© Stiebel 11091_SOM_9s.monus.indd

Designation Description

Relay Description

R1 Solar pump

R2 optional:

R3

Thermal disinfection

Booster pump

Parallel relay

purposes or options

Heat dump

R4 Backup heating/tank loading pump

Factory

setting

Change to Description Page

DT O 12 °R Switch-on temperature difference

DT F 8 °R Switch-off temperature difference

DT S 20 °R Set temperature difference

RIS 4 °R Rise

S MAX

SMAXS 2

140 °F

Tank maximum limitation

Sensor tank max 79

CEM 270 °F Collector emergency temperature

OCCO**

OFF

Option collector cooling

78

78

78

78

79

80

80

13 |

Page 14

SOM 9s

Adjustment channels

Channel Sub channel 1 Sub channel 2

CMAX 230 °F Maximum collector temperature 80

OCMI

CMIN 50 °F Minimum collector temperature 80

OTCO OFF Option evacuated tube collector function 81

TCST 07:00 Evacuated tube collector starting time 81

TCEN 19:00 Evacuated tube collector ending time 81

TCRU 30 s Evacuated tube collector runtime 81

TCIN 30 min Evacuated tube collector standstill interval 81

OCFR OFF Option collector frost protection 82

CFR O 40 °F Antifreeze temperature collector on 82

CFR F 42 °F Antifreeze temperature collector off 82

LLOGI > Loading logic

ODB > OFF Drainback option 84

OOVRU* OFF Overrun option 84

COOL > Cooling functions

OSYC** OFF System cooling 85

OSTC OFF Tank cooling 85

OHDP** OFF Heat dump 85

AH > Backup heating option

AH O 110 °F Backup heating switch-on temperature 87

AH F 120 °F Backup heating switch-off temperature 87

t1O 06:00 Switch-on time 1 88

t1F 22:00 Switch-off time 1 88

t2O 00:00 Switch-on time 2 88

t2F 00:00 Switch-off time 2 88

t3O 00:00 Switch-on time 3 88

t3F 00:00 Switch-off time 3 88

PUMP > Pump speed

PUMP1 OnOF Speed variant pump 1 79

PUMP2 OnOF Speed variant pump 2 79

PUMP3 OnOF Speed variant pump 3 79

MAN > Manual mode

MAN1 Auto Manual mode 1 88

MAN2 Auto Manual mode 2 88

MAN3 Auto Manual mode 3 88

MAN4 Auto Manual mode 4 88

BLPR >

OTDIS > OFF Thermal disinfection option 89

OPARR > OFF Parallel relay option 90

OHQM > OFF Energy metering option 90

GFDS > OFF Registration Grundfos sensors 90

PRS* > OFF Pressure monitoring option 92

DATE> Enter date 92

LANG > En Language 93

UNIT > °F Unit 92

OSDC > SD card option 93

CODE 0000 User code 96

RESET OFF Factory setting

* This channel is only available if the Grundfos sensors have been registered in the GFDS channel.

** are blocked against each other

Factory

setting

OFF Option collector minimum limitation 80

OFF Blocking protection 88

Change to Description Page

| 14

© Stiebel 11091_SOM_9s.monus.indd

Page 15

SOM 9s

R3

R1

S3

S2

S1

Temp.Sensor

Pt1000

L

R3

R2

R1

GND

S1

S2

S3

S4

S5

VBus

PWM 1

PWM 2

N

R4

V40

L'

VFS

RPS

out in

System 4

Solar system with 1 tank and 3-port valve for vertical tank loading

The controller compares the temperature at sensor S1 to

the temperatures at sensors S2 and S3. If the measured

temperature differences are higher than the adjusted switchon temperature differences, the pump (R1) will be activated

and the corresponding tank zone will be loaded up to the

adjusted maximum temperature via the valve (R3). The priority logic effects prior loading of the upper zone of the tank.

Note: 3-port valve normally open - tank bottom

Relay Description

R1 Solar pump

R2/R4 optional:

Thermal disinfection

Parallel relay

Heat dump

R3 3-port valve tank top/bottom

Change to Description Page

Sensor/Terminal

S1 TCOL Temperature collector

S2 TSTB Temperature tank bottom

S3 TSTT Temperature tank top

S4 Optional sensor for measurement

S5

Designation Description

purposes or options

VFS

RPS

V40

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

setting

ARR 1 4 System 78

LOAD1 > Loading 1

DT1O 12 °R Switch-on temperature difference 1 78

DT1F 8 °R Switch-off temperature difference 1 78

DT1S 20 °R Set temperature difference 1 78

RIS1 4 °R Rise 1 78

S1MAX 140 °F Tank maximum limitation 1 78

SMXS1 2 Sensor tank max 1 79

LOAD2 > Loading 2

DT2O 12 °R Switch-on temperature difference 2 78

DT2F 8 °R Switch-off temperature difference 2 78

DT2S 20 °R Set temperature difference 2 78

RIS2 4 °R Rise 2 78

© Stiebel 11091_SOM_9s.monus.indd

S2MAX 140 °F Tank maximum limitation 2 78

15 |

Page 16

SOM 9s

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

LST2 ON Loading tank 2 79

COL > Collector

CEM 270 °F Collector emergency temperature 80

OCCO** OFF Option collector cooling 80

CMAX 230 °F Maximum collector temperature 80

OCMI OFF Option collector minimum limitation 80

CMIN 50 °F Minimum collector temperature 80

OTCO OFF Option evacuated tube collector function 81

TCST 07:00 Evacuated tube collector starting time 81

TCEN 19:00 Evacuated tube collector ending time 81

TCRU 30 s Evacuated tube collector runtime 81

TCIN 30 min Evacuated tube collector standstill interval 81

OCFR OFF Option collector frost protection 82

CFR O 40 °F Antifreeze temperature collector on 82

CFR F 42 °F Antifreeze temperature collector off 82

LLOGI > Loading logic

PRIO Priority logic 82

PRIO 2 Priority logic 82

OSTS OFF Tank set option 83

TST1 120 °F Set tank temperature tank 1 83

TST2 120 °F Set tank temperature tank 2 83

tLB 2 min Loading break time 82

tRUN 15 min Circulation runtime 82

PSPEE OFF Pause speed option 83

PDELA OFF Pump delay option 83

OOVRU* OFF Overrun option 84

COOL > Cooling functions

OSYC** OFF System cooling 85

OSTC OFF Tank cooling 85

OHDP** OFF Heat dump 85

PUMP > Pump speed

PUMP1 OnOF Speed variant pump 1 79

PUMP2 OnOF Speed variant pump 2 79

PUMP3 OnOF Speed variant pump 3 79

MAN > Manual mode

MAN1 Auto Manual mode 1 88

MAN2 Auto Manual mode 2 88

MAN3 Auto Manual mode 3 88

MAN4 Auto Manual mode 4 88

BLPR >

OTDIS > OFF Thermal disinfection option 89

OPARR > OFF Parallel relay option 90

OHQM > OFF Energy metering option 90

GFDS > OFF Registration Grundfos sensors 90

PRS* > OFF Pressure monitoring option 92

DATE> OFF Enter date 92

LANG > En Language 93

UNIT > °F Unit 92

OSDC > SD card option 93

CODE 0000 User code 96

RESET OFF Factory setting

* This channel is only available if the Grundfos sensors have been registered in the GFDS channel.

** are blocked against each other

setting

OFF Blocking protection 88

Change to Description Page

| 16

© Stiebel 11091_SOM_9s.monus.indd

Page 17

SOM 9s

R3

R1

S4

S2

S1

Temp.Sensor

Pt1000

L

R3

R2

R1

GND

S1

S2

S3

S4

S5

VBus

PWM 1

PWM 2

N

R4

V40

L'

VFS

RPS

out in

System 5

2-tanksystemwithvalvelogic,1pump,3sensorsand3-portvalve

The controller compares the temperature at sensor S1 to

the temperatures at sensors S2 and S4. If the measured temperature differences are higher than the adjusted switch-on

temperature differences, the pump (R1) will be activated and

the corresponding tank will be loaded up to the adjusted

maximum temperature via the valve (R3). Tank 1 is loaded

with priority.

Note: 3-port valve normally open - tank 1 (S2)

Sensor/Terminal

S1 TCOL Temperature collector

S2 TST1B Temperature tank 1 bottom

S3 Optional sensor for measurement

S4 TST2B Temperature tank 2 bottom

S5 Optional sensor for measurement

VFS

RPS

V40

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

ARR

LOAD1 >

LOAD2 >

© Stiebel 11091_SOM_9s.monus.indd

Designation Description

Relay Description

R1 Solar pump

R2/R4 optional:

Thermal disinfection

Parallel relay

purposes or options

Heat dump

R3 3-port valve tank 1 / 2

purposes or options

Change to Description Page

setting

1 5 System 78

Loading 1

DT1O 12 °R Switch-on temperature difference 1

DT1F 8 °R Switch-off temperature difference 1

DT1S 20 °R Set temperature difference 1

RIS1 4 °R Rise 1

S1MAX

SMXS1 2

140 °F

Tank maximum limitation 1

Sensor tank max 1 79

Loading 2

DT2O 12 °R Switch-on temperature difference 2

DT2F

8 °R

Switch-off temperature difference 2

78

78

78

78

78

78

78

17 |

Page 18

SOM 9s

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

setting

DT2S

RIS2

S2MAX

SMXS2 4 Sensor tank max 2 79

LST2 ON Loading tank 2 79

COL > Collector

CEM 270 °F Collector emergency temperature 80

OCCO** OFF Option collector cooling 80

CMAX 230 °F Maximum collector temperature 80

OCMI OFF Option collector minimum limitation 80

CMIN 50 °F Minimum collector temperature 80

OTCO OFF Option evacuated tube collector function 81

TCST 07:00 Evacuated tube collector starting time 81

TCEN 19:00 Evacuated tube collector ending time 81

TCRU 30 s Evacuated tube collector runtime 81

TCIN 30 min Evacuated tube collector standstill interval 81

OCFR OFF Option collector frost protection 82

CFR O 40 °F Antifreeze temperature collector on 82

CFR F 42 °F Antifreeze temperature collector off 82

FRPST 1 Antifreeze tank selection 82

LLOGI > Loading logic

PRIO Priority logic 82

PRIO 1 Priority logic 82

OSTS OFF Tank set option 83

TST1 120 °F Set tank temperature tank 1 83

TST2 120 °F Set tank temperature tank 2 83

tLB 2 min Loading break time 82

tRUN 15 min Circulation runtime 82

PSPEE OFF Pause speed option 83

PDELA OFF Pump delay option 83

OOVRU* OFF Overrun option 84

COOL > Cooling functions

OSYC** OFF System cooling 85

OSTC OFF Tank cooling 85

OHDP** OFF Heat dump 85

PUMP > Pump speed

PUMP1 OnOF Speed variant pump 1 79

PUMP2 OnOF Speed variant pump 2 79

PUMP3 OnOF Speed variant pump 3 79

MAN > Manual mode

MAN1 Auto Manual mode 1 88

MAN2 Auto Manual mode 2 88

MAN3 Auto Manual mode 3 88

MAN4 Auto Manual mode 4 88

BLPR >

OTDIS > OFF Thermal disinfection option 89

OPARR > OFF Parallel relay option 90

OHQM > OFF Energy metering option 90

GFDS > OFF Registration Grundfos sensors 90

PRS* > OFF Pressure monitoring option 92

DATE> Enter date 92

LANG > En Language 93

UNIT > °F Unit 92

OSDC > SD card option 93

CODE 0000 User code 96

RESET OFF Factory setting

* This channel is only available if the Grundfos sensors have been registered in the GFDS channel.

