Page 1

Aeris System Troubleshooting

Sept 2013

STEMCO Aeris

Troubleshooting Manual

Part Number: 01-571-8301

Revised: 9/13

Rev: A

AerisTM by STEMCO, an advanced automatic tire inflation system based on patented rotary sealing

technology and precision electronic airflow detection. The system is designed to keep commercial trailer

tires properly inflated using air pressure from the trailer’s air system.

AerisTM by STEMCO includes a high resolution electronic flow detection technology capable of informing the

driver whether the system is making a minor adjustment to tire pressure or if a major leak is present. An

additional safety feature is a pressure protection valve to protect the integrity of the air brake system in the

case of a major and continuous air leak such as a blow out or other catastrophic tire failure.

Page 1 of 18

Page 2

Aeris System Troubleshooting

Sept 2013

Table of Contents

General View of Aeris Components Installed………………………………………………………3

Explanation of Words………….……………………………………………………………………………..4

Important Safety Notices…..…………………………………………………………………….…………5

General Service Information………….……………………………………………………….………….6

Aeris System Features…………….………………………………………………………………………….7

System Pre Checks…………….……………………………………………………………………………....9

How System Works…………..………………………………………...........................................8

Condition & Possible Causes - Quick Checks…….………………….…………………………..…9

Aeris System Function Test & Troubleshooting.………………………………………………..10

Normal Indication of Driver Warning Lamp……………….……………………………………...17

Notes & Diagrams…..…………………………………………………………………………………….…..18

Page 2 of 18

Page 3

Aeris System Troubleshooting

Sept 2013

General Information

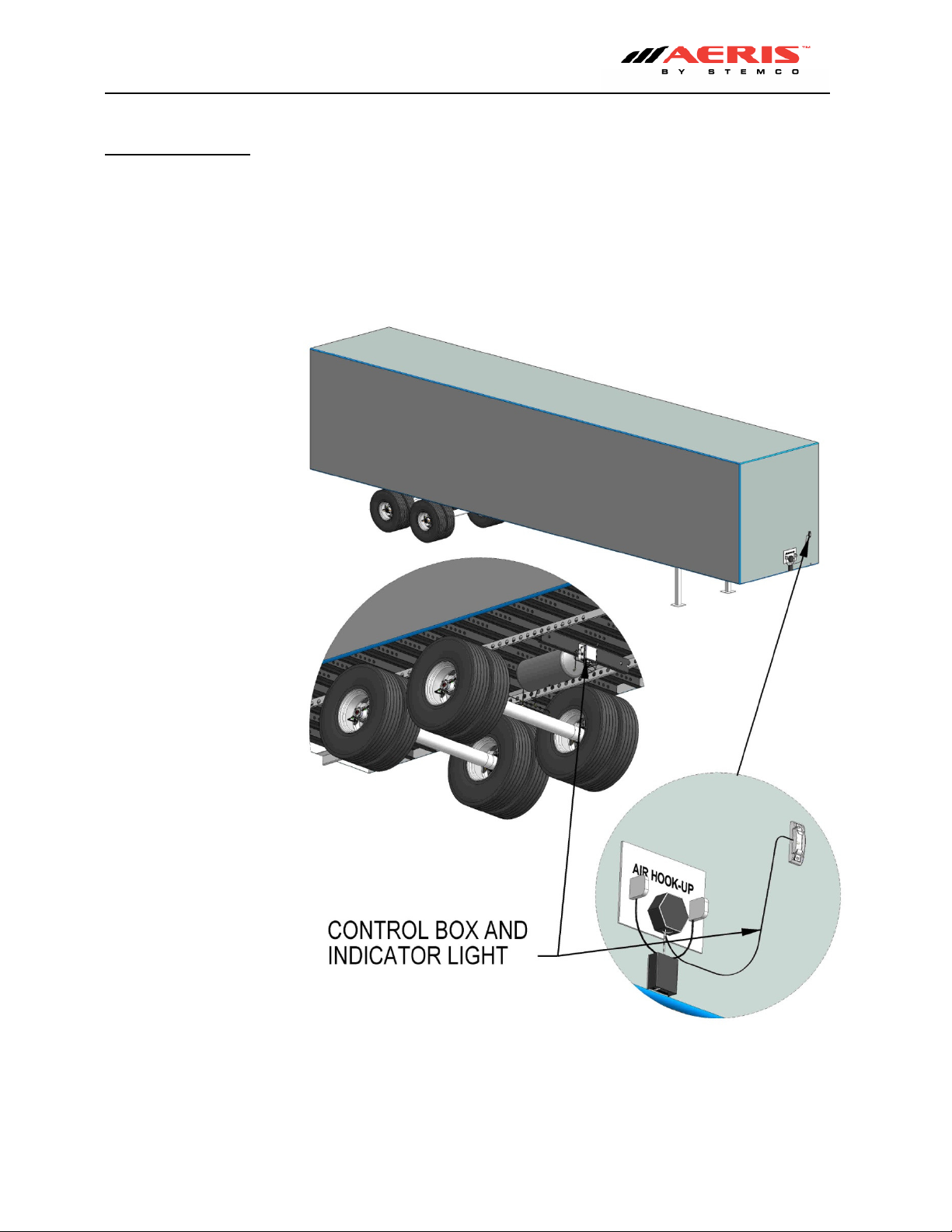

General View of Aeris Components Installed

Page 3 of 18

Page 4

Aeris System Troubleshooting

Sept 2013

About This Manual

This manual is provided to support the STEMCO Aeris tire inflation system. The manual provides the

following information needed to service and troubleshoot the Aeris system.

Explanation of Words

Please pay attention to special symbols used through this manual to convey important information.

Hazard signal words such as DANGER, WARNING, CAUTION, or NOTICE are used throughout this

manual. Information accented by these words indicates a point of emphasis and importance. The

following definitions comply with ANSI Z535.4 and indicate the use of signal words as they appear

within this manual.

! DANGER: Indicates immediate hazards which will result in severe personal injury or death.

