Page 1

OPERATION AND INSTALLATION

UTILISATION ET INSTALLATION

Condensing Gas Micro-boiler

»HydroShark 199NG

»HydroShark 199LP

Conforms to ANSI Z21.10.3/CSA 4.3

Conforme à la norme ANSI Z21.10.3/CSA 4.3

Page 2

HydroShark 199 Condensing Gas Micro Boiler

Installation Manual and Owner’s Guide

Models:

HydroShark 199NG

HydroShark 199LP

The HydroShark 199 Condensing

Gas Micro Boiler is a compact and

powerful residential unit with a versatile

BTU modulating range.

Featuring

• Effi ciency: 95 %

• Wall Hung

• Flow Activated: .5 GPM

• Copper Heat Exchanger

• Temperature Range: 80°-160° F*

• Freeze Protection

• Power Vent

• PVC Venting

*Up to 185 with optional control

Do not return. Damages or repairs call

HydroShark 800.805.5384

If the information in these instructions is

not followed exactly, a fi re or explosion

may result causing property damage,

personal injury or death.

-Do not store or use gasoline or other fl ammable

vapors and liquids in the vicinity of this or any

other appliance.

-WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance

• Do not touch any electric switch, do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fi re department.

-Installation and service must be performed by

a qualifi ed installer, service agency or the gas

supplier.

2 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Page 3

CONTENTS

Installation Manual

SPECIFICATIONS..........................................................................................................4

INTRODUCTIONS..........................................................................................................5

SAFETY GUIDELINES...................................................................................................6

INSTALLATION...............................................................................................................7

General................................................................................................................7

Clearances...........................................................................................................9

Included accessories............................................................................................9

High-altitude installations....................................................................................10

Venting instructions.............................................................................................11

Gas supply and gas pipe sizing..........................................................................21

Water connections..............................................................................................23

Condensate drain...............................................................................................25

Electrical connections.........................................................................................26

APPLICATIONS..................................................................................................27

INITIAL OPERATION..........................................................................................29

OWNER’S GUIDE

OPERATING SAFETY...................................................................................................31

NORMAL OPERATION.................................................................................................33

Temperature controller and Remote controller...................................................33

General..............................................................................................................33

Temperature Settings.........................................................................................34

Temperate table of controller..............................................................................34

Additional features..............................................................................................35

Temperature setting on the PCB (without remote controller).............................36

Flow....................................................................................................................37

Freeze protection system...................................................................................37

Maintenance and service...................................................................................38

Unit draining and fi lter cleaning..........................................................................38

TROUBLESHOOTING..................................................................................................39

General...............................................................................................................39

Error codes.........................................................................................................41

COMPONENTS DIAGRAM...........................................................................................44

PARTS LIST...................................................................................................................48

OUTPUT TEMPERATURE CHART...............................................................................50

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 3

Page 4

Installation Manual

CONGRATULATIONS

Congratulations and thank you for choosing our condensing micro boiler.

Before use, we recommend that you read through this installation manual

carefully. Keep this manual for future reference.

If you need an additional manual, contact the manufacturer or your local

distributor. When you call, please tell us the product name and the serial

number of your unit written on the rating plate of the boiler.

4 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Page 5

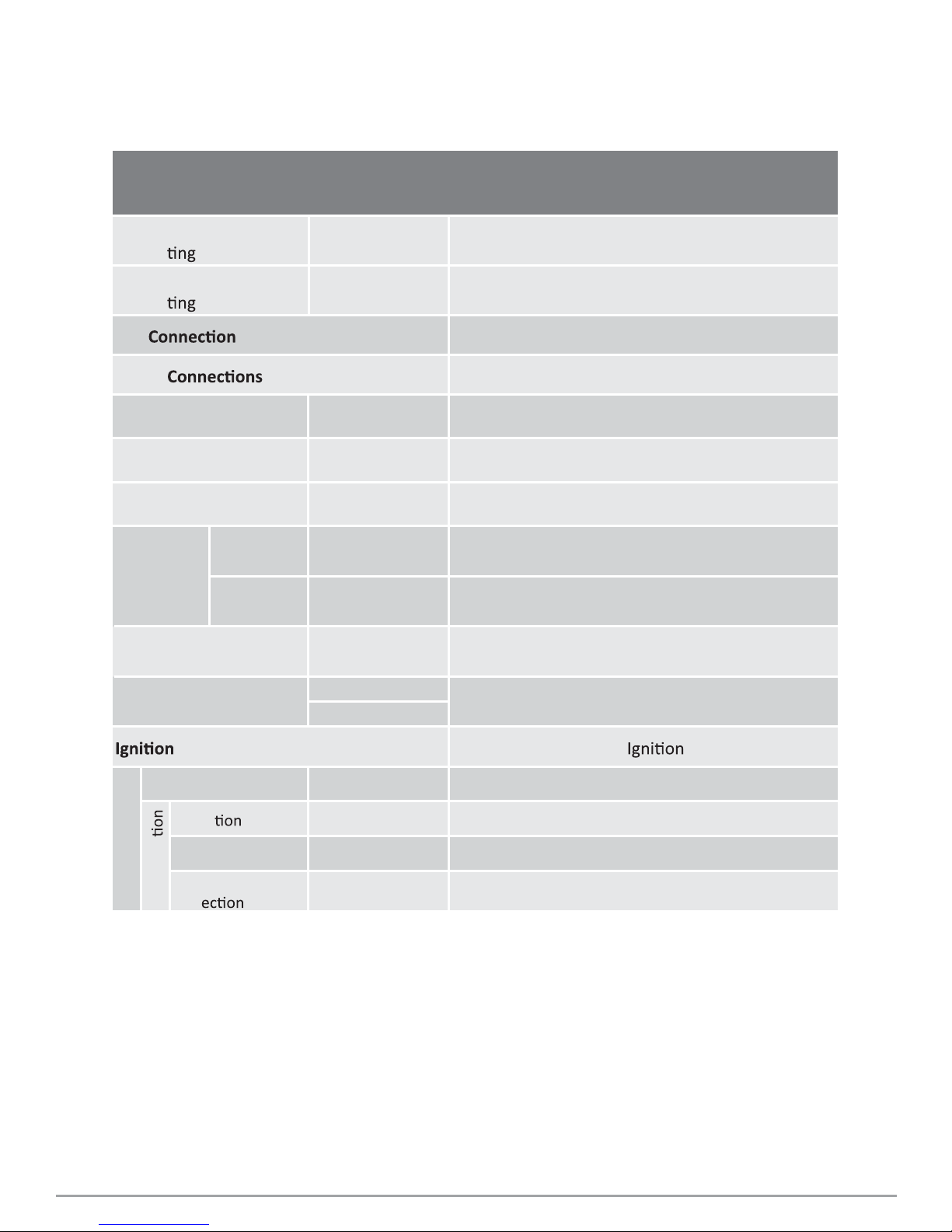

SPECIFICATIONS

HydroShark 199 Gas Condensing Micro-Boiler

Natural Gas Input

(Opera

Range)

Propane Input

(Opera

Range)

Gas

Water

Water Pressure* 15 - 150 (0.1 - 1)

Natural gas

Inlet Pressure

Propane

Inlet Pressure

Natural

Manifold

Pressure**

Gas

Propane

BTU/h

BTU/h

Max.: 199,000

Max.: 199,000

3/4" NPT

3/4" NPT

psi

(MPa)

inch W.C.

(kPa)

inch W.C.

(kPa)

Min. 5.0 (1.24)

Max. 10.5 (2.61)

Min. 8.0 (1.99)

Max. 14.0 (3.48)

inch W.C. 2.95

(Pa) (734)

inch W.C.

(Pa)

3.3

(821)

000,51 :.niM

000,31 :.niM

Weight lbs. (kg) 59 (26.8)

Dimensions

inch

mm

H 22.4 x W 17.7 x D 10.7

H 570 x W 450 x D 272

Electric

Supply

Opera W / A 89.0 / 0.74

Standby W / A 4.2 / 0.04

Electric

Freeze-

Consump

Prot

VAC/Hz 120 / 60

W / A 175 / 1.5

*18-25 PSI is recommended for maximum fl ow (Space Heating)

**The Manifold Pressure is the factory setting and generally should not need adjustment.

NOTE:

• Check the rating plate to ensure this product matches your specifi cations.

• The manufacture reserves the right to discontinue, or change at any time, specifi cations, or

designs without notice and without incurring obligation.

*When using boiler in-conjunction with HydroShark DHW Integrator Panel, system pressure may be much higher on your

domestic water side. Your space heating side should still refl ect the recommended 18-25 PSI for system pressure.

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 5

Page 6

INTRODUCTION

• This manual provides information necessary for the installation, operation, and maintenance of the

boiler.

• The model description is listed on the rating plate which is attached to the side panel of the boiler.

• Please read all instructions completely before installing this product.

• If you have any problems or questions regarding this equipment, consult the manufacturer or its

local representative.

• This equipment is a condensing micro boiler designed to effi ciently supply endless hot water for

your needs. (Radiant Heating, or Domestic Water used in-conjunction with Radiant Heating) See

DHW Integrator Panel for more information on integrating domestic water with your radiant heating system.

• These high effi ciency models have a built-in secondary heat exchanger that absorbs latent heat

from the exhaust gas.

• These boilers are only to be installed indoors.

• The principle behind condensing micro boilers is easy:

Intake port

Exhaust thermistor

Thermistor

Bypass valve

Water control valve

Computer board

Thermistor

Hot water outlet

Thermistor

Exhaust

Secondary

heat exchanger

Primary

heat exchanger

Burners

Gas valves

Fan motor

Flow sensor

Condensate

drain port

Gas

Cold water inlet

*This diagram illustrates condensing micro boiler design concepts only and does not accurately represent the boilers physical description.

1. Your thermostat indicates a need for heat and turns on the circulator pump(s).

2. Water fl ows through the boiler.

3. The fl ow sensor detects the water fl ow .

4. The computer initiates the fan motor and sends a signal to the igniter to create an ignition spark.

5. The gas ignites and fl ames appear within the burner chamber.

6. Water circulates through the heat exchanger and then gets hot.

7. Using thermistors to measure temperatures throughout the micro-boiler, the computer modulates

the gas and water valves to ensure proper output water temperature.

8. When your room reaches desired temperature the pumps turn off and the boiler shuts down.

6 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Page 7

SAFETY GUIDELINES

SAFETY DEFINITION

Indicates an imminently hazardous situation which, if not avoided, will result in

DANGER

WARNING

CAUTION

1. Follow all local codes , or in the absence of local codes, follow the current edition of the National

Fuel Gas Code: ANSI Z223.1/NFPA 54 in the USA or B149.1 Natural Gas, Propane Installation

Code in Canada.

2. Properly ground the unit in accordance with all local codes or in the absence of local codes, with

the National Electrical Codes: ANSI/NFPA 70 in the USA or CSA standard C22.1 Canadian Electrical Code Part 1 in Canada.

3. Carefully plan where you intend to install the micro boiler. Please ensure:

•Your micro boiler will have enough combustible air and proper ventilation

•Locate your micro boiler where water leakage will not damage surrounding areas.

4. Check the rating plate for the correct Gas Type, Gas Pressure, Water Pressure and Electric

Rating.

5. *If this unit does not match your requirements, do not install and consult with the manufacture.

