Page 1

)

!$%%"!($$ '#&!$(#%$

Subject to Change without Notification.

© 2012 Stellar Industries, Inc.

Stellar Industries, Inc.

190 State Street

PO Box 169

Garner, IA 50438

800-321-3741

Fax: 641-923-2811

www.stellarindustries.com

Last Revision: 01/23/12

Page 2

EC2000 Manual Revisions

Date of Revision Description of Revision

Section Revised

Page 3

Table of Contents

Chapter 1 - Specifications . . . . . . . . . . . . . . . . . . . . . . . . . .1

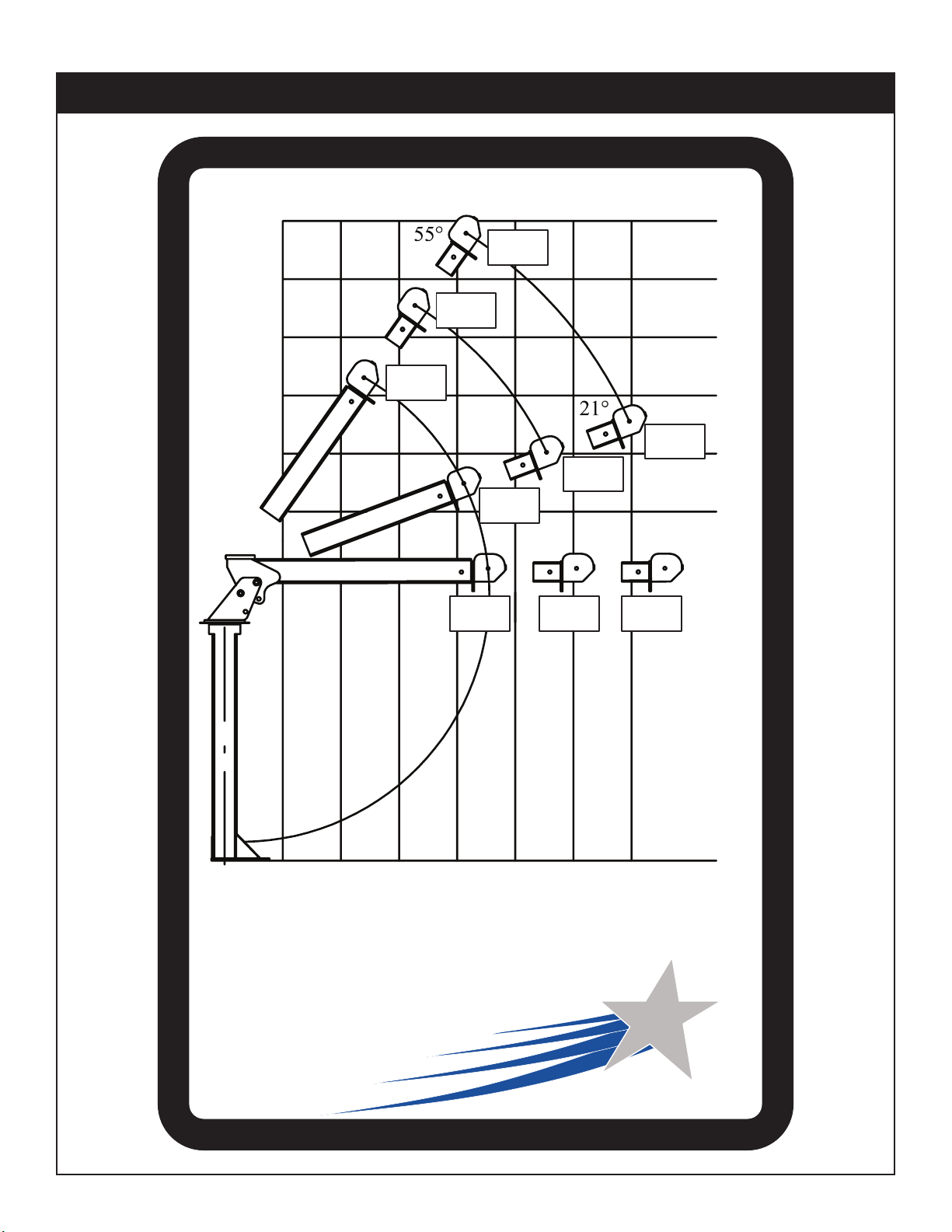

Capacity Chart - Decal PN 18039 . . . . . . . . . . . . . . . . .2

Chapter 2 - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Wiring Schematic - Power Rotation . . . . . . . . . . . . . . . .4

Wiring Schematic - Manual Rotation . . . . . . . . . . . . . . .4

Control Kit Power Rotation - PN 22930 . . . . . . . . . . . . .5

Stability Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Stability Capacity Chart . . . . . . . . . . . . . . . . . . . . . . . . . .7

Decal Kit - PN 18776 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Decals of Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Chapter 3 - Assembly Drawings . . . . . . . . . . . . . . . . . . . . .9

Standard Crane Assembly - PN 17631 . . . . . . . . . . . . . .9

50’ Wire Rope Crane Assembly - PN 33939 . . . . . . . . .10

Short Mast Crane Assembly - PN 19146 . . . . . . . . . . . .11

Power Rotation Crane Assembly - PN 22601 . . . . . . . .12

Power Rotation/Short Mast Crane Assembly -

PN 24906 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

LH Mount Crane Assembly - PN 56658 . . . . . . . . . . . . .14

Control Kit Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Table of Contents

Chapter 4 - Replacement Parts . . . . . . . . . . . . . . . . . . . . .17

Find a Dealer Near You:

http://www.stellarindustries.com/pages/dist/distsearch.htm

For Technical Questions, Information, Parts, or Warranty, Call Toll-Free at

800-321-3741

Hours: Monday - Friday, 8:00 a.m. - 5:00 p.m. CST

Or email at the following addresses:

Technical Questions, and Information service@stellarindustries.com

Order Parts parts@stellarindustries.com

Warranty Information warranty@stellarindustries.com

Page 4

EC2000 Owner’s Manual

Page 5

Chapter 1 - Specifications

Crane Rating: 6500 ft-lb (.899 TM)

Standard Boom Length: 4’ (1.219 m) from CL of Crane

Boom Extension: 1st Position: Manual 18” (45.7 cm)

2nd Position: Manual 18” (45.7 cm)

Maximum Horizontal Reach: 7’ (2.13 m) from CL of Crane

Maximum Vertical Lift (from crane base): 10’9” (3.28 m)

Boom Elevation: 0 to +21 to +56 degrees

Winch Specification

Rope Diameter: 3/16” (.476 cm)

Line Pull Speed: 20 ft/min (6.10 m)

Max. Single Part Line: 1100 lbs (495 kg)

Max. Double Part Line: 2000 lbs (905 kg)

Manual Rotation: 340˚ Manual

Power Rotation: 314˚ Power

Lifting Capacities: 1580 lbs @ 4’ (715 kg @ 1.219 m)

1190 lbs @ 5’6” (540 kg @ 1.676 m)

930 lbs @ 7’ (420 kg @ 2.13 m)

Stowed Height: 60” (152.4 cm)

Crane Only: 30” (76.2 cm) - Short Mast

Mounting Space Required: 12” x 12” (30.5 cm x 30.5 cm

Approximate Crane Weight: 275 lbs (124.7 kg)

230 lbs (104.3 kg) - Short Mast

300 lbs (136.1 kg) - Power Rotation

Weight of load handling devices are

part of the load lifted and must be

deducted from the capacity.

Maximum 1 - part line capacity is

1100lbs (495kg). For greater loads,

use 2 - part line.

Reach in Feet/Meters

Capacity in Pounds/Kilograms

1565

lbs

710

kg

1985

lbs

900

kg

2000

lbs

905

kg

1190lbs

540kg

1580lbs

715

kg

930lbs

420kg

1430lbs

650kg

1075lbs

490kg

860lbs

390kg

6’

1.83

M

0’

0’

7’

2.13 M

8’

2.44

M

9’

2.74 M

10’

3.05

M

11’

3.35

M

1’

.305 M2’.610 M3’.914 M4’1.22 M5’1.52 M6’1.83 M7’2.13 M

Specifications

Page 6

EC2000 Owner’s Manual

Weight of load handling devices are

part of the load lifted and must be

deducted from the capacity.

Maximum 1 - part line capacity is

1100lbs (495kg). For greater loads,

use 2 - part line.

Reach in Feet/Meters

Capacity in Pounds/Kilograms

PN 18039

1565lbs

710

kg

1985lbs

900

kg

2000lbs

905

kg

1190lbs

540

kg

1580lbs

715

kg

930lbs

420

kg

1430lbs

650

kg

1075lbs

490

kg

860lbs

390

kg

6’

1.83 M

0’

0’

7’

2.13 M

8’

2.44 M

9’

2.74 M

10’

3.05 M

11’

3.35 M

1’

