Page 1

OPERATING AND INSTALLATION

OPERACIÓN E INSTALACIÓN

UTILISATION ET INSTALLATION

DHW HEAT PUMP WATER HEATER

CALENTADOR DE AGUA CON BOMBA ELÉCTRICA DE CALOR

CHAUFFE-EAU THERMODYNAMIQUE

» ACCELERA® 300

A 280011-36221-8653

STIEBEL ELTRON Inc.

17 West Street | West Hatfield MA 01088

Tel. 413-247-3380 | Fax 413-247-3369

Email info@stiebel-eltron-usa.com

www.stiebel-eltron-usa.com

The Accelera® 300 Heat

Pump Water Heater is tested

and certified by WQA against

NSF/ANSI 372 for lead free

compliance.

Page 2

2 | ACCELERA® 300 HEAT PUMP WATER HEATER WWW.STIEBEL-ELTRON-USA.COM

GENERAL INFORMATION

QUICK START-UP GUIDE

Please read

Read these instructions carefully and retain them for

future reference. If the water heater is passed on to

a third party please hand these instructions to the

new user.

This manual includes important information regarding the safe

and efficient handling of the water heater. Keep this manual with

the water heater at all times.

Work must only be carried out by a licensed installer who has read

and understands these instructions. All federal, state, and local

codes must be followed. Failure to do so may result in equipment

failure, serious injury, or death.

While working on the water heater, disconnect the power supply.

Illustrations in these instructions are designed to aid a general

understanding and may deviate from the actual water heater

version. No claims can be derived from such illustrations.

Limited liability:

We have collated all details and information in this manual in due

consideration of applicable standards and regulations, the state of

the art and our long-term know-how and experience.

Losses due to the following are excluded from our liability:

- Non-observance of these instructions

- Incorrect use

- Installation of the water heater by unqualified personnel

- Unauthorized modifications

- Technical modifications

- Use of unauthorized spare parts

Copyright:

These operating and installation instructions are subject to

copyright.

Transferring these instructions to third parties, copying of any

kind, either in total or extracts therefrom, as well as their use

and/or conveying its contents are prohibited without our written

consent.

Contraventions are liable to claims for compensation. Further

claims are reserved.

We hold the copyright:

STIEBEL ELTRON Inc.

17 West Street | West Hatfield MA 01088

Tel. 413-247-3380 | Fax 413-247-3369

Email info@stiebel-eltron-usa.com

www.stiebel-eltron-usa.com

Should you have any question regarding the installation or

operation of the water heater, please contact our customer service.

Tel. (USA) 800-582-8423 or 413-247-3380

Please record your serial number and information

Serial No.:

____________________________________________________________________

Date of Purchase:

____________________________________________________________

Accelera® 300 Quick Start-up Guide

A. OVERVIEW: This water heater hooks up like any other electric water heater, with a few minor exceptions. Be sure to follow

all state and local codes during installation. This page is not intended to be a substitute for the installation manual. Be

sure to follow all safety precautions.

B. UNPACKING: DO NOT unpack water heater unit until it is located at the point of installation. Follow all instructions in the

manual and be sure to use caution, as this unit is top heavy. DO NOT lay the unit down and DO NOT jar or tip the unit past

45 degrees on the hand truck. See: 10.6

C. INSTALLATION / WATER:

a. Location: Find a suitable location according to the manual. Minimum area is 10’ x 10’ x 8’. Be sure vents are parallel to

the wall with the fan facing the most open area along that wall. Please note: a drain pan is recommended. See: 10.6

b. 3/4” Inlet from union provided. For hook-up, follow all state and local codes for check valves, expansion tanks, shut off

valves, gauges, etc. Install a 70 psi pressure reduction valve.

Please note: water pressure should not exceed 0.48 MPa (70 psi). See: 10.7

c. 3/4” Outlet from union to hot water line.

d. Install T&P Relief valve (supplied). Please note: 0.69 MPa / 99 °C (100 psi / 210 °F).

D. CONDENSATE DRAIN: Goes directly into a drain or use a condensate pump to drain into a suitable location. See: 10.6.1

E. FILL & FLUSH TANK: Run water and be sure tank is full prior to turning on the electricity.

F. INSTALLATION / ELECTRICAL: Use a 240 Volt / 15 Amp double pole breaker and connect to water heater L1, L2, and

Ground. See: 16.2

!

WITHIN ABOUT 5 HOURS OF START-UP TIME, EXHAUST

AIR FLOW SHOULD BE APPROXIMATELY -14,4°C (6°F)

LESS THAN THE INLET SIDE.

CAUTION: RISK OF SCALDING.

THERE IS A RISK OF SCALDING AT OUTLET

TEMPERATURES EXCEEDING 43 °C (110°F) RISK OF

SCALDING

Page 3

WWW.STIEBEL-ELTRON-USA.COM ACCELERA 300 | 3

QUICK START-UP GUIDE | OPERATION

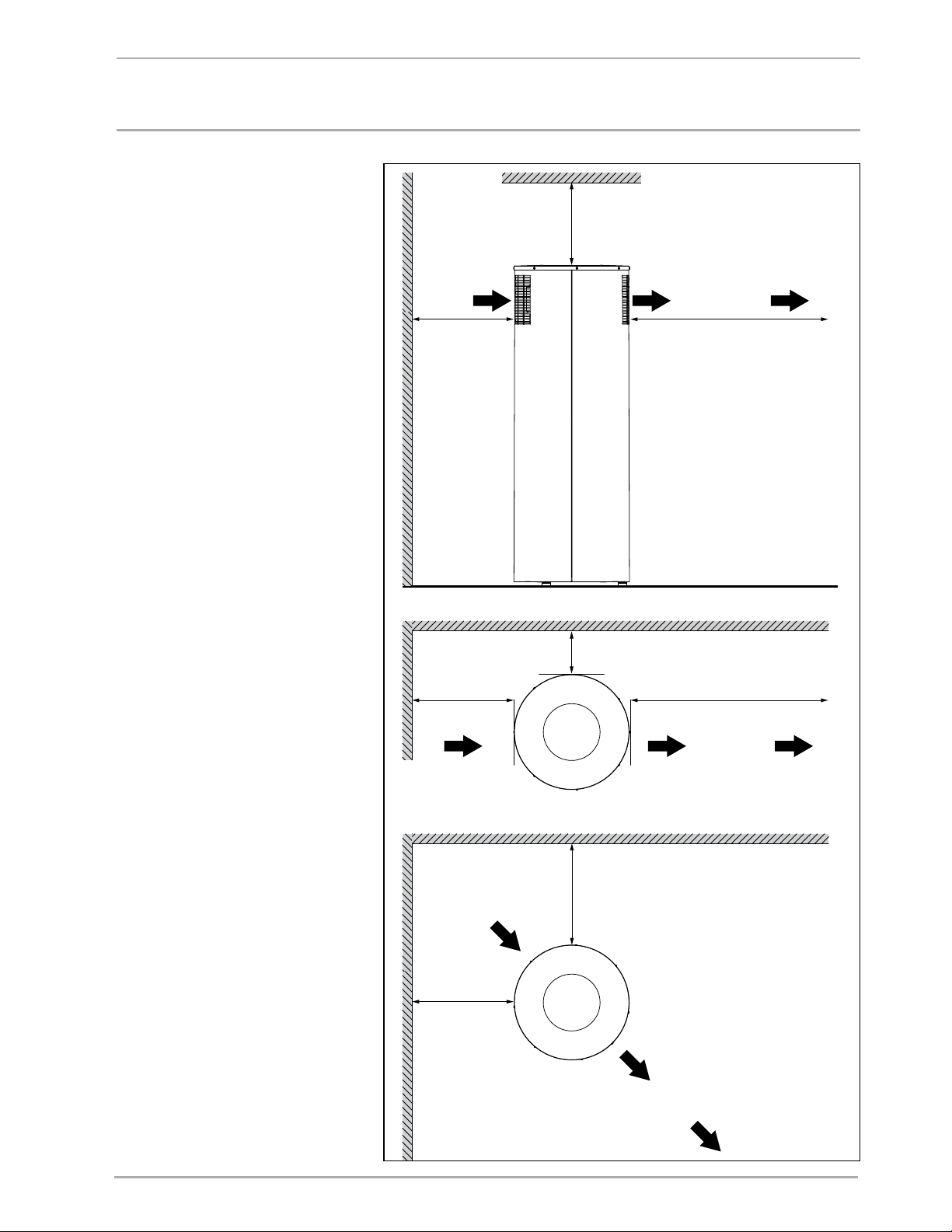

REQUIRED ROOM DIMENSIONS AND CLEARANCES

15

2´

8

´

Air flow

intake

Air flow

intake

Air flow

exhaust

Air flow

exhaust

2´

2´

2´

Air flow

intake

Air flow

exhaust

´

2

´´ x 8´

D0000018502

› Do not install in a room with

less than 800 cubic feet of

total volume (for example:

10 ft. x 10 ft. x 8 ft.).

› Do not install with the air

exhaust pointing at a wall

or any surface closer than 6

feet away.

› Do not install with the air

intake pointing to a wall or

any surface closer than 2

feet away.

Failure to follow installation

instructions will void the

factory warranty.

Page 4

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM ACCELERA 300 | 4

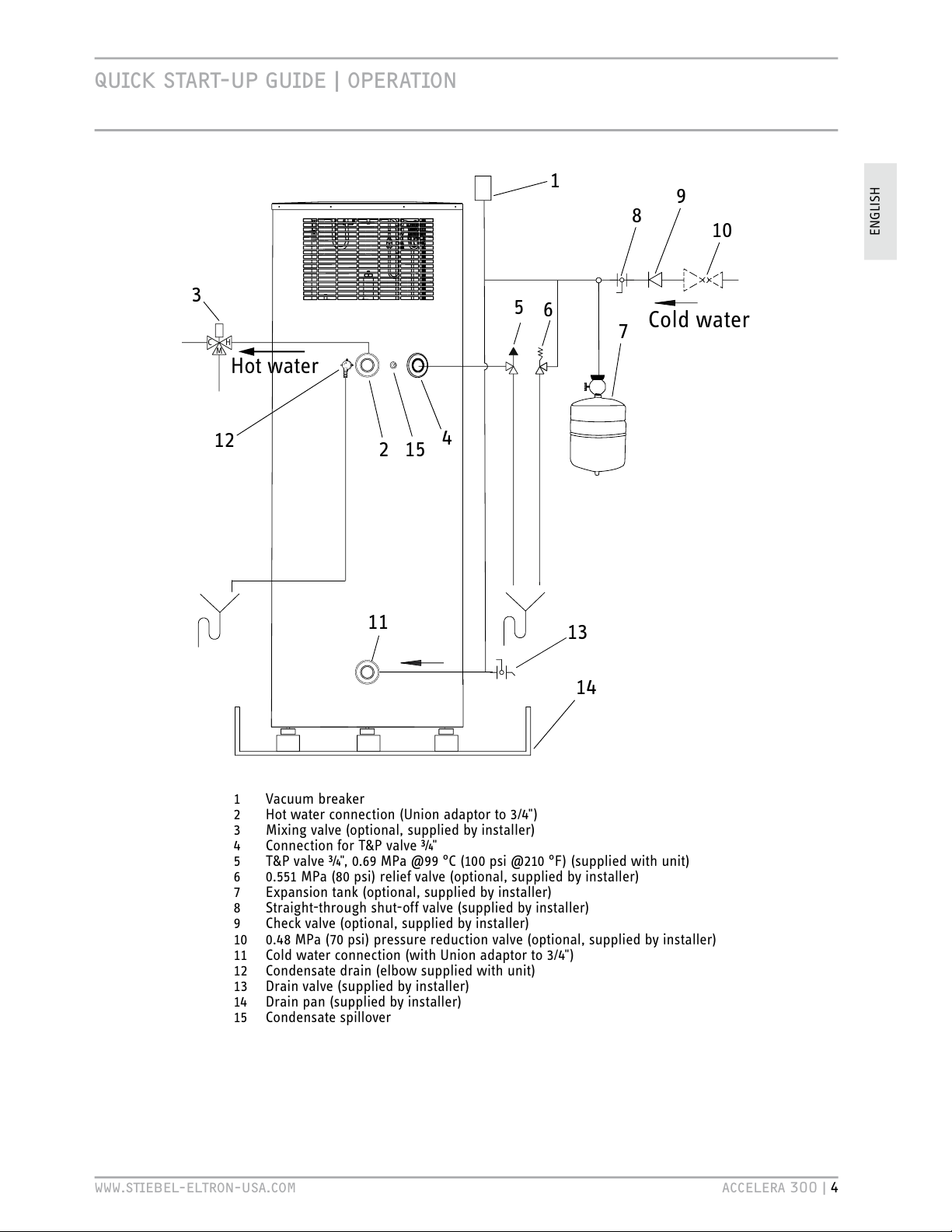

QUICK START-UP GUIDE | OPERATION

HMC

Cold water

Hot water

2

12

15

13

14

11

3

4

5

6

7

8

9

10

1

1 Vacuum breaker

2 Hot water connection (Union adaptor to 3/4")

3 Mixing valve (optional, supplied by installer)

4 Connection for T&P valve ¾"

5 T&P valve ¾", 0.69 MPa @99 °C (100 psi @210 °F) (supplied with unit)

6 0.551 MPa (80 psi) relief valve (optional, supplied by installer)

7 Expansion tank (optional, supplied by installer)

8 Straight-through shut-off valve (supplied by installer)

9 Check valve (optional, supplied by installer)

10

0.48 MPa (70 psi) pressure reduction valve (optional, supplied by installer)

11

Cold water connection (with Union adaptor to 3/4")

12 Condensate drain (elbow supplied with unit)

13 Drain valve (supplied by installer)

14

Drain pan (supplied by installer)

15 Condensate spillover

Page 5

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM ACCELERA® 300 HEAT PUMP WATER HEATER | 5