6. If any problem should occur, turn off the unit and unplug the zone controls for the space heating

and/or DHW Integrator Panel system zone controls and turn off the gas. Then call a trained technician or the Gas Company or the manufacture.

death or serious injury.

Indicates an imminently hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates an imminently hazardous situation which, if not avoided, could result in

minor or moderate injury.

GENERAL

• Water temperature over 125°F (52°C) can cause severe burns instantly or

death from scalding. The water temperature is set at 120°F (50°C) from the

factory to minimize any scalding risk. If using micro boiler with HydroShark

DHW Integrator Panel, always check the water temperature. Always verify

WARNING

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 7

emitter water delivery temperature requirements to avoid damage.

• Do not store or use gasoline or other fl ammables, vapors, or liquids in the

vicinity of this appliance.

• Do not reverse the fl uid and/or gas connections as this will damage the gas

valves and can cause sever injury or death.

• Do not use this appliance if any part has been in contact with or been immersed in water. Immediately call a licensed plumber, a licensed gas fi tter, or

a professional service technician to inspect and/or service the unit if necessary.

• Do not disconnect the electrical supply if the ambient temperature will drop

below freezing. The freeze protection system only works if the unit has electrical power. The warranty will not be covered if the heat exchanger is damaged

due to freezing.

Page 8

INSTALLATION

GENERAL

1. Follow all local codes, or in the absence of local codes, follow the current edition of the National

Fuel Gas Code: ANSI Z223.1/NFPA 54 in the USA or B149.1 Natural Gas, Propane Installation

Code in Canada.

2. All gas micro boilers require careful and correct installation to ensure safe and effi cient operation.

This manual must be followed exactly. Read the “Safety Guidelines” section.

3. The manifold gas pressure is preset at the factory. It is computer controlled and should not need

adjustment.

4. Maintain proper space for servicing. Install the unit so that it can be connected or removed easily.

Refer to the “Clearances” section for proper clearance.

5. The micro boiler must be installed in a location where the proper amount of combustible air will be

available to it at all times without obstructions.

6. The electrical connections requires a means of disconnections, to terminate power to the micro

boiler for servicing and safety purposes.

7. Do not install the unit where the exhaust vent is pointing into any opening in the building or where

the noise may disturb your neighbors. Make sure the vent termination meets the required distance

by local code from any doorway or opening to prevent exhaust from entering a building.

8. Particles from fl our, aerosols, and other contaminants may clog the air vent, build up and reduce

the functions of the rotating fan, cause improper burning of the gas, or cause damage to the micro

boiler. Regularly ensure that the area around the unit is dust or debris free. Regular maintenance

is recommended for these types of environment.

9. The HydroShark 199 condensing gas boiler is to be installed indoors only. This unit is equipped

with thermistors and a hi-limit switch for the exhaust gas, detecting excess temperatures within

the fl ue and enabling the unit to safely stop operations. These components are always monitoring

exhaust gas conditions in order to prevent heat damage to ABS, PVC, CPVC, or polypropylene

(Plastic) venting if ABS, PVC, CPVC, or polypropylene is used. If the exhaust gas temperatures

exceeds 140° F, these components will enable the unit to safely stop operations.

• The micro-boiler requires 3” or 4” make-up intake air supply pipe. The intake pipe must be sealed

airtight.

• Air supply pipe can be made of ABS. PVC (solid core), CPVC (solid core), polypropylene, corrugated stainless steel, or Category III/IV stainless steel. Regarding exhaust pipe refer to the “Exhaust section” under venting instructions.

• Sidewall venting is recommend for this boiler. Vertical venting (roof termination) is acceptable.

• The manufacturer recommends running the exhaust vent and the intake pipe as parallel as possible.

8 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Page 9

WARNING

• Installation and service must be performed by a qualifi ed installer (for

example, a licensed plumber or gas fi tter, otherwise the warranty will be

void.

• The installer (licensed professional) is responsible for the correct installation for the micro boiler and for compliance with all national, state /

provincial, and local codes.

• The manufacturer does not recommend installing the micro boiler in a

pit or location where gas and water can accumulate.

• Do not have the vent terminal pointing toward any operating window, door, or

opening into a building.

• Do not install next to any source of airborne debris, such as clothes dryer, that

can cause debris to be trapped inside the combustion chamber, unless the

system is direct vented.

• The manufacturer does not recommend installing the micro boiler in an

attic due to safety issues. If you install the micro boiler in an attic:

-Keep the area around the micro boiler clean. When dust collects on the

fl ame sensor, the micro boiler will shut down on an error code.

-Place the unit for easy access for service and maintenance.

-A drain pan, or other means of protection against water damage, is to be

installed under the micro boiler in case of leaks.

-Make sure the unit will have enough combustion air and proper ventilation.

CAUTION

• The warranty will not cover damage cause by water quality.

-Only distilled water or distilled water/glycol mixtures can be used with this

micro boiler, unless when used in-conjunction with Stiebel Eltron DHW Integrator Panel system. Do not introduce pool or spa water, or any chemically treated

water into the micro boiler.

-Water hardness levels must not exceed 7 grains per gallon (120 ppm) for

single family applications or more than 4 grains per gallon (70 ppm) for all other

types of applications/ Water hardness leads to scale formation and may affect

/ damage the micro boiler. Hard water scaling must be avoided or controlled by

proper water treatment.

-Water pH levels must be between 6.5 and 8.5.

-Well water must be treated.

• Do no install the micro boiler where water, debris, or fl ammable vapors may

get into the fl ue terminal.

• Although the micro boiler is designed to operate with minimal sound, the

manufacturer does not recommend installing the unit on a wall adjacent

to a bedroom, or a room that is intended for quiet study or meditation,

etc.

• Locate your boiler close to a drain where water leakage will not do damage to

surrounding areas. As with any water heating appliance, the potential for leakage at some time in the life of the product does exist. The manufacturer will

not be responsible for any water damage that may occur. If you install a drain

pan under the unit, ensure that it will not restrict the combustion air fl ow.

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 9

Page 10

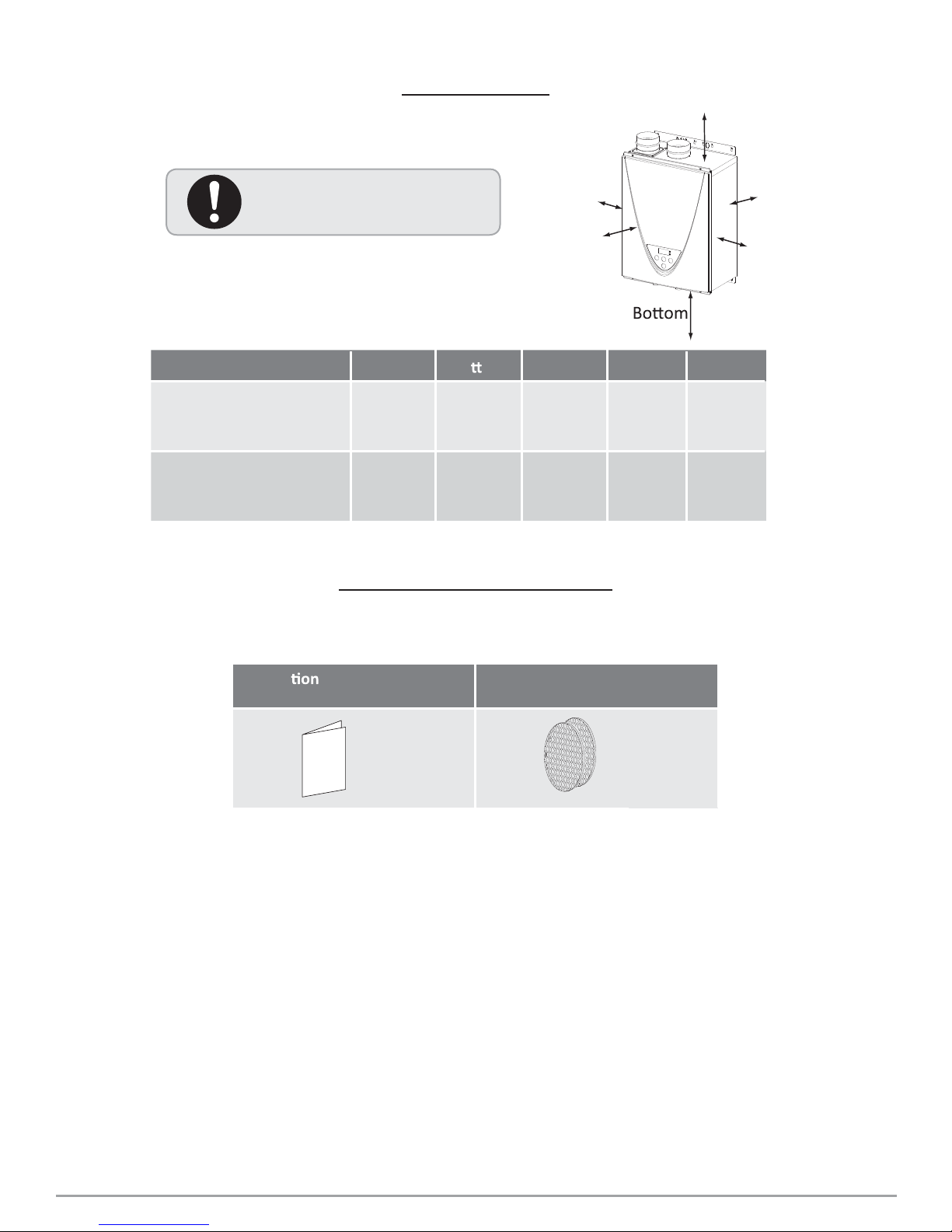

CLEARANCES

To p

Maintain all clearances around

the micro-boiler.

Side

Front

Model Top Bo om Front Back Sides

HydroShark 199LP

(Liquid propane)

HydroShark 199NG

(Natural Gas)

*24 inches recommended for maintenance.

12 in.

(914 mm)

12 in.

(914 mm)

12 in.

(305 mm)

12 in.

(305 mm)

24 in.

(610 mm)

24 in.

(610 mm)

0.5 in.

(13 mm)

0.5 in.

(13 mm)

INCLUDED ACCESSORIES

Check that these items below are included with the micro boiler.

Back

Side

2 in.

(51 mm)

2 in.

