Sterlco Royal Series Compact Temperature Control Unit User Manual

Operation and Installation Manual

Royal Series

Water Temperature

Control Units

Important! Read Carefully Before Attempting to Install or Operate Equipment

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Part No. 682.88105.00 |

Revision G |

Bulletin No. SC1-610.8 |

||||

Write down your unit serial number(s) |

________________ |

________________ |

here for future reference |

________________ |

________________ |

|

________________ |

________________ |

|

________________ |

________________ |

Sterling/Sterlco is committed

to a continuing program of product improvement. Specifications, appearance, and dimensions described in this manual

are subject to change without notice.

© Copyright Sterling/Sterlco 2008

All rights reserved. |

|

Effective 4/15/08 |

Part No. 682.88105.00 |

Revision G |

Bulletin No. SC1-610.7 |

Page 2 |

Royal Series Water Temperature Control Units |

Safety Considerations

Sterling Royal Series temperature control units are designed to provide safe and reliable operation when installed and operated within design specifications, following national and local safety codes.

To avoid possible personnel injury or equipment damage when installing, operating, or maintaining this equipment, use good judgment and follow these safe practices:

Only PROPERLY TRAINED personnel familiar with the information within this manual should work on this equipment.

Follow all local SAFETY CODES.

Royal Series cabinets and piping are hot and are a BURN HAZARD.

Do not operate a Royal Series system without all outer panels installed. Pressurized hot water leaks can cause serious injury.

Wear SAFETY GLASSES and WORK GLOVES.

Use care when LOADING, UNLOADING, RIGGING, or

MOVING this equipment.

Operate this equipment within design specifications.

OPEN, TAG, and LOCK ALL DISCONNECTS before working on equipment. Sterling recommends following OSHA Lock-Out/Tag-Out Standard 29 CFR 1910.147.

Make sure the unit is properly GROUNDED before switching power on.

When welding or brazing in or around this equipment, be sure

VENTILATION is ADEQUATE. PROTECT adjacent materials from flame or sparks by shielding with sheet metal. An approved FIRE EXTINGUISHER should be close at hand and ready for use if needed.

Do not jump or bypass any electrical safety control.

Do not restore power until all tools, test equipment, etc. have been removed and the panels replaced.

Royal Series Water Temperature Control Units |

Page 3 |

Table of Contents

|

|

|

|

1 |

................................................General Information |

6 |

|

|

1-1 |

Introduction ..................................................................................... |

6 |

|

1-3 |

Models Covered.............................................................................. |

7 |

|

1-4 |

Standard Royal Series Features ..................................................... |

7 |

2 |

1-5 |

Available Options ............................................................................ |

8 |

Shipping Information ............................................. |

12 |

||

|

2-1 |

Unpacking and Inspection............................................................. |

12 |

|

2-2 |

In the Event of Shipping Damages................................................ |

12 |

|

2-3 |

If the Shipment is Not Complete.................................................... |

13 |

|

2-4 |

If the Shipment is Not Correct ....................................................... |

13 |

|

2-5 |

Returns ......................................................................................... |

13 |

3 |

2-6 |

Uncrating Your New Royal Series System.................................... |

14 |

Installation............................................................... |

16 |

||

|

3-1 |

Installation Location Considerations.............................................. |

16 |

|

3-2 |

Process Approach Temperature Considerations........................... |

16 |

|

3-3 |

External Piping Sizing Considerations .......................................... |

16 |

|

3-4 |

Piping Considerations for Permanent Installations........................ |

17 |

|

3-5 |

Piping Considerations for High Mobility Installations..................... |

18 |

|

3-6 |

Process Water Considerations...................................................... |

18 |

|

3-7 |

Making Process Water Connections ............................................. |

19 |

|

3-8 |

Making Cooling Water Connections .............................................. |

20 |

|

3-9 |

Making System Purge Connections .............................................. |

21 |

4 |

3-10 |

Making Electrical Connections ...................................................... |

24 |

Identifying Controls and Features ........................ |

27 |

||

|

4-1 |

Identifying Mechanical Controls and Features .............................. |

27 |

|

4-2 |

The Microprocessor Controller...................................................... |

31 |

|

4-3 |

Operating the Unit with the Controller ........................................... |

31 |

5 |

4-4 |

Communications ........................................................................... |

32 |

Startup and Operation............................................ |

33 |

||

|

5-1 |

Introduction ................................................................................... |