** are blocked against each other

20 °R

4 °R

140 °F

OFF Blocking protection 88

Change to Description Page

Set temperature difference 2

Rise 2

Tank maximum limitation 2

78

78

78

| 18

© Stiebel 11091_SOM_9s.monus.indd

Page 19

SOM 9s

R2R1

S4

S2

S1

Temp.Sensor

Pt1000

L

R3

R2

R1

GND

S1

S2

S3

S4

S5

VBus

PWM 1

PWM 2

N

R4

V40

L'

VFS

RPS

out in

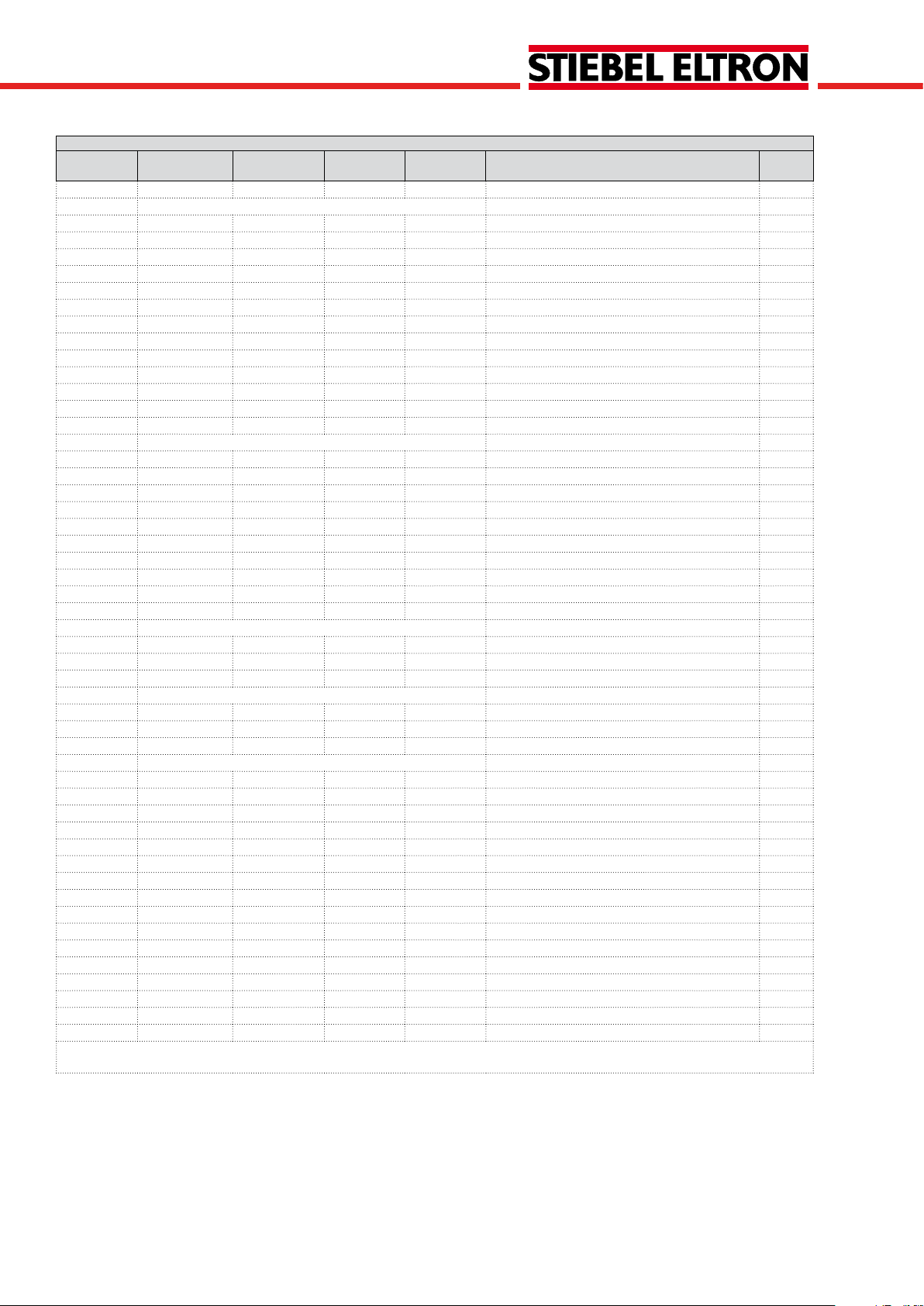

System 6

2-tank solar system with pump logic

The controller compares the temperature at sensor S1 to

the temperatures at sensors S2 and S4. If the measured

temperature differences are higher than the adjusted switchon temperature differences, the pump (R1 and R2) will be

activated and the corresponding tank will be loaded up to

the adjusted maximum temperature at most.

Sensor/Terminal

S1 TCOL Temperature collector

S2 TST1B Temperature tank 1 bottom

S3 Optional sensor for measurement

S4 TST2B Temperature tank 2 bottom

S5 Optional sensor for measurement

VFS

Designation Description

purposes or options

purposes or options

Relay Description

R1 Solar pump tank 1

R2 Solar pump tank 2

R3 optional:

R4

Thermal disinfection

Parallel relay

Heat dump

RPS

V40

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

setting

ARR 1 6 System

Change to Description Page

78

LOAD1 > Loading 1

DT1O 12 °R Switch-on temperature difference 1 78

DT1F 8 °R Switch-off temperature difference 1 78

DT1S 20 °R Set temperature difference 1 78

RIS1 4 °R Rise 1 78

S1MAX 140 °F Tank maximum limitation 1 78

SMXS1 2 Sensor tank max 1 79

LOAD2 > Loading 2

DT2O 12 °R Switch-on temperature difference 2 78

DT2F 8 °R Switch-off temperature difference 2 78

DT2S 20 °R Set temperature difference 2 78

© Stiebel 11091_SOM_9s.monus.indd

RIS2 4 °R Rise 2 78

19 |

Page 20

SOM 9s

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

S2MAX 140 °F Tank maximum limitation 2 78

SMXS2 4 Sensor tank max 2 79

LST2 ON Loading tank 2 79

COL > Collector

CEM 270 °F Collector emergency temperature 80

OCCO** OFF Option collector cooling 80

CMAX 230 °F Maximum collector temperature 80

OCMI OFF Option collector minimum limitation 80

CMIN 50 °F Minimum collector temperature 80

OTCO OFF Option evacuated tube collector function 81

TCST 07:00 Evacuated tube collector starting time 81

TCEN 19:00 Evacuated tube collector ending time 81

TCRU 30 s Evacuated tube collector runtime 81

TCIN 30 min Evacuated tube collector standstill interval 81

OCFR OFF Option collector frost protection 82

CFR O 40 °F Antifreeze temperature collector on 82

CFR F 42 °F Antifreeze temperature collector off 82

FRPST 1 Antifreeze tank selection 82

LLOGI > Loading logic

PRIO Priority logic 82

PRIO 1 Priority logic 82

OSTS OFF Tank set option 83

TST1 120 °F Set tank temperature tank 1 83

TST2 120 °F Set tank temperature tank 2 83

OSE OFF Spread function option 83

DTSE 40 Spread difference 83

tLB 2 min Loading break time 82

tRUN 15 min Circulation runtime 82

PSPEE OFF Pause speed option 83

PDELA OFF Pump delay option 83

OOVRU* OFF Overrun option 84

COOL > Cooling functions

OSYC** OFF System cooling 85

OSTC OFF Tank cooling 85

OHDP** OFF Heat dump 85

PUMP > Pump speed

PUMP1 OnOF Speed variant pump 1 79

PUMP2 OnOF Speed variant pump 2 79

PUMP3 OnOF Speed variant pump 3 79

MAN > Manual mode

MAN1 Auto Manual mode 1 88

MAN2 Auto Manual mode 2 88

MAN3 Auto Manual mode 3 88

MAN4 Auto Manual mode 4 88

BLPR >

OTDIS > OFF Thermal disinfection option 89

OPARR > OFF Parallel relay option 90

OHQM > OFF Energy metering option 90

GFDS > OFF Registration Grundfos sensors 90

PRS* > OFF Pressure monitoring option 92

DATE> Enter date 92

LANG > En Language 93

UNIT > °F Unit 92

OSDC > SD card option 93

CODE 0000 User code 96

RESET OFF Factory setting

* This channel is only available if the Grundfos sensors have been registered in the GFDS channel.

** are blocked against each other

setting

OFF Blocking protection 88

Change to Description Page

| 20

© Stiebel 11091_SOM_9s.monus.indd

Page 21

SOM 9s

Temp.Sensor

Pt1000

L

R3

R2

R1

GND

S1

S2

S3

S4

S5

VBus

PWM 1

PWM 2

N

R4

V40

L'

VFS

RPS

out in

System 7

Solar system with east-/west collectors

The controller compares the temperatures at the collector

sensors S1 and S5 to the tank temperature at sensor S2.

If one of the measured temperature differences is higher

than the adjusted switch-on temperature differences, the

corresponding pump (R1, R2) will be activated and the tank

will be loaded.