(51 mm)

Installa manual and owner’s

guide

1 :ytQ

Bird screen

Qty: 2

10 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Page 11

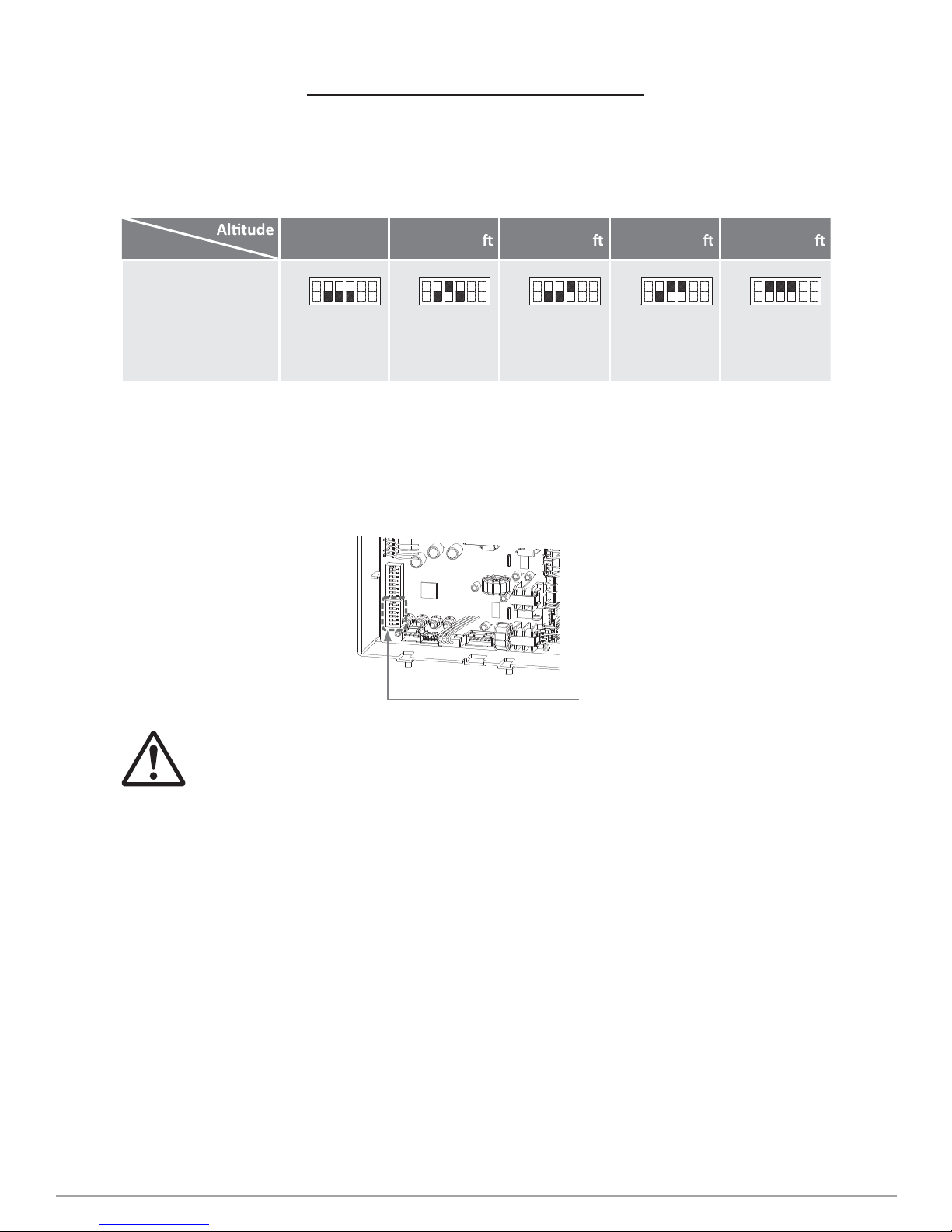

HIGH-ALTITUDE INSTALLATIONS

Check the elevation where your micro boiler is installed. Set DIPswitches shown in the table

below depending on the altitude.

DIPswitches

HydroShark 199 Boiler

(Lower bank of

DIPswitches)

0 (DEFAULT) Up to 2,500 Up to 5,000 Up to 7,500

123456

ON

OFF

No. 2 : OFF

No. 3 : OFF

No. 4 : OFF

123456

ON

OFF

No. 2 : OFF

No. 3 : ON

No. 4 : OFF

123456

ON

OFF

No. 2 : OFF

No. 3 : OFF

No. 4 : ON

123456

ON

OFF

No. 2 : OFF

No. 3 : ON

No. 4 : ON

Up to 10,100

123456

ON

OFF

No. 2 : ON

No. 3 : ON

No. 4 : ON

NOTE: The dark squares indicate the direction the DIPswitches should be set to.

Computer board

Lower bank of DIPswitches

DO NOT adjust any DIPswitches on the upper bank.

WARNING

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 11

Page 12

VENTING INSTRUCTIONS

GENERAL

• Improper venting of this appliance can result in excessive levels of carbon

monoxide which can result in severe personal injury or death.

DANGER

CAUTION

This appliance must be vented in accordance with the section” Venting of Equipment” of the current

edition of the National Fuel Gas Code: ANSI Z223.1/NFPA 54 in the United States and/or Section 8 of

the B149.1 Natural Gas and Propane Installation Code in Canada, as well as applicable local building

codes. The use of venting materials approved for Category III/IV appliances is recommended whenever possible. However, this appliance may also be vented with plastic pipe materials such as ABS,

PVC (solid core), CPVC (solid core), or polypropylene. For details, please refer toe the Exhaust

Vent (ABS, PVC, CPVC, or Polypropylene Vent) Section. Vent installations in Canada which utilize

plastic vent systems must use venting that complies with ULC S636.

• Improper installation can cause nausea or asphyxiation, severe injury or death

from carbon monoxide and fl ue gases poisoning. Improper installation will

void product warranty.

When installing the vent system, all applicable national and local codes must be

followed. If you install thimbles, fi re stops or other protective devices and they

penetrate any combustible or noncombustible construction, be sure to follow all

applicable national and local codes.

General rules for venting micro boilers are:

• Place the micro boiler as close as possible to the vent termination.

• The vent collar of the micro boiler must be fastened directly to an unobstructed vent pipe.

• Do not weld the vent pipe to the micro boiler’s vent collar.

• Do not cut the vent collar of the unit.

• The vent must be easily removable from the top of the boiler for normal service and inspection of

the unit.

• The micro boiler vent must not be connected to any other gas appliance or vent stack except an

approved common venting system.

• Avoid using an oversized vent pope or using extremely long runs of the pope unless it is part of an

approved common vent system.

• For rooftop venting, a rain cap or other from of termination that prevents rain water from entering

into the micro boiler must be installed.

• Do not terminate vent into chimney. If the vent must go through the chimney, the vent must run all

the way through the chimney with approved vent pipe.

General rules for vent terminations:

• Avoid locating the micro boiler vent termination near any air intake devices. These fans can pick

up the exhaust fl ue products from the micro boiler and return them to the building. This can create

a health hazard.

• Locate the vent termination so that it cannot be blocked by any debris, at any time. Most codes require that the termination be at least 12 in. (305 mm) above grade, but the installer may determine

if it should be higher depending on the job site condition and applicable codes.

• A proper sidewall termination is recommended when the micro boiler is vented through a sidewall.

• Be sure to check the clearance form the exhaust termination to the air inlet or opening in the vent

termination clearances section.

12 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Page 13

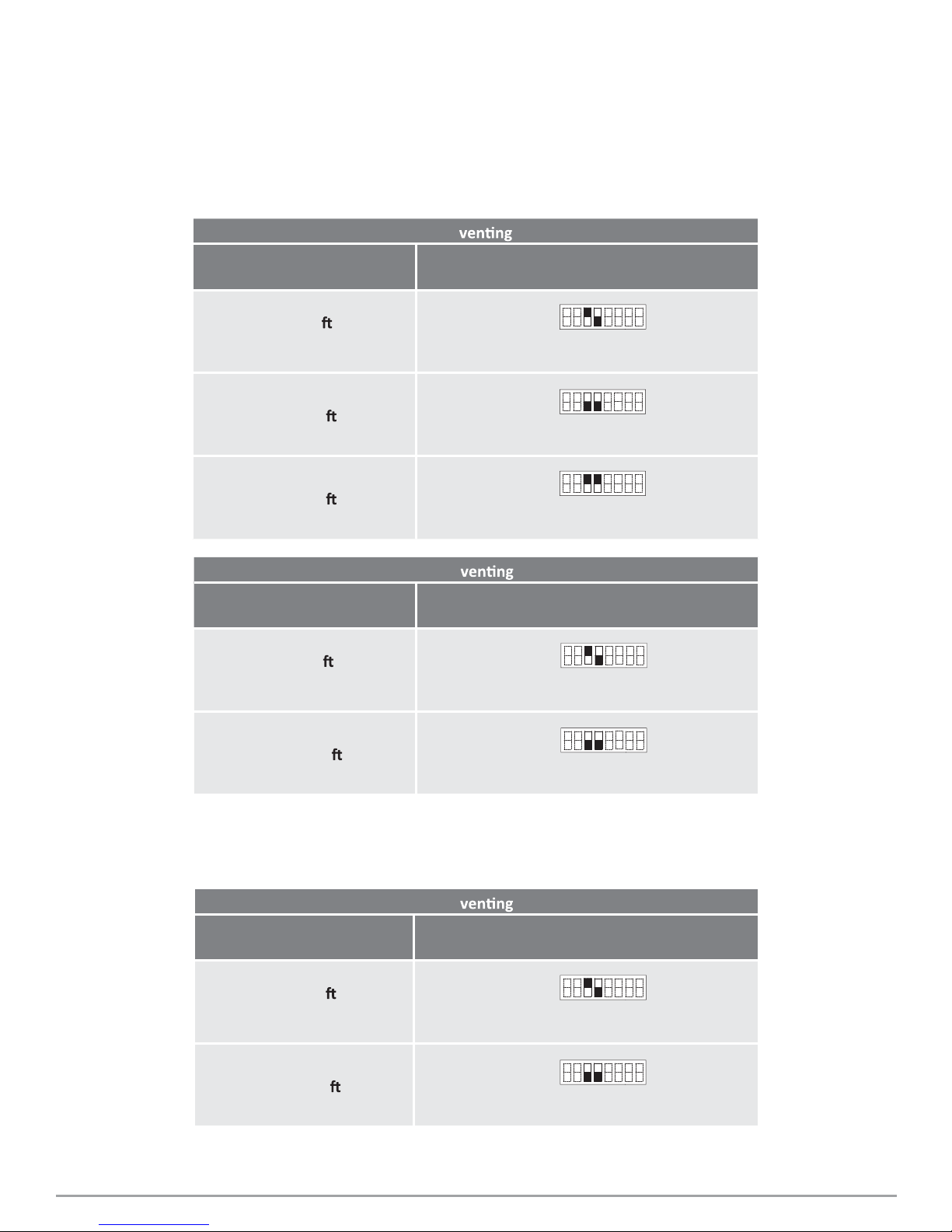

DIPswitch settings for Vent length

<Two-pipe, direct-vent installation>

Set DIPswitches shown in the tables below depending on vent length.

3"

Vent length

5 to 20

(DEFAULT)

21 to 40

41 to 70

Vent length

5 to 50

(DEFAULT)

51 to 100

4"

(Upper bank of DIPswitches)

12345678

ON

OFF

No. 3 : ON

No. 4 : OFF

123456 78

ON

OFF

No. 3 : OFF

No. 4 : OFF

123456 78

ON

OFF

No. 3 : ON

No. 4 : ON

(Upper bank of DIPswitches)

12345678

ON

OFF

No. 3 : ON

No. 4 : OFF

123456 78

ON

OFF

No. 3 : OFF

No. 4 : OFF

<Single pipe with room-air intake installation>

Set DIPswitches shown in the tables below depending on vent length.

