Page 1

OPERATION AND INSTALLATION

RESIDENTIAL SOLAR PUMP STATION

» SE FLOWSTAR PUMP STATION

Page 2

INSTALLATION INSTRUCTIONS

SE FLOWSTAR PUMP STATION - 221337

Simply the Best

Table of Contents

1 For your safety

1.1 About this manual

1.2 Designated use

1.3 Qualifi cation of the installer

1.4 Hand-over of the system (specialist)

1.5 General safety instructions

1.6 General instructions regarding solar fl uid

1.7 Frost damage

2 Description of the product

3 Assembly and installation

3.1 Wall-mounted confi guration

3.2 Tank-mounted confi guration

3.3 Wiring the pump

4 Commissioning

4.1 Flushing and fi lling the solar circuit

4.2 Preparation for fl ushing

4.3 Flushing the system

4.4 Filling the system

4.5 Setting the solar thermal system

1 For your safety

1.1 About the manual

This manual describes the function, installation,

commissioning adn operation of a Stiebel Eltron SE

Flowstar pump station. For other components of the solar

installation, such as collectors, storage tanks, expansion

tanks, controllers, and any other components, please refer

to the specifi c manuals for those parts.

1.2 Designated use

The solar station is a pre-assembled fi tting assembly

checked for tightness and used for recirculating the solar

fl uid in the solar circuit. The solar station must only be

used in solar thermal systems as pumping station. It must

be mounted in the return line of the solar circuit, taking into

consideration the technical limit values indicated in this

manual. The station may only be assembled indoors. The

station must be assembled and operated as described in

this manual!

1.3 Qualifi cation of the installer

5 Cleaning

6 Maintenance and decommissioning

6.1 Draining the solar system

6.2 Replacing the pump

7 Spare parts

8 Technical data and pressure drop characterisics

9 Commissioning log

CAUTION: READ ALL INSTRUCTIONS BEFORE

!

INSTALLING THIS PUMP STATION. ADDITIONAL

ITEMS WILL BE NEEDED TO MOUNT THIS ASSEMBLY.

17 West St., W. Ha tfi el d, MA 01088

| 800.582.8423 | 413.247.3380 | fax 413.247.3369 | info@stiebel-eltron-usa.com | www.stiebel-eltron-usa.com

Installation and commissioning of this equipment should

be done by qualifi ed installers [specialist] in accordance

with local, state and federal codes which may be

applicable.

The following must also be observed during installation and

commissioning:

» Relevant regional and national regulations

» Relevant accident prevention regulations

» Instructions and safety instructions mentioned in

this manual

1.4 Hand-over of the system

After installation and commissioning, the installer is

responsible for familiarizing the end user with the functions

of the system and the basic safety measures.

Page 3

INSTALLATION INSTRUCTIONS

SE FLOWSTAR PUMP STATION - 221337

Simply the Best

» After commissioning, fi ll in the log on the last

page of this manual.

» Hand the manual over to the end user. Instruct

the end user to keep the manual in close

proximity to the system.

» Instruct the end user to have the solar station

serviced and repaired by a specialist only. The

controller settings must not be changed by the

end user.

» Explain to the end user the function of the system

and of the safety devices. Point out to the end

user that the shell must remain mounted during

operation and that the check valve with temperature

gauge and the ball valve in the fl owmeter must be

open.

1.5 General safety instructions

Before installing and commissioning the product, you must

read and observe the following safety instructions:

A. Danger of scalding due to escaping vapor

If the system pressure is too high, hot solar fl uid will escape

from the pressure relief valves and can result in scalding.

Flush and fl l the system only if the collector temperatures

are below 150F (70C).

Connect a discharge line to the safety assembly. Observe the

instructions regarding the pressure relief valve.

damage and personal injury.

In operation, the ball valve with temperature gauge and the

ball valve at the fl owmeter must always be open.

Close the ball valve only when service is required.

1.6 General instructions regarding solar fl uid

Propylene glycol is hazardous in the case of ingestion. It is

an irritant when it comes into contact witht he eyes or skin.

Always wear chemically resistant protective gloves and

safety glasses with side-shields when handling propylene

glycol mixtures.

