Page 1

ECEC32003200

4281842818

)

!$%%"!($$ '#&!$(#%$

Subject to Change without Notification.

© 2012 Stellar Industries, Inc.

Stellar Industries, Inc.

190 State Street

PO Box 169

Garner, IA 50438

800-321-3741

Fax: 641-923-2811

www.stellarindustries.com

Last Revision: 09/06/12

Page 2

EC3200 Manual Revisions

Date of Revision Description of Revision

Section Revised

Page 3

Table of Contents

Chapter 1 - Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Capacity Chart - Decal PN 42817 . . . . . . . . . . . . . . . . . . 2

Chapter 2 - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Flatbed Body Reinforcement . . . . . . . . . . . . . . . . . . . . . . 5

EC3200 Mounting Detail . . . . . . . . . . . . . . . . . . . . . . . . . . 5

EC3200 Installation Drawing . . . . . . . . . . . . . . . . . . . . . . . 6

Hydraulic Kit - PN 42799. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Control Kit - PN 42804 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

EC3200 Wiring Diagram (Two Battery) . . . . . . . . . . . . . . 9

EC3200 Wiring Diagram (One Battery) . . . . . . . . . . . . . 10

Valve Bank Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Stability Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Stability Capacity Chart . . . . . . . . . . . . . . . . . . . . . . . . . 13

Decal Kit Placement - PN 42816 . . . . . . . . . . . . . . . . . . 14

Chapter 3 - Assembly Drawings. . . . . . . . . . . . . . . . . . . . . 15

Base Assembly - PN 42525 . . . . . . . . . . . . . . . . . . . . . . . 15

Base Assembly (Narrow Version) - PN 44613. . . . . . . . . 16

Mast Assembly - PN 42787 . . . . . . . . . . . . . . . . . . . . . . . 17

Main Boom Assembly - PN 42512. . . . . . . . . . . . . . . . . . 18

Extension Boom Assembly - PN 42520 . . . . . . . . . . . . . . 19

Cable & Hook Assembly - PN 42781 . . . . . . . . . . . . . . . 20

Radio Transmitter Assembly . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 4 - Replacement Parts . . . . . . . . . . . . . . . . . . . . . 23

Table of Contents

Find a Dealer Near You:

http://www.stellarindustries.com/pages/dist/distsearch.htm

For Technical Questions, Information, Parts, or Warranty, Call Toll-Free at

800-321-3741

Hours: Monday - Friday, 8:00 a.m. - 5:00 p.m. CST

Or email at the following addresses:

Technical Questions, and Information service@stellarindustries.com

Order Parts parts@stellarindustries.com

Warranty Information warranty@stellarindustries.com

Page 4

EC3200 Owner’s Manual

This page intentionally left blank.

Page 5

Chapter 1 - Specifications

Model EC3200 Crane

SPECIFICATION SHEET

Crane Rating: 11,500 ft-lb (1.59 TM)

Standard Boom Length: 7’ (2.13 m) from CL of Crane

Boom Extension: 1st stage: Hydraulic 48" (121.9 cm)

2nd stage: Manual 48" (121.9 cm)

Maximum Horizontal Reach: 15’ (4.57 m) from CL of Crane

Maximum Vertical Lift: 16’ 2” (4.93 m)

(from crane base)

Boom Elevation: -5 to +80 degrees

Specifications

Stowed Height: 24” (61.0 cm)

(crane only)

Mounting Space Required: 18” x 15” (45.7 x 38.1 cm)

Approximate Crane Weight: 730 lbs (331 kg)

Controls: Radio control standard for all functions.

Winch Specifications

Rope Length: 65 ft (19.8 m)

Rope Diameter: 7/32" (.56 cm)

Line pull speed: 15 ft/min (4.6 m/min)

Max. single part line: 1600 lbs (725 kg)

Max. double part line: 3200 lbs (1450 kg)

Rotation: 410 degree power

(worm gear)

Lifting Capacities: 1625 lbs @ 7’ (737 kg @ 2.1 m)

905 lbs @ 11’ (410 kg @ 3.35 m)

640 lbs @ 15’ (290 kg @ 4.6 m)

Power Supply Required: 12 volt power unit

(2.0 gpm @ 2600 psi)

(7.57 lpm @ 179 bar)

*Subject to change without notification

Page 6

EC3200 Owner’s Manual

3’

.914 M

0’

6’

1.83 M

7’

2.13 M

11’

3.35 M

15’

4.57 M

0’

3’

.914 M

6’

1.83 M

9’

2.74 M

12’

3.66 M

15’

4.57 M

16’2”

4.92 M

Reach in Feet/Meters

Capacity in Pounds/Kilograms

Weight of load handling devices are

part of the load lifted and must be

deducted from the capacity.

EC3200

PN 42817

Maximum 1 - part line capacity is

1600lbs (725kg). For greater loads,

use 2 - part line.

15º

30º

45º

60º

75º

80º

410 kg

905 lbs

1490 lbs

3200 lbs

1710 lbs

775 kg

3200 lbs

1450 kg

1450 kg

2415 lbs

862 kg

1095 kg

1900 lbs

3200 lbs

1450 kg

675 kg

1372 kg

1450 kg

3200 lbs

1450 kg

3200 lbs

973 kg

2145 lbs

703 KG

*1550 lbs

*3200 lbs

1450 kg

*3025 lbs

890 lbs

290 kg

640 lbs

550 kg

353 kg

780 lbs

492 kg

1085 lbs

404 kg

1215 lbs

1090 lbs

495 kg

83.69

®

710 kg

1565 lbs

Capacity Chart - Decal PN 42817

Page 7

Chapter 2 - Installation

Notice: Read this Page Before Installation of the Crane

Installation

General Installation

This chapter is designed to serve as a

general guide for the installation of a Stellar

EC3200 Crane on a Stellar Service Body.

