STIEBEL ELTRON HydroShark 7, HydroShark 10, HydroShark 12, HydroShark 14, HydroShark 19 Operation And Installation Manual

...Page 1

OPERATION AND INSTALLATION

UTILISATION ET INSTALLATION

Electric Modulating Micro-Boiler

»HydroShark 7

»HydroShark 10

»HydroShark 12

»HydroShark 14

»HydroShark 19

»HydroShark 24

»HydroShark 29

»HydroShark 36

HydroShark 7 - HydroShark 10:

Conforms to ANSI/UL Std. 499

Certifi ed to CAN/CSA Std. E335-1 & E335-2-35

Conforme à la norme ANSI/UL Std. 499

Certifi é à la norme CAN/CSA Std. E335-1 & E335-2-35

HydroShark 12 - HydroShark 36:

Conforms to ANSI/UL Std. 834

Certifi ed to CAN/CSA C22.2 No 64

Conforme à la norme ANSI/UL Std. 834

Certifi é à la norme CAN/CSA C22.2 No 64

Page 2

HydroShark Electric Boiler (7-36 KW)

Installation Manual and Owner’s Guide

HydroShark 12 - HydroShark 36

UL 834

HydroShark 7 - HydroShark 10

UL 499

The

HydroShark Electric Boiler features advanced

technology, impressive energy-saving performance,

and a compact design. Exclusively manufactured by

Stiebel Eltron, a leader in heating technologies for the

past 80 years.

Featuring

• Effi ciency: 100 %

• Wall Hung

• Flow Activated: .5 GPM

• Copper Heating Vessel

• Temperature Range: 86°-140° F*

• No Venting Required

• Modulation Status LED

Do not return to stores. Dam-

ages or repairs call

Stiebel Eltron 800.805.5384

Models:

HydroShark 7

HydroShark 10

HydroShark 12

HydroShark 14

HydroShark 19

HydroShark 24

HydroShark 29

HydroShark 36

2 | HYDROSHARK WWW.HYDRO-SHARK.COM

If you have any questions,

please call or write to:

17 West St.

West Hatfi eld, MA 01088

Page 3

CONTENTS

Installation Manual

SPECIFICATIONS..........................................................................................................4

INTRODUCTION............................................................................................................5

MOUNTING THE UNIT...................................................................................................6

INSTALLATION...............................................................................................................7

Electrical Connections.........................................................................................7

Fluid connections.................................................................................................10

Technical Data.....................................................................................................10

Wiring Diagrams...................................................................................................11

APPLICATIONS..............................................................................................................12

OWNER’S GUIDE

TROUBLESHOOTING..................................................................................................15

General...............................................................................................................15

Components Diagram.........................................................................................16

PARTS LIST...................................................................................................................17

PRESSURE DROP TABLE............................................................................................18

IMPORTANT!

BOILERS ARE TO BE USED FOR RADIANT FLOOR HEATING ONLY!**

THIS MANUAL MUST BE READ CAREFULLY BEFORE ATTEMPTING TO INSTALL THE HydroShark

BOILERS. IF YOU DO NOT FOLLOW THE SAFETY RULES OR THE INSTRUCTIONS OUTLINED

IN THIS MANUAL, THE UNIT MAY NOT OPERATE PROPERLY AND IT COULD CAUSE PROPERTY

DAMAGE, SERIOUS BODILY INJURY AND/OR DEATH.

MANUFACTURER WILL NOT BE LIABLE FOR ANY DAMAGES BECAUSE OF FAILURE TO COMPLY

WITH INSTALLATION AND OPERATING INSTRUCTIONS OUTLINED IN THIS MANUAL OR BECAUSE OF IMPROPER USE. IMPROPER USE INCLUDES THE USE FOR THIS APPLIANCE TO HEAT

ANY LIQUID OTHER THAN WATER OR PROPYLENE GLYCOL. FAILURE TO COMPLY WITH THE

INSTALLATION AND OPERATING INSTRUCTIONS OR IMPROPER USE VOIDS THE WARRANTY.

