Page 1

Fiberglass Cooling Towers

Part Number: 882.00440.00

Bulletin Number: SC6-610.6

Effective: 9/10/07

Write Down Your Serial Numbers Here For Future Reference:

_________________________ _________________________

_________________________ _________________________

_________________________ _________________________

We are committed to a continuing program of product improvement.

Specifications, appearance, and dimensions described in this manual are subject to change

without notice.

DCN No. ____________

© Copyright 2008

All rights reserved.

Page 2

Shipping Information

Unpacking and Inspection

You should inspect your equipment for possible shipping damage. Thoroughly check the

equipment for any damage that might have occurred in transit, such as broken or loose wiring

and components, loose hardware and mounting screws, etc.

In the Event of Shipping Damage

According to the contract terms and conditions of the Carrier, the responsibility of the

Shipper ends at the time and place of shipment.

Notify the transportation company’s local agent if you discover damage

Hold the damaged goods and packing material for the examining agent’s inspection. Do not

return any goods before the transportation company’s inspection and authorization.

File a claim with the transportation company. Substantiate the claim by referring to the

agent’s report. A certified copy of our invoice is available upon request. The original Bill of

Lading is attached to our original invoice. If the shipment was prepaid, write us for a

receipted transportation bill.

Advise customer service regarding your wish for assistance and to obtain an RMA (return

material authorization) number.

If the Shipment is Not Complete

Check the packing list as back-ordered items are noted on the packing list. In addition to the

equipment itself, you should have:

; Bill of lading

; Packing list

; Operating and Installation packet

; Electrical schematic and panel layout drawings

; Component instruction manuals (if applicable)

Re-inspect the container and packing material to see if you missed any smaller items during

unpacking.

If the Shipment is Not Correct

If the shipment is not what you ordered, please contact the parts and service department

immediately at (262) 641-8610. Have the order number and item number available.

Hold the items until you receive shipping instructions.

Returns

Do not return any damaged or incorrect items until you receive shipping instructions from the

shipping department.

Fiberglass Cooling Towers ii

Page 3

Table of Contents

CHAPTER 1: SAFETY................................................................6

1-1 How to Use This Manual.................................................................................6

Safety Symbols Used in this Manual.....................................................................6

1-2 Warnings and Precautions..............................................................................7

1-3 Responsibility.................................................................................................. 7

CHAPTER 2: FUNCTIONAL DESCRIPTION.............................8

2-1 Models Covered in This Manual......................................................................8

2-2 General Description ........................................................................................ 8

2-3 Standard Features .......................................................................................... 8

Materials of Construction.......................................................................................8

2-4 Optional Features............................................................................................ 9

CHAPTER 3: INSTALLATION..................................................10

3-1 Tower Installation Location............................................................................10

Roof Installation...................................................................................................10

Ground Installation..............................................................................................10

Alternative Installations .......................................................................................10

3-2 Assembling the Cooling Tower in the Field...................................................12

3-3 Rigging.......................................................................................................... 13

3-4 Installing the Fan Package............................................................................ 13

3-5 Installing Piping............................................................................................. 13

3-6 Setting Up the Water Balancing Valve .......................................................... 16

3-7 Initial Start-up................................................................................................ 16

CHAPTER 4: OPERATION.......................................................17

4-1 Bleed-Off and Evaporation Rates.................................................................. 17

4-2 Winter Operation Considerations.................................................................. 17

CHAPTER 5: MAINTENANCE .................................................18

5-1 Preventative Maintenance.............................................................................18

Water Treatment .................................................................................................18

Routine Maintenance ..........................................................................................18

5-2 Corrective Maintenance ................................................................................ 19

Replacing Nozzles and Fill..................................................................................19

CHAPTER 6: APPENDIX..........................................................20

6-1 Technical Assistance .................................................................................... 20

Parts Department ................................................................................................20

Service Department.............................................................................................20

Sales Department................................................................................................20

Contract Department...........................................................................................20

6-2 Drawings and Specifications.........................................................................21

Fiberglass Cooling Towers iii

Page 4

6-3 Parts List.......................................................................................................24

6-4 Electrical Schematics....................................................................................25

Fiberglass Cooling Towers iv

Page 5

List of Figures

Figure 1: Structural Steel Support Requirements ......................................................................... 11

Figure 2: Rigging Arrangement.................................................................................................... 13

Figure 3: Cooling Tower with Tower Reservoir Piping Diagram................................................ 14

Figure 4: Cooling Tower with Basin as Reservoir Piping Diagram............................................. 14

Figure 5: Flexible PVC Outlet Coupler........................................................................................15

Figure 6: Throttling Valve Pressures............................................................................................ 16

Figure 7: Dimensions and Weights............................................................................................... 21

Figure 8: Tower Performancec.................................................................................................... 22

Figure 9: Cooling Tower Nozzle Capacity................................................................................... 23

Figure 10: Supplied Parts for Field Assembly.............................................................................. 24

Figure 11: Spare Parts List............................................................................................................ 24

Figure 12: Typical Wiring Diagram ............................................................................................. 25

Fiberglass Cooling Towers v

Page 6

Chapter 1: Safety

1-1 How to Use This Manual

Use this manual as a guide and reference for installing, operating, and maintaining your

equipment. The purpose is to assist you in applying efficient, proven techniques that enhance

equipment productivity.