Vent length

5 to 45

(DEFAULT)

46 to 70

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 13

3"

(Upper bank of DIPswitches)

123456 78

ON

OFF

No. 3 : ON

No. 4 : OFF

12345678

ON

OFF

No. 3 : OFF

No. 4 : OFF

Page 14

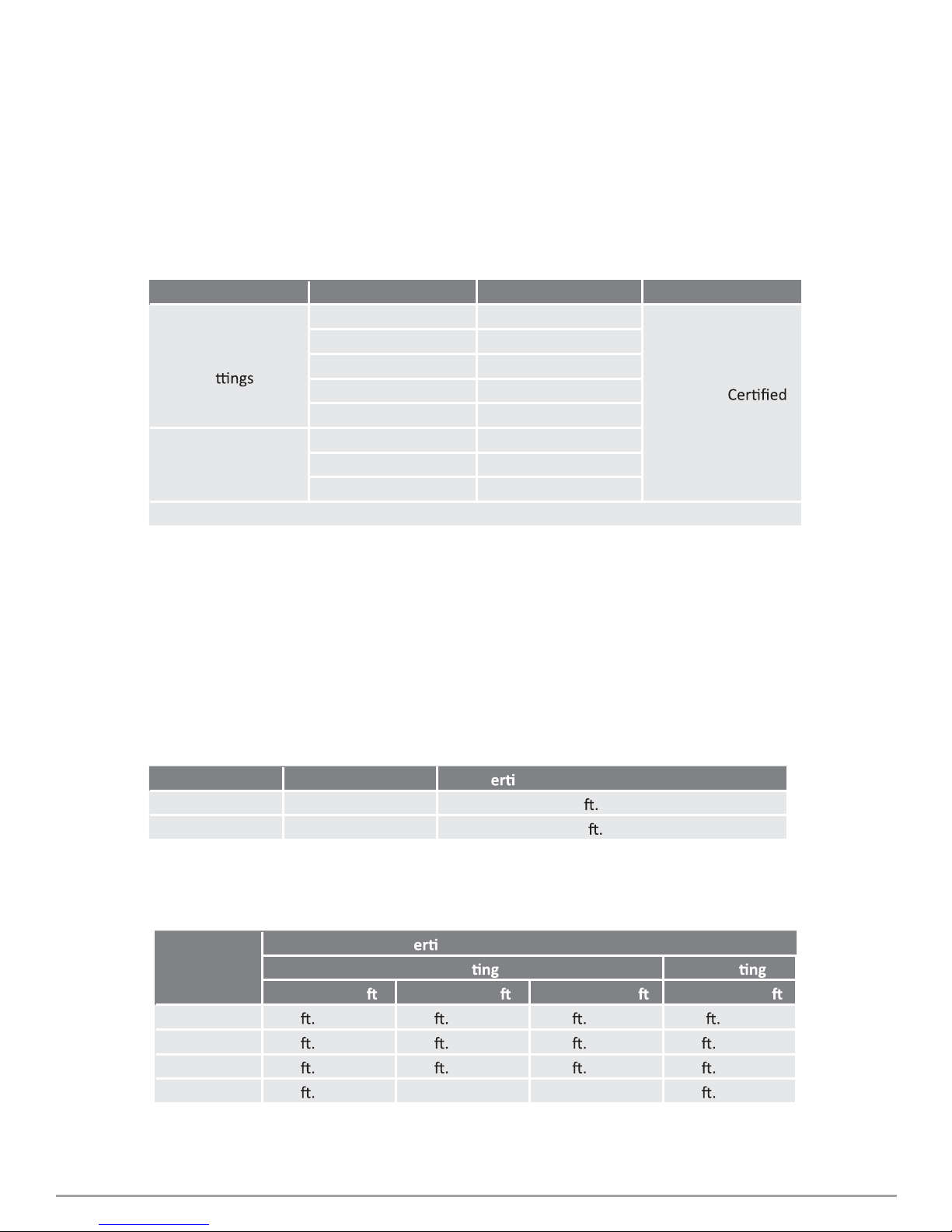

Exhaust vent (ABS, PVC, CPVC, or polypropylene vent)

This appliance can be vented with ABS, PVC, CPVC, or polypropylene (temperature rated up to

149°F). Vent material certifi ed to ULC S636 standards is recommended in the USA. In Canada, plas-

tic venting must be certifi ed to ULC S636 standards.

Item Material CanadaUnited States

Schedule 40 PVC ANSI/ASTM D1785

Exhaust pipe and

Fi

Pipe Cement/Primer

PVC-DWV

Schedule 40 CPVC ANSI/ASTM F441

Schedule 40 ABS-DWV ANSI/ASTM D2661

PVC ANSI/ASTM D2564

CPVC

ABS

NOTE: Do NOT Use Cellular Foam Core Pipe

ANSI/ASTM D2665

UL-1738Polypropylene

ANSI/ASTM F493

ANSI/ASTM D2235

ULC S636

Materials Only

• The maximum length of exhaust vent piping must not exceed 70 ft. (21.3 m) for 3” venting, which

depends on the elevation where the micro boiler is installed, and 100 ft (30.5 m) for 4” venting (deducting 5 ft. (1.5 m) for each elbow used in the venting system). Do not use more than 5 elbows.

See the table below.

• When the horizontal vent run exceeds 5 ft. (1.5 m), support the vent run at 3 ft. 0.9 m) intervals

with overhead hangers.

Diameter Max. No. of Elbows

53 in. (76 mm) 70 (21.3 m)

4 in. (102 mm) 100 (30.5 m)

5

Max. V cal and Horizontal (Total) Vent Length

*For each elbow added, deduct 5 ft. (1.5 m) from max vent length.

Max. V cal or Horizontal (Total) Vent Length

No. of Elbows 3" ven 4" ven

Up to 3,000

0

1

2

5

70 (21.3 m) 40 (12.2 m) 25 (7.6 m)

65 (19.8 m) 35 (10.7 m) 20 (6.1 m)

60 (18.3 m) 30 (19.1 m) 15 (4.6 m)

Up to 6,000

N/A45 (13.7 m) N/A 75 (22.9 m)

Up to 10,100

Up to 10,100

100 (30.5 m)

95 (29.0 m)

90 (27.4 m)

Excludes vent terminators, termination elbows, or rain caps.

