STIEBEL ELTRON SBP 100 Komfort, WPKI-H E, WPKI-P E, WPKI-W E, WPKI-V Operating And Installation Instructions

...

Operating and installatiOn instructiOns

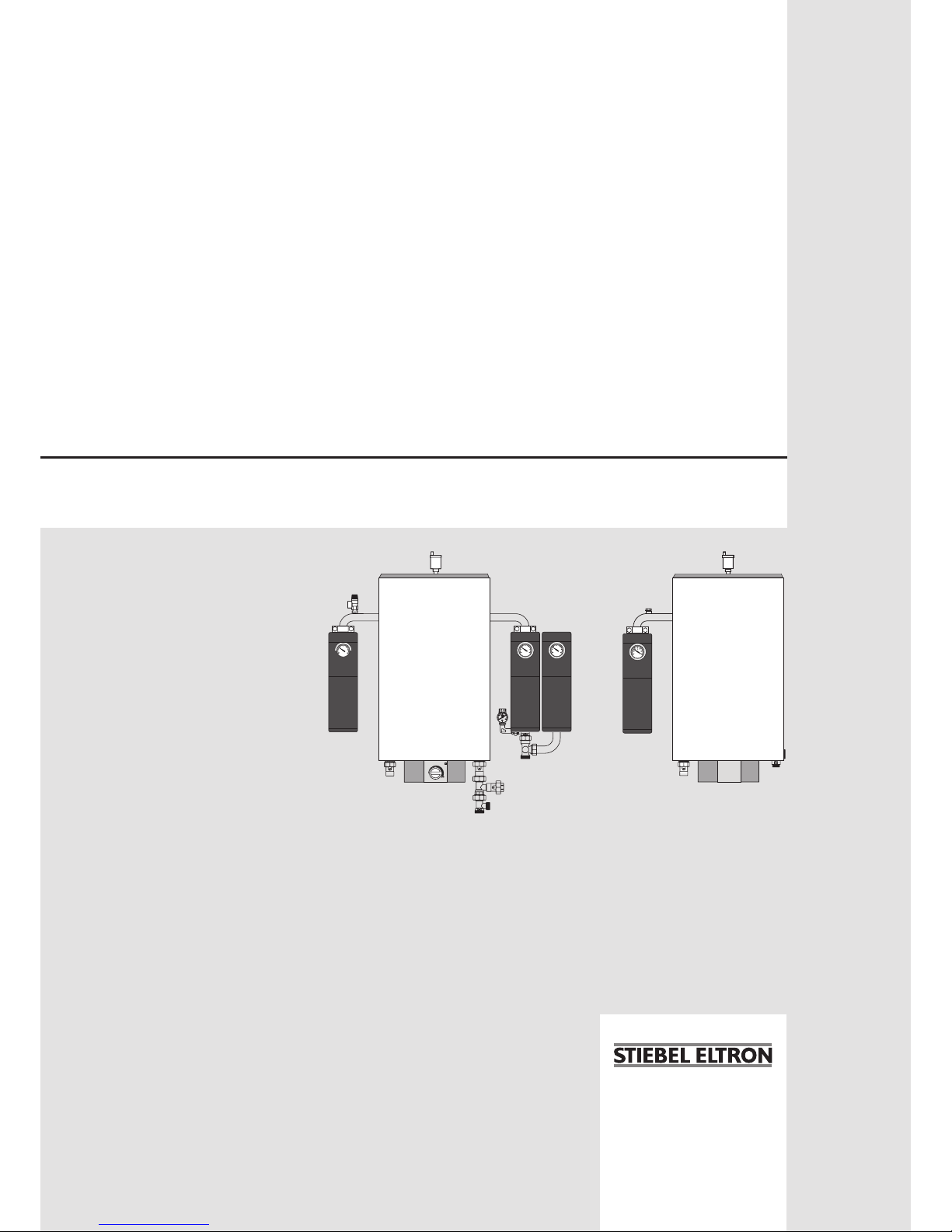

Buffer cylinder with booster heater ange/heat pump compact installation set

» SBP 100 Komfort

» sBp-HF

» WpK i-H e

» WpK i-p e

» WpK i-W e

» WpK i-V

0

bar

2

4

1

3

65°C

20

0

40

60

80

100

120

°C

20

0

40

60

80

100

120

°C

20

0

40

60

80

100

120

°C

2

Dimensions in mm

Inhalt

1 Operating instructions 3

2 Installation instructions SBP 100 Komfort 3

3

Installation instructions SBF-HF 5

4

Installation instructions WPKI-H E,

WPKI-P E, WPKI-W E 6

5 Installation instructions WPKI-H E

and WPKI-V 10

6 Specification 12

Warranty 13

Environment and recycling 13

26_03_01_0345

280

880

510

562

510

350

45 °

10

26_03_01_0340

min. 2200

8

1

9

5

4

510

2

7

562

510

350

6

3

955

880

280

ca.100

282

756

45 °

52

10

26_03_01_0337

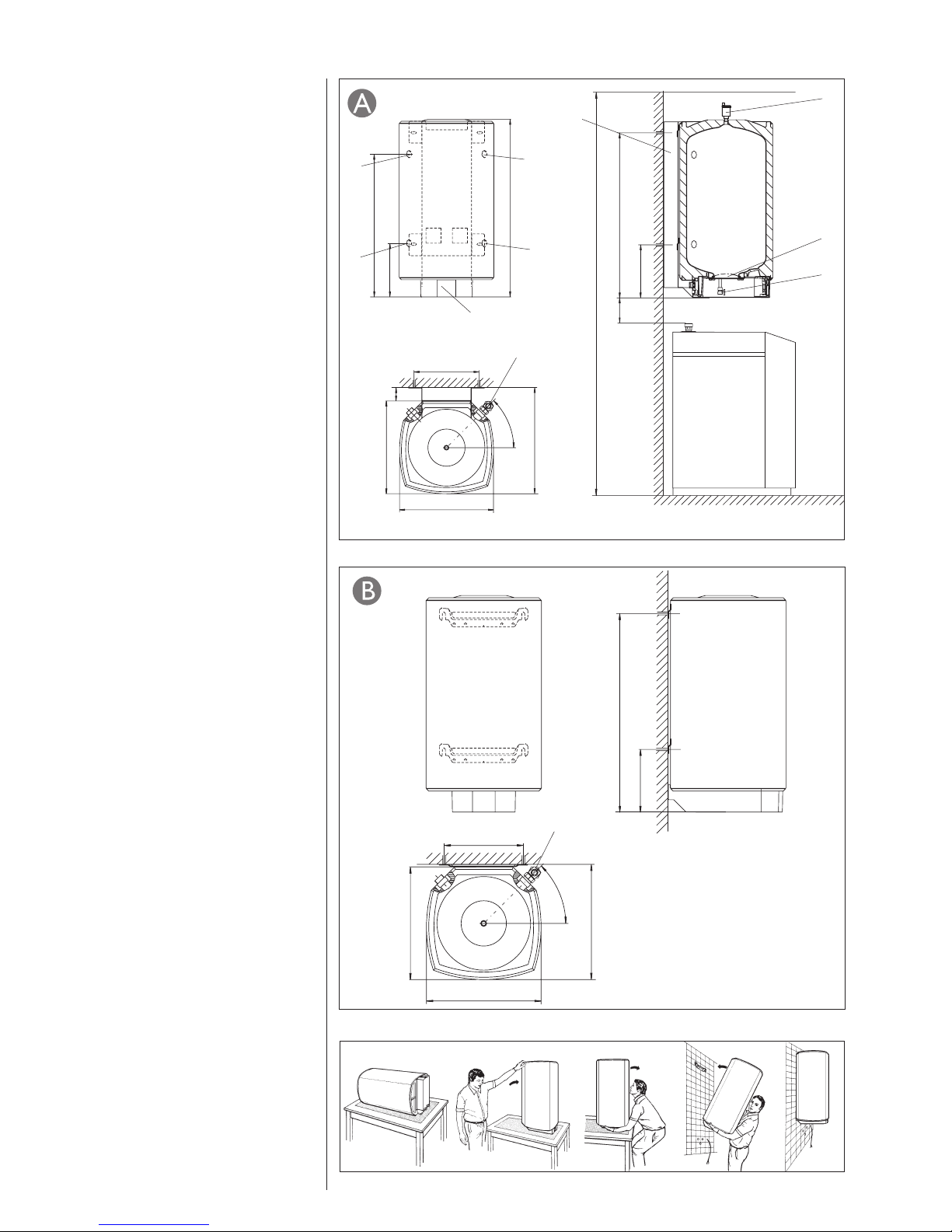

Dimensions in mm

3

2 Installation instructions SBP 100 Komfort for heating contractors

Safety

Intended use

The sealed wall mounted cylinder with 100

l capacity acts as buffer cylinder for heat

