STIEBEL ELTRON SBB 300 WP Trend, SBB 400 WP Trend, SBB 500 WP Trend Operation And Installation

BEDIENUNG UND INSTALLATION

OPERATION AND INSTALLATION

UTILISATION ET INSTALLATION

BEDIENING EN INSTALLATIE

ANVÄNDNING OCH INSTALLATION

OBSLUHA A INSTALACE

OBSŁUGA I INSTALACJA

KEZELÉS ÉS TELEPÍTÉS

ЭКСПЛУАТАЦИЯ И МОНТАЖ

KÄYTTÖ JA ASENNUS

Warmwasser-Standspeicher für Wärmepumpen | Floorstanding DHW cylinder for heat

pumps | Ballon d‘eau chaude sanitaire sur socle pour pompes à chaleur | Staande

warmwaterboiler voor warmtepompen | Stående ackumulatortank för varmvatten

för värmepumpar | Stojatý zásobník teplé vody pro tepelná čerpadla | Stojący

zasobnik c.w.u do pomp ciepła | Álló melegvíztartály hőszivattyúkhoz | Напольный

накопительный водонагреватель для тепловых насосов| Lattiamalliset lämminvesivaraajat

lämpöpumpuille

» SBB 300 WP Trend

» SBB 400 WP Trend

» SBB 500 WP Trend

ENGLISH

www.stiebel-eltron.com SBB WP Trend | 13

CONTENTS | OPERATION

General information

OPERATION

1. General information ��������������������������������������� 13

1.1 Safety instructions ����������������������������������������������13

1.2 Other symbols in this documentation ���������������������� 13

1.3 Units of measurement ����������������������������������������� 14

2. Safety �������������������������������������������������������� 14

2.1 Intended use ����������������������������������������������������� 14

2.2 Safety instructions ����������������������������������������������14

2.3 Test symbols ����������������������������������������������������� 14

3. Appliance description ������������������������������������� 14

4. Cleaning, care and maintenance ������������������������� 14

4.1 Scaling ������������������������������������������������������������ 14

5. Troubleshooting �������������������������������������������� 14

INSTALLATION

6. Safety �������������������������������������������������������� 15

6.1 General safety instructions ����������������������������������� 15

6.2 Instructions, standards and regulations ������������������� 15

7. Appliance description ������������������������������������� 15

7.1 Required accessories ������������������������������������������15

7.2 Further accessories���������������������������������������������15

8. Preparations ������������������������������������������������ 15

8.1 Installation site �������������������������������������������������� 15

8.2 Transport ��������������������������������������������������������� 15

9. Installation �������������������������������������������������� 16

9.1 Removing / fitting the cylinder casing ��������������������� 16

9.2 Indirect coil connection ���������������������������������������� 16

9.3 Water connection and safety assembly �������������������� 16

9.4 Temperature sensors������������������������������������������� 16

10. Commissioning ��������������������������������������������� 17

10.1 Initial start-up ��������������������������������������������������� 17

10.2 Recommissioning ����������������������������������������������� 17

11. Shutting down the system �������������������������������� 17

12. Troubleshooting �������������������������������������������� 17

13. Maintenance ������������������������������������������������ 17

13.1 Checking the safety valve ������������������������������������� 17

13.2 Checking / replacing the protective anode ���������������� 17

13.3 Draining the appliance ���������������������������������������� 17

13.4 Cleaning and descaling the appliance ���������������������� 17

14. Specification ������������������������������������������������ 18

14.1 Dimensions and connections ��������������������������������� 18

14.2 Details on energy consumption ������������������������������ 21

14.3 Data table �������������������������������������������������������� 21

GUARANTEE

ENVIRONMENT AND RECYCLING

OPERATION

1. General information

The chapter "Operation" is intended for appliance users and qualified contractors.

The chapter "Installation" is intended for qualified contractors.

Note

Read these instructions carefully before using the appliance and retain them for future reference.

Pass on the instructions to a new user if required.

1.1 Safety instructions

1.1.1 Structure of safety instructions

!

KEYWORD Type of risk

Here, possible consequences are listed that may result

from failure to observe the safety instructions.

Steps to prevent the risk are listed.

