Page 1

OPERATION AND INSTALLAT ION

Electronically controlled comfort instantaneous water heater

» DEL13PlusAU

» DEL18PlusAU

» DEL27PlusAU

T

Tmax

Page 2

CONTENTS

SPECIAL INFORMATION

OPERATION

1. General information �����������������������������������������3

1.1 Safety instructions ����������������������������������������������� 3

1.2 Other symbols in this documentation ����������������������� 4

1.3 Units of measurement ������������������������������������������ 4

2. Safety ���������������������������������������������������������� 4

2.1 Intended use ������������������������������������������������������ 4

2.2 General safety instructions ������������������������������������ 4

2.3 Test symbols ������������������������������������������������������ 4

3. Appliance description ���������������������������������������4

4. Settings and displays ����������������������������������������5

4.1 User interface ���������������������������������������������������� 5

4.2 Display symbols �������������������������������������������������� 5

4.3 Setting the temperature ���������������������������������������� 5

4.4 Internal anti-scalding protection (qualified contractors) 5

4.5 Setting the Tmax temperature limit �������������������������� 5

4.6 Allocating temperature memory buttons ������������������� 6

4.7 Settings menu ���������������������������������������������������� 6

4.8 Selecting ECO level ���������������������������������������������� 6

4.9 Inlet temperature information �������������������������������� 6

4.10 Recommended settings ���������������������������������������� 6

5. Cleaning, care and maintenance ���������������������������6

6. Troubleshooting ����������������������������������������������6

INSTALLATION

7. Safety ���������������������������������������������������������� 7

7.1 General safety instructions ������������������������������������ 7

7.2 Instructions, standards and regulations �������������������� 7

8. Appliance description ���������������������������������������8

8.1 Standard delivery ������������������������������������������������ 8

8.2 Accessories �������������������������������������������������������� 8

9. Preparation ���������������������������������������������������8

9.1 Installation location ��������������������������������������������� 8

9.2 Minimum clearances �������������������������������������������� 8

9.3 Water installation ������������������������������������������������ 8

10. Installation ����������������������������������������������������9

10.1 Standard installation �������������������������������������������� 9

11. Commissioning ��������������������������������������������� 11

11.1 Preparation ������������������������������������������������������ 11

11.2 Initial start-up ��������������������������������������������������� 11

11.3 Recommissioning ����������������������������������������������� 12

12. Appliance shutdown ��������������������������������������� 12

13. Alternative installation methods ������������������������� 12

13.1 Electrical connection from above on unfinished walls �� 12

13.2 Electrical connection on unfinished walls with short

power cable ������������������������������������������������������ 13

13.3 Electrical connection on finished walls �������������������� 13

13.4 Water installation on unfinished walls ��������������������� 13

13.5 Wall mounting bracket when replacing an appliance ��� 14

13.6 Installation with offset tiles ����������������������������������� 14

13.7 Pivoting appliance cover �������������������������������������� 14

13.8 Operation with preheated water ���������������������������� 14

14. Service information ���������������������������������������� 14

15. Troubleshooting �������������������������������������������� 15

16. Maintenance ������������������������������������������������ 16

17. Specification ������������������������������������������������ 16

17.1 Dimensions and connections ��������������������������������� 16

17.2 Wiring diagram ������������������������������������������������� 17

17.3 DHW output ������������������������������������������������������ 17

17.4 Application areas/ Conversion table ����������������������� 17

17.5 Pressure drop ��������������������������������������������������� 17

17.6 Fault conditions ������������������������������������������������� 17

17.7 Data table �������������������������������������������������������� 18

ENVIRONMENT AND RECYCLING

WARRANTY

2 | DEL Plus AU www.stiebel-eltron.com

Page 3

SPECIAL INFORMATION | OPERATION

General information

SPECIAL INFORMATION

- The appliance may be used by children aged3

and older and persons with reduced physical,

sensory or mental capabilities or a lack of experience and know-how, provided that they

are supervised or they have been instructed

on how to use the appliance safely and have

understood the potential risks. Children must

never play with the appliance. Children must

never clean the appliance or perform user

maintenance unless they are supervised.

- The tap can reach temperatures of up to

50°C. There is a risk of scalding at outlet temperatures in excess of 43 °C.

- The appliance is suitable for supplying a

shower (shower operation). When using preheated water, it must be ensured that the inlet

temperature does not exceed 50°C.

- Ensure the appliance can be separated from

the power supply by an isolator that disconnects all poles with at least 3mm contact

separation.

- The specified voltage must match the power

supply.

- The appliance must be connected to earth.

OPERATION

1. General information

The chapters "Special information" and "Operation" are intended

for both users and qualified contractors.

The chapter "Installation" is intended for qualified contractors.

Note

Read these instructions carefully before using the appliance and retain them for future reference.

Pass on the instructions to a new user if required.

1.1 Safety instructions

1.1.1 Structure of safety instructions

KEYWORD Type of risk

!

Here, possible consequences are listed that may result

from failure to observe the safety instructions.

Steps to prevent the risk are listed.

1.1.2 Symbols, type of risk

Symbol Type of risk

!

Injury

Electrocution

Burns

(burns, scalding)

ENGLISH

- The appliance must be permanently connect-

1.1.3 Keywords

ed to fixed wiring.

KEYWORD Meaning

- Secure the appliance as described in chapter

"Installation/ Installation".

- Observe the maximum permissible pressure

(see chapter "Installation/ Specification/ Data

DANGER Failure to obser ve this information will result in serious

injury or death.

WARNING Failure to obser ve this information may result in serious

injury or death.

CAUTION Failure to obser ve this information may result in non-seri-

ous or minor injury.

table").

- The specific water resistivity of the mains

water supply must not be undershot (see

chapter "Installation/ Specification/ Data

table").

- Drain the appliance as described in chapter

"Installation/ Maintenance/ Draining the

appliance".

www.stiebel-eltron.com DEL Plus AU | 3

Page 4

OPERATION

Safety

1.2 Other symbols in this documentation

Note

General information is identified by the adjacent symbol.

Read these texts carefully.

Symbol Meaning

!

This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

Material losses

(appliance damage, consequential losses and environmental pollution)

Appliance disposal

1.3 Units of measurement

Note

All measurements are given in mm unless stated otherwise.

2. Safety

2.1 Intended use

This appliance is suitable for heating domestic hot water or for

reheating preheated water. The appliance can supply one or more

draw-off points.

Water will not be reheated if the maximum inlet temperature for

reheating is exceeded.

The appliance is intended for domestic use. It can be used safely

by untrained persons. The appliance can also be used in non-domestic environments, e.g.in small businesses, as long as it is

used in the same way.

Any other use beyond that described shall be deemed inappropriate. Observation of these instructions and of the instructions

for any accessories used is also part of the correct use of this

appliance.

2.2 General safety instructions

CAUTION Burns

The tap can reach temperatures of up to 50°C. There is a

risk of scalding at outlet temperatures in excess of 43 °C.

CAUTION Burns

If operating with preheated water, e.g.from a solar thermal system, the DHW temperature may vary from the

selected set temperature.

WARNING Injury

!

