Page 1

DWL Quick Reference

Page 2

DWL Detailed Reference

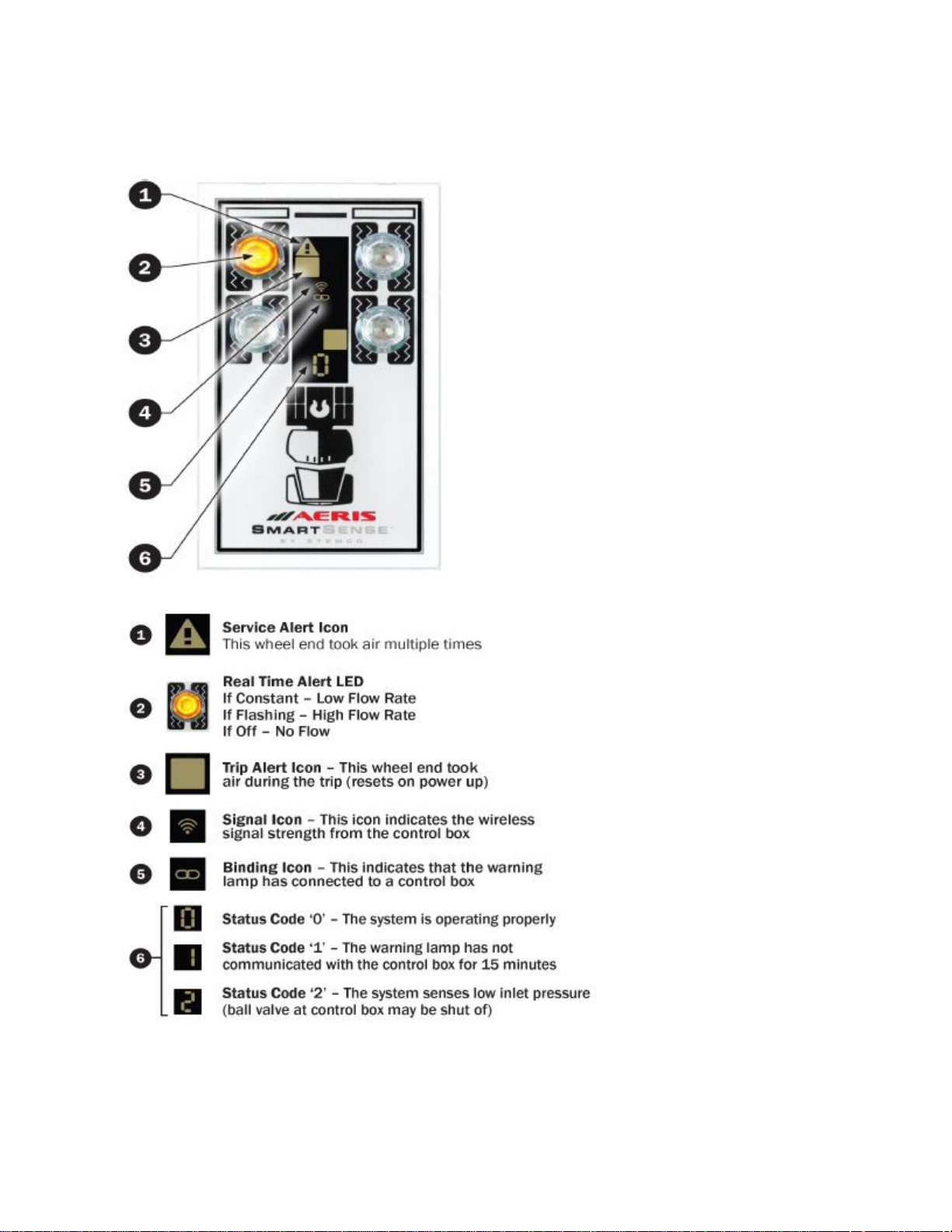

On power up all Lights (item 2) on the Driver Warning Light (DWL) will blink 3 times.

Once communications are established with the control box The DWL “Binding Icon” will turn on (item

5).

Signal Icon will appear above the “Binding Icon” icon and will be updated continuously for the first 10

minutes after each power on for determining signal strength from the control box (item 4).

During Normal Operation the lights will be off and the LCD will read “0” in the system status section

(item 6). The DWL cannot respond to flow events if we are not in this state.

If no communication has been received from the control box the LCD will read “1” in the status section

(item 6) until communications with the control box are established which can take as long as 2 minutes

after a new install but is typically less than 10 seconds.

If no pressure exists at the control box the DWL system status will read “2” (item 6).

On a low flow event that has lasted at least 10 seconds the corresponding wheelend light will turn on

continuously (item 2) and the display will show a yellow persistent block at that wheel end location

indicating flow occurred on this trip (item 3). When the flow event goes away the light will turn off but

the yellow block will stay on without power until the next power up event.