! WARNING: Indicates hazards or unsafe practices which could results in severe personal injury or

death.

! CAUTION: Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

NOTICE: Indicates hazards or unsafe practices which could result in damage to machine or

equipment.

IMPORTANT: An operating procedure, practice or condition that is essential to emphasize.

! Safety alert symbol used to indicate a condition exists that may result in personal injury or harm to

individuals. It must be applied to DANGER, WARNING and CAUTION statements which emphasize

severity.

IMPORTANT: Please pay special attention to the information supplied in the Explanation of Words

section. These words are used to help prevent immediate hazards, unsafe practices, severe

personal injury or death and damage to machines or equipment.

Page 4 of 18

Page 5

Aeris System Troubleshooting

Sept 2013

Important Safety Notices

• Proper maintenance, service and repair are important to the operation and reliability of the trailer

suspension system and its components. The procedures recommended by STEMCO as described in

this manual are methods of performing maintenance, inspection, repair and service. All warnings

and cautions should be read carefully to help prevent personal injury and to help assure proper

installation methods are used.

• Improper maintenance, service and repair can result in personal injury, vehicle damage, property

damage, unsafe operating conditions or void the manufacturer’s warranty.

• Carefully read, understand and follow all safety related information in this manual.

! WARNING: DO NOT modify or rework parts. Use only STEMCO Aeris authorized replacement

parts. Use of substitute, modified or replacement parts not authorized by STEMCO may not meet

STEMCO’s specifications. This may cause the part to fail which could result in loss of vehicle

control and possible personal injury or property damage. Do not modify parts without STEMCO’s

authorized written permission.

! WARNING: Always wear proper PPE when installing and performing maintenance repair, servicing

equipment or cleaning tractor or trailer components.

! WARNING: Solvent cleaners can be flammable, poisonous and can burns or serious injury. To

help avoid serious personal injury, carefully follow the manufacturer’s product instructions and

guidelines. Please follow the procedures below:

• Wear proper eye protection

• Wear proper protective clothing to protect your skin

• Always work in well ventilated area

• Do NOT use gasoline, or solvents that contain gasoline. Gasoline can explode and cause

serious personal injury or death.