S1

S5

R2R1

Sensor/Terminal

S1 TCOL1 Temperature collector 1

S2 TSTB Temperature tank bottom

S3 Optional sensor for measurement

S4

S5 TCOL2 Temperature collector 2

VFS Optional sensor for measurement

RPS

V40

Designation Description

purposes or options

purposes or options

S2

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

Change to Description Page

setting

ARR 1 7 System

78

LOAD > Loading

DT O 12 °R Switch-on temperature difference 78

DT F 8 °R Switch-off temperature difference 78

DT1S 20 °R Set temperature difference 78

RIS 4 °R Rise 78

S MAX 140 °F Tank maximum limitation 78

SMAXS 2 Sensor tank max 79

COL 1 > Collector 1

CEM1 270 °F Collector emergency temperature 1 80

OCCO1** OFF Option collector cooling 1 80

CMAX1 230 °F Maximum collector temperature 1 80

OCMI1 OFF Option collector minimum limitation 1 80

CMIN1 50 °F Minimum collector temperature 1 80

© Stiebel 11091_SOM_9s.monus.indd

OTCO1 OFF Option evacuated tube collector function 1 81

21 |

Page 22

SOM 9s

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

TCST1 07:00 Evacuated tube collector starting time 1 81

TCEN1 19:00 Evacuated tube collector ending time 1 81

TCRU1 30 s Evacuated tube collector runtime 1 81

TCIN1 30 min Evacuated tube collector standstill interval 1 81

OCFR OFF Option collector frost protection 82

CFR O 40 °F Antifreeze temperature collector on 82

CFR F 42 °F Antifreeze temperature collector off 82

COL 2 > Collector 2

CEM2 270 °F Collector emergency temperature 2 80

OCCO2** OFF Option collector cooling 2 80

CMAX2 230 °F Maximum collector temperature 2 80

OCMI2 OFF Option collector minimum limitation 2 80

CMIN2 50 °F Minimum collector temperature 2 80

OTCO2 OFF Option evacuated tube collector function 2 81

TCST2 07:00 Evacuated tube collector starting time 2 81

TCEN2 19:00 Evacuated tube collector ending time 2 81

TCRU2 30 s Evacuated tube collector runtime 2 81

TCIN2 30 min Evacuated tube collector standstill interval 2 81

LLOGI > Loading logic

OOVRU* OFF Overrun option 84

COOL > Cooling functions

OSYC** OFF System cooling 85

OSTC OFF Tank cooling 85

OHDP** OFF Heat dump 85

PUMP > Pump speed

PUMP1 OnOF Speed variant pump 1 79

PUMP2 OnOF Speed variant pump 2 79

PUMP3 OnOF Speed variant pump 3 79

MAN > Manual mode

MAN1 Auto Manual mode 1 88

MAN2 Auto Manual mode 2 88

MAN3 Auto Manual mode 3 88

MAN4 Auto Manual mode 4 88

BLPR >

OTDIS > OFF Thermal disinfection option 89

OPARR > OFF Parallel relay option 90

OHQM > OFF Energy metering option 90

GFDS > OFF Registration Grundfos sensors 90

PRS* > OFF Pressure monitoring option 92

DATE> Enter date 92

LANG > En Language 93

UNIT > °F Unit 92

OSDC > SD card option 93

CODE 0000 User code 96

RESET OFF Factory setting

* This channel is only available if the Grundfos sensors have been registered in the GFDS channel.

** are blocked against each other

setting

OFF Blocking protection 88

Change to Description Page

| 22

© Stiebel 11091_SOM_9s.monus.indd

Page 23

SOM 9s

System 8

Solar system with 1 tank and backup heating with solid fuel boiler

The controller calculates the temperature difference between collector sensor S1 and tank sensor S2. If the difference is larger than or identical to the adjusted switch-on

temperature difference, the pump (R1) will be switched on

and the tank will be loaded until the switch-off temperature

difference or the maximum tank temperature is reached.

With another temperature differential function (S4/S3),

backup heating of the tank can be carried out with a solid

fuel boiler (R3).

R1

VFS

RPS

Te mp. Sensor

Pt1000

S1

S2

S3

S1

S4

S5

GND

out in

PWM 1

PWM 2

L

V40

VBus

R4

L'

R1

R3

R2

N

S4

S3

R3

S2

Sensor/Ter-

Designation Description

minal

S1 TCOL Temperature collector

S2 TSTB Temperature tank bottom

S3 TSTT Temperature tank top

S4 TSFB Temperature solid fuel boiler

S5 Optional sensor for measurement

VFS

purposes or options

RPS

V40

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

setting

ARR 1 8 System

LOAD > Loading

DT O 12 °R Switch-on temperature difference 78

DT F 8 °R Switch-off temperature difference 78

DT S 20 °R Set temperature difference 78

RIS 4 °R Rise 78

S MAX 140 °F Tank maximum limitation 78

SMAXS 2 Sensor tank max 79

COL > Collector

CEM 270 °F Collector emergency temperature 80

OCCO** OFF Option collector cooling 80

CMAX 230 °F Maximum collector temperature 80

© Stiebel 11091_SOM_9s.monus.indd

OCMI OFF Option collector minimum limitation 80

Relay Description

R1 Solar pump

R3 Loading pump solid fuel boiler

R2 optional:

R4

Thermal disinfection

Booster pump

Parallel relay

Heat dump

Change to Description Page

78

23 |

Page 24

SOM 9s

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

CMIN 50 °F Minimum collector temperature 80

OTCO OFF Option evacuated tube collector function 81

TCST 07:00 Evacuated tube collector starting time 81

TCEN 19:00 Evacuated tube collector ending time 81

TCRU 30 s Evacuated tube collector runtime 81

TCIN 30 min Evacuated tube collector standstill interval 81

OCFR OFF Option collector frost protection 82

CFR O 40 °F Antifreeze temperature collector on 82

CFR F 42 °F Antifreeze temperature collector off 82

LLOGI > Loading logic

ODB > OFF Drainback option 84

OOVRU* OFF Overrun option 84

COOL > Cooling functions

OSYC** OFF System cooling 85

OSTC OFF Tank cooling 85

OHDP** OFF Heat dump 85

DT3 > Solid fuel boiler

DT3O 12 °R Switch-on difference 86

DT3F 8 °R Switch-off difference 86

DT3S 20 °R Set difference 86

RIS3 4 °R Rise 86

MAX3O 140 °F Switch-on temperature (maximum limitation) 86

MAX3F 136 °F Switch-off temperature (maximum limitation) 86

MIN3O 140 °F Switch-on temperature (minimum limitation) 86

MIN3F 150 °F Switch-off temperature (minimum limitation) 86

S2DT3 3 Reference sensor heat sink 87

PUMP > Pump speed

PUMP1 OnOF Speed variant pump 1 79

PUMP2 OnOF Speed variant pump 2 79

PUMP3 OnOF Speed variant pump 3 79

MAN > Manual mode

MAN1 Auto Manual mode 1 88

MAN2 Auto Manual mode 2 88

MAN3 Auto Manual mode 3 88

MAN4 Auto Manual mode 4 88

BLPR >

OTDIS > OFF Thermal disinfection option 89

OPARR > OFF Parallel relay option 90

OHQM > OFF Energy metering option 90

GFDS > OFF Registration Grundfos sensors 90

PRS* > OFF Pressure monitoring option 92

DATE> Enter date 92

LANG > En Language 93

UNIT > °F Unit 92

OSDC > SD card option 93

CODE 0000 User code 96

RESET OFF Factory setting

* This channel is only available if the Grundfos sensors have been registered in the GFDS channel.