This manual covers only light corrective maintenance. No other maintenance should be

undertaken without first contacting a service engineer.

The Functional Description section outlines models covered, standard features, and optional

features. Additional sections within the manual provide instructions for installation, preoperational procedures, operation, preventive maintenance, and corrective maintenance.

The Installation chapter includes required data for receiving, unpacking, inspecting, and setup

of the equipment. We can also provide the assistance of a factory-trained technician to help

train your operator(s) for a nominal charge. This section includes instructions, checks, and

adjustments that should be followed before commencing with operation of the equipment.

These instructions are intended to supplement standard shop procedures performed at shift,

daily, and weekly intervals.

The Operation chapter includes a description of electrical and mechanical controls, in

addition to information for operating the equipment safely and efficiently.

The Maintenance chapter is intended to serve as a source of detailed assembly and

disassembly instructions for those areas of the equipment requiring service. Preventive

maintenance sections are included to ensure that your equipment provides excellent, long

service.

The Troubleshooting chapter serves as a guide for identification of most common problems.

Potential problems are listed, along with possible causes and related solutions.

The Appendix contains technical specifications, drawings, schematics, and parts lists. A

spare parts list with part numbers specific to your machine is provided with your shipping

paperwork package. Refer to this section for a listing of spare parts for purchase. Have your

serial number and model number ready when ordering.

Safety Symbols Used in this Manual

The following safety alert symbols are used to alert you to potential personal injury hazards.

Obey all safety messages that follow these symbols to avoid possible injury or death.

Danger! DANGER indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

Warning! WARNING indicates a potentially hazardous situation or practice which, if not

avoided, could result in death or serious injury.

Caution! CAUTION indicates a potentially hazardous situation or practice which, if not

avoided, may result in minor or moderate injury or in property damage.

Fiberglass Cooling Towers Chapter 1: Safety Page 6 of 25

Page 7

1-2 Warnings and Precautions

Our equipment is designed to provide safe and reliable operation when installed and operated

within design specifications, following national and local safety codes.

To avoid possible personal injury or equipment damage when installing, operating, or

maintaining this equipment, use good judgment and follow these safe practices:

; Follow all SAFETY CODES.

; Wear SAFETY GLASSES and WORK GLOVES.

; Disconnect and/or lock out power before servicing or maintaining the equipment.

; Use care when LOADING, UNLOADING, RIGGING, or MOVING this

equipment.

; Operate this equipment within design specifications.

; OPEN, TAG, and LOCK ALL DISCONNECTS before working on equipment.

You should remove the fuses and carry them with you.

; Make sure the equipment and components are properly GROUNDED before you

switch on power.

; When welding or brazing in or around this equipment, make sure VENTILATION is

ADEQUATE. PROTECT adjacent materials from flame or sparks by shielding with

sheet metal. An approved FIRE EXTINGUISHER should be close at hand and

ready for use if needed.

; Refrigeration systems can develop refrigerant pressures in excess of 500 psi (3,447.5

kPa/ 34.47 bars). DO NOT CUT INTO THE REFRIGERATION SYSTEM. This

must be performed by a qualified service technician only.

; Do not restore power until you remove all tools, test equipment, etc., and the

equipment and related components are fully reassembled.

; Only PROPERLY TRAINED personnel familiar with the information in this

manual should work on this equipment.

We have long recognized the importance of safety and have designed and manufactured our

equipment with operator safety as a prime consideration. We expect you, as a user, to abide

by the foregoing recommendations in order to make operator safety a reality.

1-3 Responsibility

These machines are constructed for maximum operator safety when used under standard

operating conditions and when recommended instructions are followed in the maintenance

and operation of the machine.

All personnel engaged in the use of the machine should become familiar with its operation as

described in this manual.

Proper operation of the machine promotes safety for the operator and all workers in its

vicinity.

Each individual must take responsibility for observing the prescribed safety rules as outlined.

All warning and danger signs must be observed and obeyed. All actual or potential danger

areas must be reported to your immediate supervisor.

Fiberglass Cooling Towers Chapter 1: Safety Page 7 of 25

Page 8

Chapter 2: Functional Description

2-1 Models Covered in This Manual

This manual covers fiberglass cooling tower models. Model numbers are listed on the serial

tag. A model number followed by –Q is specially-constructed, and the information in this

manual may not apply. Make sure you know the model and serial number of your equipment

before contacting the manufacturer for parts or service.