The appliance may be used by children aged3 and older

and persons with reduced physical, sensory or mental

capabilities or a lack of experience and know-how, provided that they are supervised or they have been instructed on how to use the appliance safely and have

understood the potential risks. Children must never play

with the appliance. Children must never clean the appliance or perform user maintenance unless they are

supervised.

Where children or persons with limited physical, sensory or mental abilities are allowed to use this appliance, we recommend a

permanent temperature limit. The following limitation options

are available:

- User adjustable: Temperature limit (e.g.for childproofing)

- Qualified contractor adjustable: Internal anti-scalding

protection.

WARNING

!

For continued safety of this appliance it must be installed, operated and maintained in accordance with

the manufacturer’s instructions.

Material losses

!

The user should protect the appliance and its tap against

frost.

2.3 Test symbols

See type plate on the appliance

Information for Australia/New Zealand:

Installation shall comply with standard AS/NZS 3500.4

3. Appliance description

The appliance switches on automatically as soon as you open the

hot water valve on the tap. When you close the tap, the appliance

switches off again automatically.

The appliance heats water as it flows through it. The DHW outlet

temperature can be variably adjusted. From a certain flow rate,

the control unit regulates the correct heating output, subject to

the temperature selected and the current cold water temperature.

The electronically controlled instantaneous water heater with automatic output matching maintains a consistent outlet temperature. It is irrespective of the inlet temperature, up to the maximum

output of the appliance.

If the appliance is operated with preheated water and the inlet

temperature exceeds the selected set temperature, the word "hot"

and the inlet temperature are displayed alternately, and the "hot"

LED flashes. The water is not heated further.

You can save and quickly call up different temperatures. With

the ECO function, the flow rate is limited to 3 preset levels. The

appliance is equipped with functions to permanently limit the

temperature (e.g.for childproofing). The backlight switches on

automatically as soon as water starts to flow through the appli-

4 | DEL Plus AU www.stiebel-eltron.com

Page 5

OPERATION

Settings and displays

ance or you make a change on the user interface. The backlight

switches off automatically 5seconds after water stops flowing or

if no operation has been performed for 30seconds.

You can set the temperature unit and operating lock individually.

Heating system

The bare wire heating system is enclosed within a pressure-tested

plastic jacket. The heating system with its stainless steel heater

spiral is suitable for hard and soft water areas and is largely insusceptible to scale build-up. The heating system ensures rapid

and efficient DHW provision.

Note

The appliance is equipped with an air detector that largely prevents damage to the heating system. If, during operation, air is drawn into the appliance, the appliance

shuts down for one minute, thereby protecting the heating system.

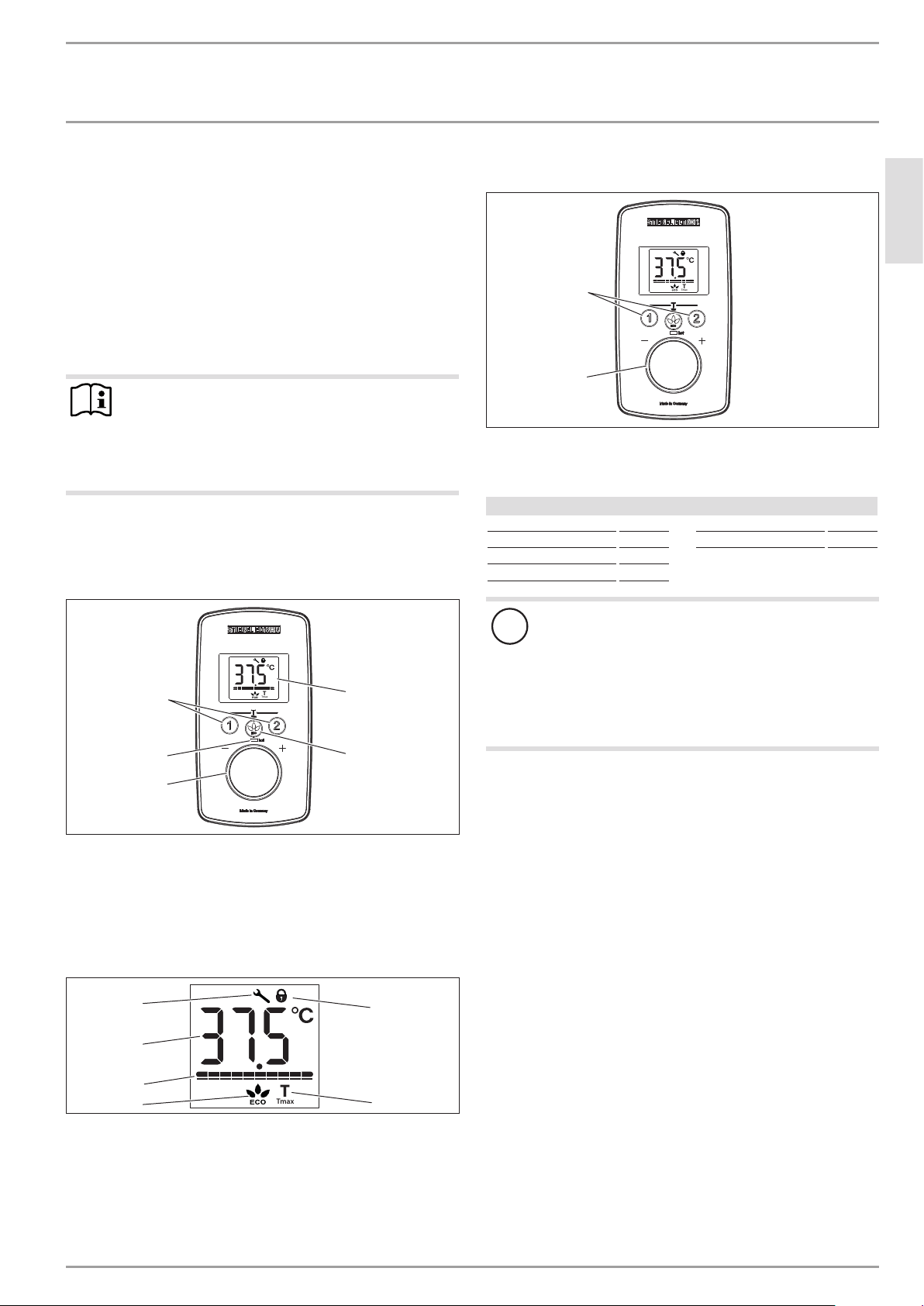

4. Settings and displays

4.1 User interface

4.3 Setting the temperature

T

2

1

1 Set temperature selector (no end-stop):

"OFF", 20 - 50°C (factory setting)

2 Call up/assign preferred temperatures

Setting steps

Temperature range Step Temperature range Step

20°C ... 35°C 1°C 68°F ... 122°F 1°F

35°C ... 43 °C 0.5°C

43°C ... 50°C 1°C

Tmax

ENGLISH

D0000073010

T

3

2

1

1 Temperature selector

2 "hot" scald warning LED, at temperatures higher than 43°C

3 Temperature memory buttons 1 and 2

4 Display

5 ECO button with ECO level selection/ Menu call-up

Tmax

4

5

4.2 Display symbols

4

3

2

1

1 ECO indicator [rolling, levels 1 - 3, OFF]

2 Output bar [10 - 100%]

3 Segment display [°C/°F]

4 In the event of an appliance fault, a spanner appears

5 Operating lock [ON/OFF]

6 Tmax, displayed when temperature limit is enabled

T

Tmax

5

6

Note

!

