Closed-loop Stepper Driver CL42T

User Manual

CL42T

Closed Loop Stepper Driver

Designed by StepperOnline®

Manufactured by Leadshine®

Address: Address: #7 Zhongke Road, Jiangning, Nanjing, China

Tel:0086-2587156578 Web:www.omc-stepperonline.com

Sales: sales@stepperonline.com Support: technical@stepperonline.com

Closed-loop Stepper Driver CL42T

Notice

Read this manual carefully before any assembling and using. Incorrect handling of products in this manual can result in

injury and damage to persons and machinery. Strictly adhere to the technical information regarding installation

requirements.

This manual is not for use or disclosure outsides of STEOOERONLINE except under permission. All rights are

reserved. No part of this manual shall be reproduced, stored in retrieval form, or transmitted by any means, electronic,

mechanical, photocopying, recording, or otherwise without approval from STEPPERONLINE. While every precaution

has been taken in the preparation of the book,STEPPERONLINE assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained herein.

This document is proprietary information of STEPPERONLINE that is furnished for customer use ONLY. Information

in this documation is subject to change without notice and does not represent a commitment on the part of

STEPPERONLINE. Therefore, information contained in this manual may be updated from time-to time due to product

improvements, etc., and may not conform in every respect to former issues.

Closed-loop Stepper Driver CL42T

Table of Contents

1. Introductions ......................................................................................................................................................... 1

1.1 Features ......................................................................................................................................................... 1

1.2 Applications .................................................................................................................................................. 1

2. Specifications ......................................................................................................................................................... 1

2.1 Electrical Specifications ................................................................................................................................. 1

2.2 Environment .................................................................................................................................................. 1

2.3 Mechanical Specifications ............................................................................................................................. 2

2.4 Elimination of Heat ....................................................................................................................................... 2

3. Connection Interface and LED Indication ........................................................................................................... 2

3.1 Connector P1 Interface .................................................................................................................................. 3

3.1.1 Pin Assignments of P1 ......................................................................................................................... 3

3.1.2 Control Signal Wiring(P1) ................................................................................................................... 3

3.2 Connector P2 ................................................................................................................................................. 4

3.2.1 Pin Assignments of P2 ......................................................................................................................... 4

3.2.2 Motor and Power Supply Wiring(P2) ................................................................................................... 4

3.3 Connector P3 ................................................................................................................................................. 4

3.4 Connector P4 ................................................................................................................................................. 5

3.5 LED Light Indication ..................................................................................................................................... 5

4. Power Supply Selection ......................................................................................................................................... 5

4.1 Regulated or Unregulated Power Supply ........................................................................................................ 5

4.2 Power Supply Sharing ................................................................................................................................... 6

4.3 Selecting Supply Voltage ............................................................................................................................... 6

5. DIP Switch Configurations ................................................................................................................................... 6

5.1 Microstep Resolution(SW1-SW4) .................................................................................................................. 6

5.2 Other DIP Switch Setting(SW5-SW8) ............................................................................................................ 7

6. Typical Connection ................................................................................................................................................ 7

7. Sequence Chart of Control Signals ....................................................................................................................... 8

8. Protection Functions ............................................................................................................................................. 9

9. Troubleshooting ..................................................................................................................................................... 9

10. Warranty ........................................................................................................................................................... 10

Closed-loop Stepper Driver CL42T

1. Introductions

This Closed Loop Stepper Driver, offers an alternative for applications requiring higher performance and higher

reliability than open loop stepper system, and it remains cost-effective. The CL42T can power 2-phase NEMA11, 14

and 17 stepper motors with incremental encoders(Encoder resolution must be 1000-line). Compared with traditional

open loop stepper systems, a CL42T adopted closed loop step system can eliminate potential loss of step, make

real-time position error correction, and do not need torque reservation (100% torque implementation). Also it can

power the driven stepper motor with reduced heating, lower noise, low vibration…

1.1 Features

No loss of step

No torque reservation

No hunting or overshooting

No tuning for easy setup

Low noise and vibration, smooth motion

20-50VDC supply voltage, max 3A output current

Max 200 KHz input frequency

15 micro step settings of 800-51,200 via DIP switches, or 200-51,200 via software (increase by 200)

Protections for over voltage, over current and position following error

1.2 Applications

Its great features of quicker response and no hunting make STEPPERONLINE’s closed loop stepper driver is ideal for

applications such as bonding and vision systems in which rapid motions with a short distance are required and hunting

would be a problem. And it is ideal for applications where the equipment uses a belt-drive mechanism or otherwise has

low rigidity and you don't want it to vibrate when stopping.

