Page 1

OPERATION AND INSTALLATION

FUNCIONAMIENTO E INSTALACIÓN

MODE D’EMPLOI ET INSTALLATION

DHW heat pump water heater

Calentador de agua con bomba eléctrica de calor

Chauffe-eau à thermopompe

» Accelera 220 E

» Accelera 300 E

Conforms to ANSI/UL 499, UL 1995, UL 94-5 VA, UL 174

Certifi ed to CAN/CSA C22.2 No. 110

Conforme a ANSI/UL 499, UL 1995, UL 94-5 VA, UL 174

Certifi cación con CAN/CSA Std. C22.2 No. 110

Conforme à la norme ANSI/UL Std. 174

Certifi é à la norme CAN/CSA Std. C22.2 No. 110

Tested and certifi ed by WQA to NSF/ANSI372

for lead free compliance.

Probado y certifi cado por WQA NSF/ANSI 372 para

el cumplimiento de las regulaciones sin plomo.

Testé et certifi é par WQA à la NSF/ANSI 372 pour

une utilisation sans plomb.

Page 2

CONTENTS

ACCELERA® 220 E QUICK START-UP GUIDE

OPERATION

1. General information _________________________________________7

2. Safety __________________________________________________________7

2.1 Intended use ______________________________________________________ 7

2.2 Incorrect use ______________________________________________________ 7

2.3 General safety instructions ____________________________________ 7

2.4 ETL designation __________________________________________________ 8

2.5 Appliance labels _________________________________________________ 8

3. Appliance description _____________________________________ 10

3.1 Heating the DHW tank _________________________________________11

3.2 Appliance operation outside the application limits ______ 11

3.3 Frost protection _________________________________________________11

4. Settings _____________________________________________________ 11

4.1 Display and controls ____________________________________________11

4.2 Settings ___________________________________________________________ 11

4.3 Calling up fault codes __________________________________________ 13

4.4 Rapid heating key ______________________________________________ 13

4.5 Emergency shutdown __________________________________________ 14

5. Maintenance and care _____________________________________ 14

6. Troubleshooting ____________________________________________ 14

6.1 Fault codes _______________________________________________________ 15

INSTALLATION

7. Safety ________________________________________________________ 16

7.1 General safety instructions ___________________________________16

7.2 Instructions, standards and regulations ___________________ 16

7.3 Incorrect use _____________________________________________________ 16

7.4 Qualifi cation _____________________________________________________ 16

8. Appliance description _____________________________________ 16

8.1 Standard delivery _______________________________________________ 16

8.2 Required accessories __________________________________________ 16

8.3 Further accessories_____________________________________________16

9. Preparations ________________________________________________ 16

9.1 Transport _________________________________________________________ 16

9.2 Storage ____________________________________________________________ 17

9.3 Installation site __________________________________________________ 17

9.4 Siting the appliance ____________________________________________18

9.5 Minimum clearances ___________________________________________ 18

10. Installation __________________________________________________ 19

10.1 Water connection _______________________________________________ 19

10.2 Condensate drain _______________________________________________ 19

10.3 Power supply ____________________________________________________ 20

10.4 Assembling the appliance ____________________________________ 21

11. Commissioning _____________________________________________ 21

11.1 Commissioning __________________________________________________ 21

11.2 Recommissioning _______________________________________________ 21

12. Shutting down ______________________________________________ 22

13. Troubleshooting ____________________________________________ 22

13.1 Fault table ________________________________________________________ 22

13.2 Resetting the safety pressure limiter _______________________22

13.3 Resetting the high limit safety cut-out _____________________22

13.4 Motor overload relay ___________________________________________ 22

14. Maintenance and cleaning ________________________________ 23

14.1 Removing the appliance cover _______________________________23

14.2 Removing the casing ring _____________________________________ 23

14.3 Cleaning the evaporator _______________________________________ 24

14.4 Draining the tank _______________________________________________24

14.5 Descaling the electric booster element ____________________ 24

14.6 Protective anode ________________________________________________ 24

14.7 Valves _____________________________________________________________ 24

14.8 Replacing the power cable ___________________________________ 24

14.9 Fitting the casing ring _________________________________________ 24

14.10 Fitting the appliance cover ___________________________________ 25

15. Specifi cation ________________________________________________ 26

15.1 Dimensions and connections _________________________________26

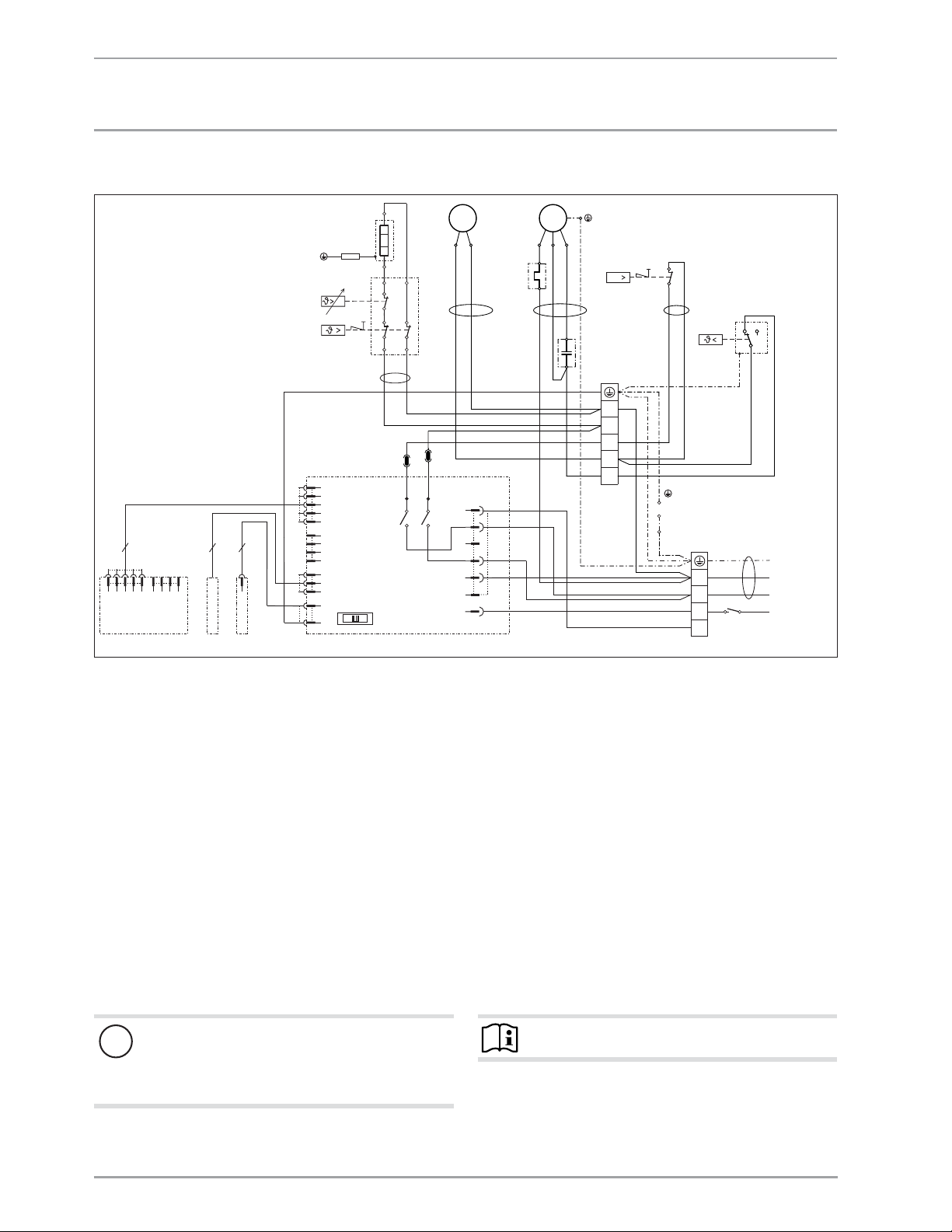

15.2 Wiring diagram _________________________________________________ 28

15.3 Data table ________________________________________________________ 29

16. Limited Warranty___________________________________________ 30

2 | Accelera® 220-300 E www.stiebel-eltron-usa.com

Page 3

SPECIAL INFORMATION

This manual includes important information regarding the safe

and effi cient handling of the water heater. Keep this manual with

the water heater at all times.

Work must only be carried out by a licensed installer who has read

and understands these instructions. All federal, state and local

codes must be followed. Failure to do so may result in equipment

failure, serious injury, or death.

While working on the water heater, disconnect the power supply.

Illustrations in these instructions are designed to aid a general

understanding and may deviate from the actual water heater version. No claims can be derived from such installations.

Limited liability:

We have collated all details and information in this manual in due

consideration of applicable standards and regulations, the state of

the art and our long-term know-how and experience.

Losses due to the following are excluded from our liability:

- Non-observance of these instructions

-Incorrect use

- Installation of water heater by unqualifi ed personnel

- Unauthorized modifi cations

- Use of unauthorized spare parts

For more information on liability, see the warranty section at the

back of this manual.

Copyright:

These operating and installation instructions are subject to copyright.

Transferring these instructions to third parties, copying of any

kind, either in total or extracts therefrom, as well as their use

and/or conveying its contents are prohibited without our written

consent.

Violations are liable to claims for compensation. Further claims

are reserved.

Register your product

NOTE:

You must register this product within 90 days

of purchase on our web site in order to activate any standard warranty or to be eligible for

the extended warranty. Go to our website at:

www.stiebel-eltron-usa.com and click on “Register Your

Product.”

Before beginning the registration process, we suggest that you

gather the necessary information as follows:

1

000000-0000-00000

1 Serial number on the type plate

Type, Example: Accelera 220 E (the type plate can be found

on the appliance above the “DHW outlet” connection).

Number listed after “Nr.”

Place of Purchase

Purchase Date

First & Last Name

Email address

Physical Address

Phone Number

If you have any questions concerning the registration process

or warranty options, please contact Stiebel Eltron USA directly

at (800)-582-8423.

ENGLISH

D0000035352

We hold the copyright:

Stiebel Eltron, Inc.

17 West Street | West Hatfi eld, MA 01088

Tel. 413-247-3380 | Fax 413-247-3369

Email info@stiebel-eltron-usa.com

www.stiebel-eltron-usa.com

Should you have any questions regarding the installation or operation of the water heater, please contact our customer service.

Tel. (USA) 800-582-8423 or 413-247-3380

Please record your serial number and information:

Serial No.:

Date of purchase:

www.stiebel-eltron-usa.com Accelera® 220-300 E | 3

Page 4

QUICK START-UP GUIDE

General information

ACCELERA® 220 E QUICK START-UP GUIDE

Overview:

Installation of this water heater is similar to standard electric water heaters, with a few minor exceptions. Be sure to follow all state

and local codes during installation. This Quick Start-up Guide is not intended to be a substitute for the complete installation manual.

Be sure to follow all safety precautions.

Unpacking:

DO NOT unpack the water heater until it is located at the point of installation. Follow all instructions in the manual and be sure to use

caution, as this unit is top heavy. After unpacking, DO NOT lay the unit down and DO NOT jar or tip the unit past 45 degrees on a hand

truck. If the appliance has not been completely vertical during transport or setup, it must rest in a vertical position for at least one hour

before commissioning.

Installation of water connections:

1. Find a suitable location that fi ts the room spacing guidelines on the next page. The minimum volume of the room is 10´ x 10´ x

10´. Be sure vents are parallel to the wall with the fan facing the most open area along that wall. Please note: a drain pan is recommended, and may be code in some areas.

2. The inlet & outlet plumbing connections on the unit are 1˝ male NPT. It is recommended to use union connections for easier serviceability. Install a boiler drain at the cold water inlet for easier draining of the tank.

3. The temperature & pressure (T&P) safety valve port is ¾˝ female NPT. A T&P valve is supplied which is rated to release water at

100 psi and/or 210°F. Plumb this connection to a bucket or directly to a drain. If it is plumbed to a bucket, check it often for any

accumulated water.

For hook-up, follow all state and local codes for check valves, expansion tanks, shut off valves, gauges, etc. Install a 70 psi pressure

reduction valve if the water pressure exceeds 70 psi (See 10.1, “Water connection”, pg. 19)

Condensate drain:

Run the condensate drain connection directly into a drain or use a condensate pump to drain into a suitable location (See 10.2, “Condensate drain”, pg. 19).

Fill & flush tank:

Run water and be sure the tank is full prior to turning on the electricity.

Installation/electrical:

Use a 240 Volt / 15 Amp double pole breaker and connect to the water heater L1,L2 & ground (See 10.3, “Power supply”, pg. 20).

4 | Accelera® 220-300 E www.stiebel-eltron-usa.com

Page 5

QUICK START-UP GUIDE

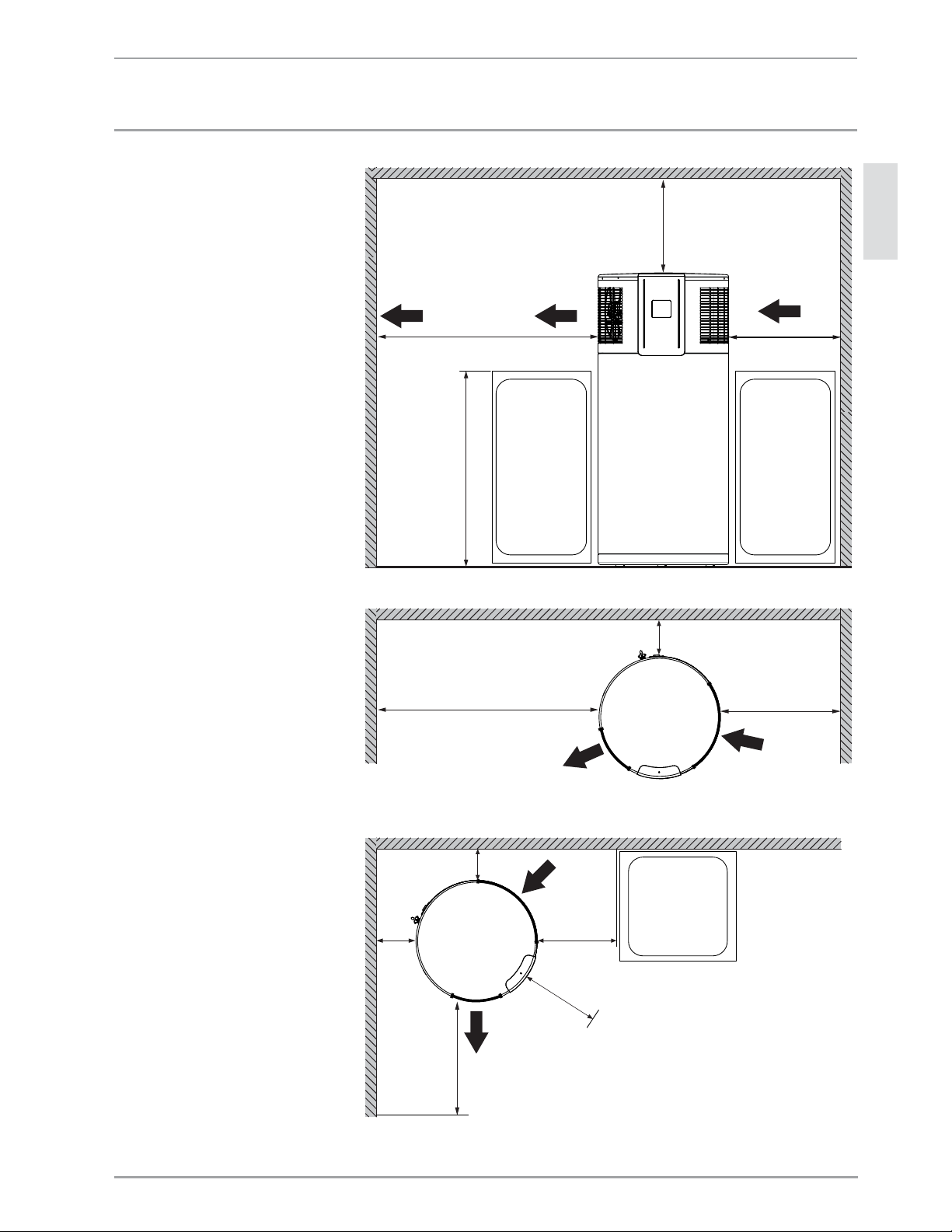

Required room dimensions and clearances

› Do not install in a room

with less than 800 cubic

feet of total volume.

