Stepperonline CL42T User Manual

Closed-loopStepper Driver CL42T

UserManual

CL42T

Closed LoopStepper Driver

Designed by StepperOnline®

Manufactured byLeadshine®

Address: Address: #7 Zhongke Road, Jiangning, Nanjing, China

Tel:0086-2587156578 Web:www.omc-stepperonline.com

Sales: sales@stepperonline.com |

Support: technical@stepperonline.com |

Closed-loopStepper Driver CL42T

Notice

Read this manual carefully before any assembling and using. Incorrect handling of products in this manual can result in injury and damage to persons and machinery. Strictly adhere to the technical information regarding installation requirements.

This manual is not for use or disclosure outsides of STEOOERONLINE except under permission. All rights are reserved. No part of this manual shall be reproduced, stored in retrieval form, or transmitted by any means, electronic, mechanical, photocopying, recording, or otherwise without approval from STEPPERONLINE. While every precaution has been taken in the preparation of the book,STEPPERONLINE assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein.

This document is proprietary information of STEPPERONLINE that is furnished for customer use ONLY. Information in this documation is subject to change without notice and does not represent a commitment on the part of STEPPERONLINE. Therefore, information contained in this manual may be updated from time-to time due to product improvements, etc., and may not conform in every respect to former issues.

|

|

Closed-loopStepper Driver CL42T |

|

Tableof Contents |

|

1. Introductions......................................................................................................................................................... |

1 |

|

1.1 |

Features......................................................................................................................................................... |

1 |

1.2Applications .................................................................................................................................................. |

1 |

|

2. Specifications......................................................................................................................................................... |

1 |

|

2.1 |

Electrical Specifications................................................................................................................................. |

1 |

2.2 |

Environment.................................................................................................................................................. |

1 |

2.3 |

Mechanical Specifications ............................................................................................................................. |

2 |

2.4 |

Elimination of Heat ....................................................................................................................................... |

2 |

3. Connection Interface and LED Indication ........................................................................................................... |

2 |

|

3.1 |

Connector P1 Interface .................................................................................................................................. |

3 |

|

3.1.1 PinAssignments of P1......................................................................................................................... |

3 |

|

3.1.2 Control Signal Wiring(P1)................................................................................................................... |

3 |

3.2 |

Connector P2................................................................................................................................................. |

4 |

|

3.2.1 PinAssignments of P2......................................................................................................................... |

4 |

|

3.2.2 Motor and Power Supply Wiring(P2)................................................................................................... |

4 |

3.3 |

Connector P3................................................................................................................................................. |

4 |

3.4 |

Connector P4................................................................................................................................................. |

5 |

3.5 |

LED Light Indication..................................................................................................................................... |

5 |

4. Power Supply Selection......................................................................................................................................... |

5 |

|

4.1 |

Regulated or Unregulated Power Supply........................................................................................................ |

5 |

4.2 |

Power Supply Sharing ................................................................................................................................... |

6 |

4.3 |

Selecting Supply Voltage ............................................................................................................................... |

6 |

5. DIP Switch Configurations ................................................................................................................................... |

6 |

|

5.1 |

Microstep Resolution(SW1-SW4).................................................................................................................. |

6 |

5.2 Other DIP Switch Setting(SW5-SW8)............................................................................................................ |

7 |

|

6. Typical Connection................................................................................................................................................ |

7 |

|

7. Sequence Chart of Control Signals....................................................................................................................... |

8 |

|

8. Protection Functions ............................................................................................................................................. |

9 |

|

9. Troubleshooting..................................................................................................................................................... |

9 |

|

10. Warranty ........................................................................................................................................................... |

10 |

|

Closed-loopStepper Driver CL42T

1. Introductions

This Closed Loop Stepper Driver, offers an alternative for applications requiring higher performance and higher reliability than open loop stepper system, and it remains cost-effective. The CL42T can power 2-phase NEMA11, 14 and 17 stepper motors with incremental encoders(Encoder resolution must be 1000-line). Compared with traditional open loop stepper systems, a CL42T adopted closed loop step system can eliminate potential loss of step, make real-time position error correction, and do not need torque reservation (100% torque implementation). Also it can power the driven stepper motor with reduced heating, lower noise, low vibration…

