STIEBEL ELTRON SBB 300 S, SBB 400 S, SBB 600 Plus, SBB 300 S Plus, SBB 400 S Plus Operating And Installation Instruction

...

OPERATING ANd INSTALLATION INSTRUCTIONS

SINGLE ANd dUAL hEAT EXChANGER SOLAR STORAGE TANKS

›› SBB 300, 400 S & SBB 300, 400, 600 PLUS

ENGLISh

WWW.STIEBEL-ELTRON-USA.COM SBB S & SBB PLUS SOLAR STORAGE TANKS | 1

1. CONTENTS

SECTION PAGE

1. Contents __________________________________________________________ 2

2. Safety Instructions _______________________________________________ 3

3. Operation and Service ___________________________________________ 4

3.1 Start-up __________________________________________________________________4

4. Maintenance and Cleaning ______________________________________ 4

4.1 Pressure Relief Valve ___________________________________________________ 4

4.2 Decalcification ___________________________________________________________ 4

4.3 Sacrificial Anode – Inspection / Replacement _____________________4

5. Failures – Cause – Correction ___________________________________ 5

6. Technical Specifications __________________________________________ 5

6.1 Technical Data & Specifications ______________________________________ 6

6.2 Dimensions ______________________________________________________________ 7

7. Installation Instructions - General ______________________________ 8

7.1 Set-up_____________________________________________________________________8

7.1.1 Brief Description of the Appliance - Applications ________________8

7.1.2 Connections ______________________________________________________________8

7.2 Delivery Configuration _________________________________________________ 8

7.3 Tasks to be performed by Installer __________________________________ 8

7.4 Regulations and Standards ___________________________________________ 8

8. Set-up and Installation __________________________________________ 9

8.1 Set-up_____________________________________________________________________9

8.2 Connections ______________________________________________________________9

8.3 Heater Installation ______________________________________________________ 9

8.4 Hot Water Installation _________________________________________________9

8.4.1 Local Site Conditions ___________________________________________________ 9

8.4.2 Required Pipe Combinations _________________________________________ 9

8.4.3 Cold Water Supply Safety Components _____________________________ 9

8.4.4 Pressure Regulator Settings __________________________________________9

8.4.5 Before Filling ____________________________________________________________ 9

8.4.6 Drainage and Re-circulation _________________________________________ 9

8.5 Hot Water Temperature Probe ______________________________________12

8.6 Solar Storage Tank – Temperature Probe _________________________12

8.7 Connection to the Solar Unit ________________________________________12

8.8 Sacrificial Anode _______________________________________________________12

9. Temperature & Pressure Relief Valve Assembly ______________13

10. Warranty _________________________________________________________15

2 | SBB S & SBB PLUS SOLAR STORAGE TANKS WWW.STIEBEL-ELTRON-USA.COM

2. SAFETY INSTRUCTIONS

ENGLISH

General Information

Read this entire manual. Failure to follow all the guides,

instructions and rules could cause personal injury or property

damage. Improper installation, adjustment, alteration, service and

use of this unit can result in serious injury.

This unit must be installed by a professional installer. The

installation must comply with all national, state and local plumbing

and electric codes. Proper installation is the responsibility of the

installer. Failure to comply with the installation and operating

instructions or improper use voids the warranty.

Save these instructions for future reference. Installer should leave

these instructions with the consumer.

Service of the unit must be performed by a qualified service agency.

Never set the solar loop pressure greater than potable (domestic)

water supply pressure. If the potable water pressure is too low, a

booster pump may be needed to assure that it exceeds the required

solar loop pressure.

If you have any questions regarding the installation, use or operation

of this water heater, or if you need any additional installation

manuals, please call our technical service line at 800-582-8423

(USA and Canada only). If you are calling from outside the USA or

Canada, please call USA 413-247-3380 and we will refer you to a

qualified Stiebel Eltron service representative in your area.

THIS IS THE SAFETY ALERT SYMBOL. IT IS USED TO ALERT YOU

TO POTENTIAL PERSONAL INJURY HAZARD. OBEYALLSAFETY

MESSAGES THAT FOLLOW THIS SYMBOL TO AVOID POSSIBLE INJURY OR

DEATH.

Safety Instructions

WARNING: NEVER INSTALL ANY VALVES OR SHUTOFF DEVICES IN

THE PIPING BETWEEN THE COLLECTORS AND THE SAFETY VALVE.

THE SAFETY VALVE IS ACTUATED AT 87 PSI PRESSURE.

DANGER: WATER TEMPERATURES OVER 125°F CAN CAUSE SEVERE

BURNS INSTANTLY OR DEATH FROM SCALDING. A HOT WATER

SCALDING POTENTIAL EXISTS IF THE THERMOSTAT ON THE UNIT IS SET

TOO HIGH. HOUSEHOLDS WITH SMALL CHILDREN, DISABLED OR ELDERLY

PERSONS MAY REQUIRE THAT THE THERMOSTAT BE SET AT 120°F OR

LOWER TO PREVENT POSSIBLE INJURY FROM HOT WATER.