1.1.2 Symbols, type of risk

Symbol Type of risk

Injury

Electrocution

Burns

(burns, scalding)

1.1.3 Keywords

KEYWORD Meaning

DANGER Failure to observe this information will result in serious

injury or death.

WARNING Failure to observe this information may result in serious

injury or death.

CAUTION Failure to observe this information may result in non-seri-

ous or minor injury.

1.2 Other symbols in this documentation

Note

General information is identified by the symbol shown

on the left.

Read these texts carefully.

!

OPERATION

Safety

14 | SBB WP Trend www.stiebel-eltron.com

Symbol Meaning

Material losses

(appliance damage, consequential losses and environmental pollution)

Appliance disposal

This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

1.3 Units of measurement

Note

All measurements are given in mm unless stated otherwise.

2. Safety

2.1 Intended use

The appliance is intended for domestic use. It can be used safely

by untrained persons. The appliance can also be used in a non-domestic environment, e.g. in a small business, as long as it is used

in the same way.

This appliance is designed to heat DHW with heat pumps.

Any other use beyond that described shall be deemed inappropri-

ate. Observation of these instructions and of instructions for any

accessories used is also part of the correct use of this appliance.

2.2 Safety instructions

WARNING Burns

There is a risk of scalding at outlet temperatures in excess of 43 °C.

!

WARNING Injury

The appliance may be used by children aged 8 and up and

persons with reduced physical, sensory or mental capabilities or a lack of experience and know-how, provided

that they are supervised or they have been instructed on

how to use the appliance safely and have understood

the resulting risks. Children must never play with the

appliance. Children must never clean the appliance or

perform user maintenance unless they are supervised.

!

Material losses

The appliance is pressurised.

During the heat-up process, expansion water will drip

from the safety valve. If water continues to drip when

heating is completed, please inform your qualified contractor.

2.3 Test symbols

See type plate on the appliance.

3. Appliance description

The DHW is heated via a smooth tube internal indirect coil. In

addition, a threaded immersion heater can be connected. You

can use the appliance to supply one or several draw-off points.

The appliance is equipped with an inspection flange and thermometer.

The steel cylinder is coated on the inside with special directly applied “anticor

®

” enamel and is equipped with a protective anode.

This anode protects the inside of the cylinder from corrosion. The

cylinder is surrounded by foam insulation and a plastic jacket.

4. Cleaning, care and maintenance

Have the function of the safety assembly and electrical safe-

ty of the fitted accessories regularly checked by a qualified

contractor.

Have the protective anode checked by a qualified contractor

after the first two years of use. The qualified contractor will

then determine the intervals at which it must be checked

thereafter.

Never use abrasive or corrosive cleaning agents. A damp

cloth is sufficient for cleaning the appliance.

4.1 Scaling

Almost every type of water will deposit lime at high temperatures.

This settles inside the appliance and affects both the performance

and service life. If a threaded immersion heater is installed, the

heating elements must be descaled from time to time. A qualified

contractor who knows the local water quality will tell you when

the next service is due.

Check the taps regularly. Limescale deposits at the spouts

can be removed using commercially available descaling

agents.

