Page 1

Bearing Removal and Installation

2002

Order Entry 1-800-527-8492 Fax 1-800-874-4297 47

BEARING REMOVAL AND INSTALLATION

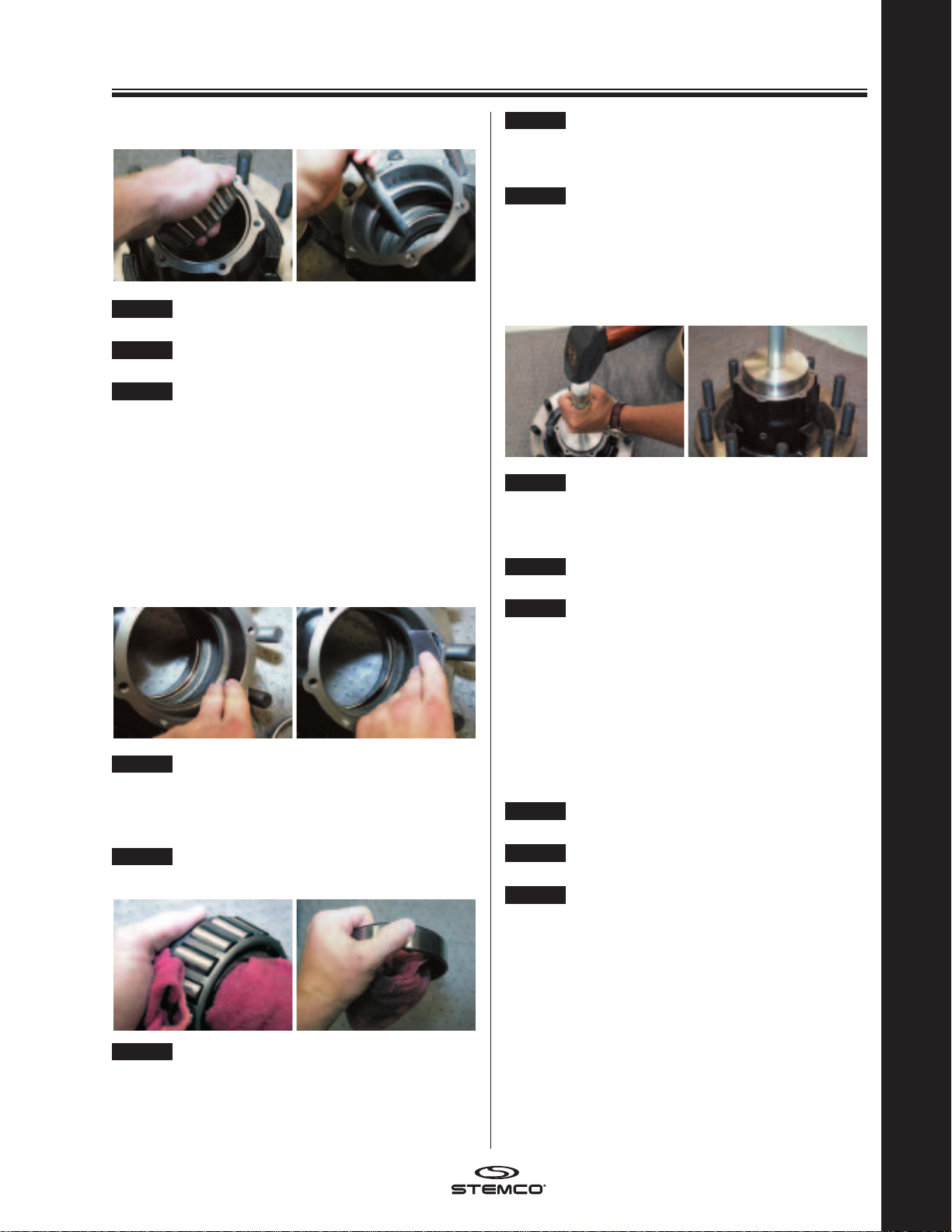

Removal

Step 1 Remove hub/wheel assembly from vehicle in

accordance with recommended practices.

Step 2 Remove inboard and outboard bearing cones

and set aside for inspection.

Step 3 Using a mild steel drift or cup driver, carefully

drive out the bearing cups.

- Caution should be used when driving bearing cups,

as drifts and other tools can damage bearings.

- Drifts can damage hub bearing bores. Be careful

not to score bores while removing cups, especially

when using aluminum hubs.

Inspection

Step 1 Inspect the hub bearing bores and shoulders

for damage. The bores should be smooth and free from

scoring, burrs, indications of cup spinning, or other

forms of damage. Remove any burrs or raised areas

using emery cloth, a file, or other appropriate tool.

Step 2 Measure the bearing cup bore and compare to

manufacturer specifications.

Step 3 Inspect bearing cups and cones for damage.

Bearings should be free from chips, contamination, and

signs of excessive wear or excessive heat. Refer to bearing damage analysis literature for identifying possible

bearing issues.

Step 4 Inspect axle spindle bearing journals for any

signs of damage or excessive wear. Remove any raised

areas or burrs using emery cloth, a file, or other

appropriate tool.

Step 5 Journals should be measured and compared

with manufacturer specifications.

Installation

Step 1 Thoroughly clean bearing cups and cones

prior to installation.

- Do not use compressed air to spin bearing rollers as

injury may result if cage does not retain the rollers.

Step 2 Lightly coat the outside of bearing cups

with oil.

Step 3 Using a cup driver, carefully drive bearing

cups into hub bearing bores. Be sure to drive cup

firmly against cup shoulder in hub.

- If a cup driver is not available, a mild steel drift can

be used to install bearing cups.

- Caution should be used when driving bearing cups,

as drifts and other tools can damage bearings.

- NEVER use a bearing cone to drive a bearing cup.

This can damage the bearings and cause premature

failure.

Step 4 Use a feeler gauge to check for gaps between

cup and shoulder.

Step 5 Inspect the bearing cups to ensure no

damage occurred during installation.

Step 6 Lubricate bearing cones according to

recommended practices and proceed with installation

of wheel assembly.

Loading...

Loading...