STIEBEL ELTRON SBS 601 W, SBS 1001 W, SBS 1501 W, SBS 601 W SOL, SBS 801 W Operation And Installation

...

BEDIENUNG UND INSTALLATION

OPERATION AND INSTALLATION

UTILISATION ET INSTALLATION

BEDIENING EN INSTALLATIE

USO E INSTALLAZIONE

OBSLUHA A INSTALACE

OBSŁUGA I INSTALACJA

KÄYTTÖ JA ASENNUS

Durchlaufspeicher | Instantaneous water heating cylinder | Ballon à écoulement

libre| Doorstroomboilers | Scaldacqua con bollitore | Průtokový zásobník |

Zasobnik przepływowy | Läpivirtausvaraajat

» SBS 601 W

» SBS 801 W

» SBS 1001 W

» SBS 1501 W

» SBS 601 W SOL

» SBS 801 W SOL

» SBS 1001 W SOL

» SBS 1501 W SOL

Contents | Operation

General information

OPERATION

1. General information ��������������������������������������� 14

1.1 Document information ����������������������������������������� 14

1.2 Safety instructions ����������������������������������������������14

1.3 Other symbols in this documentation ���������������������� 14

1.4 Units of measurement ����������������������������������������� 15

2. Safety �������������������������������������������������������� 15

2.1 Intended use ����������������������������������������������������� 15

2.2 Safety information ���������������������������������������������� 15

2.3 Test symbols �����������������������������������������������������15

3. Appliance description ������������������������������������� 15

4. Cleaning, care and maintenance ������������������������� 15

4.1 Scaling ������������������������������������������������������������ 15

5. Troubleshooting �������������������������������������������� 15

INSTALLATION

6. Safety �������������������������������������������������������� 16

6.1 General safety instructions ����������������������������������� 16

6.2 Instructions, standards and regulations ������������������� 16

6.3 Water installation ����������������������������������������������� 16

7. Appliance description ������������������������������������� 16

7.1 Standard delivery ����������������������������������������������� 16

7.2 Accessories �������������������������������������������������������16

8. Assembly ���������������������������������������������������� 16

8.1 Installation location �������������������������������������������� 16

8.2 Transport ��������������������������������������������������������� 16

8.3 Assembly ��������������������������������������������������������� 17

9. Commissioning ��������������������������������������������� 17

10. Taking the appliance out of use �������������������������� 17

11. Recommissioning ������������������������������������������ 17

12. Appliance handover ���������������������������������������� 18

13. Troubleshooting �������������������������������������������� 18

13.1 Fault table �������������������������������������������������������� 18

14. Maintenance ������������������������������������������������ 18

14.1 Checking the safety valve �������������������������������������18

14.2 Draining the appliance ����������������������������������������18

15. Specification ������������������������������������������������ 19

15.1 Dimensions and connections ��������������������������������� 19

15.2 Data table �������������������������������������������������������� 23

GUARANTEE

ENVIRONMENT AND RECYCLING

OPERATION

1. General information

1.1 Document information

The chapter “Operation” is intended for the equipment user and

the heating contractor.

The chapter “Installation” is intended for the heating contractor.

Note

Read these instructions carefully before using the appliance and retain them for future reference.

Pass on the instructions, if required, to a new user.

1.2 Safety instructions

1.2.1 Structure of safety instructions

KEYWORD Type of risk

!

Here, possible consequences are listed that may result

from failure to observe the safety instructions.

Steps to prevent the risk are listed.

1.2.2 Symbols, type of risk

Symbol Type of risk

!

1.2.3 Keywords

KEYWORD Meaning

DANGER Failure to observe this information will result in serious

WARNING Failure to observe this information may result in serious

CAUTION Failure to observe this information may result in non-

Injury

Electrocution

Burns

(burns, scalding)

injury or death.

injury or death.

serious or minor injury.

1.3 Other symbols in this documentation

Note

General information is identified by the symbol shown

on the left.

Read these texts carefully.

14 | SBS 601-1501 W SOL www.stiebel-eltron.COM

Operation

Safety

Symbol Meaning

!

This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

Material damage

(Appliance and consequential losses, environmental pollution)

Appliance disposal

1.4 Units of measurement

Note

All measurements are given in mm unless stated otherwise.

