Page 1

OPERATION AND INSTALLATION

Electronically controlled instantaneous water heater

» DEL 18 AU

» DEL 27 AU

M1

M2

Tmax

Page 2

CONTENTS | SPECIAL INFORMATION

SPECIAL INFORMATION

OPERATION

1. General information �����������������������������������������3

1.1 Safety instructions ����������������������������������������������� 3

1.2 Other symbols in this documentation ����������������������� 3

1.3 Units of measurement ������������������������������������������ 3

2. Safety ���������������������������������������������������������� 4

2.1 Intended use ������������������������������������������������������ 4

2.2 General safety instructions ������������������������������������ 4

2.3 CE designation ��������������������������������������������������� 4

2.4 Test symbols ������������������������������������������������������ 4

3. Appliance description ���������������������������������������4

4. Settings and displays ���������������������������������������� 5

4.1 User interface ���������������������������������������������������� 5

4.2 Temperature limit (childproofing) ���������������������������� 5

4.3 Inlet temperature information �������������������������������� 6

4.4 Following an interruption of the water supply ������������ 6

5. Cleaning, care and maintenance ���������������������������6

6. Troubleshooting ����������������������������������������������6

INSTALLATION

7. Safety ���������������������������������������������������������� 7

7.1 General safety instructions ������������������������������������ 7

7.2 Instructions, standards and regulations �������������������� 7

8. Appliance description ���������������������������������������7

8.1 Standard delivery ������������������������������������������������ 7

9. Preparations �������������������������������������������������� 7

9.1 Installation site ��������������������������������������������������� 8

10. Installation ����������������������������������������������������8

10.1 Standard installation �������������������������������������������� 8

10.2 Completing the installation ����������������������������������� 10

10.3 Installation options ��������������������������������������������� 11

11. Commissioning ��������������������������������������������� 13

11.1 Initial start-up ��������������������������������������������������� 13

11.2 Recommissioning ����������������������������������������������� 14

12. Shutting down the system �������������������������������� 14

13. Troubleshooting �������������������������������������������� 14

13.1 Service mode ���������������������������������������������������� 14

13.2 Indicator options for LED diagnostic traffic light ��������� 15

13.3 Fault table �������������������������������������������������������� 15

14. Maintenance ������������������������������������������������ 16

15. Specification ������������������������������������������������ 16

15.1 Dimensions and connections ��������������������������������� 16

15.2 Wiring diagram ������������������������������������������������� 17

15.3 DHW output ����������������������������������������������������� 17

15.4 Application areas/ conversion table ����������������������� 17

15.5 Pressure drop ��������������������������������������������������� 17

15.6 Fault conditions ������������������������������������������������� 17

15.7 Data table �������������������������������������������������������� 18

SPECIAL INFORMATION

- The appliance may be used by children aged 8

and up and persons with reduced physical, sensory or mental capabilities or a lack of experience

and know-how, provided that they are supervised

or they have been instructed on how to use the

appliance safely and have understood the resulting risks. Children must never play with the appliance. Children must never clean the appliance

or perform user maintenance unless they are

supervised.

- Ensure the appliance can be separated from the

power supply by an isolator that disconnects all

poles with at least 3mm contact separation.

- Secure the appliance as described in chapter "Installation/ Installation".

- Observe the maximum permissible pressure (see

chapter "Specification/ Data table").

- Drain the appliance as described in chapter "Installation/ Maintenance/ Draining the appliance".

WARRANTY | ENVIRONMENT AND RECYCLING

2 | DEL AU www.stiebel-eltron.com

Page 3

OPERATION

ENGLISH

General information

OPERATION

1. General information

The chapter "Operation" is intended for appliance users and qualified contractors.

The chapter "Installation" is intended for qualified contractors.

Note

Read these instructions carefully before using the appliance and retain them for future reference.

Pass on the instructions to a new user if required.

1.1 Safety instructions

1.1.1 Structure of safety instructions

KEYWORD Type of risk

Here, possible consequences are listed that may result

from failure to observe the safety instructions.

Steps to prevent the risk are listed.

1.2 Other symbols in this documentation

Note

Notes are bordered by horizontal lines above and below

the text. General information is identified by the symbol

shown on the left.

Read these texts carefully.

Symbol

Material losses (appliance damage, consequential losses

!

This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

and environmental pollution)

Appliance disposal

1.3 Units of measurement

Note

Unless specified otherwise, all dimensions are given in

mm.

1.1.2 Symbols, type of risk

Symbol Type of risk

Injury

!

1.1.3 Keywords

KEYWORD Meaning

DANGER Failure to observe this information will result in serious

WARNING Failure to observe this information may result in serious

CAUTION Failure to observe this information may result in non-seri-

Electrocution

Burns or scalding

injury or death.

injury or death.

ous or minor injury.

www.stiebel-eltron.com DEL AU| 3

Page 4

OPERATION

Safety

2. Safety

2.1 Intended use

This appliance is intended for domestic use. It can be used safely

by untrained persons. The appliance can also be used in a non-domestic environment, e.g. in a small business, as long as it is used

in the same way.

This pressure-tested appliance is suitable for heating domestic hot

water or for reheating preheated water. The appliance can supply

one or more draw-off points.

Any other use beyond that described shall be deemed inappropriate. Observation of these instructions and of instructions for any

accessories used is also part of the correct use of this appliance.

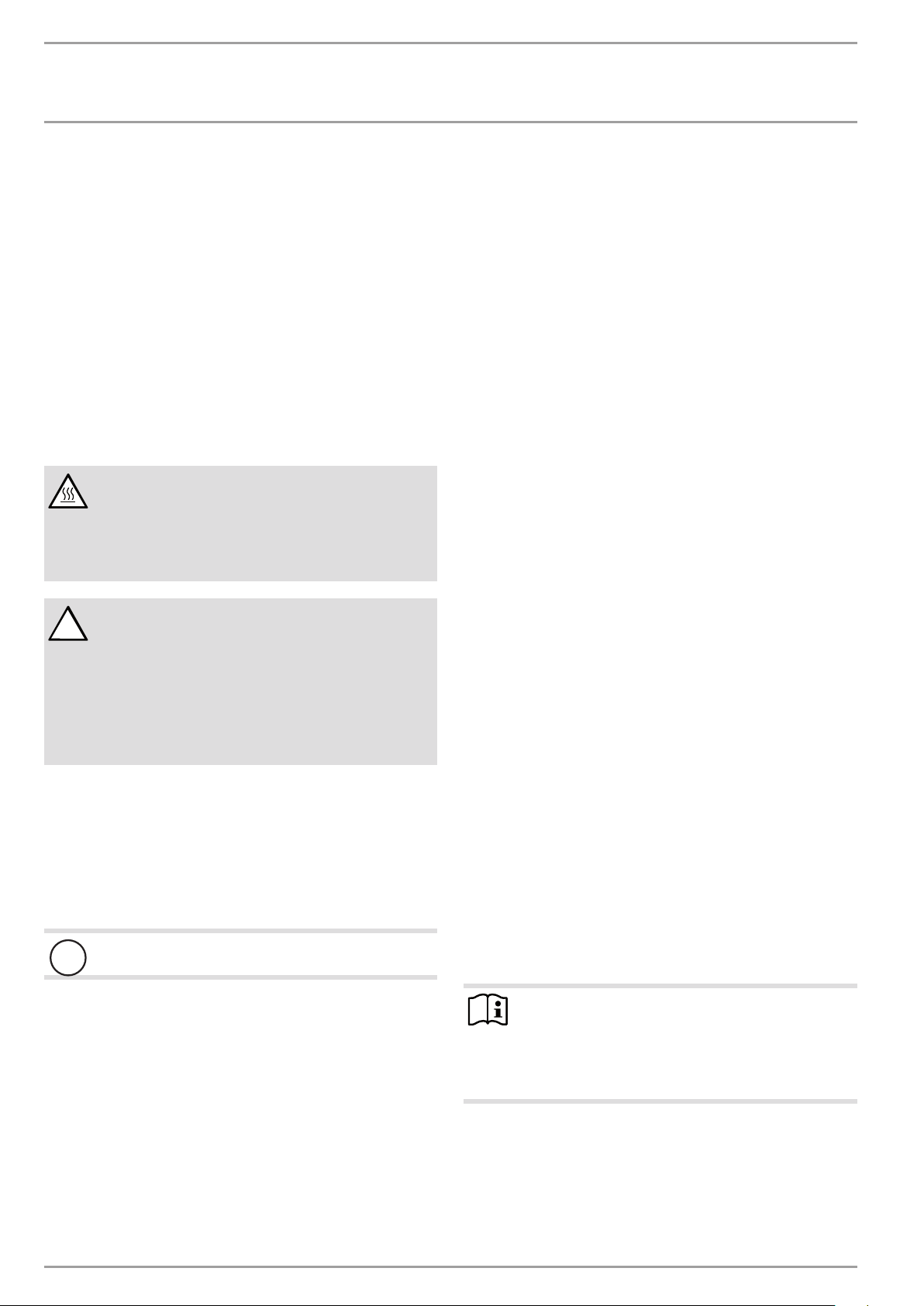

2.2 General safety instructions

CAUTION Burns

During operation, the tap can reach temperatures in

excess of 50°C, e.g. in the case of water that has been

preheated by solar energy.