• Hot tank solutions or alkaline solutions must be used correctly. Follow the manufacturer’s

product instructions and guidelines.

! WARNING: Avoid creating dust from brakes when cleaning around any brake components. Dust

from brake pads and/or parts are a possible cancer and lung disease hazard.

Page 5 of 18

Page 6

Aeris System Troubleshooting

Sept 2013

General Service Information

Before starting any work or installation, read, understand and comply with the following:

• Read all instructions and procedures.

• Company’s service, maintenance, installation and troubleshooting procedures.

• Manufacturer’s vehicle safety instructions when working on the vehicle.

• Manufacturer’s vehicle instructions not detailed in this service manual.

• Follow all local safety regulations and best safety practices when installing.

General Service Installation Notes

• Work must be performed by trained personnel.

• Use all recommended tools required to help avoid personal injury and damage to components.

• Be aware of potential power release of tensioned springs on brake chamber or the brake return

springs. The release of tension can cause injury.

System Overview

• The Aeris tire inflation system is designed to automatically inflate tires that are below the target

pressure setting. The system uses air from the trailer’s compressed air tank. The compressed

air tank pressure setting must be higher than the targeted tire pressure setting. Failure to have

the air tank pressure above the target tire pressure prevents proper operation of the inflation

system.

Page 6 of 18

Page 7

Aeris System Troubleshooting

Sept 2013

System Features

• Tire pressure is continuously monitored and adjusted automatically to the target tire pressure.

• Adjustable air pressure regulator is used for setting desired tire pressure target.

• An indicator light will illuminate when air is flowing to the tires.

• Does not pressurize axle tube (prevent contamination of seals).

• Rotary seal air leakage will not enter the wheel end, preventing oil contamination on the hubcap.

• Each wheel end has dual venting paths to prevent wheel end pressurization.

• Checks tire pressure constantly.

• Integrated check valves in the hoses isolate tires from system if a tire is damaged or leaking.

• Tire pressure check ports are integrated into each hose, eliminating the need to remove the hose to

check the tire pressure.

• An air filter is provided on the inlet air line to prevent particulates from clogging the system.

Aeris Specifications

• Tire pressure setting range: 70-120 psi

• Pressure check interval: Continuously supplies air to tires

• System power requirements at 12VDC: < 12W.

• Minimum power voltage requirement to operate: 9 VDC

• Indicator light current range: 50 mA to 600 mA

• Tire inflation capacity (per tire): 10 psi in 2-3 minutes

• The indicator light provides the following system information:

• No light: System is good or does not power

• Power up: Light blinks three times

• No pressure: Long flash followed by 2 blinks repeating.

• Low volume flow: Constantly on

• High volume flow: Blinking constantly

Page 7 of 18

Page 8

Aeris System Troubleshooting

Sept 2013

System Operation

How System Works

• The Aeris tire inflation system is designed to continuously supply filtered, regulated compressed air

to each tire on the trailer. There is no operation required of the driver for the system to function

normally. The only requirement of the driver is to verify the indicator lamp is functioning and to

monitor the system periodically.

• The Aeris system is preset to maintain a specific tire pressure in each tire. The pressure in the

trailer’s air tank must be maintained above the targeted pressure to allow the controller to

continuously supply and maintain the preset tire pressure to all tires.

IMPORTANT: For Aeris controller to operate properly the air tank pressure must be greater than

the tire pressure target. The controller cannot supply tire pressure above the air tank pressure.

• When the system is operating properly, the air tank will supply pressurized air to the Aeris

controller. The controller will supply regulated compressed air to the air lines going to each tire. If a

tire is low, air from the trailer air tank will inflate the tire until the targeted tire pressure is achieved.

Regulated air flowing from the controller to the air lines and tires may cause the indicator light to

remain on until the target pressure is reached. Constant pressure remains and is maintained in air

lines and tires at the targeted pressure.