1.7 Frost damage

Observe the instructions and specifi cations of the antifreeze

from the manufacturer.

It often happens that solar thermal systems cannot be

completely drained after fl ushing. Thus, there is a risk of

frost damage when fl ushing with water. Therefore, the solar

thermal system should only be fl ushed and fi lled with the

solar fl uid used later on.

Strictly follow the instructions of the antifreeze manufacturer

for operating a solar thermal system. All components in

the solar station are resistant to a percentage of propylene

glycol of up to 50%.

B. Risk of burns

The valves, fi ttings and the pump may heat up to more

than 212 °F (100 °C) during operation.

C. Personal injry and material damage caused by excess

pressure

Closing the ball valves both in the return and supply line of

the solar circuit, will disconnect the safety assembly from

the heat exchanger. Heating the storage tank can result in

the formation of high pressures, which may lead to material

17 West St., W. Ha tfi el d, MA 01088

| 800.582.8423 | 413.247.3380 | fax 413.247.3369 | info@stiebel-eltron-usa.com | www.stiebel-eltron-usa.com

Determine quantity according to system volume. See

instructions of the collectors, storage tank and expansion

tank.

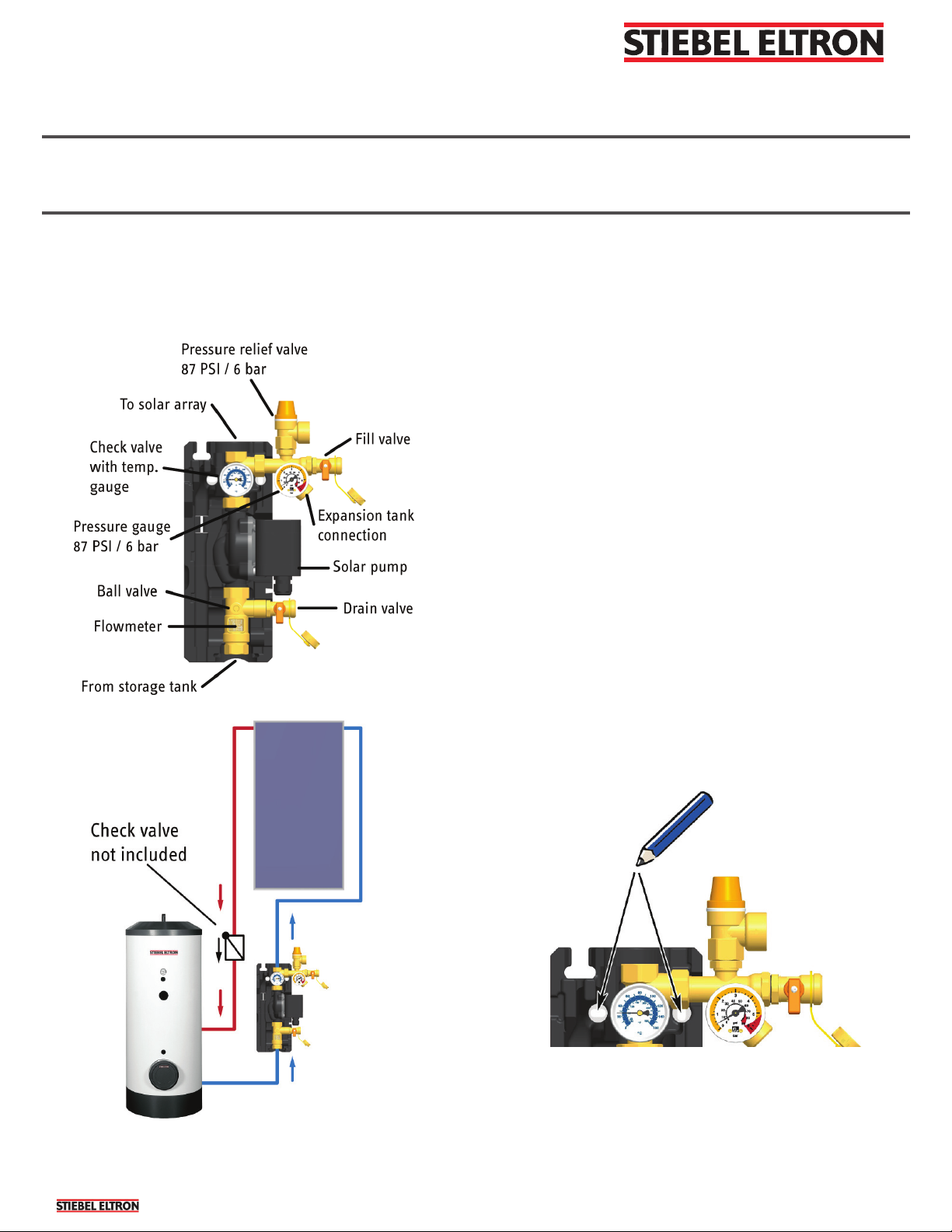

2 Description of the product

This solar pump station is designed to be mounted in one

of two ways. Both mounting options are discussed in the

manual. It can be mounted either on a wall support and

held by clip springs, or on a Stiebel Eltron solar storage tank

using a tank mounting kit.

Page 4

INSTALLATION INSTRUCTIONS

SE FLOWSTAR PUMP STATION - 221337

Simply the Best

The pump station contains important valves, fi ttings, and

safety equipment to ensure the proper operation of the solar

thermal system.

Below is a brief overview of the pump station components:

To prevent thermosiphoning of the system, a check valve

must be installed on the supply line of the solar circuit.

Stiebel Eltron provides a check valve as part of our tank

mounting kits.

3 Assembly and installation

The solar station may only be installed indoors with a power

supply of 120 V / 60 Hz. The installation site must be dry,

stable and frost-free.

NOTE: Since the solar fl uid may be very hot near the

collector, the pump station must be

installed at a suffi cient distance from the collector fi eld.

A system pre-cooling vessel may be need to protect the

expansion tank from excessively high temperatures.