There is a risk of scalding at outlet temperatures in excess of 43 °C.

WARNING Injury

!

The appliance may be used by children aged 8 and up and

persons with reduced physical, sensory or mental capabilities or a lack of experience and know-how, provided

that they are supervised or they have been instructed on

how to use the appliance safely and have understood

the resulting risks. Children must never play with the

appliance. Children must never clean the appliance or

perform user maintenance unless they are supervised.

Where children or persons with limited physical, sensory or mental abilities are allowed to use this appliance, we recommend a

permanent temperature limit. The limit can be set by you or a

qualified contractor:

- The temperature limit (childproofing) is user adjustable

- Anti-scalding protection can be enabled by a qualified

contractor.

Damage to the appliance and environment

!

Protect the appliance and its tap against frost.

2.3 CE designation

The CE designation shows that the appliance meets all essential

requirements according to the:

- Low Voltage Directive

- Electromagnetic Compatibility Directive

The maximum permissible mains impedance is indicated in

chapter "Specification".

2.4 Test symbols

See type plate on the appliance

Information for Australia/New Zealand:

Installation complies with standard AS/NZS 3500.4.

3. Appliance description

The electronically controlled instantaneous water heater with

automatic output matching maintains a consistent outlet temperature. This is irrespective of the inlet temperature, up to the

maximum output of the appliance.

DHW temperature

The DHW outlet temperature can be variably adjusted. The selected temperature is displayed.

Display backlighting

The display has white backlighting. During the draw-off process

or a temperature adjustment, backlighting is enabled.

Temperature limit (childproofing)/ anti-scalding protection

You can set the temperature limit (childproofing) individually using

the Tmax key. The selected temperature then limits the setting

range of the DHW outlet temperature.

The qualified contractor can also enable static anti-scalding protection from 43°C for you (see chapter "Alternative installation

options/ Anti-scalding protection"). The anti-scalding temperature

then functions as the upper limit for the DHW outlet temperature

and the temperature limit (childproofing).

Heating system

The heating system is suitable for hard and soft water areas; it

has low susceptibility to scale build-up. This system ensures rapid

and efficient DHW availability.

Note

The appliance is equipped with an air detector that largely prevents damage to the heating system. If, during operation, air is drawn into the appliance, heating output

is shut down automatically for one minute, thereby protecting the heating system.

4 | DEL AU www.stiebel-eltron.com

Page 5

OPERATION

ENGLISH

Settings and displays

4. Settings and displays

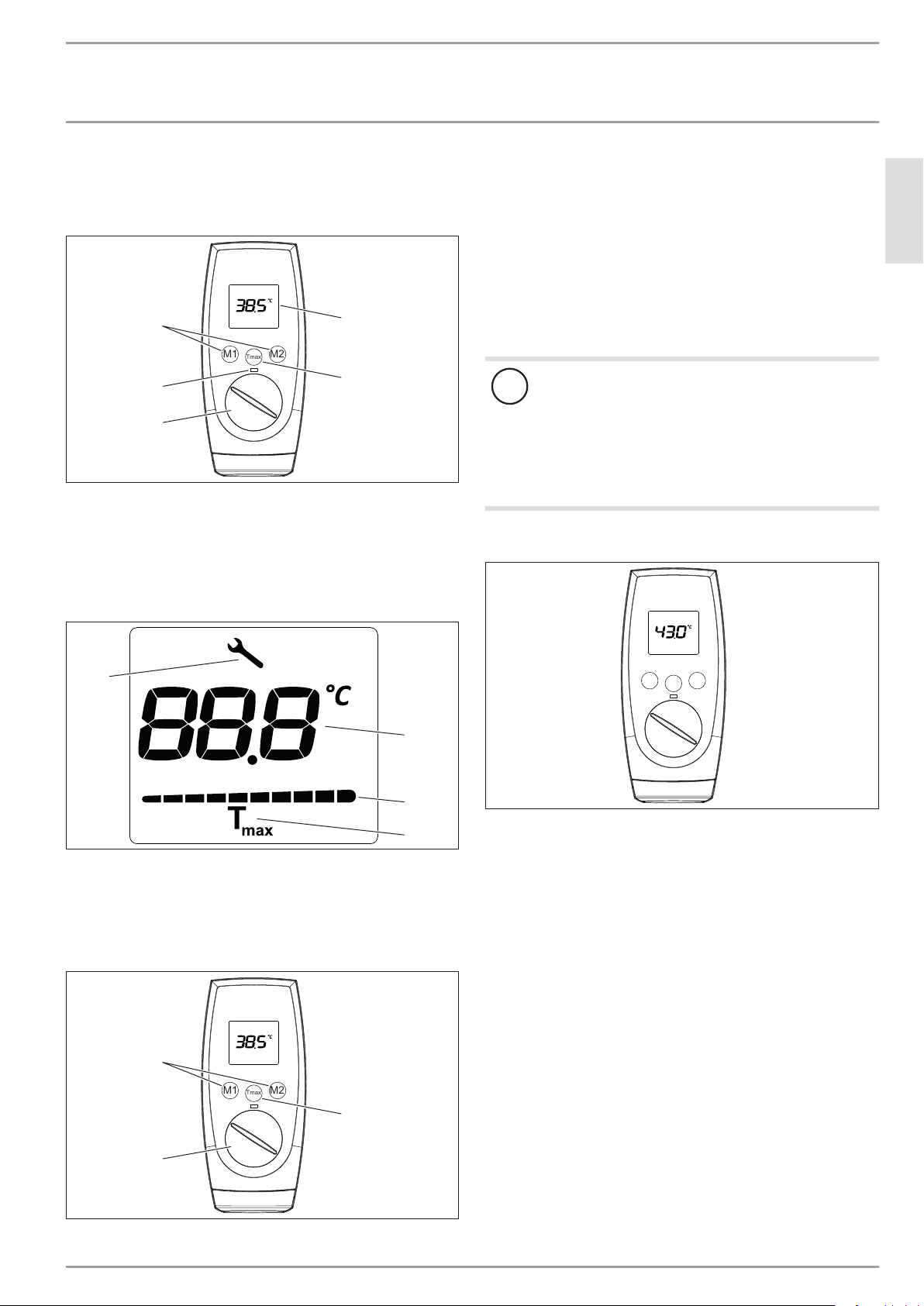

4.1 User interface

3

M1

2

1

1 Temperature selector

2 LED scalding risk indicator

3 Memory keys M1 and M2

4 Display

5 Temperature limit Tmax

Display symbols

Tmax

M2

1 Set temperature setting range 30 - 60°C (without end-stop)

35°C ... 43°C in 0.5°C increments, other temperature ranges

in 1°C increments

2 Call up preferred temperatures

3 Set the temperature limit

Memory keys M1 and M2 can each be assigned a preferred temperature.

Select a preferred temperature.

4

Press one of the M keys for 3seconds to save the preferred

temperature . The temperature is confirmed with 1x flashing.

5

Note

!

If the outlet temperature is not sufficiently high when the

draw-off valve is fully open and the temperature selector

is set to maximum, then more water is flowing through

the appliance than can be heated by the heating system

D0000040726

(working at maximum output).

Reduce the water volume at the draw-off valve until

the preferred temperature delivery is achieved.