Each installation is considered unique so

certain portions of this chapter may or may

not apply to your direct application. If a

question should arise during the installation

process, please contact Stellar Customer

Service at (800) 321 3741.

This crane is designed for use with a Stellar

Service Body installed on a vehicle that

meets the minimum chassis requirements of

the crane. It is the installer’s responsibility to

assure that the crane is mounted on a

platform that will support the maximum

crane rating of this crane.

Notice:

PTO and Pump installation instructions are

provided by the corresponding

manufacturers. For more information on

which PTO and Pump fit your application,

please contact your local Stellar Distributor

or Stellar Customer Service.

Important: When installing welder units to the service

bodies, it is highly recommended that a surge

protector is installed on the chassis batteries to protect

the crane radio receiver, wiring and other electronic

devices from an unexpected electrical spike or surge.

Failure to do so could result in extensive damage to

the service body and crane electrical circuit.

Installation Notice

According to Federal Law (49 cfr part 571),

each final-stage manufacturer shall

complete the vehicle in such a manner that

it conforms to the standards in effect on the

date of manufacture of the incomplete

vehicle, the date of final completion, or a

date between those two dates. This

requirement shall, however, be superseded

by any conflicting provisions of a standard

that applies by its terms to vehicles

manufactured in two or more stages.

Therefore, the installer of Stellar cranes and

bodies is considered one of the

manufacturers of the vehicle. As such a

manufacturer, the installer is responsible for

compliance with all applicable federal and

state regulations. They are required to

certify that the vehicle is in compliance with

the Federal Motor Vehicle Safety Standards

and other regulations issued under the

National Traffic and Motor Vehicle Safety

Act.

Please reference the Code of Federal

Regulations, title 49 - Transportation, Volume

5 (400-999), for further information, or visit

http://www.gpoaccess.gov/nara/index.html

for the full text of Code of Federal

Regulations.

Page 8

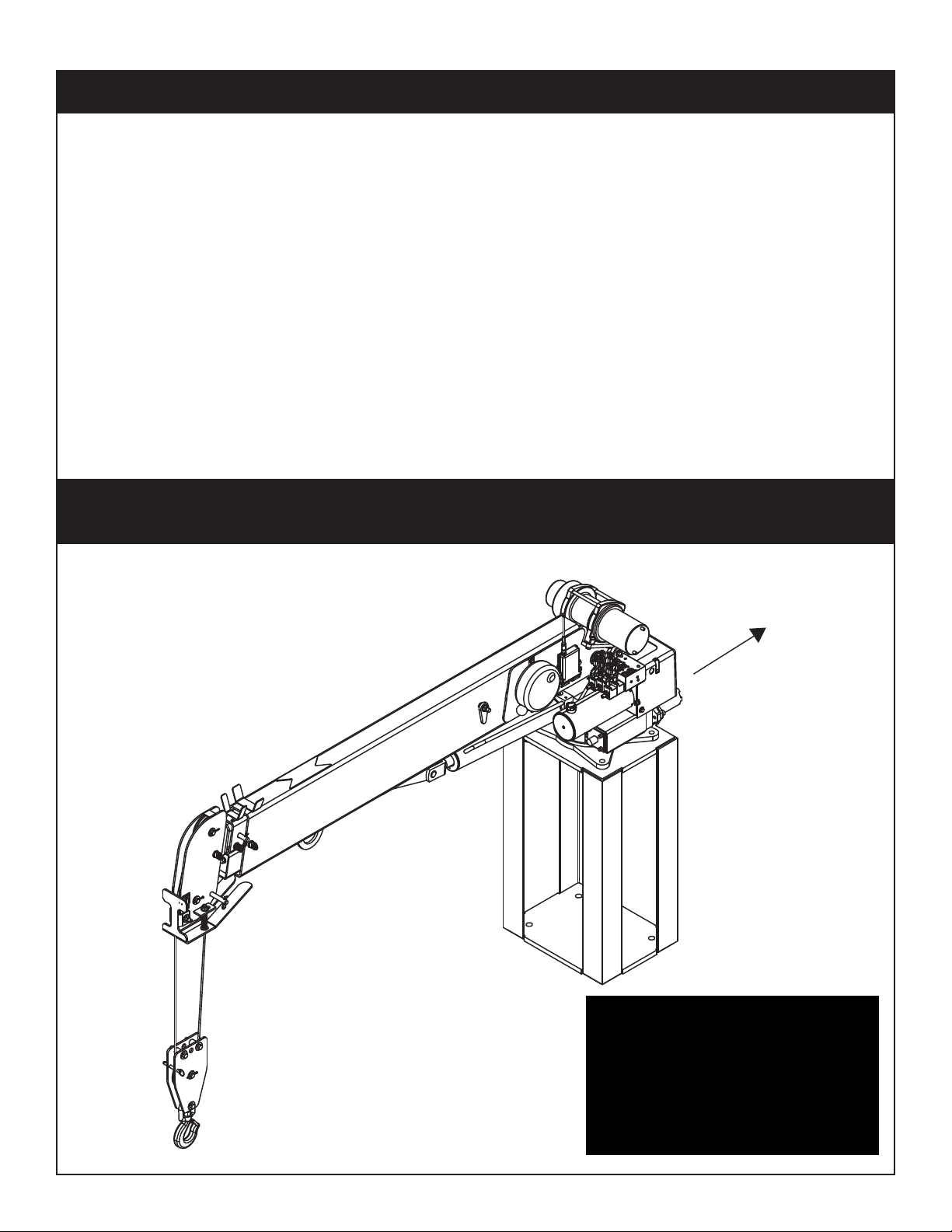

EC3200 Owner’s Manual

Front of Truck

Installation Overview

1. Determine that the mounting location for the EC3200 crane is at least 18” x 15” (45.7 x 38.1 cm).

2. Use the detail on the following page to drill .938” diameter holes into the mounting plate. Run tap on the

threads of the base to be sure they are clean.