2-2 General Description

The fiberglass cooling tower system is constructed of lightweight polyester-reinforced

fiberglass for corrosion resistance and durability. PVC fill material resists decay, corrosion,

and microorganisms, and handles temperatures up to 130ºF (54ºC). Access panels allow easy

inspection of fill material. Fan blades are factory-tuned for optimum performance. ABS water

distribution nozzles are pre-piped and feature a non-clogging design.

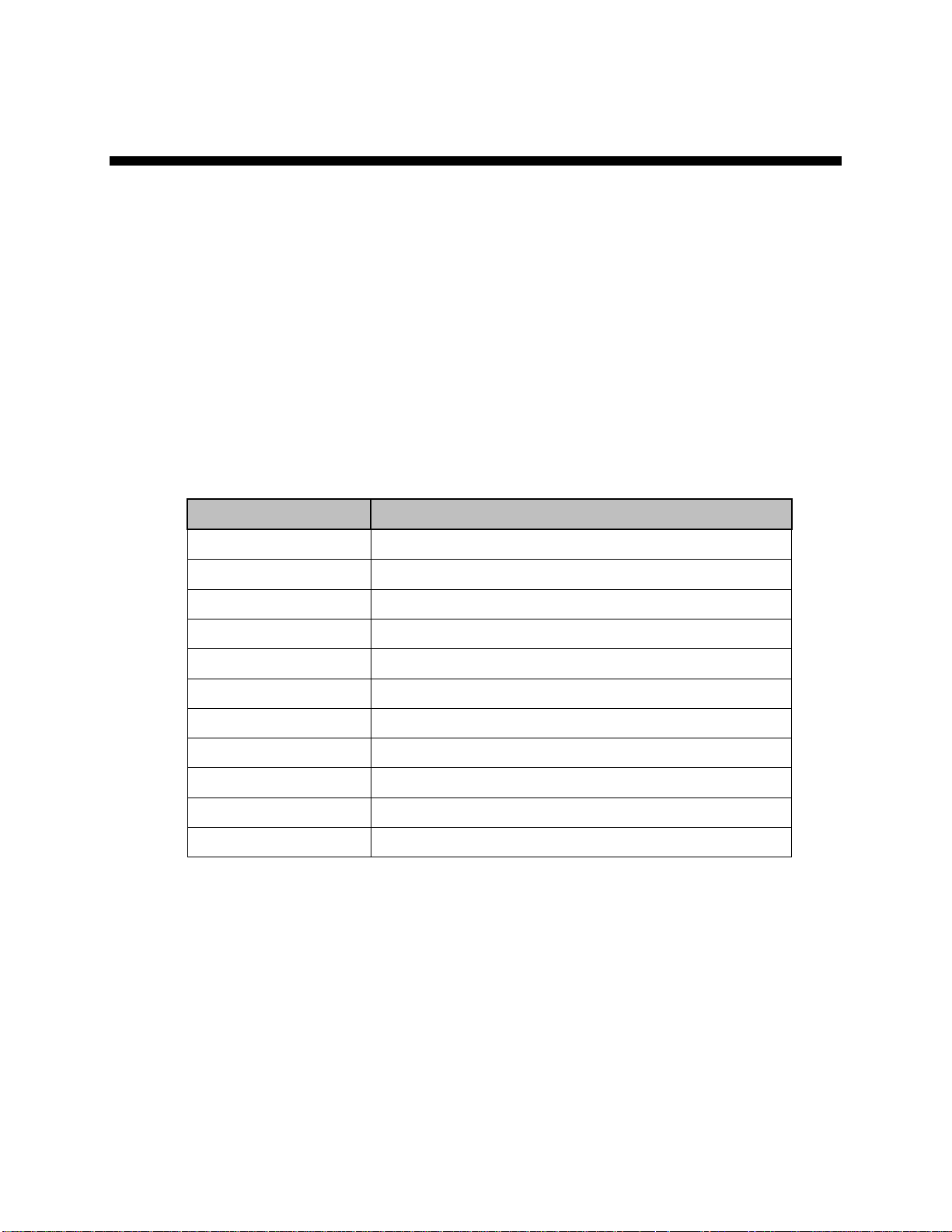

2-3 Standard Features

Materials of Construction

Component Material

Shell Fiberglass-reinforced polyester

Fan blade Aluminum fabrication

Fan motor support Galvanized, mild steel

Fill, eliminator PVC Plastic

Louver pack PVC Plastic

Nozzle ABS plastic

Piping assembly Schedule 80 PVC plastic

Fasteners Stainless Steel

Support Feet Fiberglass brackets standard

Bottom Outlet Fiberglass

Water Balancing Valve Aluminum

Fiberglass Cooling Towers Chapter 2: Functional Description Page 8 of 25

Page 9

2-4 Optional Features

Side Outlet. The side outlet is used when the tower basin is used as a reservoir.