2. Safety

2.1 Intended use

This appliance is designed for the storage of heating water and for

DHW heating. A glycol/water mixture of up to 60% is permitted

if only dezincification-resistant metals, glycol-resistant gaskets

and diaphragm expansion vessels suitable for glycol are used

throughout the installation.

Any other or additional use is inappropriate, in particular usage

with alternative storage media. Observation of these instructions

and of instructions for any accessories used is also part of the

correct use of this appliance..

2.2 Safety information

WARNING Burns

There is a risk of scalding at outlet temperatures in excess of 43 °C.

3. Appliance description

DThe appliance combines DHW heating and a buffer cylinder for

the hydraulic separation of heating system and heat pump. The

DHW is heated via a corrugated stainless steel internal indirect

coil that functions like an instantaneous water heater. The volume

of the cylinder is an energy store for DHW heating.

The appliance is ideally suited to operation with a heat pump.

In addition, a threaded immersion heater and an auxiliary heat

source can be connected.

SBS W SOL

These appliance types are also equipped with an internal indirect

coil for solar DHW heating and central heating backup.

4. Cleaning, care and maintenance

Have the function of the safety assembly and electrical safety

of the fitted special accessories regularly checked by a heating contractor/electrician.

Never use abrasive or corrosive cleaning agents. A damp

cloth is sufficient for cleaning the appliance.

4.1 Scaling

Almost every type of water deposits limescale at high tem-

peratures. This settles inside the appliance and affects both

the performance and service life. If a flanged immersion

heater is installed, the heating elements must be descaled

from time to time. A heating contractor who knows the local

water quality will tell you when the next service is due.

Check the taps regularly. You can remove limescale deposits

at the tap outlets using commercially available descaling

agents.

Regularly activate the safety valve to prevent it from becom-

ing blocked e.g. by limescale deposits.

ENGLISH

WARNING Injury

!

The appliance may be used by children aged 8 and up and

persons with reduced physical, sensory or mental capabilities or a lack of experience and know-how provided

that they are supervised or they have been instructed

on how to use the appliance safely and have understood

the resulting risks. Children must never play with the

appliance. Children must never clean the appliance or

perform user maintenance unless they are supervised.

Material damage

!

The appliance is under pressure.

During the heating process, expansion water will drip

from the safety valve. If water continues to drip when

heating is completed, please inform your heating contractor.

2.3 Test symbols

See type plate on the appliance.

5. Troubleshooting

Fault Cause Remedy

The outlet flow rate

is low.

If you cannot remedy the fault, notify your heating contractor. To

facilitate and speed up your enquiry, please provide the serial

number from the type plate (no. 000000-0000-000000):

The perlator in the tap or

shower head is scaled up

or contaminated.

Nr. 000000-0000-000000

Clean and/or descale the

perlator or the shower head.

26�03�20�0017

WWW.stiebel-eltron.COM SBS 601-1501 W SOL | 15

Installation

Safety

INSTALLATION

6. Safety

Only qualified contractors should carry out installation, commissioning, maintenance and repair of the appliance.

6.1 General safety instructions

We can only guarantee trouble-free function and operational reliability if original spare parts intended for the appliance are used.

6.2 Instructions, standards and regulations

Note

Observe all applicable national and regional regulations

and instructions.

6.3 Water installation

6.3.1 Cold water line

Steel or copper pipes or plastic pipework are approved materials.

Material damage

!

A safety valve is required.

7. Appliance description

7.1 Standard delivery

Delivered with the appliance:

- 2x temperature sensors

- 2x heat conducting paste

- additional type plate

7.2 Accessories

Depending on the static pressure, safety assemblies and pressure

reducing valves are available. These type-tested safety assemblies

protect the appliance against unacceptable excess pressure.

Flanged immersion heaters, circulation set and thermal insulation

are available as accessories.