pumps.

Observe the application limits listed in the

chapter „Specification / Data table“.

The appliance is intended for domestic use, i.e.

it can be used safely by untrained persons. The

appliance can also be used in a non-domestic

environment, e.g. in a small business, as long

as it is used in the same way.

Any other use beyond that described shall

be deemed inappropriate. Observation of

these instructions and of instructions for any

accessories used is also part of the correct use

of this appliance.

Subject to the relevant system, observe the

installation instructions of the components of

which the system comprises.

WARNING Injury

The appliance may be used by

children aged 8 and up and persons with

reduced physical, sensory or mental

capabilities or a lack of experience provided

that they are supervised or they have been

instructed on how to use the appliance safely

and have understood the resulting risks.

Children must never play with the appliance.

Children must never clean the appliance or

perform user maintenance unless they are

supervised.

Equipment description

A buffer cylinder is recommended to ensure

trouble-free heat pump operation. In addition,

they are designed to separate both heat pump

and heating circuit volume flows.

Equipment layout

There are four G 1 ¼” equipment connections

at the back of the cylinder, which are

matched to the WPKI- .... heat pump compact

installation set.

A G 1/2” connection is provided at the top of

the equipment for the air vent valve supplied

with the cylinder.

At the bottom of the equipment, an aperture is

provided for the electric booster heater.

1 Air vent valve

2 G 1 ¼” flow connector heat pump

compact installation set

3 G 1 ¼” return connector heat

pump compact installation set

4 G 1 ¼” heating flow connector

5 G 1 ¼” heating return connector

6 Type plate SBP 100

7 Cleaning aperture

8 Fill & drain valve

9 Panel

10 Connector with sensor well for return

temperature sensor

Special accessories

Heat pump compact installation sets

The heat pump compact installation sets

WPKI-P, WPKI-H, WPKI-W and WPKI-V are

components of the heat pump system and are

specifically designed for the SBP 100 buffer

cylinder.

Keep these instructions safely and

pass them on to any new user, should

the equipment change hands. Let your

contractor check their content in conjunction

with any maintenance or repair work.