3.1 Wall-mounted confi guration

1. Remove the pump station from the packaging.

2. Pull off the front shell.

3. Copy the mounting holes next to the temperature gauges

of the pump station to the mounting surface.

4. Drill the holes and fasten the pump station to the wall

using the enclosed screws and, if required, the enclosed

wall anchors.

17 West St., W. Ha tfi el d, MA 01088

| 800.582.8423 | 413.247.3380 | fax 413.247.3369 | info@stiebel-eltron-usa.com | www.stiebel-eltron-usa.com

Page 5

INSTALLATION INSTRUCTIONS

SE FLOWSTAR PUMP STATION - 221337

Simply the Best

5. Connect the pump station to the system by means of the

top and bottom connections. The bottom connection should

be piped to the heat exchanger outlet of the storage tank.

The top connection should be piped to return to the collector

fi eld. It is recommended to ensure the seal of all threaded

connections by using tefl on tape and pipe dope.

6. To prevent thermosiphoning, install a check valve in the

supply line of the solar circuit.

8. Connect the expansion tank at the connection below

the pressure gauge. Stiebel Eltron provides kits for quick

connection of the expansion tank, but it is sold separately.

9. Adapt the initial pressure of the expansion tank to

the system and connect the expansion tank. For more

information regarding the installation of the expansion tank,

please see the installation manual for that expansion tank.

10. Check all threaded connections and retighten them.

3.2 Tank-mounted confi guration

This section describes how to mount an SE Flowstar pump

station onto an SBB tank using a low tank mounting kit.

These components are sold separately.

1. Remove the pump station from the packaging.

2. Pull off the front shell.

7. Connect the discharge line to the pressure relief valve

connection. Pipe this discharge line to a heat-resistant

container.

3. Observe the lower connector of the pump station.

Remove the ¾˝ NPT adapter, revealing a ¾˝ BSP threaded

connection.

4. Inspect the threads of the tank to make sure they are

clean and free of debris.

17 West St., W. Ha tfi el d, MA 01088

| 800.582.8423 | 413.247.3380 | fax 413.247.3369 | info@stiebel-eltron-usa.com | www.stiebel-eltron-usa.com

Page 6

INSTALLATION INSTRUCTIONS

SE FLOWSTAR PUMP STATION - 221337

5. Remove the components from the tank mounting kit.

Simply the Best

6. Apply tefl on tape & pipe dope to the 1˝ BSP threads on

the lower HX assembly. Screw the assembly into the HX port

and tighten it.