8. Assembly

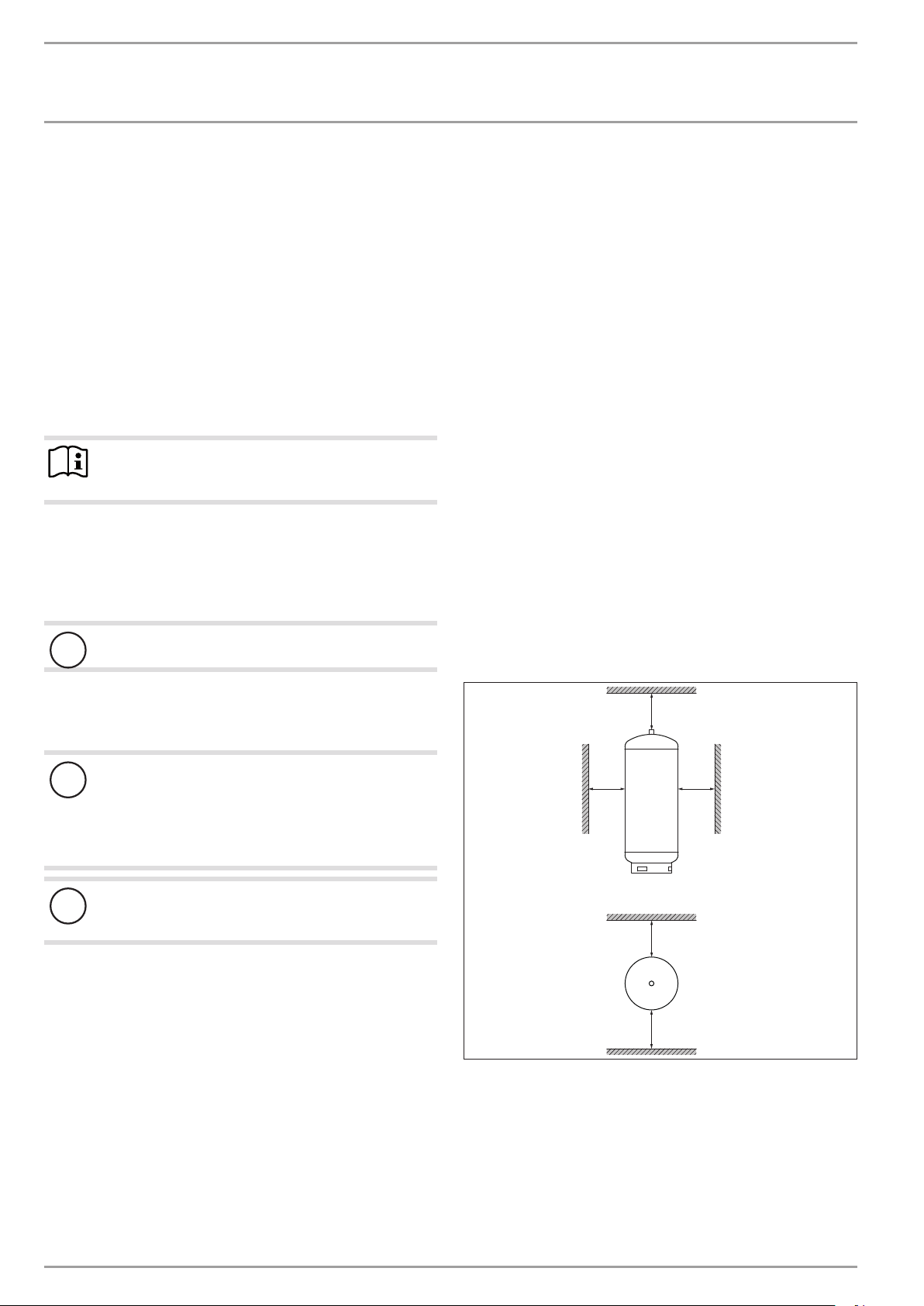

8.1 Installation location

Ensure the floor has a sufficient load bearing capacity (see

chapter “Specification/ Data table”).

Ensure the floor is level.

Check the height of the room and of the unit when tilted (see

chapter “Specification/ Data table”).

Minimum clearances

6.3.2 DHW line

Copper, stainless steel or plastic pipework are approved materials.

Material damage

!

Beim gleichzeitigen Einsatz von Kunststoff-Rohrsystemen

If a flanged immersion heater is fitted and plastic pipework systems are used at the same time, observe the

maximum permissible temperature/ the maximum permissible pressure in chapter “Specification/ Data table”.

Material damage

!

Operate the appliance only with pressure-tested taps and

valves.

≥200≥200

≥200 ≥210

≥800

Maintain the minimum clearances.

8.2 Transport

The lifting eye can be fitted to the top of the appliance to assist

handling.

D0000057346

16 | SBS 601-1501 W SOL www.stiebel-eltron.COM

Loading...

Loading...