** are blocked against each other

setting

OFF Blocking protection 88

Change to Description Page

| 24

© Stiebel 11091_SOM_9s.monus.indd

Page 25

SOM 9s

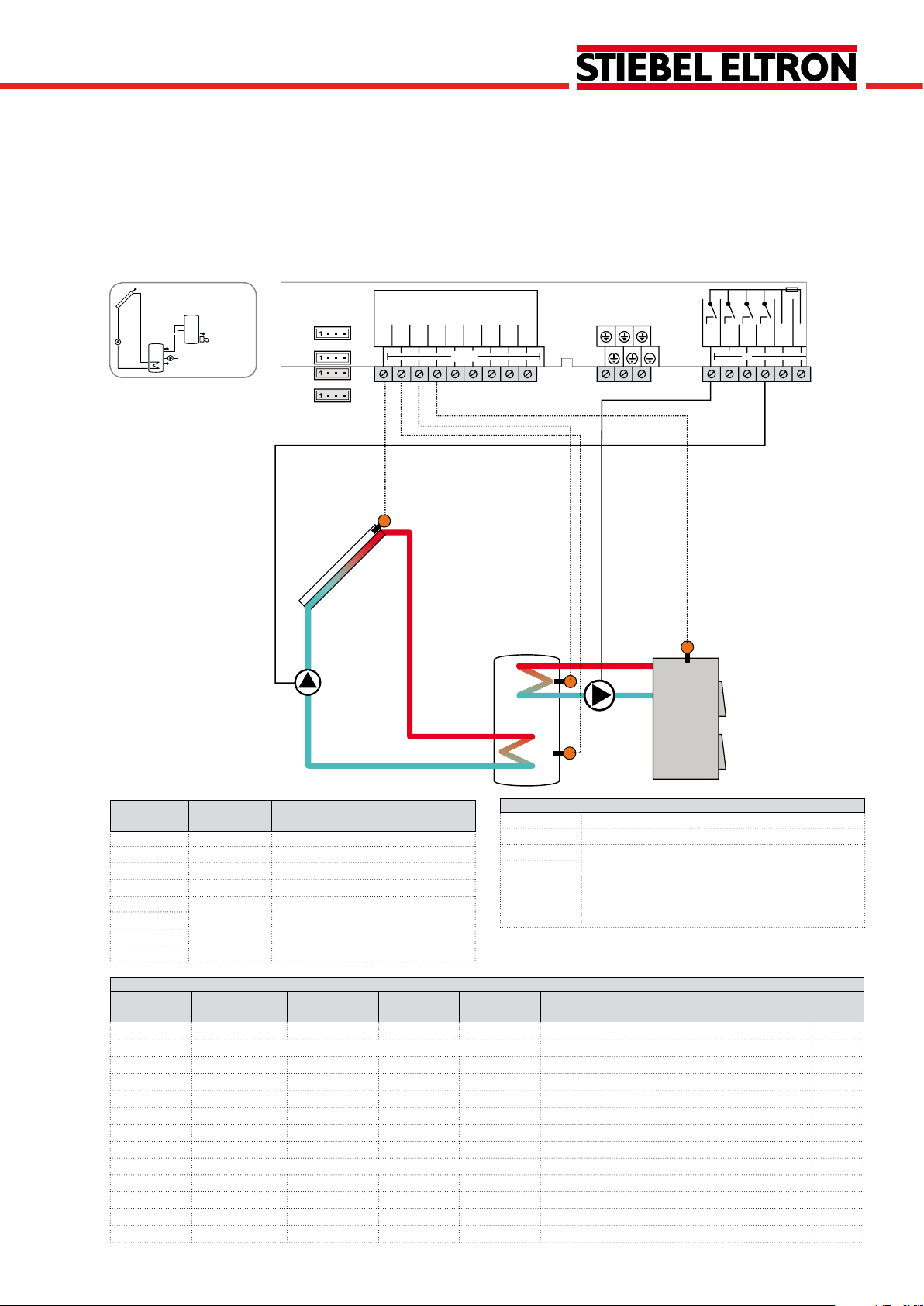

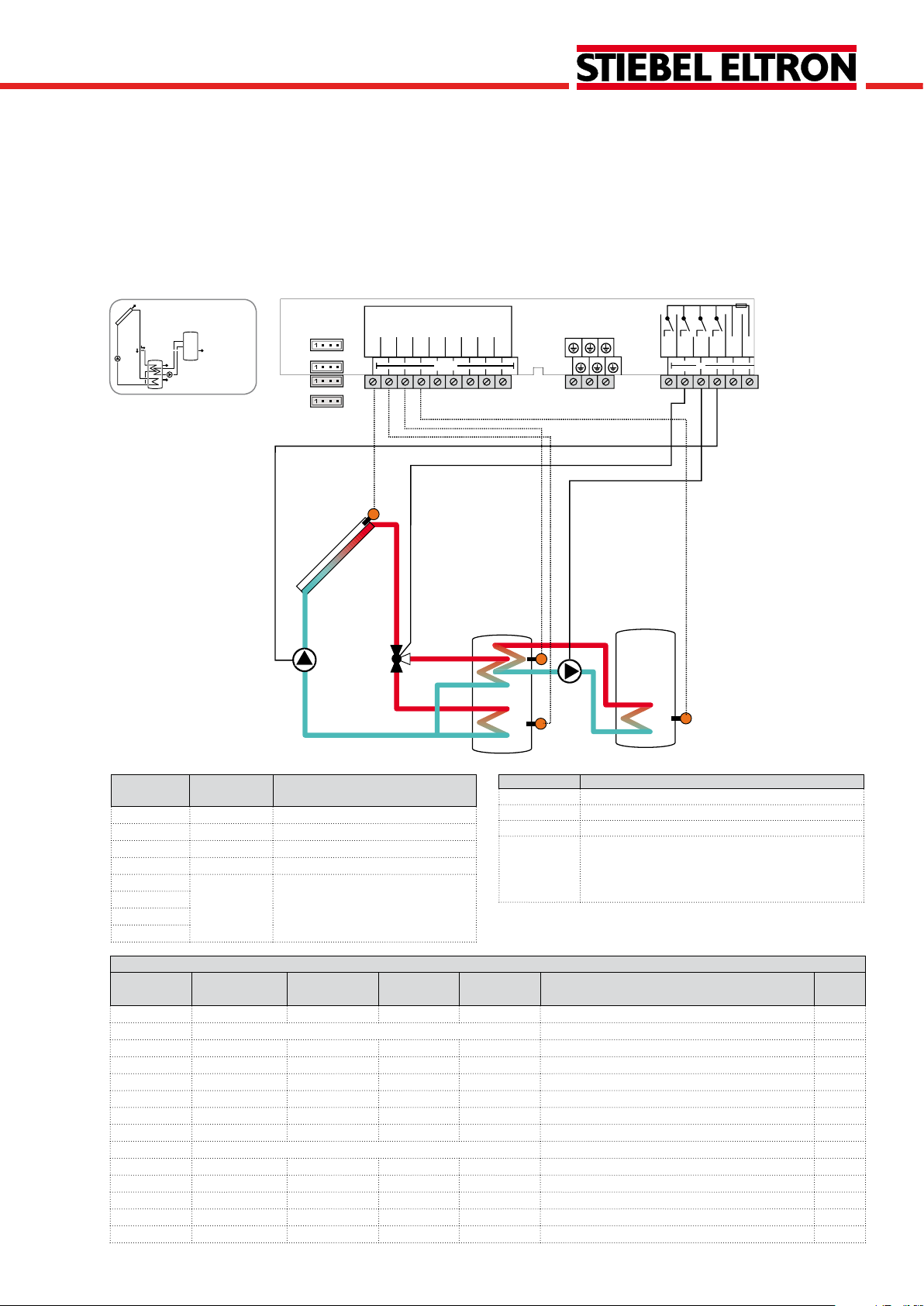

System 9

Solar system with 1 tank and heating circuit return preheating

The controller calculates the temperature difference between collector sensor S1 and tank sensor S2. If the difference is larger than or identical to the adjusted switch-on

temperature difference, the pump (R1) will be switched on

and the tank will be loaded until the switch-off temperature

difference or the maximum tank temperature is reached.

With another temperature differential function (S3/S4)

heating circuit return preheating (heating circuit backup) is

possible via a valve (R2).

R1

VFS

RPS

Te mp. Sensor

Pt1000

S1

S2

S3

S1

S4

S5

GND

out in

PWM 1

PWM 2

L

V40

VBus

R4

L'

R3

R2

R1

N

S3

S4

S2

R2

Sensor/Terminal

S1 TCOL Temperature collector

S2 TSTB Temperature tank bottom

S3 TSTR Temp. tank return preheating

S4 TRET Temperature - return

S5 Optional sensor for measurement

VFS

Designation Description

purposes or options

Relay Description

R1 Solar pump

R2 Return preheating

R3 optional:

R4

Thermal disinfection

Booster pump

Parallel relay

Heat dump

RPS

V40

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

Change to Description Page

setting

ARR 1 9 System

78

LOAD > Loading

DT O 12 °R Switch-on temperature difference 78

DT F 8 °R Switch-off temperature difference 78

DT S 20 °R Set temperature difference 78

RIS 4 °R Rise 78

S MAX 140 °F Tank maximum limitation 78

SMAXS 2 Sensor tank max 79

COL > Collector

CEM 270 °F Collector emergency temperature 80

OCCO** OFF Option collector cooling 80

CMAX 230 °F Maximum collector temperature 80

© Stiebel 11091_SOM_9s.monus.indd

OCMI OFF Option collector minimum limitation 80

25 |

Page 26

SOM 9s

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

CMIN 50 °F Minimum collector temperature 80

OTCO OFF Option evacuated tube collector function 81

TCST 07:00 Evacuated tube collector starting time 81

TCEN 19:00 Evacuated tube collector ending time 81

TCRU 30 s Evacuated tube collector runtime 81

TCIN 30 min Evacuated tube collector standstill interval 81

OCFR OFF Option collector frost protection 82

CFR O 40 °F Antifreeze temperature collector on 82

CFR F 42 °F Antifreeze temperature collector off 82

LLOGI > Loading logic

ODB > OFF Drainback option 84

OOVRU* OFF Overrun option 84

COOL > Cooling functions

OSYC** OFF System cooling 85

OSTC OFF Tank cooling 85

OHDP** OFF Heat dump 85

DT3 > Solid fuel boiler

DT3O 12 °R Switch-on difference 86

DT3F 8 °R Switch-off difference 86

S2DT3 3 Reference sensor heat source 87

PUMP > Pump speed

PUMP1 OnOF Speed variant pump 1 79

PUMP2 OnOF Speed variant pump 2 79

PUMP3 OnOF Speed variant pump 3 79

MAN > Manual mode

MAN1 Auto Manual mode 1 88

MAN2 Auto Manual mode 2 88

MAN3 Auto Manual mode 3 88

MAN4 Auto Manual mode 4 88

BLPR >

OTDIS > OFF Thermal disinfection option 89

OPARR > OFF Parallel relay option 90

OHQM > OFF Energy metering option 90

GFDS > OFF Registration Grundfos sensors 90

PRS* > OFF Pressure monitoring option 92

DATE> OFF Enter date 92

LANG > En Language 93

UNIT > °F Unit 92

OSDC > SD card option 93

CODE 0000 User code 96

RESET OFF Factory setting

* This channel is only available if the Grundfos sensors have been registered in the GFDS channel.

** are blocked against each other

setting

OFF Blocking protection 88

Change to Description Page

| 26

© Stiebel 11091_SOM_9s.monus.indd

Page 27

SOM 9s

R4

R2

R1

S4

S3

S2

S1

Temp.Sensor

Pt1000

L

R3

R2

R1

GND

S1

S2

S3

S4

S5

VBus

PWM 1

PWM 2

N

R4

V40

L'

VFS

RPS

out in

System 10

Solarsystemwith1tank,heatingcircuitreturnpreheatingandthermostaticbackupheating

The controller calculates the temperature difference between collector sensor S1 and tank sensor S2. If the difference is larger than or identical to the adjusted switch-on

temperature difference, the pump (R1) will be switched on

and the tank will be loaded until the switch-off temperature

difference or the maximum tank temperature is reached.

With another temperature differential function (S3/S4)

heating circuit backup (heating circuit return preheating) is

possible via a valve (R2). With a thermostat function (S3)

domestic hot water backup heating (R4) can be carried out.

Sensor/Terminal

S1 TCOL Temperature collector

S2 TSTB Temperature tank bottom

S3 TSTT/TSTR Temperature tank top/

S4 TRET Temperature - return

S5 Optional sensor for measurement

VFS

Designation Description

Temp. tank return preheating

purposes or options

Relay Description

R1 Solar pump

R2 Return preheating

R3 optional:

Thermal disinfection

Booster pump

Parallel relay

Heat dump

R4 Backup heating/tank loading pump

RPS

V40

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

setting

Change to Description Page

ARR 1 10 System 78

LOAD > Loading

DT O 12 °R Switch-on temperature difference 78

DT F 8 °R Switch-off temperature difference 78

DT S 20 °R Set temperature difference 78

RIS 4 °R Rise 78

S MAX 140 °F Tank maximum limitation 78

SMAXS 2 Sensor tank max 79

COL > Collector

CEM 270 °F Collector emergency temperature 80

OCCO** OFF Option collector cooling 80

© Stiebel 11091_SOM_9s.monus.indd

27 |

Page 28

SOM 9s

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

CMAX 230 °F Maximum collector temperature 80

OCMI OFF Option collector minimum limitation 80

CMIN 50 °F Minimum collector temperature 80

OTCO OFF Option evacuated tube collector function 81

TCST 07:00 Evacuated tube collector starting time 81

TCEN 19:00 Evacuated tube collector ending time 81

TCRU 30 s Evacuated tube collector runtime 81

TCIN 30 min Evacuated tube collector standstill interval 81

OCFR OFF Option collector frost protection 82

CFR O 40 °F Antifreeze temperature collector on 82

CFR F 42 °F Antifreeze temperature collector off 82

LLOGI > Loading logic

ODB > OFF Drainback option 84

OOVRU* OFF Overrun option 84

COOL > Cooling functions

OSYC** OFF System cooling 85

OSTC OFF Tank cooling 85

OHDP** OFF Heat dump 85

DT3 > Return preheating

DT3O 12 °R Switch-on difference 86

DT3F 8 °R Switch-off difference 86

S2DT3 3 Reference sensor heat source 87

AH > Backup heating option

AH O 110 °F Backup heating switch-on temperature 87

AH F 120 °F Backup heating switch-off temperature 87

t1O 06:00 Switch-on time 1 88

t1F 22:00 Switch-off time 1 88

t2O 00:00 Switch-on time 2 88

t2F 00:00 Switch-off time 2 88

t3O 00:00 Switch-on time 3 88

t3F 00:00 Switch-off time 3 88

PUMP > Pump speed

PUMP1 OnOF Speed variant pump 1 79

PUMP2 OnOF Speed variant pump 2 79

PUMP3 OnOF Speed variant pump 3 79

MAN > Manual mode

MAN1 Auto Manual mode 1 88

MAN2 Auto Manual mode 2 88

MAN3 Auto Manual mode 3 88

MAN4 Auto Manual mode 4 88

BLPR >

OTDIS > OFF Thermal disinfection option 89

OPARR > OFF Parallel relay option 90

OHQM > OFF Energy metering option 90

GFDS > OFF Registration Grundfos sensors 90

PRS* > OFF Pressure monitoring option 92

DATE> Enter date 92

LANG > En Language 93

UNIT > °F Unit 92

OSDC > SD card option 93

CODE 0000 User code 96

RESET OFF Factory setting

* This channel is only available if the Grundfos sensors have been registered in the GFDS channel.