Starter Package. The starter package includes a starter, a remote On/Off switch, a

thermostat, and a well.

Basin Reservoir. The basin reservoir includes an automatic float valve, overflow and drain

connections, and an outlet basket strainer for towers with no inside reservoir.

Basin Heater. The basin heater includes a heater and a low water level heater shutoff. It is

used on towers with basin reservoirs to guard against freeze-up when your tower system is

shut down.

Structural Base. The structural base is a factory-provided structural steel mounting base. It

speeds tower installation and gives your tower proper support.

Access Ladder. The access ladder meets OSHA specifications and allows for easier

maintenance and inspection.

Fiberglass Cooling Towers Chapter 2: Functional Description Page 9 of 25

Page 10

Chapter 3: Installation

3-1 Tower Installation Location

Roof Installation

Select a location over or nearest to the heaviest building structural members. These members

should be outside load-bearing walls, building columns, or roof joists. You may need to

spread the load over several structural members to provide support without over-stressing any

one member. See Figure 1 on page 11 for structural steel support requirements. You are

responsible for contacting a structural engineer to verify support requirements.

Choose a site with easy access to simplify routine maintenance. This consideration is

especially important when a tower is located near a roof edge.

Avoid locations where wind currents can re-circulate tower discharge air.

Stay clear of roof discharge points. Avoid stacks, exhaust fans, dust collector discharges, or

any process that can contaminate air circulating through the tower.

Caution! Multiple tower installations require at least five feet (60”/ 152cm) clearance

between towers to reduce freeze-ups. The manufacturer is not responsible for

damages resulting from improper site selection.

Ground Installation

Elevate the tower so that positive pressure is on pump suction and to allow maintenance

access to the underside of the tower cell.

Alternative Installations

Outside Installation with the Pump Tank Reservoir Inside. Water exits the tower and

drains to a pump tank reservoir inside the building below. The tower outlet must be at least

three feet (approximately 1 meter) above the top of the pump tank. The outside tower basin

must drain completely when shut down to avoid winter freeze up.

Outside Installation Using the Tower Basin as a Reservoir. Process pump suction piping

is directly connected to the bottom outlet on the tower. Install the optional outlet basket filter

and automatic float assembly. Contact the Sales department for this accessory kit.

Note: A dimension of 60”is required between the tower air inlet and the wall of a

building. See above caution for required distance between towers.

Fiberglass Cooling Towers Chapter 3: Installation Page 10 of 25

Page 11

Figure 1: Structural Steel Support Requirements

Structural steel

2 X 2 angle

to support

tower basin,

flush with top

of structural

steel rails

B

D

C

C

TSE50

C

B

A

C

Model A B C D

number in. cm in. cm in. cm in. cm

SF2003 52 132.1 50 127.0 16 40.6 78 175.3

SF2004 52 132.1 50 127.0 16 40.6 78 175.3

SF2005 68 172.7 67 170.2 22 55.9 78 175.3

SF2007 68 172.7 67 170.2 22 55.9 78 175.3

SF2009 87 221.0 85 215.9 28 71.1 78 175.3

SF2011 87 221.0 85 215.9 28 71.1 78 175.3

SF2015 87 221.0 85 215.9 28 71.1 78 175.3

Note: The illustration in Figure 1 shows structural steel with spacing for two (2) cooling towers. Your

installation may vary.

Dimension A – Centerline for fiberglass mounting feet provided with cooling tower. This is so bolt holes

can be made to secure the tower to the structural support.

Dimension B & C – Location of basin support steel.

Dimension D – Provides proper distance of 60” between cooling towers and distance between cooling

tower and the wall of a building.

Fiberglass Cooling Towers Chapter 3: Installation Page 11 of 25

Page 12

3-2 Assembling the Cooling Tower in the Field

Your cooling tower may have been shipped on two skids to reduce shipping charges.

One skid contains the lower section, identified by the black fill wrapped in plastic on the

inside of the lower section. The second skid contains the top tower section bolted over the

fan/motor assembly. Perform the following procedure to properly assemble the two sections

if the sections shipped separately.

1. Remove the clear plastic protective wrapping from the fill.

2. Inspect both sections for any damage, and locate the red orientation mark on one of

the vertical sides of each section.

3. The manufacturer supplies self-adhesive gasketing material to insure a water-tight

seal between the top and bottom sections. Install this material on the top of the

attachment flange on the lower section prior to mating the top and bottom sections.

Make sure that the flange is clean, dry, and free of rough spots before applying the

gasketing material.