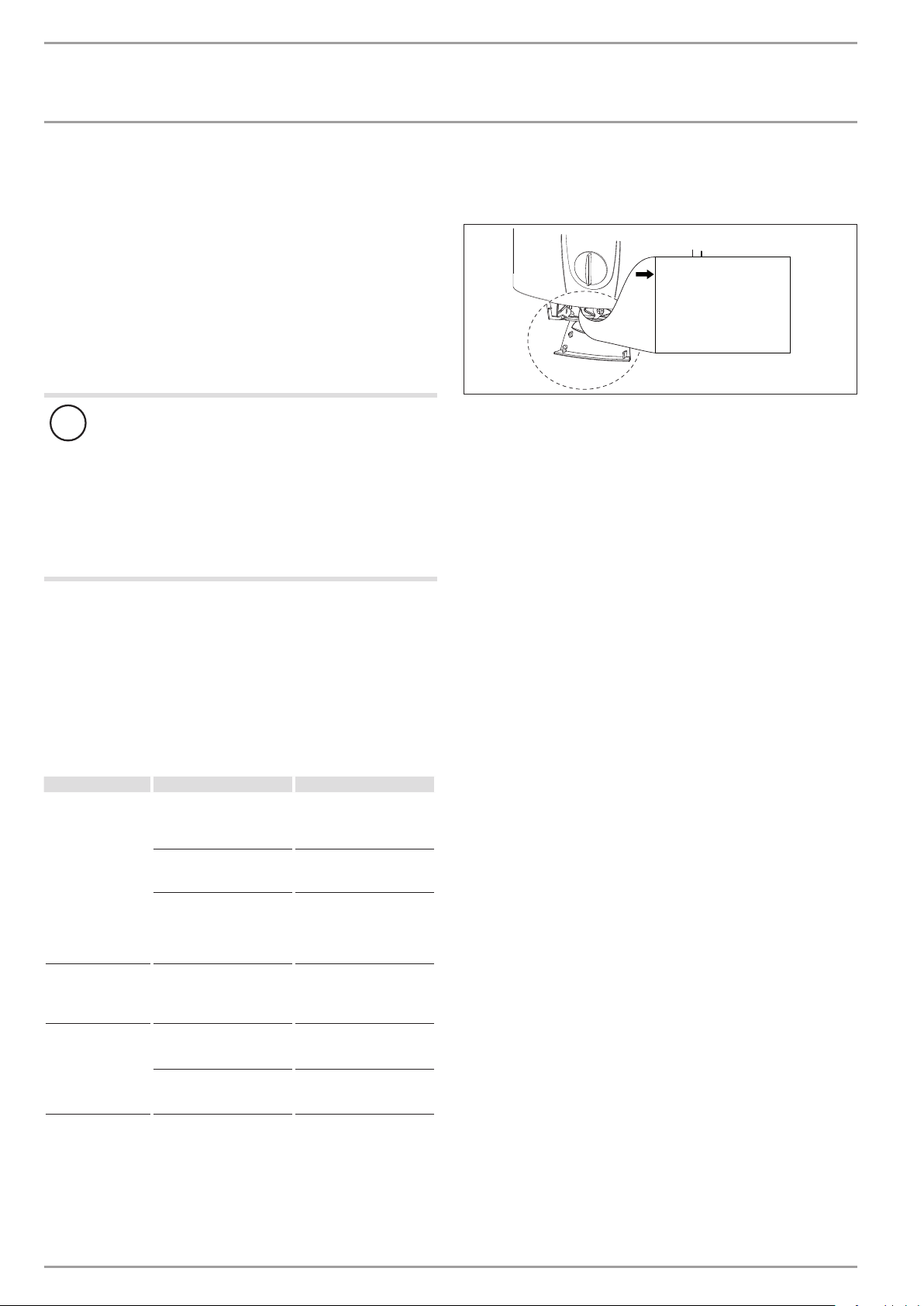

4.2 Temperature limit (childproofing)

1

1 In the event of an appliance fault, a spanner appears

2 Segment display for temperature setting with °C

3 Performance bar, 10 - 100%

4 Tmax, displayed when temperature limit is enabled

Setting the temperature

2

M1

Tmax

M2

3

M1

Tmax

M2

2

3

4

The temperature limit can be individually set between 30°C and

D0000040989

50°C.

D0000040981

Enabling the temperature limit (childproofing)

Press and hold the Tmax key for >6seconds. The set value

display flashes and the current temperature limit is shown.

The value for the temperature limit can be changed while

the display is flashing. If no key is pressed for 10seconds,

the display stops flashing and the value is stored. The display

then shows the set value and the Tmax symbol.

Disabling the temperature limit (childproofing)

Press and hold the Tmax key for >6seconds.

The Tmax symbol on the display is no longer shown.

1

D0000040726

www.stiebel-eltron.com DEL AU| 5

Page 6

OPERATION

Cleaning, care and maintenance

4.3 Inlet temperature information

If the inlet temperature is higher than the preferred temperature,

e.g. if water has been preheated by solar energy, the display alternates between showing "hot" and the measured inlet temperature.

The LED scalding risk indicator also flashes.

Recommended setting for operation with a thermostatic valve

and water preheated by solar energy

Set the temperature at the appliance to the max.

temperature.

4.4 Following an interruption of the water supply

Material losses

!

Following an interruption of the water supply the appliance must be recommissioned by carrying out the following steps, in order to prevent the destruction of the bare

wire heating system.

Disconnect the appliance from the power supply by

removing the fuses/tripping the MCBs.

Open the tap for one minute until the appliance and

its upstream cold water inlet line are free of air.

Switch the mains power back ON again.

If you cannot remedy the fault, notify your qualified contractor.

To facilitate and speed up your enquiry, please provide the serial

number from the type plate (000000-0000-000000):

DEL ... AU

No.: 000000-0000-000000

26�02�02�1125�

5. Cleaning, care and maintenance

Never use abrasive or corrosive cleaning agents. A damp

cloth is sufficient for cleaning the appliance.

Check the taps regularly. Limescale deposits at the spouts

can be removed using commercially available descaling

agents.

6. Troubleshooting

Fault Cause Remedy

The appliance will

not star t despite the

DHW valve being

fully open.

Cold water flows

briefly while hot

water is being

drawn.

The temperature at

the appliance cannot

be set to >43°C.

There is no voltage in the

appliance.

The aerator in the tap or

the shower head is scaled

up or contaminated.

The water supply has been

interrupted.

The air sensor detects air

in the water and the appliance's heating output is

briefly switched off.

The Tmax childproofing is

enabled.

The anti-scalding protection in the appliance is

enabled.

Check the fuses/MCBs in

your fuse box/distribution

panel.

Clean and/or descale the

aerator or shower head.

Vent the appliance and the

cold water inlet line (see

chapter "Settings / Following an interruption to the

water supply").

The appliance restarts automatically after 1minute.

Disable the childproofing

(see chapter "Appliance

description")

Your qualified contractor

can disable the anti-scalding protection for you.

6 | DEL AU www.stiebel-eltron.com

Page 7

ENGLISH

INSTALLATION

Safety

INSTALLATION

7. Safety

Only a qualified contractor should carry out installation, commissioning, maintenance and repair of the appliance.

7.1 General safety instructions

We guarantee trouble-free function and operational reliability only

if original accessories and spare parts intended for the appliance

are used.

Flow pressure

If the flow rate is not sufficient to switch on the appliance even

when the tap is open, remove the flow limiter and replace it with

the plastic profile washer supplied.

If required, the pressure in the water installation can also be

raised.

Note

For the thermostatic valve to function correctly, the flow

limiter for this valve must not be replaced with the plastic

profile washer.

Material losses

!

Observe the maximum inlet temperature. Higher temperatures may damage the appliance. You can limit the

maximum inlet temperature by installing a central thermostatic valve.

7.2 Instructions, standards and regulations

8. Appliance description

8.1 Standard delivery

The following are delivered with the appliance:

- Wall mounting bracket

- Installation template

- 2 plugs

- 2 extensions

- 2 caps

- 2 tees

- 8 flat gaskets

- Strainer

- 2 flow limiters

- Plastic profile washer

- Plastic connection pieces / installation aid

- Cover and back panel guides

9. Preparations

Flush the water line thoroughly.

Taps/valves

Use appropriate pressure-tested taps. Open taps are not

permitted.

A safety valve is not required.

Permissible water pipe materials

- Cold water inlet pipe:

Galvanised steel pipe, stainless steel pipe, copper pipe or

plastic pipe

- DHW outlet pipe:

Stainless steel pipe, copper pipe or plastic pipe

Note

Observe all applicable national and regional regulations

and instructions.

- The protection rating IP 25 (hoseproof) can only be ensured

with a correctly fitted cable grommet.

- The specific electrical resistance of the water must not fall

below that stated on the type plate. In a linked water network, factor in the lowest electrical resistance of the water

(see chapter "Specification/ Application areas"). Your water

supply utility will advise you of the specific electrical water

resistance or conductivity.

www.stiebel-eltron.com DEL AU| 7

Flow rate

Flexible water connection lines

Material losses

!

If plastic pipework systems are used, take into account

the maximum inlet temperature and the maximum pressure (see chapter "Specification/ Data table").

Ensure that the flow rate (see chapter "Specification/ Data

table", On) is sufficient for switching on the appliance.

Increase the mains water pressure if the required flow rate is

not sufficient with an open draw-off valve.

If the appliance is installed with flexible water connection

lines, ensure that the pipe bends do not become twisted.