** are blocked against each other

setting

OFF Blocking protection 88

Change to Description Page

| 28

© Stiebel 11091_SOM_9s.monus.indd

Page 29

SOM 9s

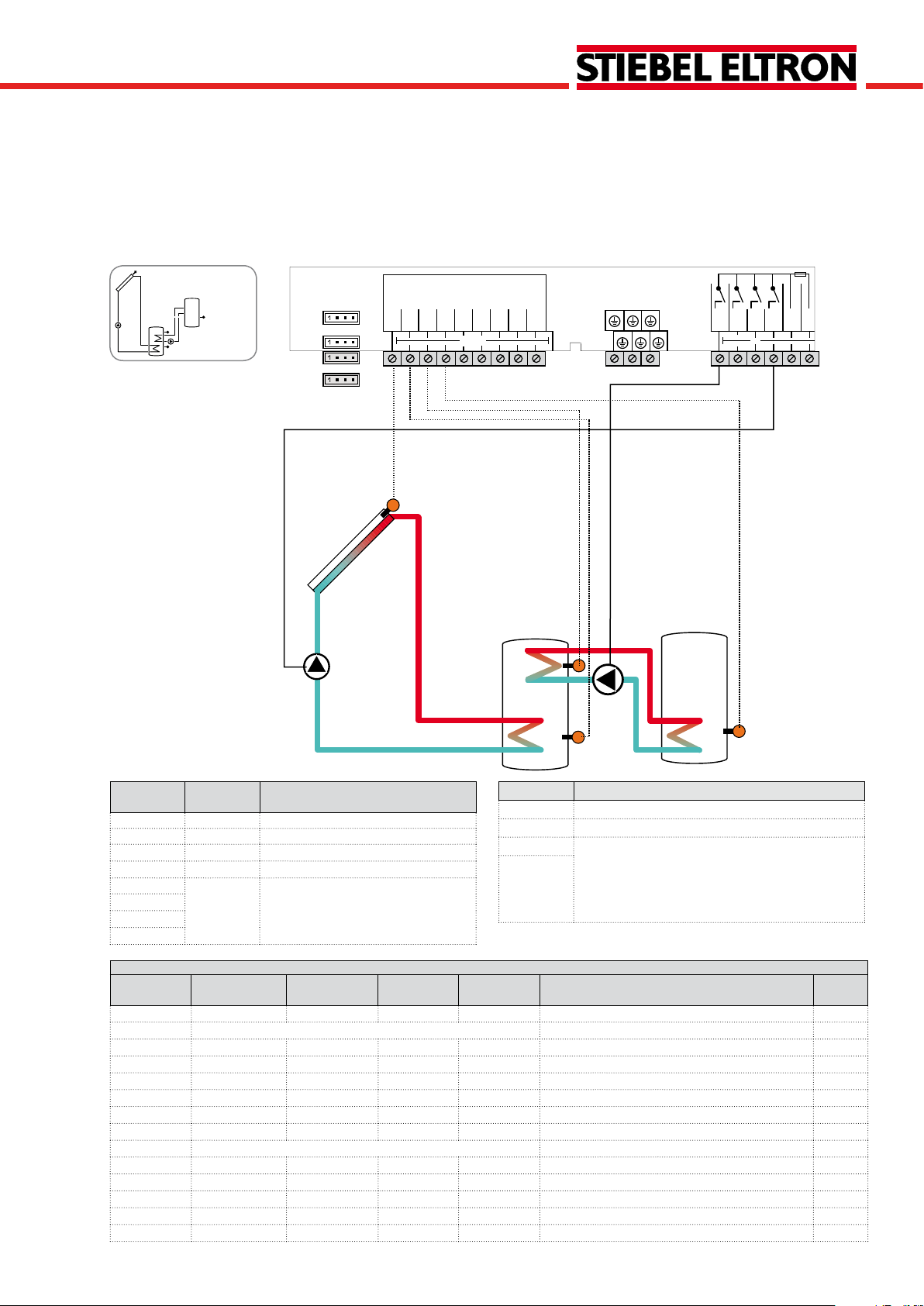

System 11

Solar system with vertical tank loading and heat exchange control

The controller compares the temperature at sensor S1 to

the temperatures at sensors S2 and S3. If the measured

temperature differences are higher than the adjusted switchon temperature differences, the pump (R1) will be activated

and the corresponding tank zone will be loaded up to the

adjusted maximum temperature via the valve (R3).

The priority logic effects prior loading of the upper zone

of the tank.

Heat exchange control to an existent tank via an additional

pump (R2) can be carried out with another temperature

differential function (S3 heat source/S4 heat sink).

Te mp.Sensor

S1

Pt1000

S2

VFS

RPS

S1

R3

R1

Note: 3-port valve normally open - tank bottom

out in

L

S3

S4

S5

PWM 1

PWM 2

V40

GND

VBus

R4

L'

R1

R3

R2

N

S3

R2

S4

S2

Sensor/Terminal

S1 TCOL Temperature collector

S2 TST1B Temperature tank 1 bottom

S3 TSTT Temperature tank 1 top

S4 TST2B Temperature tank 2 bottom

S5 Optional sensor for measurement

VFS

Designation Description

purposes or options

Relay Description

R1 Solar pump

R2 Heat exchange pump

R3 3-port valve tank top/bottom

R4 optional:

Thermal disinfection

Parallel relay

Heat dump

RPS

V40

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

Change to Description Page

setting

ARR 1 11 System 78

LOAD1 > Loading 1

DT1O 12 °R Switch-on temperature difference 1 78

DT1F 8 °R Switch-off temperature difference 1 78

DT1S 20 °R Set temperature difference 1 78

RIS1 4 °R Rise 1 78

S1MAX 140 °F Tank maximum limitation 1 78

SMXS1 2 Sensor tank max 1 79

LOAD2 > Loading 2

DT2O 12 °R Switch-on temperature difference 2 78

DT2F 8 °R Switch-off temperature difference 2 78

DT2S 20 °R Set temperature difference 2 78

RIS2 4 °R Rise 2 78

© Stiebel 11091_SOM_9s.monus.indd

S2MAX 140 °F Tank maximum limitation 2 78

29 |

Page 30

SOM 9s

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

setting

LST2 ON Loading tank 2 79

COL > Collector

CEM 270 °F Collector emergency temperature 80

OCCO** OFF Option collector cooling 80

CMAX 230 °F Maximum collector temperature 80

OCMI OFF Option collector minimum limitation 80

CMIN 50 °F Minimum collector temperature 80

OTCO OFF Option evacuated tube collector function 81

TCST 07:00 Evacuated tube collector starting time 81

TCEN 19:00 Evacuated tube collector ending time 81

TCRU 30 s Evacuated tube collector runtime 81

TCIN 30 min Evacuated tube collector standstill interval 81

OCFR OFF Option collector frost protection 82

CFR O 40 °F Antifreeze temperature collector on 82

CFR F 42 °F Antifreeze temperature collector off 82

LLOGI > Loading logic

PRIO Priority logic 82

PRIO 2 Priority logic 82

OSTS OFF Tank set option 83

TST1 120 °F Set tank temperature tank 1 83

TST2 120 °F Set tank temperature tank 2 83

tLB 2 min Loading break time 82

tRUN 15 min Circulation runtime 82

PSPEE OFF Pause speed option 83

PDELA OFF Pump delay option 83

OOVRU* OFF Overrun option 84

COOL > Cooling functions

OSYC** OFF System cooling 85

OSTC OFF Tank cooling 85

OHDP** OFF Heat dump 85

DT3 > Heat exchange

DT3O 12 °R Switch-on difference 86

DT3F 8 °R Switch-off difference 86

DT3S 20 °R Set difference 86

RIS3 4 °R Rise 86

MAX3O 140 °F Switch-on temperature (maximum limitation) 86

MAX3F 136 °F Switch-off temperature (maximum limitation) 86

MIN3O 40 °F Switch-on temperature (minimum limitation) 86

MIN3F 50 °F Switch-off temperature (minimum limitation) 86

S2DT3 4 Reference sensor heat sink 87

PUMP > Pump speed

PUMP1 OnOF Speed variant pump 1 79

PUMP2 OnOF Speed variant pump 2 79

PUMP3 OnOF Speed variant pump 3 79

MAN > Manual mode

MAN1 Auto Manual mode 1 88

MAN2 Auto Manual mode 2 88

MAN3 Auto Manual mode 3 88

MAN4 Auto Manual mode 4 88

BLPR > OFF Blocking protection 88

OTDIS > OFF Thermal disinfection option 89

OPARR > OFF Parallel relay option 90

OHQM > OFF Energy metering option 90

GFDS > OFF Registration Grundfos sensors 90

PRS* > OFF Pressure monitoring option 92

DATE> Enter date 92

LANG > En Language 93

UNIT > °F Unit 92

OSDC > SD card option 93

CODE 0000 User code 96

RESET OFF Factory setting

* This channel is only available if the Grundfos sensors have been registered in the GFDS channel.