4. Align the holes in the gasket with the bolt holes in the flange, then remove the paper

on the back side. Cut the gasketing material to fit properly, and apply the gasket to

the flange as you realign gasket holes with flange holes. Repeat on all four sides of

the tower.

5. Apply silicone caulk in cut lines and voids to complete sealing between sections.

6. Unbolt the top section from the skid and make sure that the flange on the top section

is clean, dry, and free of rough spots.

7. Place the upper section on the gasketed lower section, aligning the red orientation

marks. Take care not to disturb the gasketing and silicone caulk while aligning bolt

holes.

8. After aligning, bolt the two sections together with the fasteners provided. Use a flat

washer under the bolt head on top and a flat washer, a lock washer, and nut on the

bottom side of the flange.

Fiberglass Cooling Towers Chapter 3: Installation Page 12 of 25

Page 13

p

3-3 Rigging

Handle the fiberglass cooling tower shell section very carefully. Until installed and properly

supported, it is subject to handling damage. See Figure 2 for rigging information.

Caution! Use an appropriately rated hoist to support the equipment.

Figure 2: Rigging Arrangement

Channel

Spreader bar wide

enough to protect

cooling tower shell

Caution! Use appropriately rated

hoist to support equipment.

Do not let the rigging transfer any load to the cooling tower shell. Provide support to

the bottom of the cooling tower when rigging. Do not rig from the corners of the

o

tional base. Do not rig less than 8 inches from the corners.

3-4 Installing the Fan Package

Install the fan package after the tower is in position.

I-beam

Rope stay

The rope stay goes

all the way around the

tower to keep the

vertical rope in position.

1. Remove the dunnage securing the fan package to the pallet.

2. Carefully rig the package using the lifting eyebolts provided.

3. Mounting holes have been pre-drilled at the factory; move the package into position

and fasten it securely with the stainless steel hardware provided.

3-5 Installing Piping

Make sure that all piping attached to the cooling tower is externally supported. Do not

support anything from the cooling tower shell.

The cooling tower and related fittings and connections are constructed of plastic materials

and are not designed to bear external weight.

Do not apply high torque to the fittings that are made up into the tower fittings. Use a backup

wrench when applying torque to the fittings.

Fiberglass Cooling Towers Chapter 3: Installation Page 13 of 25

Page 14

Install the piping according to the piping diagrams in Figure 3 on page 14, Figure 4 on page

14, and Figure 5 on page 15.

Figure 3: Cooling Tower with Tower Reservoir Piping Diagram

Type 2

balancing

valve

P

Typical bottom outlet

TWR

TWR

Support piping to eliminate

load from tower casing

Type 2

pressure

gauge

Caution!

Do not apply

excessive torque

to fittings

Type 2

inlet

Cooling tower

Overflow

3/4" constant

bleed

Drain

To drain

Figure 4: Cooling Tower with Basin as Reservoir Piping Diagram

Pressure

gauge

Caution!

Do not apply

excessive torque

to fittings

Overflow

Drain

To drain

Support piping to eliminate

load from tower casing

Tower water

T

P

Cooling

tower

TR

TR

Strainer basket

reservoir

Inlet

Balancing valve

Side outlet

3/4" constant bleed

3/8" drain line

Drain line is intended to prevent

NOTE:

tower freeze-up. Do not valve.

TWR

Makeup

City water line

Building

exterior

TR

Makeup

P

P-1

Thermostat-mount

in piping (1/2" fitting)

TWS

1/4" swing check valve

12" above highest point

in return line

3/4" constant bleed

To drain

P

P-1

TWR

TWS

TWS

Bypass

Tower water return

Tower water supply

City water

TWR

TWS

Bypass

Tower water return

Tower water supply

City water

Fiberglass Cooling Towers Chapter 3: Installation Page 14 of 25

Page 15

Figure 5: Flexible PVC Outlet Coupler

g

Clamps

(from AEC)

(from Sterling)

Tower outlet

Flexible PVC

Flexible PVC

coupling

Coupling

(from AEC)

(from Sterlin

Outlet pipe must be

supported from building

structure or tower steel

)

Fiberglass Cooling Towers Chapter 3: Installation Page 15 of 25

Page 16

3-6 Setting Up the Water Balancing Valve

Install the plug provided in the unused water inlet on the side of the tower. Tighten and check

for leaks.

To prevent damage to the tower fill material, use the water throttling valve and pressure

gauge to regulate the water pressure to the tower spray nozzle(s). The recommended

throttling valve is a butterfly-type valve that can be locked in the correct position with a

locknut. See Figure 6 for recommended throttling valve pressures.

Figure 6: Throttling Valve Pressures

Pressure Model

psig KPa

SF2003 10 psig 68.95

SF2004 7 psig 48.26

SF2005 3 psig 10.68

SF2007 5 psig 34.47

SF2009 6 psig 41.37

SF2011 8 psig 55.16

SF2015 10 psig 68.95

Warning! Exceeding these pressure limits will damage the tower fill and nozzle and void

the tower warranty.