33 |

|

5-2 |

Startup Checklist ........................................................................... |

33 |

|

5-3 |

Starting the Temperature Control Unit .......................................... |

34 |

|

5-4 |

Sequence of Operation ................................................................. |

35 |

|

5-5 |

Checking Motor Rotation Direction................................................ |

36 |

6 |

5-6 |

Shutting Down the Temperature Control Unit ............................... |

36 |

Unit Maintenance.................................................... |

38 |

||

|

6-1 |

Preventive Maintenance................................................................ |

38 |

Page 4 |

Royal Series Water Temperature Control Units |

|

6-2 |

Corrective Maintenance ................................................................ |

39 |

|

6-3 Restoring the Controller to Factory Setup ..................................... |

41 |

|

|

6-4 |

Electrical Connections................................................................... |

41 |

|

6-5 |

Safety Devices .............................................................................. |

42 |

7 |

6-6 |

Cleaning and Storage ................................................................... |

44 |

Troubleshooting ..................................................... |

45 |

||

I |

Index ........................................................................ |

|

48 |

Royal Series Water Temperature Control Units |

Page 5 |

1 |

General Information |

|

|

1-1 Introduction

Sterling/Sterlco Royal Series water temperature control units are reliable, accurate, and easy-to-use process temperature control units. They are self-contained, portable, and shipped ready to use.

The Royal Series water temperature control unit is designed to circulate water through your process and to precisely, automatically, and reliably maintain it at a specified temperature. Standard unit operating range is from 0ºF (-17ºC) to 250°F (121°C), or up to 300°F (149°C) as an option. The unit is suited for use with city water, water from portable or central chillers or towers, or well water.

These units are designed for rapid recirculation of a relatively small amount of water to provide close and uniform temperature relation between To Process and From Process lines. This performance, of course, depends on the configuration of your process and any restrictions within the mold. The recirculation, combined with the large immersion heater and cooling capability, gives fast and accurate response to bring the water up to temperature or to changes in the settings when needed.

The 2010 Series water temperature control unit is a self-contained system consisting of a centrifugal pump, electric immersion heater, cool/vent solenoid valve, and electrical control, including a PID microprocessor controller and thermocouple. It is designed for use in process temperature control applications using water or a water/glycol mix. Any other use or fluid is prohibited.

Some standard safety devices include a mechanical overtemperature safety thermostat, a pressure relief valve, motor overload protection, a low pressure cutout switch, branch fusing, and non-fused lockable rotary disconnect.

A properly installed, operated, and maintained Royal Series system provides years of reliable operation. Please read and follow the instructions in this manual to get the most satisfaction from your Royal Series system.

Page 6 |

Royal Series Water Temperature Control Units |

1-2 Necessary Documents

The following documents are necessary for the operation, installation, and maintenance of Sterling/Sterlco Royal Series water temperature control units. Additional copies are available from Sterling.

Familiarize the appropriate personnel with these documents:

This manual.

The controller operation manual.

The electrical schematic and connection diagram placed inside the control enclosure.

The operation and installation manuals for accessories and options selected by the customer.

The Customer Parts List included in the information packet.

1-3 Models Covered

This manual provides operation, installation, and maintenance instructions for the Royal Series water temperature control unit.

Model numbers are listed on the serial tag. A model number followed by Q indicates a specially constructed unit, and not all information in this manual may apply. Make sure that you know the model number, serial number, and operating voltage of your temperature control unit if you contact Sterling.

1-4 Standard Royal Series Features

•Compact, rugged cabinet with easy-access side panels

•Cast-and-flange design to reduce connection points

•Halfand full-heat automatic switching capability

•Dual stage Incoloy™ immersion heater with IEC contactors

•NEMA 12 electrical enclosure

•Microprocessor controller with fuzzy logic; includes diagnostics features with indicator and warning status lights; CE and CUL

Royal Series Water Temperature Control Units |

Page 7 |

•Forward-facing liquid-filled To and From Process pressure gauges

•Independent high temperature safety thermostat

•Non-fused lockable rotary disconnect

•Branch fusing

•¼” cooling solenoid valve on ¾ to 3 hp (0.56 to 2.24 kW) models; ½” slow-close cooling solenoid valve on 5, 7½, & 10 hp (3.73, 5.60, & 7.46 kW) models

•EPDM/NI-Resist pump seal

•Adjustable low supply water pressure switch; factory-set at 16 psig (110 kPa/1.1 bars)