CONTENTS | OPERATION

GENERAL INFORMATION ____________________________________________2

QUICK START-UP GUIDE ____________________________________________2

OPERATION __________________________________________________________5

1. Overview ____________________________________________________5

2. General information ________________________________________5

2.1. Key to symbols ___________________________________________________ 5

3. Safety ________________________________________________________9

3.1. General safety instructions ____________________________________ 9

3.2. Intended use ______________________________________________________ 9

3.3. Incorrect use ______________________________________________________ 9

3.4. Personnel qualification _________________________________________ 9

3.5. Safety equipment ________________________________________________ 9

3.6. Particular risks ___________________________________________________ 9

4. Water heater description _________________________________ 10

4.1. Function description ___________________________________________10

5. Operation __________________________________________________ 10

5.1. Initial start-up by a licensed installer ______________________10

5.2. Starting and stopping __________________________________________10

5.3. Emergency stop _________________________________________________10

6. Maintenance and care ____________________________________ 10

6.1. Descaling _________________________________________________________11

7. What to do if ... ___________________________________________ 11

7.1. ... the water heater does not deliver hot water ___________ 11

7.2 . ... the safety valve of the cold water supply line is

dripping __________________________________________________________ 11

7.3 . ... the condensate drain drips ________________________________ 11

7.4 . ... the power consumption is too high ______________________11

7.5. ... the room temperature drops excessively _______________11

7.6 . ... other faults occur ____________________________________________11

8. Safety ______________________________________________________ 11

8.1. General safety instructions ___________________________________ 11

8.2. Incorrect use _____________________________________________________12

8.3. Qualification _____________________________________________________ 12

8.4. Instructions, standards and regulations ___________________12

8.5. Water installation _______________________________________________ 12

8.6. Electrical installation___________________________________________ 12

9. Water heater description _________________________________ 12

9.1. Standard delivery _______________________________________________ 13

9.2. Special accessories _____________________________________________ 13

10. Installation ________________________________________________ 13

10.1. Installation location ____________________________________________13

10.2. Shipping inspection ____________________________________________14

10.3. Handling __________________________________________________________ 14

10.4. Storage ____________________________________________________________ 14

10.5. Positioning the water heater _________________________________14

10.6. Unpacking the water heater __________________________________14

10.7. Water connection _______________________________________________17

10.8. Power supply: 240V / 15A double pole circuit breaker __ 17

11. Initial start-up ____________________________________________ 19

11.1. Initial start-up ___________________________________________________ 19

11.2. Shutting down ___________________________________________________ 19

11.3. Restarting ________________________________________________________ 19

12. Settings ____________________________________________________ 19

12.1. Adjusting the water temperature ____________________________ 19

13. Water heater hand over __________________________________ 19

14. Troubleshooting ___________________________________________ 19

14.1. Safety equipment of the water heater ______________________ 19

14.2. Troubleshooting _________________________________________________20

15. Maintenance and cleaning _______________________________ 20

15.1. Cleaning the evaporator ______________________________________ 20

15.2. Draining the tank _______________________________________________20

15.3. Sacrificial anode rod ___________________________________________20

15.4. Descaling _________________________________________________________20

15.5. Checking valves _________________________________________________21

16. Specification _______________________________________________ 21

16.1. Connection and dimensions __________________________________21

16.2. Wiring diagram _________________________________________________22

16.3.

Refrigerant diagram ___________________________________________23

16.4. Technical Data ___________________________________________________ 24

WARRANTY ________________________________________________________ 27

ENVIRONMENT AND RECYCLING _________________________________ 27

Page 6

OPERATION

OvER

vIEW

6 | ACCELERA® 300 HEAT PUMP WATER HEATER WWW.STIEBEL-ELTRON-USA.COM

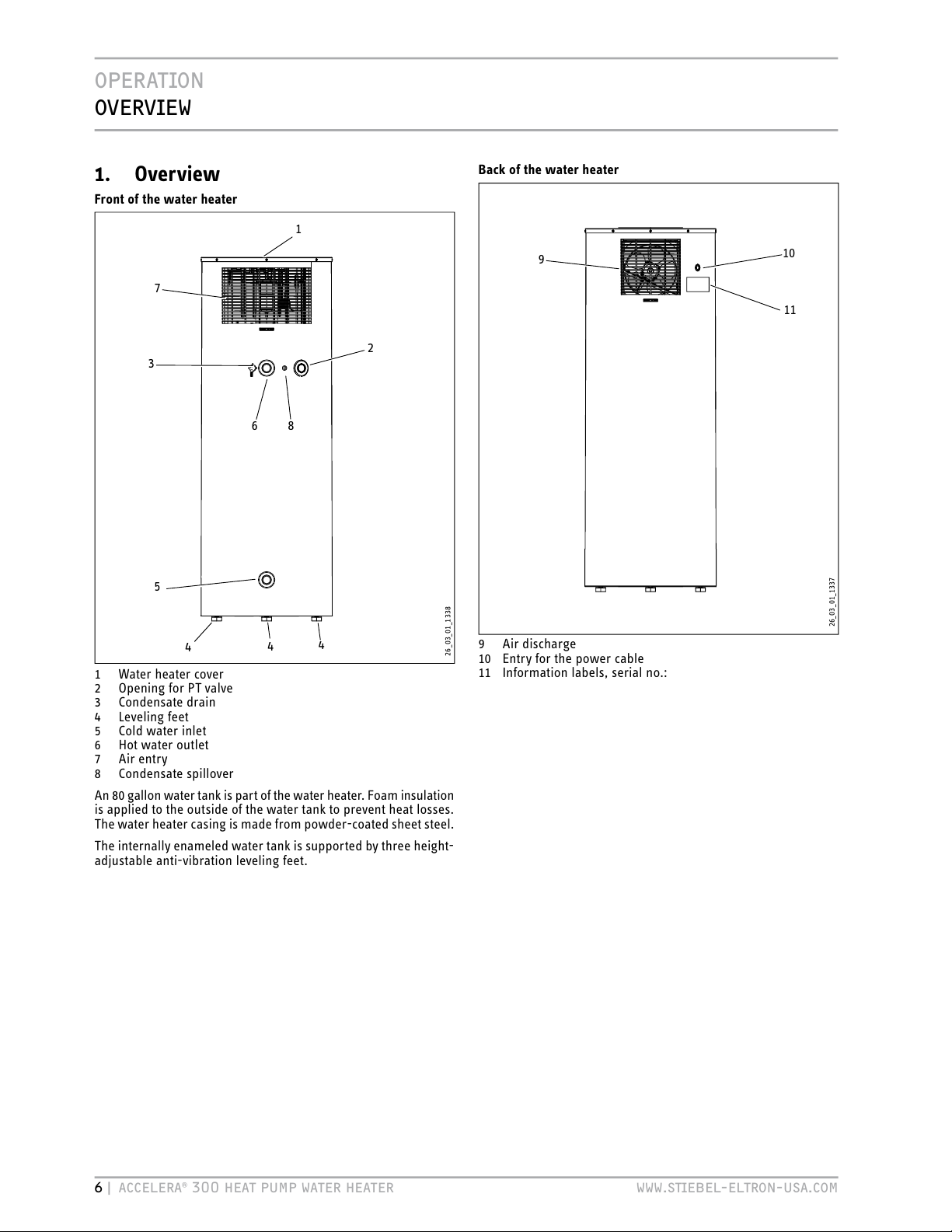

1. Overview

Front of the water heater

7

6

2

5

4

3

1

26_03_ 01_1338

4

4

8

1 Water heater cover

2 Opening for PT valve

3 Condensate drain

4 Leveling feet

5 Cold water inlet

6 Hot water outlet

7 Air entry

8 Condensate spillover

An 80 gallon water tank is part of the water heater. Foam insulation

is applied to the outside of the water tank to prevent heat losses.

The water heater casing is made from powder-coated sheet steel.

The internally enameled water tank is supported by three height-

adjustable anti-vibration leveling feet.

Back of the water heater

9

10

26_03_ 01_1337

9 Air discharge

10 Entry for the power cable

11

Information labels, serial no.:

11

Page 7

OPERATION

GENERAL

INFORMATION

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM ACCELERA® 300 HEAT PUMP WATER HEATER | 7

2. General information

The chapter Operation is intende d for users and licens ed installers .

The chapter Installation is intended for licensed installers only.

2.1 Key to symbols

2.1.1 Layout of safety information

DANGER Electric shock

Before any work on the water heater,

disconnect all poles from the power

supply.

1

3

4

2

1 Symbol (see chapter "Symbols")

2 Keyword (see chapter "Keywords")

3 Designations (see chapter "Symbols")

4 Information text

2.1.2 Symbols

Symbol Description

Injury

Electrocution

Burns or scalding

!

Other situations

Fire

Explosion

Water heater disposal

2.1.3 Keywords

KEYWORD

DANGER

The keyword DANGER indicates information

that must be observed, otherwise serious injury

or death

will result.

WARNING

The keyword WARNING indicates information

that must be observed, otherwise serious injury

or death

may result.

CAUTION The keyword CAUTION indicates information

that must be observed, otherwise relatively

serious or light injuries may result.

2.1.4 Symbols in this documentation

Read the text next to this symbol carefully.

» Passages with the symbol "»" indicate that you have to do

something. The action you need to take is described step by

step.

- Passages with this symbol "–" indicate lists.

2.1.5 Units of measure in this documentation

The dimensions in this document are given in

millimeters (inches).

2.1.6 Information on the packaging

Information label "Top heavy"

! !

Hoher Schwerpunkt

High balance point

Hoog zwaartepunt

Centre de gravité en partie haute

Hög tyngdpunkt

Alto centro di graviá

Alto centro de gravedad

Achtung - Attention - Attentie - Attention

Uppmärksamhet - Oppmerksomhet

Attenzione - Atención

264623-33631

Information label "Vertical transport"

!CHTUNG!TTENTION

4RANSP ORTUN D!UFS TELLUN G

$AMITDAS'ERËTVOR"ESCHËDIGUNGENGESCHàTZTISTSOLLTEESBISANDEN-ONTAGEORTINDER6ERPACKUNGTRANSPORTIERTWERDEN

'ERËTSENKRECHTTRANSPORTIEREN"EI

BEENGTEN4RANSPORTBEDINGUNGENKANNDAS'ERËTAUCHKURZZEITIGGENEIGTWERDEN"EACHTEN3IEDIEWEITEREN(INWEISEZUM!UFSTELLENUND!USRICHTENDES'ERË

TESINDERBEILIEGENDEN'EBRAUCHSUN D-ONTAGEANWEISUNGUM3CHËDENAM'ERËTZUVER MEIDEN

4RANSP ORTAN DINS TALLAT ION

4OPR OTEC TTH EEQ UIPM ENT AGAI NST DAMAG EIT MUS TBE TRA NSPO RTED INS IDE ITS DEDIC ATED PAC KAGI NGU NTIL THE INS TALL ATIO NFA CILI TYI SAR RIVED

4RANSP ORTTH EEQU IPMENT

UPRIGHT

7HERESPACEISRESTRICTEDYOUMAYALSOMOVEBRIEFLYTHEEQUIPMENTTIPPEDBACKWARDSATANANGLE/BSERVETHENOTESONINSTALLATIONANDFITTINGOFTHE

EQUIPMENTWHICHCANBEFOUNDINTHEENCLOSEDINSTALLATIONANDOPERATINGINSTRUCTIONSTOAVOIDPOSSIBLEDAMAGETOTHEEQUIPMENT

'ERËTNURSENKRECHTODERGGFGENEIGTTRANSPORTIEREN

-OVETHISMACHINEONLYINAVERTICALPOSITIONORIFREQUIREDSLIGHTLYINCLINEDWITHTHECONTROLFACIAPOINTUP

280306-34594

Page 8

OPERATION

GENERAL

INFORMATION

8 | ACCELERA® 300 HEAT PUMP WATER HEATER WWW.STIEBEL-ELTRON-USA.COM

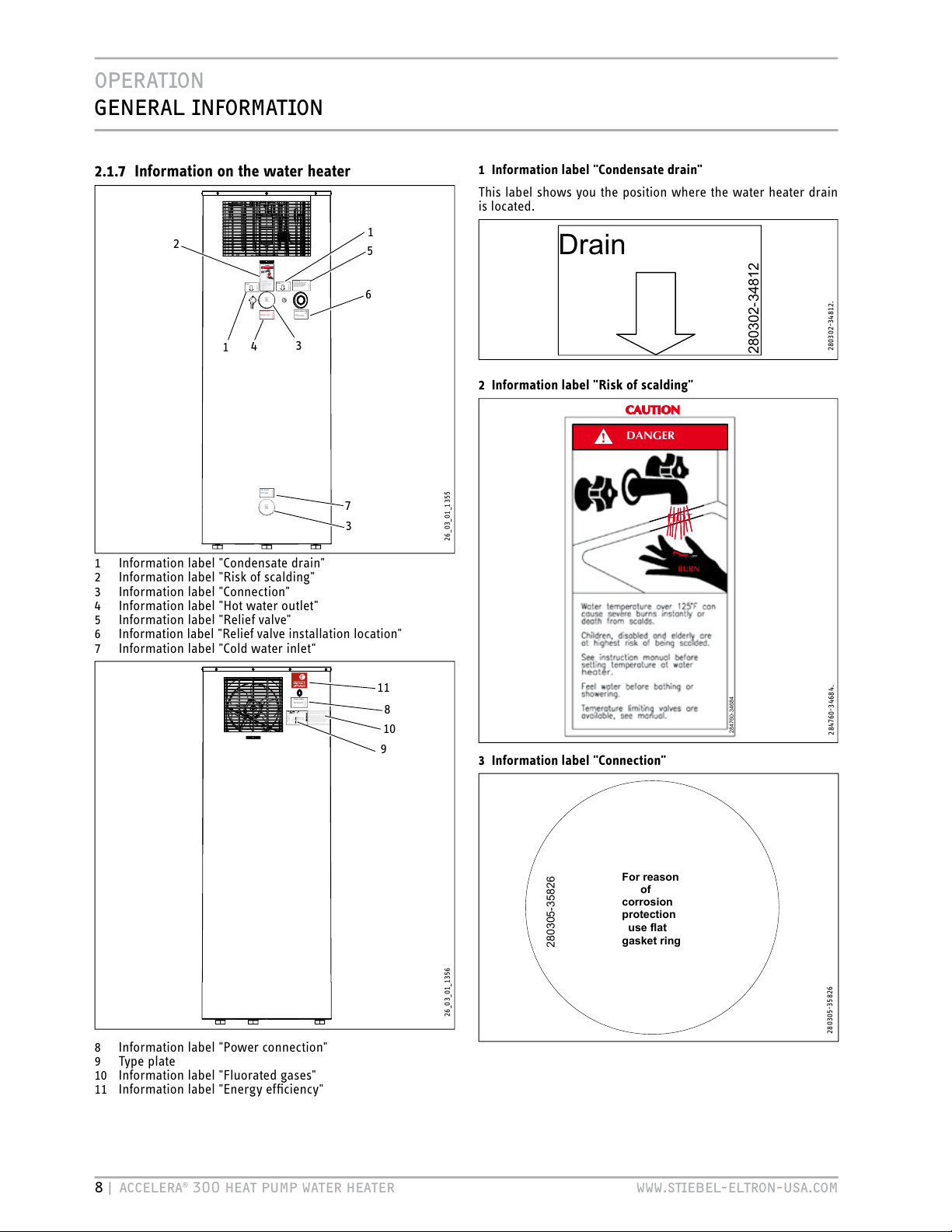

2.1.7 Information on the water heater

For reason

of

corrosion

protection

use flat

gasket ring

28030 5 - 35826

BURN

HOT

CAUTION

DANGER

!