If the outlet temperature is not high enough when the

draw-off valve is fully open and the temperature selector

is set to maximum, then more water is flowing through

the appliance than can be heated by the heating system

(appliance working at maximum output).

Use the ECO button to reduce the water volume until

the required temperature is achieved.

4.4 Internal anti-scalding protection (qualified

contractors)

D0000073010

The appliance has an anti-scalding protection function. The qualified contractor can set an anti-scalding protection level for you

on request.

If the anti-scalding protection function (43°C) is enabled, "Tmax"

flashes continually once the set temperature has been reached.

4.5 Setting the Tmax temperature limit

Enabling the temperature limit

You can activate and adjust the temperature limit individually

(e.g.for childproofing).

Press and hold buttons "1" and "2" for longer than 5seconds,

until "Tmax" and the temperature display flash.

Select a temperature limit.

D0000073009

10seconds after completing the setting, the menu item will disappear automatically.

If the high limit safety cut-out is enabled, "Tmax" is continuously

displayed.

Disabling the temperature limit

Disable the high limit safety cut-out by pressing and holding

buttons "1" and "2" for longer than 5seconds.

www.stiebel-eltron.com DEL Plus AU | 5

Page 6

OPERATION

Cleaning, care and maintenance

4.6 Allocating temperature memory buttons

Memory buttons "1" and "2" can each be assigned a required

temperature.

Select the required temperature.

To store the required temperature, press and hold button

"1" or "2" for longer than 3seconds. The temperature flashes

once to confirm.

4.7 Settings menu

Menu Description

Temperature display Select °C or °F

Operating lock Select ON or OFF. Symbol displayed

Fault code display Displays E1...E3 if there is a fault on the appli-

ance. Call qualified contractor.

To call up the menu, press and hold the ECO button for

longer than 5seconds.

To select, turn the temperature selector.

Press the ECO button once more.

To quit the menu, press and hold the ECO button for longer

than 5seconds.

The menu switches off automatically if no operation has been

performed for 30seconds.

Note

To call up the menu when the operating lock is enabled,

press and hold the ECO button for longer than 10seconds.

4.8 Selecting ECO level

ECO level Display Flow rate limitation

Level 1 8l/min (factory setting)

Level 2 7l/min

Level 3 6l/min

No symbol No flow rate limit

Saving energy

The following recommended settings will result in the lowest energy consumption:

- 38°C for hand washbasins, showers, bath

- 50°C for kitchen sinks

Internal anti-scalding protection (qualified contractors)

If required, the qualified contractor can set a permanent temperature limit, for example in nurseries, hospitals,etc.

Recommended setting for operation with a thermostatic valve

and water preheated by solar energy

Set the temperature at the instantaneous water heater to the

maximum temperature.

Following an interruption to the water supply

Material losses

!

To ensure that the bare wire heating system is not damaged following an interruption to the water supply, the

appliance must be restarted by taking the following steps.

Disconnect the appliance from the power supply by

removing the fuses/tripping the MCBs.

Open the tap for one minute until the appliance and

its upstream cold water inlet line are free of air.

Switch the power back ON.

5. Cleaning, care and maintenance

Never use abrasive or corrosive cleaning agents. A damp

cloth is sufficient for cleaning the appliance.

Check the taps regularly. Limescale deposits at the tap out-

lets can be removed using commercially available descaling

agents.

6. Troubleshooting

Briefly press the ECO button. Rolling selection, "Level1 - 3/

OFF".

4.9 Inlet temperature information

If the appliance is operated with preheated water and the inlet

temperature exceeds the selected set temperature, the word "hot"

and the inlet temperature are displayed alternately, and the "hot"

LED flashes.

4.10 Recommended settings

Your instantaneous water heater offers maximum precision and

maximum convenience in DHW provision. Should you nonetheless

be operating the appliance with a thermostatic valve, we recommend that you:

Adjust the set temperature on the appliance to maximum

temperature.

Then set the required set temperature on the thermostatic

valve.

Problem Cause Remedy

The appliance will not

start despite the DHW

valve being fully open.

The water supply has

When hot water is being

drawn off, cold water

flows for a short period.

The required temperature cannot be set.

The flow rate is too low. ECO function is enabled. Select a different ECO

No settings can be made

on the programming

unit.

There is no power.

The aerator in the tap or

the shower head is scaled

up or dirt y.

been interrupted.

The air detector de-

tects air in the water. It

switches off the heating

output briefly.

The high limit safety

cut-out and/or internal

anti-scalding protection

are enabled.

The operating lock is

enabled.

Check the fuses/MCBs in

your fuse box/distribution board.

Clean and/or descale the

aerator or shower head.

Vent the appliance and

the cold water inlet line.

The appliance restar ts

automatically after

1minute.

Deactivate the temperature limit. The internal

anti-scalding protection

can only be adjusted by

the qualified contractor.

level or disable the ECO

function.

Press and hold the ECO

button for more than

10seconds to disable the

operating lock.

6 | DEL Plus AU www.stiebel-eltron.com

Page 7

INSTALLATION

Nr. 000000-0000-00000

Safety

Note

After a power failure

Programming unit displays and selected settings are retained following a power failure.

If you cannot remedy the fault, contact your qualified contractor.

To facilitate and speed up your request, provide the number from

the type plate (000000-0000-000000).

Nr. 000000-0000-00000

INSTALLATION

7. Safety

Only a qualified contractor should carry out installation, commissioning, maintenance and repair of the appliance.

7.1 General safety instructions

We guarantee trouble-free function and operational reliability only

if original accessories and spare parts intended for the appliance

are used.

Material losses

!

Observe the maximum inlet temperature. Higher tem-

D0000053312

peratures may damage the appliance. You can limit

the maximum inlet temperature by installing a central

thermostatic valve (see chapter "Appliance description/

Accessories").

CAUTION Burns

If the water supplied to the appliance is preheated,

please note the following points:

- The internally adjustable anti-scalding protection

and the temperature limit that is adjustable by the

user may be exceeded.

- The dynamic anti-scalding protection between the

appliance and the wireless remote control may not

be effective.

In both cases, limit the temperature with an up-

stream central thermostatic valve.

ENGLISH

WARNING Electrocution

This appliance contains capacitors which are discharged

when disconnected from the power supply. The capacitor

discharge voltage may briefly reach >60VDC.

7.2 Instructions, standards and regulations

Note

Observe all applicable national and regional regulations

and instructions.

- The IP25 (hoseproof) rating can only be ensured with a correctly fitted cable grommet.

- The specific electrical resistivity of the water must not fall

below that stated on the type plate. In a linked water network, factor in the lowest electrical resistivity of the water.

