Stiebel Eltron 230628 Installation Manual

OPERATION AND INSTALLATION

OPERACIÓN E INSTALACIÓN

UTILISATION ET INSTALLATION

ELECTRONICALLY CONTROLLED ELECTRIC TANKLESS WATER HEATER

CALENTADOR INSTANTÁNEO CON CONTROLADO ELECTRÓNICA

CHAUFFE-EAU INSTANTANÉ À GESTION ÉLECTRONIQUE

» DHC-E 8/10

» DHC-E 11 L

» DHC-E 12

Conforms to ANSI/UL Std. 499

Certified to CAN/CSA Std. E335-1 & E335-2-35

Conforme a ANSI/UL Std. 499

Certificación con CAN/CSA Std. E335-1 & E335-2-35

Conforme à la norme ANSI/UL Std. 499

Certifié à la norme CAN/CSA Std. E335-1 & E335-2-35

Tested and certified by WQA to NSF/ANSI372

for lead free compliance.

Probado y certificado por WQA NSF/ANSI 372 para

el cumplimiento de las regulaciones sin plomo.

Testé et certifié par WQA à la NSF/ANSI 372 pour une

utilisation sans plomb.

CONTENTS | OPERATION

OPERATION

1. General information _________________________________________2

1.1 Safety information ����������������������������������������������� 2

1.2 Other symbols in this document ������������������������������ 3

2. Safety __________________________________________________________ 3

2.1 Intended use ������������������������������������������������������ 3

2.2 General Information��������������������������������������������� 3

2.3 Safety Precautions ����������������������������������������������� 3

2.4 Test symbols ������������������������������������������������������ 3

3. Register your product _______________________________________4

4. General ________________________________________________________4

5. Troubleshooting ______________________________________________4

INSTALLATION

6. Mounting the appliance _____________________________________5

6.1 Application �������������������������������������������������������� 5

6.2 Mounting ���������������������������������������������������������� 5

7. Water connections ___________________________________________6

8. Electrical connection _________________________________________6

8.1 DHC-E 8/10 - Appliance with output power options ������ 6

8.2 DHC-E 11 L ��������������������������������������������������������� 7

8.3 Temperature setting/anti-scalding protection ������������� 7

8.4 Terminal block ���������������������������������������������������� 7

9. Commissioning _______________________________________________7

9.1 Appliance handover ��������������������������������������������� 7

10. Troubleshooting ______________________________________________7

10.1 Diagnostic lights ������������������������������������������������� 7

10.2 Fault table ��������������������������������������������������������� 7

10.3 Resetting the safety thermal cutout ������������������������� 8

11. Normal maintenance _________________________________________8

12. Technical Data ________________________________________________8

12.1 Dimensions diagram �������������������������������������������� 8

12.2 Wiring diagram �������������������������������������������������� 9

12.3 Maximum temperature increase above ambient water

temperature ����������������������������������������������������� 10

12.4 Data table �������������������������������������������������������� 11

13. Spare parts _________________________________________________ 12

14. Warranty ____________________________________________________ 13

OPERATION

1. General information

Note

Read these instructions carefully before using the appliance and familiarize yourself with its functions. Keep

these instructions safe. Pass on the instructions to a new

user if required.

1.1 Safety information

1.1.1 Structure of safety information

KEYWORD: Type of risk

Here, possible consequences are listed that may

result from not observing the safety information.

f Steps to prevent the risk are listed.

1.1.2 Symbols. type of risk

Symbol Type of risk

Injury

!

1.1.3 Keywords

KEYWORD Description

DANGER If this information is not observed, it will result in serious

WARNING If this information is not observed, it can result in serious

CAUTION If this information is not observed, it can lead to medium

Electrocution

Burns or scalding

injury or death.

injury or death.

or minor injury.

2 | DHC-E www.stiebel-eltron-usa.com

OPERATION

SAFETY

1.2 Other symbols in this document

Note

Notes are bordered by horizontal lines above and below

the text. General information is identified by the symbol

shown on the left.

f Read these notes carefully.

Symbol

!

f This symbol indicates that you have to do something. The ac-

tion you need to take is described step by step.

Damage to the appliance and environment

Appliance disposal

2. Safety

Observe the following safety information and regulations.

Operate the appliance only when fully installed and with all safety

equipment fitted.

2.1 Intended use

The appliance is intended for heating domestic hot water and can

supply several draw-off points.

Any other use beyond that described shall be deemed inappropriate.

Observation of these instructions is also part of the correct use

of this appliance.

2.2 General Information

Read this entire manual. Failure to follow all the guides, instructions and rules could cause personal injury or property damage.

Improper installation, adjustment, alteration, service and use of

this appliance can result in serious injury.

Damage to the appliance and the environment

!

The appliance must be installed by a licensed electrician and plumber. The installation must comply with all

national, state and local plumbing and electric codes.

Service of the appliance must be performed by qualified

service TECHNICIANS.

DANGER: Electrocution

Before proceeding with any installation, adjustment.

alteration, or service of this appliance all circuit breakers and disconnect switches servicing the appliance

must be turned off. Failure to do so could result in

serious personal injury or death.

DANGER: Electrocution

Never remove the appliance‘s cover unless the electricity servicing the appliance is turned off. Failure to do

so could result in personal injury or death.

DANGER: Electrocution

The appliance must be properly grounded. Failure to

electrically ground the product could result in serious

personal injury or death.

DANGER: Burns

Water temperatures over 125 °F (52 °C) can cause severe

burns instantly or death from scalding. A hot water

scalding potential exists if the thermostat on the appliance is set too high. Households with small children,

disabled or elderly persons may require that the thermostat be set at 113 °F (45 °C) or lower to prevent possible injury from hot water.

WARNING: Injury

!

Where children or persons with limited physical, sensory or mental capabilities are to be allowed to control

this appliance, ensure that this will only happen under

supervision or after appropriate instructions by a person responsible for their safety.

Children should be supervised to ensure that they never

play with the appliance.

2.4 Test symbols

ENGLISH

This appliance must be installed by a licensed electrician and

plumber. The installation must comply with all national, state and

local plumbing and electric codes. Proper installation is the responsibility of the installer. Failure to comply with the installation

and operating instructions or improper use voids the warranty.

Save these instructions for future reference. Installer should leave

these instructions with the consumer.

If you have any questions regarding the installation, use or operation of this water heater, or if you need any additional installation

manuals, please call our technical service line, see last side.

See type plate on the appliance.

2.3 Safety Precautions

DANGER: Injury

!

Please read and follow these instructions.

Failure to follow these instructions could result in serious personal injury or death.

www.stiebel-eltron-usa.com DHC-E | 3

OPERATION

REGISTER YOUR PRODUCT

3. Register your product

You must register this product within 90 days of purchase

on our web site in order to activate the standard

warranty or to be eligible for the extended warranty. Go to

our web site at www.stiebel-eltron-usa.com and click on

“Register Your Product.”

Before beginning the registration process, we suggest that

you gather the necessary information which will be as

follows:

Type, Example: DHC-E

Number listed after “Nr.”

Place of Purchase

Purchase Date

First & Last Name

Email address

Physical Address

Phone Number

Installation Date

If you have any questions concerning the registration process

or warranty options, please contact Stiebel Eltron USA directly at 800.582.8423.

In case the “Power” light is flashing while the appliance operates,

the water flow rate exceeds the heating capacity of the appliance. Reduce the hot water flow rate in order to let the appliance

achieve the set point temperature. The maximum temperature is

electronically limited to 140 °F (60 °C). In case you have questions

regarding the way you plan to use the appliance, please call our

technical service line, see last side.