7. Apply tefl on tape & pipe dope to the 1˝ BSP threads on

the upper HX assembly. Screw the assembly into the HX

port and tighten it.

9. Attach the pump station to the lower HX connection.

Ensure that the gasket is place between the connecting

pieces.

10. Connect the discharge line to the pressure relief valve

connection. Pipe this discharge line to a heat-resistant

container.

11. Connect the expansion tank at the connection below

the pressure gauge. Stiebel Eltron provides kits for quick

connection of the expansion tank, but it is sold separately.

8. Attach the elbow piece of the lower HX assembly to the

pump station. Save the gasket for the next step.

17 West St., W. Ha tfi eld, MA 01088

| 800.582.8423 | 413.247.3380 | fax 413.247.3369 | info@stiebel-eltron-usa.com | www.stiebel-eltron-usa.com

12. Adapt the initial pressure of the expansion tank to

the system and connect the expansion tank. For more

information regarding the installation of the expansion tank,

please see the installation manual for that expansion tank.

13. Check all threaded connections and retighten them.

Page 7

INSTALLATION INSTRUCTIONS

SE FLOWSTAR PUMP STATION - 221337

Simply the Best

3.3 Wiring the pump

1. Remove the screw from the pump housing. Connect

an 18 gauge wire to the pump wiring block by threading

it through the waterproof nut at the bottom of the pump

housing. Be sure to connect the colored wires in the correct

manner.

A. Risk of burns and scalding.

The valves and fi ttings may heat up to more than 212

(100C). During fl ushing, fi lling and venting, the solar fl uid

can escape as vapor and result in scalding. Flush and fi ll the

system only if the collector temperatures are below 150F

(70C).

B. Propylene glycol safety.

Propylene glycol is hazardous in the case of ingestion. It is

an irritant when it comes into contact witht he eyes or skin.

Always wear chemically resistant protective gloves and

safety glasses with side-shields when handling propylene

glycol mixtures.

Observe the instructions and specifi cations of the antifreeze

from the manufacturer.

C. Risk of frost.

2. Close the pump housing, and reattach the front cover of

the pump station.

3. Connect the pump wire to the solar controller. The solar

controller should be installed and at this point, as it will be

necessary to manually run the pump later in the installation

process.

4 Commissioning

Before commissioning the pump station, read and observe

the following safety instructions:

It often happens that solar thermal systems cannot be

completely drained after fl ushing. There is a risk of frost

damage when fl ushing with water.

Therefore, the solar thermal system should only be fl ushed

with water, immediately followed by the solar fl uid to fi ll the

system.

Use a water and propylene glycol mixture with max. 50%

propylene glycol as a solar fl uid, in order to avoid damaging

gaskets and seals.

4.1 Flushing and fi lling the solar circuit.

The fi ll and drain connections required for fl ushing and

fi lling are integrated into the solar station. In order to fl ush

any dirt particles that may still be present out of the system,

use only fl ush and fi ll stations equipped with suitable micro

fi lters.

17 West St., W. Ha tfi eld, MA 01088

| 800.582.8423 | 413.247.3380 | fax 413.247.3369 | info@stiebel-eltron-usa.com | www.stiebel-eltron-usa.com

Page 8

INSTALLATION INSTRUCTIONS

g

SE FLOWSTAR PUMP STATION - 221337

Simply the Best

Ball valve with integrated check valve

4.2 Preparation for fl ushing

1. Conduct an air pressure test of the system before

fl ushing and fi lling. This will ensure that all gaskets,

soldering joints, or threaded connections are properly

sealed. The pressure, and length of this test is at the

discretion of the installer, but it is highly recommended by

Stiebel Eltron that this step is completed.

2. Disconnect the expansion tank from the solar thermal

system. This is typically done via a ball valve piped between

the expansion tank and the pump station.

3. Ensure the check valve in the pump station is in its 0

position.

4. Connect a hose from a domestic water connection to

connection A, as shown in the image below.

5. Connect the fl ushing hose to connection B, as shown

below.

6. Ensure that the fl ushing hose is positioned to empty into

a drain or sink.