NEVER REMOVE THE UNITS FRONT COVER UNLESS POWER IS TURNED OFF.

IF YOU HAVE ANY QUESTIONS REGARDING THE INSTALLATION OR OPERATION OF THESE BOILER,

PLEASE CALL OUR TECHNICAL SERVICE LINE AT 800.805.5384.

**Unless when used with Stiebel Eltron DHW Integrator Panels (Use HydroShark 29 or HydroShark 36 KW Boilers only with

Combi Panel Systems, Size boilers accordingly)

WWW.HYDRO-SHARK.COM HYDROSHARK| 3

Page 4

Installation Manual

CONGRATULATIONS

Congratulations and thank you for choosing our micro boiler. Before use, we

recommend that you read through this installation manual carefully. Keep

this manual for future reference.

If you need an additional manual, contact the manufacturer or your local

distributor. When you call, please tell us the product name and the serial

number of your unit written on the rating plate of the boiler.

4 | HYDROSHARK WWW.HYDRO-SHARK.COM

Page 5

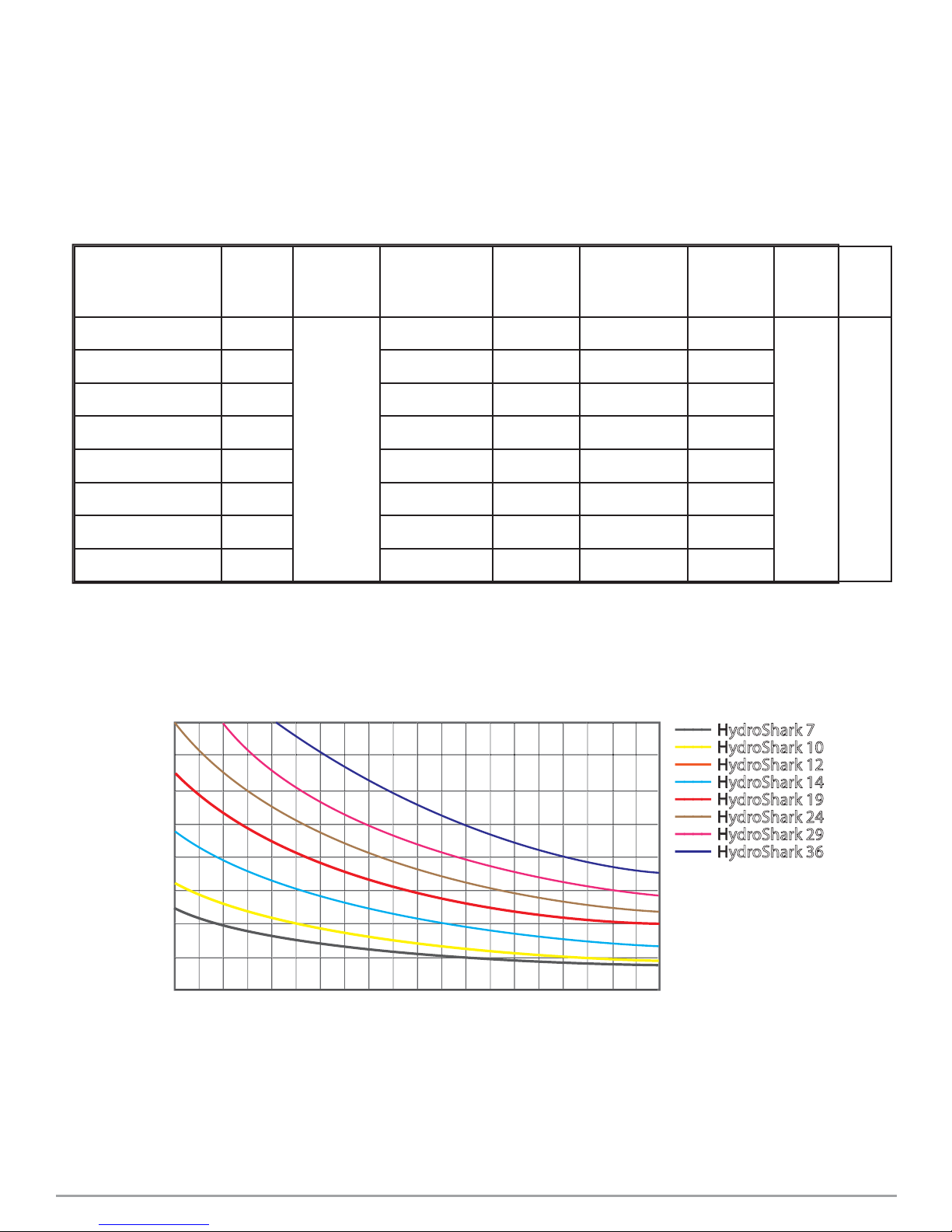

SPECIFICATIONS

HYDROSHARK

AMP

MODEL KW VOLTS WIRE SIZE

HydroShark 7 7

HydroShark 10 10 6 40 (1) 50 32,765

HydroShark 12 12 4 50 (1) 70 40,956

HydroShark 14 14 2 x 8 60 (2) 40 49,147

240

HydroShark 19 19 2 x 6 80 (2) 50 65,526

HydroShark 24 24 2 x 4 100 (2) 70 81,912

HydroShark 29 29 3 x 6 120 (3) 50 98,977

HydroShark 36 36 3 x 4 150 (3) 70 122,868

8 30 (1) 40 24,573

DRAW

(MAX)

DBL POLE

BREAKER

SIZE

BTU

HydroShark Boiler Temp vs Flow Rate

8

7

6

5

4

with 70 Deg F Return Fluid

____

HydroShark 7

____

HydroShark 10

____

HydroShark 12

____

HydroShark 14

____

HydroShark 19

____

HydroShark 24

____

HydroShark 29

____

HydroShark 36

WATER

TEMP

RANGE

86° - 140° F

3

2

Boiler Flow-GPM

1

0

90 100 110 120 130

WWW.HYDRO-SHARK.COM HYDROSHARK| 5

140

DEG F

Page 6

INTRODUCTION

IMPORTANT!

Read this entire manual. Failure to follow all the guides, instructions and rules could cause personal