5. Troubleshooting

Symptom Possible Cause f Solution

No hot water not enough flow rate to

activate appliance

Water not hot enough water flow too high reduce water flow rate until

If you cannot remedy the fault, notify the contractor who installed

the appliance. To facilitate and speed up your enquiry, please provide the serial number from the type plate (000000-0000-000000).

clean faucet aerator or shower

head

light on front cover stops

blinking

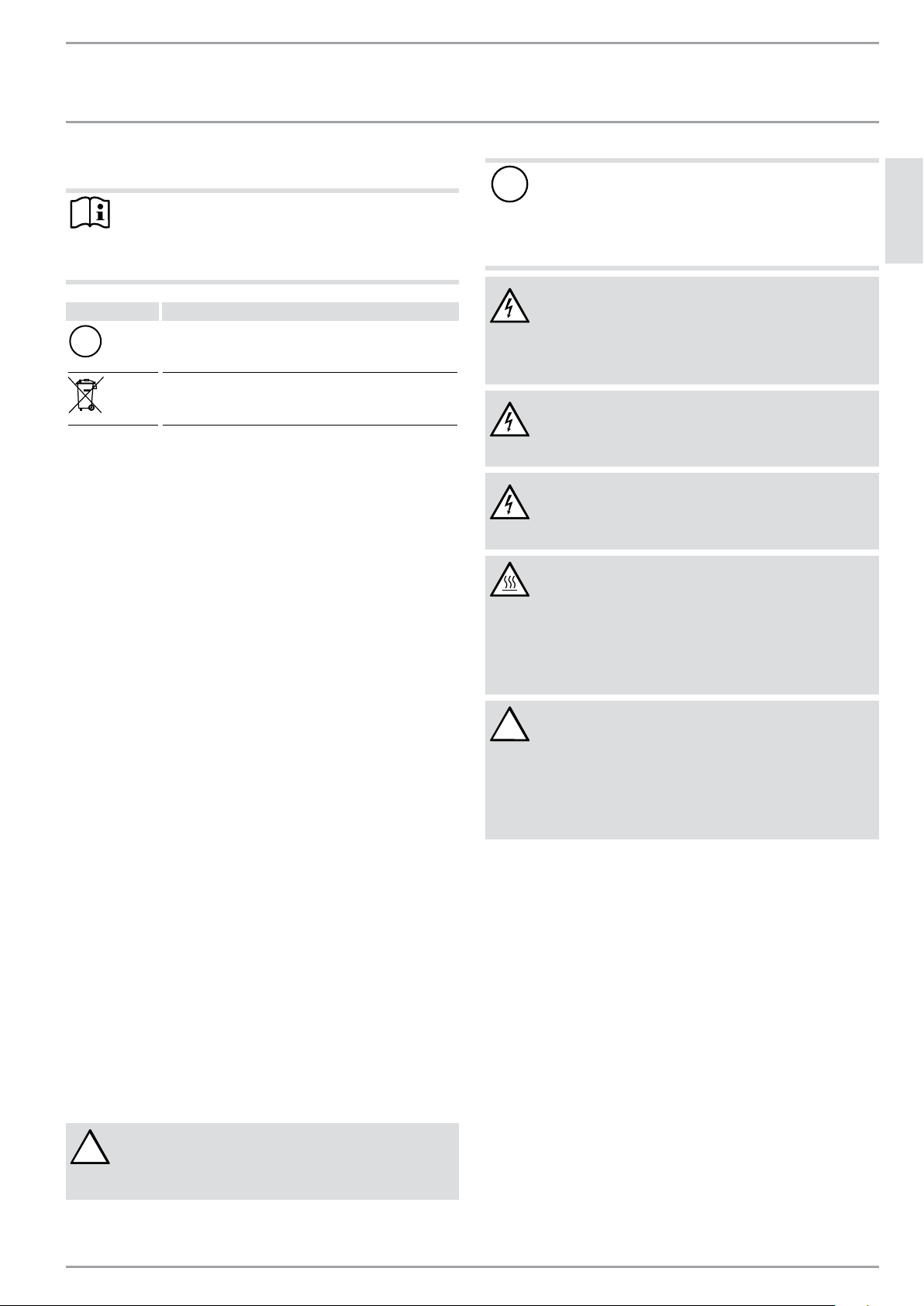

4. General

The tankless water heater differs from conventional storage type

water heaters in several ways. It does not store hot water. Instead,

water is heated instantaneously as it flows through the appliance.

Due to the absence of stand-by losses, the appliance offers greater

energy efficiency than storage type water heaters.

The input of heat into the water is electronically controlled. The

appliance will deliver any water temperature between 86 °F (30 °C)

and 140 °F (60 °C). Please set the desired temperature using the

knob on the front cover.

26�02�02�1086

Note:

For reasons of appliance efficiency and durability (scaling), the optimum temperature setting lies between 86 °F

(30 °C) and 120 °F (50 °C).