Pipe bends have a bayonet fitting and are installed inside the

appliance.

Secure the back panel with an additional screw at the

bottom.

Page 8

INSTALLATION

Installation

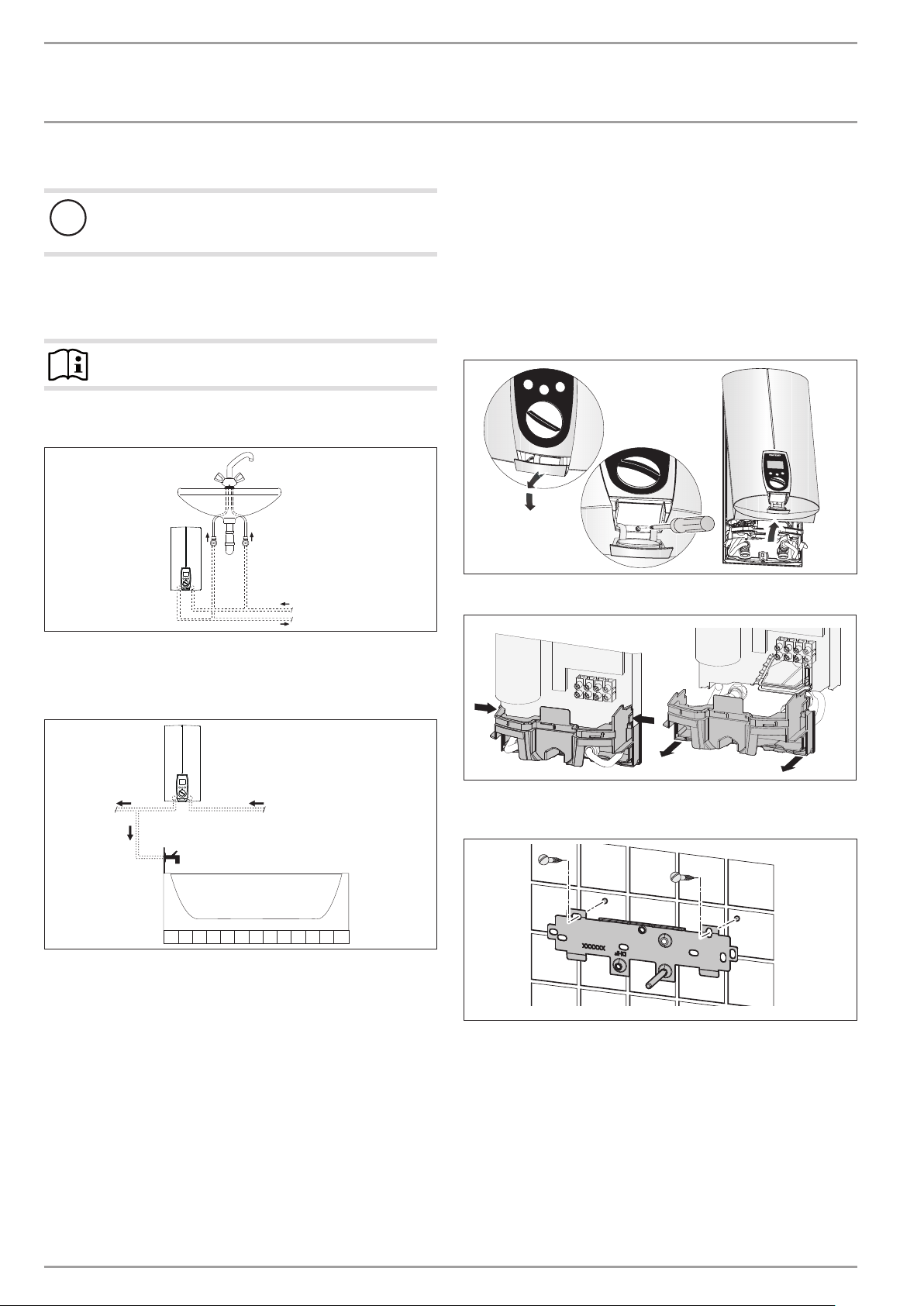

9.1 Installation site

Material losses

!

Only install the appliance in rooms free from the risk of

frost.

Always install the appliance vertically near the draw-off

point.

The appliance is suitable for undersink and oversink installations.

Note

Mount the appliance on a sufficiently load-bearing wall.

Undersink installation

1

2

1 Cold water inlet

2 DHW outlet

10. Installation

10.1 Standard installation

- Electrical connection in the lower section of the appliance for

installation on unfinished walls

- Water connection for installation on finished walls

- For the appliance with adjustable connected load, the middle

load is preset.

For further installation options, see chapter "Installation options".

electron iccomfor

t

Open the appliance.

D0000040728

D0000040738

Oversink installation

2

1 Cold water inlet pipe

2 DHW outlet pipe

26�02�02�1101

1

Remove the back panel by pressing the two locking hooks

and pulling the lower part of the back panel forwards.

D0000040736

26�02�02�0810�

Mount the wall mounting bracket.

Align the installation template based on the existing electrical

connection when marking out the drill holes (wall mounting and

lower back panel).

If you want to adapt the existing water connections, take the dimensions from the drawing when marking out the drill holes; see

chapter "Specification/ Dimensions and connections". In this case,

check beforehand that the electrical connection lies within one of

the areas marked on the installation template.

8 | DEL AU www.stiebel-eltron.com

Page 9

ENGLISH

INSTALLATION

160

Installation

30

1 Installation aid

Prepare the power cable.

Preparing the water connection

Material losses

!

Carry out all water connection and installation work in

accordance with regulations.

1

26�02�02�0824�

Installing the appliance

D0000041720

Note

Install the blue flow limiter (7.5l/min) as standard.

Use the brown flow limiter (12l/min) in the follow-

ing instances:

- With an increased cold water inlet temperature, e.g.

in the case of water preheated by solar energy.

- When using the appliance for showering.

With low water pressure.The pressure drop can be

reduced by replacing the flow limiter with the plastic

profile washer provided.

Remove the caps from the tees.

Fit the plugs and the extensions with gaskets.

Fit the strainer in the tee for the cold water inlet.

Damage to the appliance and environment

!

The strainer must be fitted for the appliance to function.

When replacing the appliance, check that the strain-

er is present.

12

1 Flow limiter

2 Plastic profile washer

Fit the flow limiter or the plastic profile washer.

D0000041721

For easy installation, push the cable grommet of the upper

electrical connection into the back panel from behind.

Remove the transport plugs from the water connections.

Remove the fixing toggle from the upper part of the back

panel.

Route the power cable through the cable grommet from be-

hind, until the power cable rests against the cable sheath.

Align the power cable.

If the cross-section is >6mm², enlarge the hole in the cable

grommet.

Press the appliance over the threaded stud of the wall

mounting bracket. When doing so, push through the soft

seal in the back panel of the appliance. If necessary, use a

D0000041722

screwdriver.

Push the fixing toggle on to the threaded stud of the wall

mounting bracket.

Push the back panel of the appliance on to the wall. Turn the

fixing toggle 90° clockwise to lock the appliance in place.

26�02�02�1336

www.stiebel-eltron.com DEL AU| 9

Page 10

INSTALLATION

Installation

Lower back panel installation

Screw the pre-assembled parts with flat gaskets to the cold

water and DHW pipes of the appliance.

Fit the cold water inlet pipe and the DHW outlet pipe from

the pipework with flat gaskets to the extensions from the

appliance.

Making the electrical connection

WARNING Electrocution

Carry out all electrical connection and installation work

in accordance with relevant regulations.

WARNING Electrocution

Connection to the power supply is only permissible in the

form of a permanent connection in conjunction with the

removable cable grommet. Ensure the appliance can be

separated from the power supply by an isolator that disconnects all poles with at least 3mm contact separation.

WARNING Electrocution

Ensure that the appliance is earthed.

2

D0000041723

1 Connection pieces delivered in the pack

2 Screw

Cut open the lower part of the back panel (see illustration).

Fit the lower back panel by bending it out at the sides and

guiding it over the pipes.

Insert the connection pieces into the lower back panel from

behind.

Click the lower back panel into place.

Align the mounted appliance by loosening the fixing toggle,

aligning the power supply and back panel, and then re-tightening the fixing toggle.

Secure the lower back panel with a screw.

1

10.2 Completing the installation

Open the shut-off valve in the cold water inlet line.

Fitting the sealing elements for the appliance cover

26�02�02�1080

Damage to the appliance and environment

!

Observe the type plate. The specified voltage must match

the mains voltage.

Connect the power cable to the mains terminal (see chapter

"Specification/ Wiring diagram"). The specified voltage must

match the mains voltage.

