Page 1

NO REAM INSTALLATION

Instructions for the Mack & Volvo FXL Axle/K536M STEMCO Kaiser Qwik Kit

• Set axle down on jack

stands placing them under

spring perches.

• Disconnect steering arms

and remove grease fittings

from top knuckle caps.

• Remove top and bottom

caps.

• Remove nut from kingpin

using an inch drive socket

and breaker bar.

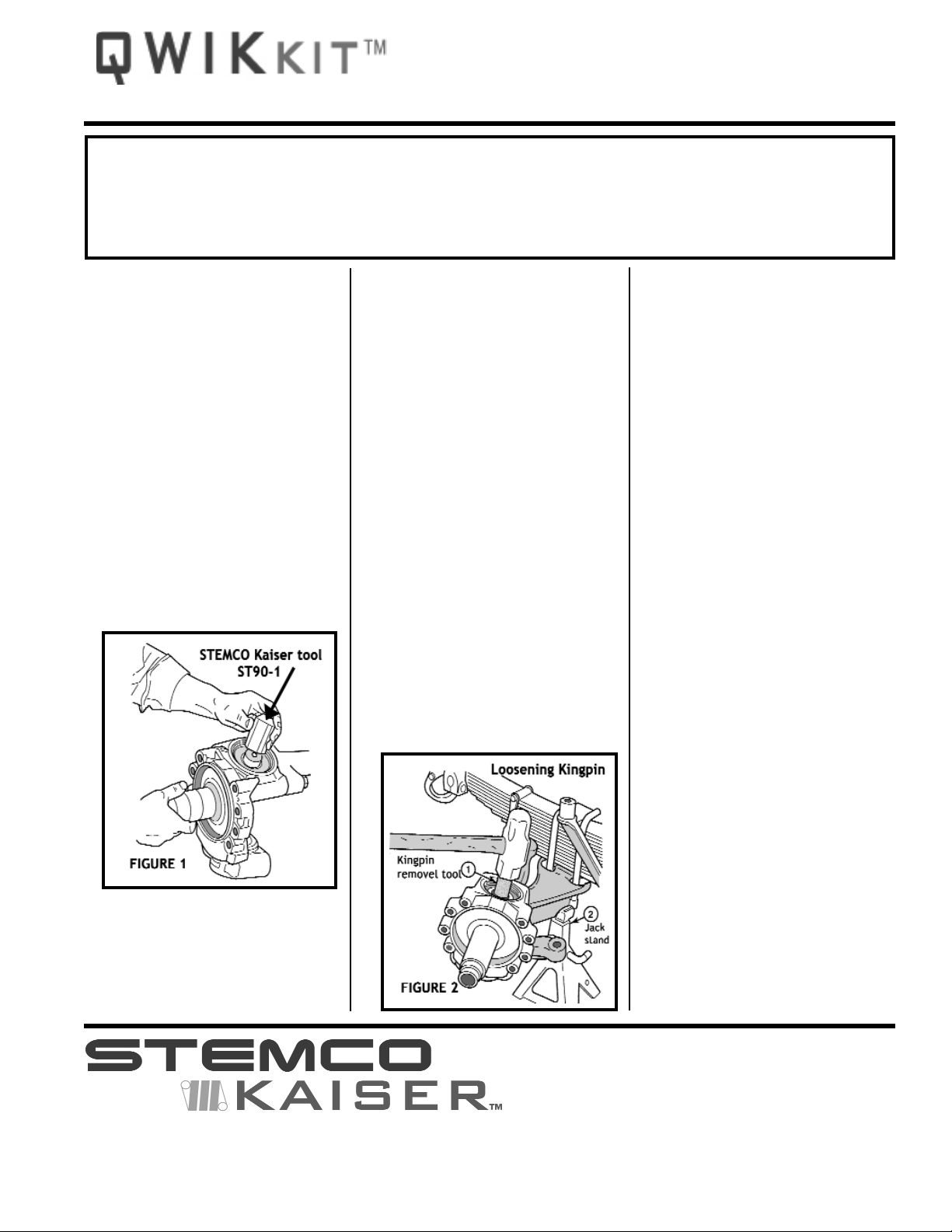

• Install kingpin removal tool

ST90-1 on top of king pin.