4 | DHC-E www.stiebel-eltron-usa.com

INSTALLATION

MOUNTING THE APPLIANCE

INSTALLATION

6. Mounting the appliance

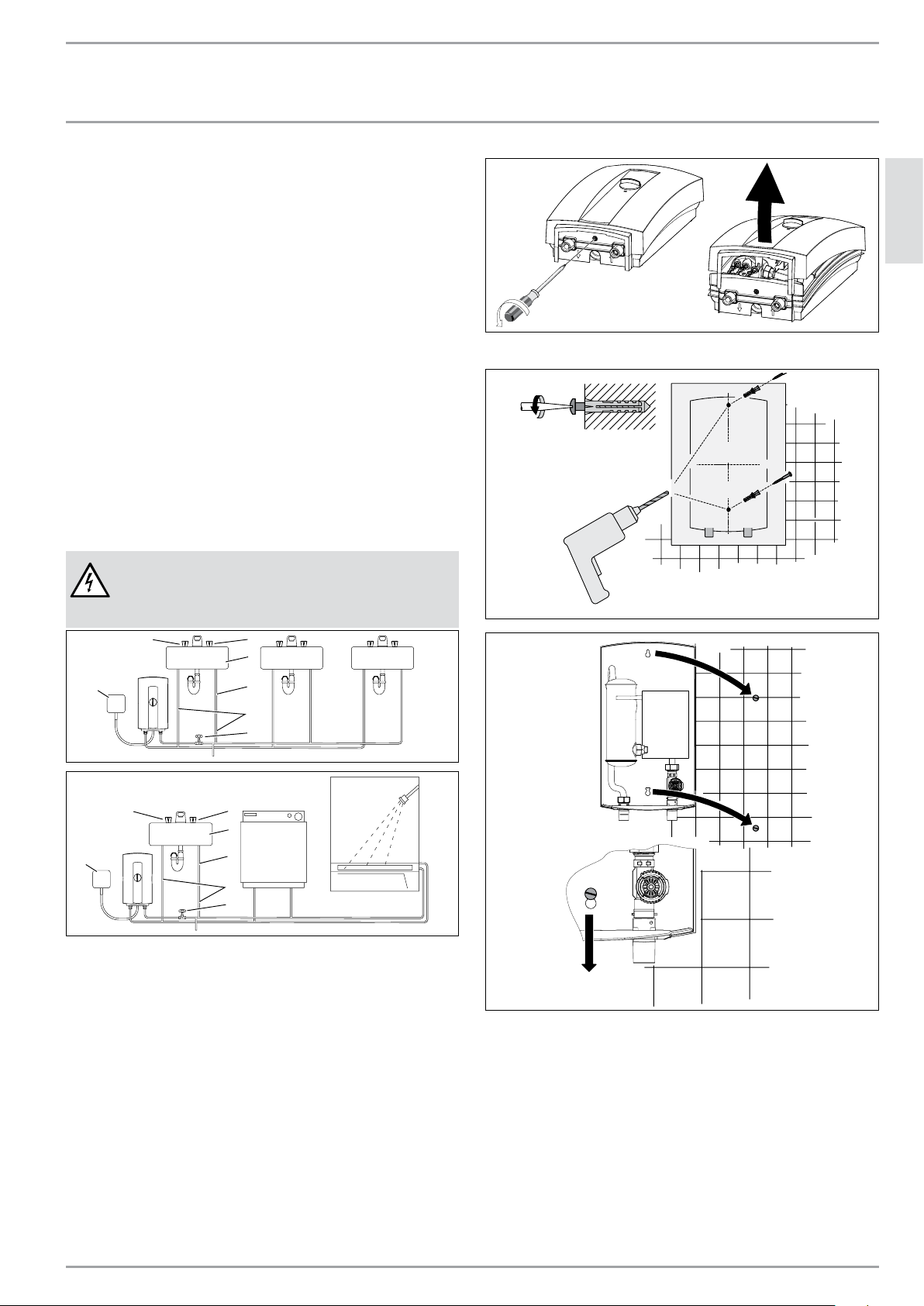

6.1 Application

ENGLISH

One appliance can be used for the following applications:

one or multiple hand washing sinks

one kitchen sink

cabins with flow restriction at shower head.

A combination of two appliance can be used for whole apartment

and house applications. Please contact STIEBEL ELTRON for special

installation instructions.

All areas with a ground water temperature likely to exceed 65 °F

(18 °C) year round:

Whole apartment or house

CAUTION: Electrocution

Unit must be installed in a vertical position with the

water fittings pointing downward. In this position the

unit is splashproof, so that no water can soak in.

1 2

3

7

4

5

6

26�02�02�1083

f Remove plastic cover.

26�02�02�033126�02�02�1090

26�02�02�1082

1

7

1 Hot valve (left)

2 Cold valve (right)

3 Sink

4 ½˝ main pipe

5 Water supply line for faucet installation

6 Shut-off valve

7 Electrical junction box

2

3

4

5

6

6.2 Mounting

f Install appliance as close as possible to the main hot water

draw-off points.

f Install appliance in a frost free area. If frost may occur, re-

move appliance before freezing temperatures set in.

f Leave a minimum of 5˝ (125 mm) of clearance on all sides for

servicing.

26�02�02�1081

f Screw the screws into the wall and hang the appliance.

Screws and plastic wall anchors for mounting on masonry or

wood are provided.

f Secure the screws.

www.stiebel-eltron-usa.com DHC-E | 5

INSTALLATION

WATER CONNECTIONS

7. Water connections

Damage to the appliance and the environment:

!

Excessive heat from soldering on copper pipes near the

DHC may cause damage.

f All plumbing work must comply with national and applicable

state and local plumbing codes.

f Notice for Australia / New Zealand:

The installation shall comply with AS/NZS 3500.4.

f A pressure reducing valve must be installed if the cold water

supply pressure exceeds 150 psi (10 bar).

f Make certain that the cold water supply line has been flushed

to remove any scale and dirt.

f Install isolating valve in cold water line as shown in illustra-

tion “Mounting the appliance”. This allows the appliance to

be isolated for maintenance purposes.

f Cold water connection (inlet) is on the right side of the ap-

pliance, hot water connection (outlet) is on the left side of

appliance.

f Tankless water heaters such as the DHC-E are not required to

be equipped with a Pressure and Temperature Relief Valve

(P&T). If the local inspector will not pass the installation

without a P&T, it should be installed on the hot water outlet

side of appliance.

f The appliance is designed for connection to copper tubing,

PEX tubing or a braided stainless steel hose with a ½˝ NPT

female tapered thread. If soldering near the appliance is necessary, please direct the flame away from the plastic housing

of the appliance in order to avoid damage.

DANGER: Electrocution

As with any electric appliance. failure to electrically

ground appliance may result in serious injury or death.

f The appliance should be connected to a properly grounded

dedicated branch circuit of proper voltage rating. In installations with several appliances, each appliance requires an

independent circuit. Please refer to the technical data table

for the correct wire and circuit breaker size.

4˝ (100 mm)

f The wire must be fed through the rubber seal located be-

tween the hot and cold water connections. Then feed wires

through strain relief clamp and tighten clamp down on wire.

The „live“ wires must be connected to the slots on the terminal block marked L and L (L and N). The ground wire must

be connected to slot marked with the ground symbol. Strain

relief clamp with screws and rubber seal are provided.

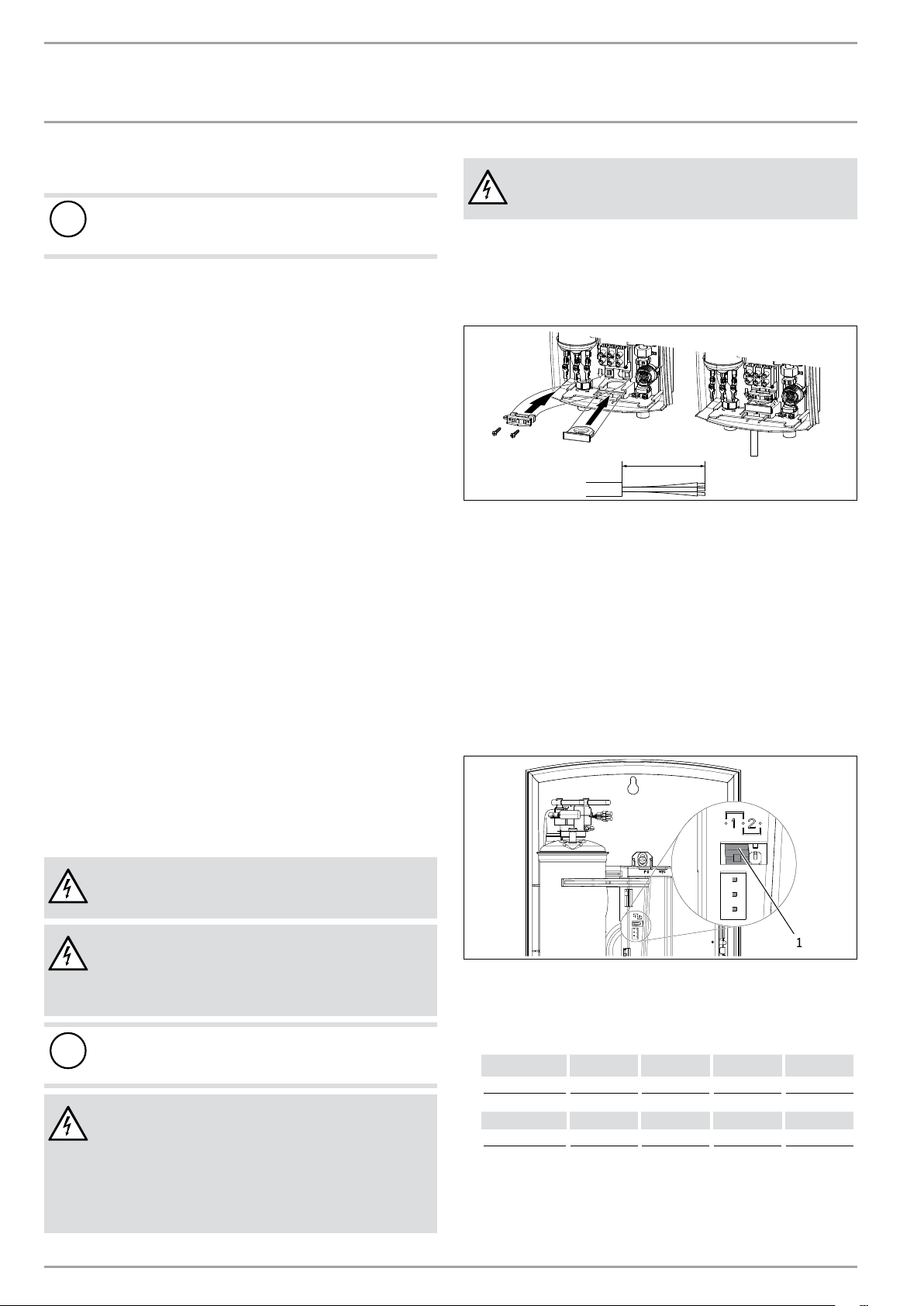

8.1 DHC-E 8/10 - Appliance with output power options

For the DHC-E 8/10 instantaneous water heater, the output power

is adjustable in 2 stages. In its delivered condition the appliance

is set to 7.2 kW@240 V.