› Do not install with the air

exhaust pointing at a wall

or any surface closer than

6 feet away.

› Do not install with the air

intake pointing to a wall or

any surface closer than 2

feet away.

› If you are installing the

water heater next to

another appliance, it

cannot be taller than 42

inches. Otherwise, it will

obstruct air fl ow to and

from the unit.

Minimum room volume:

2

800 ft

(22.7 m2, 3 m x 3 m x 2.4 m)

, 10´ x 10´ x 8´

Air flow

exhaust

6´ (1.8 m)

An object

next to the

unit must

≤42˝

(1.1 m)

be less than

42˝ high

14˝

(0.4 m)

ENGLISH

Air flow

intake

2´ (0.6 m)

› Failure to follow

installation instructions

will void the factory

warranty.

Acceptable positioning, vent parallel to a wall:

8˝ (0.2 m)

6´ (1.8 m)

Air flow

exhaust

2´ (0.6 m)

Air flow

intake

Acceptable positioning, vent parallel to a wall in a corner:

8˝ (0.2 m)

Air flow

intake

8˝

(0.2 m)

2´

(0.6 m)

2´

(0.6 m)

6´

Air flow

(1.8 m)

www.stiebel-eltron-usa.com Accelera 220-300 E | 5

exhaust

Page 6

QUICK START-UP GUIDE

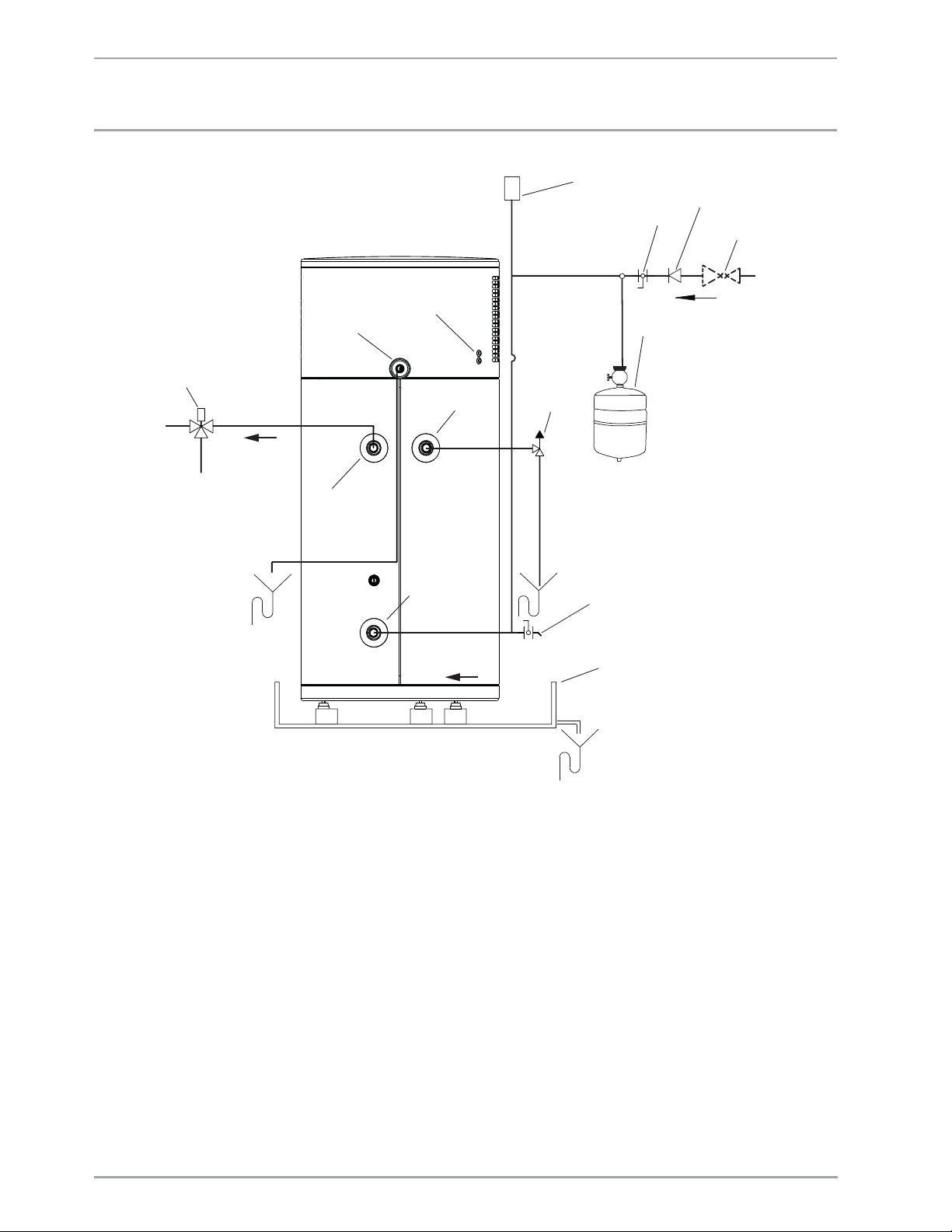

Plumbing connections

3

HMC

Hot water

1

8

7

9

11

14

4

5

Cold water

6

2

10

12

13

1 Vacuum breaker

2 Hot water connection (1˝ NPT)

3 Mixing valve (optional, supplied by installer)

4 Connection for T&P valve ¾˝ NPT

5 T&P valve ¾˝ NPT, 0.69 MPa @ 99°C (100 psi @ 210°F) (supplied with unit)

6 Expansion tank (required, supplied by installer)

7 Straight-through shut-off valve (supplied by installer)

8 Check valve (required, supplied by installer)

9 0.48 MPa (70 psi) pressure reduction valve (optional, supplied by installer)

10 Cold water connection (1˝ NPT)

11 Condensate drain (elbow supplied with unit)

12 Drain valve (supplied by installer)

13 Drain pan (supplied by installer)

14 Condensate spillover

6 | Accelera 220-300 E www.stiebel-eltron-usa.com

Page 7

OPERATION

General information

OPERATION

1. General information

The chapters “Special information” and “Operation” are intended

for appliance users and qualifi ed contractors.

The chapter “Installation” is intended for qualifi ed contractors.

Note

Read these instructions carefully before using the appliance and retain them for future reference.

Pass on the instructions to a new user if required.

2. Safety

This chapter provides an overview of all important actions required for a safe and trouble-free operation.

2.1 Intended use

The appliance is intended for DHW heating within the application

limits (See 15.3, “Data table”, pg. 29).

The appliance is intended for domestic use, i.e. it can be used

safely by untrained persons. The appliance can also be used in a

non-domestic environment, e.g. in a small business, as long as it

is used in the same way.

Any other use beyond that described shall be deemed inappropriate. Observation of these instructions and of instructions for any

accessories used is also part of the correct use of this appliance.

2.2 Incorrect use

The following are not permitted:

- Heating liquids other than potable water

- Operating the appliance with an empty DHW tank

- Operating the appliance outside the application limits (See

15.3, “Data table”, pg. 29)

- Interrupting the power supply, as without power supply the

appliance is not protected against corrosion

2.3 General safety instructions

Only qualifi ed contractors should carry out the electrical work and

installation of this appliance. Qualifi ed contractors are responsible

for adherence to all applicable regulations.

Operate the appliance only when fully installed and with all safety

equipment fi tted.

WARNING Injury

!

The appliance may be used by children aged 8 and up and

persons with reduced physical, sensory or mental capabilities or a lack of experience and know-how, provided

that t hey are supervised or they have b een instruc ted on

how to use the appliance safely and have understood

the resulting risks. Children must never play with the

appliance. Children must never clean the appliance or

perform user maintenance unless they are supervised.

WARNING Electrocution

Contact with live components presents a threat to life.

Damage to the electric insulation or to individual components may result in a threat to life.

If there is damage to the insulation, disconnect the

power supply and arrange a repair.

All work on the electrical installation must be carried

out by a qualifi ed contractor.

WARNING Scalding

The water in the DHW tank can be heated to temperatures in excess of 149°F/65°C. There is a risk of scalding

at outlet temperatures in excess of 110°F/43°C.

Ensure you do not come into contact with the water

when discharged.

WARNING Burns

Touching hot components can lead to burns.

When working on hot components, always wear protective working clothing and safety gloves.

The pipework connected to the DHW outlet of the appliance can reach temperatures in excess of 149°F/65°C.

WARNING Scalding

The appliance is fi lled with refrigerant at the factory.

In case of leaking refrigerant, avoid coming into contact

with the refrigerant or inhaling the released vapors. Ventilate the rooms affected.

CAUTION Injury

!

Never place any objects on top of the appliance. If objects

are left on the appliance, noise emissions may increase

due to resulting vibrations, and the objects could fall

and cause injury.

CAUTION

!

To reduce the risk of excessive pressures and temperatures in this water heater, install temperature and pressure protective equipment required by local codes and

no less than a combination temperature and pressure

relief valve certifi ed by a nationally recognized testing

laboratory that maintains periodic inspection of production of listed equipment or materials, as meeting the requirements for Relief Valves and Automatic Gas Shutoff

Devices for Hot Water Supply Systems, ANSI Z21.22. This

valve must be marked with a maximum set pressure not

to exceed the marked maximum working pressure of the

water heater. Install the valve into an opening provided

and marked for this purpose in the water heater, and

orient it or provide tubing so that any discharge from

the valve exits only within 6 inches above, or at any

distance below, the structural fl oor, and does not contact

any live electrical part. The discharge opening must not

be blocked or reduced in size under any circumstances.

ENGLISH

www.stiebel-eltron-usa.com Accelera® 220-300 E | 7

Page 8

OPERATION

Safety

CAUTION

!

Hydrogen gas is produced by this heater in a hot water

system that has not been used for a long period of time

(2 weeks or more). Hydrogen gas is extremely fl ammable. To reduce the risk of injury under these conditions,

it is recommended that the hot water faucet be opened

for several minutes at the kitchen sink before using any

electrical appliance connected to the hot water system.

When hydrogen is present, there will probably be an

unusual sound such as air escaping through the pipe as

the water begins to fl ow. There should be no smoking or

open fl ame near the faucet at the time it is open.

Material losses

!

If you disconnect the appliance from the power supply, it

is no longer protected against frost.

Do not interrupt the power supply to the appliance.

Material losses

!

Never cover this appliance. Covering the air intake or air

discharge leads to a reduced air supply. If the air supply

is restricted, the operational reliability of the appliance

cannot be guaranteed.

Material losses

!

Only operate the appliance when the DHW tank has been

fi lled.

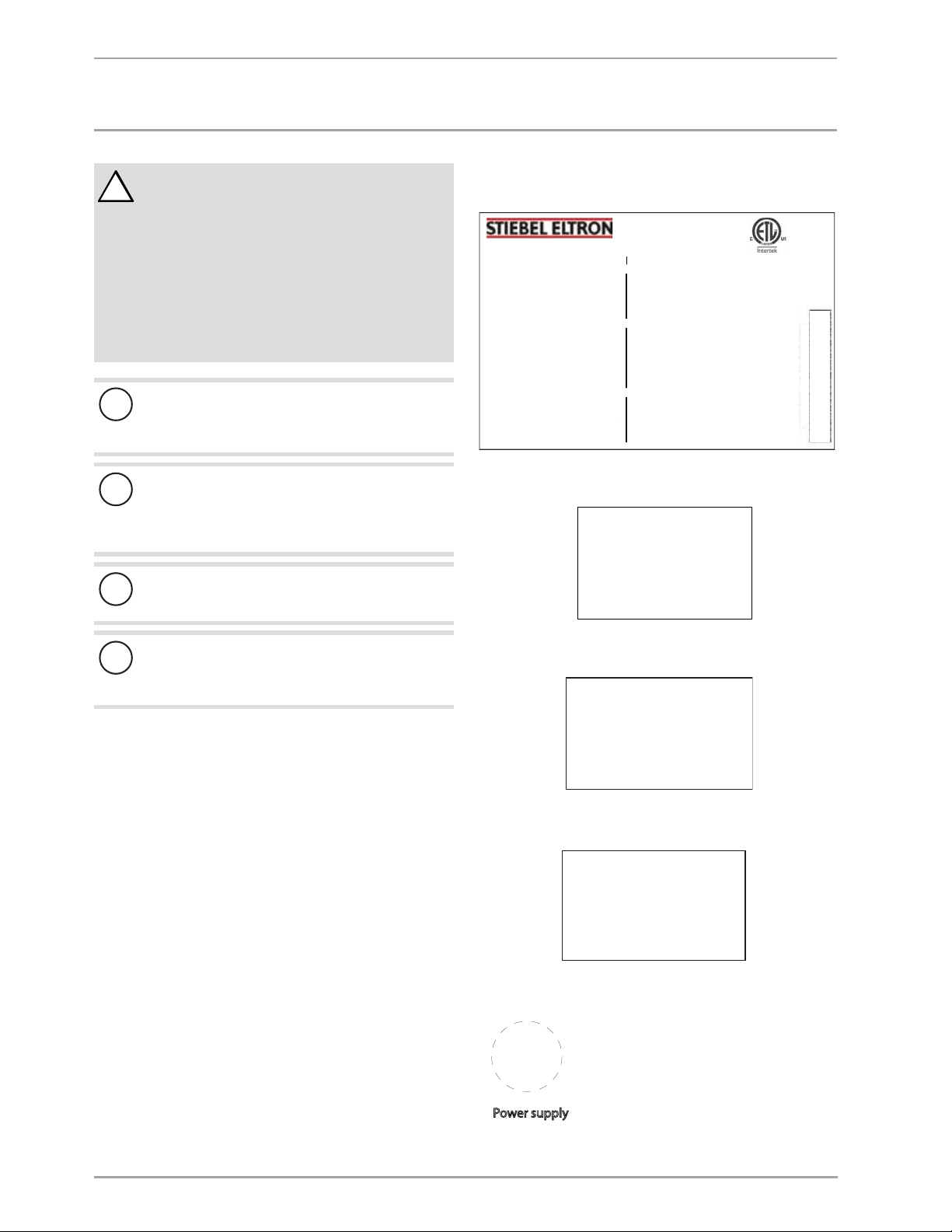

2.5 Appliance labels

1. Type plate label for the Accelera 220 E

No.:#### / ######

Accelera 220 E

Part number/code article: 233058

Electrical/électriqu e

Voltage/tension: Single phase 220-240 V

Frequency/fréquence: 50 / 60 Hz

Breaker/disjoncteur: 15 A

P

(rated power input)/puissance nominale: 2200 W

nmax

Maximum allowable ratings/courant nominal: 2200 W, 9.17 A

Protection class/i ndicie de protec tion: IP 24

Heat pump/pompe à chaleur:

(Air 107.6°F / Water 149°F): 0.54 kW

P

N

Refrigerant/frigorigène: R-134a

Refrigerant charge/frigorigène poids de remplissage: 1.874 lb / 850g

Max. operating pressure/max. pression de service: 348.1 PSI / 2,400 kPa

Lock rotor curre nt/puissance blockade : 15.3 A

MCA: 14 A

Rated compressor load/courant nominale du compresseur: 2.5 A

Motor fan/moteur d e ventilateu r: 24 W

DHW cylinder/DHW cylindre:

Backup heating element/chauffage d'appoint: 1690 W

Max. operating pressure/max. pression de service: 87 PSI / 600 kPa

Max. operating temperature/max. temperature de service: 168.8°F / 76°C

Tank materi al/matériau réservoir: Steel

Nominal capacity/capacité nominale: 58.12 gal / 220 l

Tank test pressure/contrôle de réservoir: 130.5 pSI / 900 kPa

2. Condensate drain information label

Condensate

Condenso

Condensat

285872-34892

Conforms to UL STD. 1995

Conforms to UL STD. 174

Certified to CAN/CSA STD. C22.2 No.236-05

Certified to CAN/CSA STD. C22.2 No.110-94

Stiebel Eltron Inc.