injury or property damage. Improper installation, adjustment, alteration, service and use of this unit

can result in serious injury.

This unit must be installed by a licensed electrician and plumber. The installation must comply with

all national, state and local plumbing and electric codes. Proper installation is the responsibility of the

installer. Failure to comply with the installation and operating instructions or improper use voids the

warranty.

Save these instructions for future reference. Installer should leave these instructions with the consumer.

If you have any questions regarding the installation, use or operation of this micro boiler, or if you

need any additional installation manuals call Stiebel Eltron at 800.805.5384 or visit us online at www.

hydro-shark.com

GENERAL

• The output of heat from the boiler is electronically controlled. The boiler will deliver any water temperature between 86° F - 140° F. Set the desired water delivery temperature using the knob on the

front cover. (Do not exceed temperatures above 130° when using this product with tubing in

concrete)

• When the power light is fl ashing, full element power is being applied. When the power light is not

fl ashing, the element power is being modulated to the water delivery temperature.

• Recommend setting for radiant fl oor heating (Tubing in Concrete) is 105° F - 125° F.

• Recommended setting for Staple Up (Floor Warming Only) is 130° - 140° F.

• Temperature setting and water delivery temperatures may vary depending on fl ow rates. Size boil-

er accordingly. See fl ow rate chart for more information.

6 | HYDROSHARK WWW.HYDRO-SHARK.COM

Page 7

MOUNTING THE UNIT

UNIT MUST BE INSTALLED IN A VERTICAL POSITION WITH THE WATER FITTINGS POINTING DOWNWARD. DO NOT INSTALL UNIT WHERE

IT WOULD ROUTINELY BE SPLASHED WITH WATER OR ELECTRICAL

SHOCK MAY RESULT.