.305 M2’.610 M3’.914 M4’1.22 M5’1.52 M6’1.83 M7’2.13 M

ECEC20002000

Capacity Chart - Decal PN 18039

Page 7

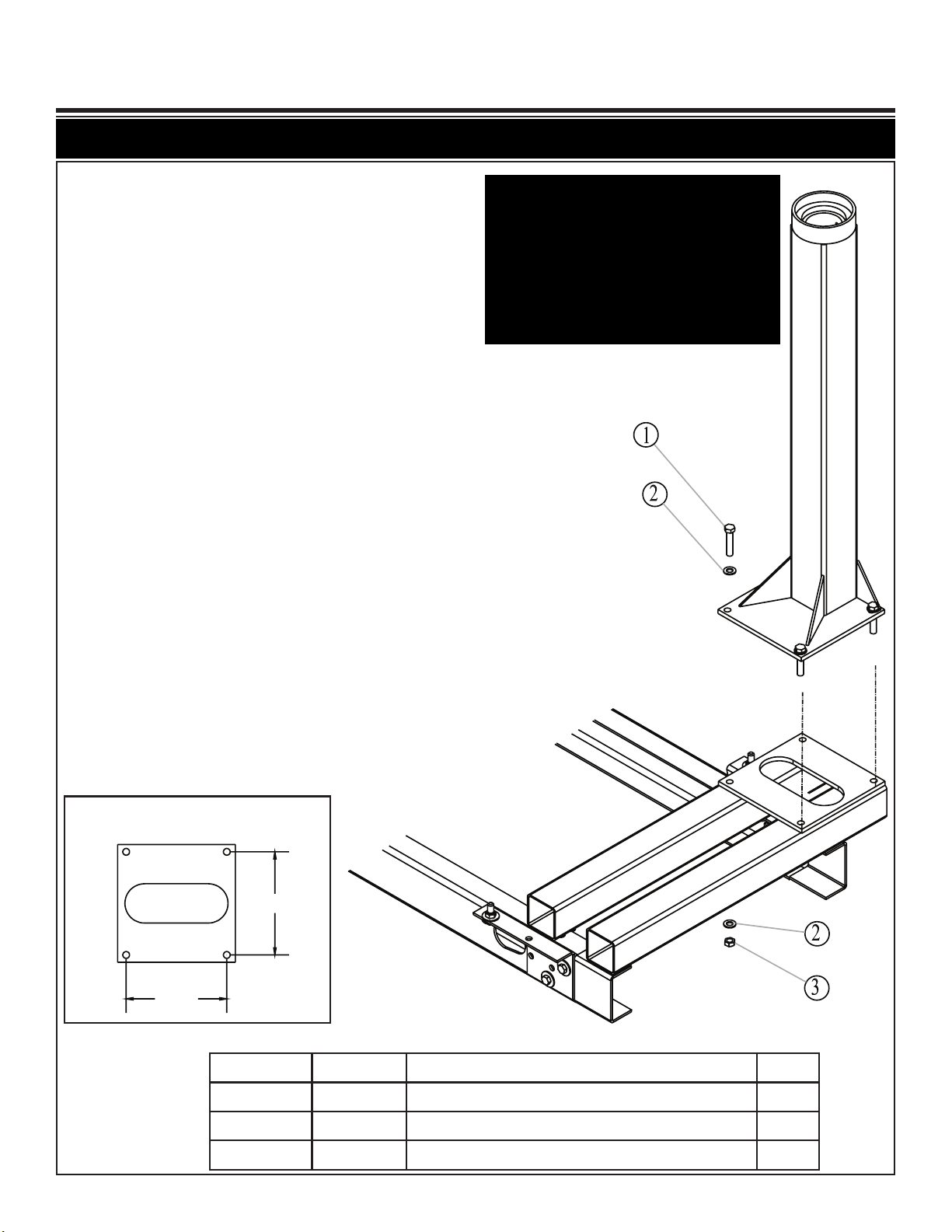

Chapter 2 - Installation

Mounting Hole Diagram

Item No. Part No. Description Qty.

1 D1034 CAP SCR 0.63-11 X 3.00 HHGR8 ZY 4

2 C5902 WASHER 0.63 FLAT GR8 8

3 2826 NUT 0.63-11 HH NYLOC 4

10.25

10.25

Notice: Read this Page Before Installation of the Crane

Installation

Installation Instructions:

Prepare Platform For Crane Installation (Not

Supplied)

1. When designing the platform, maintain a

proper clearance for the crane mounting and operation.

2. The platform must be strong enough to

support the crane and rated load.

3. Platform/crane support minimum requirements: Top plate should be made from

0.50” grade 50 plate. The structure

should be supported by 4 x 4 x 3/16 tubing.

Mounting Instructions:

1. Lower the crane onto the mounting platform.

2. Mount the crane using 5/8” grade 8

bolts, flat washers, and nyloc nuts.

3. Connect power (+12V) and ground wires

per winch manufacturer’s specifications.

Power Rotation: Route 4 ga. wires (not

included) from junction box to power

(+12V) and ground. Recommended:

Use solenoid and a toggle switch to

power the crane.

4. Operate the crane for several cycles.

Important: When installing welder units to

the service bodies, it is highly

recommended that a surge protector is

installed on the chassis batteries to protect

the crane radio receiver, wiring and other

electronic devices from an unexpected

electrical spike or surge. Failure to do so

could result in extensive damage to the

service body and crane electrical circuit.

Page 8

EC2000 Owner’s Manual

E-Brake

Ground

Groun d Stud

Ec2k M as t

WinchMotor-

Winch M o tor+

Batte ry-

Battery+

Ignition

Switch

Ignition

E-Brake

Ground

Battery -

Battery +

Ground Stud

EC2K Mast

Winch Motor -

Winch Motor +

Solid State Solonoid PN 39687

Relay PN C6072

On/Off

Switch

(PN C4815)

E-Brake

Ground

Ground Stud

Ec2k Ma s t

Battery-

Batter y

Igni tion

Swi t ch

Control Box

Ignition

On/Off

Switch

(PN C4815)

E-Brake

Ground

Ground Stud

EC2K Mast

Battery +

Battery -

Solid State Solonoid PN 39687

Relay PN C6072

Wiring Schematic - Power Rotation

Wiring Schematic - Manual Rotation

Page 9

3,4,5

RO T ATION

MOTOR

BL ACK

RED

CUT W INCH CABLETO

6.5',W I TH 6"OF W IRE

INSIDEOFBOX

2

GROUND

PO W ER

RO TATION

CW

RELAY

FRONT

VIEW

PO W ER

RO TATION

AUX

BREAKER

PO W ER

12V

BAT

GD

RT

LT

SA

TM

B

L

K

G

RN

RO TATION

CCW

RELA Y

WINCH

DOWN

UP

Rotation

ITEM PART NO. DESCRIPTION QTY

01 28834 WIRE HARNESS 1

02 22932 HANDLE ASM 2 FCTN EC2K POWER 1

03 9751 CONNECT 2 PIN SHROUD PACKARD 1

04 11359 CABLE SEAL 14-16 PACKARD 39001 2

05 13564 CONTACT M TERM SHROUD 12 32038 2

Rotation

Motor

Black

Red

3,4,5

Ground

Power

Breaker

Power

12V

Power

Rotation

Black

Green

Front

View

Bat

Aux

GD

TM LT

SA RT

Cut winch cable to

6.5’ with 6” of wire

inside of box.

Rotation

CCW

Relay

Rotation

CW

Relay

PN 22930

Control Kit Power Rotation - PN 22930

Installation

Page 10

EC2000 Owner’s Manual

Stability Procedure

Definition of Stability for the Stellar Telescopic Crane Products:

A truck is stable until the load cannot be lifted off the ground with the winch, without

tipping over the truck. Every Stellar crane installed must be tested for stability to

determine the actual load capacity of the final truck package. The actual test data

must be recorded and supplied with the truck at the time of in-service and should be kept

with the truck at all times. The following procedure will test the truck package for stability

and will provide a stability capacity chart. The load limit information shown on the

stability capacity chart is formulated on 85% tipping.

Set Up:

1. Locate the truck on a test course in position for loading and engage travel brakes.

2. Set stabilizers so that they make contact with firm, level footings.

3. Operate the crane under partial load to assure operator proficiency and proper

machine function.

EC2000 Stability Data

Max Horizontal Reach: 180” (From the center of rotation to boom tip)

Stability Test Weight: 875 lbs.