26�02�02�1084

f When all plumbing work is completed, check for leaks and

take corrective action before proceeding.

8. Electrical connection

DANGER: Electrocution

Carry out all electrical connection and installation work

in accordance with relevant regulations.

DANGER: Electrocution

Only use a permanent connection to the power supply.

The appliance must be able to be separated from the

power supply by an isolator that disconnects all poles

with at least 1/8˝ (3mm) contact separation.

Damage to the appliance and the environment:

!

Observe the type plate. The specified voltage must match

the mains voltage.

DANGER: Electrocution

Before beginning any work on the electric installation, be sure that main breaker panel switch is “off”

to avoid any danger of electric shock. All mounting and

plumbing must be completed before proceeding with

electrical hook-up. Where required by local, state or

national electrical codes the circuit should be equipped

with a “ground fault interrupter”.

1

1 coding plug

If the appliance should be installed with a different output power,

take the following steps:

f Insert the coding plug to the desired performance.

Stage 1 208 V 220 V 230 V 240 V

5.4 kW 6.0 kW 6.6 kW 7.2 k W

Stage 2 208 V 220 V 230 V 240 V

7.2 kW 8.1 kW 8.8 kW 9.6 kW

f Mark the selected output power and voltage on the type plate

with a permanent marker.

26�02�02�1088

6 | DHC-E www.stiebel-eltron-usa.com

INSTALLATION

COMMISSIONING

8.2 DHC-E 11 L

The DHC-E 11 L is only designed for a 208 V or 220 V connection.

Do not connect to a 120 V or a 230–240 V electrical service.

8.3 Temperature setting/anti-scalding protection

f Connect the lead of the electronic temperature control to po-

sition “A1” in order to get the maximum outlet temperature

of 140 °F (60 °C).

The maximum temperature can be limited to 109 °F (43 °C):

f Connect the lead of the electronic temperature control to po-

sition “A2”.

f Reinstall the plastic cover.

8.4 Terminal block

Consult the chart below for the recommended torque amounts on

the terminal block screws.

f Check the water temperature with your hand and make sure

that it does not feel too hot. Reduce temperature if this is

necessary. A setting of 108–116 °F (42–47 °C) is recommended

for most applications.

f Explain to the user how the appliance works and familiarise

him or her with its use.

f Advise the user about possible hazards (hot water tempera-

ture up to 140 °F (60 °C). Hand over these instructions, to be

kept for future reference.

f A setting of 108–116 °F (42–47 °C) is recommended for most

applications.

9.1 Appliance handover

Explain the functions of the appliance to the user. Draw special

attention to the safety information. Hand the operating and installation instructions to the user.

26�02�02�1089

10. Troubleshooting

DANGER: Electrocution

To test the appliance, it must be supplied with power.

10.1 Diagnostic lights

Display options

red illuminates in case of faults

yellow illuminates when the appliance is heating water

green flashing: The appliance is supplied with power

ENGLISH

Screw Size (mm) Min. Torque (N•cm) Min. Torque (lbf•in)

M6 200–250 17.7–22.1

Using the proper torque specifications to secure wire to the wiring

block helps to avoid personal loss or property damage.

9. Commissioning

DANGER: Electrocution

Commissioning must only be carried out by an authorized contractor in accordance with safety regulations.

Damage to the appliance and the environment:

!

Open hot water faucet for a few minutes until water flow

is continuous and all air is purged from water pipes. The

appliance’s plastic cover must be installed before the circuit breaker is turned on.

f Turn on circuit breaker to bring electrical power to the

appliance.

f Turn the temperature selector clockwise and anti-clockwise,

to calibrate the temperature selector.

f Adjust the water temperature to the desired level using the

knob on the front cover of the appliance.

f Turn on hot water and wait twenty seconds until temperature

has stabilized.

1

1 LED diagnostic “traffic lights”

10.2 Fault table

Symptom Possible Cause f Solution

No hot water

clean faucet aerator or

Not enough hot water filter screen clogged clean filter screen at appli-

Water not hot enough water flow too high

supply correct voltage to ap-

circuit breaker off

safety thermal cut-out

tripped

not enough flow rate to

activate appliance

turn circuit breaker on

reset thermal cut-out

clean filter screen at appliance

shower head

ance

reduce water flow rate until

light on front cover stops

blinking

pliance

26�02�02�1088

www.stiebel-eltron-usa.com DHC-E | 7

INSTALLATION

NORMAL MAINTENANCE

f If you are not able to resolve a problem please contact us,

(see rear cover), before removing the appliance from the

wall. STIEBEL ELTRON is happy to provide technical assistance. In most instances, we can resolve the problem over the

phone.