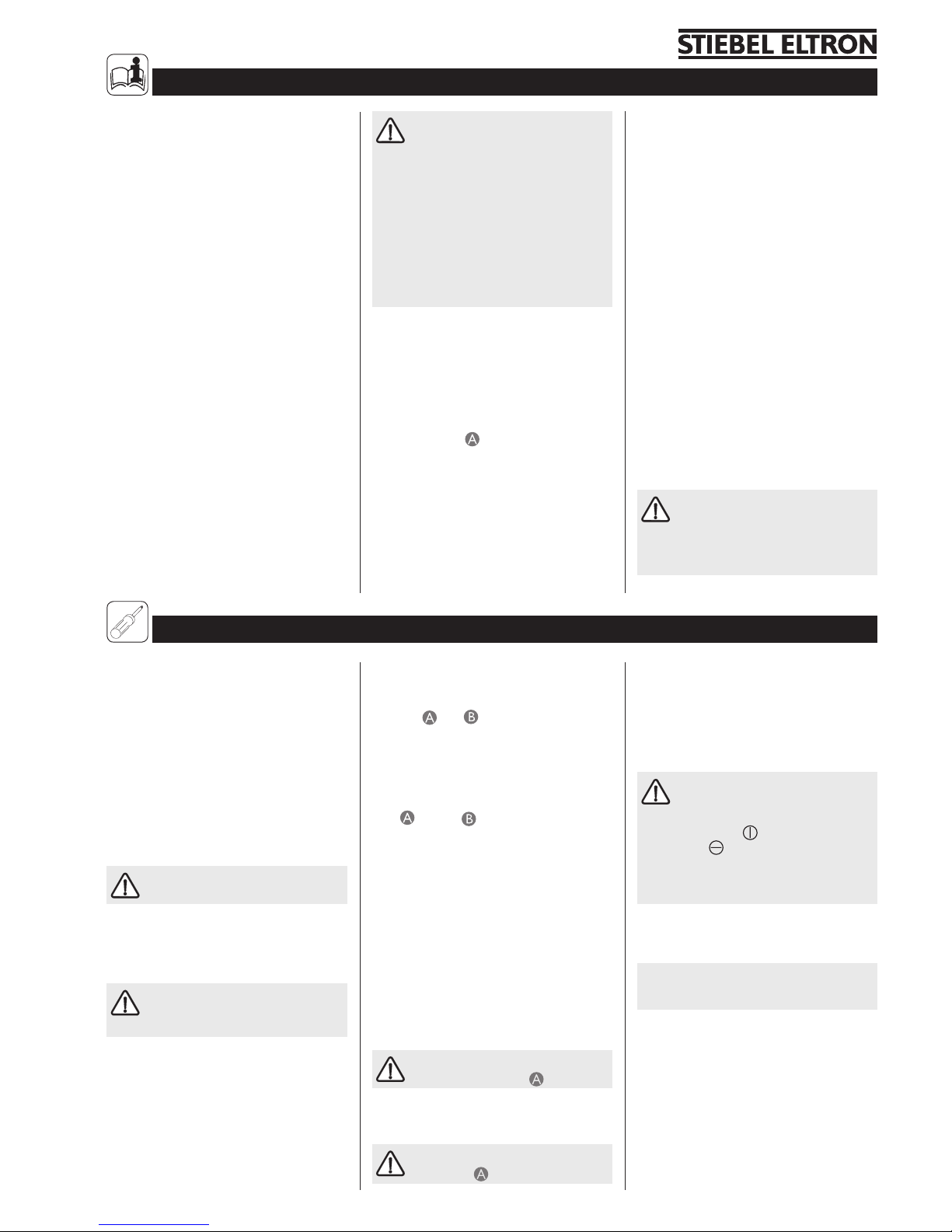

1 Operating instructions for users and contractors

Safety

Only a qualified contractor should carry out

installation, commissioning, maintenance and

repair of the appliance.

General safety instructions

We guarantee trouble-free function and

operational reliability only if the original

accessories and spare parts intended for the

appliance are used.

Instructions, standards and regulations

Observe all applicable national and

regional regulations and instructions.

Transport and packaging

This wall mounted cylinder can be transported

vertically or horizontally.

To prevent cylinder damage, remove

the packaging only at the place of

installation.

Place of installation

The installation location should be protected

from frost. If the system is not in use at times

when a frost is likely, drain the cylinder and all

connected systems to prevent damage.

The room must be at least 2.2 m high.

Ensure that the wall at the installation location

is capable of bearing the full weight of the

cylinder. Install the cylinder vertically, as

shown in and .

Cylinder installation

Prior to fitting the cylinder to the wall, insert

the connector with the sensor well for the

return temperature sensor into the cylinder

body

-10 and -10.

It is recommended that the components in the

WPKl set and the respective circulation pump

are fitted to the cylinder and hand tightened

before the installation.

Fit the heat pump compact installation set

with circulation pumps (see page 6 section

3 “Installation instructions for accessories

WPKI-P, WPKI-H, WPKI-W” and page 11

section 4 “Installation instructions for

accessory WPKI-V”.

Fit the wall mounting panel or mounting

brackets to the respective wall and hook the

cylinder into one or the other fitting.

Observe the gap between the heat

pump and the cylinder .