3-7 Initial Start-up

Check for proper rotation on all fan and pump motors. Refer to the arrows atop the tower and

on pump housings.

Fill the system with water and adjust the float valve if you are using a float. Maintain a water

level in the tower basin approximately one inch (25 mm) below the overflow opening.

The tower basin acts as a sump to maintain water level. Towers using inside tanks do not

carry water in the basin.

Fiberglass Cooling Towers Chapter 3: Installation Page 16 of 25

Page 17

Chapter 4: Operation

4-1 Bleed-Off and Evaporation Rates

A proper bleed-off rate is important to limit the concentration of minerals and foreign

materials in re-circulated water. A bleed-off equal to the evaporation rate, normally about two

gallons per hour per ton (7.57 liters per hour per 3,780 Kcal/hr), is sufficient for many

makeup water conditions. Refer to the suggested bleed-off arrangements in Figure 3 and

Figure 4 on pages 14 and 14 for more information. For automatic bleed rate control, a

conductivity controller is available through the Sales department.

4-2 Winter Operation Considerations

All cooling towers are subject to ice formation in sub-freezing weather. Your cooling tower

requires a certain amount of attention and maintenance to prevent damage during these

operating conditions.

Follow these guidelines to reduce the chance of ice buildup:

• Maintain full design flow. Any reduction in water flow greatly increases the

probability of ice forming on and around the air inlet louvers.

• Do not use free cooling applications during freezing weather. Reduced water

temperatures or loading dramatically increases the chance of ice formation. Make sure

that the leaving water temperature is set above 80ºF (27ºC) during sub-freezing

weather so heat from the water warms the air inlet louvers and reduces ice formation

when the fan is off. Using a thermostat to control fan cycling by leaving water

temperature is mandatory.

• Do not run fans backward to thaw ice. Ice can form on the fan ring, fan guard, and

support structures, and can severely damage fan blades. Reversed airflow can also

blow water vapor out onto the roof and create ice fields around the cooling tower.

• Maintain a heat load of at least 60% of tower capacity at all times during operation in

freezing weather. A lack of substantial load can create uneven temperatures in the

tower and cause freezing.

• If you shut down your cooling tower during freezing weather, you must drain it

completely. We recommend that you use an indoor reservoir tank to permit water to

drain into the tank on system shutdown, whether for emergencies or actual planned

shutdowns.

• An alternative is to use basin heaters if a tower basin is used as a sump. Basin heaters

are available as an option. However, basin heaters can permit freeze-up during power

failures if water remains in the sump. The customer is responsible for determining risk

factors for each specific application.

Fiberglass Cooling Towers Chapter 4: Operation Page 17 of 25

Page 18

Chapter 5: Maintenance

5-1 Preventative Maintenance

Water Treatment

Control of slime, algae, and bacteria growth is extremely important. Cooling towers and

reservoir pump tanks are superb environments for microorganism growth. Warm water,

organic debris, and air encourage bacterial growth. Treat your system with chemicals

(microbiocides) to control microorganism growth.

Caution! Uncontrolled microorganism growth causes system problems such as fouling

and corrosion, and can spread bacterially-transmitted diseases.

You must reduce slime growth and bacterial contamination to eliminate disease-causing

bacteria.

Properly used, environmentally approved microbiocide controls system bacteria. Chemical

treatments must be regularly monitored by qualified personnel.

The manufacturer strongly recommends use of EPA-registered microbiocides on a regular

basis. We do NOT recommend use of chlorine or backyard swimming pool chemicals.

Permitting the discharge of such chemicals into a city sewer may violate local, state, and/or

federal laws.

We offer a full-service water treatment program including chemicals, dispensing equipment,

automatic bleed-off, and monthly water analysis. Contact the Parts and Service department

for more information.

Routine Maintenance

• The fan motor has double-sealed bearings and needs no lubrication

• Inspect basket strainers (where used) and clean as needed.

• Check constant bleed back to the tank for flow during operation.

• Check the bleed-off line to verify that water flows to the drain during operation.

• Inspect the tower basin for dirt and debris, and clean as needed.

• Check the tower nozzle(s) for proper operation at full water flow.

• Check the water treatment equipment for proper operation. Refer to the information

supplied with these devices.

• Check the throttling valve pressure gauge. The pressure should be within the

recommendations in section 3-6.

Fiberglass Cooling Towers Chapter 5: Maintenance Page 18 of 25

Page 19

5-2 Corrective Maintenance

Replacing Nozzles and Fill

The PVC fill used in these cooling towers provides years of maintenance-free service under

normal conditions. If you discover dirty water or defective nozzle(s) damage the fill, you can

order a replacement kit from the parts department.