14 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Page 15

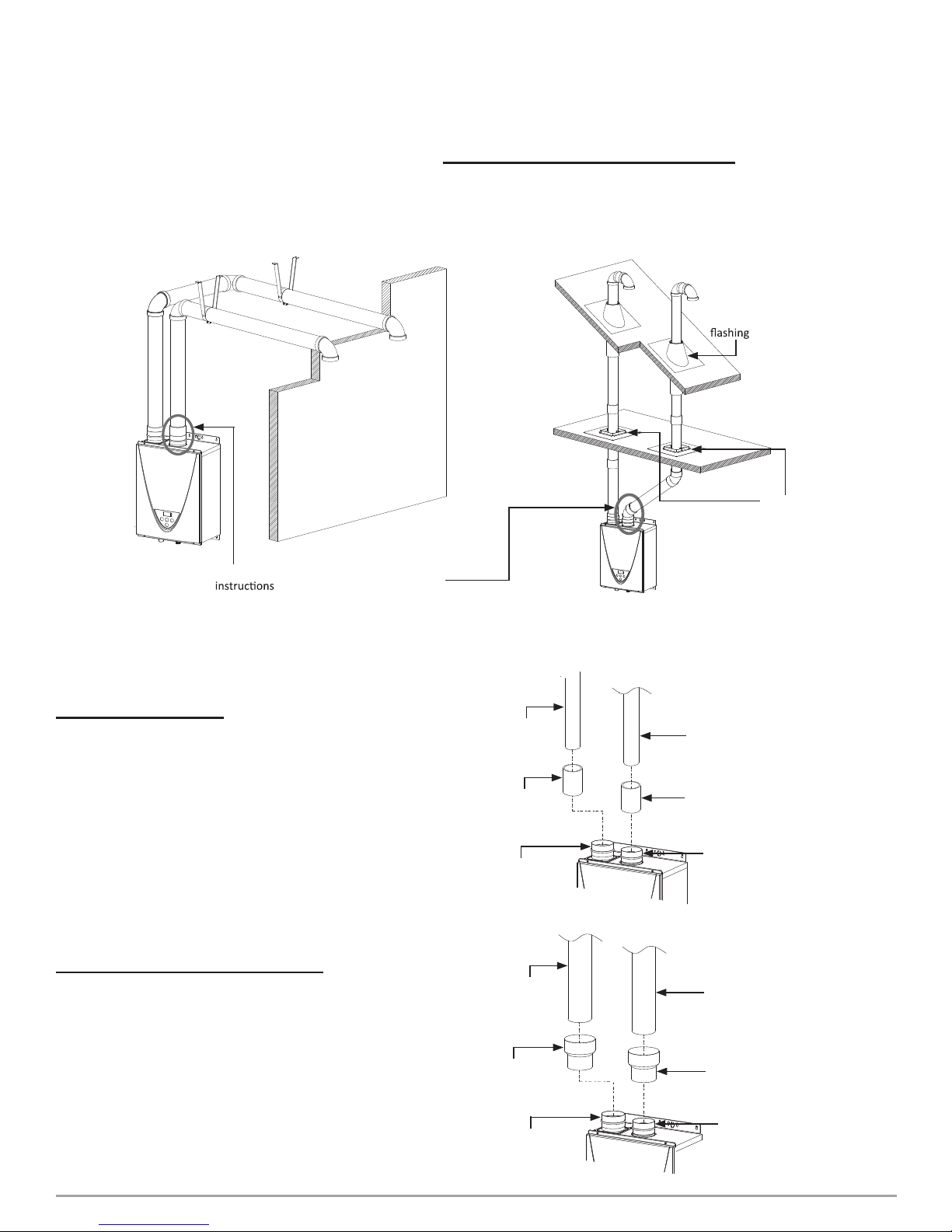

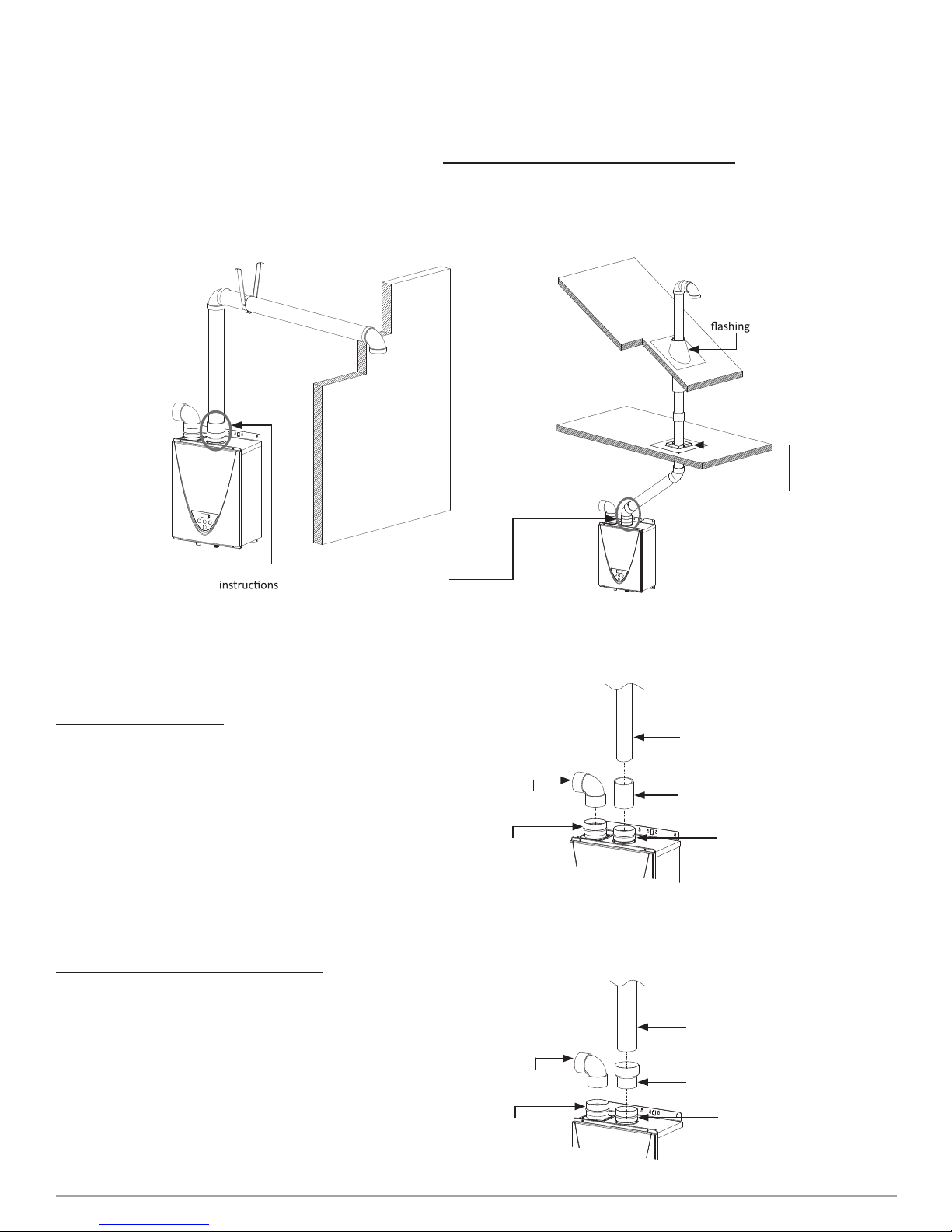

Two-pipe, direct vent illustrations

Typical installation using PVC. ABS, or polypropylene vent

Horizontal Installation Vertical Installation

Wall

Roof

Roof

Fire stop

Connect between exhaust vent collar and piping.

See the below.

For details of the optional items, refer to the installation manual for each optional item.

<How to install intake and exhaust venting (two-pipe, direct vent)

3” vent connection

1. Connect 3” couplings directly on

the exhaust and intake vent collar

of the micro boiler.

2. Connect 3” straight pipes to the

couplings.

From 3” to 4” vent connection

1. Connect 3” x 4” increasers directly

on the exhaust and intake vent

collar of the micro boiler

2. Connect 4” straight pipes to the

increasers.

3” straight pipe

3” coupling

Intake vent collar

(Female)

4” straight pipe

3"x4" increaser

3” straight pipe

3” coupling

Exhaust vent collar

(Female)

4” straight pipe

3"x4" increaser

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 15

Intake vent collar

(Female)

Exhaust vent collar

(Female)

Page 16

Single pipe with room-air intake illustrations

Typical installation using PVC. ABS, or polypropylene vent

Horizontal Installation Vertical Installation

Wall

Roof

Roof

Elbow

Connect between exhaust vent collar and piping.

See the below.

For details of the optional items, refer to the installation manual for each optional item.

3” vent connection

1. Connect 3” elbow directly on the

intake vent collar of the micro boiler.

2. Connect a 3” coupling directly on

the exhaust vent collar of the micro

boiler.

3. Connect a 3” straight pipe to the

coupling.

Elbow

<How to install single vent>

3” elbow with

bird screen

Intake vent collar

(Female)

Fire stop

3” straight pipe

3” coupling

Exhaust vent collar

(Female)

From 3” to 4” vent connection

1. Connect 3” elbow directly on the

intake vent collar of the micro boiler.

2. Connect 3” x 4” increasers directly

on the exhaust vent collar of the

micro boiler

3. Connect a 4” straight pipe to the

increasers.

16 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

3” elbow with

bird screen

Intake vent collar

(Female)

4” straight pipe

3"x4" increaser

Exhaust vent collar

(Female)

Page 17

Exhaust vent (Stainless Steel Vent)

This is a Category IV appliance and must be vented accordingly. The vent system must be sealed

airtight. All seams and joints without gaskets must be sealed with high heat resistant silicone sealant

or UL listed aluminum adhesive tape having a minimum temperature rating of 160° F. For best results,

a vent system should be as short and straight as possible.

• The micro boiler is a Category IV appliance and must be vented accordingly with any 4” vent approved for use with Category III/IV or Special BH type gas vent.

• The manufacturer recommends the NovaVent line. However, the following are also UL listed manufactures: ProTech Systems Inc.(FasNSeal), Metal-Fab Inc., and Heat-Fab Inc. (Saf-T-Vent).

• Follow the vent pipe manufacturer’s instructions when installing the vent pipe.

• The maximum length of exhaust vent piping must not exceed 100 ft. (30.5 m) (deducting 5 ft (1.5

m) for each elbow used in the venting system). Do not use more than 5 elbows.

• When the horizontal vent run exceeds 5 ft. (1.5 m), support the vent run at 3 ft. (0.9 m) intervals

with overhead hangers.

Diameter Max. No. of Elbows

54 in. (102 mm)

*For each elbow added, deduct 5 (1.5 m) from max. vent length.

No. of Elbows

0

1

2

5

Excludes vent terminators, termina elbows, or rain caps.

Max. V cal and Horizontal (Total) Vent Length

100

(30.5 m )

Max. V

cal or Horizontal Vent Length

100

(30.5 m)

95

(29.0 m)

(27.4 m)

90

(22.9 m)

75

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 17

Page 18

Direct-vent and single vent illustrations

Horizontal Installation Vertical Installation

Wall

Roof

Hanger

Hanger

Sidewall vent

Rain cap

Fire stop

• The diagram above shows direct-vent installations. For single vent installation, connect a 4” elbow

directly on the intake vent collar instead of a straight pipe. See the instructions below for the detail.

• For details of the optional items, refer to the installation manual for each optional item.

• Regarding the clearances from the exhaust terminal to the air inlet or opening, refer to next few

pages.

• Follow all vent system manufacturer’s instructions and all local codes.

• Use 4” Category III/IV approved or Special BH, single or double wall stainless steel vent pipe.

<How to install single vent>

4” vent connection for direct vent installation

1. Connect 4” stainless steel vent

straight pipes directly on the exhaust/intake vent collar of the micro

boiler.

4” vent connection for a single vent installation

1. Connect 4” stainless steel vent

straight pipes directly on the exhaust

vent collar of the micro boiler.

2. Connect a 4” elbow directly on the

intake vent collar of the micro boiler.

4" (102 mm)

stainless

steel vent

straight pipe

Intake vent

collar (Female)

4" (102 mm)elbow

with bird screen

Intake vent

collar (Female)

4" (102 mm)

stainless steel vent

straight pipe

Exhaust vent collar

of the Indoor

models (Female)

4” (102 mm)

stainless steel vent

straight pipe

Exhaust vent collar

of the Indoor models

(Female)

18 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Page 19

Vent termination clearances

INSIDE CORNER DETAIL

Vent terminal

V

Air supply inlet

X

G

V

A

D

E

V

Area where is not permi ed

H

B

C

V

FIXED

L

Clearance above grade, veranda, porch, deck, or

balcony

C Clearance to permanently closed window

V cal clearance to ven ated soĸƚ located above

the vent terminator within a horizontal distance

D

of 2 feet (61cm) from the center line of the

terminator

Clearance to each side of center line extended

above meter/regulator assembly

Clearance to non-mechanical air supply inlet to

J

building or the combus air inlet to any other

applica

Clearance above paved sidewalk or paved driveway

located on public property

V

OSE

CL D

L

OPERAB E

V

F

B

B

B

OPERABLE

V

B

B

FIXED

OSED

CL

V

J

A

Canada U.S.A

than Direct-vent Direct-vent

1 foot 1 foot 1 footA

3 feet 1 foot B Clearance to window or door that may be opened

***

***

***E Clearance to unven ated soĸƚ

***F Clearance to outside corner

***G Clearance to inside corner

3 feetI Clearance to service regulator vent outlet

3 feet 1 foot

6 feet

V

M

I

X

Gas meter / regulator

Direct-

vent

**3 feetH

**

3 feetK Clearance to mechanical air supply inlet 3 feet

*7 feetL

*1 foot *M Clearance under veranda, porch deck, or balcony

Other than Direct-vent and other

4 feet from below or

side opening. 1 foot

from above opening

4 feet from below or

side opening. 1 foot

from above opening

7 feet

X

V

K

*For clearances not specifi ed in ANSI Z223.1/NFPZ 54 (US) or B149.1 (Canada), please use clear-

ances in accordance with local installation codes and the requirements of the gas supplier.

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 19

Page 20

For sidewall terminations

Please follow all local and national codes in regards to proper termination clearances. In the absence of such codes, the clearances below can be used as

guidelines. Local codes supersede these guidelines.

1 (305 mm)

min

1

(305 mm) min

Exhaust

termina

1 (305 mm)

min

1

(305 mm) min

Combined

intake and

exhaust

termina

For direct-vent sidewall

terminations that use

two separate penetrations for the intake

and exhaust, keep the

termination clearances

shown in the diagrams

on the right.

2

(610 mm) min

Inside

corner

2

(610 mm) min

Inside

corner

<Case 1>

For multiple sidewall exhaust terminations (e.g. Multi-unit

Systems), an exhaust termination must be at least 1 ft.

(305mm) away from another exhaust termination. An exhaust termination must also be at least 2 ft. (610mm) away

from an inside corner. (If the adjacent wall is less than 2 ft.

(610mm) of length, the minimum required distance away

from the inside corner will be equal to the length of that

adjacent wall.)

For multiple-unit, direct-vent sidewall terminations that

combine the intake and exhaust into a single penetration,

space each direct-vent termination at least 1 ft. (305mm)

away from each other, no matter the orientation. A direct

vent termination must also be at least 2 ft. (610mm) away

from an inside corner. (If the adjacent wall is less than 2 ft.

(610mm) of length, the minimum required distance away

from the inside corner will be equal to the length of that

adjacent wall.)

Exhaust

Intake

1 (305 mm)

min

Exhaust

Intake

0.5

(159 mm)

min

0.5

(159 mm) min

<Case 2>

1 (305 mm) min

20 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Exhaust

Intake

Exhaust

Intake

0.5

(159 mm) min

Page 21

CAUTION

Exhaust and/or direct-vent sidewall terminations should be

at least 2 ft. (610mm) away from an opposite surface/wall.

Do not place the termination directly in front of an opening

2 (610 mm)

min

Exhaust

termina

into a building.

For rooftop terminations

Please follow all local and national codes in regards to proper termination clearances. In the absence of such codes, the clearances below can be used as

guidelines. Local codes supersede these guidelines.

Intake air

2 (610 mm) min

1

(305 mm) min

Exhaust

gas

1

(305 mm) min

1

(305 mm) min

1

(305 mm) min

3 (914 mm) min

Intake air

Exhaust gas

1

(305 mm) min

Exhaust terminations must be at least 1 ft. (305 mm) away from any obstructions.

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 21

Page 22

GAS SUPPLY AND GAS PIPING SIZE

• Check that the type of gas matches the rating plate fi rst.

• Ensure that any and all gas regulators are operating properly and

providing gas pressures withing the specifi ed range shown below.