1. Leave a minimum of 5” clearance on all sides for servicing.

2. Make sure the power is off.

3. Remove the cover.

4. Mount securely to wall by putting screws through mounting holes.

5. Screws and plastic wall anchors for mounting are provided.

A

B

C

Dimensions

A

B

C

D

E

F

3

G

/

16

2

1

3

G

EDF

WWW.HYDRO-SHARK.COM HYDROSHARK| 7

Page 8

INSTALLATION

ELECTRICAL CONNECTIONS

WARNING: BEFORE BEGINNING ANY WORK ON THE ELECTRIC INSTAL-

LATION, BE SURE THAT THE MAIN BREAKER PANEL SWITCHES ARE

“OFF” TO AVOID ANY DANGER OF ELECTRIC SHOCK. ALL MOUNTING

AND PLUMBING MUST BE COMPLETED BEFORE PROCEEDING WITH

ELECTRICAL HOOK-UP. WHERE REQUIRED BY LOCAL,STATE OR NATIONAL ELECTRICAL CODES THE CIRCUITS SHOULD BE EQUIPPED

WITH A “ GROUND FAULT INTERRUPTER”.

1. All electrical work must comply with the national, state, local & any other applicable codes.

2. The boiler should be connected to properly grounded dedicated branch circuits of proper

voltage rating. Ground must be brought to the ‘Ground’ at the circuit breaker panel.

3. HydroShark 12 can be connected to ONE independent circuit.

4. A HydroShark 14, HydroShark 19 & HydroShark 24 can be connected to TWO independent

circuits Use supply table. Protected by TWO double pole breakers sized for the load.

5. A HydroShark 29 and HydroShark 36, can be connected to THREE independent circuits.

Use supply cable protected by THREE double pole breakers sized for the load.

6. Cut the electrical connection cable to length and strip.

7. The wire must be fed through the knockouts located between the Supply and Return fl uid con-

nections. The “Live” wires must be connected to the slots on the terminal block marked “L” and

“L”. The ground wire must be connected to slot marked with the ground symbol.

8. Reinstall the cover screws.

WARNING! As with any electrical appliance, failure to electrically ground may result in serious injury or Death.

8 | HYDROSHARK WWW.HYDRO-SHARK.COM

Page 9

ELECTRICAL CONNECTIONS CONT’D

HydroShark 12 HydroShark 14, 19, 24

CKT 1

CKT 1

FFO

F

FO

NO

NO

CKT 2

FFO

FF

O

FF

O

FF

O

NO

NO

NO

NO

WWW.HYDRO-SHARK.COM HYDROSHARK| 9

Page 10

ELECTRICAL CONNECTIONS CONT’D

HydroShark 29, 36

CKT 1

CKT 2

CKT 3

FFO

FFO

FFO

FFO

FFO

FFO

N

O

N

O

NO

NO

NO

N

O

CIRCUIT CONNECTION

Please refer to specifi cation table for wiring and circuit breaker size. See technical data section for

wiring diagrams.

10 | HYDROSHARK WWW.HYDRO-SHARK.COM

Page 11

FLUID CONNECTIONS

NOTE: EXCESSIVE HEA T FROM SOLDERING COPPER PIPES NEAR THE BOILER MAY CAUSE DAMAGE.

1. All plumbing work must comply with the national, state, local & any other applicable codes.

2. Make sure the radiant fl oor system has been purged & is free of fl oating debris.

3. The return side (inlet) is on the right side of the unit, the supply side (outlet) is on the left of

the unit.

4. A pressure & temperature relief valve should be installed on the hot water supply side (outlet) of the unit. (Stiebel Eltron Pre-Plumbed Panels include pressure relief valve)

5. The boiler is designed for a connection to copper tubing and/or PEX tubing. If soldering the unit

is necessary , please direct the fl ame away from the housing of the unit to avoid damage.