1

26�02�02�1122�

1 Pipe aperture

2 Cover guides

3 Back panel guides

Material losses

!

If you cut open the wrong knock-out in the appliance

cover by mistake, you must use a new appliance cover.

Cleanly cut or break out the knock-out openings in the appli-

ance cover. If necessary, use a file.

Note

You can compensate for a slight connection pipe offset

using the tabs on the cover guides. If the connection pipes

are offset, do not fit any back panel guides.

2

3

D0000040777

10 | DEL AU www.stiebel-eltron.com

Page 11

ENGLISH

INSTALLATION

Installation

When installing connection pipes that are not offset, break

off the tabs on the cover guides.

Click the cover guides into place in the pipe apertures.

Position the back panel guides on the extensions. Push them

together. Then push the guides until they are resting against

the back panel.

10.3 Installation options

- Electrical connection from above on unfinished walls

- Electrical connection for finished walls

- Large cross-section for electrical connection from below

- Water installation on unfinished walls

- Wall mounting bracket when replacing an appliance

- Installation with offset tiles

- Pivoting appliance cover

- Operation with preheated water

- Anti-scalding protection/ temperature limit

Electrical connection from above on unfinished walls

Note

This type of connection changes the protection rating of

the appliance.

Change the type plate. Cross out "IP 25" and mark

the box "IP 24". Please use a ballpoint pen to do this.

Large cross-section for electrical connection from below

If you use cables with a large cross-section, you can fit the cable

grommet after the appliance has been installed.

1.

3.

2.

4.

Cut open the cable grommet for the power cable.

Push down the locking hook to secure the mains terminal.

Pull out the mains terminal.

Reposition the mains terminal in the appliance from the

bottom to the top and secure the mains terminal by sliding it

under the locking hook.

Lay the control wires below the wire guide.

Power cable for finished walls

Material losses

!

If you cut open the wrong knock-out in the appliance

cover by mistake, you must use a new appliance cover.

Cut or break out the required entries in the back panel and

appliance cover cleanly (for positions, see chapter "Specification/ Dimensions and connections"). If necessary, use a file.

Route the power cable through the cable grommet. Connect

the power cable to the mains terminal.

Before installing the appliance, use a screwdriver to push out

the cable grommet.

Slide the cable grommet over the power cable. For this, use

the installation aid. If the cross-section is >6mm², enlarge

the hole in the cable grommet.

Push the cable grommet into the back panel.

26�02�02�1123�

Water installation on unfinished walls

Seal and screw in the twin connectors (not included in stand-

ard delivery).

2

3

1 Tee for cold water

2 Tee for domestic hot water

3 Cover

Fit the water connections.

1

3

26�02�02�1124�

26�02�02�0798

D0000041724

www.stiebel-eltron.com DEL AU| 11

Page 12

INSTALLATION

Installation

Rotate the wall mounting bracket 180° and mount it on the

wall. Use the existing drill holes.

Installation with offset tiles

Fit the strainer and the plastic profile washer in the tee for

the cold water inlet.

Damage to the appliance and environment

!

The strainer must be fitted for the appliance to function.

When replacing the appliance, check that the strain-

er is present.

Screw the connection pipes from the appliance with flat gas-

kets to the tee.

Open the shut-off valve in the cold water inlet line.

D0000043291

2

20

110

1

1 Minimum contact area of the appliance

2 Maximum tile offset

Adjust the wall clearance. Lock the back panel with the fixing

toggle by turning it 90° clockwise.

Pivoting appliance cover

You can rotate the appliance cover for undersink installation.

26�02�02�1102�

D0000043278

Fit the lower part of the back panel. Ensure that it clicks into

place.

Align the mounted appliance by loosening the fixing toggle,

aligning the power supply and back panel, and then re-tightening the fixing toggle. If the back panel of the appliance is

not flush, the appliance can be secured at the bottom with an

additional screw.

Wall mounting bracket when replacing an appliance

When replacing an appliance, you can use an existing wall mounting bracket of a StiebelEltron appliance (except for a DHF instantaneous water heater).

Press the appliance over the threaded stud of the existing

wall mounting bracket. When doing so, push through the soft

seal in the back panel of the appliance. If necessary, use a

screwdriver.

DHF replacement

Remove the DHF wall mounting bracket.

Take the new wall mounting bracket and move the thread-

ed stud to the position marked with DHF (the stud has a

self-tapping thread).

electr

oniccom for

t

electronic

comfort

Remove the programming unit from the appliance cover by

pressing the locking hooks and taking out the programming

unit.

Turn the appliance cover (not the appliance) and refit the

programming unit, ensuring that all locking hooks click into

place. When clicking the locking hooks into place, make sure

you press against the inner side of the appliance cover (shaded area).

Plug the set value transducer cable into the PCB (see chapter

"Commissioning/ Initial start-up").

Hook the appliance cover in at the bottom. Pivot it up to the

26�02�02�0815�

back panel.

Ensure the all-round seal of the back panel is firmly seated

by pushing the cover gently forwards and back.

Secure the appliance cover.

D0000040745

12 | DEL AU www.stiebel-eltron.com

Page 13

ENGLISH

INSTALLATION

Commissioning

Operation with preheated water

You can limit the maximum inlet temperature by installing a central thermostatic valve.

Anti-scalding protection/ temperature limit

60

2

43

1

1 Position 43: Maximum temperature setting 43°C

2 Position 60: No temperature limit, for temperature setting

range, see chapter "Specification/Data table".

Remove the appliance cover.

Slide the switch to the required position.

Fit the appliance cover.

11. Commissioning

WARNING Electrocution

Commissioning may only be carried out by a qualified

contractor in accordance with safety regulations.

11.1 Initial start-up

D0000040985

e

l

c

e

n

r

t

o

o

c

c

i

f

o

m

r

t

Open and close all connected draw-off valves several times,

until all air has been vented from the pipework and the

appliance.

Check for leaks in the appliance screw joints.

Activate the safety pressure limiter for flow pressure by

firmly pressing in the reset button (the appliance is delivered

with the safety pressure limiter disabled).

Push the temperature selector plug into the "set tempera-

ture" PCB.

Fit the appliance cover and secure with a screw.

Switch the mains power ON.

Check the function of the appliance.

Remove the protective foil from the control fascia.

Appliance handover

Explain the appliance function to users and familiarise them

with its operation.

Make users aware of potential dangers, especially the risk of

scalding.

Hand over these instructions.

D0000040746

www.stiebel-eltron.com DEL AU| 13

Page 14

INSTALLATION

Shutting down the system

11.2 Recommissioning

See chapter "Settings and displays / Following an interruption to

the water supply"

12. Shutting down the system

Isolate all poles of the appliance from the power supply.

Drain the appliance (see chapter "Maintenance").

13. Troubleshooting

WARNING Electrocution

In order to check the appliance it must be connected to

the power supply.