Your water supply utility will advise you of the specific electrical water resistivity or conductivity.

www.stiebel-eltron.com DEL Plus AU | 7

Page 8

INSTALLATION

Appliance description

8. Appliance description

8.1 Standard delivery

The following are delivered with the appliance:

- Wall mounting bracket

- Installation template

- 2 plugs

- 2 extensions

- 2 caps

- 2 tees

- 8 flat gaskets

- Strainer

- Plastic profile washer

- Plastic connection pieces/installation aid

- Cover and back panel guides

- Jumper for internal anti-scalding protection

8.2 Accessories

Wireless remote control

- FFB4SetAP

9. Preparation

Oversink installation

1 Cold water inlet

2 DHW outlet

Note

Mount the appliance on the wall. The wall must have

sufficient load bearing capacity.

9.2 Minimum clearances

12

D0000057030

≥90

≥50≥50

9.1 Installation location

Material losses

!

Install the appliance in a room free from the risk of frost.

Always install the appliance vertically and near the draw-off

point.

The appliance is suitable for undersink and oversink installation.

Undersink installation

1

2

1 Cold water inlet

2 DHW outlet

≥90

Maintain the minimum clearances to ensure trouble-free op-

eration of the appliance and facilitate maintenance work.

9.3 Water installation

Flush the water line thoroughly.

Taps/valves

Use appropriate pressure taps. Open vented taps are not permissible.

Permissible water line materials

- Cold water inlet line:

Pipes made from galvanised steel, stainless steel, copper or

plastic

- DHW outlet line:

D0000056242

Stainless steel pipe, copper pipe or plastic pipe

Material losses

!

If plastic pipework systems are used, take into account

the maximum inlet temperature and the maximum permissible pressure.

D0000060809

Flow rate

Ensure that the flow rate for switching on the appliance is

achieved.

Increase the water line pressure if the required flow rate is

not achieved when the draw-off valve is fully open.

8 | DEL Plus AU www.stiebel-eltron.com

Page 9

INSTALLATION

Installation

10. Installation

Factory sett ings DEL13PlusAU DEL 18 Plus AU DEL27PlusAU

Internal anti-scalding protection Tmax (= 50°C) Tmax (= 50°C) Tmax (= 50°C)

Standard installation DEL13PlusAU DEL 18 Plus AU DEL27PlusAU

Electrical connection from below on unfinished walls x x x

Water connection, installation on finished walls x x x

ENGLISH

For further installation options, see chapter "Alternative installation methods".

10.1 Standard installation

Opening the appliance

Open the appliance by holding the fascia at the side and pull-

ing forwards away from the appliance cover. Undo the screw.

Pivot open the appliance cover.

Fitting the wall mounting bracket

Mark out the holes for drilling using the installation tem-

plate. If the appliance is to be installed on finished walls, also

mark out the fixing hole in the lower section of the template.

Drill the holes and secure the wall mounting bracket at 2

points using suitable fixing materials (screws and rawl plugs

D0000053271

D0000053272

are not part of the standard delivery).

Fit the wall mounting bracket.

Preparing the water connection

Material losses

!

Carry out all water connection and installation work in

accordance with regulations.

D0000059694

Remove the back panel by pressing the two locking tabs and

pulling the lower back panel section forwards.

Preparing the power cable on unfinished walls, for connection

from below

160

30

1 Cable entry installation aid

Prepare the power cable.

1

Remove the caps from the tees.

D0000053273

Fit the plugs and the extensions with gaskets.

Fit the strainer in the tee for the cold water inlet.

Damage to the appliance and environmental pollution

!

The strainer must be fitted for the appliance to function.

When replacing the appliance, check that the strain-

er is present.

D0000041720

D0000041721

www.stiebel-eltron.com DEL Plus AU | 9

Page 10

INSTALLATION

Installation

Installing the appliance

Note

If you are installing the appliance with flexible pipe connections, also secure the bottom of the back panel with

a screw.

1

2

1 Cable entry installation aid

2 Cable grommet

Use the installation aid for easier wiring access through the cable

grommet (see plastic parts set supplied).

Remove the cable grommet from the back panel.

Pull the cable grommet over the cable sheath of the power

cable. For large cable cross-sections, enlarge the hole in the

cable grommet if necessary.

Screw the pre-assembled parts with flat gaskets to the cold

water and DHW pipes of the appliance.

Fit the cold water inlet pipe and the DHW outlet pipe from

the pipework with flat gaskets to the extensions from the

appliance.

Making the electrical connection

WARNING Electrocution

Carry out all electrical connection and installation work

in accordance with relevant regulations.

WARNING Electrocution

D0000077728

The connection to the power supply must be in the form

of a permanent connection in conjunction with the removable cable grommet. Ensure the appliance can be

separated from the power supply by an isolator that disconnects all poles with at least 3mm contact separation.

WARNING Electrocution

Ensure that the appliance is earthed.

Material losses

!

Observe the type plate. The specified rated voltage must

match the mains voltage.

Remove the transport protection plugs from the appliance

pipe connections.

Bend the power cable 45° upwards.

Route the power cable and cable grommet through the back

panel from the rear.

Install the appliance on the threaded studs of the wall

mounting bracket.

Press the back panel firmly into place, aligning it correctly.

Lock the fixing toggle by turning it 90° clockwise.

Pull the cable grommets into the back panel until both lock-

ing tabs engage.

Connect the power cable to the mains terminal.

2

3

1

1 Lower back panel section

2 Connection piece in the standard delivery

D0000077722

3 Screw

If using threaded fittings on finished walls, the lower back panel

section can also be installed after fitting the taps. To do this, carry

out the following steps:

Cut open the lower back panel section.

Fit the lower back panel section by bending it out at the sides

and guiding it over the pipes.

Insert the connection pieces into the lower back panel sec-

tion from behind.

Click the lower back panel section into place.

Secure the lower back panel section with a screw.

Material losses

!

The cover plate of the lower back panel section must not

bend when installed.

D0000053286

D0000077727

10 | DEL Plus AU www.stiebel-eltron.com

Page 11

INSTALLATION

Commissioning

11. Commissioning

11.1 Preparation

1

43 °C

Tmax

1 Jumper for anti-scalding protection setting

Internal anti-scalding protection via jumper slot

Jumper position Description

43°C

Tmax Factory setting (50°C)

No jumper Limited to 43°C

Install the anti-scalding protection setting jumper in the re-

quired position on the upper pin strip.

CAUTION Burns

If the appliance is supplied with preheated water, the

internal anti-scalding protection may be exceeded.

In such cases, limit the temperature with an upstream

central thermostatic valve.

Note

For undersink installation, the appliance cover should

be turned round for easier operation; see chapter "Alternative installation methods/ Pivoting appliance cover".

Fit the appliance cover

1

D0000077020

4

1 Pipe knock-out

2 Cover guides

3 Back panel guides

4 Fixing screw (not part of the standard delivery)

Cleanly cut or break out the knock-out openings in the appli-

ance cover. If necessary, use a file.

Material losses

!

If you cut open the wrong knock-out in the appliance

cover by mistake, you must use a new appliance cover.