17 West Street

West Hatfield, MA 01088, USA

800.582.8423

info@stiebel-eltron-usa.com

Read the instructions carefully.

Tested for leaks.

Lira attentivement la notice.

Étanchéité testé.

Made in EU/Fabriqué en UE

315683-38055

311801-38055

XXXXXX-XXXX-XXXXXX

Material losses

!

Keep the appliance installation room free from air contaminated with oil or salt and corrosive or explosive substances.

2.4 ETL designation

The ETL designation shows that the appliance meets all essential

UL and CAN/CSA requirements. This appliance conforms to:

- UL Standard 1995

- UL Standard 174

- CAN/CSA Standard C22.2 No.236-05

- CAN/CSA Standard C22.2 No.110-94

3. Hot water outlet location label

Hot Water Outlet

Salida de agua caliente

Sortie eau chaude

4. Cold water outlet location label

Cold Water Inlet

Entrada para agua fría

Entrée eau froide

5. Power connection information label

!Attention!

Must connect to

Power supply

Disconect power supply

Before opening the cover

240 V, 15 A

Double-pole

Circuit breaker

311803-38055

311802-38055

8 | Accelera® 220-300 E www.stiebel-eltron-usa.com

Page 9

OPERATION

Safety

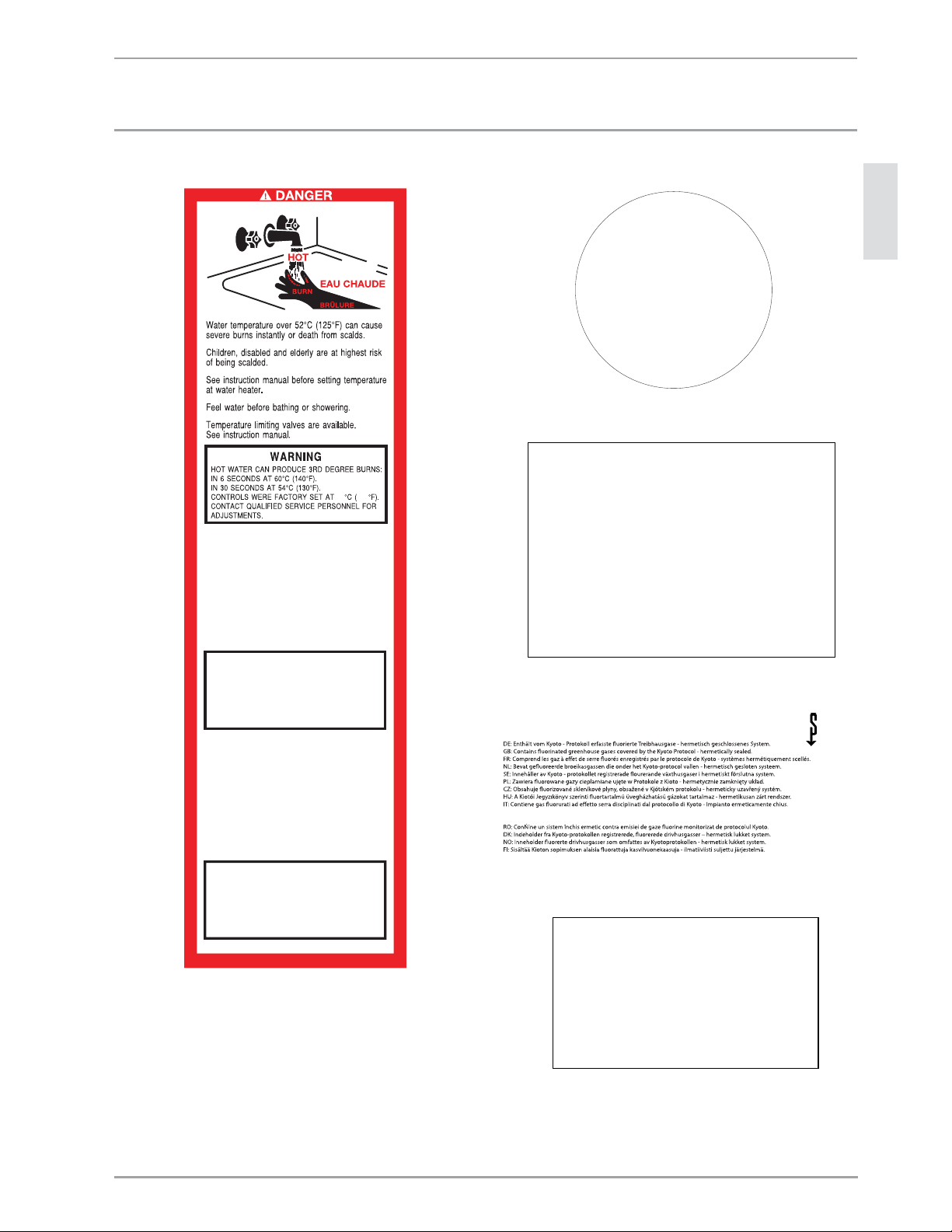

6. Scald risk information label

Une température de l'eau de plus de 52°C (125°F) peut

causer des brûlures graves ou la mort par ébo u i llantage

Les enfants, les personnes handicapées e t les personnes

âgées courent le plus grand risque de brûlures.

Lire la notice d'emploi avant d'ajuster la température du

chauffe-eau.

Vérifier la température de l'eau avant

de prendre un bain ou une do uche .

Des dispositifs de limi ta ti on de te mpé r a t ur e s on t

disponibles. Voir la notice d'emploi.

L'eau chaude peut provoquer des brûlures de 3ème

degré:

En 6 secondes à 60°C (140°F).

En 30 secondes à 54°C (130°F).

Réglé à l'usine à 52°C (125°F).

Contacter le personnel de service après-vente qualifié

pour toute modification.

Agua con temperatura de más de 52 °C (125 °F) puede

al instante causar quemaduras graves o la muerte por

escaldadura.

Niños, personas con discapacidades o mayores se

encuentran en mayor peligro de e scaldadura.

Mire las instrucciones de uso antes de ajustar la

temperatura en el calentador de agua.

Pruebe el agua antes de bañarse o de ducharse .

Están disponibles válvulas para regular la

temperatura. Mire las instrucciones de uso.

Agua muy ca lien te p uede ca us ar quem a d ur a s

de 3 grado. En 6 segundos A 60 °C (140 °F).

En 30 segundos A 54 °C (130 °F).

La regulación fue ajustada en la producción

A 52 °C (125°F) . Si necesit a a justar la regulació n,

contácte al técnico de servicio calificado.

ATTENTION

ADVERTENCIA

er

AQUA CALIENTE

ABRASAR

52

125

7. Gasket connection information label

For reason of corrosion protection use

flat gasket ring. Never seal threadshemp

(equipment Damage!).

Para la protección contra la corrosión use

sellos planos de los tubos. Una unión

con cáñamo no está permitida

(riesgo de daño del equipo!).

311804-38055

Pour des raisons de protection contre la

corrosion, le raccordement est à réaliser

par joints plats. L'étanchéïfication au

chanvre n'est pas autorisée

(dommages au matériel!).

8. Pressure & temperature relief valve information label

Relief valve

Plumber:

The re lief valve i nsta llati on m ust b e fitted to this s oc ke t.

The pressure and temperature relief valve has to meet

local codes and comply with ANSI Z21.22.

Soupape de sûreté

Plombier:

L'installation de la soupape de sûreté doit être branchée sur cette prise.

La soupape de sûreté pour la pression et la température doit être conforme

à la réglementation locale et à ANSI Z21.22.

Válvula de seguridad

Plomero:

La válvula de seguridad debe instalarse en esta conexión.

Las válvulas limitadoras de presión y temperatura tienen que

ajustarse al código local y cumplir con la norma ANSI Z21.22.

9. Kyoto protocol information label

ES: Sistema herméticamente cerrado que contiene gases de efecto invernadero mencionados en el protocolo de Kioto.

BG: Съдържа посочените в Протокола от Киото флуорирани парникови газове - херметически затворена система.

299581-36960

10. Supplemental heat element information label

If the water heater is retrofitted with a supplemental heat element

make sure that both thermostat are adjusted on the same

water temperature set point.

Si le chauffe-eau est rénové avec un élément de chauffe supplémentaire,

assurez-vous que les deux thermostats soient ajustés

à la même température de réglage de l'eau.

Si el calentador de agua está adaptado a un elemento calentador

suplementario, asegúrese que ambos termostatos estén ajustados

a la misma temperatura de agua.

ENGLISH

315321-38055

315322-38055

www.stiebel-eltron-usa.com Accelera® 220-300 E | 9

Page 10

OPERATION

Appliance description

11. Booster heater element information label

:

CAUTION

for use only in water

ATTENTION

pour l'utilisation dans l'eau

ATENCIÓN

se usa sólo para en agua

:

:

315683-38055

12. Appliance must be vertical for at least one hour before commissioning information label

WARNING / WARNUNG

The unit must remain in vertical position for at least

one hour before putting unit into operation.

Die Anlage muss min. 1 Stunde lang vor deren

Inbetriebnahme in senkrechter Position bleiben.

L’appareil doit être placé en position verticale

au moins une heure avant sa mise en route.

La unidad tiene que quedar en la posición vertical

al menos durante una hora antes de poner la unidad

en funcionamiento.

315125-38055

3. Appliance description

The appliance is designed for indoor installation. The appliance

recirculates ambient air and does not require outdoor air. The

appliance extracts heat from the ambient air. This heat is utilized

to heat the water in the DHW tank with added electric power. The

amount of electric energy and time required to heat-up the DHW

depends on the temperature and humidity of the ambient air.

This heat extraction results in a drop in the ambient temperature

inside the installation room by between 2°F/1°Cand 5.5°F/3°C.

The appliance also extracts moisture from the air, which turns

into condensate. The condensate is drained from the appliance

via the condensate drain.

When a hot water draw-off point is opened, the hot DHW is pushed

out of the appliance by the in-fl ow of cold DHW.

To protect against corrosion, the inside of the DHW tank is coated

with special enamel and is additionally equipped with an impressed current anode.

The electronic control unit makes energy saving adjustments easier. Subject to the power supply and usage pattern, the water is

heated up automatically to the set temperature.

Heat pump operating principle

A hermetic circuit within the appliance contains refrigerant (See

15.3, “Data table”, pg. 29). This refrigerant evaporates at low

temperatures and collects heat from the ambient air.

In the evaporator, the refrigerant changes from its liquid into its

gaseous state. A compressor draws in the gaseous refrigerant

and compresses it. This increase in pressure raises the refrigerant

temperature.

The compression process requires electrical energy. The energy

(motor heat) is not lost, but is discharged to the downstream

condenser. The cooled refrigerant passes a fi lter dryer. There, the

refrigerant indirectly transfers heat to the DHW tank and the liquid

refri gerant is route d to a t wo- fl ood evaporator. An expansion valve

then reduces the still prevalent pressure and the cycle starts again.

Note

In the event of an interruption of the power supply, the

compressor is blocked from operating for at least one

minute. The electronic control board (ECB) delays electronic starting for one minute while the appliance goes

through its initializing process.

If the compressor subsequently fails to start, it may be

blocked by additional safety devices (Klixon and high

pressure switch). If the compressor is switched off due

to the Klixon, the pressure difference between the high

and low pressure sides of the refrigerant circuit may be

the cause. When the pressure difference is equalized

(approximately 5 minutes), the compressor turns on. If a

tripped high pressure switch caused the blocking of the

compressor, this may be due to a failed thermostat or

high ambient air temperature. After the power supply has

been re-established, the appliance continues to operate

with the parameters that were selected before the power

supply was interrupted.

10 | Accelera® 220-300 E www.stiebel-eltron-usa.com

Page 11

OPERATION

comfor

omf

or

t

e

ron

Settings

3.1 Heating the DHW tank

The water is heated by the heat pump through the condenser

wrapped around the tank. This is the appliance’s standard mode

of operation.

An integral sensor in the tank is connec ted to an electronic device

to measure the thermal energy content of the water in the DHW

tank. The water in the DHW tank is heated if its temperature is

lower than the set temperature.

For information on the heat-up time of the water in the DHW tank,

See 15.3, “Data table”, pg. 29.

3.1.1 Electric booster element

The electric booster element is automatically activated in case

of a damaged heat pump or to provide more hot water than the

current tank supply.

In the event of an unexpectedly high hot water demand, the booster heater can be manually activated. Se e 4.4.1, “Comfo rt heating”,

pg. 13.

In the event of an appliance fault, a backup mode can be set to

activate the electric booster element. See 4.4.2, “Emergency back

up mode”, pg. 13.

3.2 Appliance operation outside the application

limits

3.2.1 Ambient temperatures below the application limit

If hoar frost is growing on the evaporator fi ns, the hoar frost

temperature monitor switches the heat pump compressor off.

The compressor switches on automatically once the evaporator

defrosts.

To guarantee fault-free operation of the appliance, make sure

you operate the appliance within its application limits (See

15.3, “Data table”, pg. 29).

Note

Heat-up times are longer while the evaporator is defrosting.

3.2.2 Ambient temperatures above the application limit

The safety equipment switches the appliance off if the upper application limit is exceeded.

Following a cooling time of several minutes, the appliance is

switched back on automatically. The appliance is switched off

again if the ambient temperature rises above the permissible temperature value again.

To guarantee fault-free operation of the appliance, make sure

you operate the appliance within its application limits (See

15.3, “Data table”, pg. 29).

3.3 Frost protection

The appliance activates a frost protection function if the integral

sensor in the DHW tank detects a temperature below 50°F/10°C.

The appliance then heats the water in parallel mode by using both

the heat pump and the electric booster element. The heat pump

and electric booster element switch off once the temperature detected by the integral sensor is more than 65°F/18°C.