284760-34684

WW Austritt

DHW outlet

2

803

0

4

-34

6845

Warning

A temperature and pressure relief valve

must be fitted to the clearly marked

socket. The valve drain outlet pipe

must not be sealed or blocked, and the

valve easy gear is to be operated

at least once every six month.

28

0

5

58-

34684

Drain

28

0

3

0

2-3481284594

KW Eintritt

CW Inlet

2

80303

-

3

46845

For reason

of

corrosion

protection

use flat

gasket ring

28030 5 - 35826

Drain

28

0

3

0

2-3481284594

Relief valve

Plumber:

The relief valve installation

must be fitted to this socket.

280557-35826

2

4

6

1

7

3

5

26_03_ 01_1355

3

1

1 Information label "Condensate drain"

2 Information label "Risk of scalding"

3 Information label "Connection"

4 Information label "Hot water outlet"

5 Information label "Relief valve"

6 Information label "Relief valve installation location"

7 Information label "Cold water inlet"

Power supply

Disconnect power supply

before opening the cover.

2

80

5

56-3

4

68425

Type: Accelera 300/WHP 300

Heat pump:

PN (Air 42° / Water 60°):

IN (Air 42° / Water 60°):

Type of Refrigerant:

Refrigerant charge:

Max. operating pressure:

Lock rotor current:

MCA:

Rated load compressor:

Motor fan:

Order-No.: 222423

DHW-cylinder:

Additional heating element:

Max. operating pressure:

Max. operating temperature:

Type of cylinder material:

Cylinder capacity:

Test pressure storage tank:

Observe the installation manual! Tested for leaks!

Made in Germany

No.: 8443 / 005204

Voltage / Frequency:

Breaker:

P (rated power input):

Maximum allowable ratings

Protection class:

Nmax

Single phase 220-240 V, 50/60 Hz

15 amp.

2200 W, 9.17 A

IP 24

*222423844300520415*

1690 W

87 psi /600

kPa

168.8 °F /76 °C

Glass lined steel

80.044 Gal /303 l

130.5 psi / 900 kPa

0.5 kW

2.17 A

R134A

1.9842 Lb. /900 g

348.1 psi /2.4 MPa

13.4 A

10.4 A

2.3 A

38 W

STIEBEL ELTRON INC

17 West Street

West Hatfield, MA 01088

USA

282209-35237

DE: Enthält vom Kyoto - Protokoll erfasste fluorierte Treibhausgase - hermetisch geschlossenes System.

GB: Contains fluorinated greenhouse gases covered by the Kyoto Protocol - hermetically sealed.

FR: Comprend les gaz à effet de serre fluorés enregistrés par le protocole de Kyoto - systèmes hermétiquement scellés.

NL: Bevat gefluoreerde broeikasgassen die onder het Kyoto-protocol vallen - hermetisch gesloten systeem.

SE: Innehåller av Kyoto - protokollet registrerade flourerande växthusgaser i hermetiskt förslutna system.

PL: Zawiera fluorowane gazy cieplarniane ujęte w Protokole z Kioto - hermetycznie zamknięty układ.

CZ: Obsahuje fluorizované skleníkové plyny, obsažené v Kjótském protokolu - hermeticky uzavřený systém.

ES: Sistema herméticamente cerrado que contiene gases de efecto invernadero mencionados en el protocolo de Kioto.

DK: Indeholder fra Kyoto-protokollen registrerede, fluorerede drivhusgasser – hermetisk lukket system.

NO: Inneholder fluorerte drivhusgasser som omfattes av Kyotoprotokollen - hermetisk lukket system.

FI: Sisältää Kioton sopimuksen alaisia fluorattuja kasvihuonekaasuja - ilmatiiviisti suljettu järjestelmä.

284436-34741

BG: Съдържа посочените в Протокола от Киото флуорирани парникови газове - херметически затворена система.

HU: A Kiotói Jegyzıkönyv szerinti fluortartalmú üvegházhatású gázokat tartalmaz - hermetikusan zárt rendszer.

IT: Contiene gas fluorurati ad effetto serra disciplinati dal protocollo di Kyoto - Impianto ermeticamente chius.

RO: Conține un sistem închis ermetic contra emisiei de gaze fluorine monitorizat de protocolul Kyoto.

8

11

26_03_ 01_1356

10

9

8 Information label "Power connection"

9 Type plate

10

Information label "Fluorated gases"

11

Information label "Energy efficiency"

1 Information label "Condensate drain"

This label shows you the position where the water heater drain

is located.

Drain

280302-3481284594

280302-34812.

2 Information label "Risk of scalding"

BURN

HOT

CAUTION

DANGER

!

284760-34684

284760-34684.

3 Information label "Connection"

For reason

of

corrosion

protection

use flat

gasket ring

28030 5 - 35826

280305-35826

Page 9

OPERATION

GENERAL

INFORMATION

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM ACCELERA® 300 HEAT PUMP WATER HEATER | 9

4 Information label "Hot water outlet"

WW Austritt

D

HW outlet

280304-346845

280304-34684

5 Information label "Relief valve"

Warning

A

temperature and pressure relief valve

m

ust be fitted to the clearly marked

s

ocket. The valve drain outlet pipe

m

ust not be sealed or blocked, and the

v

alve easy gear is to be operated

a

t least once every six month.

280558-34684

280558-34684

6

Information label "Relief valve installation location"

R

elief valve

P

lumber:

T

he relief valve installation

m

ust be fitted to this socket.

280557-35826

280557-35826

7 Information label "Cold water inlet"

K

W Eintritt

C

W Inlet

280303-346845

280303-34684

8 Information label "Power connection"

Power supply

D

isconnect power supply

b

efore opening the cover.

280556-3468425

280556-34684

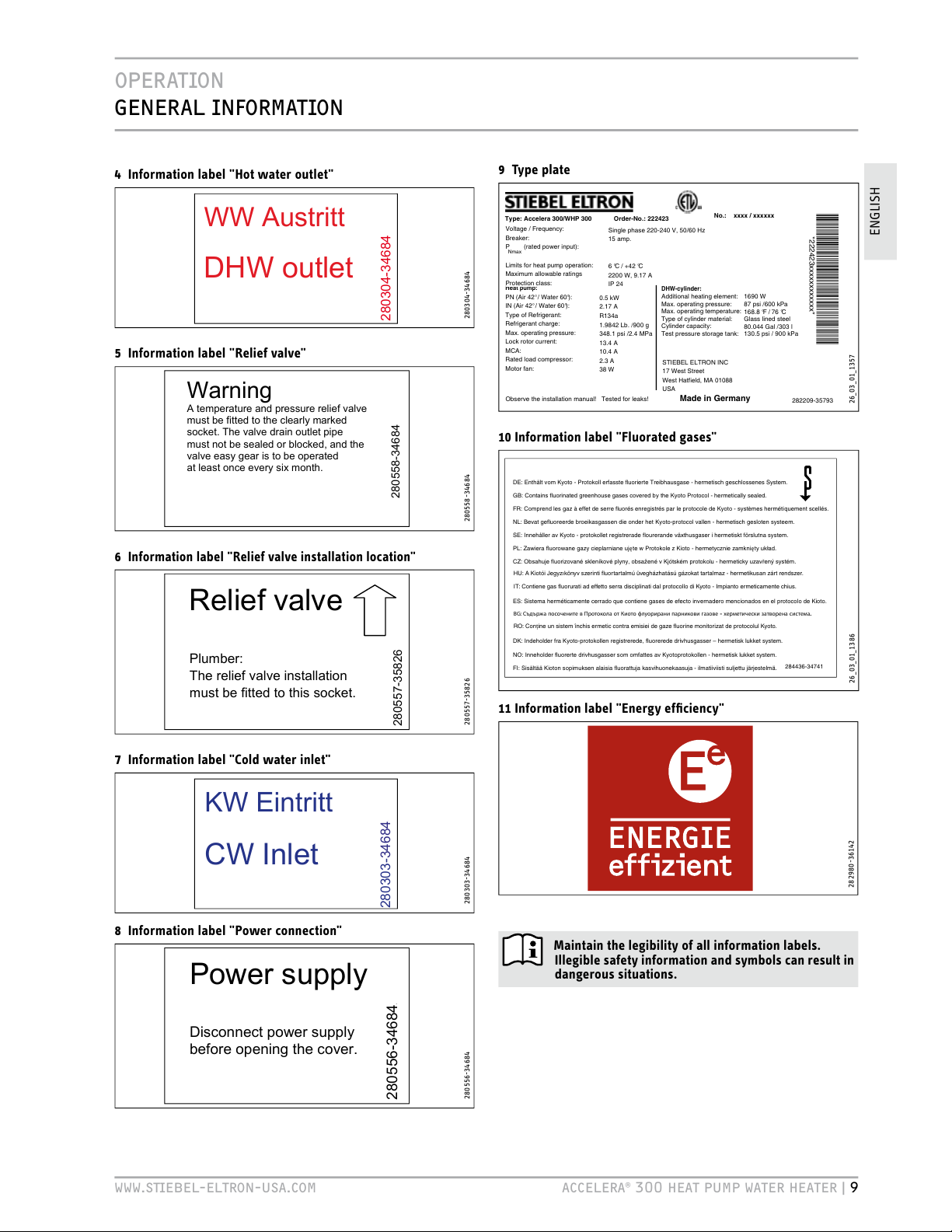

9 Type plate

Type: Accelera 300/WHP 300

Heat pump:

PN (Air 42° / Water 60°):

IN (Air 42° / Water 60°):

Type of Refrigerant:

Refrigerant charge:

Max. operating pressure:

Lock rotor current:

MCA:

Rated load compressor:

Motor fan:

Order-No.:

222423

DHW-cylinder:

Additional heating element:

Max. operating pressure:

Max. operating temperature:

Type of cylinder material:

Cylinder capacity:

Test pressure storage tank:

Observe the installation manual! Tested for leaks!

Made in Germany

No.: xxxx / xxxxxx

Voltage / Frequency:

Breaker:

P (rated power input):

Limits for heat pump operation

:

Maximum allowable ratings

Protection class:

Nmax

Single phase 220-240 V, 50/60 Hz

15 amp.

6 °C / +42 °C

2200 W, 9.17 A

IP 24

*222423xxxxxxxxxxxx*

1690 W

87 psi /

600 kPa

168.8 °F /

76

°C

Glass lined steel

80.044 Gal /303 l

130.5 psi / 900 kPa

0.5

kW

2.17

A

R134a

1.9842 Lb. /900 g

348.1 psi /2.4

MPa

13.4 A

10.4 A

2.3 A

38 W

STIEBEL ELTRON INC

17 West Street

West Hatfield, MA 01088

USA

282209

-35793

26_03_ 01_1357

10 Information label "Fluorated gases"

DE: Enthält vom Kyoto - Protokoll erfasste fluorierte Treibhausgase - herm etisch geschlossenes System.

GB: Contains fluorinated greenhouse gases covered by the Kyoto Protocol - herm etically sealed.

FR: Comprend les gaz à effet de serre fluorés enregistrés par le pro tocole de Kyoto - systèmes hermétiquement scellés.

NL: Bevat gefluoreerde broeikasgassen die onder het Kyoto-protocol vallen - hermetisch gesloten systeem.

SE: Innehåller av Kyoto - protokollet registrerade flourerande växthusgase r i hermetiskt förslutna system.

PL: Zawiera fluorowane gazy cieplarniane ujęte w Protokole z Kioto - hermetycznie zamknięty układ.

CZ: Obsahuje fluorizované skleníkové plyny, obsažené v Kjótském protokolu - her meticky uzavřený systém.

ES: Sistema herméticamente cerrado que contiene gases de efecto invernadero mencionados en el protocolo de Kioto.

DK: Indeholder fra Kyoto-protokollen registrerede, fluorerede drivhusgasser – hermetisk lukket system.

NO: Inneholder fluorerte drivhusgasser som omfattes av Kyotoprot okollen - hermetisk lukket system.

FI: Sisältää Kioton sopimuksen alaisia fluorattuja kasvihuonekaasuja - ilmatiiviisti suljettu järjeste lmä.

284436-34741

BG: Съдържа посочените в Протокола от Киото флуорирани парникови газове - херметически затворена система.

HU: A Kiotói Jegyzıkönyv szerinti fluortartalmú üvegházhatású gázokat tartalmaz - hermetikusan zárt rendszer.

IT: Contiene gas fluorurati ad effetto serra disciplinati dal protocollo di Kyoto - Impianto ermeticamente chius.

RO: Conține un sistem închis ermetic contra emisiei de gaze fluorine monitorizat de protocolul Kyoto.

26_03_ 01_1386

11 Information label "Energy efficiency"

282980-36142

Maintain the legibility of all information labels.

Illegible safety information and symbols can result in

dangerous situations.

Page 10

OPERATION

SAFETY

10 | ACCELERA® 300 HEAT PUMP WATER HEATER WWW.STIEBEL-ELTRON-USA.COM

3. Safety

This chapter provides an overview of all important actions required

for a safe and trouble-free operation.