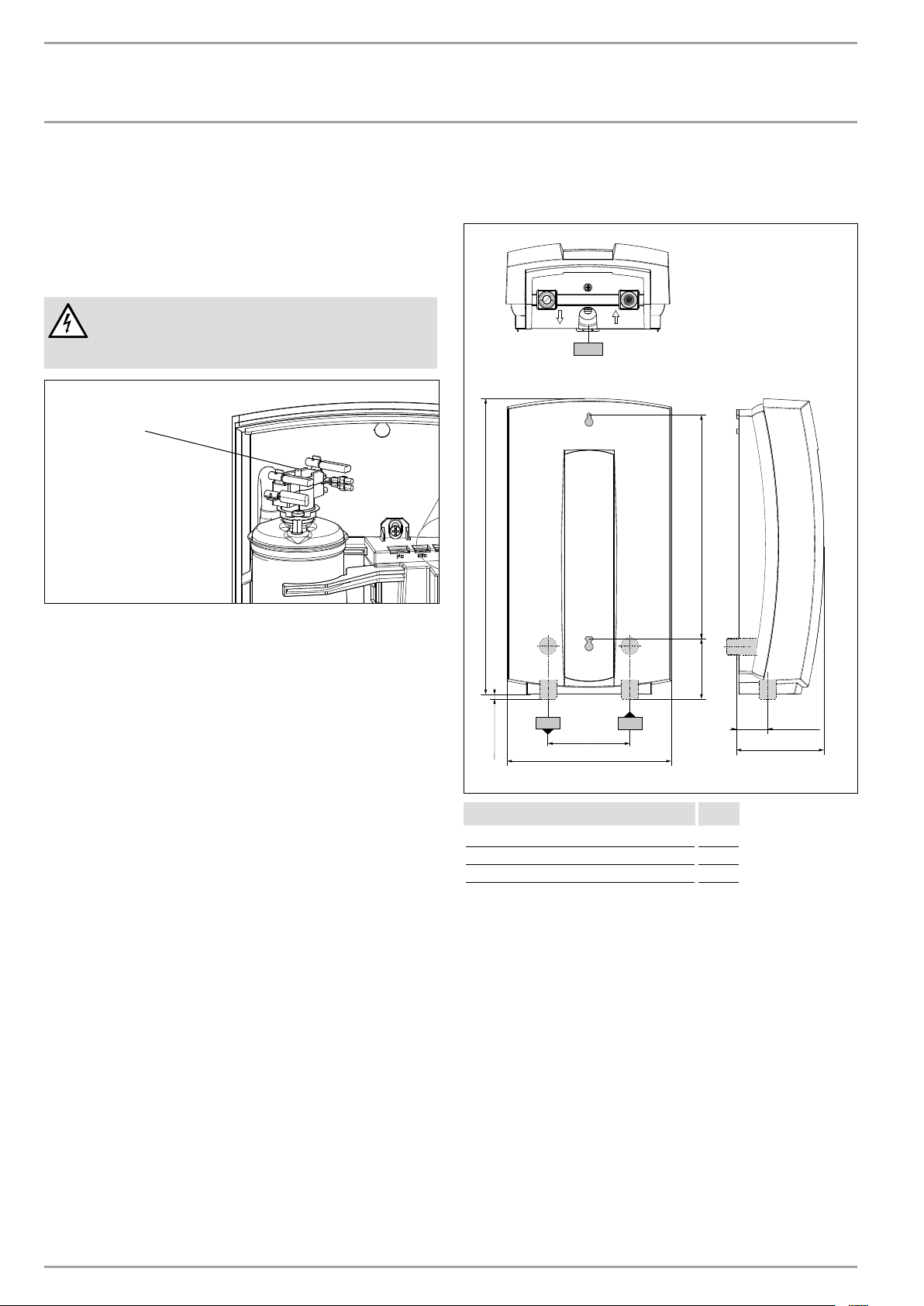

10.3 Resetting the safety thermal cutout

DANGER: Electrocution

Do not attempt to reset the safety thermal cutout of

this water heater unless power to the unit has been

completely shut off at the circuit breakers.

Safety

thermal

cutout

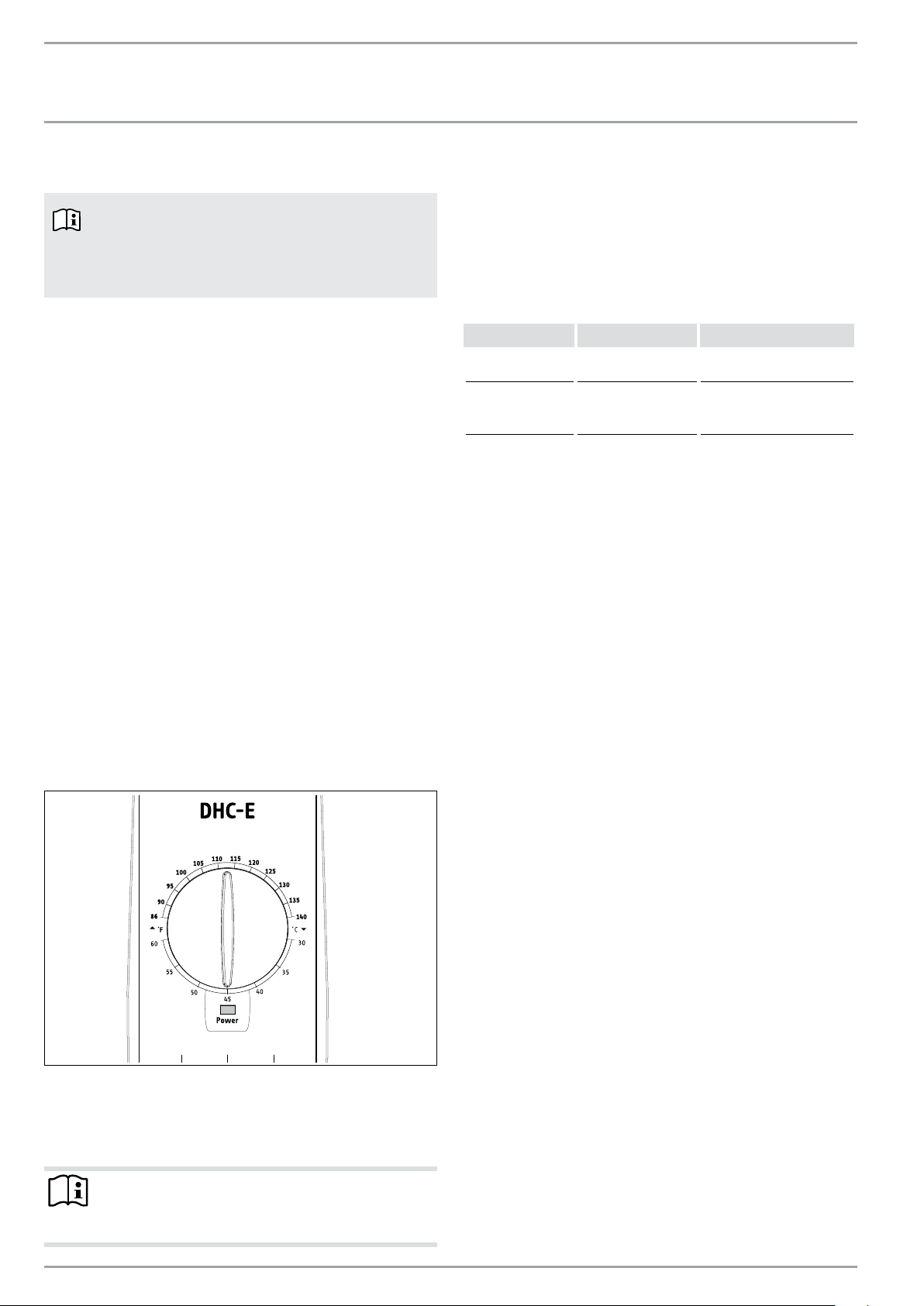

12. Technical Data

12.1 Dimensions diagram

b01

26�02�02�1089

14¼˝(36 cm)

10¾˝(27.3 cm)

The safety thermal cutout on the DHC-E is designed to cut off

electrical power to the heating elements if water of too high a

temperature is encountered. When the safety cutout has tripped,

it must be reset manually.

To reset the safety cutout, use the following procedure:

f Turn off the circuit breaker attached to the water heater

f Remove the front cover of the water heater

f Identify the safety thermal cutout on the top of the copper

heating canister. The button at the top is the reset button.

f Press down on the button, take note of whether it clicks or

not when pressed.

11. Normal maintenance

STIEBEL ELTRON tankless water heaters are designed for a very

long service life. Actual life expectancy will vary with water quality and use. The appliance itself does not require any regular

maintenance.

However, to ensure consistent water flow, it is recommended to

periodically remove scale and dirt that may build up at the aerator of the faucet(s), the filter screen in the appliance, or in the

shower head.