CAUTION

• The minimum and maximum inlet gas pressures are:

Excess gas inlet pressure may cause serious accidents.

• Conversion of this unit from natural gas to propane or vice versa will void all

warranty. Contact your local distributor to get the correct unit for your gas

type. The manufacturer is not liable for nay property and/or personal

damage resulting from gas conversions.

Gas type Inlet gas pressure

Natural Gas

Propane

Min. 5.0” W.C. (1.24 kPa) – Max. 10.5” W.C. (2.61 kPa)

Min. 8.0” W.C. (1.99 kPa) – Max. 14.0” W.C. (3.48 kPa)

• Inlet gas pressures that fall outside the range of values listed above may adversely affect the performance of the micro boiler. These pressures are measured when the micro boiler is in full operation.

• Inlet gas pressure must not exceed the above maximum values; gas pressure above the specifi ed

range will cause dangerous operating conditions a damages to the unit.

• Until testing of the main gas line supply pressure is completed, ensure the gas line to the micro

boiler is disconnected to avoid any further damage.

Gas connections

1. Install a manual gas shutoff valve between the micro boiler and the gas supply.

2. When the gas connections are completed, it is necessary to perform a gas leak test either by

applying soapy water to all gas fi ttings and observing for bubble or by using a gas leak detection

device.

• The micro boiler and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at the test pressures in excess of 1/2 psi

(3.5kPa).

• The micro boiler must be isolated from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at test pressures

equal to or less than 1/2 psi (3.5 kPa).

3. Always purge the gas line of any debris and/or water before connecting to the gas inlet.

Size the gas pipe appropriately to supply the necessary volume of gas required for

NOTICE

the micro boiler using ANSI Z223.1/NFPA 54 in the USA of B149.1 in Canada or

local codes. Otherwise, fl ow capabilities and output temperatures will be limited.

22 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Page 23

Natural Gas Supply Piping

Maximum delivery Capacity of Cubic Feet of Gas per Hour of IPS Pipe carrying Natural Gas with 0.60

Specifi c Gravity Based on Pressure Drop of 0.5”W.C.

Based on Energy Content of 1,000 BTU/Cubic ft.: The micro boiler requires 199 Cubic ft./hr.

Unit: Cubic feet per hour

Pipe Size Length

10' 20'Diameter 30' 40' 50' 60' 70' 80' 90' 100' 125' 150' 200'

3/4"

1" 684 470 377 323 286 259 239 222 208

1/4"

1

1/2"

1

2" 4,050 2,784 2,235 1,913 1,696 1,536 1,413 1,315 1,234 1,165 1,033 936 801

363 249 200

1,404 965 775 663 588 532 490 456 428 404 358 324 278

2,103 1,445 1,161 993 880 798 734 683 641 605 536 486 416

Propane (LP) Supply Piping

Maximum Capacity of Propane (LP) Based on 11” W.C. supply pressure at 0.5” W.C. pressure drop.

Unit: kBTU per hour

LengthPipe Size

10'Diameter 20' 30' 40' 50' 60' 70' 80' 90' 100' 125' 150' 200'

3/4"

1" 1,071 732 590 504 448 409 378 346 322 307 275 252 213

1/4"

1/2"

1

2" 6,221 4,331 3,465 2,992 2,646 2,394 2,205 2,047 1,921 1,811 1,606 1,496 1,260

567 393 315 267 237 217

2,2051

1,496 1,212 1,039 913 834 771 724 677 630 567 511 440

3,307 2,299 1,858 1,559 1,417 1,275 1,181 1,086 1,023 976 866 787 675

elpmaxe gnizis saG

(Natural Gas)

5' Length

1-1/4" Pipe size

5' Length

1-1/4" Pipe size

Gas meter

Based on Energy Content of 1,000 BTU/Cubic ft.

Divide each appliance’s BTU/h requirement by 1,000 BTU/ft³ to get the appliances ft³/h requirement.

Take into account the distance the appliance is from the gas meter, look in the above gas chart to properly size the line.

For sections of the gas line supplying gas to more than one appliance (Ex. Point A to Point B), add up the cubic ft. per

hour requirements of the appliances that are being supplied by that section, and size to the farthest appliance.

For Example: The section from A to B supplies gas to the furnace, range and dryer. Adding up the BTU/h requirements

and dividing by 1,000 yields a cubic ft. per hour requirements of 220 cubic ft. of gas per hour. The farthest appliance is the

range, which is 50 ft. away form the meter. Looking at the above chart, and under column of 50 ft., Section A to B needs to

be 1” in order to supply 220 cubic ft.

Micro-

boiler

199,000 BTU/h

10' Length

3/4" Pipe size

A

10' Length

1" Pipe size

B

10' Length

3/4" Pipe size

Furnace

120,000 BTU/h

15' Length

1" Pipe size

Dryer

35,000 BTU/h

10' Length

1/2" Pipe size

15' Length

1/2" Pipe size

C

Range

65,000 BTU/h

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 23

Page 24

Measuring inlet gas pressure

1. Turn off all electric power to the micro boiler if service is to be performed.

2. Turn the manual gas valve located on the outside of the unit clockwise to

the off position.

WARNING

The micro boiler cannot perform properly without suffi cient inlet gas pressures. Below are instructions

on how to check the inlet gas pressure.

1. Shut off the manual gas valve on the gas supply line.

2. Remove the screw for the pressure port located on the

gas inlet of the micro boiler shown in the diagram on the

right.

3. Connect the manometer to the pressure port.

4. Re-open the manual gas valve. Check to see that there

are no gas leaks.

5. Check in inlet gas pressure. When the micro boiler is on

maximum and minimum burn, the manometer should

read from 5.0” W.C. to 10.5” W.C. (1.24 to 2.61 kPa) for

Natural Gas, from 8.0” to 14.0” W.C. (1.99 to 3.48 kPa)

for Propane.

3. Failure to follow these steps could lead to a fi re or explosion, resulting in

personal injury or death.

THIS IS ONLY TO BE DONE BY A LICENSED PROFESSIONAL.

Pressure port

WATER CONNECTIONS

Do not use the micro boiler if any part has been under water. Immediately

contact a qualifi ed installer or licensed professional to inspect the boiler to

WARNING

NOTICE

determine if it needs to be replaced.

Do not reverse the hot outlet and cold inlet connections to the micro boiler.

This will not properly activate the micro boiler.

All pipes, pipe fi ttings, valves and other components, including soldering materials, must be suitable

for potable water systems (when using DHW Integrator Panel), or distilled water or distilled water/glycol mix.

1. A manual shutoff valve must be installed on the cold water inlet to the micro boiler between the

main water supply line and the micro boiler.

2. In addition, a manual shutoff valve is also recommended on the hot water outlet of the unit. If the

micro boiler is installed within, or subjected to, a closed loop system (recommended), a thermal

expansion tank or code approved device to handle the thermal expansion must be installed.

3. Before installing the micro boiler, fl ush the

water line to remove all debris, and after installation is complete, purge the air from the

line. Failure to do so may cause damage to the

boiler.

As Close as

Possible

24 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Hot

outlet

Cold

inlet

Gas inlet

Pressure relief valve

Page 25

Pressure relief valve

The micro boiler has a high-temperature shutoff switch built in as a standard safety feature (called a

Hi-Limit switch) therefore a “pressure only” relief valve is required.

• This unit does not come with an approved pressure relief valve.

• An approved pressure relief valve must be installed on the hot water outlet.

• The pressure relieve vale must conform to ANSI Z21.22 or Can 1-4.4 and installation must follow

local codes.

• The discharge capacity must be at least 199,000 BTU/h.

• The pressure relief valve needs to be rated for a maximum of 150 psi (1 MPa).

• The discharge piping for the pressure relief valve must be directed so that the hot water cannot

splash on anyone or on nearby equipment.

• Attach the discharge tube to the pressure relief valve and run the end of the tube to within 6

in.(152 mm) from the fl oor. This discharge tube must allow free and complete drainage without any

restrictions.

• If the pressure relive valve installed on the micro boiler discharges periodically, this may be due to

a defective thermal expansion tank or defective pressure relief valve.

• The pressure relief valve must be manually operated periodically to check for correct operation.

• No valve must be placed between the relief valve and the micro boiler.

CONDENSATE DRAIN

• The micro boiler does not include a built-in condensate neutralizer cartridge for reducing the pH

level of condensate water. If local codes dictate that condensate must be neutralized prior to

drainage, a condensate neutralizer must be installed. An accessory Neutralizer assembly is sold

separately.

• In the absence of applicable local codes and regulations, th manufacture recommends that condensate be disposed of into a standard drain. Connect a drain tube from the condensate drain port

(shown below) located on the bottom of the micro boiler to a standard drain.

Follow all code requirements

of the local authority on

condensate neutralizers and

whether or not they are required

for the installa

Condensate drain port

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 25

Page 26

Condensate Drain Connections

Discharge condensate (acidic water) in accordance with all local codes

WARNING

The micro boiler is a high effi ciency condensing micro boiler that produces condensate (acidic water).

The acidic condensate generated in the secondary heat exchanger can be neutralized by the Neutralizer accessory.

Case A: If a neutralizer is not required

1. Connect a 1/2” FPT X 3/8” (or 1/2”) HB Adaptor to the condensate drain port at the bottom of the

micro boiler.

2. Connect a condensate drain tube to the 1/2” FPT X 3/8” (or 1/2”) HB Adaptor. The manufacturer

recommends the material of the condensate tube be either EPDM or PVC.

3. Leave an adequate amount of space between the end of the drain tube and the actual drain, to

facilitate proper drainage.

Case B: If a neutralizer is required (installing the Neutralizer assembly)

1. Connect a 1/2” FPT X 3/8” (or 1/2”) HB Adaptor to the condensate drain port at the bottom of the

micro boiler.

2. Connect the Neutralizer to the 3/8” MPT connection of the adapters. There is a fl ow direction

indicator on the neutralizer. Please orient the neutralizer in the proper direction.

3. Connect a 1/2” drain tube to the other end of neutralizer.

4. Leave an adequate amount of space between the end of the drain tube and the actual drain, to

facilitate proper drainage.

and common safety practices.

Case A

1/2" FPT x 3/8"

(or 1/2") HB

3/8" or 1/2"

Condensate

drain tube

Drain

Condensate

drain port

Adequate space

Case B

1/2" FPT x 3/8" MPT

(Included with

Neutralizer accessory)

Neutralizer cartridge

(Included with

Neutralizer accessory)

3/8" MPT x 1/2" HB

(Included with

Neutralizer accessory)

Drain

Condensate

drain port

1/2" Condensate

drain tube

Adequate space

26 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Page 27

WARNING

• The condensate drain is at atmospheric pressure (non-pressurized) and

therefore must be allowed to drain freely with gravity only. Please ensure that

there are no blockages along the condensate drain tube. All portions of the

condensate drain (neutralizer and drain tube) must be at a lower elevation than the micro boiler to prevent condensate water from building up

inside the heat exchanger.

• Condensate cannot be effectively neutralized if the neutralizer elements inside

the Neutralizer accessory have been completely consumed. if this happens,

condensate will remain acidic and can possibly cause damage to items such

as pipes, concrete, etc., if drained improperly.

• The neutralizer cartridge is designed to last for 3 years before replacement.

However, the actual life of the neutralizer may vary, depending on the application and usage. Please ensure that the cartridge is properly replaced before

the neutralizer elements have been completely consumed.