3.1 General safety instructions

Operate the water heater only when fully installed and with all

safety equipment in place.

Unsuitable tools or incorrect handling can result in damage to

the water heater.

DANGER Scalding

The water is heated inside the water tank to60 °C

(140 °F). There is a risk of scalding at outlet

temperatures above 43 °C (109 °F).

» Ensure that outflowing water does not directly

contact your body.

CAUTION Injury

Where children or persons with limited physical,

sensory or mental capabilities are allowed to control

this water heater, ensure that this will only happen

under supervision or after appropriate instruction by

a person responsible for their safety.

» Children should be supervised to ensure that they

never play with the water heater.

Never place any objects on top of the water heater.

Objects placed on top of the water heater can increase

the noise level developed by the water heater through

vibrations.

Never cover the water heater.

The water heater draws in air. Covering the inlet slots

reduces the air intake. This reduces the efficiency of

the water heater and can even lead to one of the safety

devices interrupting the water heater operation.

3.2 Intended use

This water heater produces hot water automatically.

The water heater can be installed and operated in the open as well

as in enclosed spaces. The temperature of the air that is drawn in

during operation must not fall below 6 °C (43 °F).

Any other use beyond that described shall be deemed inappropriate.

Observation of these instructions is also part of the correct use of

this water heater.

Any changes or modifications to this water heater void all warranty

rights.

3.3 Incorrect use

The following are not permitted:

- Do not heat anything other than potable water

- Do not use unqualified (unlicensed) personnel for installation

- Do not use in an environment with greasy extract air

This water heater must not be operated at ambient

temperatures in excess of 42 °C (107 °F) or below 6 °C

(43 °F).

If outside air is directly drawn in ensure, that the

water heater is isolated from its power supply when

the air temperature falls below 6 °C (43 °F).

3.4 Personnel qualification

DANGER Injury

Incorrect handling can result in severe injuries and

material losses. Inadequately qualified personnel

cannot assess the potential risks.

Have the installation, initial start-up, maintenance

and repair steps carried out only by the qualified

individuals specified in the respective chapters.

In the remainder of this manual, such qualified individuals will be

described as the "licensed installer."

3.5 Safety equipment

Wear safety shoes/boots during the transportation and positioning

of the water heater. Dry, this water heater weighs 130 kg (290 lb).

Safety shoes/boots reduce the risk of injury.

3.6 Particular risks

3.6.1 Electric current

WARNING Electric shock

Contacting parts that carry live power is associated

with a direct risk to life. Damaging the insulation or

individual components can result in a risk to life.

» If you detect damaged insulation, immediately

switch off the power supply and arrange for the

necessary repair.

» Have all electrical work carried out by a qualified

electrician.

3.6.2 Hot surfaces

CAUTION Burning

Contact with hot components can result in burning.

» When working near hot components, wear

protective clothing and gloves.

» The pipework connected to the hot water outlet of

the water heater can reach temperatures in excess

of 60 °C (140 °F).

3.6.3 Refrigerant

The water heater is filled with R134A refrigerant at the factory.

WARNING Freezer burn

Should the water heater leak refrigerant, avoid contact

with the refrigerant or breathing in any released

vapors. Immediately vent the room.

In normal water heater operation, the refrigerant is contained in

a sealed circuit.

Page 11

OPERATION

WATER HEATER DESCRIPTION

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM ACCELERA® 300 HEAT PUMP WATER HEATER | 11

4. Water heater description

This water heater is an automatic hot water generator with approx.

303 l (80gallon) capacity. The hot water temperature is factory

set to 60 °C (140 °F).

After opening a hot water faucet, the hot water is pushed out of

the water heater by the incoming cold water.

This water heater works like an air conditioner but does not need

to be vented. The water heater extracts heat from the ambient air

to heat the water. The demand for electrical energy and the heatup time depend on the ambient air temperature and humidity.

When installing the water heater inside, the space where it is

installed will be cooled down during the operation by 1 to 3 °C

(2 to 6 °F).

The water heater also extracts moisture from the air that creates

condensate, which must be drained off. For this purpose, a

condensate drain is integrated in the water heater. This is where

you can connect a hose to a drain.

To protect the steel tank against corrosion, the interior is coated

with a special enamel and is equipped with a replaceable sacrificial

anode.

Heat pump function:

A sealed circuit inside the water heater contains R134A refrigerant

(see "Specification/data table"); this does not deplete ozone, is

non-flammable, and evaporates at low temperatures.

In the evaporator, where heat is extracted from the outside air,

the refrigerant changes from its liquid into its gaseous state. A

compressor draws in the gas in and compresses it. The increase

in pressure raises the refrigerant temperature and heats the water

tank.

This process requires electrical energy. The energy (motor heat)

is not lost, but reaches the condenser downstream together with

the compressed refrigerant. Here, the gas transfers heat to the

water tank. An expansion valve then reduces the pressure and

the process starts again.

4.1 Function description

4.1.1 Heat pump operation

The heat pump unit located on top of the water heater extracts

heating energy from the ambient air.

If the water heater was separated from the power

supply during operation, the compressor will only

restart if the pressure inside the refrigerant circuit has been

balanced. Pressure balance can only be created after waiting

15 minutes.

4.1.2 Booster heater

Primarily, the water inside the tank is heated by the heat pump.

When there is a higher hot water demand or when the water heater

was switched OFF and you require hot water quickly, the integral

booster heater will turn on. To save energy, the booster heater

only heats the top third of the tank (approx. 102 l (27 gallons)).

A thermostat switches the booster heater on if the water

temperature inside the tank falls below 45 °C (112 °F). A thermostat

switches the booster heater off if the water temperature inside the

tank exceeds 60 °C (140 °F).

4.1.3 Defrosting

The lower limit of use of the water heater is permanently set to

6 °C (42 °F). It is possible that at this limit, the evaporator will be

coated in frost. This is subject to the air temperature and humidity

level, particularly at low hot water temperatures.

The compressor will be switched off as soon as the evaporation

temperature falls below -7 °C (20 °F) for any length of time. When

the temperature at the evaporator fins rises above 3 °C (38°F), the

compressor starts again, and the hot water heating continues. The

fan continues to run during defrosting.

5. Operation

You do not have to make any adjustments. The water heater

is therefore not equipped with any controls. The hot water

temperature is factory set to 60 °C (140 °F).

Should you wish to operate with different settings, contact your

local licensed installer.

WARNING Scalding

The water is heated inside the water tank to

60 °C (140 °F). There is a risk of scalding at outlet

temperatures in excess of 42 °C (108 °F).

Ensure that outflowing water does not directly contact

your body.

5.1 Initial start-up by a licensed installer

Initial start-up should be done by a licensed installer.

5.2 Starting and stopping

The water heater is not equipped with an ON/OFF switch. If a

power plug was fitted during installation, you can disconnect

the water heater from the power supply by pulling that plug.

Alternatively, you can terminate the water heater operation by

tripping the circuit breaker.

5.3 Emergency stop

In case of emergency, carry out the following steps:

» Isolate the power supply by tripping the circuit breaker or by

pulling the power plug.

» Shut off the cold water inlet.

6. Maintenance and care

A damp cloth is sufficient for cleaning the exterior of the water

heater. Never use abrasive or corrosive cleaning agents. Do not

hose down the water heater.

» Monthly, check that the condensate drain is clear.

» Monthly, carry out a visual inspection of the condensate

pan drain (in the top of the water heater; see the following

diagram). Look through the air intake grille at the front of the

water heater. If required, notify your local licensed installer

who will remove any contamination.

Page 12

OPERATION

WHAT

TO DO IF ...

12 | ACCELERA® 300 HEAT PUMP WATER HEATER WWW.STIEBEL-ELTRON-USA.COM

1

26_03_ 01_1404

1 Condensate pan drain

6.1 Descaling

At high temperatures water separates out lime. This is deposited

on the inside of the tank. With increasing limescale build-up, the

amount of hot water inside the tank is reduced.

» Have a licensed installer descale the booster heater from

time to time. This extends the service life of the booster

heater.

» Scale cannot build up on the heat pump element.

A licensed installer who knows the local water quality will tell you

when the next maintenance appointment is due.

» Have your licensed installer check the sacrificial anode

regularly.

7. What to do if ...

7.1 ... the water heater does not deliver hot

water

» Check the water heater power supply.

» Check your fuse box for a tripped circuit breaker.

» Make sure there is a 15A double pole circuit breaker

If the circuit breaker has tripped, reset it or replace it. Notify your

local licensed installer if the circuit breaker trips again.

» Ensure that the air intake and air discharge are unobstructed.

Excessively high ambient temperature, excessively high

temperature of the air drawn in (>42 °C (108 °F)) or a fault in the

refrigerant circuit can result in the compressor being overloaded.

The thermal protective 'auto reset' motor switch or the high limit

'manual reset' cut-out can both shut off the compressor off.

The high limit pressure limiter must only be reset by

your licensed installer after they have removed the

cause of the relevant fault.

After a short cooling down period, the thermal protective motor

auto reset switch will restart the compressor automatically.

Notify your local licensed installer if the water heater does not

restart automatically.

7.2 ... the safety valve of the cold water supply

line is dripping

This unit can operate up to 0.48 MPa (70psi) of inlet pressure.

Expansion water drips from the safety valve during heat-up. This

is completely normal. Notify your local licensed installer if water

still drips after heat-up has been completed.

7.3 ... the condensate drain drips

This is quite normal and always happens when the surface

temperature of the evaporator is lower than the dew point

temperature of the ambient air.

7.4 ... the power consumption is too high

Please consult a qualified licensed installer.

7.5 ... the room temperature drops excessively

The water heater operation reduces the ambient air by

1 to 3 °C (2 to 6°F). Notify your local licensed installer if the

ambient temperature drops abnormally.

7.6 ... other faults occur

Notify your local licensed installer. Refer to the water heater

number on the type plate next to the barcode.

Type: Accelera 300/WHP 300

Heat pump:

PN (Air 42° / Water 60°):

IN (Air 42° / Water 60°):

Type of Refrigerant:

Refrigerant charge:

Max. operating pressure:

Lock rotor current:

MCA:

Rated load compressor:

Motor fan:

Order-No.:

222423

DHW-cylinder:

Additional heating element:

Max. operating pressure:

Max. operating temperature:

Type of cylinder material:

Cylinder capacity:

Test pressure storage tank:

Observe the installation manual! Tested for leaks!

Made in Germany

No.: xxxx / xxxxxx

Voltage / Frequency:

Breaker:

P (rated power input):

Limits for heat pump operation

:

Maximum allowable ratings

Protection class:

Nmax

Single phase 220-240 V, 50/60 Hz

15 amp.

6 °C / +42 °C

2200 W, 9.17 A

IP 24

*222423xxxxxxxxxxxx*

1690 W

87 psi /

600 kPa

168.8 °F /

76

°C

Glass lined steel

80.044 Gal /303 l

130.5 psi / 900 kPa

0.5

kW

2.17

A

R134a

1.9842 Lb. /900 g

348.1 psi /2.4

MPa

13.4 A

10.4 A

2.3 A

38 W

STIEBEL ELTRON INC

17 West Street

West Hatfield, MA 01088

USA

282209

-35793

26_03_ 01_1357

1

1 Water heater number

8. Safety

Only qualified licensed installers should carry out installation,

initial start-up, maintenance and repair of the water heater.

8.1 General safety instructions

Use only original accessories and spare parts intended for this

water heater.

DANGER Electric shock

Disconnect the water heater from the power supply

prior to its installation.

WARNING Injury

If the pipes inside the water heater are damaged,

leaking refrigerant gas can result in severe physical

freezer burns.

Do not inhale refrigerant. Immediately vent the room

thoroughly.

» Wear safety goggles and gloves during water heater

installation.

Page 13

OPERATION

WATER

HEATER DESCRIPTION

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM ACCELERA® 300 HEAT PUMP WATER HEATER | 13

WARNING Injury

Moving parts represent a risk of injury.

» Before opening the water heater, ensure that the fan

has come to a complete standstill.

8.2 Incorrect use

The following are not permitted:

- Do not install the water heater on non-load bearing floors

- Do not install the water heater where it is at risk from frost

- Do not install in rooms where the water heater is at risk from

explosions as a result of dust, gases or vapors

- Do not ignore safety clearances and safety zones

- Do not incorrectly install the power connection

- Do not operate the water heater with the tank empty

- Do not operate the water heater with an open casing

- Do not heat anything other than potable water

- Do not fill with any other Freon, use only R134A

8.3 Qualification

WARNING Injury

Incorrect handling can result in severe injuries and

material losses. Inadequately qualified personnel

cannot assess the impending danger.

Have only personnel mentioned in the appropriate

sections of this manual carry out specific measures.

In this manual, such qualified individuals will be described as the

"licensed installer".

Licensed installers are responsible for adherence to all currently

applicable regulations during installation and initial start-up.

8.3.1 Licensed installer

Licensed installers are specially trained in their field. Licensed

installers work on systems on the basis of their training, knowledge

and experience, as well as their knowledge of applicable standards

and regulations. They are able on their own to recognize and

prevent possible problems.

8.3.2 Electrician (licensed)

An electrician is a licensed installer who meets the above

requirements with regard to electrical installations.

8.3.3 Plumber (licensed)

A plumber is a licensed installer who meets the above requirements

with regard to water-related installations.

8.3.4 Customer service

For customer service inquiries, please contact Stiebel Eltron

directly at 1-800-582-8423, ext. 25 or ext. 33.

8.4 Instructions, standards and regulations

Follow all national, state, and local codes.

Observe the regulations of your local energy and water supply

utilities.

The following standards were taken into account:

UL 499, UL 1995, UL 94-5 VA, UL 174

IEC 60335-1-2-40, IEC 61000-3-2; 1995

IEC 61000-3-3, IEC 55014-1 IEC 55014-2

EMC Directive 89/336/EEC

EN 255 T3

Read the water heater type plate and the chapter "Specification".

8.5 Water installation

The following materials may be used:

- Cold water line: steel, copper or plastic pipework.

- Hot water line: copper or plastic pipework.