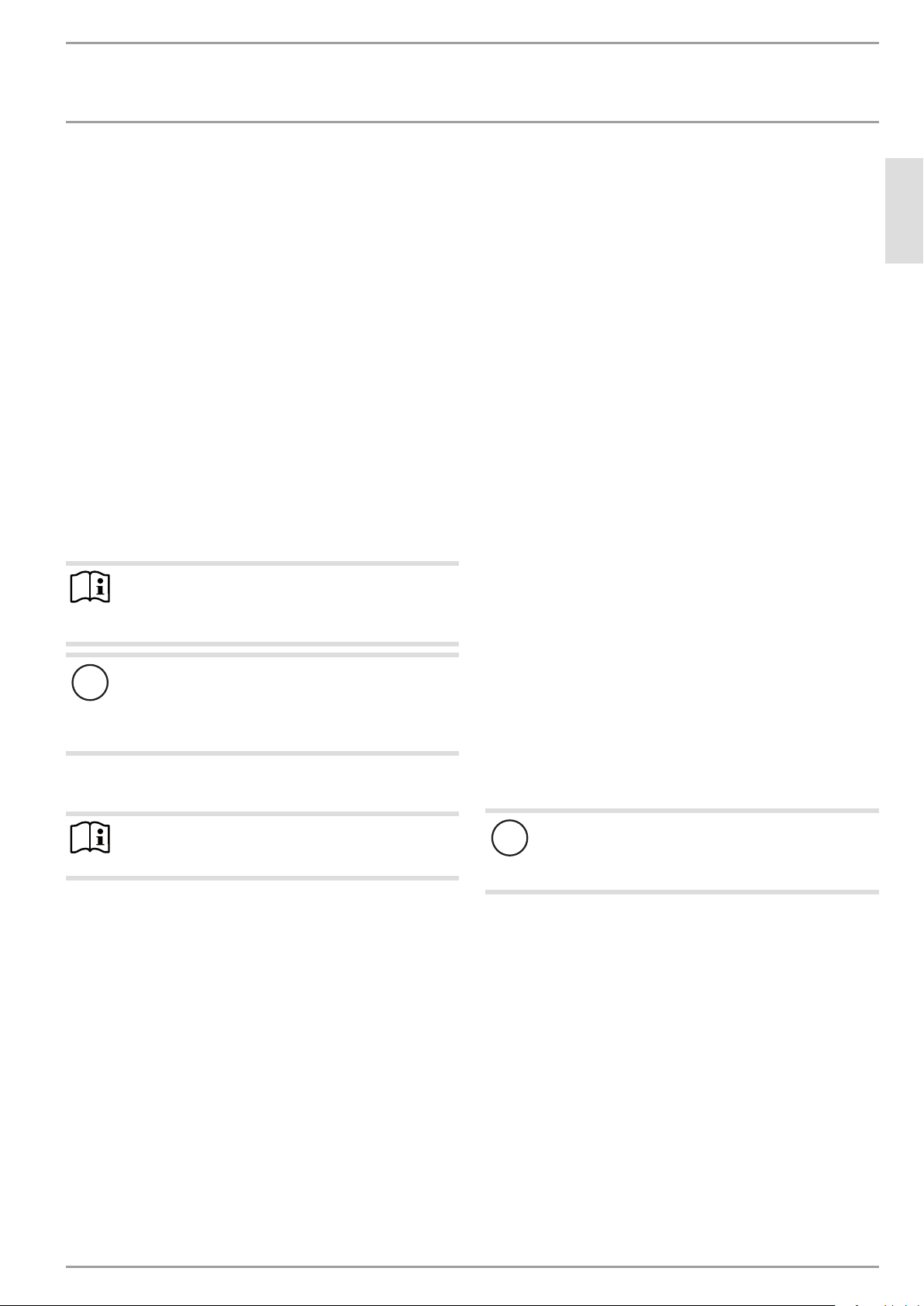

13.1 Service mode

1

M1

1 Memory keys M1 and M2

2 Spanner symbol

The spanner symbol is displayed in the event of a fault.

Activate customer service mode by pressing and holding

down both memory keys M1 and M2 for >6seconds.

Disable customer service mode by briefly pressing one of the

three keys. Service mode is automatically terminated after

30seconds of inactivity.

Fault displays

--- No display, there is no fault

ntc Outlet sensor malfunction

ELE Faulty PCB

Tmax

M2

2

D0000040982

14 | DEL AU www.stiebel-eltron.com

Page 15

ENGLISH

INSTALLATION

Troubleshooting

13.2 Indicator options for LED diagnostic traffic light

Indicator options

Red Illuminates in the event of a fault

Yellow Illuminates during heating mode

Green Flashing: Appliance is supplied with mains power

13.3 Fault table

LED diagnost ic

traff ic light

No display No hot water. The fuse/MCB in the fuse box has blown/responded. Check the fuses/MCBs in your fuse box/distribution

The safety pressure limiter has responded.

The PCB is faulty. Check the PCB, replace if required.

Flashing green

light

No hot water at flow rate

The flow sensor (DFE) is faulty. Check the flow sensor and replace if required.

Flashing green

light and steady

yellow light

The set temperature is not

A set temperature of >43°C is not

Flashing green

light and steady

red light

Selected temperatures above 45°C

Fault Cause Remedy

panel.

Remove the cause of the fault (e.g. faulty pressure

washer).

The appliance does not start.

Inadequate flow rate. Clean the strainer in the water inlet.

>3l/min.

No hot water at flow rate

>3l/min.

achieved.

The appliance is at its output limit. Reduce the flow rate or install the flow limiter.

The outlet temperature is approx.

45°C, irrespective of the set value

transducer

achieved.

No hot water.

The flow rate is >25l/min. Reduce the flow rate or install the flow limiter.

are not achieved.

Inadequate flow rate. Descale/ clean the connected aerator/ shower

The flow sensor (DFE) plug has not been inserted. Plug the flow sensor plug back in.

The high limit safety cut-out has responded or its

lead is broken.

One phase down. Check the fuses/MCBs in your fuse box/distribution

The heating system is faulty. Measure the resistance of the heating system and

The outlet temperature sensor is faulty. Check the outlet temperature sensor and replace if

The set value transducer or connecting cable is faulty,

or the connecting cable is not attached.

The temperature limit (childproofing)/ anti-scalding

protection is enabled.

The outlet temperature sensor is faulty.

The cold water sensor is faulty. Check the PCB, replace if required.

The air sensor detects the presence of air in the water

and briefly interrupts the heating output.

The cold water inlet temperature is above 45°C (e.g.

in the case of water preheated by solar energy).

Protect the heating system against overheating by

opening a draw-off valve downstream of the appliance for one minute. This depressurises and cools

down the heating system.

Activate the safety pressure limiter at flow pressure

by pressing the reset button; see also chapter "Commissioning/ Initial start-up".

head.

Check the appliance and the high limit safety cutout.

panel.

replace if required.

required.

Attach the connecting cable; replace the set value

transducer if required.

Disable the temperature limit (childproofing)/ anti-scalding protection.

Check the outlet temperature sensor and replace if

required.

The appliance restarts after one minute.

Reduce the cold water inlet temperature to the appliance.

www.stiebel-eltron.com DEL AU| 15

Page 16

INSTALLATION

105≤ 20225

338

Maintenance

14. Maintenance

WARNING Electrocution

Before any work on the appliance, disconnect all poles

from the power supply.

Draining the appliance

You can drain the appliance for maintenance work or to protect

it from frost.

CAUTION Scalding

Hot water may escape when draining the appliance.

Close the shut-off valve in the cold water inlet line.

Open all draw-off valves.

Undo the water connections on the appliance.

Store the dismantled appliance in a room free from the risk

of frost, as water residues remaining inside the appliance can

freeze and cause damage.

Cleaning the strainer

A strainer is located in the tee from the cold water inlet pipe. In

case of contamination, you can remove this strainer and clean it.

15. Specification

15.1 Dimensions and connections

140

414

473

493

368

b02

30

44

100

c01c06

478

35

35

114

D0000043287

1 32

1 Flow limiter or

2 Plastic profile washer

3 Strainer

Remove the flow limiter or plastic profile washer (selected

during installation).

Remove the strainer and clean the components.

Fit the strainer and the plastic profile washer or flow limiter.

b02 Entry electrical cables I

c01 Cold water inlet Male thread G 1/2 A

c06 DHW outlet Male thread G 1/2 A

Alternative connection options

D0000041722

b04

47

b03

325

b04

50

44

b04

b02 Entry electrical cables I

b03 Entry electrical cables II

b04 Entry electrical cables III

b02

30

165

b04

72

35

b04

D0000043288

16 | DEL AU www.stiebel-eltron.com

Page 17

ENGLISH

INSTALLATION

Specication

15.2 Wiring diagram

3/PE ~ 380-415 V

1 Heater

2 High limit safety cut-out

3 Safety pressure limiter

15.3 DHW output

DHW output is subject to the mains voltage, the appliance's connected load and the cold water inlet temperature. The rated voltage and rated output can be found on the type plate (see chapter

"Troubleshooting").

Connected load in kW 50 °C DHW output in l/min.

Rated voltage Cold water inlet temperature

380 V 400 V 415 V 5°C 10°C 15°C 20°C

10.1 3.2 3.6 4.1 4.8

11.0 3.5 3.9 4.5 5.2

12.0 3.8 4.3 4.9 5.7

12.2 3.9 4.4 5.0 5.8

13.2 4.2 4.7 5.4 6.3

13.5 4.3 4.8 5.5 6.4

13.6 4.3 4.9 5.6 6.5

14.2 4.5 5.1 5.8 6.8

14.5 4.6 5.2 5.9 6.9

15.0 4.8 5.4 6.1 7.1

16.2 16.2 5.1 5.8 6.6 7.7

16.3 5.2 5.8 6.7 7.8

18.0 5.7 6.4 7.3 8.6

19.0 6.0 6.8 7.8 9.0

19.4 6.2 6.9 7.9 9.2

85�02�02�0005�

21.0 6.7 7.5 8.6 10.0

21.7 6.9 7.8 8.9 10.3

22.6 7.2 8.1 9.2 10.8

23.5 7. 5 8.4 9.6 11.2

24.0 7.6 8.6 9.8 11.4

24.4 7.7 8.7 10.0 11.6

25.8 8.2 9.2 10.5 12.3

26.0 8.3 9.3 10.6 12.4

27.0 8.6 9.6 11.0 12.9

28.0 8.9 10.0 11.4 13.3

29.1 9.2 10.4 11.9 13.9

Connected load in kW 38 °C DHW output in l/min.