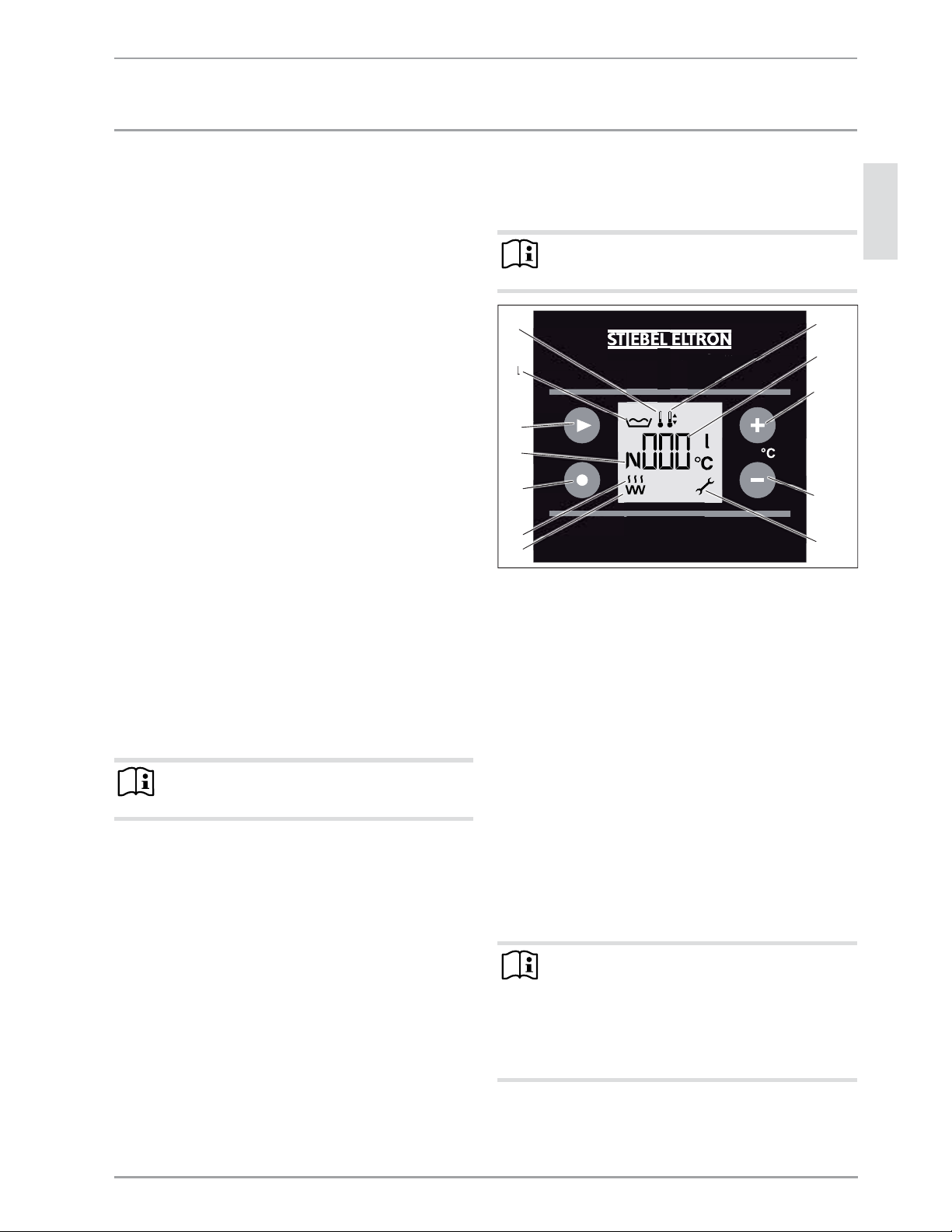

4. Settings

4.1 Display and controls

Note

The back-light of the display will illuminate for 15 seconds

after pressing any button.

12

elctronic comfort

11

10

9

8

7

6

1 Set temperature symbol

2 Amount of amount of mixed water display (l

1

04°F)

Actual temperature display, upper tank section/

Set temperature1display

Set temperature2display

Fault code display

3 Plus key

4 Minus key

5 Service/error symbol

6 Electric booster element symbol

7 Heat pump symbol

8 Rapid heating key

9 Set temperature2 symbol

10 Menu key

11 Amount of mixed water symbol

12 Actual temperature symbol

The "electric booster element" and "heat pump" symbols are displayed when these appliance components are active. The display

of these symbols does not necessarily mean that the electric booster element and the heat pump are running.

Service/fault symbol

Note

Notify your contractor if the service/fault symbol appears on the display. Continuous illumination of the

symbol indicates that the fault is not preventing appliance operation.

A fl ashing service/fault symbol indicates that the water

is not being heated and that it is essential you notify

your contractor.

lct

@

40°C /gal

4.2 Settings

In standard display mode, the display shows the current amount

of mixed water.

1

2

3

4

5

@

ENGLISH

26_03_13_0006_

www.stiebel-eltron-usa.com Accelera® 220-300 E | 11

Page 12

OPERATION

Settings

Note

15seconds after every adjustment, the appliance automatically switches back to the standard display and saves

the set value.

With the menu key, all information and

setting options are called up in sequence.

The relevant symbol appears with each

setting.

4.2.1 Amount of mixed water display (standard display)

The currently available amount of mixed

water at 104°F/40°C when mixed with

59°F/15°C cold water is shown.

If there is no usable hot water in the tank,

the display shows < 10 l.

DHW demand for Amount of mixed water at 104°F/40 °C)

Bath 32-40 gal (120-150 l)

Shower 9-13 gal (30-50 l)

Hand washing ½-1½ gal (2-5 l)

The amount of mixed water that can be achieved depends on the

set point temperature.

4.2.2 Actual temperature display

In the mixed water menu, press the

menu key once to get to the actual temperature menu.

The current actual temperature in

the upper section of the DHW tank is

shown. This largely corresponds to the

outlet temperature.

4.2.3 Set temperature1

Note

For reasons of legionella prevention, never set the DHW

temperature lower than 124°F/50°C).

The set temperature1 is the DHW temperature to which the appliance regulates if no external signal transmitter is connected

and active. Set temperature1 is set to 131°F/55°C at the factory.

In the actual temperature menu, press

the menu key once to get to the menu

for set temperature1.

The set temperature1 symbol appears.

Adjust set temperature1 from 69 to

149°F / 20.5 to 65°C using the plus and

minus keys.

Note

Another way to adjust set temperature1 is to press the

plus or minus key when in standard display (amount of

mixed water).

Frost protection

If the set temperature is set to less than

69°F/20.5°C, only frost protection remains active. The water heater will not

run.

4.2.4 Set temperature2

Note

For reasons of legionella prevention, never set the DHW

temperature lower than 124°F/50°C).

Set temperature2 is the DHW temperature to which the appliance

regulates if an external signal transmitter is connected and active.

In the set temperature1 menu, press

the menu key once to get to the menu

for set temperature2.

The set temperature2 symbol appears.

The display of set temperature2 is denoted with an "N".

Adjust set temperature2 from 69 to

149°F / 20.5 to 65°C) using the plus and

minus keys.

Operation with external signal transmitter (240 V input)

The connection of the heat pump to an external signal offers the

possibility of heating water to a raised temperature set point

during periods when electric rates are favorable, for example

during times when PV power is available or low tariff utility rates

are in effect.

The external signal may be offered by a PV system or low tariff

transmission of a utility.

This set temperature2 is activated when a phase (LF signal) is

present at terminal X0/LF (See 10.3.1, “Connection with external

signal transmitter”, pg. 20). While activated, set temperature2

replaces the standard set DHW temperature ("set temperature1").

If set temperature2 has been activated by the external signal

transmitter, this set temperature will then be active for at least

20minutes. If the signal remains active after those 20minutes

passed, the compressor will run until the LF signal ends. If not,

the selected set temperature1 is activated again.

12 | Accelera® 220-300 E www.stiebel-eltron-usa.com

Page 13

OPERATION

Settings

If the relevant set DHW temperature is accomplished, the compressor switches off and remains off for a minimum idle time of

20minutes.

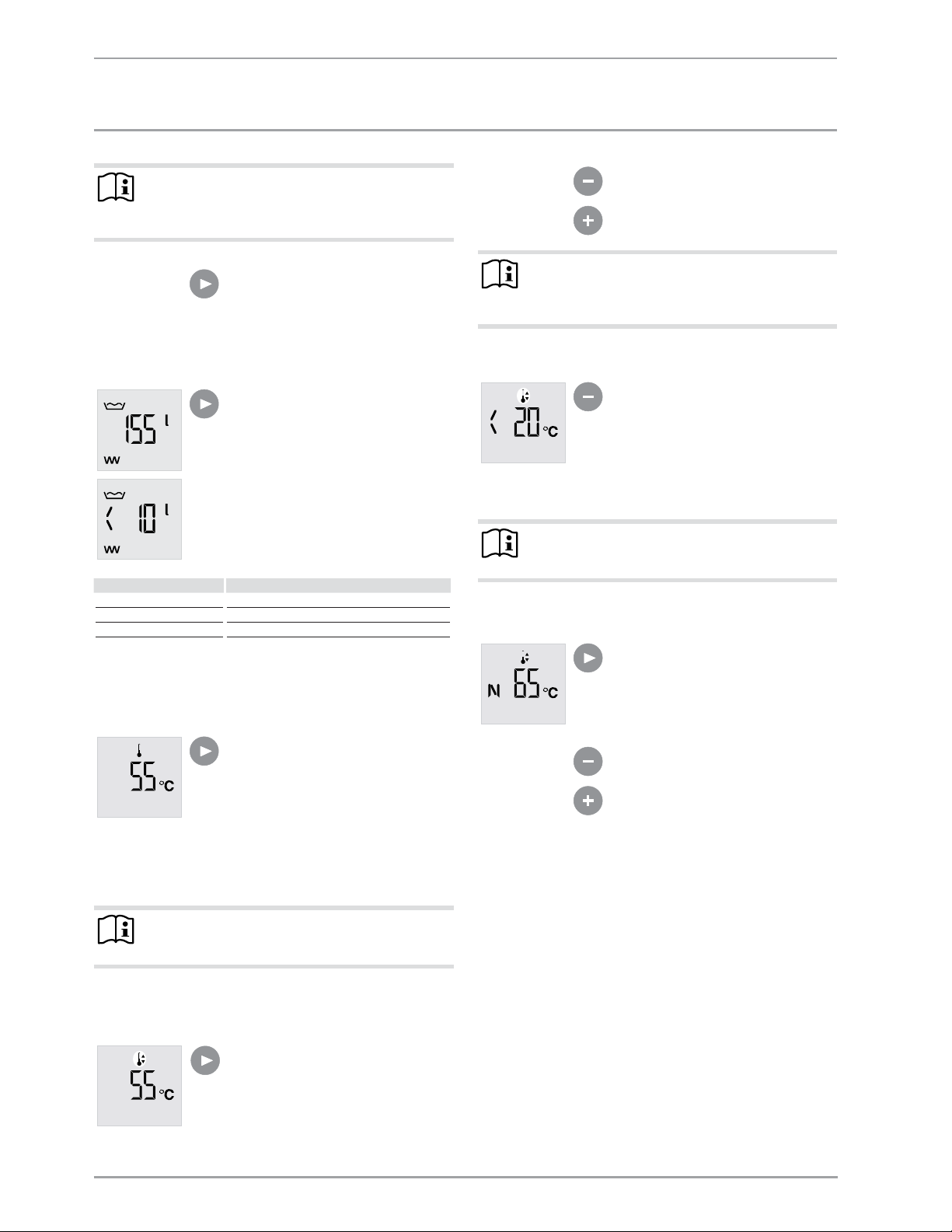

The following diagram illustrates the connections by means of a

sample signal sequence of an external signal transmitter.

Example:

- DHW temperature = 131°F /55°C)

- Set temperature 1 = 124°F/ 50°C)

- Set temperature 2 = 149°F /65°C)

A

1

0

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 t [min]

B

1

0 2

0 5 1015202530354045505560657075t [min]

A LF signal

B Compressor

1 20 min. minimum runtime, set temperature 2

2 20 min. minimum compressor idle time

Note

An LF signal must be active for at least 60seconds before

the control unit responds to it. This prevents cycling of the

compressor due to fast changing sun radiation condition.

1

4.3 Calling up fault codes

Based on the set temperature2 menu,

press the menu key once to get to the

fault code menu. A fault code will appear

if a fault has occurred. If no error has

occurred, this menu is not available.

See 6.1, “Fault codes”, pg. 15 .

4.4 Rapid heating key

Press the rapid heating key.

The heat pump and electric booster ele-

ment symbols appear.

4.4.1 Comfort heating

Normally, the rapid heating key is used to activate the comfort

heating function, which enables the water heater to satisfy an

unexpectedly high DHW demand without changing any of the appliance's standard settings.

When comfort heating is activated by pressing the rapid heating

key, the heat pump and the electric booster element will start

in parallel, irrespective of the selected set temperature. To save

energy, the electric booster element switches off as soon as a

temperature of 149°F/65°C has been achieved in the upper tank

section (rapid heating).

The heat pump remains on and the comfort heating function remains active until a temperature of 149°F/65°C) has been achieved

in the entire DHW tank (comfort heating). The appliance then automatically switches back to the previously set parameters.

Note

The electric booster element and heat pump symbols are

displayed until the comfort heating function has terminated.

During comfort heating, the electric booster element

symbol is displayed until the heat pump has heated the

entire tank to 149°F/65°C and the function is terminated,

e ven though t he electric booster element switches off

when the 149°F/65°C) has been achieved in the upper

tank section.

Note

If comfort heating has been activated, it can be canceled

D0000034613

by reducing the set temperature.

Hold down the minus key, until you hear a clicking

noise caused by the heat pump and booster heater

switching off. The set temperature will jump back to

the value that was selected before comfort heating

was activated.

4.4.2 Emergency back up mode

If the heat pump is out of order, it is possible to use the electric

booster element in back up mode to ensure hot water production.

The electric supply to the compressor shuts down if the water

temperature increase is less than 0.5°F/0.25°C) in a time frame

of 13 hours. In this case the fault code is activated and will fl ash.

The fault key fl ashes on the display and a fault code indicates that

the appliance is not heating the water.

To activate the backup mode, press the rapid heating key. After

the rapid heating key has been pressed, the indicated fault code

increases by a value of 256, as the fault codes are summed together (See 6.1, “Fault codes”, pg. 15). The fault key continues

to fl ash. The electric booster element is activated.

The current set temperature (set temperature1 or set temperature2) is ignored. In emergency mode, the appliance operates

with a fi xed set temperature of 104°F/40°C). After a one-off activation of the function via the rapid heating key, this function

remains active for 7days.

Following 7days of backup operation, the electric booster element

is deactivated. The fault code shown on the display decreases by

256.

If the rapid heating key is pressed again within the 7days of

backup operation, the 7-day run time for emergency mode will

start afresh from that point.

Pressing the rapid heating key only activates backup mode if a

fault with fault code8 occurred previously. In standard mode

pressing the rapid heating key only triggers a one-off heating of

the DHW tank for a single instance.

An interruption of the power supply will disable the back up mode

immediately. The heat pump will try to heat again for a duration of

13 hours after the power outage. After 13 hours without a water

temperature increase, the fl ashing service key occurs again and

the back up function may be activated.

ENGLISH

www.stiebel-eltron-usa.com Accelera® 220-300 E | 13

Page 14

OPERATION

Maintenance and care

4.5 Emergency shutdown

In the event of an emergency, carry out the following steps:

Interrupt the power supply by unplugging the appliance or by

shutting off the circuit breaker.

Shut off the cold water supply.

Immediately notify a qualifi ed contractor, as the appliance

is not protected against corrosion while the power supply is

interrupted.