You can easily remove and replace the fill by removing the tower access door on the side of

the tower. Open the door to gain access to the nozzle system.

Fiberglass Cooling Towers Chapter 5: Maintenance Page 19 of 25

Page 20

Chapter 6: Appendix

6-1 Technical Assistance

Parts Department

Call Toll-Free 7am–6pm CST [800] 423-3183 or call [262] 641-8610

Our Parts Department is ready to provide the parts to keep your systems up and running.

OEM replacement parts ensure operation at design specifications. Please have the model and

serial number of your equipment when you call. Consult the Customer Parts List included in

your information packet for replacement part numbers.

Service Department

Call toll-free 8am–5pm CST [800] 423-3183 or call [262] 641-8610.

Emergency Service is available 24 hours a day. We have a qualified service department ready

to help. Service contracts are available for most of our products.

www.acscustomerservice.com

Sales Department

Call [262] 641-8610 Monday–Friday, 8am–5pm CST

Our products are sold by a world-wide network of independent sales representatives. Contact

our Sales Department for the name of the sales representative nearest you.

Contract Department

Call [262] 641-8610 Monday–Friday, 8am–5pm CST

Let us install your system. The Contract Department offers any or all of these services:

project planning; system packages including as-built drawings; equipment, labor, and

construction materials; union or non-union installations; and field supervision.

Fiberglass Cooling Towers Chapter 6: Appendix Page 20 of 25

Page 21

6-2 Drawings and Specifications

g

A

A0536711

B

Top View

Fan guard

Fan motor

Fan blade

Motor support

assembly

Supply piping

Access

door

Nozzle

C

Return

E

pipin

Side View Cutaway View

adaptor

Nozzle

Rigid PVC

tower fill

Water

diverter

D

Figure 7: Dimensions and Weights

Dimensions Weights

Model A B C D (supply) E (return) Shipping Operating

number in. cm in. cm in. cm in. mm c in. mm c lbs. kg lbs. kg

SF2003 64 163 64 163 104 264 3” 76.2 mm 4” 101.6 mm 600 273 1,300 591

SF2004 64 163 64 163 125 318 3” 76.2 mm 6” 152.4 mm 750 341 1,700 772

SF2005 82 208 82 208 121 307 4” 101.6 mm 8” 203.2 mm 1,400 636 2,900 1,317

SF2007 82 208 82 208 121 307 4” 101.6 mm 8” 203.2 mm 1,500 681 3,200 1,453

SF2009 100 254 100 254 123 313 4” 101.6 mm 8” 203.2 mm 1,950 886 3,800 1,726

SF2011 100 254 100 254 123 313 4” 101.6 mm 8” 203.2 mm 2,100 954 4,400 1,998

SF2015 100 254 100 254 124 315 4” 101.6 mm 8” 203.2 mm 2,600 1,181 5,200 2,361

c Millimeter measurement is approximate. Customer is responsible for converting to metric piping sizes.

Fiberglass Cooling Towers Chapter 6: Appendix Page 21 of 25

Page 22

Figure 8: Tower Performancec

Cooling Fan NEC Nominal

Model capacity Nozzles motor amp draw air flow

number tons Kcal/hr no. hp kW rpm 460/3/60 cfm cmh

SF2003 50 151,200 1 2 1.5 1,200 3.4 12,000 20,388

SF2004 75 226,800 4 5 3.7 1,200 7.6 18,000 30,582

SF2005 100 302,400 4 5 3.7 900 7.6 23,500 39,926

SF2007 125 378,000 4 5 3.7 900 7.6 26,000 44,174

SF2009 150 453,600 4 10 7.5 900 14.0 30,000 50,970

SF2011 175 529,200 4 10 7.5 900 14.0 33,000 56,067

SF2015 200 604,800 4 15 11.2 900 21.0 43,000 73,057

c Rating conditions are based on 78ºF (26ºC) wet bulb, 95ºF (35ºC) entering water

temperature, and 85ºF (29ºC) leaving water temperature; flow capacity is based on 3

gpm/ton (2.563 lpm per 1,000 Kcal/hr).

Fiberglass Cooling Towers Chapter 6: Appendix Page 22 of 25

Page 23

Figure 9: Cooling Tower Nozzle Capacity

Fiberglass Cooling Towers Chapter 6: Appendix Page 23 of 25

Page 24

6-3 Parts List

Figure 10: Supplied Parts for Field Assembly

Part Number Quantity Description

A0101485 1 Silicone

A0533163 110 Stainless steel flat washers, 5/16”

A0539417 55 Stainless steel screws, 5/16”-18 x 1 3/4”

A0533167 55 Stainless steel hex nut, 5/16”-18

A0534122 55 Stainless steel split lock washers, 3/8”

A0539598 40 ft. FG Tower gasketing

Figure 11: Spare Parts List

Part

description qty Part no. qty Part no. qty Part no. qty Part no. qty Part no. qty Part no. qty Part no.

