Page 1

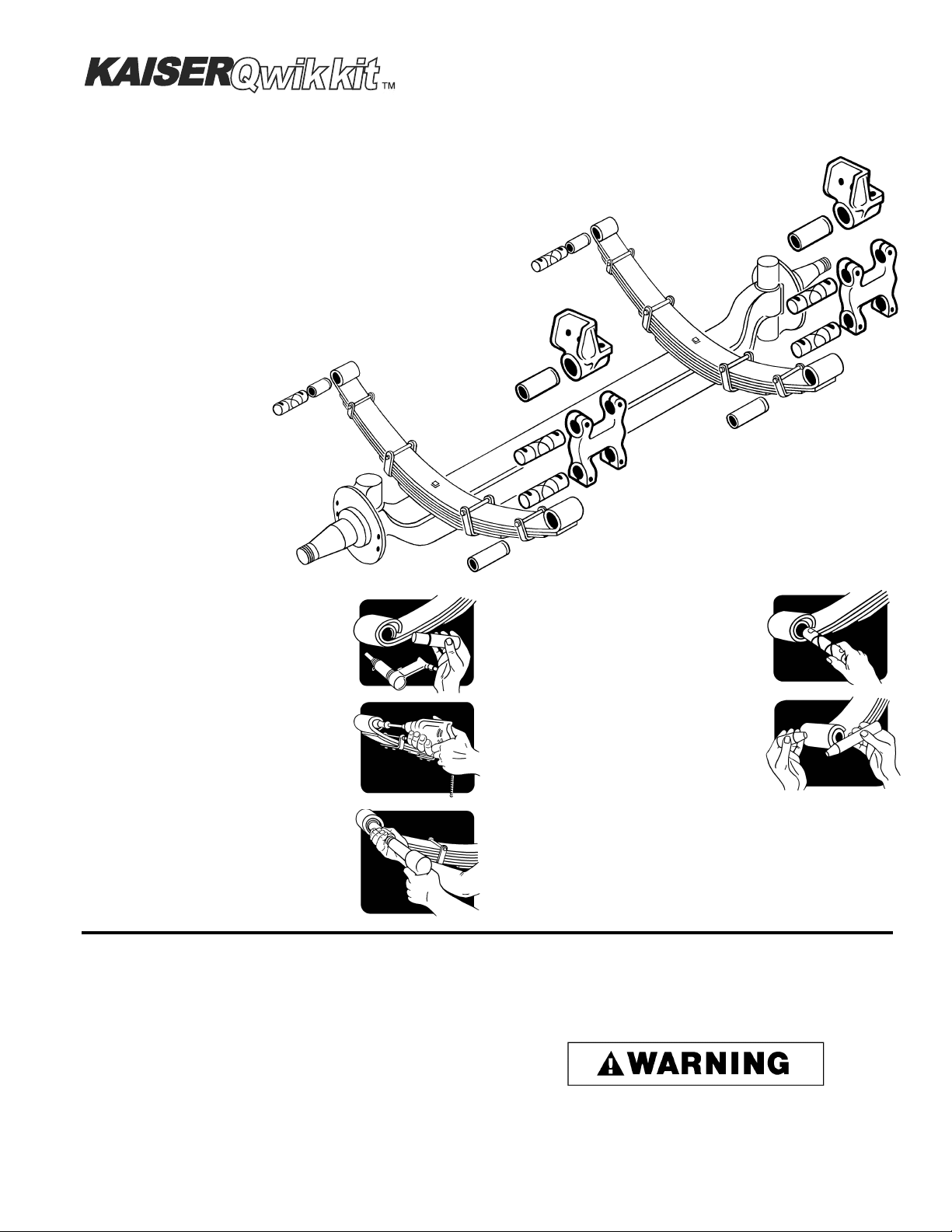

This kit has 2 Grease grooved pins and 2 no-ream

bushing

assemblies with seals

There is a repair kit for each positions on the front

springs and some rear spring applications.