DANGER: SETTING THE MAXIMUM TANK TEMPERATURE HIGHER

THAN 140°F AT THE CONTROL UNIT IS PERMISSIBLE ONLY IN

CONJUNCTION WITH A THERMOSTATICALLY-CONTROLLED DHW MIXING

VALVE. OTHERWISE THERE CAN BE A RISK OF SCALDING AT THE DRAWOFF

POINT.

CAUTION: ALL SENSOR WIRING SHOULD BE RATED FOR EXPECTED

TEMPERATURES AND MUST BE PROTECTED FROM DEGRADATION

AND ELECTRICAL INTERFERENCE.

Solar Loop

Use only a mixture of 50% GRAS (food grade) Propylene Glycol and

de-ionized water. (Heat Exchanger type SW, AWWA Fluid Class II see MSDS for handling instructions.)

WARNING: FLUID MAY BE DISCHARGED AT HIGH TEMPERATURE

AND/OR PRESSURE. THERE CAN BE A RISK OF SCALDING AT THE

DISCHARGE POINT.

WWW.STIEBEL-ELTRON-USA.COM SBB S & SBB PLUS SOLAR STORAGE TANKS | 3

NO OTHER FLUID SHALL BE USED THAT WOULD CHANGE THE ORIGINAL

CLASSIFICATION OF THIS SYSTEM. UNAUTHORIZED ALTERATIONS TO THIS

SYSTEM COULD RESULT IN A HAZARDOUS CONDITION.

3. OPERATION AND SERVICE

3.1 Start-up

The hydronic back-up boiler (see Figure 5) and solar storage

tank (see Figures 4 & 5), constitute a functional unit. Hot water is

generated throughout the year by the solar collectors (see Figure 4).

Supplemental heat is provided by the back-up boiler when there is

insufficient solar energy available (see Figure 5).

The entire heater and hot water system must be filled with water

and have adaquate air ventilation. Please refer to the solar

collector’s and the boiler’s installation instructions.

4. MAINTENANCE AND CLEANING

Routine care and maintenance extends the life expectancy and

operating safety of the hot water storage unit. The outer casing

should be cleaned with a slightly damp cloth and commercially

available neutral cleaning agent. This should be done on a regular

basis.

4.1 Temperature / Pressure Relief Valve

WARNING: THE T&P RELIEF VALVE IS DESIGNED TO RELIEVE BUILT

UP PRESSURE IN THE WATER HEATER. FLUID MAY BE DISCHARGED

AT HIGH TEMPERATURE AND/OR PRESSURE. SCALDING HOT WATER

INJURIES CAN OCCUR.

NOTICE: THE WATER HEATER AND T&P RELIEF VALVE SHOULD BE

INSTALLED AND PIPED IN AND TO AN AREA WHERE WATER DISCHARGE

AND LEAKING WILL NOT CAUSE PROPERTY DAMAGE.

The proper function of the Temperature / Pressure (“T&P”) relief

valve is required to prevent damage to the hot water storage unit.

The T&P valve needs to be open during cold-water addition. The

water has to flow from the relief line at full stream.

4.3 Replacement of the Sacrificial Anode

Depending on the composition of the tap water, an inspection

of the sacrificial anode (Pos. 1, Figure 1) at timely intervals is

recommended. With heavy wear, an original equipment replacement

anode must be installed to protect the inner container from

corrosion. An inspection should be performed at least once a year.

4.2 Decalcification

With hard tap water, a deposit of scale will form on the inside of

the storage unit. Based on professional experience, it is necessary

to decalcify with commercially available solvents at timely intervals.

Follow the manufacturers instructions for solvent use. The hot water

storage unit needs to be emptied. The inspection cover must be

removed and sediments on the tank bottom must be flushed.

4 | SBB S & SBB PLUS SOLAR STORAGE TANKS WWW.STIEBEL-ELTRON-USA.COM

5. FAILURES – CAUSES – CORRECTION

Failures Causes Correction

Inadequate water pressure Shut-off valve is not completely open.

Cold or hot water line is obstructed.

Hot water flow inadequate

Hot water storage tank not being heated Program selection at the heater control is not

Outlet quantity inadequate Aerator at the extraction point blocked. Unscrew aerator and clean.

Hot water supply exhausted too quickly Flow rate too high. Recommended 2.6-3.9 gal./min.

Boiler temperature is set too low.

Recommended 176 to 185 °F / 80 to 85 °C.

Heat exchanger is calcified.

properly selected.

or 9.8-14.8 l/min.

Open Shut-off valve. Clean or exchange pipes.

Set boiler to recommended temperature.

Clean heat exchanger.

Select and set program per instructions.