4.3 Flushing the system

1. Open the fi ll and drain valves.

17 West St., W. Ha tfi eld, MA 01088

| 800.582.8423 | 413.247.3380 | fax 413.247.3369 | info@stiebel-eltron-usa.com | www.stiebel-eltron-usa.com

Page 9

INSTALLATION INSTRUCTIONS

SE FLOWSTAR PUMP STATION - 221337

2. Open the domestic water connection to allow water to

begin fl ushing through the system.

3. Leave the water running through the system and into

the drain for a full 5 minutes after the fl ushing hose has

begun purging water.

4. Close the fi ll and drain valves, as well as the domestic

water connection.

5. Use the solar controller to manually circulate the fl uid.

The process for doing this will depend on the controller you

are using. Circulate the fl uid for 30 minutes.

4.4 Filling the system

Simply the Best

12. Insert the fl ushing hose into the same bucket of

propylene glycol mixture as the charging hose.

13. Open the ball valve that is isolating the expansion tank.

14. Open the drain valve to continue the circulation of solar

fl uid through the system. This confi guration will allow any

air in the system to be discharged via the bucket. Circulate

the fl uid in this manner for 15 minutes.

15. Close the drain valve again. The system will now begin

building pressure. Observe the pressure on the pump

station gauge until it reaches the intended cold system

pressure.

1. Stop the manual operation of the pump and turn the

pump to off on the controller.

2. Open the check valve in the pump station to its 45

position.

3. Close the ball valve in the fl ow meter.

4. Connect the charging pump hose to connection A, as

shown above.

5. Make sure the fl ushing hose is still connected to the

drain connection B.

6. Insert the fi lling hose (on the back end of the charging

pump) into the solar fl uid.

7. Start the charging pump.

8. Open the fi ll valve.

9. Open the drain valve.

10. Observe the discharge of the fl ushing hose and make

note of the color change of the fl uid to the propylene glycol

mixture.

11. Close the drain valve.

16. Close the fi ll valve and turn off the charging pump.

17. Open the ball valve in the fl ow meter.

18. Set the check valve to the 0 operating position.

19. Manually run the pump via the pump station to ensure

that the system is working propery.

20. Air may have accumulated at the solar collectors. It is

important to bleed off any air from them to ensure that they

are performing uniformly.

4.5 Setting the solar system

Observe the specifi cations of the manufacturer of the

collectors for the correct adjustment of the fl ow rate. For

Stiebel Eltron SOL 27 Premium collectors, the recommended

fl ow rate is 0.75 gpm/collector.

Part: # of Collectors in Array:

12 3 4

Flow Rate (gpm):

SOL 27 Premium collector 0.75 1.5 2.25 3.0

1. Set the desired max. fl ow rate voa the rotation speed

of the solar pump. The controller will set the speed

accordingly.

17 West St., W. Ha tfi eld, MA 01088

| 800.582.8423 | 413.247.3380 | fax 413.247.3369 | info@stiebel-eltron-usa.com | www.stiebel-eltron-usa.com

Page 10

INSTALLATION INSTRUCTIONS

SE FLOWSTAR PUMP STATION - 221337

Simply the Best

2. Observe the fl ow via the fl owmeter.

2. Re-mount the front shell on the solar station.

3. Set the controller to automatic mode.

5 Cleaning

Before decommissioning, wait until the solar fl uid has

cooled down below 122F (50C).

6.1 Draining the solar installation

Complete draining allows components in the pump station

to be replaced.

1. Disconnect the controller from the power supply and

secure it against being switched on again.

2. Open the check valve to the 45 position.

3. Connect a heat-resistant hose to the drain valve. Make

sure that the solar fl uid is collected in a heat-resistant

container.

4. Open the drain valve.

5. To accelerate the draining of the solar circuit, open the

bleeding device at the collectors.

Clean the pump station only from the outside with a damp

cloth. Never use scouring or sand-containing cleaning

agents.

6 Maintenance and decommissioning

Before maintaining and decommissioning the system, read

and observe the following safety instructions.

A. Risk of electric shock

Disconnect all electrical devices in the solar circuit from

the power supply before carrying out maintenance work or

decimmissioning.