» Ensure that no contamination reaches the water heater

through the pipework.

8.6 Electrical installation

Protect the water heater electrically with a 15A double pole circuit

breaker.

Where the water heater is permanently connected to the power

supply, it must be able to be separated from the mains power

supply by an additional isolator that disconnects all poles with

at least 3

mm (0.12") contact separation. For this purpose, use

contractors, circuit breakers, fuses, etc. on site.

In case of a fault, the safety equipment interrupts the relevant

power circuit.

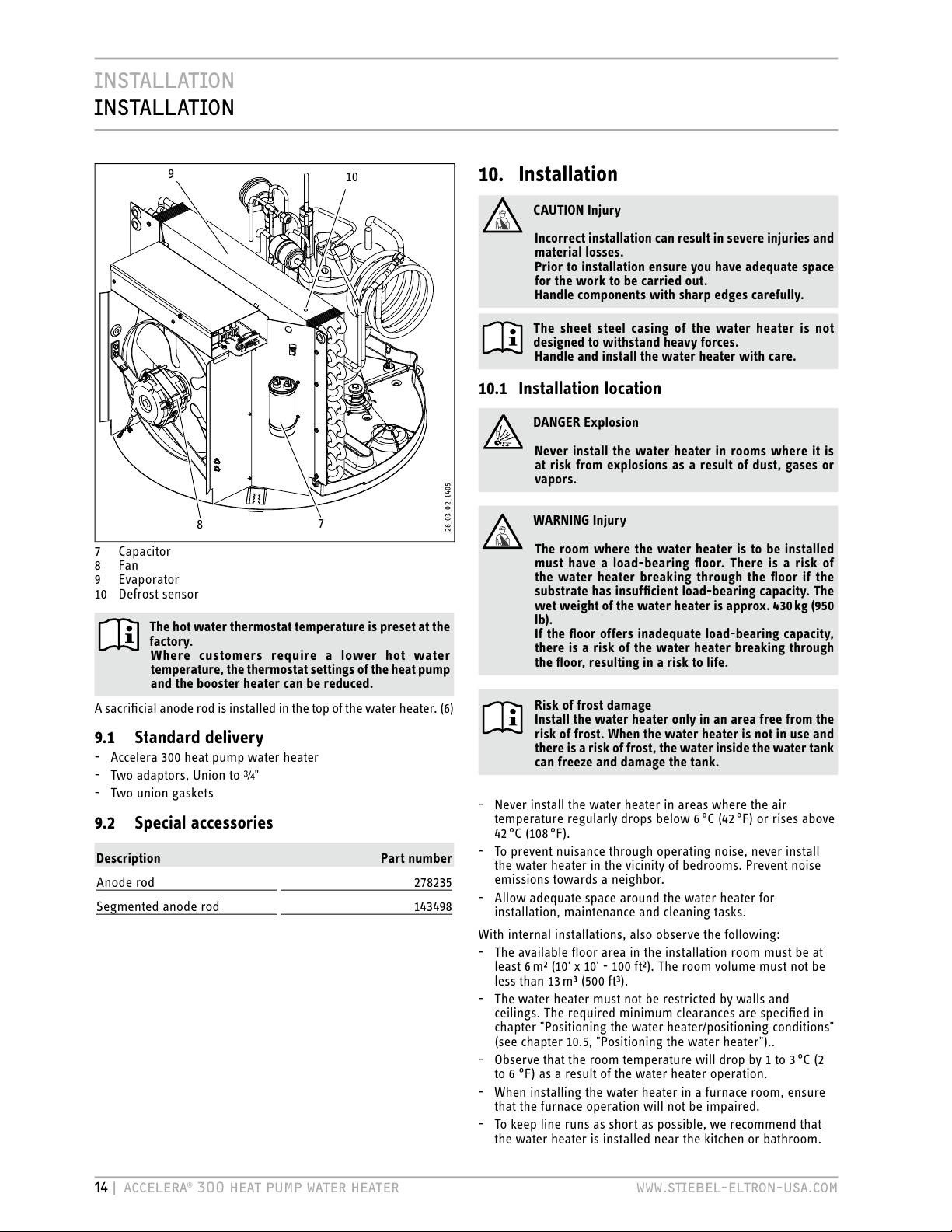

9. Water heater description

3

2

1

4

5

26_03_ 02_1404

1 High limit safety cut-out - manual reset

2 Compressor

3 Condensate drain

4 Filter dryer

5 Service valve, high pressure

6 Sacrificial anode

6

Page 14

14 | ACCELERA® 300 HEAT PUMP WATER HEATER WWW.STIEBEL-ELTRON-USA.COM

INSTALLATION

INSTALLATION

8

7

9

10

26_03_ 02_1405

7 Capacitor

8 Fan

9 Evaporator

10 Defrost sensor

The hot water thermostat temperature is preset at the

factory.

Where customers require a lower hot water

temperature, the thermostat settings of the heat pump

and the booster heater can be reduced.

A sacrificial anode rod is installed in the top of the water heater. (6)

9.1 Standard delivery

- Accelera 300 heat pump water heater

- Two adaptors, Union to ¾"

- Two union gaskets

9.2 Special accessories

Description Part number

Anode rod 278235

Segmented anode rod 143498

10. Installation

CAUTION Injury

Incorrect installation can result in severe injuries and

material losses.

Prior to installation ensure you have adequate space

for the work to be carried out.

Handle components with sharp edges carefully.

The sheet steel casing of the water heater is not

designed to withstand heavy forces.

Handle and install the water heater with care.

10.1 Installation location

DANGER Explosion

Never install the water heater in rooms where it is

at risk from explosions as a result of dust, gases or

vapors.

WARNING Injury

The room where the water heater is to be installed

must have a load-bearing floor. There is a risk of

the water heater breaking through the floor if the

substrate has insufficient load-bearing capacity. The

wet weight of the water heater is approx. 430 kg (950

lb).

If the floor offers inadequate load-bearing capacity,

there is a risk of the water heater breaking through

the floor, resulting in a risk to life.

Risk of frost damage

Install the water heater only in an area free from the

risk of frost. When the water heater is not in use and

there is a risk of frost, the water inside the water tank

can freeze and damage the tank.

- Never install the water heater in areas where the air

temperature regularly drops below 6 °C (42 °F) or rises above

42

°C (108 °F).

- To prevent nuisance through operating noise, never install

the water heater in the vicinity of bedrooms. Prevent noise

emissions towards a neighbor.

- Allow adequate space around the water heater for

installation, maintenance and cleaning tasks.

With internal installations, also observe the following:

- The available floor area in the installation room must be at

least 6 m² (10' x 10' - 100 ft²). The room volume must not be

less than 13 m³ (500 ft³).

- The water heater must not be restricted by walls and

ceilings. The required minimum clearances are specified in

chapter "Positioning the water heater/positioning conditions"

(see chapter 10.5, "Positioning the water heater")..

- Observe that the room temperature will drop by 1to3 °C (2

to 6 °F) as a result of the water heater operation.

- When installing the water heater in a furnace room, ensure

that the furnace operation will not be impaired.

- To keep line runs as short as possible, we recommend that

the water heater is installed near the kitchen or bathroom.

Page 15

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM ACCELERA® 300 HEAT PUMP WATER HEATER | 15

INSTALLATION

INSTALLATION

10.2 Shipping inspection

» Upon receipt, check your delivery for completeness and

possible transport damage.

If transport damage is visible, proceed as follows:

- Do not accept the delivery or only with reservations.

- Note down the extent of the damage on the shipping

documents or on the delivery note of the carrier.

- Initiate a complaint.

Immediately give notice of any damage.

Give notice of all damage as soon as it has been

identified. Claims can only be accepted within the

applicable claim period.

10.3 Handling

CAUTION Injury through heavy loads

Dry, this water heater weighs 130 kg (290 lb.). Use

suitable aids and sufficient personnel when handling

this water heater.

Risk of damage through incorrect handling.

Incorrect handling can result in substantial material

losses.

Observe the information on the packaging.

Remove the packaging just before the installation.

Risk of damage through overturning.

The water heater has a high centre of gravity and a

low overturning moment. Protect the water heater

against overturning.

Only position the water heater on a level substrate.

To protect the water heater against damage, it should be

transported vertically inside its packaging. Where space is

restricted, you can also tilt (max. 45°) the water heater briefly

to move it.

10.4 Storage

Where it is necessary to store the water heater prior to installation

for a longer period, observe the following:

- If possible, store the water heater in a dry and dust-free

ambience.

- Prevent the water heater from coming into contact with

aggressive materials.

- Prevent the water heater from being exposed to shocks or

vibrations.

- In case of prolonged storage, check the condition of the

water heater and its packaging regularly.

10.5 Positioning the water heater

» Position the water heater with its wooden pallet at the final

installation location in a 10’ x 10’ x 8’ area.

Install the water heater so that there is an adequate clearance

adjacent to the air grilles (see the following diagrams).

10.5.1 Installation conditions

It is important for water heater performance and to avoid damage

to adjacent surfaces that adequate clearance remains available

on the air flow intake (min. 2') and air flow exhaust sides (min

6') of the unit.

It is important for water heater maintenance that adequate space

remains available above the water heater.

15

2´

8

´

Air flow

intake

Air flow

intake

Air flow

exhaust

Air flow

exhaust

2´

2´

2´

Air flow

intake

Air flow

exhaust

´

2

´´ x 8´

D0000018502

» Level the water heater horizontally by adjusting the feet.

10.6 Unpacking the water heater

Ensure that the casing material in the lower section

will not be damaged.

Advice - The longer you keep the packaging foil

wrapped around the water heater, the longer it will

be protected against damage.

» Remove the packaging straps.

Page 16

16 | ACCELERA® 300 HEAT PUMP WATER HEATER WWW.STIEBEL-ELTRON-USA.COM

INSTALLATION

INSTALLATION

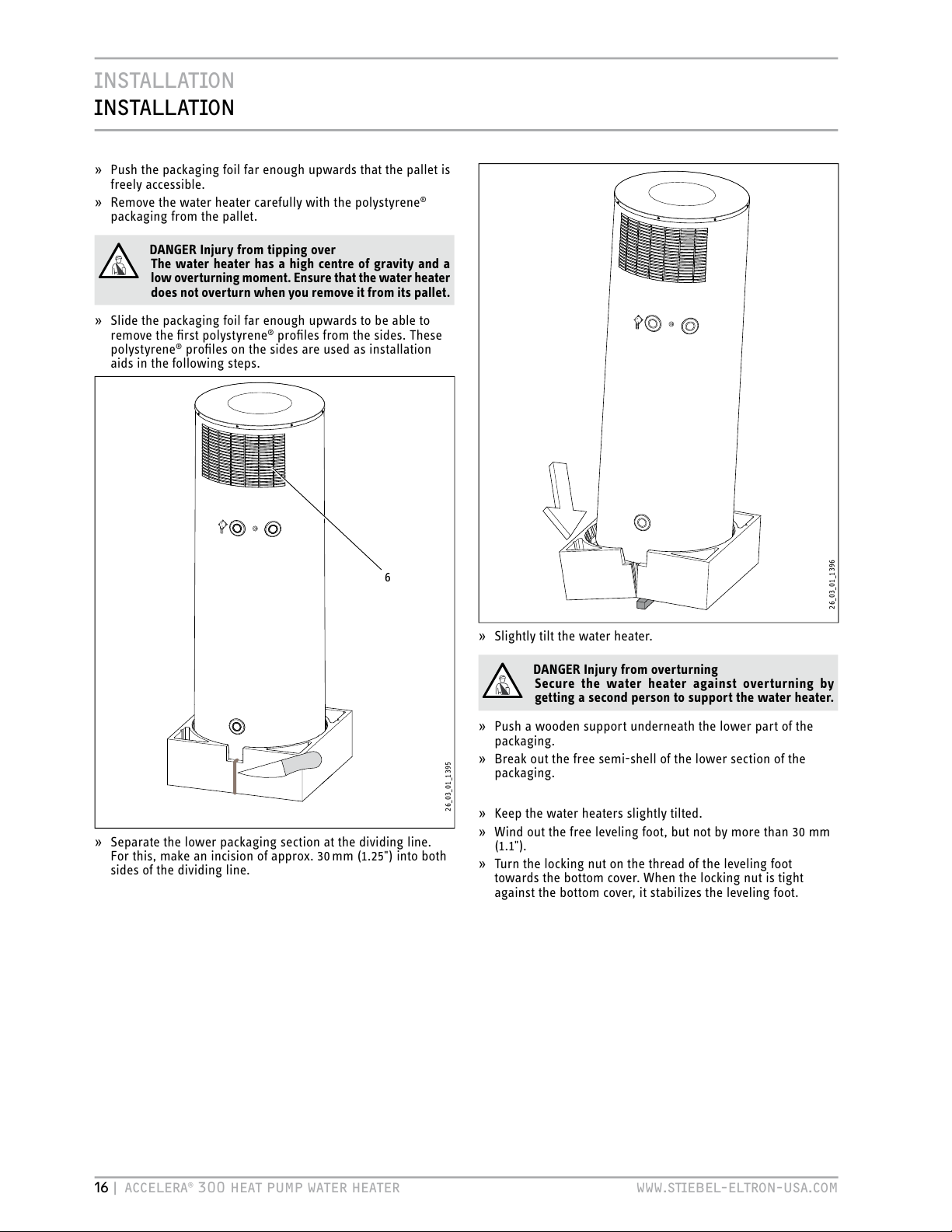

» Push the packaging foil far enough upwards that the pallet is

freely accessible.

» Remove the water heater carefully with the polystyrene

®

packaging from the pallet.

DANGER Injury from tipping over

The water heater has a high centre of gravity and a

low overturning moment. Ensure that the water heater

does not overturn when you remove it from its pallet.

» Slide the packaging foil far enough upwards to be able to

remove the first polystyrene

®

profiles from the sides. These

polystyrene® profiles on the sides are used as installation

aids in the following steps.

26_03_ 01_1395

» Separate the lower packaging section at the dividing line.

For this, make an incision of approx. 30 mm (1.25") into both

sides of the dividing line.

6

26_03_ 01_1396

» Slightly tilt the water heater.

DANGER Injury from overturning

Secure the water heater against overturning by

getting a second person to support the water heater.