One kit will repair the front eyes and a kit for each of the rear

shackles. The repair of all 6 (six) positions on both front

springs will require 3 (three) repair kits. (see Kaiser

“Cross Reference Catalog”.

PREPARATION

1. It is not necessary to remove the spring

from the vehicle. Repairing one end of the

spring at a time will keep its position with

the hanger. Remove spring pin and drive

out old bushing. Inspect and clean

spring eye.

2. Remove grit, dirt and burrs

NO REAM INSTALLATION

KAISER INSTALLATION

3. Wipe small amount of grease in the spring eye.

Start the bushing assembly into the eye by hand.

Drive the bushing assembly into the eye until centered in the bore using a drive adapter with an

impact hammer or hand drive arbor.

4. Test the pin in the bushing. Pin should pass

through with some resistance from the seals.

IF THE PIN DOESN’T GO THROUGH BUSHING ,

DO NOT FORCE IT.

Remove pin and drive the bushing assembly out.

Remove the obstruction with emery cloth, rotary

file or similar tool and repeat steps 3. and 4..

COMPLETING ASSEMBLY

5. Raise spring up to hanger. Use alignment pins

to position spring eye in the hanger. Place short

pin in the backside of the hanger until it is in the

spring eye. Tap the long pin into the hanger

opposite the short pin.

WARRANTY:

V.W. Kaiser Engineering, Inc. warrants the parts contained in Kaiser products* to be free from defects in

material and workmanship, under normal use and maintenance for a period of one year. This warranty shall

be limited to replacing or allowing credit for the parts contained in the Kaiser products* provided that notice

of defects and proof is promptly given. This warranty does not apply to damage or to defects In any parts

contained In the Kaiser products* caused by misuse, neglect, accident, incorrect Installation, alteration or

repair. THIS WARRANTY, AND THE MANUFACTURER'S OBLIGATION HEREUNDER IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS, IMPLIED OR STATUTORY, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE, AND ALL OTHER OBLIGATIONS OR LIABILITIES, INCLUDING SPECIAL OR CONSEQUENTIAL DAMAGES.

WARRANTY CLAIMS:

The following procedure applies under this warranty: All parts under warranty must be returned to the seller (authorized distributor). The seller returns the parts in question with a complete history along with information of the vehicle from which the parts were removed, prepaid, to V.W. Kaiser Engineering, Inc., 4641

Industrial Drive, Millington, Michigan, 48746, for SERVICE ANALYSIS. Items approved as defective under

terms of the warranty will be replaced. All claims will receive a SERVICE ANALYSIS report.

*Kaiser products consist of Qwlk KIt™ and Kaiser PLUS™

Call for assistance:

Business hours: 8:00 A.M. to 5:00 P.M. EST. Call will be answered direct

by technical service people. After hours: Place message on answering

machine. Calls will be returned next working day or sooner.

CUSTOMER SERVICE: 888-854-6474 (888-8KingPin)

WARNING: During removal and installation procedures, never use steel hammer or tool to

strike hardened metal parts, i.e. King Pin. Failure to heed warning could crack or shatter

part, creating a risk of personal injury to the servicing technician and/or component damage which may Jeopardize the safety of the vehicle user. For proper removal and installation procedures, refer to axle manufacturer's service literature.

5. continued

Drive the long pin in until it is flush with the

hanger. Place the spring pin behind the long

alignment pin. Drive the spring pin into the eye

until it lines up with the hanger. Finish the assembly using normal installation procedures.

NOTE: markings on the end of the pin are

parallel with the lock flats on the pin to help with

alignment.

GREASING

6. The Kaiser grease grooved pin and bushing

provides more lubrication in the spring eye. Apply

grease until it appears at each end of the bushing assembly between the spring and the hanger. Kaiser grooved spring

pins will take grease every time without additional work while using normal

maintenance procedures.

CAUTION: Grease must appear at each end of the spring for proper

lubrication. The seals in each end of the bushing assembly will not

function if torn. The pin may have to be removed for inspection.

See your local distributor for damaged seal replacement.

01 577 0044

Loading...

Loading...