ENGLISH

2

3

D0000040777

11.2 Initial start-up

≥ 60 s

Open and close all connected draw-off valves several times,

until all air has been purged from the pipework and the

appliance.

Carry out a tightness check.

Activate the safety switch by firmly pressing the reset button

(the appliance is delivered with the safety switch disabled).

Note

You can compensate for a slight connection pipe offset

using the tabs on the cover guides. If the connection pipes

are offset, do not fit any back panel guides.

When installing connection pipes without offset, break off

D0000053277

D0000053278

the tabs on the cover guide pieces.

Click the cover guides into place in the openings.

Position the back panel guides on the extensions. Push them

toge ther. Then push the guides against the back panel as far

they will go.

Hook the appliance cover at the top rear into the back panel.

Pivot the appliance cover downwards. Check that the appliance cover is securely seated at both top and bottom.

Secure the appliance cover with the screw.

Fit the fascia to the appliance cover.

D0000053280

D0000073198

Connect the programming unit connecting cable to the PCB.

www.stiebel-eltron.com DEL Plus AU | 11

Page 12

INSTALLATION

140

Appliance shutdown

13.1 Electrical connection from above on unfinished

walls

D0000053281

Switch on the power supply.

11.2.1 Appliance handover

Explain the appliance function to users and familiarise them

with how it works.

Make the user aware of potential dangers, especially the risk

of scalding.

Hand over the instructions.

11.3 Recommissioning

Material losses

!

To ensure that the bare wire heating system is not damaged following an interruption to the water supply, the

appliance must be restarted by taking the following steps.

Disconnect the appliance from the power supply by

removing the fuses/tripping the MCBs.

Open the tap for a minimum of one minute until the

appliance and its upstream cold water inlet line are

free of air.

Switch the power back ON.

12. Appliance shutdown

Isolate all poles of the appliance from the power supply.

Drain the appliance (see chapter "Installation/ Maintenance/

Draining the appliance").

13. Alternative installation methods

Overview of the alternative types of installation

Electrical connection IP rating

On unfinished walls, connected from above IP25

On unfinished walls, connected from below, short

power cable

On finished walls IP24

IP25

30

1 Cable entry installation aid

Prepare the power cable.

1 Cable routing

Reposition the mains terminal from the bottom to the top. To

do this, undo the fixing screw. Turn the mains terminal with

connecting cables 180° clockwise. Route the cable around

the cable guide when doing so. Secure the mains terminal in

place.

Replace the cable grommets.

Install the cable grommet from the top at the bottom.

Pull the cable grommet over the cable sheath of the power

cable.

Install the appliance on the threaded studs of the wall

mounting bracket.

Push the back panel firmly against the wall. Lock the fixing

toggle by turning it 90° clockwise.

Pull the cable grommets into the back panel until both lock-

ing tabs engage.

Connect the power cable to the mains terminal.

1

1

D0000076507

D0000053282

Water connection IP rating

On unfinished walls IP25

Other IP rating

Installation with offset tiles IP25

Pivoting appliance cover IP25

WARNING Electrocution

Before any work on the appliance, disconnect all poles

from the power supply.

12 | DEL Plus AU www.stiebel-eltron.com

WARNING Electrocution

The connecting wires must not protrude beyond the level

of the mains terminal.

Page 13

INSTALLATION

A

30

Alternative installation methods

13.2 Electrical connection on unfinished walls with

short power cable

Reposition the mains terminal further downwards. To do this,

undo the fixing screw. Secure the mains terminal in place.

13.3 Electrical connection on finished walls

Note

This type of connection changes the IP rating of the appliance.

Change the type plate. Cross out "IP25" and mark

the box "IP24". Use a ballpoint pen to do this.

13.4 Water installation on unfinished walls

12

Seal and screw in the twin connectors (not included in stand-

ard delivery).

D0000060387

1 Tee for cold water

2 Tee for domestic hot water

3 Cap

Fit the water connections.

2

3

1

3

ENGLISH

D0000053319

D0000041724

1

1 Cable grommet

Dimension A Elec trical connect ion on finished walls

160 Positioned in lower section of appliance

110 Positioned in upper section of appliance

Prepare the power cable. Fit the cable grommet.

Material losses

!

If you break out the wrong knock-out in the back panel/

appliance cover by mistake, you must use a new back

panel/appliance cover.

Cleanly cut and break out the required cable entries from the

back panel and appliance cover (for the positions, see chapter "Specification/ Dimensions and connections"). Deburr any

sharp edges with a file.

Route the power cable through the cable grommet.

Connect the power cable to the mains terminal.

Note

If the appliance is rated IP24, amend the appliance type

plate.

Cross out "IP25" and mark the box "IP24". Use a

ballpoint pen to do this.

D0000076506

Fit the strainer and the plastic profile washer in the tee for

the cold water inlet.

Material losses

!

The strainer must be fitted for the appliance to function.

When replacing the appliance, check that the strain-

er is present.

Screw the connection pipes from the appliance to the tee.

Open the shut-off valve in the cold water inlet line.

1

1 Diffuser on lower back panel

Fit the lower back panel section into the back panel. Check

that both locking tabs are engaged.

Align the mounted appliance by undoing the fixing toggle,

aligning the power supply and back panel, and then re-tightening the fixing toggle. If the back panel does not sit flush

against the wall, you can secure the appliance at the bottom

with an additional screw.

D0000043291

D0000053275

www.stiebel-eltron.com DEL Plus AU | 13

Page 14

INSTALLATION

Service information

Material losses

!

The cover plate of the lower back panel section must not

bend when installed.

13.5 Wall mounting bracket when replacing an

appliance

An existing STIEBELELTRON wall mounting bracket may be used

when replacing appliances (except the DHF instantaneous water

heater), as long as the fixing screw is in the lower right position.

Replacing a DHF instantaneous water heater

Reposition the fixing screw on the wall mounting bracket (the

fixing screw has a self-tapping thread).

Rotate the wall mounting bracket 180° and mount it on the

wall (the DHF logo is then turned towards you).

13.6 Installation with offset tiles

20

2

Remove the programming unit from the appliance cover by

pressing the locking hooks and removing the programming

unit.

Turn the appliance cover (not the appliance) the other way

up and refit the programming unit. Push the programming

unit home in parallel until all locking tabs engage. When

engaging the locking tabs, apply counter pressure by pushing

against the appliance cover from the inside.

WARNING Electrocution

All 4locking tabs on the programming unit must click into

place. The locking tabs must be complete and undamaged. If the programming unit is not inserted correctly,

user protection against contact with live components

cannot be ensured.

Insert the connecting cable plug of the programming unit

26�02�02�0815�

into the PCB (see chapter "Commissioning/ Initial start-up").

Hook the appliance cover in at the bottom. Pivot the appli-

ance cover up to the back panel.

Secure the appliance cover.

Fit the cover onto the appliance cover.

13.8 Operation with preheated water

You can restrict the maximum inlet temperature by installing a

central thermostatic valve.

110

1

1 Minimum contact area of the appliance

2 Maximum tile offset

Adjust the wall clearance. Lock the back panel in place using

the fixing toggle (turn 90° clockwise).