Test Procedure

1. Rotate the crane into Zone 1 position.

2. With the crane fully retracted and the boom horizontal, winch the test weight off the

ground. Note: Keep weight within six inches of the ground at all times.

3. Extend the boom outward until full extension has been reached or until the truck

becomes unstable (Again, use the winch to keep the weight within six inches of the

ground.)

4. If the boom goes full extension without becoming unstable, the crane is termed stable

for this zone and 100% can be written in the Zone 1 data box.

5. If the truck becomes unstable prior to going full extension, retract the boom until the

truck becomes stable and measure the horizontal reach in this position (center of

rotation to boom tip). This is the stable horizontal reach for this zone. Stable horizontal

reach divided by Maximum horizontal reach multiplied by 100 equals the percentage

of rated capacity for this zone. Use the following formula to determine the percentage

of rated capacity:

6. Record this number in the data box for Zone 1. This is the revised capacity due to

stability for this zone.

7. Repeat this procedure for each zone until the worksheet is completed.

8. This is the revised capacity based on stability of this package.

Page 11

STABILITY CAPACITY CHART

Stability Capacity Chart

Installation

Page 12

EC2000 Owner’s Manual

Item Part No. Description QTY

01 18040 DECAL IDENTIFICATION EC2K 2

02 18039 DECAL CAPACITY EC2K 2

03 4214 DECAL CONTACT STELLAR 1

04 6727 DECAL DANGER ELECTROCUTION VERT 1

05 C4540 DECAL DANGER 1

06 4190 DECAL DANGER OPERATION CONDITION 1

07 4189 DECAL DANGER OPERATION RESTRICTION 1

08 C4544 DECAL CAUTION 1

ECEC20002000

1804018040

ECEC20002000

1

80

40

1

8

0

4

0

PN 18776

DANGER

• Main safe clearances from electrical lines. This crane

does not provide protection from contact with or proximity to

an electrically charged conductor. Allow for boom, electrical

line and load line swaying.

• Maintain a clearance of at least 10 feet between any part of

the crane, load line or load and any electrical line carrying

up to 50,000 volts.

• One foot additional clearance is required for every additional

30,000 volts or less.

ELECTROCUTION HAZARD

THIS CRANE IS NOT INSULATED

DEATH OR SERIOUS INJURY

WILL RESULT FROM CONTACT

OR INADEQUATE CLEARANCE

6727

DANGER

FAILURE TO OBEY THE FOLLOWING

WILL RESULT IN

INSTABILITY OR

STRUCTURAL DAMAGE

• Read, understand and follow the equipment

load and work area charts.

• Do not exceed winch or equipment ratings.

• Do not exceed jib load ratings at reduced

boom lengths.

• Weights of accessories attached to the

boom or loadline must be deducted from

the load chart ratings or be added to the

load weight.

4189

DEATH OR SERIOUS INJURY

DANGER

AN UNTRAINED OPERATOR

SUBJECTS HIMSELF AND

OTHERS TO

YOU MUST NOT OPERATE

THIS EQUIPMENT UNLESS

• You have been trained in the safe

operation of this equipment.

• You read, understand and follow the

safety and operating recommendations

contained in the equipment manufacturer’s

manuals, your employer’s work rules and

applicable government regulations.

C4540

DEATH OR SERIOUS INJURY

DANGER

FAILURE TO OBEY THE FOLLOWING

WILL RESULT IN

• Inspect equipment and its operation daily.

• For equipment stability, use only on solid,

level surface with outriggers properly

extended.

• Equipment must be level.

• Operate all controls slowly and smoothly.

• Never operate the equipment with

personnel under boom or load.

• Keep load underboom tip. Do not side

load boom or drag loads. Avoid free

swinging loads.

• Keep at least 3 wraps of loadline on

winch drum.

• For travel, boom and outriggers must be

in stowed position.

C4544

DEATH OR SERIOUS INJURY

DANGER

FAILURE TO OBEY THE FOLLOWING

WILL RESULT IN

• Follow all recommended inspections and

maintenance practices listed in the equipment

manufacturer’s manuals. If manuals are

missing from this equipment, contact

manufacturer for replacement.

• Do not modify or alter this equipment without

written manufacturers approval. Use only

manufacturer approved attachments or parts

on this equiupment.

• Equipment must be mounted on factory

recommended chassis. If re-mounted or

rebuilt, the equipment must be re-certified.