** are blocked against each other

| 30

Change to Description Page

© Stiebel 11091_SOM_9s.monus.indd

Page 31

SOM 9s

R3

R1

S3

S2

S1

Temp. Sensor

Pt1000

L

R3

R2

R1

GND

S1

S2

S3

S4

S5

VBus

PWM 1

PWM 2

N

R4

V40

L'

VFS

RPS

out in

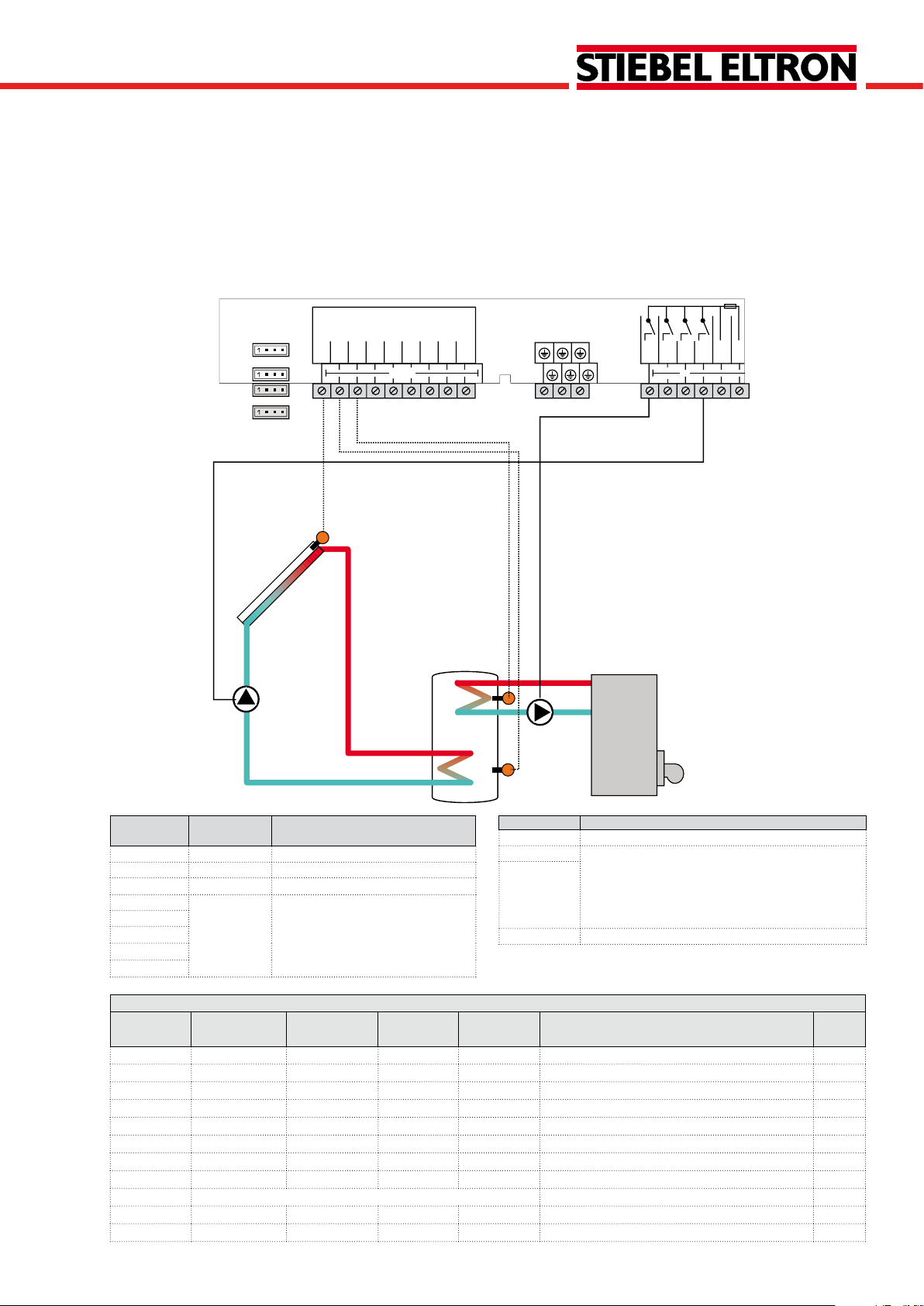

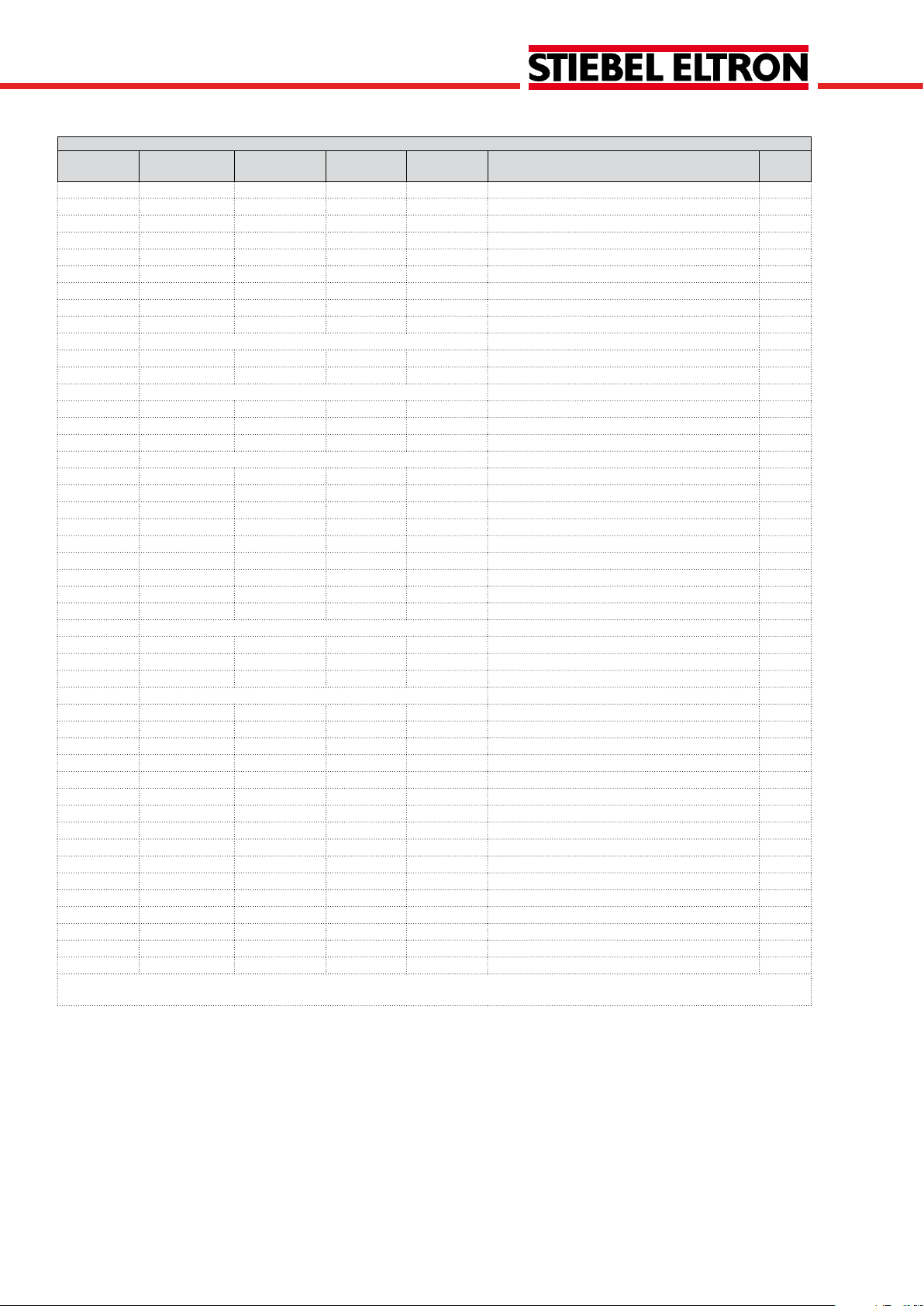

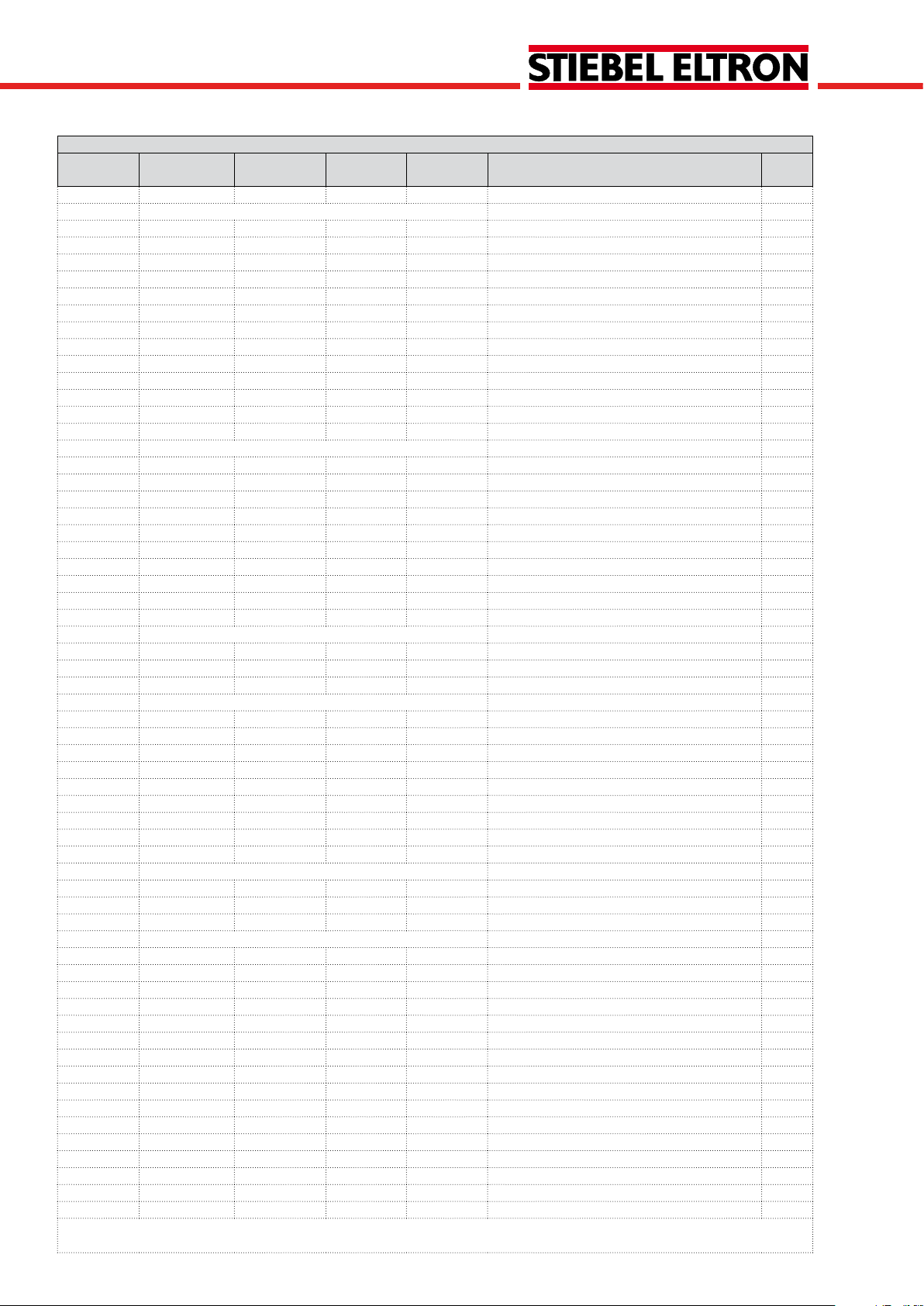

System 12

Solar system with vertical tank loading and thermostatic backup heating

The controller compares the temperature at sensor S1 to

the temperatures at sensors S2 and S3. If the measured

temperature differences are higher than the adjusted switchon temperature differences, the pump (R1) will be activated

and the corresponding tank zone will be loaded up to the

adjusted maximum temperature via the valve (R3). The priority logic effects prior loading of the upper zone of the tank.