13.7 Pivoting appliance cover

The appliance cover should be turned round for undersink installation.

14. Service information

Overview of connections

D0000043278

1 Flow limit

2 Flow sensor

3 High limit safety cut-out, automatic reset

4 NTC sensor

5 Pin strip for anti-scalding protection

6 Programming unit plug-in position

7 Diagnostic traffic light

1

2

3

4

5

6

7

D0000073174

D0000076838

14 | DEL Plus AU www.stiebel-eltron.com

Page 15

INSTALLATION

Troubleshooting

Appliance cover retainer

15. Troubleshooting

ENGLISH

D0000056216

WARNING Electrocution

To test the appliance, it must be connected to the power

Note

The diagnostic traffic light is displayed when water flows.

supply.

Display indication Cause

E1 | Spanner Fault in electronic safety circuit.

E2 flashing Break or shor t circuit in inlet sensor.

E3 flashing Short circuit in outlet sensor.

Diagnostic traf fic

light

No LED illuminates The appliance does not heat

The electronic assembly is faulty. Replace the test assembly.

Green flashing, yellow

off, red off

The electronic assembly is faulty. Replace the test assembly.

Green flashing, yellow

on, red off

Green flashing, yellow

on, red off

The electronic assembly is faulty. Replace the test assembly.

Green flashes, yellow

off, red on, E1 displayed

The high limit safety cut-out is faulty. Replace the high limit safety cut-out.

Fault Cause Remedy

up.

No DHW

The display is completely off.

No DHW; the outlet temperature does not match the set

value.

No DHW; the outlet temperature does not match the set

value.

There is no power supply. Check the fuse/MCB in your fuse box/distribution

The shower head/aerator are scaled up. Descale or replace the shower head/aerator if nec-

The strainer in the cold water inlet is dir ty. Clean the strainer.

The flow meter is not plugged in. Reconnec t the connecting cable on the PCB.

The flow meter is faulty. Replace the flow meter.

Loose set value transducer cable bet ween PCB and

display.

The programming unit connecting cable is faulty. Check the connecting cable and replace if necessary.

The programming unit PCB is faulty. Check the programming unit and replace if neces-

The downstream tap is faulty.

Internal anti-scalding protection is activated. Deactivate the internal anti-scalding protection.

The heating system is faulty. Replace the test assembly.

The outlet sensor is faulty. Replace the outlet sensor.

The high limit safety cut-out is not enabled.

The high limit safety cut-out is not connected. Reconnect the connecting cable on the PCB.

The high limit safety cut-out has tripped. Remedy the cause and activate the safety switch.

Indicator options for diagnostic traf fic light (LED)

Red Illuminates in the event of a fault

Yellow Illuminates in heating mode/flashes when output limit

reached

Green Flashing: Appliance connected to power supply

board.

essar y.

Check the set value transducer cable and plug the

cable into the programming unit and/or PCB.

sary.

Replace the faulty tap.

Activate the safety switch.

www.stiebel-eltron.com DEL Plus AU | 15

Page 16

INSTALLATION

481

225

105≤ 20

b04

b04

Maintenance

16. Maintenance

WARNING Electrocution

Before any work on the appliance, disconnect all poles

from the power supply.

Draining the appliance

The appliance can be drained for maintenance work.

WARNING Burns

Hot water may escape when you drain the appliance.

Close the shut-off valve in the cold water inlet line.

Open all draw-off valves.

Undo the pipe connections from the appliance.

Store the dismantled appliance in a room free from the risk

of frost, as water residues remaining inside the appliance can

freeze and cause damage.

Cleaning the strainer

If dirty, clean the strainer in the threaded cold water fitting. Close

the shut-off valve in the cold water inlet line before removing,

cleaning and refitting the strainer.

17. Specification

17.1 Dimensions and connections

140

414

368

466

b02

30

35

38

100

c01c06

DELPlusAU

b02 Entry electrical cables I On unf inished walls

c01 Cold water inlet Male thread G 1/2 A

c06 DHW outlet Male thread G 1/2 A

35

116

D0000077739

1

2

1 Strainer

2 Plastic profile washer

Remove the plastic profile washer and the strainer.

Clean the components.

Fit the strainer and the plastic profile washer.

Alternative connection options

D0000077740

DELPlusAU

b02 Entry electrical cables I On unf inished walls

b03 Entry electrical cables II On unfinished walls

b04 Entry electrical cables III On finished walls

b03

330

69

b04

20

b02

30

165

b04

b04

35

325

69

D0000077736

16 | DEL Plus AU www.stiebel-eltron.com

Page 17

INSTALLATION

Specication

17.2 Wiring diagram

3/PE ~ 380-415 V

2

3

1

4

1 Power PCB with integral safety switch

2 Bare wire heating system

3 High limit safety cut-out

4 Mains terminal

17.3 DHW output

The DHW output is subject to the connected power supply, the

appliance's connected load and the cold water inlet temperature.

The rated voltage and rated output can be found on the type plate.

Connected load in kW 38°C DHW output in l/min

Rated voltage Cold water inlet temperature

380 V 400 V 415 V 5°C 10°C 15°C 20°C

DEL 13

Plus AU

14.5 6.3 7.4 9.0 11.5

DEL 18

Plus AU

19.4 8.4 9.9 12.0 15.4

DEL 27

Plus AU

28 12.1 14.3 17.4 22.2

12.2 5.2 6.1 7. 5 9.5

13.5 5.8 6.9 8.4 10.7

16.2 7.0 8.3 10.1 12.9

18 7. 8 9.2 11.2 14.3

23.5 10.2 12.0 14.6 18.7

26 11.3 13.3 16.1 20.6

17.4 Application areas/ Conversion table

Specific electrical resistance and specific electrical conductivity

Standard specifica-

tion at 15 °C

Resis-

Conductivity σ≤ Resistivity

ρ≥

Ωcm mS/m μS/cm Ωcm mS/m μS /cm Ωcm mS/m μS/cm

900 111 1111 800 125 1250 735 136 1361

20°C

Conductivity σ≤ Resistivity

ρ≥

25°C

tivity

ρ≥

Conductivity σ≤

17.5 Pressure drop

Taps/valves

Tap pressure drop at a flow rate of 10 l/min

Mono lever mixer tap, approx. MPa 0.04 - 0.08

D0000053424

Thermostatic valve, approx. MPa 0.03 - 0.05

Shower head, approx. MPa 0.03 - 0.15

Sizing the pipework

When calculating the size of the pipework, an appliance pressure

drop of 0.1MPa is recommended.

17.6 Fault conditions

In the event of a fault, loads up to 80°C at a pressure of 1.0 MPa

can occur very briefly in the installation.