4190

DEATH OR SERIOUS INJURY

Decal Kit - PN 18776

Decals of Note

Page 13

#40365 ON BACK SIDE

1

26

27

5

7

6

8

12

9

10

2

18

17

25

24

23

2221

11

16

15

28

15

13

14

19

16

20

3

4

30

31

22

32

33

43

34

15

35

Ship Loose

36

37

38

29

39

41

Mounting Hardware

42

40

USE COMPOUND

11

.YTQNOITPIRCSEDTRAPMETI

1K2CE ESAB396931

1K2CE TSAMCP006712

1K2CE MOOB NIAM196933

1K2CE MOOB TXE096934

5 18069 BEARING RADIAL BALL 6" BRB6217-2RS 1

16104-RIROT "05.2 RENNI ECAR860816

7 18067 BEARING DRAWN CUP NEEDLE 2.75" TORB-44161

8 18475PCBR 1K2CE TNEMDLEW EKA

1K2CE TNEMDLEW ELDNAHCP384819

1K2CE PIRG ELDNAH5848101

11 17222 SHEAVE EC2K 5.00 DIA .19R/.75 THK2

183.2X04HCS 57.0 EPIPCP1178121

2KCOLB HCTANS K2CE ETALPCP5697131

14 18036PC1K2CE KCOLB HCTANS RECAPS

6COLYN HH 11-36.0 TUN628251

25RGHH 00.2X11-36.0 RCS PAC993061

1COLYN 8RGHH 01-57.0 TUN8350C71

18 18712 CAP SCR 0.75-10X7.50 HHGR8 ZY1

1GNIHCTAL TNEMDLEW NIPCP4178191

1K2CE TXE POTSCP5178102

2TALF 52.0 REHSAW043012

25RGHH 57.0X02-52.0 RCS PAC974022

.YTQNOITPIRCSEDTRAPMETI

120030 0001 HCNIW4778132

28RG TALF 83.0 REHSAW3536C42

28RGHH 52.1X61-83.0 RCS PAC6753152

1TALF 83.0 REHSAW643062

15RGHH 00.1X61-83.0 RCS PAC153072

1TF04 CAG 91X7 61/3 EPOR ERIW3778182

1HCNYL 65.1X91.0 NIP357592

30 18778 PIN HITCH 0.75X6.25 W\ LANYARD1

31 18777 PIN HITCH 0.63X4.00 W\ LANYARD1

1KCOL 52.0 REHSAW125023

1NOT 3-ENARC KOOH8106C33

34 D1034 CAP SCR 0.63-11 X 3.00 HHGR8 ZY4

35 C5902 WASHER 0.63 SAE FLAT YELLOW GR8 8

15RGHH 57.1X81-13.0 RCS PAC784063

37 19374PC1K2CE PIT MOOB RECAPS

1COLYN HH 81-13.0 TUN243083

39 39687 SOLENOID SOLID STATE SSC 10-1001

40 37751 BOOT TERML SOLENOID SOLID TB-22-22

4CNIZ TALF EAS #8 REHSAW529014

48-32X0.63 BTNHD SS# WERCS6279224

43 C0078HOSE CLAMP #8 RUBBER COATED2

PN 17631

Chapter 3 - Assembly Drawings

Standard Crane Assembly - PN 17631

Assembly Drawings

Page 14

EC2000 Owner’s Manual

11

1

26

27

5

7

6

8

12

9

10

2

18

17

25

24

23

22

21

11

16

15

28

15

13

14

19

16

20

3

4

30

31

22

33

21

34

32

35

15

36

Ship Loose

37

38

39

29

40

42

43

41

Mounting Hardware

#40365 ON BACK SIDE

USE COMPOUND

13

.YTQNOITPIRCSEDTRAPMETI .YTQNOITPIRCSEDTRAPMETI

1K2CE ESAB396931

1K2CE TSAMCP006712

1K2CE MOOB NIAM196933

1K2CE MOOB TXE096934

5 18069 BEARING RADIAL BALL 6" BRB6217-2RS 1

16104-RIROT "05.2 RENNI ECAR860816

7 18067 BEARING DRAWN CUP NEEDLE 2.75" TORB-44161

8 18475PCBR 1K2CE TNEMDLEW EKA

1K2CE TNEMDLEW ELDNAHCP384819

1K2CE PIRG ELDNAH5848101

11 17222 SHEAVE EC2K 5.00 DIA .19R/.75 THK2

183.2X04HCS 57.0 EPIPCP1178121

2KCOLB HCTANS K2CE ETALPCP5697131

14 18036PC1K2CE KCOLB HCTANS RECAPS

6COLYN HH 11-36.0 TUN628251

25RGHH 00.2X11-36.0 RCS PAC993061

1COLYN 8RGHH 01-57.0 TUN8350C71