Ensure that the electrical devices cannot be switched on

again.

B. Risk of burns and scalding.

The valves and fi ttings may heat up to more than 212

(100C).

6. If discarding the solar fl uid, dispose of it observing any

local regulations.

6.2 Replacing the pump

1. After performing the draining process as in 6.1,

disconnect the pipe joint between the pump station and the

storage tank.

2. Dismount the fl owmeter connection to the pump.

3. Dismount the pump connection from the upper

assembly.

4. Install the new pump, making sure to include new

gaskets.

5. Mount the fl owmeter.

6. Connect the pump station to its original connections.

Repeat the commissioning process as described in section 4.

7 Spare parts

17 West St., W. Ha tfi eld, MA 01088

| 800.582.8423 | 413.247.3380 | fax 413.247.3369 | info@stiebel-eltron-usa.com | www.stiebel-eltron-usa.com

Page 11

INSTALLATION INSTRUCTIONS

SE FLOWSTAR PUMP STATION - 221337

Simply the Best

Below is a diagram of the spare parts that can be ordered

from Stiebel Eltron. If you need to order a replacement part,

please contact Stiebel Eltron and use the part numbers

below as a reference.

8 Technical data and pressure drop curve

Technical data

SE Flowstar Pump Station

Dimensions

Height 14.9 in. / 379 mm

Width 8.94 in. / 227 mm

Depth 5.9 in. / 150 mm

Upper & lower connections ¾˝ Male NPT or ¾˝ Female BSP

Exp. tank connection ¾˝ Male BSP

PRV connection ¾˝Female BSP

Temperature & Pressure

Max. pressure 145 PSI / 10 bar

Max. temp. 248F / 120C

Max. short term temp. 320F / 160C for < 15 min.

Max. propylene glycol % 50%

Equipment

Pressure relief valve 87 psi / 6 bar

Pressure gauge 0-87 psi / 0-6 bar

Check valve 7.9 in. head / 200 mmWC

Flowmeter 0.1-4 gpm

Material

Valves & fi ttings Brass

Gaskets EPDM

Check valves Brass

Insulation EPP, λ=0.043 W/(m•K)

17 West St., W. Ha tfi eld, MA 01088

Dimensions

| 800.582.8423 | 413.247.3380 | fax 413.247.3369 | info@stiebel-eltron-usa.com | www.stiebel-eltron-usa.com

Page 12

INSTALLATION INSTRUCTIONS

SE FLOWSTAR PUMP STATION - 221337

Pressure drop curve

Simply the Best

17 West St., W. Ha tfi eld, MA 01088

For any service or warranty related issue, contact

Stiebel Eltron at:

17 West Street

West Hatfi eld, MA 01088

TOLL FREE 800.582.8423

PHONE 413.247.3380

FAX 413.247.3369

info

www.stiebel-eltron-usa.com

Printed on recycled chlorine-free paper with soy-based inks.

Due to our continuous process of engineering and technological

advancement, specifi cations may change without notice.

| 800.582.8423 | 413.247.3380 | fax 413.247.3369 | info@stiebel-eltron-usa.com | www.stiebel-eltron-usa.com

800.582.8423

@

stiebel-eltron-usa.com

Page 13

This page intentionally left blank

Page 14

Simply the Best

COMMISSIONING LOG

SE FLOWSTAR PUMP STATION

The installer should fi ll out this sheet at the end of the installation, and leave it at the installation site.

Site:

System operator:

Installation site:

Collectors:

Collectors (number / type):

Collector surface area:

System specifi cations:

System height:

Pipe run length:

Ventilation:

Solar fl uid (type / concentration):

Max. fl ow rate:

Pump station:

Pump setting (low/med/high):

System pressure (cold):

System pressure (hot):

Expansion tank:

Checklist:

Mark for condition (checked, closed, open, etc.)

Pressure relief valve:

Check valves:

Ball valves:

Serial numbers:

Pump station:

Controller:

Software version:

Installation company:

Signature: Date:

17 West St., W. Ha tfi eld, MA 01088

| 800.582.8423 | 413.247.3380 | fax 413.247.3369 | info@stiebel-eltron-usa.com | www.stiebel-eltron-usa.com

Loading...

Loading...