2. Specifications

2.1 Electrical Specifications

Parameters

Min Typical Max Unit

Output Current 0 - 3 A

Supply Voltage 24 24 48 VDC

Logic signal current 7 10 16 mA

Pulse input frequency 0 - 200 kHz

Minimal pulse width 2.5 - - μS

Minimal direction setup 5.0 - - μS

Isolation resistance 500 MΩ

CL42T

2.2 Environment

Cooling Natural Cooling or Forced cooling

Tel: 0086-2587156578 Web: www.omc-stepperonline.com

Email:sales@stepperonline.com 1

Operating Environment

Storage Temperature

Weight Approx. 220 g (7.76 oz)

2.3 Mechanical Specifications

(unit: mm [1inch=25.4mm])

Closed-loop Stepper Driver CL42T

Environment

Ambient Temperature

Humidity

Operating Temperature

Vibration

Avoid dust, oil fog and corrosive gases

0°C - 65°C (32°F - 149°F)

40%RH-90%RH

0°C - 50°C (32°F - 122°F)

10-50Hz / 0.15mm

-20°C - 65°C (-4°F - 149°F)

Figure 1: Mechanical specifications

* Side mounting recommended for better heat dissipation

2.4 Elimination of Heat

CL42T reliable working temperature should be < 60℃ (140°F)

It is recommended to mount the driver vertically to maximize heat sink area. Use forced cooling method to cool if

necessary.

3. Connection Interface and LED Indication

Tel: 0086-2587156578 Web: www.omc-stepperonline.com

Email:sales@stepperonline.com 2

Closed-loop Stepper Driver CL42T

The CL57T has four connector blocks P1&P2&P3&P4 (see above picture). P1 is for control signals connections, P2 is

for power and motor connections, P3 is for encoder signals input connections, and P4 is for connecting with PC tuning

software. The following tables are brief descriptions of the four connectors. More detailed descriptions of the pins and

related issues are presented in section 4, 5, 9.

3.1 Connector P1 Interface

3.1.1 Pin Assignments of P1

Pin Name I/O

PUL+ I

PUL- I

DIR+ I

DIR- I

ENA+ I

ENA- I

ALM+ O

ALM- O

Details

Pulse signal: In single pulse mode (setting by DIP switch SW7), 4.5-24V when PUL-HIGH,

0-0.5V when PUL-LOW. The same as DIR and ENA signals. Minimal pulse width of 2.5μs and

dutycycle of pulse is recommended 50%. In double pulse mode, this input represents clockwise

(CW) pulse, active both at high level and low level.

DIR signal: In single pulse mode, this signal has low/high voltage levels to represent two

directions of motor rotation. Minimal direction setup time of 5μs. Also swapping the

connection of two wires of a coil (e.g. A+ and A-) to the driver will reverse motor direction. In

double pulse mode, this signal is counter-clock (CCW) pulse, active both at high level and low

level.

Enable signal: This signal is used for enabling/disabling the driver. High level 4.5-24V (NPN

control signal) for enabling the driver and low level for disabling the driver. PNP and

Differential control signals are on the contrary, namely Low level for enabling. By default it

is left UNCONNECTED (ENABLED).

Fault Signal: OC output signal, active when one of the following protection is activated:

over-voltage, over current, short circuit and position following error. This port can sink or

source 20mA current at 24V. In default, the resistance between ALM+ and ALM- is low

impedance in normal operation and become high when the driver goes into error.

!

Notice

Notes: (1) shielding control signal wires is suggested; (2) To avoid interference, don’t tie PUL/DIR control

signal and motor wires together;(3) No need connect resistance for 12V or 24V control signal.

3.1.2 Control Signal Wiring(P1)

The CL42T can accept differential and single-ended inputs (including open-collector and PNP output). The CL42T has

Tel: 0086-2587156578 Web: www.omc-stepperonline.com

Email:sales@stepperonline.com 3

Closed-loop Stepper Driver CL42T

3 optically isolated logic inputs which are located on connector P1 to accept line drive control signals. These inputs are

isolated to minimize or eliminate electrical noises coupled with the drive control signals. Recommend using line drive

control signals to increase noise immunity for the driver in interference environments. In the following figures,

connections to open-collector and PNP signals are illustrated.

Figure 2: Connections to PNP signal Figure 3: Connections to open-collector signal

(common-cathode) (common-anode)

3.2 Connector P2

3.2.1 Pin Assignments of P2

Pin Name Details

A+, A- Motor Phase A connections. Connect motor A+ wire to A+ Pin; motor A- wire to A-

B+, B- Motor Phase B connections. Connect motor B+ wire to B+ Pin; motor B- wire to B-

+Vdc Power supply positive connection. Suggest 24-48VDC power supply voltage

GND Power supply ground connection.

