Page 1

Q

TM

WIK

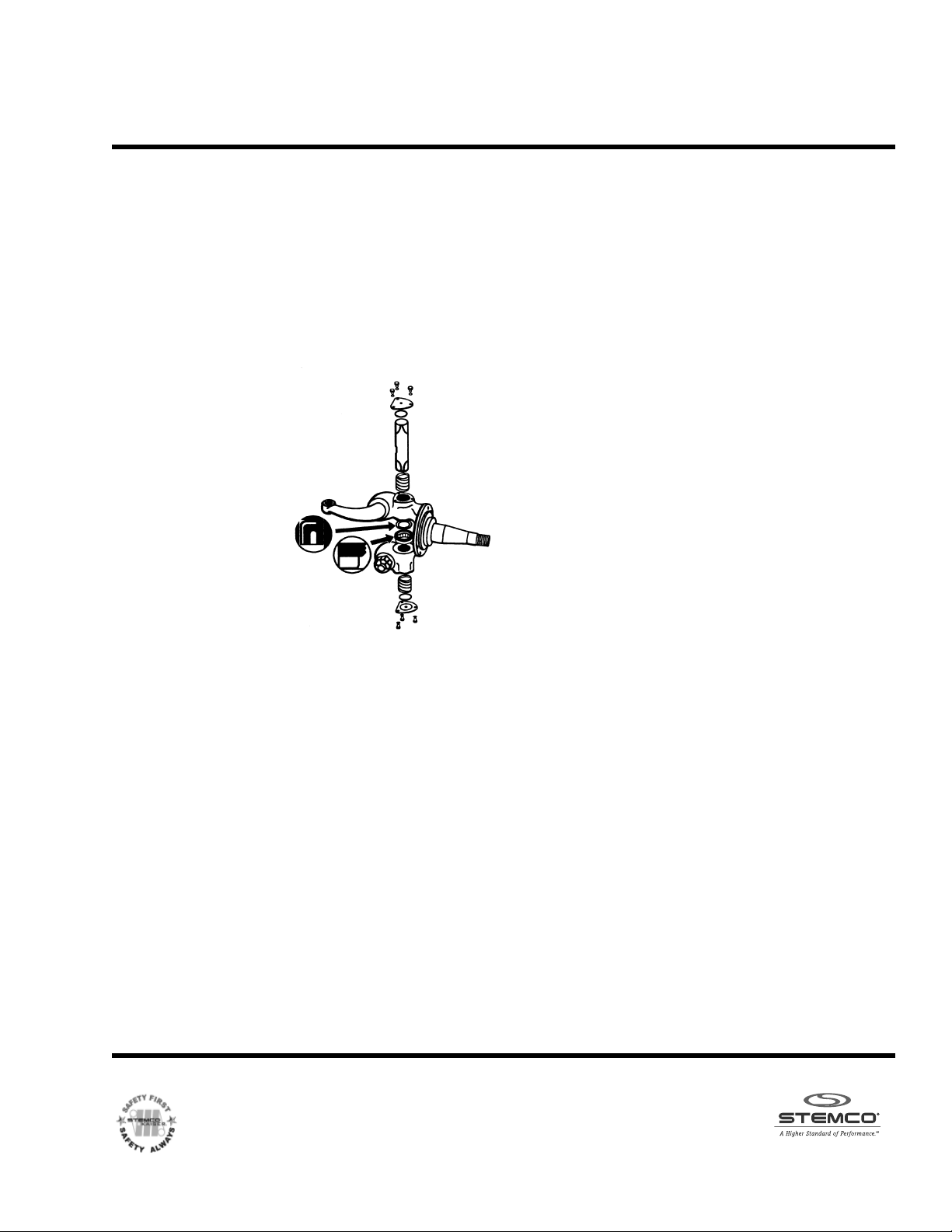

USING BUSHING ASSEMBLIES FOR KING PIN STEERING KNUCKLE REPAIRS

KIT

NO REAM INSTALLATION

REMOVAL

• Use established procedures for teardown.

STEERING KNUCKLE AND AXLE

PREPARATION

• Clean spindle and axle eyes, wipe dry.

• Remove any burrs from spindle bores and axle

eyes using brake hone or similar device.

INSTALLING BUSHING LIP SEALS

• Handle with care, lip seals are easily damaged.

• Using a bushing driver or similar

device, drive the seals into the

bore leaving the seal ush with

the axle side of each spindle bore.

• Be sure to position the seal

so the lip is pointing

towards the axle eye.

(see gure

SPECIAL INSTRUCTIONS FOR

INSTALLING SPIRAL BUSHING

• Using the STEMCO Kaiser

speci cally designed for the kit, drive both

bushings into bores.

• Wipe bushings clean.

• Using king pin check for t, rst insert pin into

each bushing individually then insert pin into both

bushings, king pin should slide through both

bushings simultaneously.

• If pin ts through bushings individually but not

simultaneously the spindle has spread and may

need replacement.

• Prepack bearings with grease.

#

1)

Cross section

of bushing lip seal.

ASSEMBLY

TM

bushing driver

CHECK BEFORE ASSEMBLY

BEARING INSTALLATION

gure #1

#

• For proper bearing orientation refer to gure

• Place needed shims under upper spindle bore.

• Position king pin through upper spindle bore and

through needed shims, be sure TOP of pin is parallel to axle for proper lock at alignment.

• Place spindle, shims and pin into axle, allow pin

to drop into axle bore about 2”.

• Tap bearing into place, a properly t bearing will

require a slight tap t without damaging the

bearing case.

• If bearing is too tight or too loose, adjust the

number of shims being used.

• When working on an application where the

bearing has a shoulder, the bearing must be

installed before the shims.

COMPLETE PIN INSTALLATION

• Once the bearing t is correct, allow pin to slip

into lower bushing.

• Position lock pin ats on pin so they line up with

lock holes.

• Pound lock pins into place, lock pins with threads

apply 25-30 ft. lbs of torque.

END PLATE OR END PLUG

INSTALLATION

• Install end plates or end plugs, using the proper

seal under plates.

• Install grease tting into end plate or end plug.

GREASING

• Apply grease until it can be seen between axle

and spindle.

CHECK INSTALLATION

• Once greased the spindle should turn easily from

side to side.

• There should be very little up and down movement.

• If unit seems loose or too tight we recommend

calling our tech line for assistance.

1.

Customer Service - www.stemcokaiser.com or 888-854-6474

The fi rst step in using STEMCO Kaiser products is SAFETY FIRST SAFETY ALWAYS. Please take a moment

to make sure these safety precautions are in place. Some components are heavy! For your protection

wear safety shoes, safety glasses, safety gloves, use proper lifting techniques and secure the unit

before work begins.

4641 Industrial Drive, Millington, MI 48746 • 888-854-6474 • Fax: 989-871-4640

Qwik kit BUSHING ASSEMBLIES installation Febuary 2014 01 577 0103

an EnPro Industries company

Loading...

Loading...