Select fixing materials in accordance with the

wall construction/condition.

Fit the air vent valve into the top of

the cylinder

-1.

Maintenance

Regularly vent the safety valve until water

streams from it. Close the safety valve after

checking.

Commissioning

(only by a qualified contractor)

1. Fill and vent the cylinder.

2. Check the safety valve function.

Water connection

For connector allocation, see equipment

layout.

Implement the water connections in

accordance with the installation drawings in

the heat pump installation instructions.

For filling, venting and draining the

system, open the non-return valves

of the heat pump compact installation

set, i.e. set them to

. Then return them

into position

. The setting screw of the

WPKI-H non-return valve is located behind

the thermometer.

4

21

8

4

9

7

6 5

2

11

600

710

78.5 110

High limit safety cut-out Controller

1

13

C26_03_01_0336

13

8

10

12

C26_03_01_0339

26_03_01_0342

C26_03_01_0341

D0000035884

20

0

40

60

80

100

120

°C

5

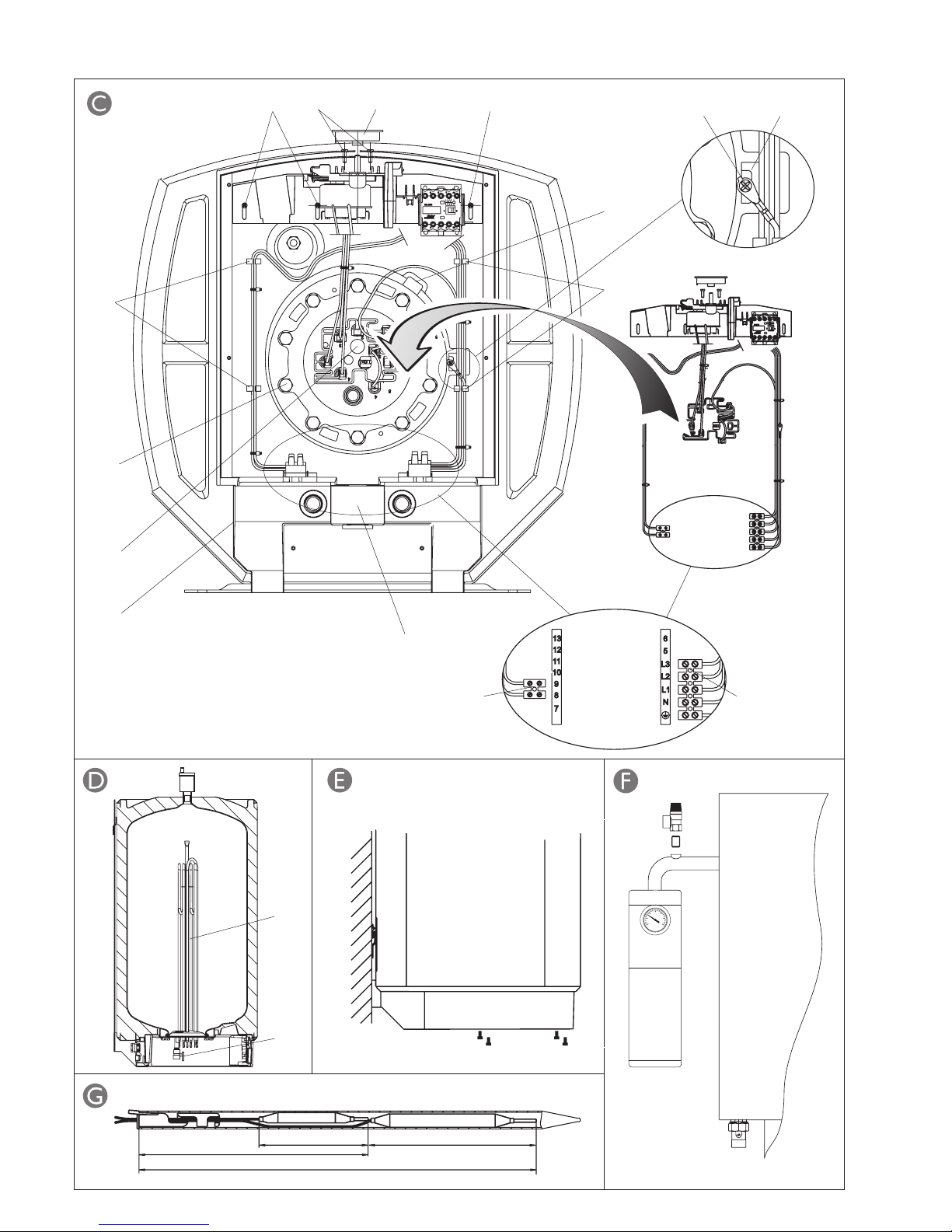

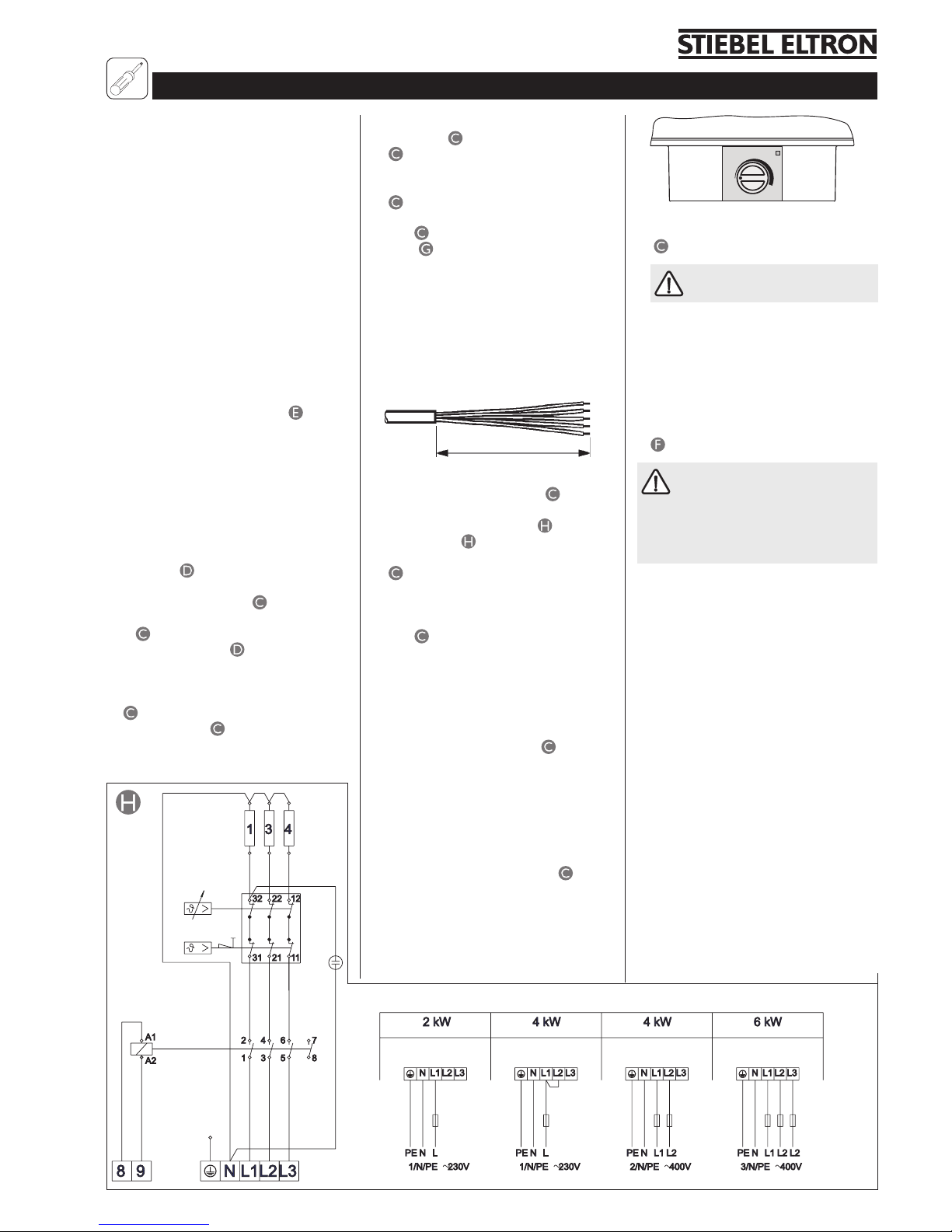

Installing the electric booster heater

SBP-HF Part no. 074252

Instructions and regulations

– DIN VDE 100

– DIN VDE 0701

– Regulations of your local electricity supply

company

– The equipment type plate

The wall mounted cylinder with electric

booster heater is only designed for a

permanently connected power supply in

conjunction with the knock-out cable entry.

The equipment must be able to be separated

from the mains supply, for example by fuses,

which disconnect all poles with at least 3 mm

contact separation.

Fitting the booster heater flange:

– Open the control chamber lid (

).

– When retrofitting the heater:

Drain the water from the cylinder,

release the pipe fittings and remove the

equipment from the wall.

– Remove the drain valve (to be re-used).

– Remove the flange plate. The semi-shells,

pressure plate and insulating plate will

be re-used.

– Install the booster heater flange into the

cylinder ( ), use new gaskets, push on

the insulating plate, position the pressure

plate inside the recess ( -12) of the

plastic casing, and tighten 10 screws

( -4) with 8 Nm.

– Fit the drain valve ( -2) with a new

flange gasket and tighten with 20 Nm.

Fit the wiring set:

– Fit the component support with 3 screws

( -1).

– Fit the terminals ( -5 and 6).

– Secure the earth strap with a self-tapping

screw (M5) (

-9) on the cylinder tab

( -10).

– Secure the straps in the strap holders

( -8).

– Insert the controller bulbs into the sensor

pipe ( -11) until the limiter clicks into

place ( ).

– Push the red plug onto the booster heater

flange.

Mount the cylinder on the wall.

Install the heat pump compact installation

set WPKI-...

Fill the cylinder or the complete system with

water.

Power supply preparation

250 mm

26_03_01_0338

Route the power supply cable through the

PG21 fitting of the strain relief ( -7) and

connect in accordance with the connection

diagram (see wiring diagram ) at the

terminal strip ( -5).

Remove the knock-out in the strain relief

( -7) for the control cable from the heat

pump manager, and route the control

cable via the PG11 fitting into the cylinder.

Connect the control cable at the terminal

strip ( -6) at terminals 8-9.

Control chamber cover

– Remove the adhesive cover strip.

– Affix a new adhesive cover strip and push

firmly down.

– Affix the wiring diagram pad to the