•150 psig (1,034 kPa/10.3 bars) pressure relief valve

•Choice of 230 or 460 operating voltages

•¾” water supply and drain connections; 1½” process connections

•Automatic vent sequence

•3” (76 mm) casters

•Operating range of 0ºF to 250ºF (-17ºC to 121ºC)

•Three (3) -year parts and labor warranty at the factory; five

(5)-year controller warranty, and limited lifetime warranty on wetted pump components and pump seal; subject to factory review

1-5 Available Options

Royal Series systems are available with options to tailor the unit to your requirements. Some are factory installed; some can be retrofitted in the field. Consult your Sterling sales representative for more information. Available Royal Series options include:

• Controller with integral flow meter; with: Up to 30 gpm (114 lpm) flow indicator - or -

30 to 75 gpm (114 to 284 lpm) flow indicator 0-20 mA and 4-20 mA current control output

Page 8 |

Royal Series Water Temperature Control Units |

Remote set point and retransmission; 0-20 mA and 4-20 mA

RS-232 or RS-485 communications Remote sensor; 10 ft. (3 m)

•Remote controller enclosure

•Heaters available in 12 kW, 18 kW, 24 kW, 36 kW, and 48 kW on direct-injection compact models; 36 kW and 48 kW heaters available on direct-injection upright models

•Closed-loop heat exchanger available in 3.7 sq. ft. (0.344 sq. m) on compact models; 3.7, 7.4, 11.2, 18.1, and 27.0 sq. ft. (0.135, 0.688, 1.042, 1.683, and 2.511 sq. m) on upright models

•Quick Cool function

•Auto system water purge (mold purge)

•Y-strainer

•Hammer arrestor (water hammer shock stop)

•Remote start/stop control

•Rubber feet; available in lieu of casters

•Non-ferrous brass construction

•Slow-close cooling solenoid valves available in 1/2” x 9/16” (CV = 3.5) and 3/4” x 3/4” (CV = 5.5)

•Modulating valves available in 1/2” (CV = 0.4, 1.3, 2.2, or 4.4), 3/4” (CV = 5.5 or 7.5), 1” (CV = 10 or 14),

and 11/4” (CV = 20)

•Two-zone stack rack with casters, common wiring and piping available; compact units only

•300ºF (149ºC) operation; includes graphite-impregnated silicon carbide seal

•Audible and visual general fault alarm

•Electrical operation available in 208, 230, 460, and 575 volts, 60 Hz; 200, 380, and 415 volts, 50 Hz

•UL/CUL-listed electrical subpanel

Royal Series Water Temperature Control Units |

Page 9 |

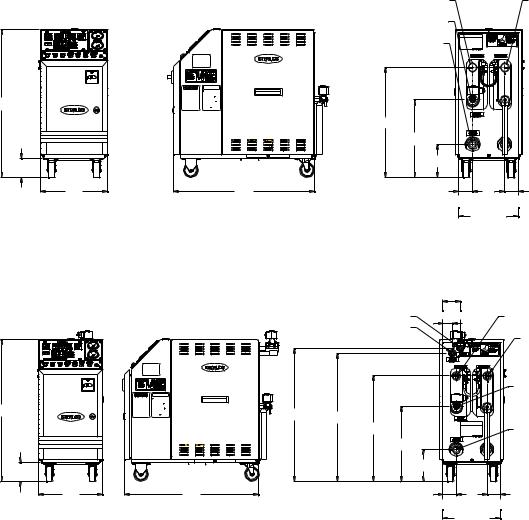

Figure 1

Typical Royal Series Water Temperature Control Unit and Specifications

Direct Injection

FROM PROCESS

COOLING WATER OUT

COOLING WATER IN

28 3/4"

|

21 7/16" |

|

15 1/8" |

3 3/4" |

6 7/16" |

|

|

13" |

28" |

|

2 3/4" |

TO PROCESS

2 3/4" |

11 3/4"