Rated voltage Cold water inlet temperature

380 V 400 V 415 V 5°C 10°C 15°C 20°C

10.1 4.4 5.2 6.3 8.0

11.0 4.8 5.6 6.8 8.7

12.0 5.2 6.1 7.5 9.5

12.2 5.3 6.2 7. 6 9.7

13.2 5.7 6.7 8.2 10.5

13.5 5.8 6.9 8.4 10.7

13.6 5.9 6.9 8.4 10.8

14.2 6.1 7.2 8.8 11.3

14.5 6.3 7.4 9.0 11.5

15.0 6.5 7.7 9.3 11.9

16.2 16.2 7.0 8.3 10.1 12.9

16.3 7.1 8.3 10.1 12.9

18.0 7.8 9.2 11.2 14.3

19.0 8.2 9.7 11.8 15.1

19.4 8.4 9.9 12.0 15.4

21.0 9.1 10.7 13.0 16.7

21.7 9.4 11.1 13.5 17. 2

22.6 9.8 11.5 14.0 17.9

23.5 10.2 12.0 14.6 18.7

24.0 10.4 12.2 14.9 19.0

24.4 10.6 12.4 15.2 19.4

25.8 11.2 13.2 16.0 20.5

26.0 11.3 13.3 16.1 20.6

27.0 11.7 13.8 16.8 21.4

28.0 12.1 14.3 17. 4 22.2

29.1 12.6 14.8 18.1 23.1

15.4 Application areas/ conversion table

Specific electrical resistance and specific electrical conductivity

(see chapter "Data table").

Standard specification

at 15 °C

Resist-

Conductivity σ Resist-

ance ρ

Ωcm mS/m μS/cm Ωcm mS/m μS/cm Ωcm mS/m μS/cm

900 111 1111 800 125 1250 735 136 1361

1000 100 1000 890 112 1124 815 123 1227

1100 91 909 970 103 1031 895 112 1117

1200 83 833 1070 93 935 985 102 1015

1300 77 769 1175 85 851 1072 93 933

20°C

Conductivity σ Resist-

ance ρ

25°C

Conductivity σ

ance ρ

15.5 Pressure drop

Taps/valves

Pressure drop at taps at flow rate of 10 l/min

Mono lever mixer tap, approx. MPa 0.04 - 0.08

Thermostatic valve, approx. MPa 0.03 - 0.05

Hand shower, approx. MPa 0.03 - 0.15

Sizing the pipework

To calculate pipework sizing, apply a pressure drop of 0.1MPa to

the appliance.

15.6 Fault conditions

In case of faults, loads up to 80°C at a pressure of 1.2MPa can

occur temporarily in the installation.

www.stiebel-eltron.com DEL AU| 17

Page 18

INSTALLATION

Specication

15.7 Data table

DEL 18 AU DEL 27 AU

233741 233742

Electrical data

Rated voltage V 380 400 415 380 400 415

Rated output kW 16.2 18 19.4 23.5 26 28

Rated current A 24.7 26 27 35.6 37.7 38.9

Fuse/MCB rating A 25 25 32 35 40 40

Phases 3/PE 3/PE

Frequency Hz 50/60 50/60 50/- 50/- 50/- 50/Specific resistance ρ

Specific conductivity σ15 ≤ (at ϑcold ≤25°C) μS/cm 1111 1111 1000 1111 1111 1000

Specific resistance ρ

Specific conductivity σ15 ≤ (at ϑcold ≤45°C) μS/cm 833 833 770 833 833 770

Max. mains impedance at 50Hz Ω 0.474 0.450 0.433 0.316 0.3 0.289

Max. mains impedance at 380V / 60Hz Ω 0.392

Max. mains impedance at 400V / 60Hz Ω 0.372

Connections

Water connection G 1/2 A G 1/2 A

Application limits

Max. permissible pressure MPa 1.0 1.0

Max. inlet temperature for reheating °C 45 45

Values

Max. permissible inlet temperature °C 65 65

On l/min >2.5 >2.5

Flow rate for pressure drop l/min 5.2 7.7

Pressure drop at flow rate MPa 0.08 (0.06 without DMB) 0.16 (0.12 without DMB)

Flow rate limit at l/min 12 ( 7.5) 12 ( 7.5)

DHW delivery l/min 9.9 at 415V 14.3 bei 415 V

Δϑ on delivery K 28 28

Hydraulic data

Nominal capacity l 0.4 0.4

Versions

Connected load options - Temperature setting °C 30-50 30-50

Safety category 1 1

Insulating block Plastic Plastic

Heating system Bare wire Bare wire

Cover and back panel Plastic Plastic

Colour white white

IP rating IP25 IP25

Dimensions

Height mm 478 478

Width mm 225 225

Depth mm 105 105

Weights

Weight kg 3.6 3.6

≥ (at ϑcold ≤25°C) Ω cm 900 900 1000 900 900 1000

15

≥ (at ϑcold ≤45°C) Ω cm 1200 1200 1300 1200 1200 1300

15

18 | DEL AU www.stiebel-eltron.com

Page 19

ENGLISH

WARR$NTY | ENVIRONMENT AND RECYCLING

Warranty

Component Warranty period

The warranty conditions of our German companies do not

All components 1 year from the date of completion of the installa-

apply to appliances acquired outside of Germany. In countries

where our subsidiaries sell our products, it is increasingly the

case that warranties can only be issued by those subsidiaries.

Such warranties are only granted if the subsidiary has issued

its own terms of warranty. No other warranty will be granted.

We shall not provide any warranty for appliances acquired in

countries where we have no subsidiary to sell our products.

Your entitlement to make a warranty claim

8. You are entitled to make a warranty claim if:

8.1. you own the unit or if you have the owner's consent to represent the owner of the unit;

This will not aect warranties issued by any importers.

8.2. you contact us within a reasonable time of discovering the

problem with the unit; How you make a warranty claim

Environment and recycling

We would ask you to help protect the environment. After use,

dispose of the various materials in accordance with national

regulations.

Stiebel Eltron Warranty for Water Heaters – Models DELAU

Who gives the warranty

1. The warranty is given by Stiebel Eltron (Aust) Pty Ltd

(A.B.N. 82066271083) of Unit 4/8 Rocklea Drive, Port Melbourne, Victoria, 3207 ("we", "us" or "our").

9. To make a warranty claim you must provide us with the

following information:

9.1. The model number of the unit;

9.2. A description of the problem with the unit;

9.3. The name, address and contact details (such as phone

number and e-mail address) of the owner;

9.4. The address where the unit is installed and the location

(e.g. in laundry);

tion of the unit.

The warranty

2. This warranty applies to Stiebel Eltron Water Heaters –

3. Subject to the warranty exclusions we will repair or re-

4. If we repair or replace a faulty component to your unit

5. The warranty period commences on the date of completion

6. The warranty period for a unit used for domestic purposes

Models DEL18AU and DEL27AU (the "unit") manufactured after 1 March 2014.

place, at our absolute discretion, a faulty component in

your unit free of charge if it fails to operate in accordance

with its specifications during the warranty period.

under this warranty, the warranty period is not extended

from the time of the repair or replacement.

of the installation of the unit. Where the date of completion

of installation is not known, then the warranty period will

commence 2 months after the date of manufacture.

is shown in the table below. Domestic purposes means

that the unit is used in a domestic dwelling.

Component Warranty period

All components 5 years from the date of completion of the installa-

tion of the unit.

9.5. The serial number of the unit;

9.6. The date of purchase of the unit and the name of the seller

of the unit;

9.7. The date of installation of the unit;

9.8. A copy of the certificate of compliance when the unit was

installed.

10. The contact details for you to make your warranty claim

are:

Name:

Address:

Telephone:

Contact person:

E-mail:

Stiebel Eltron (Aust) Pty Ltd

Unit 4, 8 Rocklea Drive, Port Melbourne, Victo-

ria, 3207

1800 153 351 (8.00am to 5.00pm AEST

Monday to Friday)

Customer Service Representative

service@stiebel.com.au

Warranty exclusions

12. We may reject your warranty claim if:

12.1. The unit was not installed by registered and qualified

tradespeople.

7. The warranty period for a unit used for commercial purposes is shown in the table below. Commercial purposes

means that the unit is used for a non-domestic purpose

and includes but is not limited to being used in a motel,

hotel, mining camp or nursing home.