3. Use a crane or lifting device capable of lifting the weight of the Stellar crane. The Stellar EC3200 weighs

approximately 800 lbs (360 kg). Note: cranes are shipped with rotation positioned at 180 degrees from

normal stowed travel position. This will allow for easy installation of the crane and permanent connection

of all hydraulic and electrical components prior to repositioning into the crane saddle.

4. Connect straps or chain from the lifting device to the main boom of the Stellar EC3200.

5. Use four (4)

6. Install a washer on each bolt.

7. Apply Loctite Thread locker #277 to the bolts.

8. Using the lifting device, lower the Stellar EC3200 just above the crane compartment and start the bolts.

Have someone assist in leveling the crane.

9. Secure the crane using the mounting hardware provided. Note: longer or shorter cap screws may be

required – recommended thread engagement into crane base is 0.75” – use grade 8, zinc plated cap

screws only.

10. Torque the cap screws to 454 ft-lbs.

11. Remove supporting crane.

12. Hook-up hydraulics and electrical using the schematics provided at the end of this chapter.

7

⁄8” x 1-3⁄4” #8 bolts and four (4) #8 7⁄8” flat washers.

Note: If questions should arise during any portion of this installation,

please contact Stellar Customer Service at (800) 321-3741.

WARNING!

The use of this crane on a

body not capable of handling

the loads imposed on it may

result in serious injury or

death.

Page 9

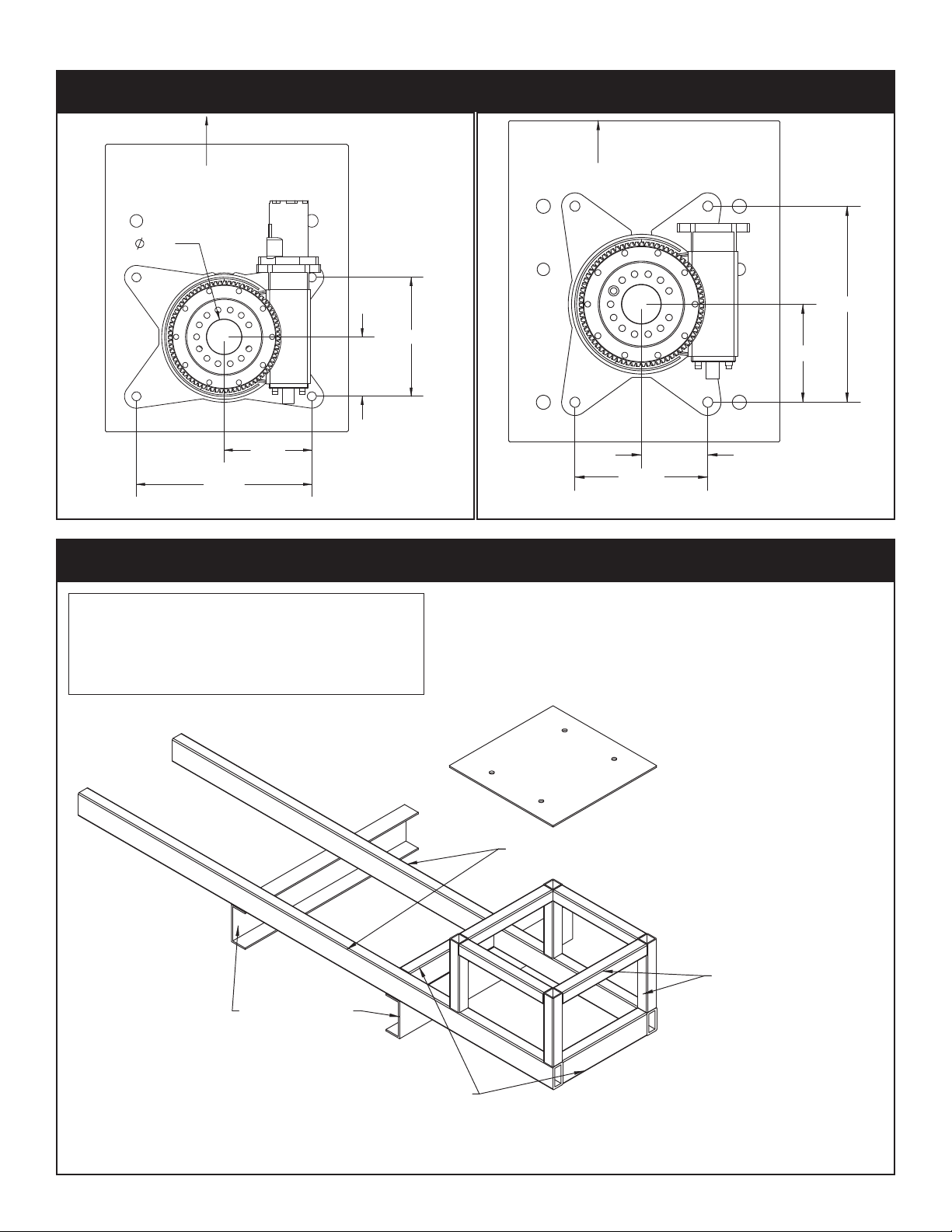

HOLE MOUNTING DETAIL

FRONT

7.38

5.00

10.00

14.75

3.00

EC3200 Mounting Detail

TUBE 4X2X0.38

TRUCK FRAME

TUBE 4X2X0.38

3/8 PLATE

TUBE 2X2X0.38(TYP 4)

HOLE MOUNTING DETAIL

FRONT

7.38

14.75

5.00

10.00

Installation

Standard

Flatbed Body Reinforcement

Narrow

Base

If it has been determined that the destination

body won’t support the crane with a fully

rated load, the body must be reinforced.