Drain the water out of the tank if there is a power outage

longer than 2 days.

5. Maintenance and care

WARNING Electrocution

Do not insert objects through the grille into the interior

of the appliance.

Never spray the appliance with water.

Never spray water into the appliance.

WARNING Injury

!

Maintenance work, such as checking the electrical safety, must only be carried out by a qualifi ed contractor.

Appliance

components

Casing Use a damp cloth to clean the casing sections. Never

Air intake grille / air

discharge grille

DHW tank The DHW tank is equipped with a maintenance-free

Electric booster element

Appliance Have the safety assembly and the evaporator checked

Condensate drain Undo the condensate drain. Check that the condensate

Care and maintenance t ips

use abrasive or corrosive cleaning agents.

Clean the air intake grille and air discharge grille

every six months. Cobwebs or other kinds of contamination can restrict the air supply to the appliance.

impressed current anode to safeguard against corrosion. The power supply must not be interrupted

while the appliance is filled with water to enable the

impressed current anode to provide protection. Otherwise there is a risk of corrosion.

Have the electric booster element descaled from time

to time. This will extend the expected life of the electric booster element.

regularly by a qualified contractor.

drain is clear and remove any dirt from the condensate drain connection of the appliance.

Problem Cause Remedy

No hot water is

available.

The appliance is

not heating the

DHW tank although

the heat pump

symbol is illuminated.

The safety valve

of the cold water

supply line is dripping.

The condensate

drain drips.

The room temperature drops too

low.

Service symbol

is continuously

illuminated.

The air intake or air discharge of the appliance is

blocked.

The ambient temperature

exceeds the upper application limit (See 15.3,

“Data table”, pg. 29).

The appliance safety

equipment has responded

and the appliance has

switched off automatically.

The ambient temperature

falls below the lower application limit (See 15.3,

“Data table”, pg. 29).

The evaporator is currently being defrosted.

The blocking time for

compressor has not

yet elapsed. Once the

compressor has been

switched off, it will only

be switched back on

again after the 20minute

compressor blocking time

has elapsed.

These units are under

water mains pressure.

During the heat-up process, expansion water will

drip from the safety valve.

The surface temperature

of the evaporator is lower

than the dew point temperature of the ambient

air. Condensate forms.

See 6.1, “Fault codes”,

pg. 15

Check the air intake grille

and air discharge grille for

contamination. Remove any

contamination (See 14, “Maintenance and cleaning”, pg.

23).

Wait for the appliance to cool

down. Call a qualified contractor if the appliance does

not switch back on automatically.

Wait until the appliance

switches back on automatically.

Notify a qualified contractor if

water continues to drip when

heating is completed. Check

the sealing of the P&T valve if

a sand filter is used.

The amount of condensate

depends on the air humidity

level.

Due to the heat pump process the room temperature

drops. The temperature drop

depends on the hot water

demand and the size of the

installation room. If the

temperature drop of the installation room is more than

7°F (4 °C) check the size of the

installation room.

Notify a qualified contractor.

6. Troubleshooting

Problem Cause Remedy

No hot water is

available.

14 | Accelera® 220-300 E www.stiebel-eltron-usa.com

No power to the appliance.

The circuit breaker in the

electric panel has tripped.

Check that the appliance

is connected to the power

supply.

Check whether the circuit

breaker in the electrical panel

has tripped. If required, disconnect the appliance from

the power supply and replace

the circuit breaker. Contact

your contractor if the circuit

breaker blows again after the

appliance is connected to the

power supply.

Service symbol

flashes and the

water does not

heat up.

See 6.1, “Fault codes”,

pg. 15

It is imperative that you notify

a qualified contractor.

Page 15

OPERATION

Troubleshoot ing

6.1 Fault codes

If the service/fault symbol is fl ashing or continuously illuminated

on the display, you can call up a fault code.

Repeatedly press the menu key until the

fault code is shown following set temperature2.

Fault code appears

Fault

Service

code

symbol

0 No fault

2 continu-

ously illuminated

4 continu-

ously illuminated

6 flashing Dome sensor and integral sen-

8 flashing The appliance has recognized

continu-

16

ously illuminated

32 flashing

The anode current is inter-

128 continu-

ously illuminated

256 flashing Manually activated Emergency

If more than a single fault occurs, the fault code gets summed.

Example: If both the dome sensor and integral sensor failed, the

display shows fault code6(=2+4).

Fault description Remedy

The dome sensor has failed.

The temperature displayed is

measured by the integral sensor. The appliance will continue

to work properly.

The integral sensor has failed.

The mixed water display will

not show the correct amount

but the appliance will continue

to work properly.

sor failed. The appliance stops

heat delivery.

that the DHW tank is not heated

for 13 hours, despite there

being a demand.

Short circuit impressed current

anode / protective anode failed

The appliance is operating with

an empty tank or the appliance

is not delivering heat.

rupted. The appliance does not

heat up.

No communication between

controller and display. The

most recently selected set values are active.

backup mode (only electric

booster element active).

Call Stiebel Eltron for

more information if

this error occurs.

Call Stiebel Eltron for

more information if

this error occurs.

Contact a qualified

contractor.

You can continue to use

the appliance by activating backup mode.

See 4.4.2, “Emergency

back up mode”, pg.

13

Immediately inform a

qualified contractor,

as the appliance is not

protected against corrosion if the impressed

current anode is faulty.

Fill the appliance with

water. The fault code

disappears and the

appliance starts.

The contractor needs to

check the connection of

the impressed current

anode and the internal

wiring.

See 4.4.2, “Emergency

back up mode”, pg.

13.

Application scenarios for emergency mode

If the appliance shows fault code8, you can manually activate

emergency mode. If a different fault occurred previously, but did

not cause the appliance to switch off, the display may show a fault

code that is the result of several faults added together.

Listed below are the fault codes which will allow you to activate

emergency mode.

Fault code displ ayed Indiv idual fault code(s)

8 8

10 Fault code 8 + fault code 2

12 8+4

24 8+16

26 8+2+16

28 8+4+16

138 8+2+128

140 8+4+128

152 8+16+128

154 8+2+16+128

156 8+4+16+128

When the appliance is operating in emergency backup mode, the

fault code shown is increased by 256.

Fault code displ ayed in

emergency backup mode

264 8+256

266 8+2+256

268 8+4+256

280 8+16+256

282 8+2+16+256

284 8+4+16+256

394 8+2+128+256

396 8+4+128-256

408 8+16+128+256

410 8+2+16+128+256

412 8+4+16+128+256

Indiv idual fault code(s)

Notifying a qualifi ed contractor

If you cannot remedy the fault, notify your qualifi ed contractor. To

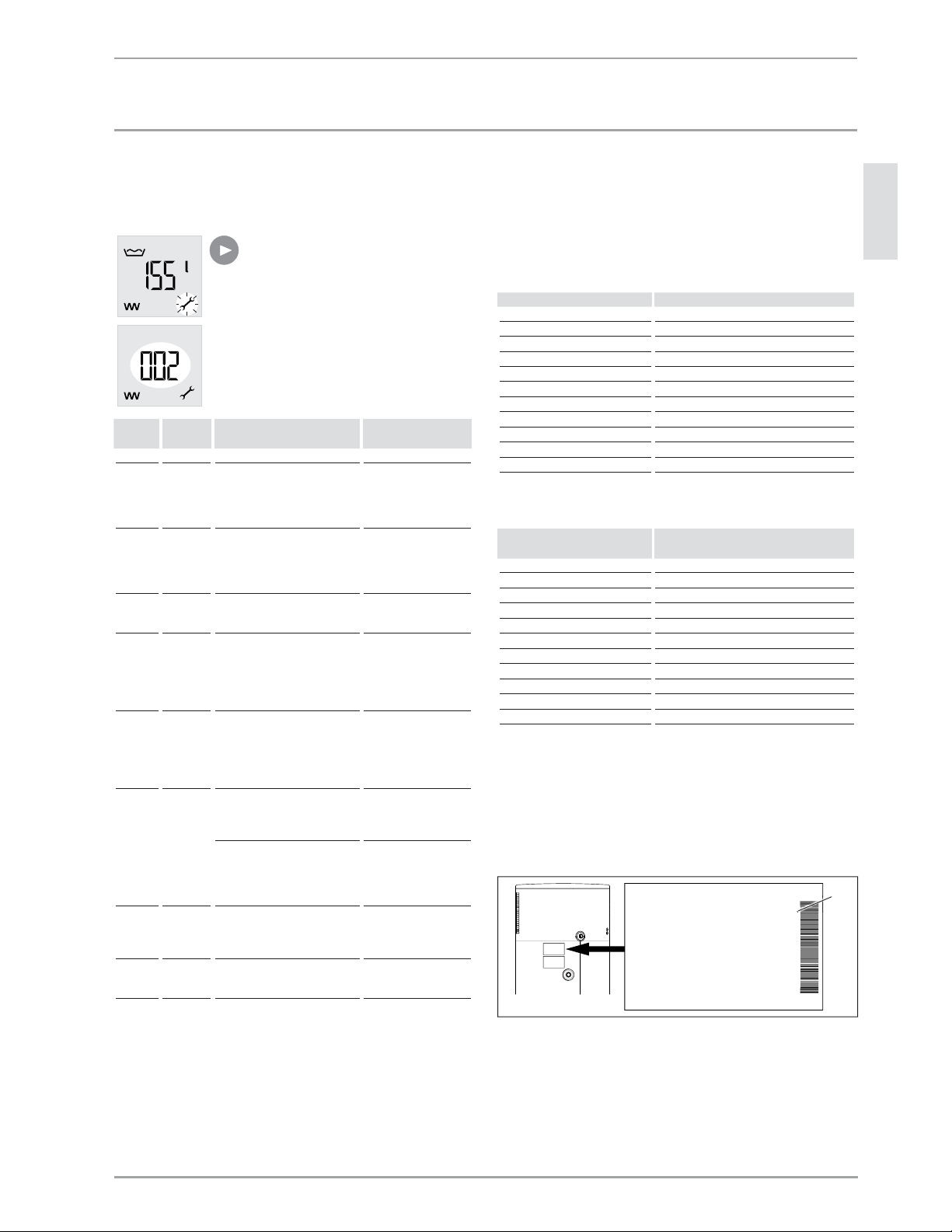

facilitate and speed up your request, provide the serial number

from the type plate (000000-0000-00000). The type plate can be

found on the appliance above the "DHW outlet" connection.

Sample type plate

1

000000-0000-00000

1 Serial number on the type plate

ENGLISH

D0000035352

www.stiebel-eltron-usa.com Accelera® 220-300 E | 15

Page 16

INSTALLATION

Safety

INSTALLATION

7. Safety

Only a qualifi ed contractor should carry out the installation, commissioning, maintenance and repair of the appliance.

7.1 General safety instructions

To prevent your warranty claim, use only original accessories and

spare parts. If you need spare parts, call 800.582.8423.

7.2 Instructions, standards and regulations

Note

Observe all applicable national and regional regulations

and instructions.

Take note of the appliance type plate and chapter "Specifi cation".

7.3 Incorrect use

The following are not permitted:

- Do not install the water heater on non-load bearing fl oors

- Do not install the water heater where it is at risk from frost

- Do not install in rooms where the water heater is at risk from

explosions as a result of dust, gases or vapors

- Do not ignore safety clearances and safety zones

- Do not incorrectly install the power connection

- Do not operate the water heater with an open casing

- Do not heat anything other than potable water

- Do not fi ll with any other Freon, use only R134a

7.4 Qualifi cation

In this manual, qualifi ed individuals will be described as the “licensed installer”.

Licensed installers are responsible for adherence to all currently

applicable regulations during installation and initial start-up.

7.4.1 Licensed installer

Licensed installers are specially trained in their fi eld. Licensed

installers work on systems on the basis of their training, knowledge and experience, as well as their knowledge of applicable

standards and regulations. They are able on their own to recognize

and prevent possible problems.

7.4.2 Electrician (licensed)

An electrician is a licensed installer who meets the above requirements with regard to electrical-related installations.

7.4.3 Plumber (licensed)

A plumber is a licensed installer who meets the above requirements with regard to water-related installations.

7.4.4 Customer service

For customer service inquiries, please contact Stiebel Eltron directly at 1-800-582-8423