• All preventive measures and safety practices must be adhered to when draining condensate. The manufacturer will not be responsible for any damage

caused by condensate.

• A drain pan, or other means of protection against water damage, is required to

be installed under the micro boiler in case of leaks.

WARNING

ELECTRICAL CONNECTIONS

• Follow the electrical code requirements of the local authority having jurisdiction. In the absence of such requirements, follow the current edition of the National Electrical Code ANSI/NFPA 70 in the U.S. or the current edition of CSA

C22.1 Canadian Electrical Code Part 1 in Canada.

• When servicing or replacing parts with the micro boiler, label all wires prior to

disconnection to facilitate an easy and error-free reconnection. Wiring errors

can cause improper and dangerous operation. Verify proper operation after

servicing.

• Failure to observe these warnings could result in personal injury or loss of life.

This unit comes with a power plug instead of a junction box.

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 27

Page 28

APPLICATIONS

Space Heating Applications

• In order to purge air in water pipes within a closed loop system, an air vent,

air separator, and expansion tank should be installed in the system. (Hydro-

Shark pre-built space heating panels incorporate all of these features).

WARNING

HydroShark per-plumbed panels help make space heating easy and reliable. These panels are professionally engineered and use proven Primary/Secondary hydronic practices. Call Tech Support

(800.805.5384) for assistance.

• Water temperature over 125° F (52° C) can cause sever burns instantly of

death from scalding.

• Chemicals such as diluted Glycol can be used for radiant fl oor, Hydro/fan

coil air or Baseboard heating only. The diluted solution of glycol must contain

between 25% and 55% of Glycol. Be aware that in a closed loop system, low

pressure in the heat exchanger can cause low-temperature boiling, resulting

in excessive noise and damage to the micro boiler. Consult with the glycol

maker for specifi cations prior to use.

HydroShark Pre-Built Space Heating Panels

Sample:

1 Zone Panel:

28 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Page 29

Dual-purpose hot water heating

(Domestic and Space Heating)

Insert a HydroShark DHW Integrator Panel to provide potable heated water and Hydronic Heating

(with space heating panel(s)) with one heat source.

The HydroShark DHW Integrator Panel integrates with a wide variety of boilers and delivers “Priority”

potable heated water with no storage tank and hydronic space heating in a small reliable package.

NOTICE

Follow all local codes, or in the absence of local codes, follow the most recent

edition of the National Standard Code, ANSI Z21.10.3.

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 29

Page 30

INITIAL OPERATION

• Check the Gas and Water Connections for leaks before fi ring the unit for the fi rst time.

• Open the main gas supply valve to the unit using only your had to avoid and spark. Never use

tools. If the knob will not sure by had, do not try to force it; call a qualifi ed service technician.

Forced repair may result in a fi re or explosion due to gas leaks.

• Be sure to check for the presence of leaking gas toward the bottom of the unit because some gases are heavier than air and may settle towards the fl oor.

• Check the Gas Pressure.

• Do not try to light the burner manually. It is equipped with an electric ignition device which automatically lights the burner.

• Check for proper venting and combustible air to the micro boiler.

• Purge the gas and water lines to remove any air pockets.

• Do not use this micro boiler if any part has been under water. Immediately call a qualifi ed installer

or service technician to inspect the micro boiler to determine if it needs replacement.

IF YOU SMELL GAS:

• Do not try to start the micro boiler.

• Do no touch any electric switches; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas

WARNING

supplier’s instructions.

• If you cannot reach your gas supplier, call the fi re department.

Opera

Once the above checks have been completed, please clean

1.

Įůter of any debris.

Fully open the manual ǁater control valve on the ǁater

2.

supply line.

Turn on the thermostat and verify thĂƚŇƵŝĚŇŽǁƐ

through your radiant system. Then tuƌŶŽīLJŽƵƌ

3.

thermostat.

Fully open the manual gas control valve installed.

4.

urn on the 120 VAC, 60 Hz poǁer supply to the ǁater

T

5.

heater.

EŽǁƚƵƌŶŽŶƚŚĞƚŚĞƌŵŽƐƚĂƚzŽƵĂƌĞƌĞĂĚLJƚŽĞŶũŽy hours

6.

of endless comfort.

30 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Page 31

Owner’s Guide

CONGRATULATIONS

Congratulations and thank you for choosing our condensing micro

boiler. Before use, we recommend that you read through this owner’s

guide carefully. Keep this manual for future reference.

If you need an additional manual, contact the manufacturer or your

local distributor. When you call, please tell us the product name and

the serial number of your unit written on the rating plate of the boiler.

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 31

Page 32

OPERATING SAFETY

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING: If you do not follow these instructions exactly, a fi re or explosion may result

causing property damage, personal injury or loss of life.

1. The micro boiler does not have a pilot. It is equipped with an ignition device that automatically

lights the burner. Do NOT try to light the burner by hand.

2. Before operating smell all around the micro boiler area for evidence of leaking gas. Be sure to

smell next to the fl oor because some gas is heavier than air and will settle on the fl oor .

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone.

• Follow the gas suppliers instructions. If gas supplier cannot be reached, call fi re dept.

3. Use only your hand to turn the gas shutoff valve. Never use tools. If the valve will not turn by hand,

don’t try to repair it, call a qualifi ed service technician. Force or attempted repair may result in a

fi re or explosion.

4. Do not use this micro boiler if any part has been under water. Immediately call a qualifi ed service

technician to inspect the micro boiler and to replace the unit if needed.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above or in the Owner’s Manual.

2. Turn off all electric power to the micro boiler.

3. Do not attempt to light the burner by hand.

4. Turn the manual as valve located on the outside of the unit clockwise to the OFF position.

5. Wait fi ve (5) minutes to clear out any gas. If you then smell gas, STOP! Follow “B” in the safety

information above on this label. If you don’t smell gas, go to next step.

6. Turn the manual gas valve located on the outside of the unit counterclockwise to the ON position.

7. Turn on all electrical power to the micro boiler.

8. If the micro boiler will not operate, follow the instructions “To turn off Gas to appliance” and call

your service technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1. Turn off all electric power to the micro boiler if service is to be performed.

2. Turn the manual gas valve located on the outside of the unit clockwise to the OFF position.

32 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Page 33

DANGER

Vapors from fl ammable liquids will explode and catch fi re causing death or sever burns.

Do not use or store fl ammable products such as gasoline, solvents or adhesives in the same

room or area near the micro boiler.

Flammable Vapors

Read and follow micro boiler warnings and instructions. if the owner’s manual is missing, contact the manufacturer.

Keep fl ammable products: V apors:

1. Far away from boiler.

2. In approved containers.

3. Tightly closed and out of reach of children.

4. Micro boiler has a main burner, which may

come on at any time and will ignite fl am-

1. Cannot be seen.

2. Are heavier than air.

3. Go a long way on the fl oor.

4. Can be carried form other rooms to the

main burner by air currents.

mable vapors.

DANGER

When using micro boiler with DHW Integrator Panel for Domestic Hot Water:

1. Water temperature over 125° F can cause severe burns instantly or death from scalds.

2. Children, disabled and elderly are at highest risk of being scalded

3. Feel water before bathing or showering.

4. Temperate limiting valves are available on the DHW Integrator Panel(s). Adjust these mixing

valves accordingly.

5. The outlet temperature of the micro boiler is set at 120° F (50° C). If you require water temperatures below this setting, follow the instruction manual.

6. Test the boiler before bathing or showering. Do not leave children or an infrim person unsupervised.

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 33

Page 34

NORMAL OPERATION

TEMPERATURE CONTROLLER AND REMOVE CONTROLLER

The illustration below shows an example of the controllers. The exact display may differ from examples.

Built-in controller

Temperature Controller

Display for Temperature

When the STAND BY LED is ON, the

hot water temperature will be

displayed.

"HOT" BuƩon

"COLD" ƵƩŽŶ

Press the "HOT" buƩon or the "COLD"

buƩon to set the hot water temperature.

• When the remote controller is installed it will take priority over the built-in controller.

NOTICE

• dŚĞĐŽŶƚƌŽůůĞƌŚĂƐĂŶĞŶĞƌŐLJƐĂǀŝŶŐŵŽĚĞ&ŝǀĞŵŝŶƵƚĞƐĂŌĞƌƚŚĞǁĂƚĞƌŚĞĂƚĞƌƐƚŽƉƐ

ŽƉĞƌĂƟŶŐƚŚĞďĂĐŬůŝŐht of the controller turns oī.

• The backlight of the remote will turn back on once the water heater begŝŶƐĮring again.

"INFO" ƵƩŽŶ

Each ƟŵĞ the buƩon is pressed,

the operaƟŽŶ mode is selected

in the sequence of the following.

Inlet water

temperature

Outlet water

temperature

Water

Ňow

IN USE LED (Green)

The indicator lights during combusƟŽŶ

STAND BY LED (Orange)

The indicator is ON to show that

power is ON.

"ON/OFF" ƵƩŽŶ

Press this buƩon to

start or stop operaƟŽŶ

Remote controller

NOTICE

GENERAL

• Flow rate to active micro boiler: 0.5 gallon per minute at the default set

temperature

• Flow rate to keep the micro boiler running: 0.4 gallon per minute.

• The controllers have an energy saving mode. Five minutes after the micro

boiler stops operating, the back-light of the controllers turn off.

• The back-light of the controllers will turn back on once the micro boiler begins fi ring again.

34 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Page 35

TEMPERATURE SETTINGS

Set Temperature

OperaƟŽŶ

Turn on the 120 VAC power supply to the unit.

1.

Press the "ON/OFF" buƩon on the controller in order to

2.

turn the controller on.

When ON, the STAND BY LED is lit.

3.

It showsthe set temperature on its display as shown in

4.

the picture on the right. (EX.: 120 °F)

Press the "HOT" buƩon or the "COLD" buƩon to set the

temperature seƫŶŐ of the unit.

/ŶcreĂƐŝŶg temperature frŽm 120 °F (50 °C) tŽ 125 °F (52 °C) :

1. The micro boiler must be in Stand By to increase the

temperature.

2. Press the "HOT" buƩon to set 120 °F (50 °C).

3. Press and hold the "INFO" buƩon and the "HOT"

buƩon for at least 3 seconds. The remote will emit a

beep and change to 125 °F (52 °C).

4. Press the "HOT" buƩon to set up to 140 °F (60 °C).

5.

ScrĞĞŶ ŽŶ the cŽŶtrŽůůĞƌ

ƵŝůtͲŝŶ cŽŶtrŽůůĞƌ

RĞŵŽte cŽŶtrŽůůĞƌ

(EX.: 120 °F)

/ŶĐrĞĂƐŝŶŐ temperature abŽve 140 °F (60 °C)

1. The micro boiler must be in Stand By to increase the

temperature.

2. Press the "HOT" buƩon to set 140 °F (60 °C).

3. Press and hold the "INFO" buƩon and the "HOT"

buƩon for at least 3 seconds. The remote will emit a

beep and change to 145 °F (63 °C).

4. Press the "HOT" buƩon to set up to 160 °F (70 °C).

TEMPERATURE TABLE OF CONTROLLER

°F 100 105 110 115 120* 125 130 135 140 145 150

°C

38 40 43 45 50* 52 55 57 60 63 65 68 70

*Factory seƫŶŐ (Default): 120 °F

155 160

165 175

75 80

185

85

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 35

Page 36

ADDITIONAL FEATURES

Information mode

You can get some information about the micro boiler condition by pressing “Info” button. For more

information, follow the procedures below:

Screen on the controller

Opera

Temperature controller Remote controller

First of all, inlet water temperature will be displayed

1.

on the controller by pressing the "INFO" bu on.