18 18712 CAP SCR 0.75-10X7.50 HHGR8 ZY1

1GNIHCTAL TNEMDLEW NIPCP4178191

1K2CE TXE POTSCP5178102

2TALF 52.0 REHSAW043012

25RGHH 57.0X02-52.0 RCS PAC974022

120030 0001 HCNIW4778132

28RG TALF 83.0 REHSAW3536C42

28RGHH 52.1X61-83.0 RCS PAC6753152

1TALF 83.0 REHSAW643062

15RGHH 00.1X61-83.0 RCS PAC153072

28 33940 WIRE ROPE 3/16 7X19 IWRC-XIP 50 FT1

1HCNYL 65.1X91.0 NIP357592

30 18778 PIN HITCH 0.75X6.25 W\ LANYARD1

31 18777 PIN HITCH 0.63X4.00 W\ LANYARD1

32 C5946HOSE CLAMP #8 RUBBER COATED2

1KCOL 52.0 REHSAW125033

1NOT 3-ENARC KOOH8106C43

35 D1034 CAP SCR 0.63-11 X 3.00 HHGR8 ZY4

36 C5902 WASHER 0.63 SAE FLAT YELLOW GR8 8

15RGHH 57.1X81-13.0 RCS PAC784073

38 19374PC1K2CE PIT MOOB RECAPS

1COLYN HH 81-13.0 TUN243093

40 39687 SOLENOID SOLID STATE SSC 10-1001

41 37751 BOOT TERML SOLENOID SOLID TB-22-22

4CNIZ TALF EAS 8# REHSAW529024

4#8-32X0.63 BTNHD SS WERCS6279234

PN 33939

50’ Wire Rope Crane Assembly - PN 33939

Page 15

MOUNTING HARDWARE

38

1

26

27

5

7

6

8

12

9

10

2

18

17

25

24

23

22

21

11

16

15

28

15

29

13

14

19

16

20

3

4

30

31

33

34

42

32

35

41

15

36

SHIP LOOSE

21

39

22

37

40

43

USE COMPOUND

#40365 ON BACK SIDE

.YTQNOITPIRCSEDTRAPMETI .YTQNOITPIRCSEDTRAPMETI

1TROHS K2CE ESAB307931

1K2CE TSAMCP006712

1K2CE MOOB NIAM196933

1K2CE MOOB TXE096934

5 18069 BEARING RADIAL BALL 6" BRB6217-2RS 1

16104-RIROT "05.2 RENNI ECAR860816

7 18067 BEARING DRAWN CUP NEEDLE 2.75" TORB-44161

8 18475PCBR 1K2CE TNEMDLEW EKA

1K2CE TNEMDLEW ELDNAHCP384819

1K2CE PIRG ELDNAH5848101

11 17222 SHEAVE EC2K 5.00 DIA .19R/.75 THK2

183.2X04HCS 57.0 EPIPCP1178121

2KCOLB HCTANS K2CE ETALPCP5697131

14 18036PC1K2CE KCOLB HCTANS RECAPS

6COLYN HH 11-36.0 TUN628251

25RGHH 00.2X11-36.0 RCS PAC993061

1COLYN HH 01-57.0 TUN828271

18 18712 CAP SCR 0.75-10X7.50 HHGR8 ZY1

1GNIHCTAL TNEMDLEW NIPCP4178191

1K2CE TXE POTSCP5178102

2TALF 52.0 REHSAW043012

25RGHH 57.0X02-52.0 RCS PAC974022

120030 0001 HCNIW4778132

28RG TALF 83.0 REHSAW3536C42

28RGHH 52.1X61-83.0 RCS PAC6753152

1TALF 83.0 REHSAW643062

15RGHH 00.1X61-83.0 RCS PAC153072

1TF04 CAG 91X7 61/3 EPOR ERIW3778182

1HCNYL 65.1X91.0 NIP357592

30 18778 PIN HITCH 0.75X6.25 W\ LANYARD1

31 18777 PIN HITCH 0.63X4.00 W\ LANYARD1

15RGHH 57.1X81-13.0 RCS PAC784023

1COLYN HH 81-13.0 TUN243033

34 19374PC1K2CE PIT MOOB RECAPS

35 D1034 CAP SCR 0.63-11 X 3.00 HHGR8 ZY4

36 C5902 WASHER 0.63 SAE FLAT YELLOW GR8 8

1NOT 3-ENARC KOOH8106C73

38 C5946HOSE CLAMP #8 RUBBER COATED2

1KCOL 52.0 REHSAW125093

40 39687 SOLENOID SOLID STATE SSC 10-1001

41 37751 BOOT TERML SOLENOID SOLID TB-22-22

4#8-32X0.63 BTNHD SS WERCS

5290

24

4CNIZ TALF EAS 8# REHSAW

62792

34

PN 19146

Short Mast Crane Assembly - PN 19146

Assembly Drawings

Page 16

EC2000 Owner’s Manual

?