6. When all plumbing work is completed, check for leaks & take corrective action before proceeding.

TECHNICAL DATA

WIRING DIAGRAMS

642

531

6

11/12

5

4

9/10

3

2

7/8

1

13

CKT 1

14 15

4

6

1

3

5

24

51

2

SH-12

42

51

6

11/12

5

4

9/10

3

2

7/8

1

13

CKT 1

14 15

CKT 2

4

2

1

5

SH-14, SH-19

HydroShark 12 HydroShark 14,19

WWW.HYDRO-SHARK.COM HYDROSHARK| 11

Page 12

WIRING DIAGRAMS

642

1

53

462

642

531

6

11/12

5

4

9/10

3

2

7/8

1

13

CKT 1

14 15

CKT 2

4

1

3

HydroShark 24

46

2

642

42

51

6

2

5

SH-24

42

15

42

15

6

11/12

5

4

9/10

3

2

7/8

1

13

CKT 1

14 15

CKT 2

1

CKT 3

4

2

5

SH-29

HydroShark 29

21

4

56

3

351

531

531

6

11/12

5

4

9/10

3

2

7/8

1

13

CKT 1

14 15

CKT 2

1

CKT 3

4

6

3

HydroShark 36

Note:

1. Boilers are considered a continuous load.

2. Copper conductors only .

2

>

5

SH-36

56

2

3

4

1

L

L

12 | HYDROSHARK WWW.HYDRO-SHARK.COM

HydroShark 7, 10

Page 13

APPLICATIONS

Space Heating Applications

• In order to purge air in water pipes within a closed loop system, an air vent,

air separator, and expansion tank should be installed in the system. (Stiebel

Eltron pre-built space heating panels incorporate all of these features).

• Water temperature over 125° F (52° C) can cause sever burns instantly of

WARNING

Stiebel Eltron pre-plumbed panels help make space heating easy and reliable. These panels are

professionally engineered and use proven Primary/Secondary hydronic practices. Call Tech Support

(1-800.805.5384) for assistance.

death from scalding.

• Chemicals such as diluted Glycol can be used for radiant fl oor, Hydro/fan

coil air or Baseboard heating only. The diluted solution of glycol must contain

between 25% and 55% of Glycol. Be aware that in a closed loop system, low

pressure in the heat exchanger can cause low-temperature boiling, resulting

in excessive noise and damage to the micro boiler. Consult with the glycol

maker for specifi cations prior to use.

Stiebel Eltron Pre-Built Space Heating Panels

Sample:

HSPS120LT 1 Zone Panel:

For more information on Stiebel Eltron pre-plumbed panels and zoning options for this boiler please

visit www.hydro-shark.com or call 800.805.5384.

WWW.HYDRO-SHARK.COM HYDROSHARK| 13

Page 14

Dual-purpose hot water heating

(Domestic and Space Heating)

Insert a Stiebel Eltron DHW integrator Panel to provide potable heated water and Hydronic Heating

(with space heating panel(s)) with one heat source.

The Stiebel Eltron DHW Integrator Panel integrates with a wide variety of boilers and delivers “Priority” potable heated water with no storage tank and hydronic space heating in a small reliable package.

Follow all local codes, or in the absence of local codes, follow the most recent

NOTICE

edition of the National Standard Code, ANSI Z21.10.3.

For more information on Stiebel Eltron DHW Integrator panels and integrating space heating and domestic water for this boiler please visit www.hydro-shark.com or call 800.805.5384.

NOTICE

Use Combi Panel with HydroShark 29 or HydroShark 36 Boilers Only. Size boiler

for domestic and radiant applications accordingly.

14 | HYDROSHARK WWW.HYDRO-SHARK.COM

Page 15

Owner’s Guide

CONGRATULATIONS

Congratulations and thank you for choosing our micro boiler. Before

use, we recommend that you read through this owner’s guide carefully.

Keep this manual for future reference.

If you need an additional manual, contact the manufacturer or your local

distributor. When you call, please tell us the product name and the serial

number of your unit written on the rating plate of the boiler.