3˝(7.5 cm)

c06

c06 c01

¼˝(.8 cm)

b01 Electrical cable entry

c01 cold water inlet ½˝ NPT

c06 hot water outlet ½˝ NPT

4˝(10 cm)

7¾˝(20 cm)

c01

1½˝(3.8 cm)

4¼˝(11 cm)

D0000017762

8 | DHC-E www.stiebel-eltron-usa.com

INSTALLATION

TECHNICAL DATA

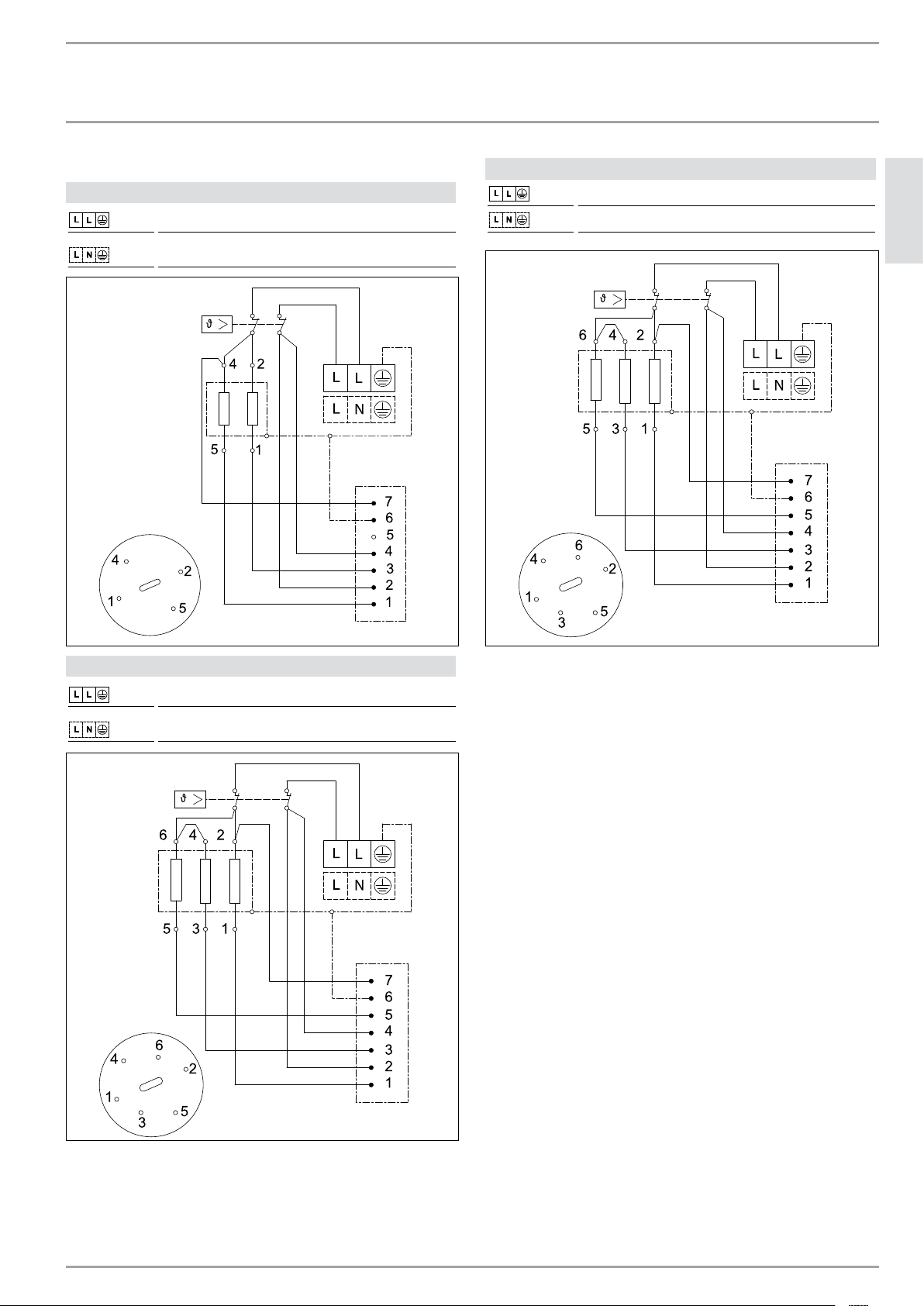

12.2 Wiring diagram

DHC-E 8/10

2/GRD ~ 208 / 240 V

1/N/PE ~ 220 / 230 / 240 V

DHC-E 12

2/GRD ~ 208 / 240 V

1/N/PE ~ 220 / 230 / 240 V

ENGLISH

DHC-E 11 L

2/GRD ~ 208 V

1/N/PE ~ 220 V

85�02�03�0001

85�02�03�0002

85�02�03�0001

www.stiebel-eltron-usa.com DHC-E | 9

INSTALLATION

TECHNICAL DATA

12.3 Maximum temperature increase above ambient water temperature

Hot water flow rate [ gpm ]

Hot water outlet temperature 104 °F

Cold water inlet temperature °F 39 50 59 68 77 86 95 104 113 122 131

DHC-E 8/10

9.6 kW @ 240 V 1.01 1.21 1.45 1.82 2.42 3.63 6.61 - - - DHC-E 11 L

11.6 kW @ 220 V 1.22 1.47 1.76 2.2 2.93 4.18 6.61 - - - DHC-E 12

12 kW @ 240 V 1.26 1.51 1.82 2.27 3.03 4.31 6.61 - - - -

Hot water outlet temperature 113 °F

Cold water inlet temperature °F 39 50 59 68 77 86 95 104 113 122 131

DHC-E 8/10

9.6 kW @ 240 V 0.89 1.04 1.21 1.45 1.82 2.42 3.63 6.61 - - DHC-E 11 L

11.6 kW @ 220 V 1.07 1.26 1.47 1.76 2.2 2.79 4.18 6.61 - - DHC-E 12

12 kW @ 240 V 1.11 1.30 1.51 1.82 2.27 2.88 4.31 6.61 - - -

Hot water outlet temperature 140 °F

Cold water inlet temperature °F 39 50 59 68 77 86 95 104 113 122 131

DHC-E 8/10

9.6 kW @ 240 V 0.65 0.73 0.81 0.91 1.04 1.21 1.45 1.82 2.42 3.63 6.61

DHC-E 11 L

11.6 kW @ 220 V 0.78 0.88 0.98 1.1 1.26 1.39 1.67 2.09 2.79 4.18 6.61

DHC-E 12

12 kW @ 240 V 0.81 0.91 1.01 1.14 1.30 1.44 1.73 2.16 2.88 4.31 6.61

5.4 kW @ 208 V 0.57 0.68 0.82 1.02 1.36 2.04 4.09 - - - -

7.2 kW @ 240 V 0.76 0.91 1.09 1.36 1.82 2.72 5.45 - - - -

7.2 kW @ 208 V 0.76 0.91 1.09 1.36 1.82 2.72 5.45 - - - -

10.4 kW @ 208 V 1.09 1.31 1.57 1.97 2.62 3.74 6.61 - - - -

9 kW @ 208 V 0.95 1.14 1.36 1.70 2.27 3.23 6.47 - - - -

5.4 kW @ 208 V 0.50 0.58 0.68 0.82 1.02 1.36 2.04 4.09 - - -

7.2 kW @ 240 V 0.66 0.78 0.91 1.09 1.36 1.82 2.72 5.45 - - -

7.2 kW @ 208 V 0.66 0.78 0.91 1.09 1.36 1.82 2.72 5.45 - - -

10.4 kW @ 208 V 0.96 1.12 1.31 1.57 1.97 2.49 3.74 6.61 - - -

9 kW @ 208 V 0.83 0.97 1.14 1.36 1.70 2.16 3.23 6.47 - - -

5.4 kW @ 208 V 0.36 0.41 0.45 0.51 0.58 0.68 0.82 1.02 1.36 2.04 4.09

7.2 kW @ 240 V 0.49 0.54 0.61 0.68 0.78 0.91 1.09 1.36 1.82 2.72 5.45

7.2 kW @ 208 V 0.49 0.54 0.61 0.68 0.78 0.91 1.09 1.36 1.82 2.72 5.45

10.4 kW @ 208 V 0.70 0.79 0.87 0.98 1.12 1.25 1.50 1.87 2.49 3.74 6.61

9 kW @ 208 V 0.61 0.68 0.76 0.85 0.97 1.08 1.29 1.62 2.16 3.23 6.47

Hot water flow rate [ l/min ]