1.1 Features

No loss of step

No torque reservation

No hunting or overshooting

No tuning for easy setup

Low noise and vibration, smooth motion

20-50VDC supply voltage, max 3Aoutput current

Max 200 KHz input frequency

15 micro step settings of 800-51,200 via DIP switches, or 200-51,200 via software (increase by 200)

Protections for over voltage, over current and position following error

1.2 Applications

Its great features of quicker response and no hunting make STEPPERONLINE’s closed loop stepper driver is ideal for applications such as bonding and vision systems in which rapid motions with a short distance are required and hunting would be a problem. And it is ideal for applications where the equipment uses a belt-drive mechanism or otherwise has low rigidity and you don't want it to vibrate when stopping.

2. Specifications

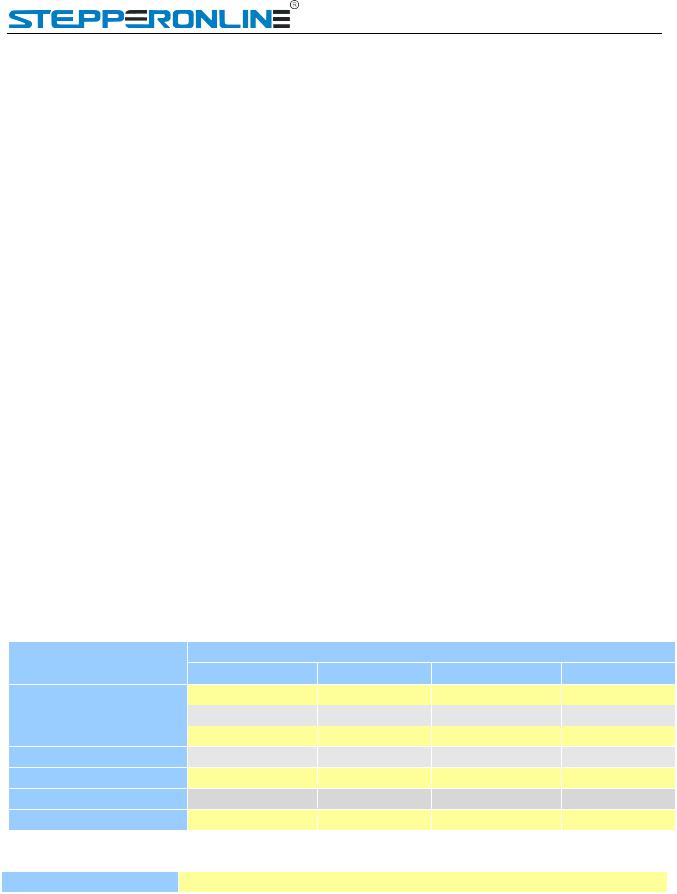

2.1 Electrical Specifications |

|

|

|

|

|

|

Parameters |

|

|

CL42T |

|

|

|

Min |

Typical |

Max |

Unit |

|||

|

||||||

Output Current |

0 |

- |

3 |

A |

||

Supply Voltage |

24 |

24 |

48 |

VDC |

||

Logic signal current |

7 |

10 |

16 |

mA |

||

Pulse input frequency |

0 |

- |

200 |

kHz |

||

Minimal pulse width |

2.5 |

- |

- |

μS |

||

Minimal direction setup |

5.0 |

- |

- |

μS |

||

Isolation resistance |

500 |

|

|

MΩ |

||

2.2 Environment |

|

|

|

|

|

|

Cooling |

|

Natural Cooling or Forced cooling |

|

|

||

|

|

|

|

|

||

Tel:0086-2587156578 |

|

|

Web: www.omc-stepperonline.com |

|||

Email:sales@stepperonline.com |

|

1 |

|

|

|

|

Loading...

Loading...