Outlet water temperature will be displayed on the

2.

controller by pressing the "INFO" bu

And then, water ŇŽǁ will be displayed on the

3.

controller by pressing the "INFO" bu

Press the "INFO" bu on to ĮŶŝƐŚ informa mode.

4.

on.

on.

Inlet water temperature

(EX.: 60 °F)

Outlet water temperature

(EX.: 120 °F)

Water Ňow

(EX.: 3.5 GPM)

Unit Conversion Mode

The remote controller has a function that can change units of temperature and fl ow rate from °F to

°C and from gallon per minute to liter per minute and vice versa, please follow the procedure below.

ScrĞĞŶ ŽŶ the cŽŶtrŽůůĞƌ

OperaƟŽŶ

Press the "ON/OFF" buƩon on the controller in

1.

order to turn the controller on.

ƵŝůtͲŝŶ cŽŶtrŽůůĞƌ

RĞŵŽte cŽŶtrŽůůĞƌ

When ON, the orange LED is lit.

2.

The previous set temperature will be displayed on

3.

the screen.

Press the "INFO" buƩons for at least 3 seconds.

4.

The set temperature should now be displayed in the

5.

alternate unit of measurement.

When the micro boiler is connected with the remote controller, the temperature

controller will not operate temperate settings, as only work for the information

mode.

36 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

(EX.: 100 °F)

(EX.: 38 °C)

Page 37

TEMPERATURE SETTINGS ON THE PCB

(WITHOUT REMOTE CONTROLLER)

There are 2 preset DIPswitches (120° F (50° C) and 140° F (60° C)) that you can select from by

changing the DIPswitch settings on the computer board without the remote controller. See the table

below. When the remote controller is in normal operation, the set temperature of the remote controller

is given priority over th set temperature of the DIPswitch settings.

• The temperature has been preset at the factory to 120° F (50° C).

WARNING

(Lower bank of DIPswitches)

120 °F (49 °C)

DEFAULT

123456

ON

OFF

No. 5 : OFF No. 5 : ON

140 °F (60 °C)

12233445566

ON

OFF

Upper bank of

DIPswitches

Lower bank of

DIPswitches

Computer board

NOTE: Only change the switches with dark squares. The dark squares indicate the

direction the DIPswitches should be set to.

• DO NOT adjust the upper bank of DIPswitches

• Turn off the power supply to the micro boiler before changing the DIPswitch settings.

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 37

Page 38

FLOW

• The fl ow rate through the micro boiler is limited to a maximum of 10.0 GPM (38 L/min).

• The temperature setting, along with the supply temperature of the water will determine the fl ow

rate output of the unit.

FREEZE PROTECTION SYSTEM

• This unit comes equipped with heating blocks to protect it against damages associated with freezing.

• For this freeze protection system to operate, there has to be electrical power to the unit. Damage

to the heat exchanger caused by freezing temperates due to a power loss is not covered under

warranty. In cases where power losses can occur, consider the use of a backup power supply.

• The freeze protection system will activate when the surrounding and/or outside temperature drop.

• It is the installer’s responsibility to be aware of freezing issues and take all preventive measures.

The manufacture will not be responsible for any damage to the heat exchanger as a result of

freezing.

• In any area subject to freezing temperatures, freezing issues can occur if cold air enters through

the venting into the heat exchanger by either negative pressures within the installation location or

by strong outside wind. The manufacturer highly recommends the use of a back fl ow preventer

(sold separately) to minimize the amount of cold air entering through the exhaust venting when the

micro boiler is off.

• It is the installer’s responsibility to be aware of freezing issues and take all preventive measures.

The manufacture will not be responsible for any damage to the heat exchanger as a result of

freezing.

• If you will not be using your boiler for a long period of time:

1. Completely drain the water out of the unit.

2. Disconnect power to your boiler.

This will keep your unit from freezing and being damaged.

Only pipes within the micro boiler are protected by the freeze protection system.

Any water pipes (hot or cold) located outside the unit will no be protected. Properly

CAUTION

38 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

protect and insulate these pipes from freezing.

Page 39

MAINTENANCE AND SERVICE

Turn off the electrical power supply and close the manual gas shutoff valve

and the manual water control valve before servicing.

• Be sure that all openings for combustion and ventilation air are not blocked.

• The venting system should be checked annually for any leaks, corrosion, blockages or damage.

• The burner should be checked annually for dust, lint, grease or dirt.

• Keep the area around the micro boiler clear. Remove any combustible materials, gasoline or any

fl ammable vapors and liquids.

• In accordance with all local codes and common safety practices, water discharged from the pressure relief valve can cause severe burns instantly from scalding. DO NOT touch the pressure relief

valve.

• If the relief valve discharges periodically, it may be due to thermal expansion in a closed water

supply system. Contact the water supplier or local plumbing inspector on how to correct this situation.

• Visual check of burner fl ames (see below) through the burner window in the burner assembly lo-

cated at the middle of the micro boiler.

Flame

blowing up

Red or Yellow

The manufacturer recommends having the unit checked once a year or as necessary by a licensed

technician. If repairs are needed, any repairs should be done by a licensed technician.

UNIT DRAINING

1. Close the manual gas shutoff valve.

2. Turn off power to the unit and wait a couple of

seconds.

Turn on again.

3. Wait 30 seconds, and then turn off power to

the unit, yet again.

4. Close the water shut off valve.

5. Have a bucket or pan to catch the water from

the unit’s drain plugs. Unscrew the two drain

plugs (large and small) to drain all the water

out of the unit.

6. Wait a few minutes to ensure all water has

completely drained from the unit.

Drain plug

(Small)

Drain plug

(Large)

Gas

valve

Water valve

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 39

Page 40

TROUBLESHOOTING

PROBLEM SOLUTIONS

General

The water is not hot

enough.

The water is too hot. • Is the set temperature set too high?

The hot water is not

available when there

is a call for heat.

The hot water turns

cold and stays cold.

Fluctua

water temperature.

TEMPERATURE and AMOUNT OF HOT WATER

in hot

•Compare the Ňow and temperature.

• Check cross plumbing between cold water lines and hot water lines.

• Is the gas supply valve fully open?

• Is the gas line sized properly?

• Is the gas supply pressure suĸĐŝĞnt?

• Is the set temperature set too low?

• Make sure the unit has 120 VAC, 60 Hz power supply.

• If you are using the remote controller and/or temperature controller, is

the power bu

• Is the gas supply valve fully open?

• Is the water supply valve fully open?

• Is the unit frozen?

• Is ther e enough gas in the t ank / cy linde r? (For Propane models)

• Is the Ňow rate enough to keep the micro-boiler running?

• Is the gas supply valve fully open?

•Are the Įxtures clean of debris and obs

•Check if the Ňow rate is too low.

• Is the gas line sized properly?

• Is the supply gas pressure suĸĐŝĞnt?

•Check for cross c

on turned on?

between cold water lines and hot water lines.

40 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Page 41

Troubleshooting (Cont’d)

PROBLEM SOLUTIONS

Unit does not ignite

when water goes

through the unit.

The fan motor is

sƟůů spinning aŌer

operaƟŽŶ has stopped.

WATER HEATER

Unit sounds abnor-

ŵĂů ǁŚŝůĞ in opera-

ƟŽŶ

ContrŽůůĞƌ does not

ĚŝƐƉůay anything

when the power

buƩon is

turned on.

•Is the Ňow rate over 0.5 GPM (1.9 L/min)?

• Check for the Įůter on the cŽůĚ water ŝŶůet.

• Check for reverse cŽŶŶĞĐƟŽŶ and cross cŽŶŶĞĐƟŽŶ

• If you use the remote contrŽůůĞƌ and/or temperature contrŽůůĞr, is the

power buƩon turned on?

•Check if the ŝŶůet temperature is too high. If it is too ĐůŽƐĞ to the set

temperature, the water heater ǁŝůů not ĂĐƟvate.

•This is ŶŽƌŵĂů AŌer operaƟŽŶ has stopped, the fan motor keeps running

from 15 to 70 seconds in order to re-ignite ƋƵŝĐŬůy, as wĞůů as purge Ăůů the

exhaust gas out of the ŇƵĞ

• Contact the manufacturer at 1-763-331-3066

• Make sure the unit is ƐƵƉƉůŝĞĚ with power.

• Make sure the cŽŶŶĞĐƟŽŶ to the unit is correct.

NOTICE:

When the unit has not operated for Įve minutes or more, the ĚŝƐƉůay

of the contrŽůůers turns oī to conserve energy.

Ƶŝůt-in contrŽůůĞƌ

When the

contrŽůůĞƌƚƵƌŶĞĚ

ON, STAND BY LED

ŝƐůŝƚ

REMOTE CONTROLLER

An ERROR code is

ĚŝƐƉůayed.

BUILT-IN CONTROLLER AND

ůƚŚŽƵŐŚ the contrŽůůĞƌ of the parent unit ǁŝůů

temperature at the Easy-Link System, the contrŽůůĞƌ of the ĐŚŝůĚ unit

ǁŝůů not ĚŝƐƉůay the set temperature.

• WůĞĂƐĞ see ƌƌŽƌŽĚĞ^ĞĐƟŽŶ

ĚŝƐƉůay the set

WWW.HYDRO-SHARK.COM HYDROSHARK 199 | 41

Page 42

ERROR CODES

• The units are self-diagnostic for safety and convenience when troubleshooting.

• If there is a problem with the installation or the unit, the error code will be displayed on the temperature controller and remote controller.

• Consult with the table on the following pages for the description of each error code.

Error code indicator on

the temperature controller

Error code indicator on the remote

controller

Green LED

Single unit installations

Example: if your unit has the “321” error code (which signifi es an inlet thermistor failure)

• Indicator on the temperature

controller or remote controller: “321” will be displayed on the screen in its entirety.

• Green LED on the computer board: The green LED on the computer board will be

blinking two times.

42 | HYDROSHARK 199 WWW.HYDRO-SHARK.COM

Page 43

Fault Analysis of Error Codes

If the error code is displayed on the computer board of the micro boiler or remote controller and/or

temperature controller, please check the following. After checking, Consult with the manufacturer.

Remote

031

101

111

121

Green

LED

One Time Incorrect DIPswitch

Five Times

Three Times failure

Three Times Loss of ŇĂŵĞ

descrip

se

Warning for the

“991” error code

Diagnosis

• Check the DIPswitch se on the PCB (Part #701).

• Check the gas type of the micro-boiler.

• Check if there is any blockage in the intake air and/

or exhaust.

• If the micro-boiler is installed as a direct-vent

system, check whether there is enough distance

between the intake air terminal and the exhaust

terminal.

•Check the

micro-boiler is installed.

• Check if there is grease and/or dirt in the burner (Part

#101) and the fan motor (Part #103), especially if the

micro-boiler has been installed in a contaminated area.

• Check if the Hi-limit switch (Part #412) is properly

•Check for connec reakage of wires (Part #413, 708,

709, 710, 712), burn marks on the computer board (Part

#701), and/or soot on the Ňame rod (Part #108).