Closed Circuit

|

3 9/16" |

|

COOLING WATER OUT |

1 15/16" |

FROM PROCESS |

|

||

COOLING WATER IN |

|

|

|

|

TO PROCESS |

|

|

|

PROCESS WATER VENT |

28 3/4" |

27 1/8" |

26 1/16" |

|

|

|

||

|

|

|

|

|

|

21 7/16" |

PROCESS WATER IN |

|

|

15 1/8" |

|

3 3/4" |

|

6 7/16" |

|

|

|

|

|

13" |

28" |

2 3/4" |

2 3/4" |

|

|

||

|

|

|

11 3/4" |

Model |

|

|

|

|

|

|

|

Dimensions |

|

|

|

Shipping |

||||

number |

|

|

Pump |

|

|

H |

|

W |

|

|

D |

weight |

||||

460 / 230 |

hp |

kW |

gpm |

lpm |

psig |

kPa |

in. |

cm |

in. |

cm |

|

in. |

|

cm |

lbs. |

Kg |

|

¾ |

0.56 |

30 |

113.6 |

25 |

172.4 |

|

|

|

|

|

|

|

|

|

|

2010, |

1 |

0.75 |

35 |

132.5 |

30 |

206.9 |

|

|

|

|

|

|

|

|

210 |

96 |

2 |

1.50 |

50 |

189.3 |

30 |

206.9 |

28¾” |

73.0 |

13” |

33 |

|

28” |

|

71.1 |

|||

|

|

|

|

|

||||||||||||

9 kW heater |

3 |

2.24 |

60 |

227.1 |

35 |

241.3 |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||||

5 |

3.73 |

75 |

283.9 |

54 |

372.3 |

|

|

|

|

|

|

|

|

240 |

109 |

|

|

|

|

|

|

|

|

|

|

||||||||

|

7½ |

5.60 |

90 |

454.2 |

63 |

434.4 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

Page 10 |

Royal Series Water Temperature Control Units |

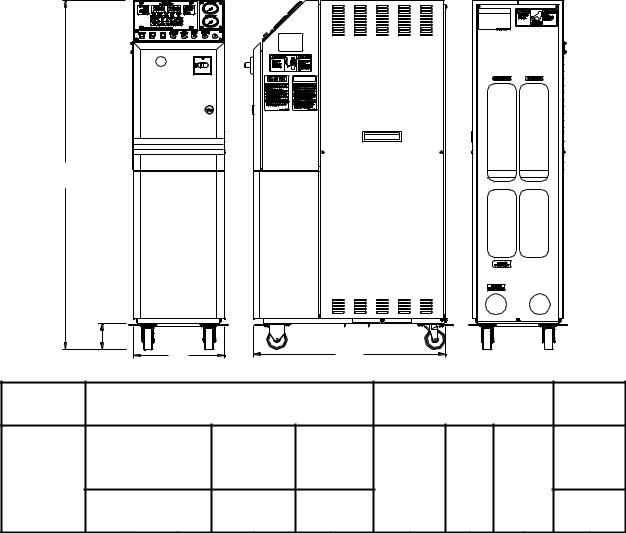

Figure 2

Typical Royal Upright Series Water Temperature Control Unit and Specifications

4948"7/8”