Shell, top section 1 A0533079 1 A0539552 1 A0536702 1 A0536702 1 A0535879 1 A0535879 1 A0539581

Shell, side outlet 1 A0533078 1 A0539550 1 A0536700 1 A0536700 1 A0535880 1 A0535880 1 A0539582

Shell, bottom outlet 1 A0536666 1 A0539551 1 A0536701 1 A0536701 1 A0536668 1 A0536668 1 A0539583

Tower access door 1 A0533082 1 A0533082 2 A0533082 2 A0533082 2 A0533082 2 A0533082 2 A0533082

Motor support assy. 1 A0533090 1 A0533090 1 A0536712 1 A0536712 1 A0539586 1 A0539586 1 A0539586

Fan Motor Spcr. Brkt. 1 A0539566 -- --- 1 A0536717 -- -- -- -- -- -- -- --

Fan guard 1 A0533092 1 A0533092 1 A0536706 1 A0536706 1 A0535883 1 A0535883 1 A0535883

Fan motor e

Fan blade 1 A0533097 1 A0539556 1 A0547121 1 A0536708 1 A0541387 1 A0541387 1 A0539576

PVC fill e

Eliminator e

Louver 16 A0533106 16 A0539559 20 A0533106 20 A0533106 24 A0533106 24 A0533106 28 A0539580

Nozzle e

Nozzle adaptere

Nozzle 4

Nozzle adapter 4

PVC plug 6

Flexible coupling 1 A0502553 1 A0502554 1 A0535957 1 A0535957 1 A0535957 1 A0535957 1 A0535957

Balancing valve 6

Pressure gauge 1 A0102314 1 A0102314 2 A0102314 2 A0102314 2 A0102314 2 A0102314 2 A0102314

Strainer basket 1 A0500860 1 A0539574 1 A0535956 1 A0535956 1 A0535956 1 A0535956 1 A0535956

Float valve assy. 1 A0076209 1 A0076209 1 A0076029 1 A0538700 1 A0538700 1 A0538700 1 A0538700

Starter kit, 208 VAC 1 A0518023 1 A0518055 1 A0538701 1 A0538704 1 A0518030 1 A0518030 1 A0518059

Starter kit, 230 VAC 1 A0518024 4 A0518056 4 A0538702 4 A0538705 4 A0518031 4 A0518031 4 A0518060

Starter kit, 460 VAC 1 A0518025 4 A0518057 4 A0538703 4 A0538706 4 A0518032 4 A0518032 4 A0518061

c Fan motor spacer bracket part no. A0539566; available on FG2003 models only.

d Fan motor spacer bracket part no. A0536717; available on FG2005 models only.

e Recommended spare parts prior to April 2002.

4 Recommended spare parts list after 2002.

5 Recommended spare parts prior to February 2005 (A0504421 and A0064023)

6 Recommended spare parts list after February 2005

SF2003 c 5 SF2004 5 SF2005 d

1 A0533094 1 A0539555 1 A0536709

10 A0533101 15 A0539557 26 A0533099

5 A0533104 5 A0539558 13 A0533103

1 A0064022 4 A0539572 4 A0064022

1 A0101006 4 A0101006 4 A0101006

1 A0547133 4 A0547131 4 A0547131

1 A0547130 4 A0547130 4 A0547130

1 A0500867 1 A0500867 2 A0500867

1 A0504422 2 A0504422 2 A0504422

SF2007 SF2009 SF2011 SF2015

1 A0536710 1 A0547120 1 A0547120 1 A0539577

39 A0533099 32 A0533099 48 A0533099 48 A0539578

13 A0533103 16 A0533103 16 A0533103 16 A0539579

4 A0064022 4 A0064022 4 A0064022 4 A0064022

4 A0101006 4 A0101006 4 A0101006 4 A0101006

4 A0547132 4 A0547132 4 A0547133 4 A0547133

4 A0547130 4 A0547130 4 A0547130 4 A0547130

2 A0500867 2 A0500867 2 A0500867 2 A0500867

2 A0504422 2 A0504422 2 A0504422 2 A0504422

Fiberglass Cooling Towers Chapter 6: Appendix Page 24 of 25

Page 25

6-4 Electrical Schematics

Figure 12: Typical Wiring Diagram

Fused

disconnect

switch

ON/OFF

switch

Immerse

bulb in tank

Thermostat

115/1/60

208-230-460/3/60

M

Starter with

overloads

Non-fused

disconnect

at tower

Fan

Fiberglass Cooling Towers Chapter 6: Appendix Page 25 of 25

Loading...

Loading...