interior of the control chamber cover.

– Undo the controller screws ( -2) from

the support and remove the temperature

selector (to be re-used later).

– Position the control chamber cover and

secure with 4 screws.

– Secure the controller to the control

chamber cover with the previously

undone screws.

– Push the temperature selector ( -3)

onto the controller axis.

26_03_01_0343

65°C

– Affix the rating plate of the booster heater

flange set on the l.h. side of the casing

( -13) and tick the selected output.

Install the safety valve into the

heating flow.

The safety valve must not be able to be

closed towards the cylinder.

The blow-off aperture of the safety valve

must remain open towards the atmosphere.

When using the heat pump compact

installation set WPKI-H, the safety valve can

be inserted into the threaded hole provided

for this purpose in the upper pipe bend (

).

Before and after fitting the control

chamber cover, the contractor must

carry out the following checks in accordance

with DIN VDE 0701

[or local regulations] after fitting the electric

booster heater:

Visual inspection of:

– The condition and security of the control

chamber cover, the adhesive strip and

the temperature selector.

– Connecting cables.

– Strain relief and cable routing.

– Cable routing.

– Positioning of the capillary tubes from

the temperature controller and the

temperature limiter.

Check the earth connection

Check the ionisation resistance

Check the system for leaks

Check the safety valve function

Check the safety labels

Function check

Check the heating up and the first

switching of the temperature controller.

26_03_01_0344

3 Installation instructions SBF-HF for heating contractors

Loading...

Loading...