On a high flow event that has lasted at least 10 seconds the corresponding wheelend light will begin

blinking (item 2)and the display will show a yellow persistent block at that wheel end location

indicating flow occurred on this trip (item 3). When the flow event goes away the light will stop blinking

but the yellow block will stay on without power until the next power up event.

If the system detects that repeated or severe flow events are occurring and the system the “service

alert icon” will turn on and stay on until the system is repaired (item 1). The service alert indicator will

clear itself after 1-2 days of good conditions on that wheel end. A Stemco HandBat can also be used to

clear the service event manually if desired.

Page 3

Smart Sense Control box Detailed Reference

On power up the status light on the flow meter will blink red 3 times.

If all is good then each channel light will be off and status light will blink green.

If no pressure exists at the control box the status and individual channel lights will blink two red quick

blinks then 1 long red blink repeated as long as the system air pressure is low.

If the system detects flow events on different channels of varying flow amounts then the corresponding

channel lights will light up corresponding to the flow conditions on their respective channels.

On a low flow event the red status light will turn on corresponding to that wheel end and with a short

intermittent off blink until the flow event goes away.

On a high flow event the red status light will blink corresponding to that wheel end in a long on/off

pattern until the flow event goes away.

Page 4

AERIS smart sense debugging techniques using the DWL

1. With the entire system connected apply power. Does the red light on the circuit board blink at

power up?

If no then check power connections +12 and Ground continuity to the circuit board and

7 pin connector.

2. After power up works successfully take off the power lead and the light lead and connect them

together the Driver Warning Light (DWL) should light up and blink 3 times.

If no then the connection to the light yellow line is not connected or the light is not

grounded.

3. If both light and board power up then connect all wires back to the circuit board and verify that

system powers up and blinks three times on a power up event both on the circuit board and at

the front light on the trailer.

If the lights on the circuit board blink but the light on the trailer does not then you have

a control box circuit board problem.

4. If both the light on the trailer and the light on the board blink 3 times next check that the

blinking stops or that the light on the front of the trailer goes to a solid on state or consistent

blink state or an off state. Those are all three valid states.

If the light on the trailer stops blinking but the DWL display has a status code of “2” this

means that pressure has not reached the control box yet. Check that the air control valve is

in the on position.

If the control valve is in the on position then the brake system has not received enough

air to open the PPV valve yet. Wait for the airbrake tank to fill or check glad hands are

connected to the tractor.

5. If the light stays on solid or blinks consistently in timing then the system is taking air. If no

hissing is heard coming out of the air connections then the tires are low and simply taking air.

If hissing is coming from an air connection, fix the leak.

6. If the light goes out after 3 blinks but the display has a status code of “1” then communications

have not been established yet. Wait 2 minutes and verify that the status has changed to

something other than “1”

If the status stays at 1 then no communication is being received at the DWL. Use a

HandBat to reset DWL alerts and verify that the top left LED blinks when alerts are reset.

If the light does not blink then the DWL is bad and needs to be replaced.

If the light blinks then there is a circuit board problem in the control box.

Page 5

7. If a flow event is shown but not on the correct wheel position then verify air hoses in the control

box are connected to the correct locations on the manifold

8. If the display has a status code of “0” after power up but the signal strength above the “chain

link” icon only shows a single dot instead of any signal bars then check to make sure that the

control box is mounted at the front of the axles facing the front of the trailer.

9. If the light goes out after the first 3 blinks and the display has a status code of “0” then all is ok

and tires are aired up.

Page 6

Certifications

FCC (USA)

This unit complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

FCC ID: SRA-830025X

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

„„ Reorient or relocate the receiving antenna.

„„ Increase the separation between the equipment and receiver.

„„ Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

„„ Consult the dealer or an experienced radio/TV technician for help.

NOTE: The manufacturer is not responsible for any radio or TV interference caused by unauthorized

modifications to this equipment. Such modifications could void the user’s authority to operate the

equipment. The antenna(s) used for this transmitter must be installed to provide a separation distance of

at least 20 cm from all persons and must not be co-located or operating in conjunction with any other

antenna or transmitter. Users and installers must be provided with antenna installation instructions and

transmitter operating conditions for satisfying Rf exposure compliance. Should you need any additional

assistance with any problems or issues please contact STEMCO Customer Service at (800) 527-8492.

Industry Canada

IC: 7413A-830025X

NOTICE: This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject

to the following two conditions: (1) this device may not cause interference, and (2) this device must

accept any interference, including interference that may cause undesired operation of the device.

Cet appareil est conforme avec Industrie Canada RSS standard exempts de licence (s). Son

fonctionnement est soumis aux deux conditions suivantes: (1) cet appareil ne peut pas provoquer

d’interférences et (2) cet appareil doit accepter toute interférence, y compris les interférences qui

peuvent causer un mauvais fonctionnement du dispositif.

Loading...

Loading...