|

3 3/4" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13" |

|

|

|

28" |

|

|

|

|

|

|

|

|

Model |

|

|

|

|

|

|

|

|

|

Dimensions |

|

|

Shipping |

|||

number |

|

|

|

|

Pump |

|

|

|

H |

|

W |

|

D |

weight |

||

460 230 |

|

letter |

hp |

kW |

gpm |

lpm |

psig |

kPa |

in. |

cm |

in. cm |

in. |

cm |

lbs. |

Kg |

|

|

|

C |

¾ |

0.56 |

30 |

113.6 |

25 |

172.4 |

|

|

|

|

|

|

|

|

|

|

D |

1 |

0.75 |

35 |

132.5 |

30 |

206.9 |

|

|

|

|

|

|

210 |

96 |

2012, |

|

F |

2 |

1.50 |

50 |

189.3 |

30 |

206.9 |

|

|

|

|

|

|

||

|

48 |

122 |

13 |

33 |

28 |

71.1 |

|

|

||||||||

9 kW heater |

G |

3 |

2.24 |

60 |

227.1 |

35 |

241.3 |

|

|

|||||||

H |

5 |

3.73 |

75 |

283.9 |

54 |

372.3 |

|

|

|

|

|

|

240 |

109 |

||

|

|

|

|

|

|

|

|

|||||||||

|

|

J |

7½ |

5.60 |

90 |

340.7 |

63 |

434.4 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

K |

10 |

7.46 |

120 |

454.2 |

55 |

379.2 |

|

|

|

|

|

|

270 |

123 |

Figure 3

Royal Series Unit Full-Load Amps

|

Model |

|

|

Full-load amps at 460 volts |

|

|

||

hp |

|

kW |

9 kW heater |

12 kW heater |

18 kW heater |

24 kW heater |

36 kW heater |

48 kW heater |

0.75 hp |

0.56 kW |

12.7 amps |

16.5 amps |

24.0 amps |

31.6 amps |

47.4 amps |

62.4 amps |

|

1.00 hp |

0.75 kW |

13.1 amps |

16.9 amps |

24.4 amps |

32.0 amps |

47.8 amps |

62.8 amps |

|

2.00 hp |

1.50 kW |

14.7 amps |

18.5 amps |

26.0 amps |

33.6 amps |

49.4 amps |

64.4 amps |

|

3.00 hp |

2.24 kW |

16.1 amps |

19.9 amps |

27.4 amps |

35.0 amps |

50.8 amps |

65.8 amps |

|

5.00 hp |

3.73 kW |

18.9 amps |

22.7 amps |

30.2 amps |

37.8 amps |

56.6 amps |

71.6 amps |

|

7.50 hp |

5.60 kW |

22.3 amps |

26.1 amps |

33.6 amps |

41.2 amps |

57.0 amps |

72.0 amps |

|

10.00 hp |

7.46 kW |

26.0 amps |

30.0 amps |

37.0 amps |

45.0 amps |

60.0 amps |

75.0 amps |

|

Royal Series Water Temperature Control Units |

Page 11 |

2 |

Shipping Information |

|

|

2-1 Unpacking and Inspection

You should inspect your Sterling/Sterlco Royal Series temperature control unit for possible shipping damage. If the container and packing materials are in re-usable condition, save them for reshipment if necessary.

Thoroughly check the equipment for any damage that might have occurred in transit, such as broken or loose wiring and components, loose hardware and mounting screws, etc. In case of breakage, damage, shortage, or incorrect shipment, refer to the following sections.

2-2 In the Event of Shipping Damages

Important!

According to the contract terms and conditions of the Carrier,

the responsibility of the Shipper ends at the time and place of shipment.

Notify the transportation company’s local agent if you discover damage.

Hold the damaged goods and packing material for the examining agent’s inspection. Do not return any goods to

Sterling before the transportation company inspection and authorization.

File a claim against the transportation company. Substantiate the claim by referring to the agent’s report. A certified copy of our invoice is available upon request. The original Bill of Lading is attached to our original invoice. If the shipment was prepaid, contact Sterling at (262) 641-8610 for a receipted transportation bill.

Advise Sterling regarding your request for assistance and to obtain an RGA (return goods authorization) number.

Page 12 |

Royal Series Water Temperature Control Units |

2-3 If the Shipment is Not Complete

Check the packing list. The apparent shortage may be intentional.

Back-ordered items are noted on the packing list. You should have:

Sterling/Sterlco Royal Series water temperature control unit

Bill of lading

Packing list

Operating and Installation packet

Electrical schematic and panel layout drawings

Component instruction manuals

Re-inspect the container and packing material to see if you missed any smaller items during unpacking. Determine that the item was not inadvertently taken from the area before you checked in the shipment. Notify Sterling immediately of the shortage.

2-4 If the Shipment is Not Correct

If the shipment is not what you ordered, contact the parts and service department immediately at (262) 641-8610. Have the order number and item number available. Hold the items until you receive shipping instructions.

2-5 Returns

Important!

Do not return any damaged or incorrect items until you receive shipping instructions from Sterling.

Royal Series Water Temperature Control Units |

Page 13 |

2-6 Uncrating Your New Royal Series System

Royal Series water temperature control units are shipped fastened to a skid and covered with a cardboard box.

Carefully remove the staples on the bottom of the box, lift off the box, and remove the bolts holding the unit to the skid.

Caution!

Be careful when cutting straps.

Straps may spring back and cause injury!

From the side, slip two lifting straps between the skid and temperature control unit. Spread the straps from the center line so it is balanced.

Loop the straps over a fork truck fork. Lift slowly and only high enough to clear the skid. Use a pry bar if necessary to remove the skid from the unit.

Carefully slide the skid from beneath the unit and lower the unit. Lower slowly. The unit should land on its casters and can be rolled into position.

Retain the crating in case reshipment is necessary due to hidden shipping damage.

Page 14 |

Royal Series Water Temperature Control Units |

- Notes -

Royal Series Water Temperature Control Units |

Page 15 |

Loading...

Loading...