38

#40365 ON BACK SIDE

1

31

17

32

14

33

34

17

18

2

11

10

18

17

16

15

14

5

9

8

19

8

20

6

7

12

9

13

3

4

21

22

15

24

14

25

26

27

Ship Loose

28

29

30

35

36

14

33

37

8

40

39

Mounting Hardware

USE COMPOUND

23

.YTQNOITPIRCSEDTRAPMETI .YTQNOITPIRCSEDTRAPMETI

1REWOP K2CE ESAB886931

222608PCMAST EC2K POWER ROTATION1

1K2CE MOOB NIAM196933

1K2CE MOOB TXE096934

5 17222 SHEAVE EC2K 5.00 DIA .19R/.75 THK 2

6 17965PC PLATE EC2K SNATCH BLOCK 2

7 18036PC SPACER SNATCH BLOCK EC2K 1

8 2826 NUT 0.63-11 HH NYLOC 6

9 0399 CAP SCR 0.63-11X2.00 HHGR5 2

10 C0538 NUT 0.75-10 HHGR8 NYLOC 1

11 18712 CAP SCR 0.75-10X7.50 HHGR8 ZY1

12 18714PC PIN WELDMENT LATCHING 1

1K2CE TXE POTSCP5178131

9TALF 52.0 REHSAW043041

15 0479 CAP SCR 0.25-20X0.75 HHGR52

120030 0001 HCNIW4778161

17 C6353 WASHER 0.38 FLAT GR8 20

18 13576 CAP SCR 0.38-16X1.25 HHGR8 10

19 18773 WIRE ROPE 3/16 7X19 GAC 40FT1

1

4

4

HCNYL 65.1X91.0 NIP357502

21 18778 PIN HITCH 0.75X6.25 W\ LANYARD1

22 18777 PIN HITCH 0.63X4.00 W\ LANYARD1

1LYNIV KLB 05.0 PMALC1800C32

1KCOL 52.0 REHSAW125042

1NOT 3-ENARC KOOH8106C52

26 D1034 CAP SCR 0.63-11 X 3.00 HHGR8 ZY4

27 C5902 WASHER 0.63 SAE FLAT YELLOW GR8 8

28 0487 CAP SCR 0.31-18X1.75 HHGR51

29 19374PC SPACER BOOM TIP EC2K1

30 0342NUT 0.31-18 HH NYLOC1

31 22924 CAP SCR 0.38-16X2.25 HHGR8 10

1K2CE BTT DRAUGCP6162223

33 0478 CAP SCR 0.25-20X0.50 HHGR57

34 22612 BEARING HOUSING SD14511S1

35 22613 BEARING GEAR SY7B0101N-10-B1

36 22930PCCONTROL KIT EC2K POWER 1

37 39687 SOLENOID SOLID STATE SSC 10-1001

38 37751 BOOT TERML SOLENOID SOLID TB-22-22

39 62792 SCREW #8-32X0.63 BTNHD SS

40 5290 WASHER #8 SAE FLAT ZINC

PN 22601

Power Rotation Crane Assembly - PN 22601

Page 17

20

1

31

17

32

14

33

22

17

18

2

11

23

18

17

16

15

14

5

9

8

19

8

14

6

7

12

9

13

3

4

21

15

10

24

8

27

25

26

34

Ship Loose

28

29

30

35

36

14

33

37

39

40

38

Mounting Hardware

#40365 ON BACK SIDE

USE COMPOUND

5

.YTQNOITPIRCSEDTRAPMETI .YTQNOITPIRCSEDTRAPMETI

139696PCBASE EC2K POWER SHORT1

2 22608PC MAST EC2K POWER ROTATION1

1K2CE MOOB NIAMCP196933

1K2CE MOOB TXECP096934

5 17222 SHEAVE EC2K 5.00 DIA .19R/.75 THK2

6 17965PC PLATE EC2K SNATCH BLOCK2

7 18036PC SPACER SNATCH BLOCK EC2K1

8 2826 NUT 0.63-11 HH NYLOC 6

9 0399 CAP SCR 0.63-11X2.00 HHGR52

10 C0538 NUT 0.75-10 HHGR8 NYLOC 1

11 18712 CAP SCR 0.75-10X7.50 HHGR8 ZY1

12 18714PC PIN WELDMENT LATCHING1

1K2CE TXE POTSCP5178131

9TALF 52.0 REHSAW043041

15 0479 CAP SCR 0.25-20X0.75 HHGR52

120030 0001 HCNIW4778161

17 C6353WASHER 0.38 FLAT GR820

18 13576 CAP SCR 0.38-16X1.25 HHGR810

19 18773 WIRE ROPE 3/16 7X19 GAC 40FT1

1HCNYL 65.1X91.0 NIP357502

PN 24906

21 18778 PIN HITCH 0.75X6.25 W\ LANYARD1

22 18777 PIN HITCH 0.63X4.00 W\ LANYARD1

23 C0081 CLAMP 0.50 BLK VINYL1

1KCOL 52.0 REHSAW125042

1NOT 3-ENARC KOOH8106C52

26 D1034 CAP SCR 0.63-11 X 3.00 HHGR8 ZY4

27 C5902 WASHER 0.63 SAE FLAT YELLOW GR88

28 0487 CAP SCR 0.31-18X1.75 HHGR51

29 19374PC SPACER BOOM TIP EC2K1

30 0342 NUT 0.31-18 HH NYLOC 1

31 22924 CAP SCR 0.38-16X2.25 HHGR810

1K2CE BTT DRAUGCP6162223

33 0478 CAP SCR 0.25-20X0.50 HHGR57

34 22612 BEARING HOUSING SD14511S1

35 22613 BEARING GEAR SY7B0101N-10-B1

36 22930CONTROL KIT EC2K POWER 1

37 39687SOLENOID SOLID STATE SSC 10-1001

38 37751BOOT TERML SOLENOID SOLID TB-22-22

39 62792 SCREW #8-32X0.63 BTNHD SS

40 5290 WASHER #8 SAE FLAT ZINC

4

4

Power Rotation Short Mast Crane Assembly - PN 24906

Assembly Drawings

Page 18

EC2000 Owner’s Manual

.YTQNOITPIRCSEDTRAPMETI

1 56659PC BASE EC2K POWER LH MNT1

2 22608PC MAST EC2K POWER ROTATION1

1K2CE MOOB NIAMCP196933

1K2CE MOOB TXECP096934

5 17222 SHEAVE EC2K 5.00 DIA .19R/.75 THK2

6 17965PC PLATE EC2K SNATCH BLOCK2

7 18036PC SPACER SNATCH BLOCK EC2K1

8 2826 NUT 0.63-11 HH NYLOC 6

9 0399 CAP SCR 0.63-11X2.00 HHGR52

10 C0538 NUT 0.75-10 HHGR8 NYLOC 1

11 18712 CAP SCR 0.75-10X7.50 HHGR8 ZY1

12 18714PC PIN WELDMENT LATCHING1

1K2CE TXE POTSCP5178131

9TALF 52.0 REHSAW043041

15 0479 CAP SCR 0.25-20X0.75 HHGR52

120030 0001 HCNIW4778161

17 C6353WASHER 0.38 FLAT GR820

18 13576 CAP SCR 0.38-16X1.25 HHGR810

19 18773 WIRE ROPE 3/16 7X19 GAC 40FT1

20 5753 PIN 0.19X1.56 LYNCH1

.YTQNOITPIRCSEDTRAPMETI

38

2

1

31

17

32

14

33

34

17

18

22

11

#40365 ON BACK SIDE

18

17

16

15

14

5

9

8

19

8

20

6

7

12

9

13

3

4

21

15

10

24

14

25

26

27

Ship Loose

28

29

30

35

36

14

33

37

8

40

39

Mounting Hardware

USE COMPOUND

23

PN 56658

21 18778 PIN HITCH 0.75X6.25 W\ LANYARD1

22 18777 PIN HITCH 0.63X4.00 W\ LANYARD1

23 C0081 CLAMP 0.50 BLK VINYL1

1KCOL 52.0 REHSAW125042

25 C6018 HOOK CRANE-3 TON 1

26 D1034 CAP SCR 0.63-11 X 3.00 HHGR8 ZY4

27 C5902 WASHER 0.63 SAE FLAT YELLOW GR88

28 0487 CAP SCR 0.31-18X1.75 HHGR51

29 19374PC SPACER BOOM TIP EC2K1

30 0342 NUT 0.31-18 HH NYLOC 1

31 22924 CAP SCR 0.38-16X2.25 HHGR810

1K2CE BTT DRAUGCP6162223

33 0478 CAP SCR 0.25-20X0.50 HHGR57

34 22612 BEARING HOUSING SD14511S1

35 22613 BEARING GEAR SY7B0101N-10-B1

36 22930CONTROL KIT EC2K POWER 1

37 39687SOLENOID SOLID STATE SSC 10-1001