!

Warning

is powered on.

3.2.2 Motor and Power Supply Wiring(P2)

The CL42T can drive NEMA11, 14 and 17 closed loop stepper motor with encoder resolution of 1000 ppr. The current

loop PID will be adjusted automatically regarding to function of motor auto-identification and parameter

auto-configuration, to output optimal torque from wide-range motors. However, the user can also configure the current

in the tuning software. The configurable parameters include motor peak current, closed loop holding current, micro

step and etc.

3.3 Connector P3

Warning: Don’t plug or unplug the P1 & P2 terminal block to avoid driver damage or injury when CL42T

Drive Pin Name Description

EB+

EB-

EA+

Tel: 0086-2587156578 Web: www.omc-stepperonline.com

Email:sales@stepperonline.com 4

Encoder B+ input

Encoder B- input

Encoder A+ input

Closed-loop Stepper Driver CL42T

EA-

VCC

EGND

Encoder A- input

+5V power output

Signal ground

3.4 Connector P4

It is a RS232 communication port using to connect with PC software to configure the motor peak current, closed loop

holding current, microstep, active level.

RS232 Communication Port – RJ11

Pin Name I/O Description

1

2

3

4

5

6

!

Notice

Notes: RS232 connection of CL42T is for tuning purpose only, not for RS232 command controls.

NC - Not connected.

+5V O +5V power output.

TxD O RS232 transmit.

GND GND Ground.

RxD I RS232 receive.

NC - Not connected.

3.5 LED Light Indication

There are two LED lights for CL42T. The GREEN one is the power indicator which will be always on generally. The

RED one is a protection indicator which will flash 1,2 or 7 times in a 5-second period, when protection enabled for a

CL42T. Different number of flashes indicates different protection type (read section 8 for detail).

4. Power Supply Selection

The CL42T can power medium and small size closed loop stepper motors (frame size from NEMA11 to 17). To get

good driving performances, it is important to select supply voltage and output current(by configuring motor peak

current) properly. Generally speaking, supply voltage determines the high speed performance of the motor, while

output current determines the output torque of the driven motor (particularly at lower speed). Higher supply voltage

will allow higher motor speed to be achieved, at the price of more noise and heating. If the motion speed requirement is

low, it’s better to use lower supply voltage to decrease noise, heating and improve reliability.

4.1 Regulated or Unregulated Power Supply

Both regulated and unregulated power supplies can be used to supply the driver. However, unregulated power supplies

are preferred due to their ability to withstand current surge and fast response for current change. If you prefer to a

regulated power supply, it is suggested to choose such a power supply specially designed for stepper/servo controls Or,

in the case when only normal switching power supplies are available, it is important to use “OVERSIZE” high current

output rating power supplies (for example, using a 4A power supply for 3A stepper motor) to avoid problems such as

Tel: 0086-2587156578 Web: www.omc-stepperonline.com

Email:sales@stepperonline.com 5

Closed-loop Stepper Driver CL42T

cunt clamp. On the other hand, if unregulated supply is used, one may use a power supply of lower current rating than

that of motor (typically 50%~70% of motor current). The reason is that the driver draws current from the power

supply capacitor of the unregulated supply only during the ON duration of the PWM cycle, but not during the OFF

duration. Therefore, the average current withdrawn from power supply is considerably less than motor current. For

example, two 3A motors can be well supplied by one power supply of 4A rating.

4.2 Power Supply Sharing

Multiple CL42T drivers can share one power supply to reduce cost, if that power supply has enough power capacity. To

avoid cross interference, connect each stepper driver directly to the shared power supply separately. To avoid cross

interference, DO NOT daisy-chain connect the power supply input pins of the Drivers. Instead connect them to power

supply separately.

4.3 Selecting Supply Voltage

The CL42T is designed to operate within +24 - +48VDC voltage input. When selecting a power supply, besides

voltage from the power supply power line voltage fluctuation and back EMF voltage generated during motor

deceleration needs also to be taken into account. Ideally it is suggested to use a power supply with the output of

+24VDC, leaving room for power line voltage fluctuation and back -EMF.

Higher supply voltage can increase motor torque at higher speeds, thus helpful for avoiding losing steps. However,

higher voltage may cause bigger motor vibration at lower speed, and it may also cause over-voltage protection or even

driver damage. Therefore, it is suggested to choose only sufficiently high supply voltage for intended applications.