• If a tire is leaking or there is a leak in the lines, the indicator light may illuminate and stay on. If the

indicator light stays on for more than 15 minutes, the system is attempting to inflate the tire or

trying to correct for the air line loss to the targeted air pressure. If this happens, the operator

should stop and check the tires manually to determine if it’s safe to continue to operate the vehicle.

Operator should seek service at the next available opportunity.

• Remaining tires are protected from pressure loss by check valves integrated into each tire hose.

Page 8 of 18

Page 9

Aeris System Troubleshooting

Condition

Possible Causes

Actions

The Driver Warning Lamp is

The Driver Warning Lamp is

The Driver Warning Lamp is

The Driver Warning

Lamp is

Tire pressure is low

Lubricant is leaking from the

Tire pressure is high.

The trailer tire deflates when

Sept 2013

ON.

(See Aeris System Function

Test on Page 10

If NO Leak is Found)

flashing ON & OFF

(See Aeris System Function

Test on Page 10

If NO Leak is Found)

ON and air is leaking from the

wheel-end hubcap or Axle

vent

OFF during system operation

(See Aeris System Function

Test on Page 10

If Power & Ground Supply to

Trailer is good)

(See Aeris System Function

Test on Page 10 for

Troubleshooting)

wheel-end vent.

parked.

The system is delivering air during initial

system charging for a slow leak on tire of 2-3

psi

The system is delivering air to a leaking tire. Repair the tire.

The system is delivering air to a leaking

system component.

The system wiring is incorrect. Correct the system wiring.

Lamp circuit board is defective Replace control box

The system is delivering air to a tire with a

fast leak of 4-6 psi or more.

The system is delivering air to a leaking tire

at 4-6psi or more.

The system is delivering air to a leaking

system component.

The system wiring is incorrect. Correct the system wiring.

Lamp circuit board is defective Replace control box

The system is delivering air to a leaking

system component.

The delivery hose in axle is damaged Replace DOT 1/4" airline in axle tube

Hubcap RUA has face seal leaking Replace hubcap assembly

Hose seal or gasket defective Replace hose or install new seal

The trailer is not supplied with 12-volt power

or ground

The Driver warning lamp is inoperative.

Lamp circuit board is defective Replace control box

The system wiring is damaged. Repair the system wiring.

The system wiring is incorrect. Correct the system wiring.

The shut-off valve is off. Turn on the shut-off valve.

The system pressure setting is too low. Increase the system pressure setting at

Defective pressure protection valve in air

tank

Kinked or Damaged 1/4" air line to wheel

end

The incorrect valve cores are installed or

damaged hose check valve.

The wheel end is overfilled with lubricant. Fill the wheel end to the correct level.

The tire is manually over inflated. Reduce the tire pressure. The system will

The system pressure setting is too high. Lower the system pressure setting at

The system hose or tire valve stem

connection is leaking.

The hose valve core is leaking. Clean or replace the hose valve core.

The tire is leaking. Repair the tire.

The system is functioning correctly.

Repair the system component.

The system is functioning correctly.

Repair the tire.

Repair the system component.

Repair the system component.

Supply 12-volt power & ground to the

trailer.

Replace the Driver warning lamp.

Control box regulator

Replace Pressure protection valve

Repair 1/4" air line to wheel end position

that is not getting air supply.

Replace hose assemblies

inflate to the correct level.

control box regulator.

Correctly tighten the connection or replace

the seals.

Page 9 of 18

Page 10

Aeris System Troubleshooting

Does Driver Warning

Yes

Proceed to

Does Driver

Warning Lamp

Yes

No

No

Are all tires filled to

Yes

System is operating

No

Proceed to

Does Driver Warning

Proceed to

Proceed to

No

Sept 2013

Aeris System Function Test

THIS MUST BE COMPLETED BEFORE BEGINNING SYSTEM TROUBLESHOOTING

Power on Test – This is referenced throughout the troubleshooting procedures and consist of

connect air and power supply to the trailer while watching Driver Warning Lamp on the nose of the

trailer

Important initial steps:

• Verify valve on control box is open and pressure regulator is set to desired pressure

• Deflate all tires to at least 5 psi below regulator setting

• Connect air supply and power to the trailer and observe Driver Warning Lamp for the following

conditions

Initially do not connect air supply or power until instructed below

come on, flash three times

when power is connected?