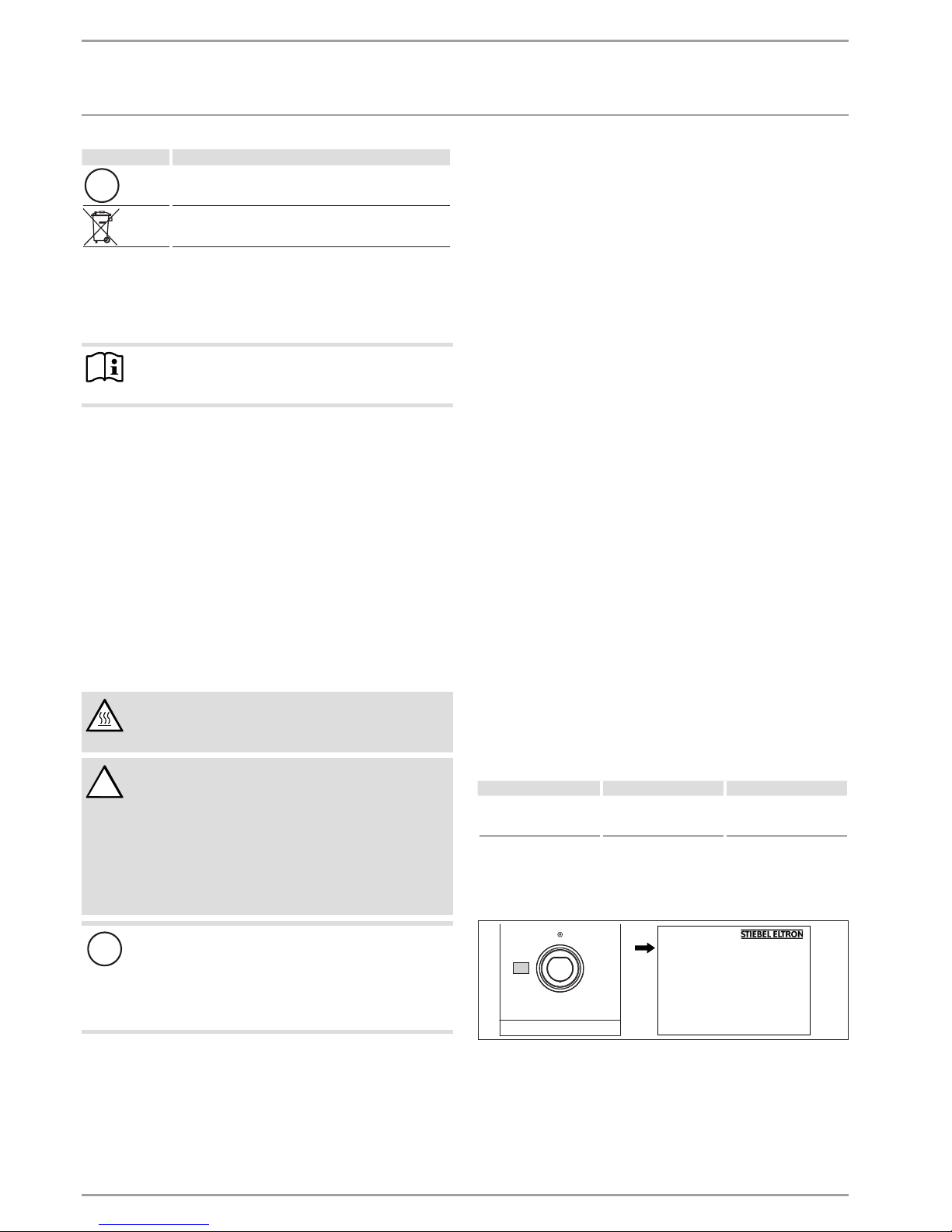

5. Troubleshooting

Problem Cause Remedy

The flow rate is low. The aerator in the tap or

the shower head is scaled

up or contaminated.

Clean and/or descale the

aerator or shower head.

If you cannot remedy the fault, notify your qualified contractor.

To facilitate and speed up your enquiry, please provide the serial

number from the type plate (no. 000000-0000-000000):

Nr. 000000-0000-000000

D0000063493

!

ENGLISH

www.stiebel-eltron.com SBB WP Trend | 15

INSTALLATION

Safety

INSTALLATION

6. Safety

Only a qualified contractor should carry out installation, commissioning, maintenance and repair of the appliance.

6.1 General safety instructions

We can only guarantee trouble-free function and operational reliability if original spare parts intended for the appliance are used.

6.2 Instructions, standards and regulations

Note

Observe all applicable national and regional regulations

and instructions.

7. Appliance description

7.1 Required accessories

Depending on the static pressure, safety assemblies and pressure

reducing valves are available. These type-tested safety assemblies

protect the appliance against unacceptable excess pressure.

7.2 Further accessories

Threaded immersion heaters are available as accessories.

If it is not possible to insert a rod anode from above, install a

segmented anode.