Hot water outlet temperature 40 °C

Cold water inlet temperature °C 4 10 15 20 25 30 35 40 45 50 55

DHC-E 8/10

9.6 kW @ 240 V 3.82 4.58 5.50 6.87 9.16 13.75 25.00 - - - DHC-E 11 L

11.6 kW @ 220 V 4.62 5.55 6.66 8.33 11.11 15.83 25.02 - - - DHC-E 12

12 kW @ 240 V 4.77 5.73 6.87 8.59 11.46 16.32 25.00 - - - -

Hot water outlet temperature 45 °C

Cold water inlet temperature °C 4 10 15 20 25 30 35 40 45 50 55

DHC-E 8/10

9.6 kW @ 240 V 3.35 3.93 4.58 5.50 6.87 9.16 13.75 25.00 - - DHC-E 11 L

11.6 kW @ 220 V 4.05 4.76 5.55 6.66 8.33 10.55 15.83 25.02

DHC-E 12

12 kW @ 240 V 4.19 4.91 5.73 6.87 8.59 10.88 16.32 25.00 - - -

5.4 kW @ 208 V 2.15 2.58 3.09 3.87 5.16 7.73 15.47 - - - -

7.2 kW @ 240 V 2.86 3.44 4.12 5.16 6.87 10.31 20.62 - - - -

7.2 kW @ 208 V 2.86 3.44 4.12 5.16 6.87 10.31 20.62 - - - -

10.4 kW @ 208 V 4.13 4.96 5.96 7.45 9.93 14.15 25.02 - - - -

9 kW @ 208 V 3.58 4.30 5.16 6.44 8.59 12.24 24.49 - - - -

5.4 kW @ 208 V 1.89 2.21 2.58 3.09 3.87 5.16 7.73 15.47 - - -

7.2 kW @ 240 V 2.51 2.95 3.44 4.12 5.16 6.87 10.31 20.62 - - -

7.2 kW @ 208 V 2.51 2.95 3.44 4.12 5.16 6.87 10.31 20.62 - - -

10.4 kW @ 208 V 3.62 4.26 4.96 5.96 7.45 9.43 14.15 25.02 - - -

9 kW @ 208 V 3.14 3.68 4.30 5.16 6.44 8.16 12.24 24.49 - - -

10 | DHC-E www.stiebel-eltron-usa.com

INSTALLATION

TECHNICAL DATA

Hot water outlet temperature 60 °C

Cold water inlet temperature °C 4 10 15 20 25 30 35 40 45 50 55

DHC-E 8/10

9.6 kW @ 240 V 2.45 2.75 3.05 3.44 3.93 4.58 5.50 6.87 9.16 13.75 25.00

DHC-E 11 L

11.6 kW @ 220 V 2.97 3.33 3.7 4.17 4.76 5.28 6.33 7.91 10.55 15.83 25.02

DHC-E 12

12 kW @ 240 V 3.07 3.44 3.82 4.30 4.91 5.44 6.53 8.16 10.88 16.32 25.00

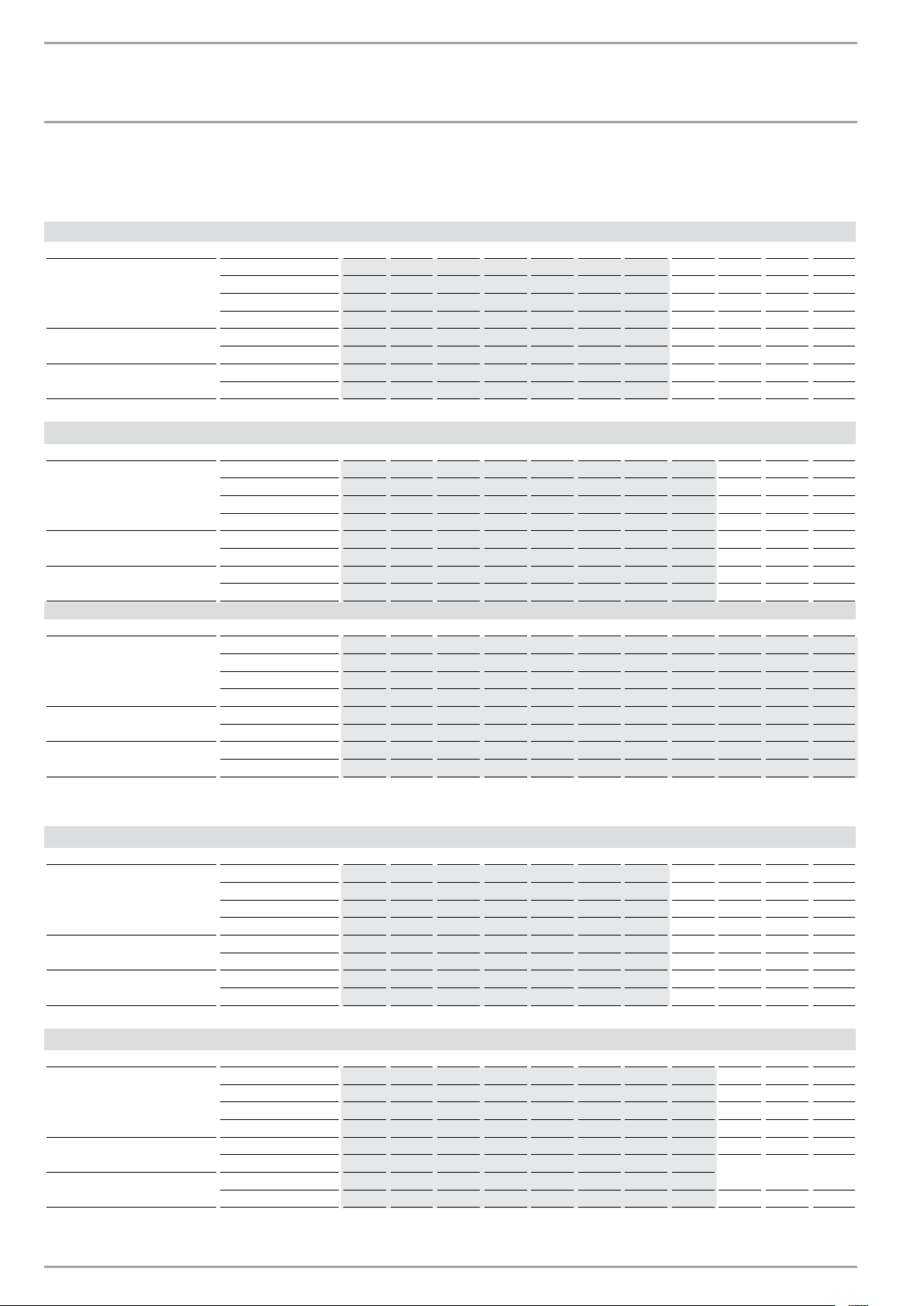

12.4 Data table

Part number 224201 (U.S. & Canada) / 234450 (Export)