(FIG. 1)

• Strike the removal tool with a

large hammer to break kingpin loose from axle eye.

(FIG. 2)

• Remove the removal tool

from kingpin.

• Using a suitable brass drift

punch and hammer drive

kingpin down through axle

and spindle.

• Remove knuckle from axle.

• Remove lower seal from

knuckle and discard. Clean

knuckle thoroughly, so it is

free of grease and dirt.

• Remove old nylon bushing

from knuckle using a brass

drift punch. Remove top

bearing cup using a suitable

steel drift punch.

• Measure the thickness of

the bearing cup seat with a

micrometer. (Measure in

four places) Thickness

should be between .392 and

.394. If thickness is not within these specs replace

knuckle.

• Inspect axle and knuckle for

wear that might have been

caused by faulty wheel bearings or kingpin components

and replace if necessary.

• Install spiral bushing into

lower knuckle bore.

• Coat the under ledge surface, in the area of the

knuckle upper bearing, with

grease. This allows the

knuckle to slide onto the

axle during later assembly.

Clean all grease and dirt

from axle eye thoroughly.

• Position a new lower seal on

the knuckle (the white nylon

insert inside the seal faces

down against the knuckle).

Do not coat lower seal with

grease.

• Slide the knuckle onto the

axle eye while pressing the

lower seal down at the same

PAGE 1 01 577 1005 NOV-2010

GETTING HELP

USE THE STEMCO Kaiser TECHNICAL SERVICE LINE

888-854-6474

WARNING: STRIKING STEEL PARTS WITH HAMMERS CAN RESULT IN CHIP PROJECTILES, ALWAYS WEAR SAFETY GLASSES TO PROTECT YOURSELF AGAINST

INJURY. STEMCO Kaiser IS NOT RESPONSIBLE FOR ANY INJURY THAT MAY OCCUR DURING THIS PROCESS.

4641 Industrial Drive, Millington, MI 48746 • 888-854-6474 • Fax: 989-871-4640 www.stemcokaiser.com

CONTINUED

The following assembly instructions are recommended for completing the MACK &

VOLVO FXL front steering axle king pin repair. This is a very unusual and unique

designed axle in comparison to the majority of common axle assemblies. Reading and

following these instructions is critical to successfully performing the king pin procedure!

Page 2

NO REAM INSTALLATION

Instructions for the Mack & Volvo FXL Axle/K536M STEMCO Kaiser Qwik Kit

time. Make sure lower seal

is properly aligned when

knuckle is installed. (Be sure

the ABS sensor is on the

front side. If it is on the rear

side switch knuckle to the

other side of the axle)

• Insert kingpin up from the

bottom side of the knuckle

firmly by hand slowly to be

sure axle eye, knuckle and

seal are properly aligned.

The kingpin should begin to

seat into the axle eye.