8. Preparations

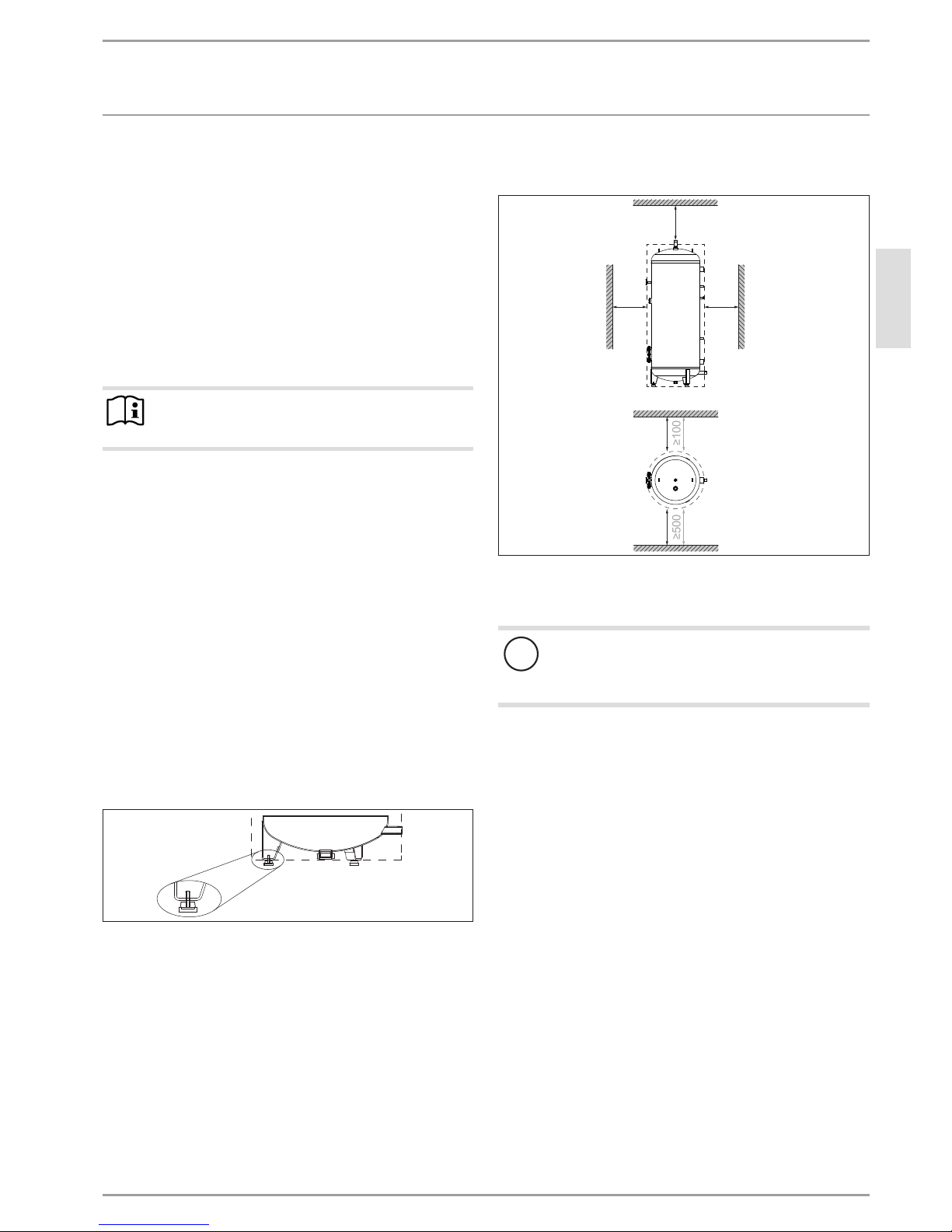

8.1 Installation site

Always install the appliance in a room free from the risk of

frost and near the draw-off point.

26�05�20�0004

Ensure the floor is level. Use the adjustable feet to compen-

sate for any unevenness in the floor.

Ensure the floor has a sufficient load bearing capacity (see

chapter "Specification / Data table").

Observe the room height and height when tilted (see chapter

"Specification / Data table").

Minimum clearances

The minimum side clearances can be swapped to left or right.

≥300

≥300≥800

≥500

≥100

≥100

≥500

D0000059973

Maintain the minimum clearances.

8.2 Transport

!

Material losses

We recommend removing the cylinder casing for transportation to the installation location to prevent it from

becoming dirty or damaged.

For transportation, the appliance is secured to the pallet with

metal brackets.

Remove the screws from the pallet.

Turn the metal brackets to the inside of the adjustable feet

under the appliance.

Loading...

Loading...