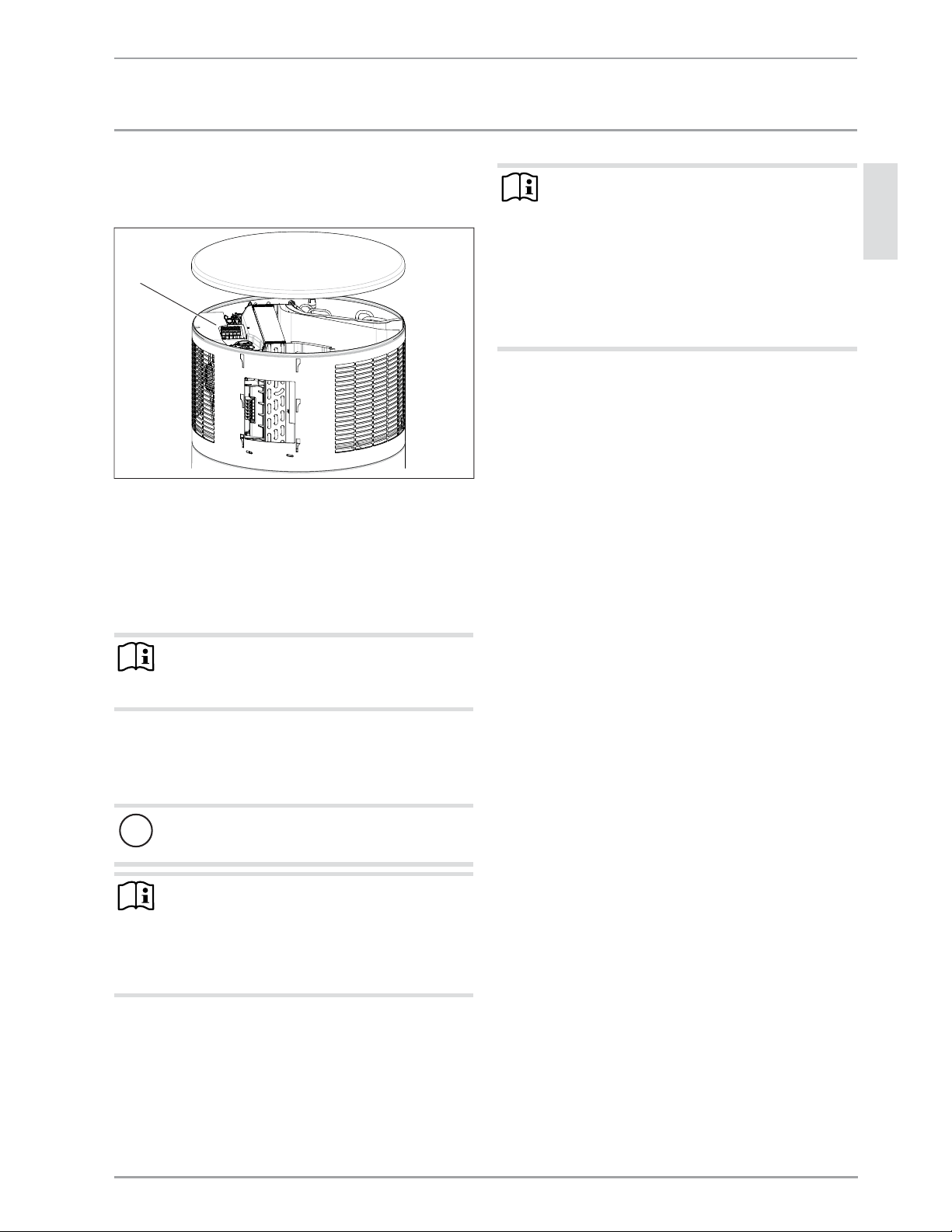

8. Appliance description

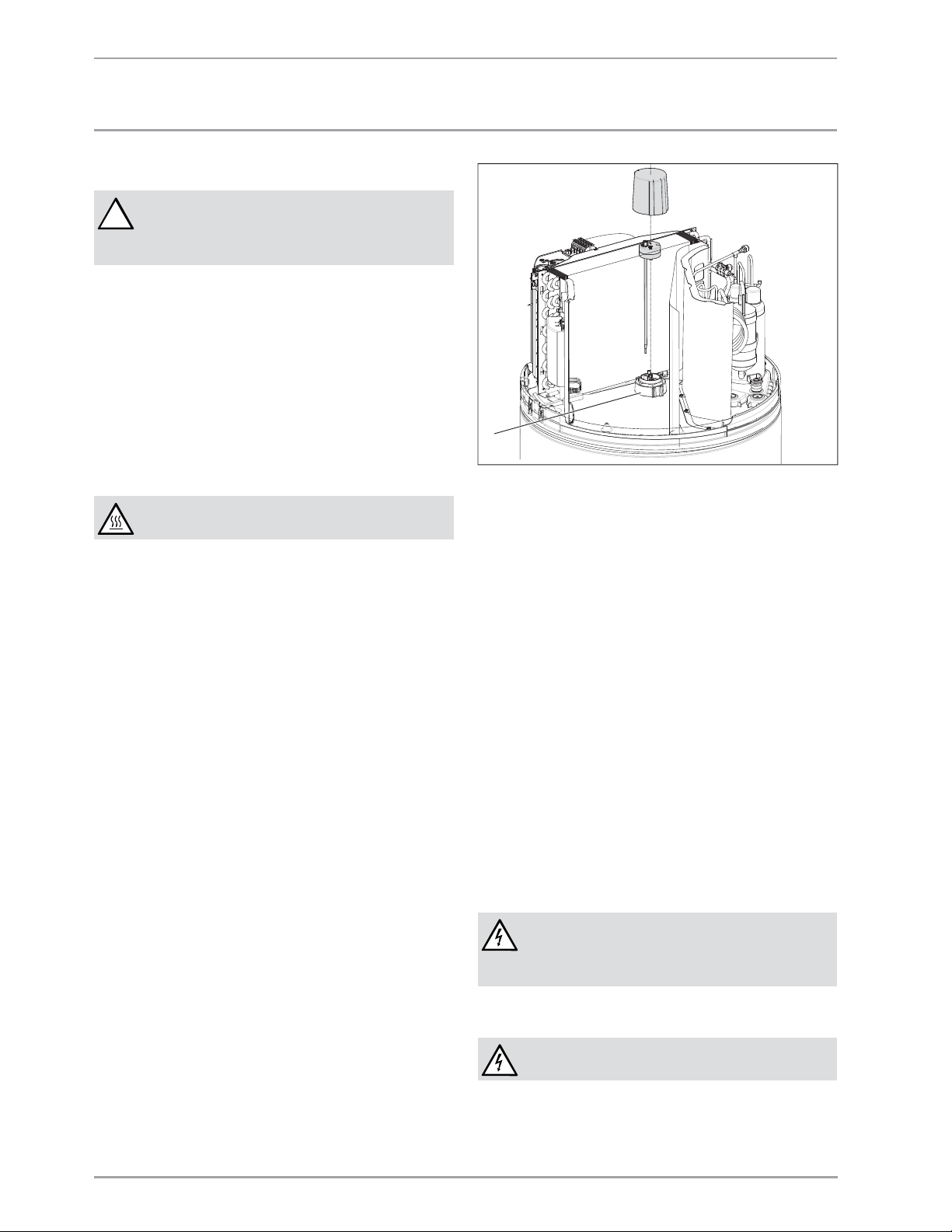

The heat pump unit is located in the upper section of the appliance.

The DHW tank is located in the lower section of the appliance.

8.1 Standard delivery

The following are delivered with the appliance:

- Condensate drain

- T&P valve, 100 psi at 210°F/99°C

8.2 Required accessories

Various safety assemblies are available that need to be selected

subject to the respective static pressure. These type-tested safety assemblies protect the appliance against unacceptable excess

pressure.

- Pressure reducing valve (70 psi) if the water mains pressure

exceeds this

-Expansion tank

8.3 Further accessories

– Condensate pump (if there is a minor base slope for draining

the condensate, use a condensate pump)

9. Preparations

9.1 Transport

CAUTION Injury

!

Take note of the weight of the appliance.

Use suitable transport aids (e.g. a hand truck) and

enough personnel for transportation.

Material losses

!

The appliance is top heavy and can easily tip over.

Make sure the unit is not tilted.

Only set the appliance down on an even base.

Material losses

!

The appliance casing is not designed to withstand strong

forces. Incorrect handling can lead to considerable loss.

Observe the information on the packaging.

Leave the appliance in its packaging and on the pallet while transporting. This enables horizontal transport and protects the appliance during transport.

Remove the packaging shortly before the installation and do not

unpack the appliance until it has arrived in the fi nal installation

room.

16 | Accelera® 220-300 E www.stiebel-eltron-usa.com

Page 17

INSTALLATION

Preparations

Vehicular transport

Material losses

!

Storing and transporting the appliance vertically is recommended.

The appliance may be transported horizontally on good roads.

Strong shocks to the appliance are not permissible.

Material losses

!

The duration in a horizontal position may not exceed

more than 24 hours.

If the appliance was transported horizontally, leave it to

rest in a vertical position for at least one hour before

commissioning.

Observe the information on the packaging.

1

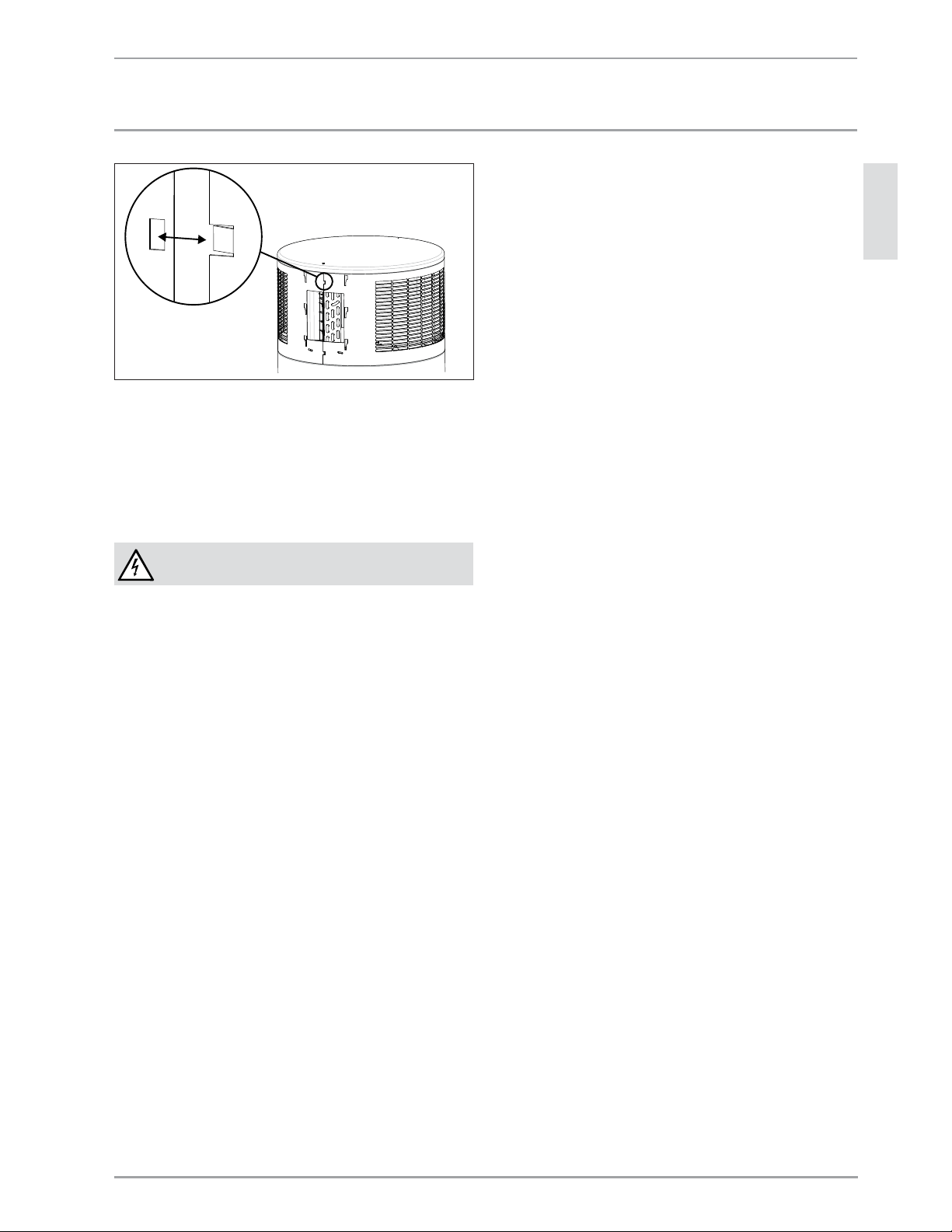

1 Recessed grips

Transport from vehicle to installation room

The cardboard box has reinforced recessed grips along the top of

the appliance. You can use these recessed grips, as well as the

pallet at the lower end, to carry the appliance into the installation

room. Take note of the weight of the appliance and ensure a suffi cient number of personnel is available for handling the appliance.

- The installation room must be free from the risk of frost.

- The intake temperature of the appliance must be within the

permissible application limits (See 15.3, “Data table”, pg.

29).

- The fl oor of the installation room must be level and have suffi cient load bearing capacity. Take note of the weight of the

appliance with a full DHW tank (See 15.3, “Data table”, pg.

29). A fl oor with insuffi cient foundation pressure capacity

is in danger of collapse. If the appliance is not evenly balanced, there may be a risk of appliance damage.

- The size of the installation room must correspond to the

application limits of the appliance (See 9.5, “Minimum clearances”, pg. 18 and See 15.3, “Data table”, pg. 29).

- Observe the safety clearances and protection zones.

- Always leave suffi cient distance to provide access for installation, maintenance and cleaning. Observe the required minimum clearances (See 9.4, “Siting the appliance”, pg. 18).

- Ensure that the operation of other equipment in the installation room is not impaired.

- To reduce the pipe runs, install the unit close to the kitchen

or bathroom.

- To prevent disturbance from operating noise, never install

the appliance close to bedrooms.

The following installation locations are not permissible, due to

risk of appliance damage:

- Locations where the air is contaminated with oil or salt

- Saline environments

- Areas in proximity to high frequency machines

- Places where the air contains ammonia (e.g.sewage works)

D0000034797

- Places where the air contains chlorine (e.g.swimming pools)

- Generally places where the air is strongly contaminated, e.g.

due to dust, or contains aggressive substances

Note

The performance data indicated for this appliance has

been determined in line with the relevant standard at an

air temperature of 59°F/15°C). Below this temperature,

the effi ciency of the appliance decreases.

ENGLISH

9.2 Storage

If it is necessary to store the appliance for a prolonged period

before installation, observe the following information:

- Only store the appliance in a vertical position. Never store

the appliance horizontally.

- Store the appliance in a location that is dry and largely

dust-free.

- Protect the appliance from coming into contact with corrosive

substances.

9.3 Installation site

The appliance is not approved for outdoor installation except for

garages.

To prevent appliance damage:

- The installation location must be free from fl ammable, highly

combustible gases and substances, as well as high levels of

dust.

www.stiebel-eltron-usa.com Accelera® 220-300 E | 17

Note

It is possible to improve the effi ciency of the appliance by

utilizing the waste heat and humidity from other appliances to heat the DHW tank, e.g. boilers, tumble dryers

or freezers.

Sound emissions

The air intake and air discharge sides of the appliance emit more

noise than other sides of the housing.

Never direct the air intake or air discharge towards

noise-sensitive rooms of the house, e.g. bedrooms.

Note

For details on noise emission, see chapter "See 15.3,

“Data table”, pg. 29".

Page 18

INSTALLATION

Preparations

9.4 Siting the appliance

Carefully undo the cardboard packaging at the clips.

1

1 Cardboard packaging clips

The appliance is secured to the pallet with metal brackets and

screws. The metal brackets are hooked on to the feet underneath

the fl oor plate of the appliance.