12.2. The unit was not installed and commissioned:

a) in Australia;

b) in accordance with the Operating and Installation

Guide; and

c) in accordance with the relevant statutory and local

requirements of the State or Territory in which the unit

is installed.

www.stiebel-eltron.com DEL AU| 19

Page 20

WARR$NTY | ENVIRONMENT AND RECYCLING

12.3. The unit has not been operated or maintained in accordance with the Operating and Installation Guide.

12.4. The unit does not bear its original Serial Number or Rating

Label.

12.5. The unit was damaged by any or any combination of the

following:

a) normal fair wear and tear;

b) connection to an incorrect water supply;

c) connection to water from a bore, dam or swimming

pool;

d) connection to an incorrect power supply;

e) connection to faulty equipment, such as damaged

valves;

f) foreign matter in the water supply, such as sludge or

sediment;

g) corrosive elements in the water supply;

h) accidental damage;

i) act of God, including damage by flood, storm, fire,

lightning strike and the like;

j) excessive water pressure, negative water pressure (par-

tial vacuum) or water pressure pulsation.

12.6. The unit was damaged before it was installed e.g. it was

damaged in transit.

Australian Consumer Law

18. Our goods come with guarantees that cannot be excluded

under the Australian Consumer Law. You are entitled to a

replacement or refund for a major failure and compensation for any other reasonably foreseeable loss or damage.

You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the

failure does not amount to a major failure.

19. The Stiebel Eltron warranty for the unit is in addition to any

rights and remedies you may have under the Australian

Consumer Law.

12.7. An unauthorised person has modified, serviced, repaired

or attempted to repair the unit without our consent.

12.8. Non genuine parts other than those manufactured or approved by us have been used on the unit.

13. We may charge you:

13.1. for any additional transport costs if the unit is installed

more than 30 kilometres from our closest authorised service technician.

13.2. for the extra time it takes our authorised service technician

to access the unit for inspection and testing if it is not sited

in accordance with the Operating and Installation Guide

and not readily accessible for inspection.

13.3. for any extra costs of our authorised service technician to

make the unit safe for inspection.

14. You must ensure that access to the unit by our authorised

service technician is safe and free from obstruction.

15. Our authorised service technician may refuse to inspect

and test the unit until you provide safe and free access to

it, at your own cost.

16. If we reject your warranty claim in accordance with clause

12, we may charge you for our authorised service technician's labour costs to inspect and test the unit.

17. In order to properly test the unit we may remove it to another location for testing.

20 | DEL AU www.stiebel-eltron.com

Page 21

ENGLISH

NOTES

www.stiebel-eltron.com DEL AU| 21

Page 22

NOTES

22 | DEL AU www.stiebel-eltron.com

Page 23

ENGLISH

NOTES

www.stiebel-eltron.com DEL AU| 23

Page 24

Deutschland

STIEBEL ELTRON GmbH & Co. KG

Dr.-Stiebel-Straße 33 | 37603 Holzminden

Tel. 05531 702-0 | Fax 05531 702-480

info@stiebel-eltron.de

www.stiebel-eltron.de

Australia

STIEBEL ELTRON Australia Pty. Ltd.

6 Prohasky Street | Port Melbourne VIC 3207

Tel. 03 9645-1833 | Fax 03 9645-4366

info@stiebel.com.au

www.stiebel.com.au

Austria

STIEBEL ELTRON Ges.m.b.H.

Eferdinger Str. 73 | 4600 Wels

Tel. 07242 47367-0 | Fax 07242 47367-42

info@stiebel-eltron.at

www.stiebel-eltron.at

Belgium

STIEBEL ELTRON bvba/sprl

't Hofveld 6 - D1 | 1702 Groot-Bijgaarden

Tel. 02 42322-22 | Fax 02 42322-12

info@stiebel-eltron.be

www.stiebel-eltron.be

China

Stiebel Eltron (Guangzhou) Technology

Development Co., Ltd.

Rm 102, F1, Yingbin-Yihao Mansion, No. 1

Yingbin Road

Panyu District | 511431 Guangzhou

Tel. 020 61952996 | Fax 020 61952990

info@stiebeleltron.cn

www.stiebeleltron.cn

Czech Republic

STIEBEL ELTRON spol. s r.o.

K Hájům 946 | 155 00 Praha 5 - Stodůlky

Tel. 251116-111 | Fax 235512-122

info@stiebel-eltron.cz

www.stiebel-eltron.cz

Denmark

Pettinaroli A/S

Mandal Allé 21 | 5500 Middelfart

Tel. 06341 666-6 | Fax 06341 666-0

info@stiebel-eltron.dk

www.stiebel-eltron.dk

Finland

STIEBEL ELTRON OY

Kapinakuja 1 | 04600 Mäntsälä

Tel. 020 720-9988

info@stiebel-eltron.fi

www.stiebel-eltron.fi

Verkauf Tel. 05531 702-110 | Fax 05531 702-95108 | info-center@stiebel-eltron.de

Kundendienst Tel. 05531 702-111 | Fax 05531 702-95890 | kundendienst@stiebel-eltron.de

Ersatzteilverkauf Tel. 05531 702-120 | Fax 05531 702-95335 | ersatzteile@stiebel-eltron.de

France

STIEBEL ELTRON SAS

7-9, rue des Selliers

B.P 85107 | 57073 Metz-Cédex 3

Tel. 0387 7438-88 | Fax 0387 7468-26

info@stiebel-eltron.fr

www.stiebel-eltron.fr

Hungary

STIEBEL ELTRON Kft.

Gyár u. 2 | 2040 Budaörs

Tel. 01 250-6055 | Fax 01 368-8097

info@stiebel-eltron.hu

www.stiebel-eltron.hu

Japan

NIHON STIEBEL Co. Ltd.

Kowa Kawasaki Nishiguchi Building 8F

66-2 Horikawa-Cho

Saiwai-Ku | 212-0013 Kawasaki

Tel. 044 540-3200 | Fax 044 540-3210

info@nihonstiebel.co.jp

www.nihonstiebel.co.jp

Netherlands

STIEBEL ELTRON Nederland B.V.

Daviottenweg 36 | 5222 BH 's-Hertogenbosch

Tel. 073 623-0000 | Fax 073 623-1141

info@stiebel-eltron.nl

www.stiebel-eltron.nl

Poland

STIEBEL ELTRON Polska Sp. z o.o.

ul. Działkowa 2 | 02-234 Warszawa

Tel. 022 60920-30 | Fax 022 60920-29

stiebel@stiebel-eltron.pl

www.stiebel-eltron.pl

Russia

STIEBEL ELTRON LLC RUSSIA

Urzhumskaya street 4,

building 2 | 129343 Moscow

Tel. 0495 7753889 | Fax 0495 7753887

info@stiebel-eltron.ru

www.stiebel-eltron.ru

Slovakia

TATRAMAT - ohrievače vody, s.r.o.

Hlavná 1 | 058 01 Poprad

Tel. 052 7127-125 | Fax 052 7127-148

info@stiebel-eltron.sk

www.stiebel-eltron.sk

Switzerland

STIEBEL ELTRON AG

Industrie West

Gass 8 | 5242 Lupfig

Tel. 056 4640-500 | Fax 056 4640-501

info@stiebel-eltron.ch

www.stiebel-eltron.ch

Thailand

STIEBEL ELTRON Asia Ltd.

469 Moo 2 Tambol Klong-Jik

Amphur Bangpa-In | 13160 Ayutthaya

Tel. 035 220088 | Fax 035 221188

info@stiebeleltronasia.com

www.stiebeleltronasia.com

United Kingdom and Ireland

STIEBEL ELTRON UK Ltd.

Unit 12 Stadium Court

Stadium Road | CH62 3RP Bromborough

Tel. 0151 346-2300 | Fax 0151 334-2913

info@stiebel-eltron.co.uk

www.stiebel-eltron.co.uk

United States of America

STIEBEL ELTRON, Inc.

17 West Street | 01088 West Hatfield MA

Tel. 0413 247-3380 | Fax 0413 247-3369

info@stiebel-eltron-usa.com

www.stiebel-eltron-usa.com

4<AMHCMO=bdbeij>

Irrtum und technische Änderungen vorbehalten! | Subject to errors and technical changes! | Sous réserve

d‘erreurs et de modifications techniques! | Onder voorbehoud van vergissingen en technische wijzigingen! |

Salvo error o

ewentualne błędy | Omy

fenntartjuk! |

technické zmeny sú vyhradené! Stand 8870

modificación técnica! | Excepto erro ou alteração técnica | Zastrzeżone zmiany techniczne i

ly a technické změny jsou vyhrazeny! | A muszaki változtatások és tévedések jogát

Отсутствие ошибок не гарантируется. Возможны технические изменения.

| Chyby a

A 313148-37836-8944

B 313881-37836-8943

Loading...

Loading...