Phase 1 1 1 1 1 1 1 1

Coding plug Position 1 1 1 1 2 2 2 2

Voltage V 208 220 230 240 208 220 230 240

Frequency Hz 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60

Output power kW 5.4 6.0 6.6 7.2 7.2 8.1 8.8 9.6

Amperage A 26 28 29 30 35 37 39 40

Min. recommended circuit breaker1 (DP) A 30 30 30 30 35 40 40 40

Min. recommended wire size2 (copper) AWG 10 10 10 10 8 8 8 8

Min. water flow to activate appliance gpm / l/min 0.26 / 1

Protection level according to IP 24

Max. inlet water temperature °F / °C 131 / 55

Nominal water volume gal / l 0.13 / 0.5

Working pressure max. psi / bar / MPa 150 / 10 / 1

Tested to pressure psi / bar / MPa 300 / 20 / 2

Weight lb / kg 5.9 / 2.7

Water connections 1/2˝ NPT

5.4 kW @ 208 V 1.38 1.55 1.72 1.93 2.21 2.58 3.09 3.87 5.16 7.73 15.47

7.2 kW @ 240 V 1.84 2.06 2.29 2.58 2.95 3.44 4.12 5.16 6.87 10.31 20.62

7.2 kW @ 208 V 1.84 2.06 2.29 2.58 2.95 3.44 4.12 5.16 6.87 10.31 20.62

10.4 kW @ 208 V 2.65 2.98 3.31 3.72 4.26 4.72 5.66 7.07 9.43 14.15 25.02

9 kW @ 208 V 2.30 2.58 2.86 3.22 3.68 4.08 4.90 6.12 8.16 12.24 24.49

DHC-E 8/10

*

ENGLISH

DHC-E 11 L DHC-E 12

Part number 235235 (Not available in North

America)

Phase 1 1 1 1 1 1

Voltage V 208 220 208 220 230 240

Frequency Hz 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60 50 / 60

Output power kW 10.4 11.6 9 10 11 12

Amperage A 50 52.8 44 46 48 50

Min. recommended circuit breaker1 (DP) A 50 60 50 50 50 50

Min. recommended wire size2 (copper) AWG COPPER 8 6 8 8 8 8

Protection level according to IP 24

Min. water flow to activate unit gpm / l/min 0.26 / 1

Max. inlet water temperature °F / °C 131 / 55

Nominal water volume gal / l 0.13 / 0.5

Working pressure max. psi / bar / MPa 150 / 10 / 1

Tested to pressure psi / bar / MPa 300 / 20 / 2

Weight lb / kg 5.9 / 2.7

Water connections 1/2˝ NPT

*

DHC-E 8/10 is a single unit that is switchable at installation via jumper for output at 7.2 kW (Stage 1) or 9.6 kW (Stage 2).

1

Overcurrent protection sized at 100% of load. Tankless water heaters are considered a non-continuous load.

2

Copper conductors with a temperature rating of 75 °C or greater must be used. Conductors should be sized to maintain a voltage drop of less than 3% under load.

These are our recommendations. Check local codes for compliance if necessary.

230628 (U.S. & Canada) /

234451 (Export)

www.stiebel-eltron-usa.com DHC-E | 11

INSTALLATION

SPARE PARTS

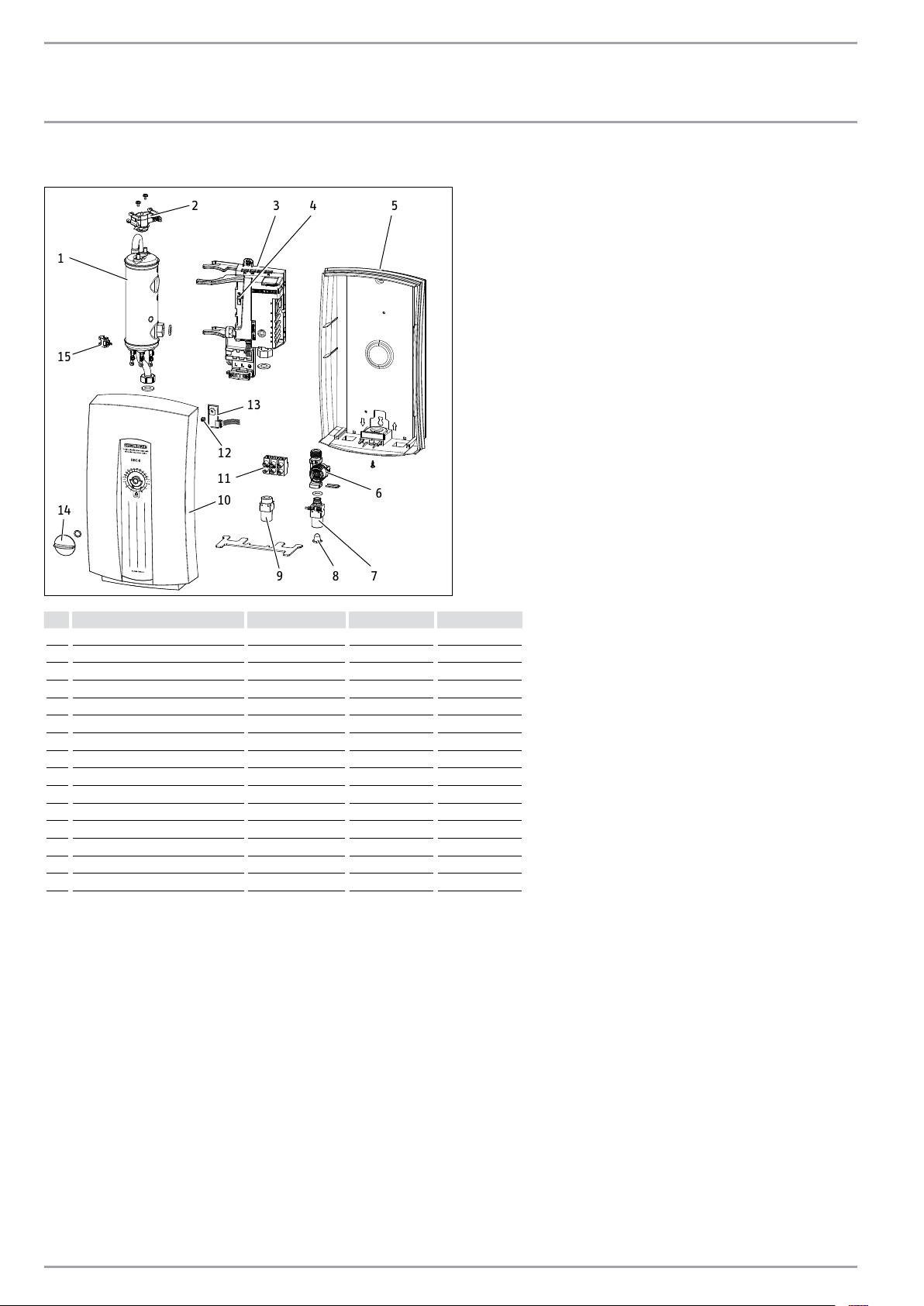

13. Spare parts

2

3 5

4

1

15

13

12

11

14

10

9 8 7

No. No. Spare par t DHC-E 8/10 DHC-E 11 L DHC-E 12

1 Heating system 292575 320979 292576

2 Safety thermal cut out 286369 286369 286369

3 Electronic control appliance 291851 291852 291852

4 Coding plug 283455 - 5 Back panel 292578 292578 292578

6 Flow sensor DFE 286461 286461 286461

7 Cold water connection 291699 291699 291699

8 Filter screen 252430 252430 252430

9 Hot water connection 278634 278634 278634

10 Plastic cover 292577 292577 292577

11 Wiring block 279998 279998 279998

12 Axis connection plug 254312 254312 254312

13 Electronic temperature control 286359 286359 286359

14 Temperature adjustment knob 254307 254307 254307

15 Outlet temperature sensor 280677 280677 280677

6

26�02�02�1091

12 | DHC-E www.stiebel-eltron-usa.com

Loading...

Loading...