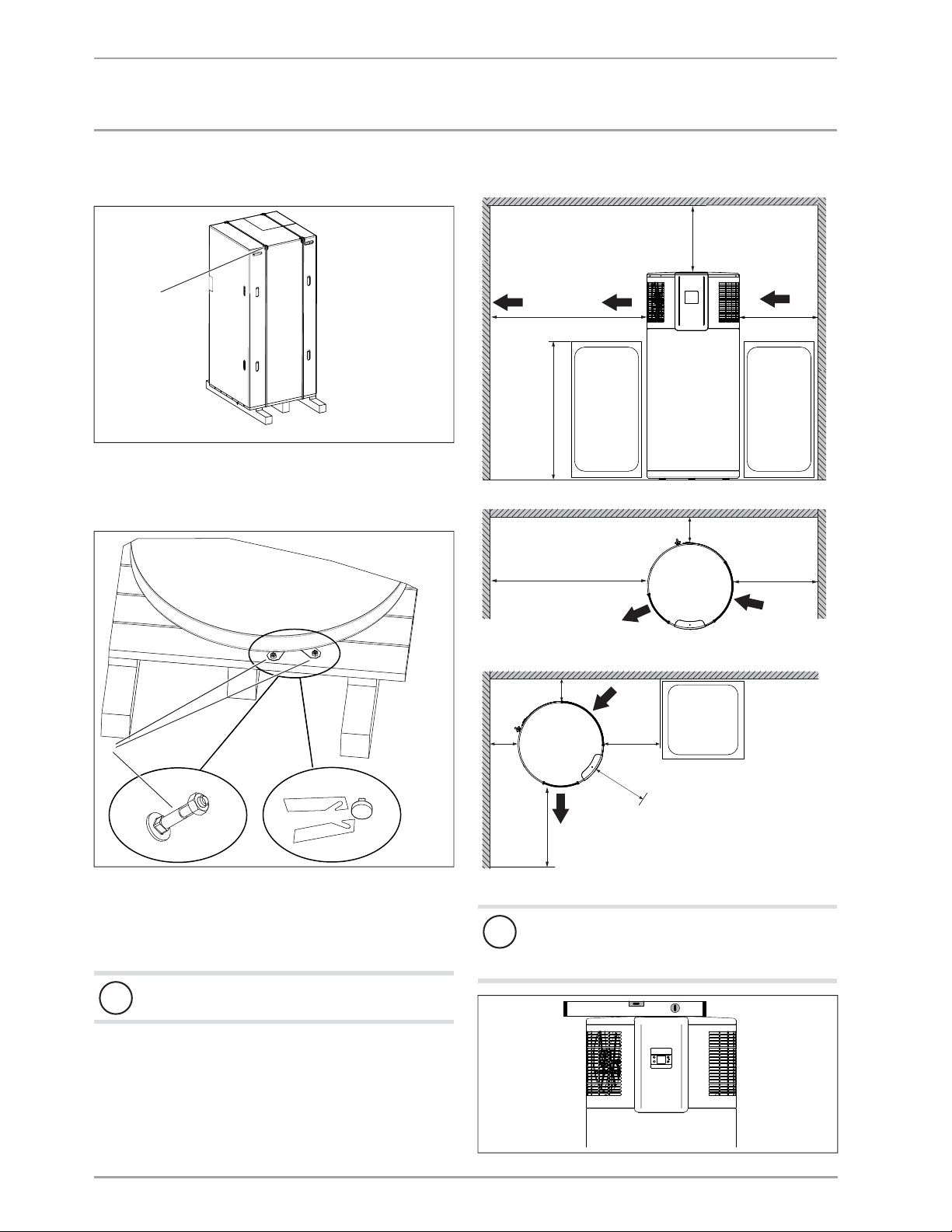

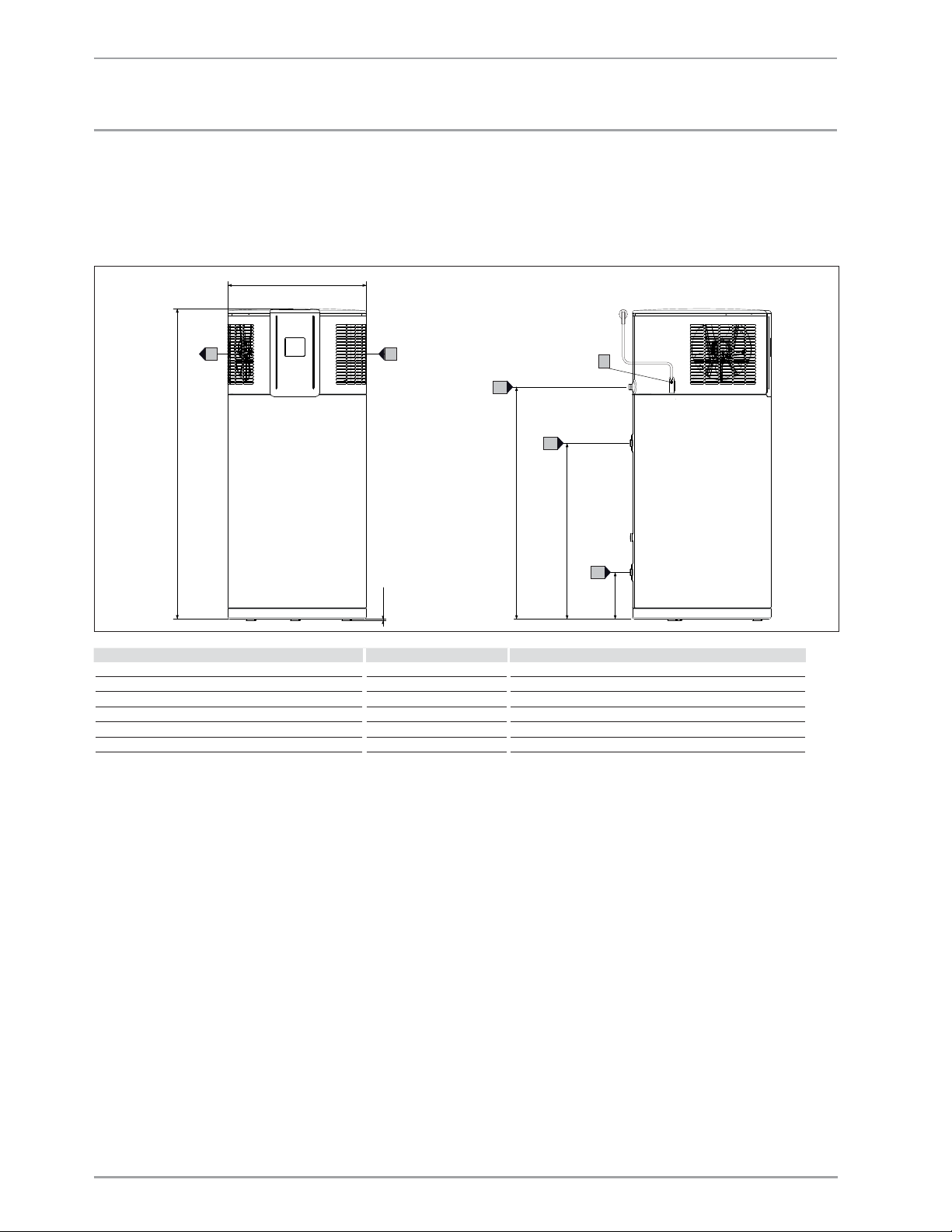

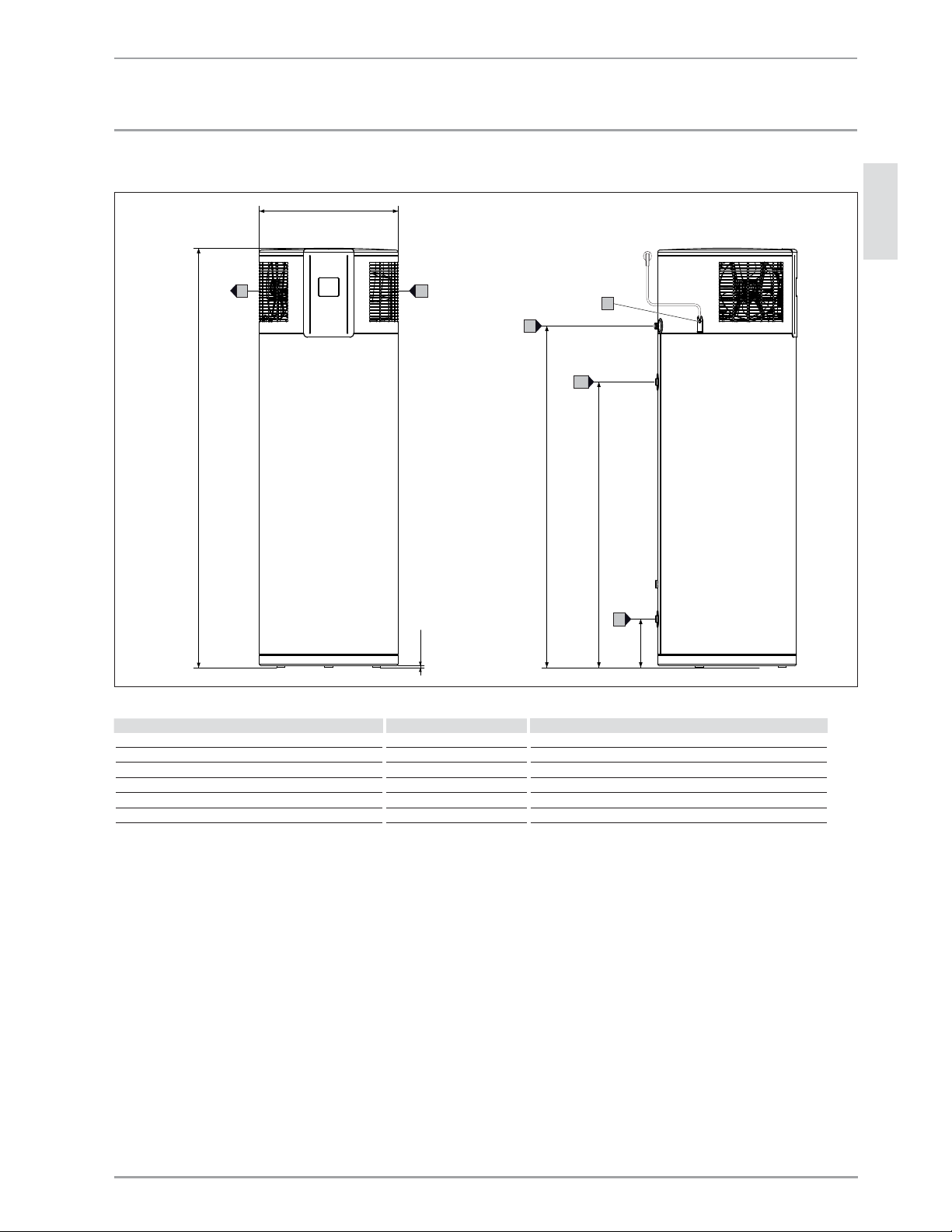

9.5 Minimum clearances

Minimum room volume:

2

800 ft

, 10´ x 10´ x 8´

(22.7 m2, 3 m x 3 m x 2.4 m)

Air flow

exhaust

6´ (1.8 m)

An object

next to the

unit must

≤42˝

D0000034797

(1.1 m)

Acceptable positioning, vent parallel to a wall:

be less than

42˝ high

6´ (1.8 m)

Air flow

exhaust

14˝

(0.4 m)

Air flow

intake

2´ (0.6 m)

8˝ (0.2 m)

2´ (0.6 m)

Air flow

intake

1

1.

1 Metal bracket fi xing bolt

Remove the fi xing bolts of the metal brackets from the pallet.

Push the metal brackets a little towards the tank center, to

unhook them from the appliance feet.

Pull the metal brackets out from underneath the appliance.

Material losses

!

Take note of the appliance's weight and top-heaviness.

Slightly tip the appliance and carefully roll the appliance off

the pallet.

Bring the appliance in its fi nal location.

2.

Acceptable positioning, vent parallel to a wall in a corner:

8˝ (0.2 m)

Air flow

intake

8˝

(0.2 m)

6´

D0000034798

(1.8 m)

Maintain the minimum clearances.

!

Air flow

exhaust

Material losses

The top of the appliance should be made horizontal.

Level the appliance horizontally using the height-ad-

justable feet.

(0.6 m)

2´

(0.6 m)

2´

18 | Accelera® 220-300 E www.stiebel-eltron-usa.com

D0000034806

Page 19

INSTALLATION

Installation

10. Installation

WARNING Injury

!

Incorrect installation can lead to serious personal injury

or material losses.

Before any work, ensure suffi cient clearances for the

installation.

Handle sharp-edged components carefully.

10.1 Water connection

Material losses

!

Carry out all water connection and installation work in

accordance with local plumbing regulations.

The following material combinations are approved for pipework

installations:

Cold water inlet DHW outlet

Copper pipe Copper pipe

Steel pipe Steel pipe or copper pipe

PEX tubing PEX tubing

Thoroughly fl ush the pipework before connecting the ap-

pliance. Foreign bodies, such as welding pearls, rust, sand

or sealant can impair the operational reliability of the

appliance.

Material losses

!

To protect the connection nipples against corrosion the

water tube connection must be made with plumber’s

thread seal tape (PTFE). The use of hemp on nipple

threads is not permissible.

maximum pressure in the cold water supply line is higher, install

a pressure reducing valve.

Check valve

Install a check valve in the cold water line (after the pressure reducing valve if installed). This check valve is necessary to prevent

water from fl owing backwards into the cold water piping.

Drain valve

Install a suitable drain valve at the lowest point in the cold

water inlet line.

DHW circulation

The heat losses incurred in a DHW circulation line and the electrical power consumption of the circulation pump reduce the effi ciency of the system. The cooled water in a circulation line mixes

with the tank content. Where possible, avoid installing a DHW

circulation line. Where that is not possible, the DHW circulation

pump must be controlled thermally or by time switch.

Thermal insulation

Insulate the DHW line against heat loss in accordance with

locally applicable regulations.

10.2 Condensate drain

Install a condensate drain hose to remove the condensate which

forms.

Connect the condensate drain included in the standard deliv-

ery to the “condensate drain” connection.

Connect a condensate drain hose to the condensate drain

bend.

ENGLISH

Safety valve

The appliance is a sealed unvented DHW tank. The appliance is

supplied with a temperature and pressure relief valve that has

been factory installed and leak-tested.

Install a type-tested safety valve in the cold water supply

line. The response pressure of the safety valve must be below

or equal to the permissible operating pressure of the DHW

tank.

The safety valve protects the appliance against unacceptable excess pressure.

Ensure that the expansion water escaping from the safety

valve can drip into a drain, e.g. a tank or sink.

Ensure the drain cannot be shut off.

Size the drain in a way that water can drain off unimpeded

when the safety valve is fully opened.

Ensure that the discharge pipe of the safety valve is open to

atmosphere.

Fit the discharge pipe of the safety valve with a constant

downward slope and in a room free from the risk of frost.

Pressure reducing valve

The maximum pressure in the cold water supply line must be at

least 20% below the response pressure the safety valve. If the

Material losses

!

Ensure condensate drain cannot retain water.

Use a condensate drain hose with a diameter great-

er than the diameter of the condensate drain bend.

Ensure the condensate drain hose is not bent.

Route the condensate drain hose with a continuous

base slope.

The condensate drain must be open to the atmosphere.

Use a suitable condensate pump if there is insuffi cient base

slope. Observe the building characteristics.

www.stiebel-eltron-usa.com Accelera® 220-300 E | 19

Page 20

INSTALLATION

Installation

10.3 Power supply

WARNING Electrocution

Carry out all electrical connection and installation work

in accordance with national and regional regulations.

WARNING Electrocution

If the appliance is permanently connected to the power

supply, ensure that the appliance can be separated from

the power supply by an isolator that disconnects double

termi nal with at least

disconnect switches or circuit breakers can be used for

this.

WARNING Electrocution

Observe the safety regulations to prevent contact

with dangerous 'live' parts.

WARNING Electrocution

Coming into contact with 'live' components presents a

threat to life. Disconnect the appliance from the power

supply before carrying out work on the control panel.

Prevent the power supply from being switched on while

you are working on the system.

WARNING Electrocution

Insuffi cient grounding can lead to electrocution. Ensure

the appliance is grounded according to locally applicable

requirements.

WARNING Electrocution

The power cable must only be replaced (for example if

damaged) with an o riginal spare par t by a qualifi ed contractor authorized by the manufacturer. For an original

spare part contact Stiebel Eltron 800-582-8423 for part

number 315650.

Material losses

!

The voltage to the appliance must match the voltage specifi ed on the type plate .

Material losses

!

Never connect the appliance to the power supply before

the DHW tank is fi lled.

Standard connection without external signal transmitter

˝

1

/4 mm contact gap. Contactors,

/8

10.3.1 Connection with external signal transmitter

An external potential free signal transmitter for controlling DHW

temperature (set temperature2) can be connected to terminal

X0/LF.

In the delivered status, terminal X0/LF is not assigned. If this

terminal is connected to 240V AC, the appliance activates set

temperature2.

Following a one-off activation (the external signal is present for at

least one minute), set temperature2 applies for at least 20minutes.

Material losses

!

If the 240V AC signal of an external signal transmitter

is to be connected to terminal X0/LF, do not interchange

phase and neutral.

Note

Never wire up terminal X0/FB.