Restrict spigot valve rate.

6. TECHNICAL SPECIFICATIONS

ENGLISH

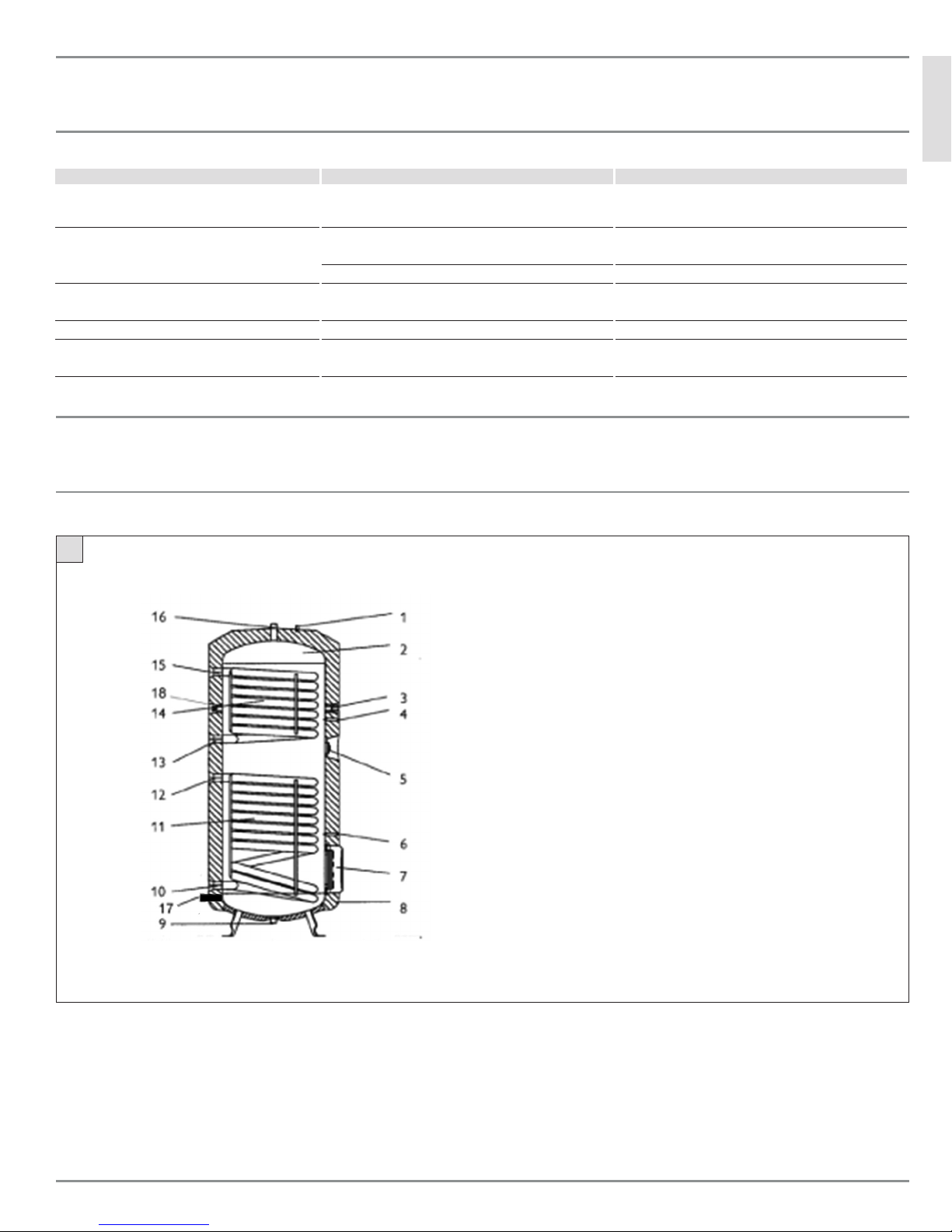

1

Components of the SBB S / SBB Plus

1. Sacrifical anode indicator

2. Glass lined steel tank

3. Thermometer well

4. Immersion sleeve for boiler temperature probe

5. Spare port

6. Immersion sleeve for solar temperature probe

7. Inspection port

8. Expanded polystyrene-thermal insulation

9. Cold water inlet (SBB 300 & 400 S/Plus)

10. Heat exchanger solar return

11. Solar/main heat exchanger

12. Heat exchanger solar feed

13. Heat exchanger boiler return (SBB 300, 400, 600 Plus)

14. Upper heat exchanger (SBB 300, 400, 600 Plus)

15. Heat exchanger boiler feed (SBB 300, 400, 600 Plus)

16. Warm water outlet / T&P relief valve location

17. Cold water inlet (SBB 600 Plus)

18. Circulation port

WWW.STIEBEL-ELTRON-USA.COM SBB S & SBB PLUS SOLAR STORAGE TANKS | 5

Loading...

Loading...