5. DIP Switch Configurations

This drive uses an 8-bit DIP switch to set microstep resolution, motor direction, auto tuning switch and so on.

5.1 Microstep Resolution(SW1-SW4)

Microstep resolution is set by SW1, 2, 3, 4 of the DIP switches as shown in the following table:

Steps/Revolution SW1 SW2 SW3 SW4

Software Configured (Default 1600)

800

1600

3200

6400

12800

25600

Tel: 0086-2587156578 Web: www.omc-stepperonline.com

Email:sales@stepperonline.com 6

on on on on

off on on on

on off on on

off off on on

on on off on

off on off on

on off off on

Closed-loop Stepper Driver CL42T

51200

1000

2000

4000

5000

8000

10000

20000

40000

5.2 Other DIP Switch Setting(SW5-SW8)

SW5

SW6

SW7

SW8

Function

Default Direction

Auto Tuning No Yes

Pulse Model CW/CCW(double pulse) PUL/DIR(single pulse)

Pulse Edge Falling Rising

off off off on

on on on off

off on on off

on off on off

off off on off

on on off off

off on off off

on off off off

off off off off

On Off

CW (clock-wise) CCW (counter-clock-wise)

!

Notice

Notes: (1) The factory setting of DIP switch are ‘on off on on off off off off’; (2) The default direction is

related to the DIR level, you can toggle SW5 to change it .