Lamp go off after 5-15

minutes?

Lamp come on at all?

Page 13

Page 14

Page 11

consistence level?

(Usually 2-3 psi below

regulator setting)

normally. See page 17

for normal operation

indications

Page 15

Page 10 of 18

Page 11

Aeris System Troubleshooting

Open control box. Is light

board (flashing or solid)?

Yes

Yes

Yes

No

No

No

Disconnect Yellow and Brown

Poor lamp ground,

burnt

Reconnect Yellow wire then

Yes

Complete

Power on Test

If circuit board light does not

Go to Page 12

Verify repairs

Power on Test

Sept 2013

Condition: Driver Warning Lamp does not come on at all

Possible Causes: Loose, broken or corroded connection or wires, bad bulb or bad control box circuit board

Before starting this section

Verify power and ground connections supplying the trailer

Verify control box is wired correctly (see figure 3 on page 18)

CAUTION: DO NOT SHORT CONTROL BOX WIRES TOGETHER WHILE THEY ARE CONNECTED TO THE CIRCUIT

BOARD. CONTROL UNIT DAMAGE MAY RESULT

(Note: Do not use a volt meter to conduct these tests. A test light is required)

illuminated on circuit

wires from the circuit board

and short them together. Is

Driver Warning Lamp on?

Brown wire to circuit board.

Did circuit board light come

on and flash 3 times?

out bulb or wiring to the

front of trailer is bad,

repair as needed

by completing

flash three times a bad circuit

board is indicated

(See note 1 on Page 18 before

replacing control box)

again, circuit board is

operating properly

Page 11 of 18

Page 12

Aeris System Troubleshooting

No

No

If test light did not

Connect

test light to the

Yes

Remove white & yellow

Connect Test light to the

Yes

Complete

Power

No

Yes

System ground is bad.

Verify repairs

Power on Test

System power is bad.

Verify repairs

Power on Test

Sept 2013

Continued from Page 11

Condition: Driver Warning Lamp does not come on at all & Circuit board light is off

wires from circuit board.

Connect test light to the

circuit board light terminal

and reconnect ground. Did

test light flash 3 times?

on Test again,

circuit board is

operating properly

circuit board brown & white

wires. Is test light bright?

flash three times a bad

circuit board is

indicated

(See note 1 on Page 18

before replacing

control box)

brown wire and chassis

ground. Does test light

illuminate?

Restore ground on

white wire.

by completing

Restore power on

brown wire.

by completing

Page 12 of 18

Page 13

Aeris System Troubleshooting

Connect test light to the

Yes

No

If test light illuminates and

Remove yellow wire from

Yes

No

Connect test light to top

Yellow Driver

Verify repairs

Driver Warning Lamp is

Verify repairs

Power on Test

Sept 2013

Condition: Driver Warning Lamp comes on but does not flash three times and does not go off

Possible cause: Driver Warning Lamp has constant power

Before starting this section

Verify the wires are attached to control unit circuit board as shown in figure 3 on page 18

(Note: Incorrect attachment of wires may cause circuit board damage)

circuit board yellow & white

wires. Is test light on?

circuit board. Did Driver

Warning Lamp go off?

terminal on circuit board.

did not flash a bad circuit

board is indicated

(See note 1 on Page 18

before replacing control box)

Warning Lamp wire

is shorted to power.

Find short & repair

by completing

Power on Test

not correctly wire at the

nose of the trailer.

Correct wiring

by completing

Page 13 of 18

Page 14

Aeris System Troubleshooting

Verify air supply valve on the

Open Valve

Recheck

Complete

Check

pressure

Low tire

Set to desired

No problem

No

Yes

No

Yes

Yes

No

Repair

Complete

Complete

Inspect all air

leaks

Repair leak

Leak

Yes

No

Complete

Complete

Sept 2013

Condition: Light stays on after 3 flashes at power up (flashing or steady Driver Warning Lamp) and does

not go off

Possible causes: System has detected air flow or has no air supply (check air supply to trailer before

continuing)

regulator setting

inside control box.