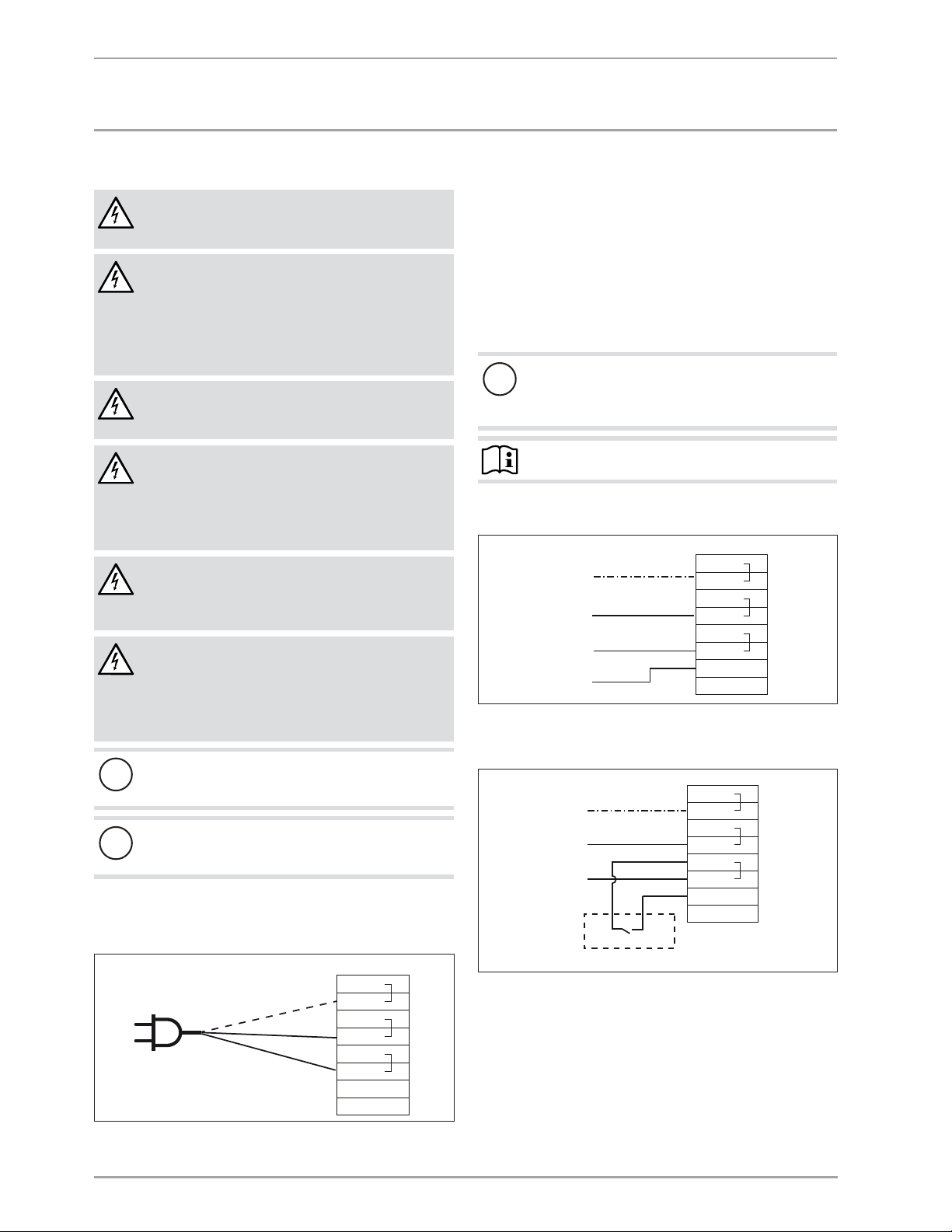

Example 1: Power-OFF signal with own 240V AC phase

X0

PE

N

L1

L1, L2 oder L3

EVU:

Example 2: Photo-voltaic signal via on-site relay and phase

routed outside the appliance

PE

N

L1

PE

PE

N

N

L1

L1

LF

FB

X0

PE

PE

N

N

L1

L1

LF

FB

D0000034589

X0

PE

PE

N

N

L1

L1

LF

FB

20 | Accelera® 220-300 E www.stiebel-eltron-usa.com

1 Inverter (fl oating contact)

The inverter power feed is located at a central distribution point

(e.g. in the main fuse box).

D0000034487

1

D0000034590

Page 21

INSTALLATION

Commissioning

Connection to terminal block X0

Remove the appliance cover (See 14.1, “Removing the appli-

ance cover”, pg. 23).

1

1 Terminal X0

Prepare the leads for connection to X0 in such a manner that

each lead terminating at X0 has a wire ferrule.

Route leads through the strain relief.

Connect the leads to X0 (see chapter "See 10.3.1, “Connection

with external signal transmitter”, pg. 20).

10.4 Assembling the appliance

Note

Refi t the appliance cover after completing your work.

See chapter "See 14.10, “Fitting the appliance cover”,

pg. 25).

11. Commissioning

11.1 Commissioning

Material losses

!

Never connect the appliance to the power supply before

the DHW tank is fi lled.

Note

At temperatures below 5°F/-15°C, the high limit safety

cut-out may respond. The appliance may be subjected to

these temperatures during storage or transport.

If required, press the high limit safety cut-out reset

button. See 13.3, “Resetting the high limit safety

cut-out”, pg. 22

Note

After an interruption of the power supply, compressor operation remains blocked for at least one minute to allow

the electronic main board to initialize.

If the compressor subsequently fails to start, it may be

disrupted by additional safety devices (Klixon and high

pressure switch). This interruption due to the compressor

motor klixon is terminated automatically.

If the high pressure switch responds, it can be manually

reset after the pressure is less than 246 PSI. This normally

occurs 5 minutes after responding.

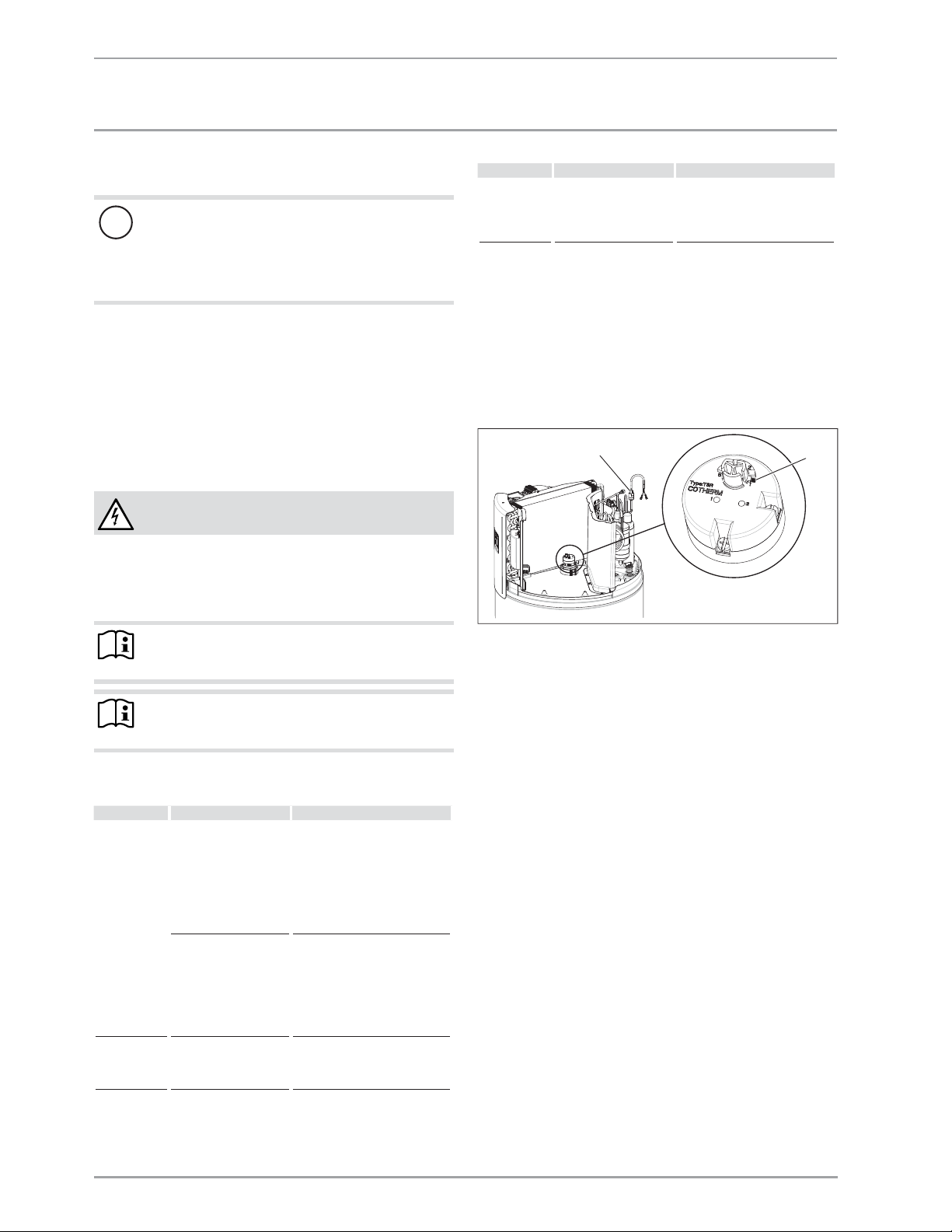

11.1.1 Filling the DHW tank

Fill the DHW tank and vent the pipework by following the procedure below:

Close the drain valve.

Open all DHW tap points and the shut-off valve in the cold

D0000034803

water supply.

Close the DHW tap points as soon as water starts to emerge

from them.

11.1.2 Settings / function check

To check the function, select the maximum set temperature.

A higher set temperature allows for more mixed water but lower

effi ciency. A lower set temperature is more effi cient but less

mixed water is available. Never reduce the set temperature below

1 22°F/50°C to reduce problems with legionella.

11.1.3 Appliance handover

Explain the appliance function to users and familiarize them

with its operation.

Make users aware of potential dangers, especially the risk of

scalding.

Make users aware of critical environmental factors and re-

quirements concerning the installation location.

Inform users that water may drip from the safety valve

during the heating operation.

Hand over these operating and installation instructions to

users for safe-keeping.

11.2 Recommissioning

If the appliance is switched off due to an interruption to the power

supply, no specifi c measures for restarting are required once the

power supply has been restored. The appliance has saved the

parameters most recently set and continues operating with these.

If the comfort heating function was active before interruption of

the power supply, this is reactivated with a set temperature of

149°F/65°C once the power supply has been established again.

Remote function is not reactivated after an interruption of the

power supply.

ENGLISH

www.stiebel-eltron-usa.com Accelera® 220-300 E | 21

Page 22

INSTALLATION

Shutting down

12. Shutting down

Material losses

!

If the appliance is disconnected from the power supply,

it is no longer protected against frost.

Only disconnect the appliance from the power sup-

ply for longer periods if you are also draining the

DHW tank.

If there is no usage of hot water for a long period of time, always

drain the DHW tank. See chapter "See 14.4, “Draining the tank”,

pg. 24".

The appliance can only be switched off by interrupting the power

supply.

Pull the plug from the socket or disconnect the circuit breaker

to the appliance.

13. Troubleshooting

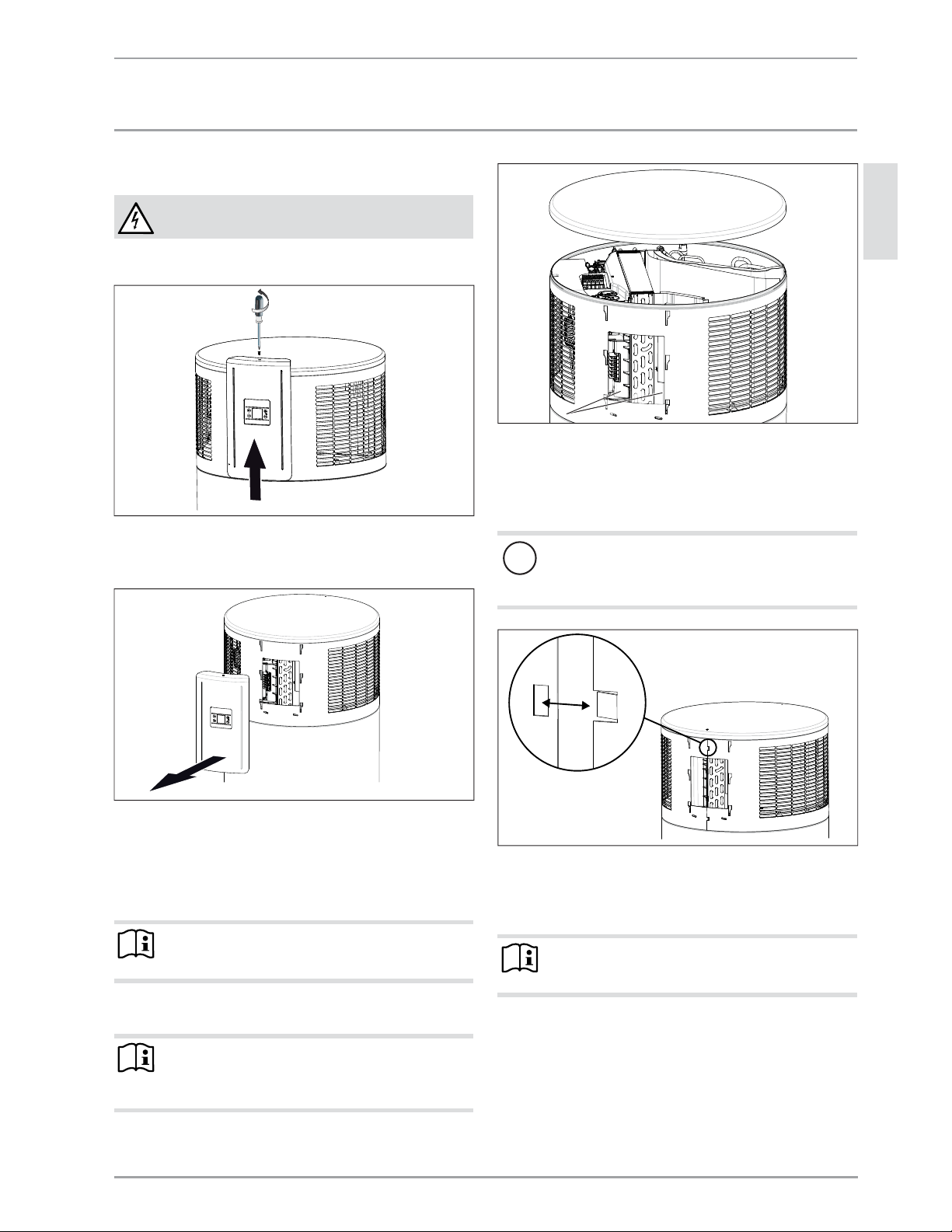

WARNING Risk of electrocution

Prior to all work on the appliance, turn off all power to it.

For work inside the appliance, remove the appliance cover

(See 14.1, “Removing the appliance cover”, pg. 23).

If necessary, remove the upper section of the casing jacket

(See 14.2, “Removing the casing ring”, pg. 23).

Note

Refi t the casing ring after completing the work. See 14.9,

“Fitting the casing ring”, pg. 24.

Note

Refi t the appliance cover after completing your work. See

14.10, “Fitting the appliance cover”, pg. 25.

13.1 Fault table

Fault Cause Remedy

The appliance

switches off

unexpectedly

and does not

switch on

again.

The compressor switches off

unexpectedly.

Excessive pressure in

the refrigerant circuit.

The safety pressure limiter has responded. The

compressor has been

switched off.

The appliance is operated

outside the operation

limit. The ambient temperature is higher than

the permissible value.

The safety pressure limiter has responded.

The thermal load of the

compressor has been exceeded. The motor overload relay has responded.

Eliminate the cause of the increase in pressure in the refrigerant circuit.

Wait approx.5 to 15minutes for

the appliance to equalize the

pressure. Reset the safety pressure limiter (See 13.2, “Resetting

the safety pressure limiter”, pg.

22).

Ensure that the operation limit is

observed.

Wait approx.5 to 15minutes for

the appliance to equalize the