Use 1/4” fillet welds and an ASWS qualified

welder to proceed as shown in this drawing:

Note: Tubing must be

at least 4” x 2” x 0.38”

(Except where noted)

Page 10

EC3200 Owner’s Manual

IS PART OF THIS KIT

STABILITY DECAL P/N 16881

NOTE:

2

3

.YTQNOITPIRCSEDTRAPMETI

2 18041 WASHER 0.88 SAE FLAT YELLOW GR94

3 51377 CAP SCR 0.88-9X2.00 HHGR94

Stowed Position

EC3200 Installation Drawing

NOTICE!

Route hoses correctly to ensure

they do not become pinched or

crushed during installation.

Page 11

BOOM UP

BOOM DOWN

MAIN UP

ROTATI ON CCW

ROTATI ON CW

MAIN DOWN

EXT IN

EXT OUT

ROTATION CW

ROTATION CCW

ROTATION

2

05 43847

ITEM

01

02

03

04

42980

42800

PART No.

42983

42981

06

07

09

08

10

42982

42984

C1111

PN 42799

FTG ADAPT MSTR/FSTR 10-6 F5OG5

HOSE KIT 3315 CRANE (incl:2-11)

DESCRIPTION

HOSE-HYD .25 X 20

HOSE-HYD .25 X 22

HOSE-HYD .25 X 23

HOSE-HYD .25 X 19

HOSE-HYD .25 X 42

HOSE-HYD .25X 43

QTY

1ref

1

1ref

1ref

1ref

1ref

1ref

13

11

12

14

15

49315

D1291

C4922

3861

16

MAIN

EXTENSION RETRACT

EXTENSION EXTEND

EXT

FTG ADAPT 4-F5OLO-S

FTG ADAPT 4-6 F5OLO-S

FTG ML FM O'RING 90 DEG

SWITCH PRES OVERLD CD-11C-2900R/WD

1

4

8

1

02 06 07

12 12

03

12 12

12 12

04

05

12

10

12

10

13

14

11

11

11

11

Installation

Hydraulic Kit - PN 42799

Page 12

EC3200 Owner’s Manual

NOTE: P/N 47409 INCLUDES

HARNESS & WINCH CONTROLLER

7,8

9

POWER

GROUND

OPT1

OPT2

WINCH UP RELAY

1

WINCH DOWN

POWER 12 V

3

POWER UNIT SIGNAL

POWER 12 V

2

4,5,6

SWITCH

4,5,6

A2B

PRESSURE SWITCH

RADIO CNTRL ASM 5 FCTN ON/OFF

SWITCH PUSH BUTTON 9216-03

WIRE HARNESS 3315 MULTI FUNCTION VB

PART No.ITEM

42976

17771

42805

03

01

02

DESCRIPTION

COVER SWITCH EC3200

SWITCH MOM SPST 20A

CABLE SEAL 18-20 PACKARD 39000

CONNECT 2 PIN SHROUD PACKARD

CONTACT M TERM SHROUD 14-16 3103406 9756

8384

9752

05

04

47409

47410

08

07

WIRE HARNESS 3315 MULTI FUNCTION VB

FUSE HOLDER 46039

FUSE 250 AMP 4627611 36436

47092

3252310

09

12

QTY

1

1

1

4

4

2

1

1

1

1

1

MAIN

CONTACT

GROUND

PN 42804

7

6

8

5

A

109

4 3

11

2

12

1

87A

30

86

85

87

A

B

B

A

8

5

12

1

B

11

2

10

3

9

4

A

B

B

A

7

6

A

B

B

A

A

B

B

A

A

B

B

A

A

B

B

A

ROTCWROT

CCW

INNER

DOWN

INNER

UP

EXTINEXT

OUT

A

B

A

B

WINCH

DOWN

GROUND

WINCH

UP

REPLACEMENT CONTROLLER

STELLAR P/N 42821

B

A

B

A

B

A

C

Winch

Power

Unit

Control Kit - PN 42804

Page 13

+

-

FUSE 250 AMP

(STELLAR SUPPLIED)

UNDERHOOD

TRUCK BATTERY

MASTER

250 AMP

AUX BATTERY

-

+

CRANE

COMPARTMENT

CAB OR CRANE

10 AMP

POWER

SWITCH

START MOTOR

SOLENOID

GROUND POST

CRANE HARNESS

GROUND

GROUND

LOCATE AUX BATTERY AS

CLOSE TO CRANE AS POSSIBLE

GROUND

POWER

OPT1

OPT2

SWITCH

(NOT SUPPLIED)

POWER SOURCE FOR

RADIO REMOTE

Torque Spec

Large Nuts: 35 in-lbs

Small Nuts: 15 in-lbs

FUSE 250 AMP

(STELLAR SUPPLIED)

Recommended Wire Sizes:

EC3200 - #2

EC4000 - #2

EC5000 - #2

EC6000 - 1/0

EC3200 Wiring Diagram (Two Battery)

Installation

Page 14

EC3200 Owner’s Manual

+

-

FUSE 250 AMP

(STELLAR SUPPLIED)

UNDERHOOD

TRUCK BATTERY

CRANE

COMPARTMENT

CAB OR CRANE

10 A MP

POWER

SWITCH

START MOTOR

SOLENOID

GROUND POST

CRANE HARNESS

GROUND

GROUND

GROUND

POWER

OPT1

OPT2

POWER SOURCE FOR

RADIO REMOTE

Torque Spec

Large Nuts: 35 in-lbs

Small Nuts: 15 in-lbs

SAFETY BRAKE

87A

30

86

85

87

Note:

With a single battery configuration,

operating the crane when the truck

is not running will drain the truck battery.