» Push a wooden support underneath the lower part of the

packaging.

» Break out the free semi-shell of the lower section of the

packaging.

» Keep the water heaters slightly tilted.

» Wind out the free leveling foot, but not by more than 30mm

(1.1").

» Turn the locking nut on the thread of the leveling foot

towards the bottom cover. When the locking nut is tight

against the bottom cover, it stabilizes the leveling foot.

Page 17

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM ACCELERA® 300 HEAT PUMP WATER HEATER | 17

INSTALLATION

INSTALLATION

26_03_ 01_1384

» Push two polystyrene® installation aids with the step-shaped

corner underneath the water heater. The water heater is

subsequently set and tilted onto this profile. Ensure that you

do not set the water heater down in the area of the joint edge

of the sheet steel jacket, but at least 150 mm (6") along.

26_03_01_1388

» Tilt the water heater that has been set down on the

polystyrene® installation aids.

» Remove the remaining floor semi-shell.

» In the tilted state of the water heater, wind out the second

and third leveling foot, but not by more than 30 mm (1.1").

» In both cases, tighten the locking nut against the bottom

cover.

» Position the water heater on the three leveling feet.

» Level the water heater vertically by adjusting the three

leveling feet.

» Remove any packaging that remains on the water heater.

» Install condensate drain elbow.

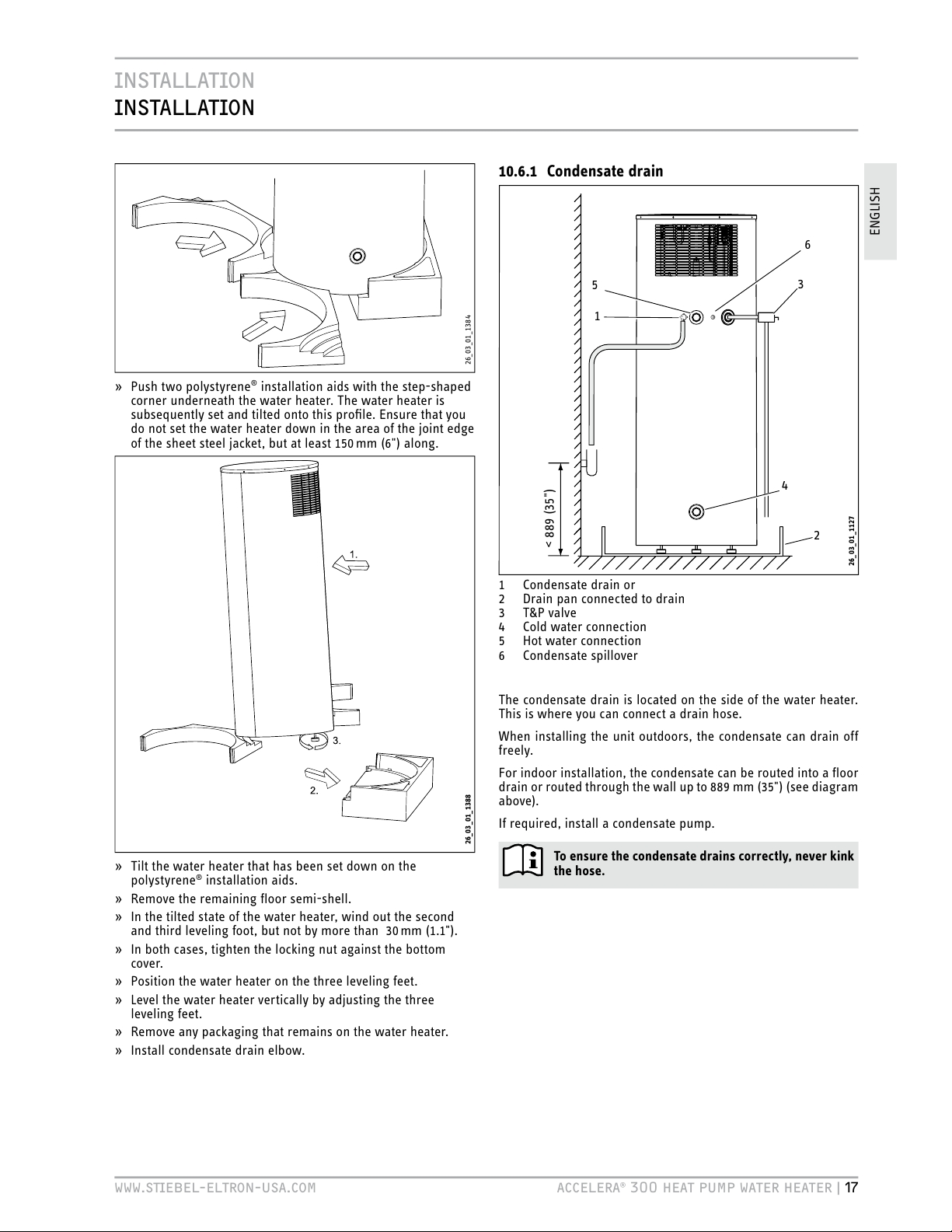

10.6.1 Condensate drain

26_03_01_1127

1

< 889 (35")

2

3

4

5

6

1 Condensate drain or

2 Drain pan connected to drain

3 T&P valve

4 Cold water connection

5 Hot water connection

6 Condensate spillover

The condensate drain is located on the side of the water heater.

This is where you can connect a drain hose.

When installing the unit outdoors, the condensate can drain off

freely.

For indoor installation, the condensate can be routed into a floor

drain or routed through the wall up to 889mm (35") (see diagram

above).

If required, install a condensate pump.

To ensure the condensate drains correctly, never kink

the hose.

Page 18

18 | ACCELERA® 300 HEAT PUMP WATER HEATER WWW.STIEBEL-ELTRON-USA.COM

INSTALLATION

INSTALLATION

10.7 Water connection

The water connection must be carried out by a qualified licensed

plumber.

The cold water connection must comply with DIN1988 [or state

and local codes]

» Prior to installing the water heater, flush the line thoroughly.

HMC

1

5

6

2

3

4

Cold water

7

8

9

10

Hot water

13

14

12

11

26_03_ 01_1123

15

1 Vacuum breaker

2 Hot water connection (Union adaptor to 3/4")

3 Mixing valve (optional, supplied by installer)

4 Connection for T&P valve ¾"

5 T&P valve ¾", 0.69 MPa @99 °C (100 psi @210 °F) (supplied

with unit)

6 0.551 MPa (80 psi) relief valve (optional, supplied by

installer)

7 Expansion tank (optional, supplied by installer)

8 Straight-through shut-off valve (supplied by installer)

9 Check valve (optional, supplied by installer)

10

0.48 MPa (70 psi) pressure reduction valve (optional,

supplied by installer)

11 Cold water connection (with Union adaptor to 3/4")

12

Condensate drain (elbow supplied with unit)

13 Drain valve (supplied by installer)

14 Drain pan (supplied by installer)

15 Condensate spillover

» Remove the protective rubber caps from the connectors.

» With a sharp knife, cut a hole into the protective caps and

install them over the pipe to be connected.

» Connect the plumbing.

» After connecting the plumbing, connect the protective caps

so that the sheet steel casing of the water heater grips into

the outer groove of the protective cap.

Risk of damage through corrosion

To protect against the risk of corrosion, make the

connection with flat gaskets.

» Insulate the hot water line against heat loss.

» Install a drain valve at the lowest point of the cold water

supply.

Install a 0.48 MPa (70 psi) pressure reducing valve on the cold

water inlet.

Accurately maintain the order of fittings on the cold water side

(see diagram 10.7).

10.7.1 Safety valve (on-site provision)

This water heater is a sealed unit. A 0.69MPa, 99°C (100psi,

210°F) T&P relief valve must be installed.

When installing the T&P valve, observe the following:

- Size the drain line so that water can drain off completely,

even if the safety valve is fully open.

- The drain outlet must not be able to be closed and must

always remain open to atmosphere.

- The T&P valve must open at a pressure of 0.69MPa (100 psi)

and be 3/4" pipe thread.

10.7.2 T&P valve (on-site provision)

WARNING Risk of injury through excessive pressure

and temperatures.

Install safety equipment that meets the applicable

regulations for the installation locations. In any case

install a "Pressure and Temperature Relief valve (T&P

relief)" that complies with the requirements of the

ANSIZ21.22 ("Requirements for Relief Valves and

Automatic Gas Shut-off Water heaters for Hot Water

Supply Systems").

The T&P valve must respond at a pressure of 0.69MPa

(100 psi). Fit the T&Pvalve into the opening on the

circumference of the water heater indicated.

Ensure that any expelled water cannot come into

contact with 'live' parts and will not run onto sensitive

surfaces. Ensure that the T&P valve outlet remains

free at all times.

10.8 Power supply: 240V / 15A double pole

circuit breaker

The electrical connection must be carried out by a qualified

electrician.

DANGER Electric shock

Contacting 'live' components results in a risk to life.

» Disconnect the water heater from the power supply

before carrying out work on the control panel.

» Be sure that no one can reconnect the power while

you are working.

When making a connection use code compliant disconnects.

» Undo the screws and remove the water heater cover.

Page 19

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM ACCELERA® 300 HEAT PUMP WATER HEATER | 19

INSTALLATION

INSTALLATION

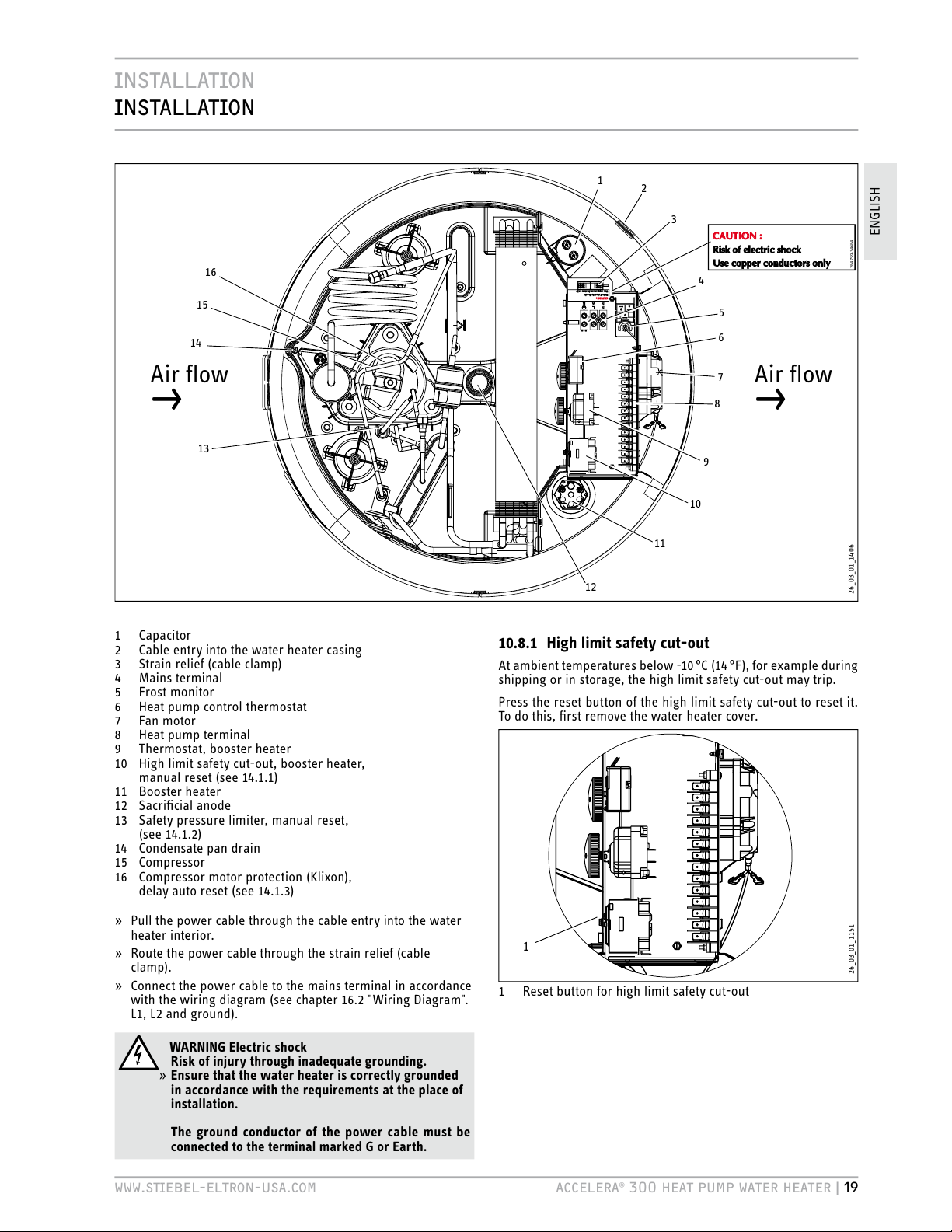

Air flow

→

Air flow

→

CAUTION :

Risk of electric shock

Use copper conductors only

11

10

4

6

3

1

16

15

13

12

8

7

14

9

5

26_03_ 01_1406

2

CAUTION :

Risk of electric shock

Use copper conductors only

1 Capacitor

2 Cable entry into the water heater casing

3 Strain relief (cable clamp)

4 Mains terminal

5 Frost monitor

6 Heat pump control thermostat

7 Fan motor

8 Heat pump terminal

9 Thermostat, booster heater

10

High limit safety cut-out, booster heater,

manual reset (see 14.1.1)

11

Booster heater

12 Sacrificial anode

13

Safety pressure limiter, manual reset,

(see 14.1.2)

14 Condensate pan drain

15

Compressor

16 Compressor motor protection (Klixon),

delay auto reset (see 14.1.3)

» Pull the power cable through the cable entry into the water

heater interior.

» Route the power cable through the strain relief (cable

clamp).

» Connect the power cable to the mains terminal in accordance

with the wiring diagram (see chapter 16.2 "Wiring Diagram".

L1, L2 and ground).

WARNING Electric shock

Risk of injury through inadequate grounding.

» Ensure that the water heater is correctly grounded

in accordance with the requirements at the place of

installation.