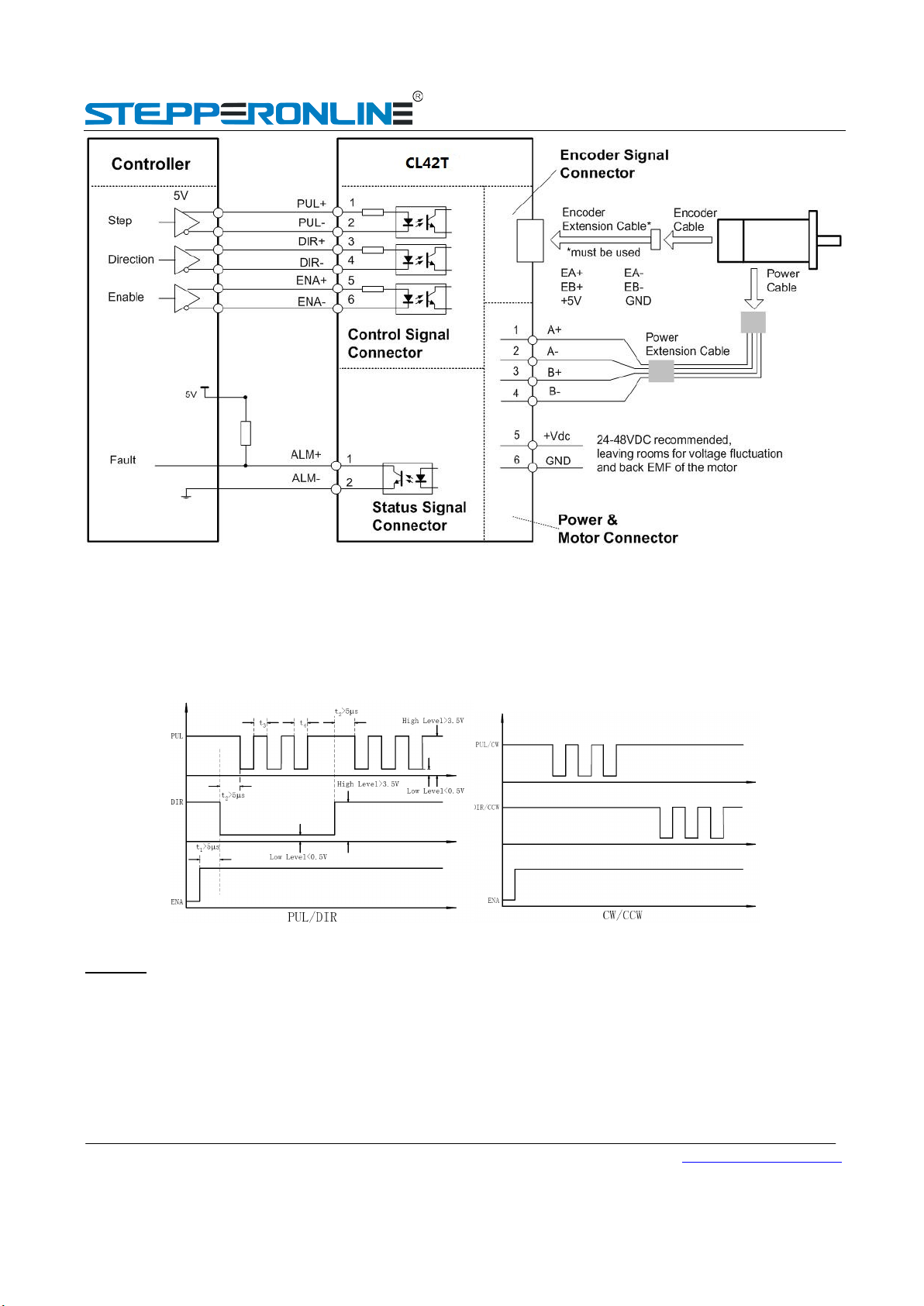

6. Typical Connection

A complete closed loop stepper system should include closed loop motor, driver, power supply and controller (pulse

generator). A typical connection is shown as figure 9.

Tel: 0086-2587156578 Web: www.omc-stepperonline.com

Email:sales@stepperonline.com 7

Closed-loop Stepper Driver CL42T

Figure 9: Typical connection

7. Sequence Chart of Control Signals

In order to avoid some fault operations and deviations, PUL, DIR and ENA should abide by some rules, shown as

following diagram:

Figure 10: Sequence chart of control signals

Remark:

a) t1: ENA must be ahead of DIR by at least 5s. Usually, ENA+ and ENA- are NC (not connected). See

“Connector P1 Configurations” for more information.

b) t2: DIR must be ahead of PUL effective edge by 5s to ensure correct direction;

c) t3: Pulse width not less than 2.5s;

d) t4: Low level width not less than 2.5s.

Tel: 0086-2587156578 Web: www.omc-stepperonline.com

Email:sales@stepperonline.com 8

Closed-loop Stepper Driver CL42T

8. Protection Functions

To improve reliability, the drive incorporates some built-in protections features.

Priority

1st

2nd

3nd

Time(s) of

Blink

1

2

7

Sequence wave of red LED Description

0.2S

0.2S

0.3S

0.2S

0.3S

5S

5S

5S

Over-current protection activated when peak

current exceeds the limit.

Over-voltage protection activated when driver

working voltage is greater than 90VDC

Position following error

When above protections are active, the motor shaft will be free or the red LED blinks. Reset the driver by repowering it

to make it function properly after removing above problems.

9. Troubleshooting

In the event that your driver doesn’t operate properly, the first step is to identify whether the problem is electrical or

mechanical in nature. The next step is to isolate the system component that is causing the problem. As part of this

process you may have to disconnect the individual components that make up your system and verify that they operate

independently. It is important to document each step in the troubleshooting process. You may need this documentation

to refer back to at a later date, and these details will greatly assist our Technical Support staff in determining the

problem should you need assistance.

Many of the problems that affect motion control systems can be traced to electrical noise, controller software errors, or

mistake in wiring.

Problem Symptoms and Possible Causes

Symptoms Possible Problems

No power

Motor is not rotating

Motor rotates in the wrong direction

The driver in fault

Erratic motor motion

Tel: 0086-2587156578 Web: www.omc-stepperonline.com

Email:sales@stepperonline.com 9

Microstep resolution setting is wrong

Fault condition exists

The driver is disabled

The Direction signal level is reverse

Power supply voltage beyond driver’s input range

Something wrong with motor coil

Wrong connection

Control signal is too weak

Control signal is interfered

Wrong motor connection

Motor stalls during acceleration

Excessive motor and driver heating

Closed-loop Stepper Driver CL42T

Something wrong with motor coil

Current setting is too small

Motor is undersized for the application

Acceleration is set too high

Power supply voltage too low

Inadequate heat sinking / cooling

Motor peak current setting is too high

Motor vibration when power on

Speed loop Kp is too high

10. Warranty

StepperOnline warrants its products against defects in materials and workmanship for a period of 12 months from

shipment. During the warranty period, StepperOnline will either, at its option, repair or replace products which proved

to be defective. To obtain warranty service, a returned material authorization number (RMA) must be obtained before

returning product for service.

Exclusions: The above warranty does not extend to any product damaged by reasons of improper or inadequate

handlings by customer, improper or inadequate customer wirings, unauthorized modification or misuse, or operation

beyond the electrical specifications of the product and/or operation beyond environmental specifications for the

product.

If your product fail during the warranty period, please contact your seller for how and where to ship the failed product

for warranty or repair services first,you can also e-mail at technical@ stepperonline.com to obtain a retured material

authorization number (RMA ) before returning product for service. Please include a written description of the problem

along with contact name and address.

Tel: 0086-2587156578 Web: www.omc-stepperonline.com

Email:sales@stepperonline.com 10

Loading...

Loading...