Recommended Wire Sizes:

EC3200 - #2

EC4000 - #2

EC5000 - #2

EC6000 - 1/0

EC3200 Wiring Diagram (One Battery)

Page 15

ROT

CCW

ROT

CW

INNER

UP

INNER

DOWN

EXT

OUT

EXT

IN

Valve Bank Drawing

Installation

Page 16

EC3200 Owner’s Manual

Stability Procedure

Definition of Stability for the Stellar Telescopic Crane Products:

A truck is stable until the load cannot be lifted off the ground with the winch, without

tipping over the truck. Every Stellar crane installed must be tested for stability to

determine the actual load capacity of the final truck package. The actual test data

must be recorded and supplied with the truck at the time of in-service and should be kept

with the truck at all times. The following procedure will test the truck package for stability

and will provide a stability capacity chart. The load limit information shown on the

stability capacity chart is formulated on 85% tipping.

Set Up:

1. Locate the truck on a test course in position for loading and engage travel brakes.

2. Set stabilizers so that they make contact with firm, level footings.

3. Operate the crane under partial load to assure operator proficiency and proper

machine function.

EC3200 Stability Data

Max Horizontal Reach: 180” (From the center of rotation to boom tip)

Stability Test Weight: 755 lbs.

Test Procedure

1. Rotate the crane into Zone 1 position.

2. With the crane fully retracted and the boom horizontal, winch the test weight off the

ground. Note: Keep weight within six inches of the ground at all times.

3. Extend the boom outward until full extension has been reached or until the truck

becomes unstable (Again, use the winch to keep the weight within six inches of the

ground.)

4. If the boom goes full extension without becoming unstable, the crane is termed stable

for this zone and 100% can be written in the Zone 1 data box.

5. If the truck becomes unstable prior to going full extension, retract the boom until the

truck becomes stable and measure the horizontal reach in this position (center of

rotation to boom tip). This is the stable horizontal reach for this zone. Stable horizontal

reach divided by Maximum horizontal reach multiplied by 100 equals the percentage

of rated capacity for this zone. Use the following formula to determine the percentage

of rated capacity:

6. Record this number in the data box for Zone 1. This is the revised capacity due to

stability for this zone.

7. Repeat this procedure for each zone until the worksheet is completed.

8. This is the revised capacity based on stability of this package.

Page 17

STABILITY CAPACITY CHART

Stability Capacity Chart

Installation

Page 18

EC3200 Owner’s Manual

PART No.

DESCRIPTION

ITEM

QTYQTY

PART No.ITEM

DESCRIPTION

DECAL-ELECTROCUTION 2x2.75

DECAL-ELECTROCUTION 4.5x7.5

DECAL ASME/ANSI B30.22/B30.5

4190

*10

DECAL-DANGER

09

*08

*06

07

*05

*03

*04

02

01

C4540 DECAL-DANGER

DECAL CAPACITY

DECAL-ELECTROCUTION 5x13

DECAL IDENTIFICATION

15172

42818

42817

C4545

DECAL-DANGER

DECAL-ROTATE/GREASE

DECAL-DANGER

C4544

4186

9188

4189

15

14

*12

*13

*11

13819 DECAL-ANGLE INDICATOR SS

DECAL-DANGER O.R.