Domestic hot water backup heating (R4) can be carried out

with a thermostat function (S3).

Note: 3-port valve normally open - tank bottom

Sensor/Terminal

S1 TCOL Temperature collector

S2 TSTB Temperature tank bottom

S3 TSTT Temperature tank top

S4 Optional sensor for measurement

S5

VFS

RPS

V40

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

ARR 1 12 System 78

LOAD1 > Loading 1

LOAD2 > Loading 2

© Stiebel 11091_SOM_9s.monus.indd

Designation Description

Relay Description

R1 Solar pump

R2 optional:

Thermal disinfection

purposes or options

R3 3-port valve tank top/bottom

Parallel relay

Heat dump

R4 Backup heating/tank loading pump

Change to Description Page

setting

DT1O 12 °R Switch-on temperature difference 1 78

DT1F 8 °R Switch-off temperature difference 1 78

DT1S 20 °R Set temperature difference 1 78

RIS1 4 °R Rise 1 78

S1MAX 60 Tank maximum limitation 1 78

SMXS1 2 Sensor tank max 1 79

DT2O 12 °R Switch-on temperature difference 2 78

DT2F 8 °R Switch-off temperature difference 2 78

DT2S 20 °R Set temperature difference 2 78

RIS2 4 °R Rise 2 78

31 |

Page 32

SOM 9s

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

setting

S2MAX 140 °F Tank maximum limitation 2 78

LST2 ON Loading tank 2 79

COL > Collector

CEM 270 °F Collector emergency temperature 80

OCCO** OFF Option collector cooling 80

CMAX 230 °F Maximum collector temperature 80

OCMI OFF Option collector minimum limitation 80

CMIN 50 °F Minimum collector temperature 80

OTCO OFF Option evacuated tube collector function 81

TCST 07:00 Evacuated tube collector starting time 81

TCEN 19:00 Evacuated tube collector ending time 81

TCRU 30 s Evacuated tube collector runtime 81

TCIN 30 min Evacuated tube collector standstill interval 81

OCFR OFF Option collector frost protection 82

CFR O 40 °F Antifreeze temperature collector on 82

CFR F 42 °F Antifreeze temperature collector off 82

LLOGI > Loading logic

PRIO Priority logic 82

PRIO 2 Priority logic 82

OSTS OFF Tank set option 83

TST1 120 °F Set tank temperature tank 1 83

TST2 120 °F Set tank temperature tank 2 83

tLB 2 min Loading break time 82

tRUN 15 min Circulation runtime 82

PSPEE OFF Pause speed option 83

PDELA OFF Pump delay option 83

OOVRU* OFF Overrun option 84

COOL > Cooling functions

OSYC** OFF System cooling 85

OSTC OFF Tank cooling 85

OHDP** OFF Heat dump 85

AH > Backup heating option

AH O 110 °F Backup heating switch-on temperature 87

AH F 120 °F Backup heating switch-off temperature 87

t1O 06:00 Switch-on time 1 88

t1F 22:00 Switch-off time 1 88

t2O 00:00 Switch-on time 2 88

t2F 00:00 Switch-off time 2 88

t3O 00:00 Switch-on time 3 88

t3F 00:00 Switch-off time 3 88

PUMP > Pump speed

PUMP1 OnOF Speed variant pump 1 79

PUMP2 OnOF Speed variant pump 2 79

PUMP3 OnOF Speed variant pump 3 79

MAN > Manual mode

MAN1 Auto Manual mode 1 88

MAN2 Auto Manual mode 2 88

MAN3 Auto Manual mode 3 88

MAN4 Auto Manual mode 4 88

BLPR > OFF Blocking protection 88

OTDIS > OFF Thermal disinfection option 89

OPARR > OFF Parallel relay option 90

OHQM > OFF Energy metering option 90

GFDS > OFF Registration Grundfos sensors 90

PRS* > OFF Pressure monitoring option 92

DATE> Enter date 92

LANG > En Language 93

UNIT > °F Unit 92

OSDC > SD card option 93

CODE 0000 User code 96

RESET OFF Factory setting

* This channel is only available if the Grundfos sensors have been registered in the GFDS channel.

** are blocked against each other

| 32

Change to Description Page

© Stiebel 11091_SOM_9s.monus.indd

Page 33

SOM 9s

R4

R3

R1

S4

S3

S2

S1

Temp. Sensor

Pt1000

L

R3

R2

R1

GND

S1

S2

S3

S4

S5

VBus

PWM 1

PWM 2

N

R4

V40

L'

VFS

RPS

out in

System 13

Solar system with vertical tank loading and backup heating with solid fuel boiler

The controller compares the temperature at sensor S1 to

the temperatures at sensors S2 and S3. If the measured temperature differences are higher than the adjusted switch-on

temperature differences, the pump (R1) will be activated and

the corresponding tank zone will be loaded up to the adju-

sted maximum temperature via the valve (R4). The priority

logic effects prior loading of the upper zone of the tank.

With another temperature differential function (S4/S3),

backup heating of the tank can be carried out with a solid

fuel boiler (R3).

Note: 3-port valve normally open - tank bottom

Sensor/Terminal

S1 TCOL Temperature collector

S2 TSTB Temperature tank bottom

S3 TSTT Temperature tank top

S4 TSFB Temperature solid fuel boiler

S5 Optional sensor for measurement

VFS

RPS

V40

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

ARR 1 13 System 78

LOAD1 > Loading 1

LOAD2 > Loading 2

© Stiebel 11091_SOM_9s.monus.indd

Designation Description

Relay Description

R1 Solar pump

R2 optional:

Thermal disinfection

Parallel relay

Heat dump

R3 Loading pump/solid fuel boiler

purposes or options

R4 3-port valve tank top/bottom

Change to Description Page

setting

DT1O 12 °R Switch-on temperature difference 1 78

DT1F 8 °R Switch-off temperature difference 1 78

DT1S 20 °R Set temperature difference 1 78

RIS1 4 °R Rise 1 78

S1MAX 140 °F Tank maximum limitation 1 78

SMXS1 2 Sensor tank max 1 79

DT2O 12 °R Switch-on temperature difference 2 78

DT2F 8 °R Switch-off temperature difference 2 78

DT2S 20 °R Set temperature difference 2 78

RIS2 4 °R Rise 2 78

S2MAX 140 °F Tank maximum limitation 2 78

33 |

Page 34

SOM 9s

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

setting

LST2 ON Loading tank 2 79

COL > Collector

CEM 270 °F Collector emergency temperature 80

OCCO** OFF Option collector cooling 80

CMAX 230 °F Maximum collector temperature 80

OCMI OFF Option collector minimum limitation 80

CMIN 50 °F Minimum collector temperature 80

OTCO OFF Option evacuated tube collector function 81

TCST 07:00 Evacuated tube collector starting time 81

TCEN 19:00 Evacuated tube collector ending time 81

TCRU 30 s Evacuated tube collector runtime 81

TCIN 30 min Evacuated tube collector standstill interval 81

OCFR OFF Option collector frost protection 82

CFR O 40 °F Antifreeze temperature collector on 82

CFR F 42 °F Antifreeze temperature collector off 82

LLOGI > Loading logic

PRIO Priority logic 82

PRIO 2 Priority logic 82

OSTS OFF Tank set option 83

TST1 120 °F Set tank temperature tank 1 83

TST2 120 °F Set tank temperature tank 2 83

tLB 2 min Loading break time 82

tRUN 15 min Circulation runtime 82

PSPEE OFF Pause speed option 83

PDELA OFF Pump delay option 83

OOVRU* OFF Overrun option 84

COOL > Cooling functions

OSYC** OFF System cooling 85

OSTC OFF Tank cooling 85

OHDP** OFF Heat dump 85

DT3 > Solid fuel boiler

DT3O 12 °R Switch-on difference 86

DT3F 8 °R Switch-off difference 86

DT3S 20 °R Set difference 86

RIS3 4 °R Rise 86

MAX3O 140 °F Switch-on temperature (maximum limitation) 86

MAX3F 136 °F Switch-off temperature (maximum limitation) 86

MIN3O 140 °F Switch-on temperature (minimum limitation) 86

MIN3F 149 °F Switch-off temperature (minimum limitation) 86

S2DT3 3 Reference sensor heat sink 87

PUMP > Pump speed

PUMP1 OnOF Speed variant pump 1 79

PUMP2 OnOF Speed variant pump 2 79

PUMP3 OnOF Speed variant pump 3 79

MAN > Manual mode

MAN1 Auto Manual mode 1 88

MAN2 Auto Manual mode 2 88

MAN3 Auto Manual mode 3 88

MAN4 Auto Manual mode 4 88

BLPR > OFF Blocking protection 88

OTDIS > OFF Thermal disinfection option 89

OPARR > OFF Parallel relay option 90

OHQM > OFF Energy metering option 90

GFDS > OFF Registration Grundfos sensors 90

PRS* > OFF Pressure monitoring option 92

DATE> Enter date 92

LANG > En Language 93

UNIT > °F Unit 92

OSDC > SD card option 93

CODE 0000 User code 96

RESET OFF Factory setting

* This channel is only available if the Grundfos sensors have been registered in the GFDS channel.