Is regulator set to

desired pressure?

outside of the control box is in

the open position (See figure 1

on page 18)

level

pressure

in all tires

found?

leak in tire

Power on Test

again

Power on Test

again

lines, fittings

and hoses for

found?

Power on Test

again

Power on Test

again

found

Power on Test

again

Page 14 of 18

Page 15

Aeris System Troubleshooting

Go to tire that is low and

Low volume or no air flow is

hose?

Verify air supply valve on the

page 1

8)

No

Open Valve

Complete

Yes

No

Check valve stem core for

Complete

Yes

No

Hose was damaged,

Complete

Yes

Continue

Sept 2013

Condition: Tires are not within a few PSI of each other after light goes off after power up.

Possible causes: Kinked or damaged ¼ inch air line. Incorrect valve core in hose or damage hose check valve.

disconnect hose from tire valve

stem. Is there a high volume of

air coming out of hose?

proper operation. Repair as

needed.

outside of the control box is in

the open position and air filter

is not plugged. Is valve open

and filter clear? (See figure 1 on

Power on Test

again

caused by restriction in ¼” air

line or hose. Replace hose with

known good. Is there a high

volume of air coming out of

Power on Test

again

on page 16

replace hose

Power on Test

again

Page 15 of 18

Page 16

Aeris System Troubleshooting

Low or

no air flow

¼” air line is restricted

Yes

No

Remove RAU from hub

RAU is damaged,

Verify repairs

Verify repairs

Sept 2013

Continued from Page 15

Condition: Tires are not within a few PSI of each other after light goes off after power up.

Possible causes: Kinked or damaged ¼ inch air line. Incorrect valve core in hose or damage hose check valve.

(From Previous Page)

detected with hose

removed from tire

valve stem.

and disconnect the ¼” air

line. Is high volume of air

flow detected?

replace RAU hose

between RAU & control

box. Check line in axle

tube and work backwards.

Repair as needed.

by completing

Power on Test

by completing

Power on Test

Page 16 of 18

Page 17

Aeris System Troubleshooting

Sept 2013

Section 4

Normal conditions that maybe observed on power up

1. Driver Warning Lamp comes on, flashes three times and goes off

a. Indicates system is working and no air flow is being detected

2. Driver Warning Lamp comes on, flashes three times but light flashes every other second (It may take

several minutes for light to stop flashing if a tire is being filled)

a. Indicates system is working and is adding air at high volume

i. Light may become solid and then variable after a period of time before no longer

illuminating (this could take up to 15 minutes if tires are low and no air leak is

present)

ii. If light does not go off after 15 minutes large air leak is present

3. Driver Warning Lamp comes on, flashes three times but light remains on as a steady light for a

period of time (It may take several minutes for light to go off if a tire is being filled)

a. Indicates system is working and is adding air at low volume (light may become variable after

a period of time before no longer illuminating)

i. If light does not go off after 15 minutes large air leak is present

4. Driver Warning Lamp comes on, flashes three times but light remains on as a variable light for a

period of time (It may take several minutes for variable light to stop flashing if a tire is being filled)

a. Indicates system is working and is adding air at very low volume

i. If light does not go off after 15 minutes large air leak is present

Page 17 of 18

Page 18

Aeris System Troubleshooting

Figure 1

Figure 2

Figure 3

Air Supply

Shut

-

Off Valve

trailer

12 volts

when light is on

at nose of trailer

Sept 2013

Note 1:

Before replacing control box verify condition by completing Power on Test again and verify you are

connecting test light to the top terminal marked “light”. Recheck all trailer and control box connections

Yellow Wire is power to Driver Warning Lamp at nose of

Brown Wire is 12 volt supply at 7 pin connector

at nose of trailer

White Wire is Ground wire at 7 pin connector

Page 18 of 18

Loading...

Loading...