DECAL ANGLE INDICATOR CS

DECAL-DANGER MOVING O.R.C5918

C4795

13820

C1179

1

1

15171

25

DECAL GREASE WORM DRIVE BEARINGS

DECAL-STELLAR 4x9.5

DECAL HOISTING PERSONNEL

DECAL-CRANE STOWING

DECAL-TWO BLOCKING

DECAL-STELLAR 2x4.5

DECAL MANUAL EXT

DECAL-DIESEL

DECAL-SERVICE

1C0568

*20

2

*16

1

*17

4

*19

2

*18

12451

C5910

12452

C5911

1

*21

1

22

1

24

1

*23

4214

12300

C4541

2

1

1

3

1

1

1

1

DECAL VB CONTROL EC3200

*USE THESE DECALS WITH BODY PACKAGE

DECAL STELLAR MADE IN THE USA

DECAL SNATCH BLOCK CAP 3 TON

DECAL WARNING OVERLOAD DEVICE

DECAL WARNING MANUAL OVERRIDES

DECAL CAUTION STOW HOOK

35234

30

1

2

26

2

27

29

1

2

28

24712

25159

42819

28256

**31

**THESE DECALS NOT INCLUDED WITH THE DECAL KIT

42820

1

1

1

1

1

1

18472 DECAL MANUAL OPERATION 1

PN 42816

30

31

26

9

24

27

29

01

28

14,15

25

22

7

03

02

3030

2020

5050

6060

7070

4040

1010

00

D1196D1196

IndicatorIndicator

8080

AngleAngle

ECEC32003200

4281842818

Decal Kit Placement - PN 42816

Page 19

11

5

3

4

2

6

1

8

7

9

10

9

12

.YTQNOITPIRCSEDTRAPMETI

10023CE ESAB487241

241640BEARING SWING DRIVE 170-00058-1 1

13 MOTOR 80CC EC3200 YMPH-80-H2(R)-K-S-B62487

4 21151GASKET MOTOR 008-10056-1 1 ref

2HS 52.1X31-05.0 RCS PAC7031D5

6 30750 CAP SCR 0.50-13X3.50 HHGR813

10023CE GNIDILS POTS597247

318RG TALF 05.0 REHSAW0970D8

9D1345 FTG CPRSN 0.12NPT/0.25 TUBE2

10 D1810 TBE AIR SAEJ844 TYPE A .25 (RM)1

131.0 EPIP RELPUOC GTF6522C11

12 56589 ZERK 1/8 NPT STRAIGHT LONG THREAD 1

PN 42525

Chapter 3 - Assembly Drawings

Base Assembly - PN 42525

Assembly Drawings

Page 20

EC3200 Owner’s Manual

.YTQNOITPIRCSEDTRAPMETI

1

1

WORRAN 0023CE ESAB416441

3

241640BEARING SWING DRIVE 170-00058-1 1

4 21151GASKET MOTOR 008-10056-1 1 ref

5D1307 CAP SCR 0.50-13X1.25 SH2

6 30750 CAP SCR 0.50-13X3.50 HHGR813

10023CE GNIDILS POTS597247

318RG TALF 05.0 REHSAW0970D8

9D1345 FTG CPRSN 0.12NPT/0.25 TUBE2

10 D1810 TBE AIR SAEJ844 TYPE A .25 (RM)1

131.0 EPIP RELPUOC GTF6522C11

12 56589 ZERK 1/8 NPT STRAIGHT LONG THREAD 1

11

5

3

4

2

6

1

8

7

10

9

12

PN 44613

MOTOR 80CC EC3200 YMPH-80-H2(R)-K-S-B62487

Base Assembly (Narrow Version) - PN 44613

Page 21

9

*

10

4

3

5

12

3

2

13

8

11

1

6

7

MOUNTING HOLE

10

*

14

16 15

16

15

NOTE: WINCH CONTROLLER(P/N 42821)

SHOWN FOR REFERENCE

18

19

22

9

20

21

9

P/N 42798 MUST

GO IN THIS MAST

22

PN 42787

.YTQNOITPIRCSEDTRAPMETI

10023CE TSAM813241

242513 POWER UNIT 12V EC3200 1

342788 WASHER 0.44 SAE FLAT YELLOW GR8 8

442789 CAP SCR 0.44-14X2.25 HHGR8 ZY 7

520362 BUSHING IGUS GFI-1618-08 4

60345 CAP SCR 0.38-16X1.50 HHGR5 2

2TALF 83.0 REHSAW64307

80479 CAP SCR 0.25-20X0.75 HHGR5 2

6SS TALF 52.0 REHSAW7190D9

10 0478 CAP SCR 0.25-20X0.50 HHGR5 3

2TALF 52.0 REHSAW043011

12 43579 CAP SCR 0.44-14X2.75 MOD EC3200 1

13 47411 BRKT OVERRIDE BUTTON EC3200 1

1EPDH 0023CE REVOC5744441

15 0343 WASHER 0.31 USS FLAT ZINC 3

16 0420 CAP SCR 0.31-18X0.75 HHGR5 3

18 5870 WASHER 0.38 STAR EXTERNAL 1

19 0492 CAP SCR 0.38-16X0.75 HHGR5 1

20 51896 BRKT COVER EC CRANES 1

21 30659 NUT 0.25-20 HH NYLOC SS 1

22 C6021 CAP SCR 0.25-20X0.75 BTNHD SS 2

Mast Assembly - PN 42787

Assembly Drawings

Page 22

EC3200 Owner’s Manual

.YTQNOITPIRCSEDTRAPMETI

10023CE MOOB RENNI303241

2 41641WINCH DC2000 WARN 638991

10266 LEER DROC445113

3TALF 52.0 REHSAW04304

1LYNIV KLB 52.0 PMALC6065C5

6 43845 CAP SCR 0.25-20X0.38 HHGR52

1THGIARTS TPN 8/1 KREZ2951c7

8 42508 WEAR PAD 0.50X1.50X2.001

48RG TALF 05.0 REHSAW0970D9

10 13815PC PLATE ANGLE INDICATOR 2

11 C6106 NUT 0.50-13 HHGR5 NYLOC 2

261-8161-ISQ GNIHSUB960021

13 20362BUSHING IGUS GFI-1618-08 1

100.31X00.3 REDNILYC3052441

2T&D 83.6X00.1 NIPPZ5152451

16 9320 PIN CAP 0.44X1.75X0.19 SS6

1T&D 31.5X00.1 NIPPZ6152471

18 42517ZP PIN TEAR DROP 1.00X2.191

19 5591WASHER 0.31 SAE FLAT YELLOW GR81

20 21170 CAP SCR 0.31-18X1.00 HHGR81

21 0345 CAP SCR 0.38-16X1.50 HHGR54

2SS TALF 52.0 REHSAW7190D32

24 0479 CAP SCR 0.25-20X0.75 HHGR53

2KCOL 52.0 REHSAW125052

1LYNIV KLB 05.0 PMALC1800C62

27 C6353 WASHER 0.38 SAE FLAT YELLOW GR86

28 9843 CAP SCR 0.38-16X0.75 HHGR86

4

1

8

14

18

19

20

13

15

16

27

28

16

27

28

10

9

11

17

16

28

28

27

16

15

12

2

21

6

4

5

3

USE ALL HARDWARE, EXCEPT BOLTS.

7

23

24

25

26

MOUNTING HARDWARE WILL

BE PART OF THE WINCH PACKAGE.