WWW.HYDRO-SHARK.COM HYDROSHARK| 15

Page 16

TROUBLESHOOTING

Symptom Possible Cause Solution

General

No Hot Water •No Power

•Safety ermal Cut O Tripped

•Not Enough Flow Rate To Activate

•Plugged Flow Sensor

Water Not Hot Enough •Water Flow Too High

•Voltage To Low

•Glycol/Water Ratio Too High

•Manifold or Ball Valve Closed

LEDs Do Not Light •Problem With Electronic Controls Call Tech Support at 800.805.5384

•Utility Controlling Load

•Reset ermal Cut O

•Wrong Size Pump

•Activate ermostat/

Clean Flow Sensor

•Reduce Water Flow Rate

•Supply Correct Voltage to Unit

•More than 20%, less than 50%

•Open Loops/Ball Valves

16 | HYDROSHARK WWW.HYDRO-SHARK.COM

Page 17

COMPONENTS DIAGRAM

A

I

C

D

E

A- Fluid Temp.Controller

B- High Limit Safety

C- Flow Meter

D- Wiring Terminal

E- Control Board

WWW.HYDRO-SHARK.COM HYDROSHARK| 17

B

H

F- Cold Fluid Return - 3/4” MPT

G- Electrical Circuit Knock-Outs

H- Hot Fluid Supply - 3/4” MPT

I- Hinged Cover on 12- 36 KW Units

G

F

Page 18

PARTS LIST

Part Number Description

286356 Housing, HydroShark 12 to HydroShark 36

245307 Temperature Control Knob, HydroShark 12 to HydroShark 36

279998 Wiring Block, HydroShark 7 to HydroShark 12

279997 Wiring Block, HydroShark 14 to HydroShark 24

279996 Wiring Block, HydroShark 29 to HydroShark 36

286360 Heating System, HydroShark 12

286361 Heating System, HydroShark 14

286362 Heating System, HydroShark 19

286364 Heating System, HydroShark 24

286373 Heating System, HydroShark 29

286374 Heating System, HydroShark 36

286369 High Limit, HydroShark 7 to HydroShark 36

286366 Electronic Control Device Board, HydroShark 12

286844 Electronic Control Device Board, HydroShark 14 to HydroShark 19

286367 Electronic Control Device Board, HydroShark 24

296888 Electronic Control Device Board, HydroShark 29

296889 Electronic Control Device Board, HydroShark 36

286461 Flow Sensor, HydroShark 7 to HydroShark 36

278698 Plumbing Connection, S-R 3/4” NPT

286359 Electronic Temp Control, HydroShark 7 to HydroShark 36

280677 Outlet Temperature Sensor, HydroShark 7 to HydroShark 36

280730 Set Point Knob Board, HydroShark 12 to HydroShark 36

292575 Housing, HydroShark 7 to HydroShark 10

291851 Electronic Control Device Board, HydroShark 7 to HydroShark 10

283455 Code Plug, HydroShark 7 to HydroShark 10

292578 Back Panel, HydroShark 7 to HydroShark 10

291699 Return Fluid Connection, HydroShark 7 to HydroShark 10

278634 Supply Fluid Connection, HydroShark 7 to HydroShark 10

292577

Cover, HydroShark 7 to HydroShark 10

254312

18 | HYDROSHARK WWW.HYDRO-SHARK.COM

Axis Connection Plug, HydroShark 7 to HydroShark 10

Page 19

Boiler Pressure Drops Table

(Boilers HydroShark 7 to HydroShark 36)

This table is used for sizing Primary (Boiler) Circulator

All boilers must use Primary/Secondary circuitry. This is used to create Hydraulic

seperation between the Boiler and Emitter circulators allowing you to create

69

57.5

46

34.5

23

11.5

0

30

25

HydroShark 29, 36

20

15

HydroShark 7, 10

10

5

HydroShark 12

0

0 .5 1 1.5 2 2.5 3 3.5 4 4.5 5

HydroShark 14, 19, 24

FLOW GPM

(PSI)

(HD Feet)

Flow Pressure

Flow Pressure

WWW.HYDRO-SHARK.COM HYDROSHARK| 19

Page 20

STIEBEL ELTRON, Inc.

17 West Street | West Hatfield MA 01088

Tel. 800-805-5384

hydroshark@stiebel-eltron-usa.com

www.hydro-shark.com

4<AMHCMO=bgibea>

Subject to errors and technical changes! |

Sous réserve d‘erreurs et de modifi cations techniques!

Subject to errors and technical changes!

331125-40419-9328

Loading...

Loading...