The ground conductor of the power cable must be

connected to the terminal marked G or Earth.

10.8.1 High limit safety cut-out

At ambient temperatures below -10 °C (14 °F), for example during

shipping or in storage, the high limit safety cut-out may trip.

Press the reset button of the high limit safety cut-out to reset it.

To do this, first remove the water heater cover.

1

26_03_ 01_1151

1 Reset button for high limit safety cut-out

Page 20

20 | ACCELERA® 300 HEAT PUMP WATER HEATER WWW.STIEBEL-ELTRON-USA.COM

INSTALLATION

INITIAL

START-UP

11.

Initial start-up

11.1 Initial start-up

Only approved, licensed installers may perform the initial start-up

of this water heater, and instruct the user in its operation.

» Fill and vent the water heater. For this, open the cold water

supply and one hot water tap.

» Thoroughly flush the water heater.

» Check the safety valves. Inform the user that water may drip

from the safety valve while water is being heated up.

» Connect power by resetting the circuit breaker.

This water heater must not be operated at ambient

temperatures below 6 °C (43 °F) or above42 °C (107 °F).

11.2 Shutting down

The water heater can only be switched off by disconnecting the

power supply.

11.3 Restarting

If power has been switched off or interrupted, wait 15 minutes

before turning unit back on.

12. Settings

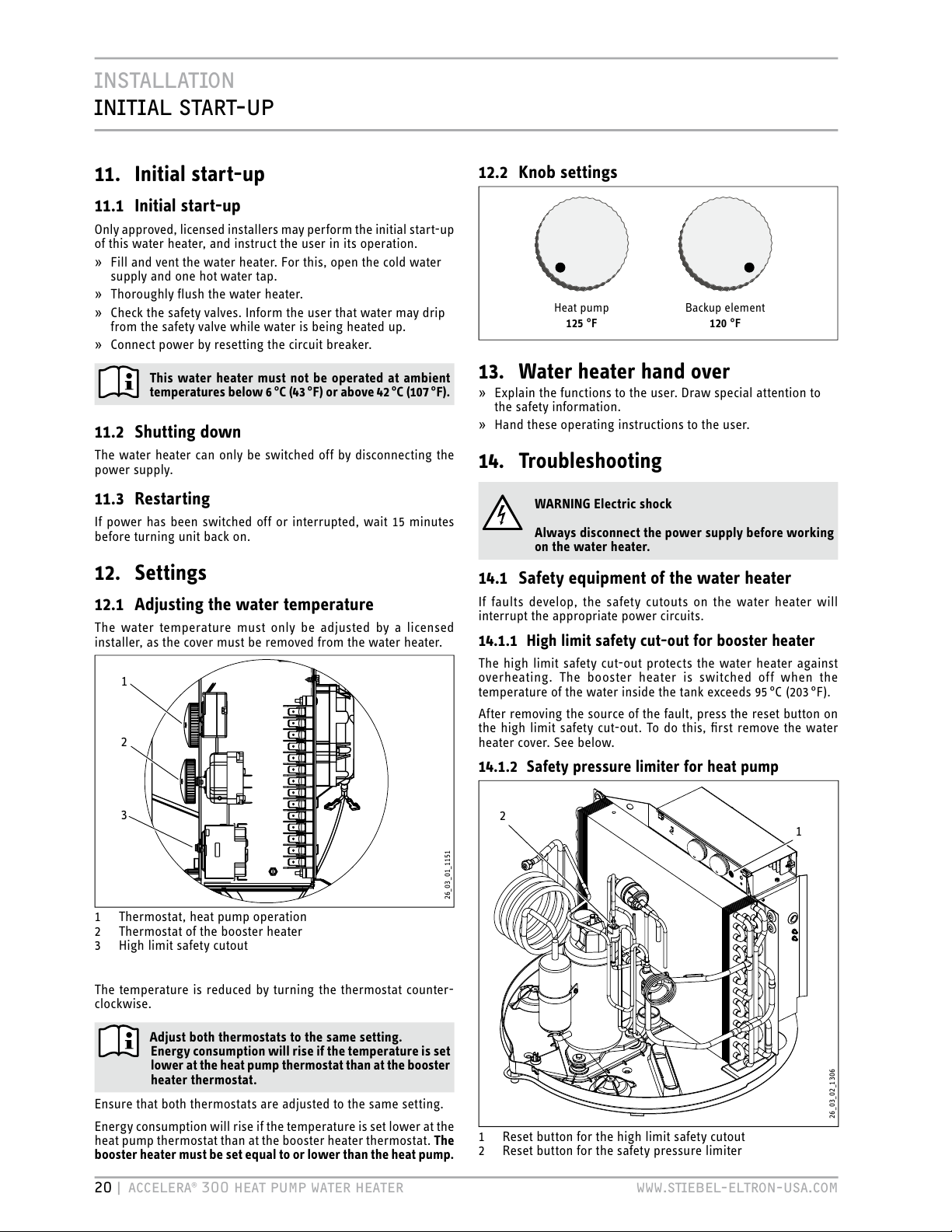

12.1 Adjusting the water temperature

The water temperature must only be adjusted by a licensed

installer, as the cover must be removed from the water heater.

3

26_03_ 01_1151

1

2

1 Thermostat, heat pump operation

2 Thermostat of the booster heater

3 High limit safety cutout

The temperature is reduced by turning the thermostat counter-

clockwise.

Adjust both thermostats to the same setting.

Energy consumption will rise if the temperature is set

lower at the heat pump thermostat than at the booster

heater thermostat.

Ensure that both thermostats are adjusted to the same setting.

Energy consumption will rise if the temperature is set lower at the

heat pump thermostat than at the booster heater thermostat. The

booster heater must be set equal to or lower than the heat pump.

12.2 Knob settings

Heat pump

125 °F

Backup element

120 °F

13. Water heater hand over

» Explain the functions to the user. Draw special attention to

the safety information.

» Hand these operating instructions to the user.

14. Troubleshooting

WARNING Electric shock

Always disconnect the power supply before working

on the water heater.

14.1 Safety equipment of the water heater

If faults develop, the safety cutouts on the water heater will

interrupt the appropriate power circuits.

14.1.1 High limit safety cut-out for booster heater

The high limit safety cut-out protects the water heater against

overheating. The booster heater is switched off when the

temperature of the water inside the tank exceeds 95 °C (203 °F).

After removing the source of the fault, press the reset button on

the high limit safety cut-out. To do this, first remove the water

heater cover. See below.

14.1.2 Safety pressure limiter for heat pump

2

26_03_ 02_1306

1 Reset button for the high limit safety cutout

2 Reset button for the safety pressure limiter

1

Page 21

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM ACCELERA® 300 HEAT PUMP WATER HEATER | 21

INSTALLATION

MAINTENANCE

AND CLEANING

The safety high pressure limiter shuts down the compressor if

the pressure inside the refrigerant circuit exceeds the permissible

maximum value. The safety high pressure limiter may also trip if

the water heater is operated above its permissible limit, i.e. above

an air temperature of 42 °C (107 °F). (See above)

The safety pressure limiter also trips if the heat pump thermostat

fails.

» After the cause of the fault has been removed, reset the

safety pressure limiter by pressing the reset button.

14.1.3 Protective motor switch - klixon

The protective motor switch will shut down the compressor if it is

overloaded because of excessive thermal load. Remove the cause.

After a short cool-down phase, the protective motor switch will

restart the compressor automatically.

14.2 Troubleshooting

14.2.1 Excessive power consumption

» Lower the temperature of the booster heater.

14.2.2 The room temperature falls excessively

One possible cause is an inadequate air flow over the evaporator.

» Check the fan.

» Check for clogged evaporator.

» Ensure that the intake and discharge flow are not restricted.

15. Maintenance and cleaning

Only qualified licensed installers must carry out maintenance work

in accordance with these instructions.

WARNING Electric shock

Maintenance work, such as checking the electrical

safety, must only be carried out by an electrician.

Always disconnect the power supply before working

on the water heater.

15.1 Cleaning the evaporator

WARNING Injury

The evaporator has many sharp-edged fins. When

cleaning the evaporator, proceed with caution and

wear protective clothing, in particular safety gloves.

Maintaining the full output of the water heater at all times requires

an occasional professional cleaning of the evaporator.

» Undo the screws that connect the water heater cover and

remove.

» Carefully clean the evaporator fins. Only use water and a soft

brush. Never use acidic or alkaline cleaning agents.

15.2 Draining the tank

WARNING Scalding

Hot water can be expelled when draining the tank.

» Close the shut-off valve in the cold water line.

» Fully open the hot faucets at all points.

The tank is drained via the cold water supply. Some residual water

will remain in the bottom of the tank.

» Open the drain valve (see chapter 10.7, "Water connection").

If a drain valve was not installed, undo the fitting on the cold water

supply of the water heater.

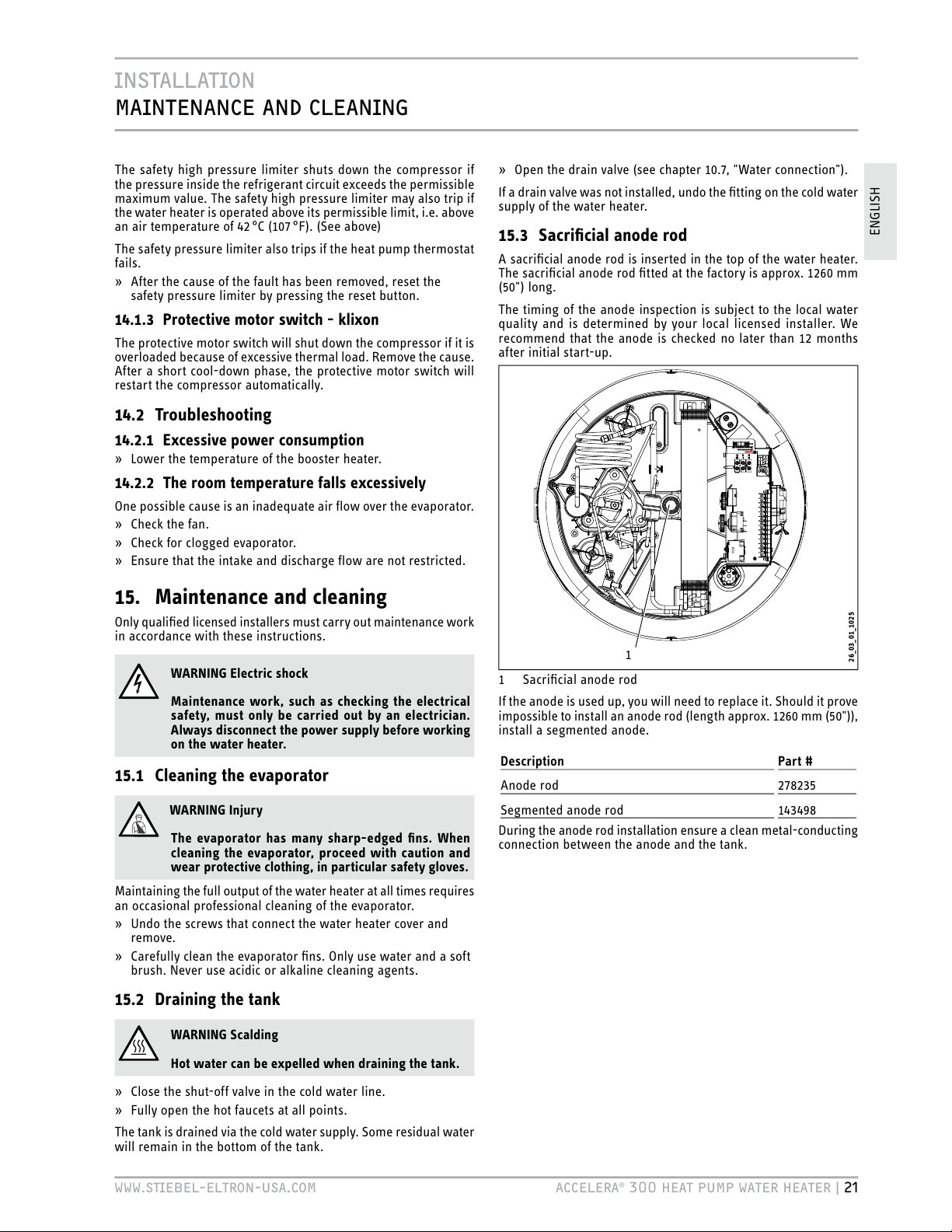

15.3 Sacrificial anode rod

A sacrificial anode rod is inserted in the top of the water heater.

The sacrificial anode rod fitted at the factory is approx. 1260 mm

(50") long.

The timing of the anode inspection is subject to the local water

quality and is determined by your local licensed installer. We

recommend that the anode is checked no later than 12months

after initial start-up.

CAUTION :

Risk of electric shock

Use copper conductors only

26_03_01_1025

1

1 Sacrificial anode rod

If the anode is used up, you will need to replace it. Should it prove

impossible to install an anode rod (length approx. 1260 mm (50")),

install a segmented anode.

Description Part #

Anode rod 278235

Segmented anode rod 143498

During the anode rod installation ensure a clean metal-conducting

connection between the anode and the tank.

Page 22

22 | ACCELERA® 300 HEAT PUMP WATER HEATER WWW.STIEBEL-ELTRON-USA.COM

INSTALLATION

MAINTENANCE

AND CLEANING

15.4 Descaling

» Close the shut-off valve in the cold water supply to the tank.

» Draw water from the tank to relieve the pressure inside the

water heater.

CAUTION :

Risk of electric shock

Use copper conductors only

26_03_01_1025

3

1 Low pressure fill port

2 High pressure fill port

3 Booster heater flange

» Unscrew the booster heater flange and remove element.

» Immerse scaled sections of the heater element into a

descaling liquid (for example citric acid), until the limescale

has dissolved.

» Flush the descaling liquid (white vinegar is another example)

off and allow the immersion heater element to dry.

15.5 Checking valves

15.5.1 Safety valve (on-site provision)

For reasons of safety, it is necessary to check the T&P valve for

proper function from time to time.

» Crack open the safety valve until a full jet of water is

discharged.

» Close the safety valve when the check is complete.