24

PN 42512

Main Boom Assembly - PN 42512

Page 23

.YTQNOITPIRCSEDTRAPMETI

1 42311 EXT BOOM 1ST EC32001

100.84X05.1 REDNILYC705242

3D0790 WASHER 0.50 FLAT GR8 9

4 10172 CAP SCR 0.50-13X1.00 HHGR8 ZY1

5 42509 WEAR PAD 0.38X1.38X1.502

6 42312 EXT BOOM 2ND EC32001

7 42978PC FLAT BOOM STOP EC32001

200.4X36.0 HCTIH NIP779248

9 42317 SHEAVE EC3200 5.00 DIA .22R/1.00THK2

2RETTOC 05.2X57.0 NIPPZ4252401

11 0423 MACHY WASHER 0.75ID 10GA4

400.1X521. NIP RETTOC4287321

13 0507 CAP SCR 0.50-13X4.50 HHGR52

14 27710 SPRING ANTI 2 BLOCK SUMMIT2

15 C6106 NUT 0.50-13 HHGR5 NYLOC 3

16 0352 WASHER 0.50 USS FLAT ZINC2

17 35105 SWITCH LIMIT E1117-B9111-6C1

18 D0178 WASHER #10 SAE FLAT ZINC2

19 0505 CAP SCR 0.50-13X3.50 HHGR51

20 D0561 CAP SCR 0.25-20X0.50 BTNHD SS2

21 42505PC PLATE CRADDLE EC32001

22 43846 SCREW #10-24X0.38 SH SS2

PN 42520

2

3

4

8

1

6

5

5

7

20

12

11

9

10

11

12

17

18

22

15

3

14

3

21

16

15

3

13

19

16

8

Extension Boom Assembly - PN 42520

Assembly Drawings

Page 24

8

13

11

12

11

13

4

3

1

2

10

9

1

5

3

7

6

PN 42781

.YTQNOITPIRCSEDTRAPMETI

1 42523PC PLATE SNATCH BLOCK EC32002

2 42317 SHEAVE EC3200 5.00 DIA .22R/1.00THK1

3 0352 WASHER 0.50 USS FLAT ZINC6

4 5468 NUT 0.50-13 HHGR8 NYLOC 3

5 27810 SPACER 3315 SNATCH BLOCK UHMW2

6 16607PC SPACER 3315 SNATCH BLOCK1

7 47868 CAP SCR 0.50-13X2.75 HHGR83

8 42316 WIRE ROPE 7/32 7X19 GAC 65FT1

9 9263 PIN .38X3.00 QUICK RELEASE 1

1NOT 3-ENARC KOOH8106C01

11 0375MACHY WASHER 0.75ID 14GA2

1RETTOC 05.2X57.0 NIPPZ4252421

200.1X521. NIP RETTOC4287331

EC3200 Owner’s Manual

Cable & Hook Assembly - PN 42781

Page 25

.YTQNOITPIRCSEDTRAPMETI

1 20088 CONTROL HANDLE HOUSING 4 FCTN HET1

2 51830 CONTROL HANDLE FACE PLT 5 FCTN1

3 24385 GUARD RADIO SWITCH 4 FCTN1

4 50932 CONTROL HANDLE GRIP LESS TRIGGER HET H21

5 22600 SWITCH TOGGLE HET RADIO 630193005

6 35441 BATTERY TUBE AA HETRONIC RADIO1

7 16975 SWITCH E STOP ASM HETRONIC RADIO1

8 51831 DECAL CONTROL HANDLE 5 FCTN1

4

6

3

NOTE: 1) P/N'S 25999 & 24958 ARE OPTIONAL COVERS

FOR THE SWITCHES AND TRIGGER

1

2

7

5

8

Radio Transmitter Assembly

Assembly Drawings

Page 26

EC3200 Owner’s Manual

This page intentionally left blank.

Page 27

Chapter 4 - Replacement Parts

HYDRAULIC COMPONENTS

PART# DESCRIPTION

42840 HYDRAULIC SWING MOTOR

21151 GASKET - HYDRAULIC SWING MOTOR

42513 POWER UNIT 12V EC3200

44028 VALVE CARTRIDGE - POWER UNIT 12V #19012-D

44027 VALVE COIL - POWER UNIT 12V #1149 4-D

44029 MOTOR 12V - POWER UNIT #08111-1

44030 12V SOLENOID (12volt hydraulic system) #17757

44026 HYDRAULIC RESERVOIR - POWER UNIT 12V #14071

44025 FILL CAP - HYDRAULIC RESERVOIR

9803 C-BALANCE VA LVE

43892 SEAL KIT - MAIN LIFT CYLINDER

43893 SEAL KIT - EXTENSION CYLINDER

49315 PRESSURE SWITCH

42821 CONTROLLER SOLENOID

C2027 O'RING - # 4 FACE SEAL

C2028 O'RING - # 6 FACE SEAL

D1245 O'RING - # 4 SAE

D1246 O'RING - # 6 SAE

ASSEMBLY COMPONENTS

44375 WORM GEAR - ROTATION BEARING

44383 BEARING & SEAL KIT - ROTATION BEARING

44376 BEARING RETAINER - ROTATION BEARING

44377 ADAPTER HOUSING - HYDRAULIC MOTOR

20362 BUSHING 1.00" X 0.50"

0069 BUSHING 1.00" X 1.00"

42508 WEAR PAD 0.38" X 1.50" X 2.00"

42509 WEAR PAD 0.38" X 1.38" X 1.50"

42978 BOOM STOP FLAT

9320 PIN CAP 0.44" X 1.75" X 0.25" SS

C6353 WASHER 0.38 FLAT GR8

13573 CAP SCR. 0.38-16 X 1.00" GR8

0375 MACHINE WASHER -0.75" ID 14GA.

0423 MACHINE WASHER -0.75" ID 10GA.

42317 SHEAVE

42316 WIRE ROPE

42977 HITCH PIN 0.63" X 4.00"

9263 QUICK RELEASE PIN .38 X 3.00"

42505PC CRADLE PLATE

27710 SPRING ANTI-2-BLOCK

C6018 HOOK 3-TON

10709 SAFETY LATCH FOR 3 TON HOOK

C1592 GREASE ZERK

ELECTRICAL COMPONENTS

35105 LIMIT SWITCH

11544 CORD REEL

17771 PUSH BUTTON (12volt hydraulic system)

47410 MOMENTA RY SWITCH

41641 WINCH

28978 BOSCH RELAY

36436 FUSE 250 AMP

RADIO REMOTE COMPONENTS

42976 RADIO REMOTE SYSTEM

50932 HANDLE ASM

16975 E-STOP SWITCH

22600 TOGGLE SWITCH

20088 LOWER TRANSMITTER HOUSING

35441 BATTERY TUBE HOLDER

35916 BACK UP CORD

Replacement Parts

Page 28

Limited Warranty Statement

Stellar Industries, Inc. (Stellar) warrants products designed and manufactured by Stellar to be free from defects in material and workmanship under

proper use and maintenance. Products must be installed and operated in accordance with Stellar’s written instructions and capacities. This warranty

shall cover the following:

Stellar Cranes, Stellar Hooklift Hoists, Stellar Cable Hoists, Stellar Container Carriers, Stellar Service Trucks, and Stellar X-Tra-Lift Systems:

Twelve (12) month warranty on parts from the date recorded by Stellar as the in-service date, not to extend beyond twenty-four (24) months from date

ofmanufacture,

Twelve (12) month repair labor from the date recorded by Stellar as the in-service date, not to extend beyond twenty-four (24) month from date of

manufacture, and

Thirty-six (36) month warranty on all Stellar Manufactured structural parts from the date recorded by Stellar as the in-service date, not to extend beyond

forty-eight (48) months from date of manufacture.

Stellar Tarper Systems:

Twelve (12) month warranty on parts from the date recorded by Stellar as the in-service date, not to extend beyond twenty-four (24) months from date

of manufacture and

Three (3) month repair labor from the date recorded by Stellar as the in-service date, not to extend beyond fifteen (15) month from date of

manufacture.

The in-service date will be derived from the completed warranty registration card. In the event a warranty registration card is not received by Stellar, the

factory ship date will be used.

Stellar’s obligation under this warranty is limited to, and the sole remedy for any such defect shall be, the repair and/or replacement (at Stellar’s option)

of the unaltered part and/or component in question. Stellar after-sales service personnel must be notified by telephone, fax, or letter of any warrantyapplicable damage within fourteen (14) days of its occurrence. If at all possible, Stellar will ship the replacement part within 24-hours of notification by

the most economical, yet expedient, means possible. Expedited freight delivery will be at the expense of the owner.

Warranty claims must be submitted and shall be processed in accordance with Stellar’s established warranty claim procedure. Stellar after-sales service

personnel must be contacted prior to any warranty claim. A return materials authorization (RMA) account number must be issued to the claiming party

prior to the return of any warranty parts. Parts returned without prior authorization will not be recognized for warranty consideration. All damaged parts

must be returned to Stellar freight prepaid; freight collect returns will be refused. Freight reimbursement of returned parts will be considered as part of

the warranty claim.

Warranty service will be performed by any Stellar new equipment distributor, or by any Stellar-recognized service center authorized to service the type

of product involved, or by the Stellar factory in the event of a direct sale. At the time of requesting warranty service, the owner must present evidence

of date of delivery of the product. The owner shall be obligated to pay for any overtime labor requested of the servicing company by the owner, any

field service call charges, and any towing and/or transportation charges associated with moving the equipment to the designated repair/service

provider.

All obligations of Stellar and its authorized dealers and service providers shall be voided if someone other than an authorized Stellar dealer provides

other than routine maintenance service without prior written approval from Stellar. In the case repair work is performed on a Stellar-manufactured

product, original Stellar parts must be used to keep the warranty in force. The warranty may also be voided if the product is modified or altered in any

way not approved, in writing, by Stellar.

The owner/operator is responsible for furnishing proof of the date of original purchase of the Stellar product in question. Warranty registration is the

ultimate responsibility of the owner and may be accomplished by the completion and return of the Stellar product registration card provided with the

product. If the owner is not sure of registration, he is encouraged to contact Stellar at the address below to confirm registration of the product in

question. This warranty covers only defective material and workmanship. It does not cover depreciation or damage caused by normal wear and tear,

accident, mishap, untrained operators, or improper or unintended use. The owner has the obligation of performing routine care and maintenance

duties as stated in Stellar’s written instructions, recommendations, and specifications. Any damage resulting from owner/operator failure to perform such

duties shall void the coverage of this warranty. The owner will pay the cost of labor and supplies associated with routine maintenance.

The only remedies the owner has in connection with the breach or performance of any warranty on the Stellar product specified are those set above.

In no event will Stellar, the Stellar distributor/dealer, or any company affiliated with Stellar be liable for business interruptions, costs of delay, or for any

special, indirect, incidental, or consequential costs or damages. Such costs may include, but are not limited to, loss of time, loss of revenue, loss of use,

wages, salaries, commissions, lodging, meals, towing, hydraulic fluid, or any other incidental cost.

All products purchased by Stellar from outside vendors shall be covered by the warranty offered by that respective manufacturer only. Stellar does not

participate in, or obligate itself to, any such warranty.

Stellar reserves the right to make changes in design or improvement upon its products without imposing upon itself the same upon its products

theretofore manufactured.

This warranty will apply to all Stellar Cranes, Stellar Hooklift Hoists, Stellar Cable Hoists, Stellar Container Carriers, Stellar Service Trucks, Stellar X-Tra-Lift

Systems, and Stellar Tarper Systems shipped from Stellar’s factory after January 1st, 2010. The warranty is for the use of the original owner only and is not

transferable without prior written permission from Stellar.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE. REMEDIES UNDER THIS WARRANTY ARE LIMITED TO THE PROVISION OF MATERIAL AND SERVICES, AS SPECIFIED HEREIN. STELLAR

INDUSTRIES, INC. IS NOT RESPONSIBLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Revision Date: February 2010

Document Number: 37040

EC3200 Owner’s Manual

Loading...

Loading...