** are blocked against each other

| 34

Change to Description Page

© Stiebel 11091_SOM_9s.monus.indd

Page 35

SOM 9s

R3

R2

R1

S4

S3

S2

S1

Temp. Sensor

Pt1000

L

R3

R2

R1

GND

S1

S2

S3

S4

S5

VBus

PWM 1

PWM 2

N

R4

V40

L'

VFS

RPS

out in

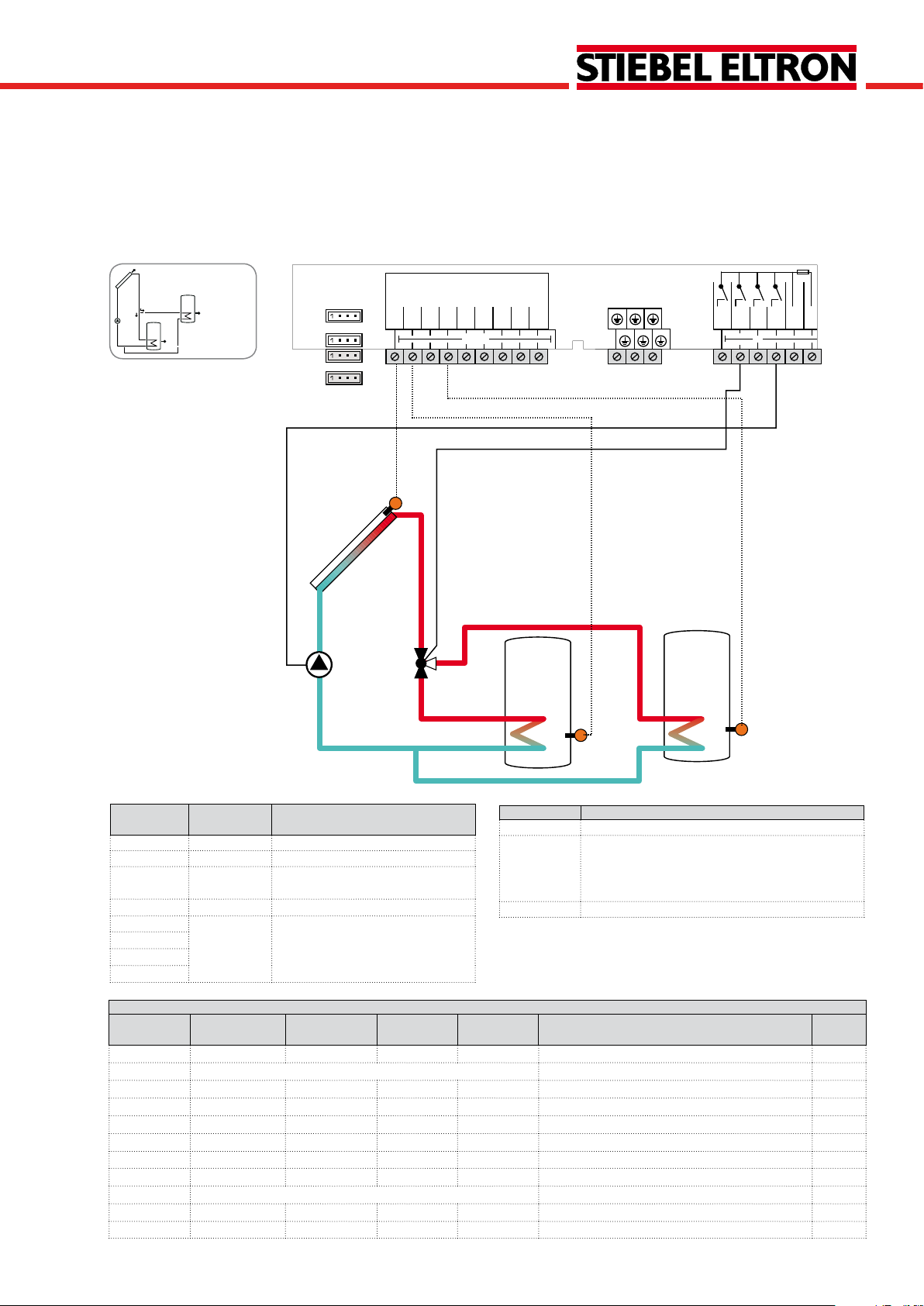

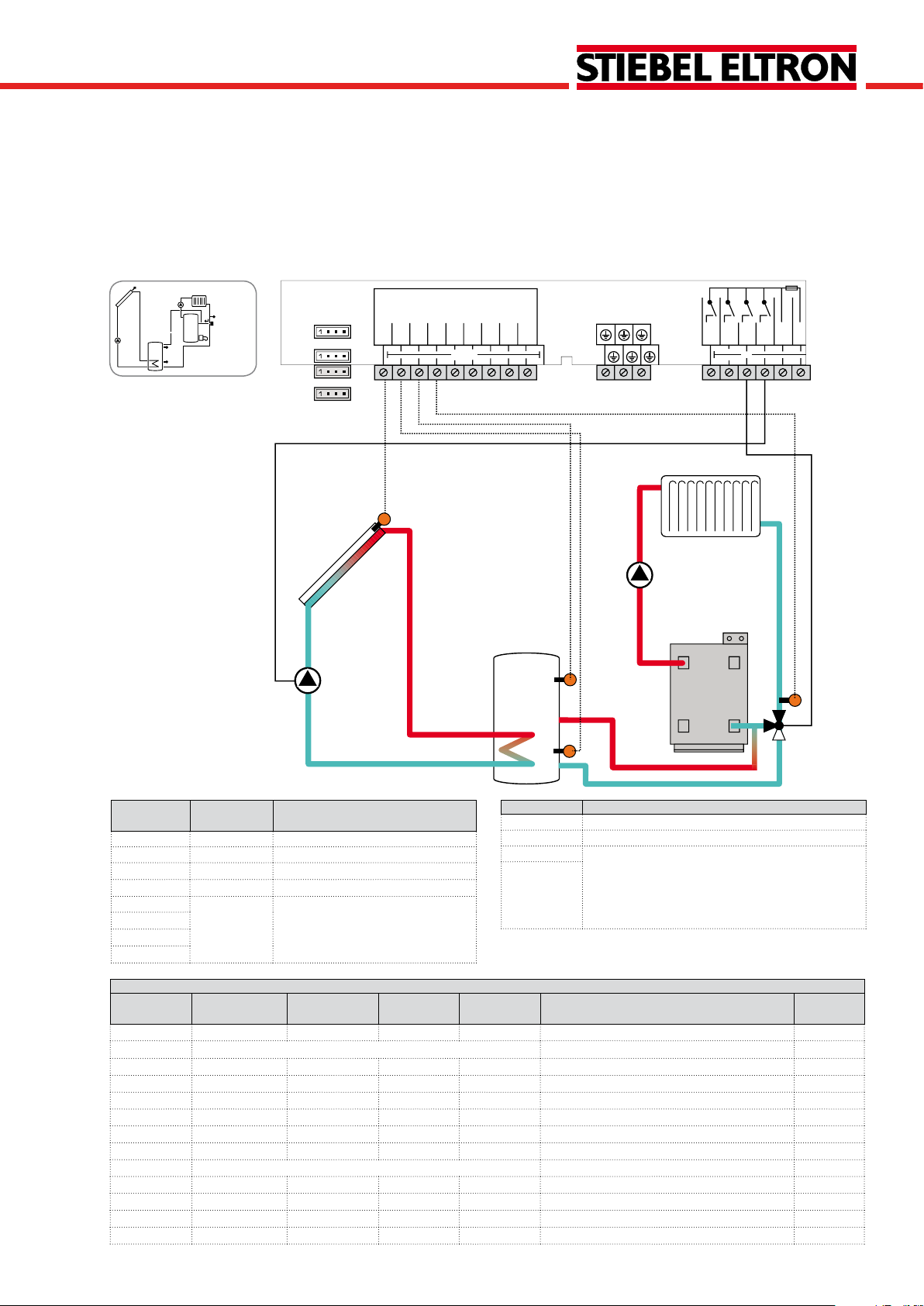

System 14

Solar system with vertical tank loading and return preheating

The controller compares the temperature at sensor S1 to

the temperatures at sensors S2 and S3. If the measured

temperature differences are higher than the adjusted switchon temperature differences, the pump (R1) will be activated

and the corresponding tank zone will be loaded up to the

adjusted maximum temperature via the valve (R3). The priority logic effects prior loading of the upper zone of the tank.

With another temperature differential function (S3-heat

source/S4-heat sink) heating circuit return preheating (heating circuit backup) is possible via another valve (R2).

Note: 3-port valve normally open - tank bottom

Sensor/Terminal

S1 TCOL Temperature collector

S2 TSTB Temperature tank bottom

S3 TSTT/TSTR Temperature tank top/

S4 TRET Temperature return

S5 Optional sensor for measurement

VFS

RPS

V40

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

ARR 1 14 System 78

LOAD1 > Loading 1

LOAD2 > Loading 2

© Stiebel 11091_SOM_9s.monus.indd

Designation Description

Relay Description

R1 Solar pump

R2 Return preheating

R3 3-port valve tank top/bottom

R4 optional:

Thermal disinfection

Parallel relay

Heat dump

Temp. tank return preheating

purposes or options

Change to Description Page

setting

DT1O 12 °R Switch-on temperature difference 1 78

DT1F 8 °R Switch-off temperature difference 1 78

DT1S 20 °R Set temperature difference 1 78

RIS1 4 °R Rise 1 78

S1MAX 140 °F Tank maximum limitation 1 78

SMXS1 2 Sensor tank max 1 79

DT2O 12 °R Switch-on temperature difference 2 78

DT2F 8 °R Switch-off temperature difference 2 78

DT2S 20 °R Set temperature difference 2 78

RIS2 4 °R Rise 2 78

35 |

Page 36

SOM 9s

Adjustment channels

Channel Sub channel 1 Sub channel 2 Factory

S2MAX 140 °F Tank maximum limitation 2 78

LST2 ON Loading tank 2 79

COL > Collector

CEM 270 °F Collector emergency temperature 80

OCCO** OFF Option collector cooling 80

CMAX 230 °F Maximum collector temperature 80

OCMI OFF Option collector minimum limitation 80

CMIN 50 °F Minimum collector temperature 80

OTCO OFF Option evacuated evacuated tube collector function 81

TCST 07:00 Evacuated evacuated tube collector starting time 81

TCEN 19:00 Evacuated evacuated tube collector ending time 81

TCRU 30 s Evacuated tube collector runtime 81

TCIN 30 min Evacuated evacuated tube collector standstill interval 81

OCFR OFF Option collector frost protection 82

CFR O 40 °F Antifreeze temperature collector on 82

CFR F 42 °F Antifreeze temperature collector off 82

LLOGI > Loading logic

PRIO Priority logic 82

PRIO 2 Priority logic 82

OSTS OFF Tank set option 83

TST1 120 °F Set tank temperature tank 1 83

TST2 120 °F Set tank temperature tank 2 83

tLB 2 min Loading break time 82

tRUN 15 min Circulation runtime 82

PSPEE OFF Pause speed option 83

PDELA OFF Pump delay option 83

OOVRU* OFF Overrun option 84

COOL > Cooling functions

OSYC** OFF System cooling 85