ENGLISH

Connected load in kW 50 °C DHW output in l/min

Rated voltage Cold water inlet temperature

380 V 400 V 415 V 5°C 10°C 15°C 20°C

DEL 13

Plus AU

14.5 4.6 5.2 5.9 6.9

DEL 18

Plus AU

19.4 6.2 6.9 7.9 9.2

DEL 27

Plus AU

28 8.9 10.0 11.4 13.3

12.2 3.8 4.3 4.9 5.7

13.5 4.3 4.8 5.5 6.4

16.2 5.1 5.8 6.6 7.7

18 5.7 6.4 7.3 8.6

23.5 7. 5 8.4 9.6 11.2

26 8.3 9.3 10.6 12.4

www.stiebel-eltron.com DEL Plus AU | 17

Page 18

INSTALLATION

Guarantee

The guarantee conditions of our German companies do not

apply to appliances acquired outside of Germany. In countries

where our subsidiaries sell our products a guarantee can only

be issued by those subsidiaries. Such guarantee is only grant-

ed if the subsidiary has issued its own terms of guarantee. No

other guarantee will be granted.

We shall not provide any guarantee for appliances acquired in

countries where we have no subsidiary to sell our products.

This will not aect warranties issued by any importers.

Environment and recycling

We would ask you to help protect the environment.

dispose of the various materials in accordance with national

regulations.

Specication

17.7 Data table

DEL 13 Plus AU DEL 18 Plus AU DEL 27 Plus AU

23 4470 236741 236742

Electrical data

Rated voltage V 380 400 415 380 400 415 380 400 415

Rated output kW 12.2 13.5 14.5 16.2 18 19.4 23.5 26 28

Rated current A 18.5 19.5 20.2 24.7 26 27 35.6 37.7 38.9

Fuse protection A 20 20 20 25 25 32 40 40 40

Frequency Hz 50/60 50/60 50 50/60 50/60 50/- 50/- 50/- 50/Phases 3/PE 3/PE 3/PE

Specific resistivity ρ15 ≥ Ω cm 900 900 900

Specific conductivity σ15 ≤ μS/cm 1111 1111 1111

Max. mains impedance Ω 0.459 0.436 0.42 0.331 0.315 0.304 0.221 0.21

Versions

Heating system heat generator Bare wire Bare wire Bare wire

Adjustable connected load - - Temperature settings °C Off, 20-50 Off, 20-50 Off, 20-50

Protection class 1 1 1

Insulating block Plastic Plastic Plastic

Cover and back panel Plastic Plastic Plastic

IP rating IP25 IP25 IP25

Colour White White White

Connections

Water connection G 1/2 A G 1/2 A G 1/2 A

Application limits

Max. permissible pressure MPa 1 1 1

Max. inlet temperature for reheating °C 50 50 50

Values

Max. permissible inlet temperature °C 50 50 50

ON l/min >2.5 >2.5 >2.5

Flow rate at 28K l/min 7.4 at 415V 9.9 at 415V 14.3 at 415V

Flow rate at 50 K l/min 4.2 at 415V 5.6 at 415V 8.0 at 415V

Pressure drop for flow rate at 50K (without flow limiter) MPa 0.04 0.06 0.14

Hydraulic data

Nominal capacity l 0.4 0.4 0.4

Dimensions

Height mm 466 466 466

Width mm 225 225 225

Depth mm 116 116 116

Weights

Weight kg 3.1 3.1 3.1

Note

The appliance conforms to IEC 61000-3-12.

After use,

18 | DEL Plus AU www.stiebel-eltron.com

Page 19

WARRANTY

D0000053038

Who gives the warranty

1. The warranty is given by Stiebel Eltron (Aust) Pty Ltd (A.B.N. 82

066 271 083) of 294 Salmon Street, Port Melbourne, Victoria, 3207

(“we”, “us” or “our”).

The warranty

2. This warranty applies to the Stiebel Eltron Water Heaters - WaterMark Approved (the “unit”) listed within this operating and installation guide manufactured after 1 May 2015.

3. Subject to the warranty exclusions we will repair or replac

e, at

our absolute discretion, a faulty component in your unit free of

charge if it fails

to operate in accordance with its specifications

during the warranty period.

4. If we repair or replace a faulty component to your unit under this

warranty, the warranty period is not extended from the time of

the repair or replacement.

5. The warranty period commences on the date of completion of

the installation of the unit. Where the date of completion of installation is not known, then the warranty period will commenc

e

2 months after the date of manufacture.

6. The warranty period for a unit used for domestic purposes is

shown in the table below. Domestic purposes means that the

unit is used in a domestic dwelling.

Component Warranty period

All components 5 years from the date of completion of the

installation of the unit.

7. The warranty period for a unit used for commercial purposes is

shown in the table below. Commercial purposes means that the

unit is used for a non-domestic purpose and includes but not limited to being used in a motel, hotel, mining camp or nursing

home.

Component Warranty period

All components 1 year from the date of completion of the

installation of the unit.

Your entitlement to make a warranty claim

8. You are entitled to make a warranty claim if:

8.1. you own the unit or if you have the owner’s consent to represent

the owner of the unit;

8.2. you contact us within a reasonable time of discovering the problem with the unit;

How you make a warranty claim

9. To make a warranty claim you must provide us with the following

information:

9.1. The model number of the unit;

9.2. A description of the problem with the unit;

9.3. The name, address and contact details (such as phone number

and e-mail address) of the owner;

9.4. The address where the unit is installed and the location (e.g. in

laundry);

9.5. The serial number of the unit;

9.6. The date of purchase of the unit and the name of the seller of the

unit;

9.7. The date of installation of the unit;

9.8. A copy of the certificate of compliance when the unit was installed.

10. The contact details for you to make your warranty claim are:

Name:

Address:

Telephone:

Contact person:

E-mail:

11. We will arrange a suitable time with you to inspec

t and test the

unit.

Warranty e

xclusions

12. We may reject your warranty claim if:

12.1. The unit was not installed by registered and qualified tradespeople.

12.2. The unit was not installed and commissioned:

(a) in Australia;

(b) in accordance with the Operating and Installation Guide; and

(c) in accordance with the relevant statutory and local require-

ments of the State or Territory in which the unit is installed.

12.3. The unit has not been operated or maintained in accordance

with the Operating and Installation Guide.

12.4. The unit does not bear its original Serial Number for Rating Label.

12.5. The unit was damaged by any or any combination of the following:

(a) normal fair wear and tear;

(b) connection to an incorrect water supply;

(c) connection to water from a bore, dam or swimming pool;

(d) connection to an incorrect power supply;

(e) connection to faulty equipment, such as damaged valves;

(f) foreign matter in the water supply, such as sludge or sedi-

ment;

(g) corrosive elements in the water supply;

(h) accidental damage;

(i) act of God, including damage by flood, storm, fire, lightning

strike and the like;

(j) excessive water pressure, negative water pressure (partia

l

vacuum) or water pressure pulsation.

12.6. The unit was damaged before it was installed e.g. it was damaged in transit.

12.7. An unauthorised person has modified, serviced, repaired or

attempted to repair the unit without our consent.

12.8. Non genuine parts other than those manufactured or approved

by us have been used on the unit.

13. We may charge you:

13.1. for any additional transport costs if the unit is installed more than

30 kilometres from our closest authorised service technician.

13.2. for the extra time it takes our authorised service technician to

access the unit for inspection and testing if it is not sited in accordance with the Operating and Installation Guide and not

readily accessible for inspection.