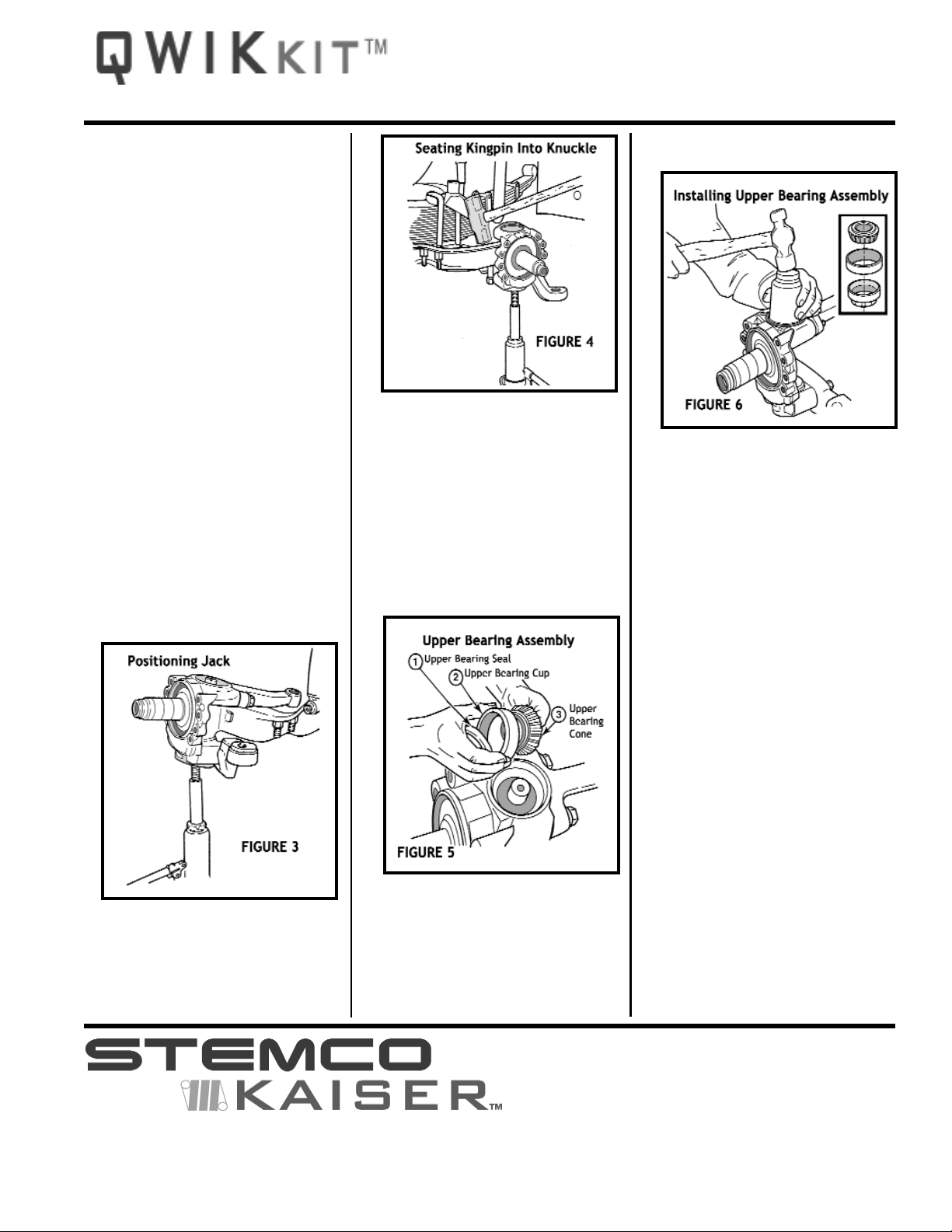

• Using a bottle jack against

the bottom of the kingpin

jack up until axle is lifted

slightly off the jack stand (be

sure the weight of the axle is

supported by the kingpin on

the jack only) (FIG. 3).

Strike the top of the axle with

a large hammer just behind

the knuckle to seat the king-

pin into the axle eye (FIG. 4).

• Pack upper bearing with

grease. Assemble bearing

and cup with the new bearing seal on the flange of the

bearing cup.

• Install bearing assembly

(FIG. 5) in the knuckle using

a suitable bearing driver to

“TAP” the bearing assembly

into the knuckle far enough

down the kingpin threads to

get the nut started on the

kingpin (FIG. 6). Tighten nut

on kingpin to 200 ft. lbs. After

tightening remove bottle jack

from bottom of king pin.

Rotate knuckle back and

forth several times to make

sure knuckle turns freely. If

no binding occurs tighten

kingpin to 600 ft. lbs.

• Install top cap with new oring (coat o-ring with grease

before installing cap.) and

tighten to 120 ft. lbs. At this

time install grease fittings in

cap.

• Repeat above procedure for

lower cap.

• Grease top and bottom fittings while moving knuckle

back and forth. (Be sure

grease purges past upper

and lower seals)

• Reconnect steering arms

and wheel end components.

PAGE 2 01 577 1005 NOV-2010

GETTING HELP

USE THE STEMCO Kaiser TECHNICAL SERVICE LINE

888-854-6474

WARNING: STRIKING STEEL PARTS WITH HAMMERS CAN RESULT IN CHIP PROJECTILES, ALWAYS WEAR SAFETY GLASSES TO PROTECT YOURSELF AGAINST

INJURY. STEMCO Kaiser IS NOT RESPONSIBLE FOR ANY INJURY THAT MAY OCCUR DURING THIS PROCESS.

4641 Industrial Drive, Millington, MI 48746 • 888-854-6474 • Fax: 989-871-4640 www.stemcokaiser.com

Loading...

Loading...