How quickly limescale builds up depends on the local water quality

and the hot water temperature. As your local licensed installers

are familiar with your local water quality, let them determine the

timing of the next service.

15.5.2 Pressure reducing valve (on-site provision)

» Check the on site pressure relief valve for function. If

required, replace the valve.

15.5.3 Checking refrigerant levels

» When checking refrigerant levels at fill ports be sure to use

new crush washers (supplied with unit).

1

2

Page 23

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM ACCELERA® 300 HEAT PUMP WATER HEATER | 23

INSTALLATION

SPECIFICATION

16. Specification

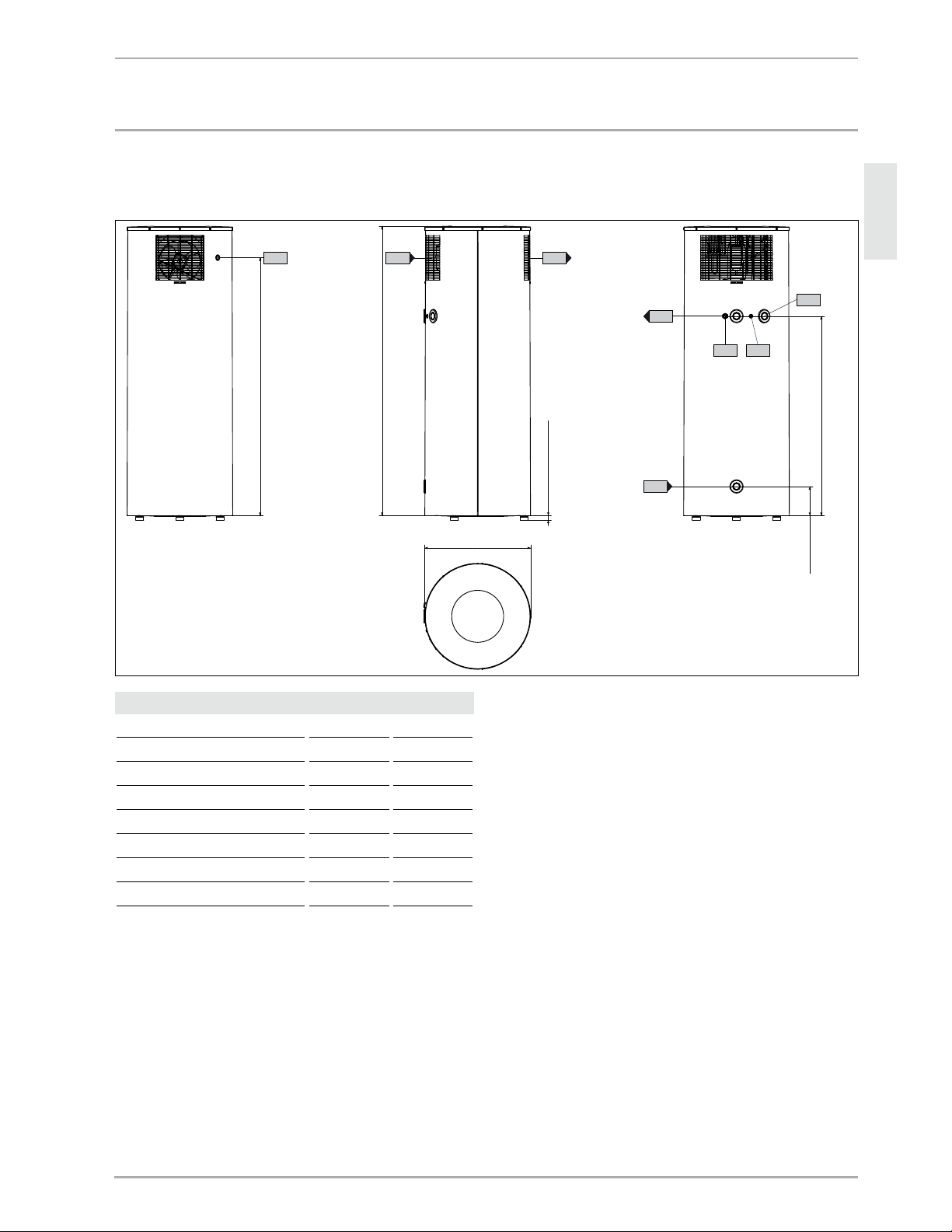

16.1 Connection and dimensions

1840 (72.44")

22-32 (0.87"-1.26")

660 (25.98")

1695 (66.73")

185 (7.28")

1265 (49.8")

b01

g02

g01

c01

c06

c13

d45 d43

D0000018497

Accelera® 300 Connections and dimensions

b01 Entry electrical cables

c01 Cold water inlet Male thread G 1

c06 DHW outlet Male thread G 1

c13 T&P valve Male thread G 3/4

d43 Condensate overflow

d45 Condensate drain Male thread G 3/4

g01 Air intake

g02 Air discharge

Page 24

24 | ACCELERA® 300 HEAT PUMP WATER HEATER WWW.STIEBEL-ELTRON-USA.COM

INSTALLATION

SPECIFICATION

16.2 Wiring diagram

1,65 kW

L1 L2

G

26_03_ 01_0882

E1 Booster heater

F1 High limit safety cut-out, booster heater

F2 Compressor motor protection (Klixon)

F3 Safety pressure limiter (high pressure)

M1 Compressor

M2 Fan

N0 Heat pump control thermostat

N1 Thermostat - booster heater

N2 Frost monitor

X0 Main terminal

X1 Heat pump terminal

X2 Ground, compressor

X3 Ground, booster heater

Z1 Capacitor

Page 25

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM ACCELERA® 300 HEAT PUMP WATER HEATER | 25

INSTALLATION

SPECIFICATION

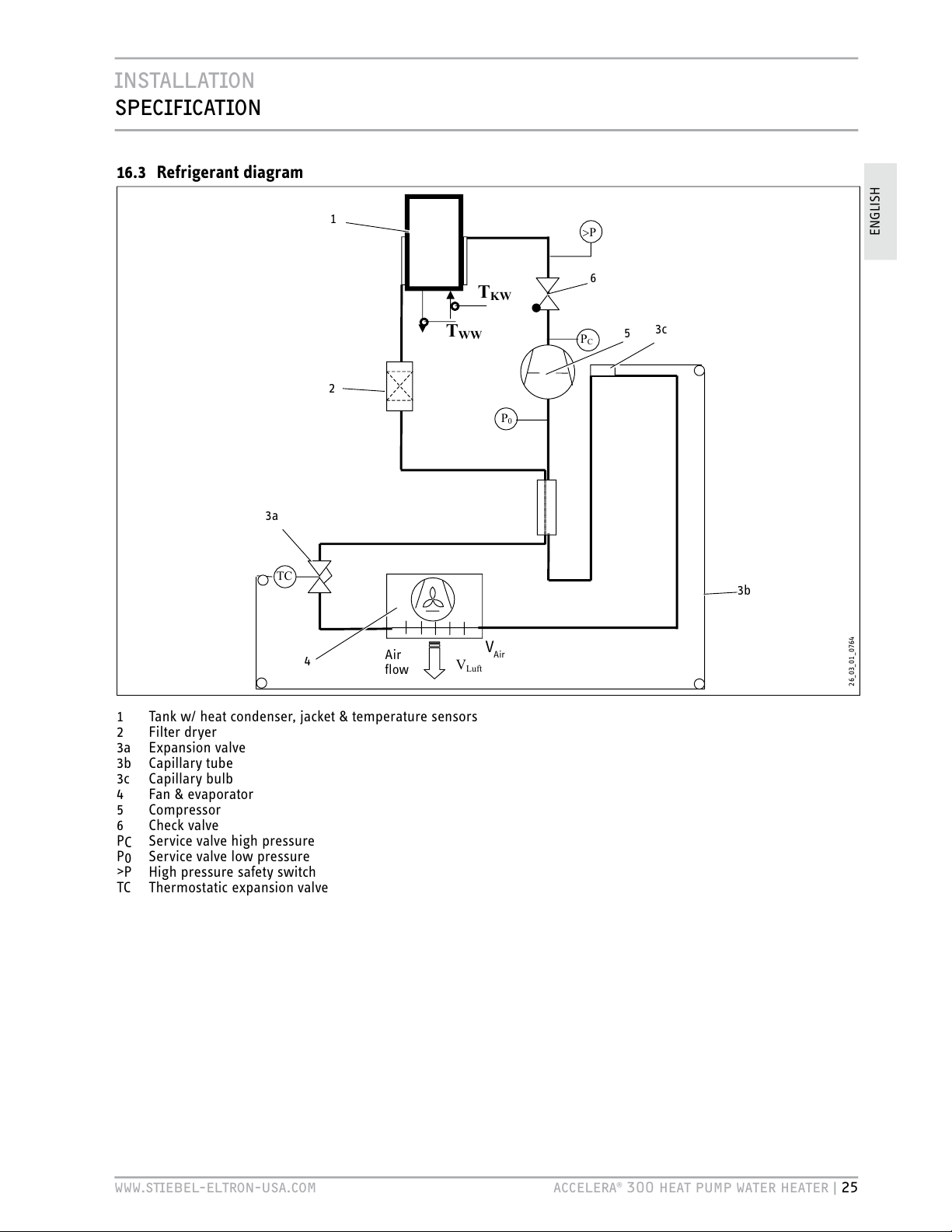

16.3 Refrigerant diagram

P

C

P

TC

V

Luft

T

KW

T

WW

P

0

1

2

3a

3b

4

Air

flow

5

6

26_03_ 01_0764

V

Air

3c

1 Tank w/ heat condenser, jacket & temperature sensors

2 Filter dryer

3a Expansion valve

3b

Capillary tube

3c Capillary bulb

4 Fan & evaporator

5 Compressor

6 Check valve

PC Service valve high pressure

P0 Service valve low pressure

>P

High pressure safety switch

TC

Thermostatic expansion valve

Page 26

26 | ACCELERA® 300 HEAT PUMP WATER HEATER WWW.STIEBEL-ELTRON-USA.COM

INSTALLATION

SPECIFICATION

16.4 Technical Data

Model Heat pump water heater

Type Accelera 300

Part number 222423

Version With passive defrosting and booster heater

Operating details

Lower application limit for heat pump operation

(air temperature)

°C (°F)

6 (42.8)

Upper application limit for heat pump operation

(air temperature)

°C (°F)

42 (107.6)

Hot water temperature, heat pump °C (°F) 60 (140)

Hot water temperature, booster heater °C (°F) 60 (140)

Air flow rate m3/h (CFMs) 550 (324)

Tank capacity l (Gal) 303 (80.044)

Refrigerant R 134a

Refrigerant / filling weight g (oz) 900 (32)

Water heater height (minimum) mm (inch) 1865 (73.43)

Water heater height (maximum) mm (inch) 1903 (74.92)

Water heater diameter mm (inch) 660 (25.98)

Dimension when tilted incl. packaging mm (inch) 2225 (87.60)

Dimension when tilted, excl. top packaging mm (inch) 2150 (84.65)

Dimension when tilted, excl. wooden pallet and top packaging mm (inch) 2030 (79.92)

Dimension when tilted, excl. packaging mm (inch) 1990 (78.35)

Weight (dry tank) kg (lb) 130 (287)

Weight (wet) kg (lb) 432 (950)

Water connection with adaptor Union to 3/4"

Condensate drain 3/4"

Condenser Rollbond safety heat exchanger

Permissible operating pressure, low (cold) side* MPa (Psi) 0.6 (87)

Permissible positive pressure, high (hot) side* MPa (Psi) 2.4 (348.1)

Sound pressure level (spl) dB(A) 55.2

Maximum inlet water temperature °F (°C) 140 (60)

Page 27

ENGLISH

WWW.STIEBEL-ELTRON-USA.COM ACCELERA® 300 HEAT PUMP WATER HEATER | 27

INSTALLATION

SPECIFICATION

Model Heat pump water heater

Electrical details

Power connection, voltage / frequency L1,L2,G / 208-240 V / 60/50 Hz

Protection IP 24

Maximum power consumption (Tamb = 42 °C (108 °F),

Twater = 60 °C (140 °F), 240 V)

kW

2.2

Required circuit breaker size A 15A double pole breaker

Rated power consumption, heat pump A 2.5

Rated power consumption HP (in accordance with

DIN 8947, at 15 °C (59°F) air temperature, 70% relative humidity

and 45 °C (113°F)water temperature)

kW

0.5

Power consumption, booster heater kW 1.690

Heating output HP (at 15 °C (59°F) air temperature, 70% relative

humidity, water heat-up from 15 °C(59°F) to 60 °C (140 °F), in

accordance with EN 255 T3, 240V/60Hz)

kW

approx. 1.7

Coefficient of Performance (COP) (t) (at 15 °C (59 °F) air

temperature, 70% relative humidity, water heat-up from 15 °C (59

°F) to 60 °C (140 °F), in accordance with

EN 255 T3, 240V/60Hz)

3.18

* Standard automotive R-12/R-134A manifold gauge set can be used to test and fill refrigerant.

Page 28

WARRANTY

ENvIRONMENT AND RECYCLING

28 | ACCELERA 300 WWW.STIEBEL-ELTRON-USA.COM

Environment and recycling

Please help us protect the environment. Dispose of the appliance

and its packaging in accordance with national regulations.

KYOTO | R134a

This device is filled with refrigerant R134a.

Refrigerant R134a is a CFC greenhouse gas mentioned in the Kyoto

protocol with a global greenhouse potential (GWP) = 1300.

Never release refrigerant R134a to atmosphere.

WARRANTY

Stiebel Eltron warrants to the original owner that the Accelera® 300 heat pump water heater will be free from defects in

workmanship and materials for a period of ten (10) years from the date of purchase.

Should the part(s) prove to be defective under normal use during this period, Stiebel Eltron, Inc. will be responsible for

replacement of the defective part(s) only. Stiebel Eltron, Inc. will not be liable for any costs of transportation, removal,

reinstallation, or any other labor or freight charges that may arise in connection with a warranty claim or any incidental or

consequential expenses.

This warranty does not apply:

1. To conditions resulting from a failed component or part that is not part of the heat pump

Water heater

2. To freeze damage

3. To conditions resulting from misuse, abuse, neglect, accident, or alteration