13.3. for any extra costs of our authorised service technician to make

the unit safe for inspection.

14. You must ensure that access to the unit by our authorised service

technician is safe and free from obstruction.

15. Our authorised service technician may refuse to inspect and test

the unit until you provide safe and free access to it, at your cost.

16. If we reject your warranty claim in accordance with clause 12, we

may charge you for our authorised service technician’s labour

costs to inspect and test the unit.

17. In order to properly test the unit we may remove it to another

location for testing.

Australian Consumer Law

18. Our goods come with guarantees that cannot be excluded under

the Australian Consumer Law. You are entitled to a replac

ement

or refund for a major failure and compensation for any other reasonably foreseeable loss or damage. You are also entitled to have

the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

19. The Stiebel Eltron warranty for the unit is in addition to any rights

and remedies you may have under the Australian Consumer Law.

Stiebel Eltron (Aust) Pty Ltd

294 Salmon Street, Port Melbourne,

Victoria, 3207

1800 153 351

(8.00 am to 5.00 pm AEST Monday to Friday)

Customer Service Representative

service@stiebel-eltron.com.au

www.stiebel-eltron.com DEL Plus AU | 19

ENGLISH

Page 20

Deutschland

STIEBEL ELTRON GmbH & Co. KG

Dr.-Stiebel-Straße 33 | 37603 Holzminden

Tel. 05531 702-0 | Fax 05531 702-480

info@stiebel-eltron.de

www.stiebel-eltron.de

Verkauf Tel. 05531 702-110 | Fax 05531 702-95108 | info-center@stiebel-eltron.de

Kundendienst Tel. 05531 702-111 | Fax 05531 702-95890 | kundendienst@stiebel-eltron.de

Ersatzteilverkauf Tel. 05531 702-120 | Fax 05531 702-95335 | ersatzteile@stiebel-eltron.de

Australia

STIEBEL ELTRON Australia Pty. Ltd.

294 Salmon Street | Port Melbourne VIC 3207

Tel. 03 9645-1833 | Fax 03 9645-4366

info@stiebel.com.au

www.stiebel.com.au

Austria

STIEBEL ELTRON Ges.m.b.H.

Gewerbegebiet Neubau-Nord

Margaritenstraße 4 A | 4063 Hörsching

Tel. 07221 74600-0 | Fax 07221 74600-42

info@stiebel-eltron.at

www.stiebel-eltron.at

Belgium

STIEBEL ELTRON bvba/sprl

't Hofveld 6 - D1 | 1702 Groot-Bijgaarden

Tel. 02 42322-22 | Fax 02 42322-12

info@stiebel-eltron.be

www.stiebel-eltron.be

China

STIEBEL ELTRON (Tianjin) Electric Appliance

Co., Ltd.

Plant C3, XEDA International Industry Cit y

Xiqing Economic Development Area

300085 Tianjin

Tel. 022 8396 2077 | Fax 022 8396 2075

info@stiebeleltron.cn

www.stiebeleltron.cn

Czech Republic

STIEBEL ELTRON spol. s r.o.

Dopraváků 749/3 | 184 00 Praha 8

Tel. 251116-111 | Fax 235512-122

info@stiebel-eltron.cz

www.stiebel-eltron.cz

Finland

STIEBEL ELTRON OY

Kapinakuja 1 | 04600 Mäntsälä

Tel. 020 720-9988

info@stiebel-eltron.fi

www.stiebel-eltron.fi

France

STIEBEL ELTRON SAS

7-9, rue des Selliers

B.P 85107 | 57073 Metz-Cédex 3

Tel. 0387 7438-88 | Fax 0387 7468-26

info@stiebel-eltron.fr

www.stiebel-eltron.fr

Hungary

STIEBEL ELTRON Kft.

Gyár u. 2 | 2040 Budaörs

Tel. 01 250-6055 | Fax 01 368-8097

info@stiebel-eltron.hu

www.stiebel-eltron.hu

Japan

NIHON STIEBEL Co. Ltd.

Kowa Kawasaki Nishiguchi Building 8F

66-2 Horikawa-Cho

Saiwai-Ku | 212-0013 Kawasaki

Tel. 044 540-3200 | Fax 044 540-3210

info@nihonstiebel.co.jp

www.nihonstiebel.co.jp

Netherlands

STIEBEL ELTRON Nederland B.V.

Daviottenweg 36 | 5222 BH 's-Hertogenbosch

Tel. 073 623-0000 | Fax 073 623-1141

info@stiebel-eltron.nl

www.stiebel-eltron.nl

Poland

STIEBEL ELTRON Polska Sp. z O.O.

ul. Działkowa 2 | 02-234 Warszawa

Tel. 022 60920-30 | Fax 022 60920-29

biuro@stiebel-eltron.pl

www.stiebel-eltron.pl

Russia

STIEBEL ELTRON LLC RUSSIA

Urzhumskaya street 4,

building 2 | 129343 Moscow

Tel. 0495 7753889 | Fax 0495 7753887

info@stiebel-eltron.ru

www.stiebel-eltron.ru

Slovakia

TATRAMAT - ohrievače vody s.r.o.

Hlavná 1 | 058 01 Poprad

Tel. 052 7127-125 | Fax 052 7127-148

info@stiebel-eltron.sk

www.stiebel-eltron.sk

Switzerland

STIEBEL ELTRON AG

Industrie West

Gass 8 | 5242 Lupfig

Tel. 056 4640-500 | Fax 056 4640-501

info@stiebel-eltron.ch

www.stiebel-eltron.ch

Thailand

STIEBEL ELTRON Asia Ltd.

469 Moo 2 Tambol Klong-Jik

Amphur Bangpa-In | 13160 Ayutthaya

Tel. 035 220088 | Fax 035 221188

info@stiebeleltronasia.com

www.stiebeleltronasia.com

United Kingdom and Ireland

STIEBEL ELTRON UK Ltd.

Unit 12 Stadium Court

Stadium Road | CH62 3RP Bromborough

Tel. 0151 346-2300 | Fax 0151 334-2913

info@stiebel-eltron.co.uk

www.stiebel-eltron.co.uk

United States of America

STIEBEL ELTRON, Inc.

17 West Street | 01088 West Hatfield MA

Tel. 0413 247-3380 | Fax 0413 247-3369

info@stiebel-eltron-usa.com

www.stiebel-eltron-usa.com

4<AMHCMO=ciccdf>

Irrtum und technis che Änderunge n vorbehalten! | Subject to errors and technical changes! | S ous réserv e

d‘erreur s e t de m odif icatio ns techniqu es! | Onder voorbehoud van vergissingen en technische wijzigingen! |

Salvo error o modif icación técnica! | Excepto erro ou alteração técnica | Zastrzeżone zmiany technic zne i

ewentualne błędy | O myly a technické změny jsou vyhraze ny! | A muszaki változ tatások és tévedé sek jogát

fenntartjuk ! | Отсу тстви е ошибок не гарантиру ется. Воз можны тех нические и зменени я. | Chyb y a

technické zmeny sú vyhradené! Stand 9 460

A 328223-41140-9448

B 328224-41140-9448

Loading...

Loading...