38 37751 BOOT TERML SOLENOID SOLID TB-22-22

39 62792 SCREW #8-32X0.63 BTNHD SS 4

40 5290 WASHER #10 SAE FLAT ZINC4

LH Mount Crane Assembly - PN 56658

Page 19

.YTQNOITPIRCSEDTRAPMETI.YTQNOITPIRCSEDTRAPMETI

122925ENCLOSURE 6.00X4.00 MACHINED 1 9 D0561 CAP SCR 0.25-20X0.50 BTNHD SS 2

222927PLATE ELECTRICAL MTG EC2K1100333NUT 0.25-20 HHGR5 NYLOC 2

4CNIZ TALF EAS 01# REHSAW8710D112PMA 03-02 HCSOB YALER2706C3

414994CONNECTOR SOCKET TRAILER 6 PIN 1126684CAP SCR #10-32X0.50 SH 4

522931CIRCUIT BREAKER 12V 20 AMP AUTO RES 1 13 12870 STRAIN RELIEF .38 NPT .08-.24 CABLE 1

623892JUNCTION BLOCK 5/16" 2 POST 1 14 23893 GROMENT RUBBER 1.75 1

7D0896CAP SCR #10-24X0.75 FHSH SS 2 15 23908 BOOT CIRCUIT BREAKER RED 23540 1

2SS COLYN HH 42-01# TUN6594C8

Control Kit Assembly

Assembly Drawings

Page 20

EC2000 Owner’s Manual

Page 21

Chapter 4 - Replacement Parts

ASSEMBLY COMPONENTS

22612 BEARING HOUSING - ROTATION (POWER ROTATION MODELS)

22613 GEAR BEARING - ROTATION (POWER ROTATION MODELS)

18069 BEARING - RADIAL BALL 6.00”

18068 RACE - INNER 2.50”

18067 BEARING DRAWN CUP NEEDLE 2.75”

17222 SHEAVE 5.00” DIA.

18773 WIRE ROPE 40 FT (STANDARD MODELS)

33940 WIRE ROPE 50 FT

18483PC HANDLE WELDMENT EC2K

18485 HANDLE GRIP EC2K

18715PC STOP - EXTENSION WELDMENT

18777 HITCH PIN 0.63”X 4.00” W / LANYARD

18778 HITCH PIN 0.75”X 6.25” W / LANYARD

18714PC PIN WELDMENT - LATCHING

5753 PIN - LYNCH 0.19”X1.56”

C6018 HOOK 3-TON

10709 SAFETY LATCH FOR 3 TON HOOK

ELECTRICAL COMPONENTS

22932 HANDLE ASM 2 FUNCTION EC2K (POWER ROTATION MODELS)

22620 HANDLE ASM - WINCH FUNCTION ONLY (MANUAL ROTATION)

18774 WINCH

39836 COVER - PLASTIC (WINCH)

39687 SOLENOID - SOLID STATE SSC 10-100

37751 BOOT - SOLID STATE SOLENOID TERMINALS

28834 WIRE HARNESS (POWER ROTATION MODELS)

C6072 BOSCH RELAY (POWER ROTATION MODELS)

22931 CIRCUIT BREAKER (POWER ROTATION MODELS)

23908 BOOT - CIRCUIT BREAKER RED (POWER ROTATION MODELS)

14994 CONNECTOR SOCKET - TRAILER 6 PIN (POWER ROTATION MODELS)

23892 JUNCTION BLOCK 5/16” 2 POST (POWER ROTATION MODELS)

Replacement Parts

Page 22

Limited Warranty Statement

Stellar Industries, Inc. (Stellar) warrants products designed and manufactured by Stellar to be free from defects in material and workmanship under

proper use and maintenance. Products must be installed and operated in accordance with Stellar’s written instructions and capacities. This warranty

shall cover the following:

Stellar Cranes, Stellar Hooklift Hoists, Stellar Cable Hoists, Stellar Container Carriers, Stellar Service Trucks, and Stellar X-Tra-Lift Systems:

Twelve (12) month warranty on parts from the date recorded by Stellar as the in-service date, not to extend beyond twenty-four (24) months from date

ofmanufacture,

Twelve (12) month repair labor from the date recorded by Stellar as the in-service date, not to extend beyond twenty-four (24) month from date of

manufacture, and

Thirty-six (36) month warranty on all Stellar Manufactured structural parts from the date recorded by Stellar as the in-service date, not to extend beyond

forty-eight (48) months from date of manufacture.

Stellar Tarper Systems:

Twelve (12) month warranty on parts from the date recorded by Stellar as the in-service date, not to extend beyond twenty-four (24) months from date

of manufacture and

Three (3) month repair labor from the date recorded by Stellar as the in-service date, not to extend beyond fifteen (15) month from date of

manufacture.

The in-service date will be derived from the completed warranty registration card. In the event a warranty registration card is not received by Stellar, the

factory ship date will be used.

Stellar’s obligation under this warranty is limited to, and the sole remedy for any such defect shall be, the repair and/or replacement (at Stellar’s option)

of the unaltered part and/or component in question. Stellar after-sales service personnel must be notified by telephone, fax, or letter of any warrantyapplicable damage within fourteen (14) days of its occurrence. If at all possible, Stellar will ship the replacement part within 24-hours of notification by

the most economical, yet expedient, means possible. Expedited freight delivery will be at the expense of the owner.

Warranty claims must be submitted and shall be processed in accordance with Stellar’s established warranty claim procedure. Stellar after-sales service

personnel must be contacted prior to any warranty claim. A return materials authorization (RMA) account number must be issued to the claiming party

prior to the return of any warranty parts. Parts returned without prior authorization will not be recognized for warranty consideration. All damaged parts

must be returned to Stellar freight prepaid; freight collect returns will be refused. Freight reimbursement of returned parts will be considered as part of

the warranty claim.

Warranty service will be performed by any Stellar new equipment distributor, or by any Stellar-recognized service center authorized to service the type

of product involved, or by the Stellar factory in the event of a direct sale. At the time of requesting warranty service, the owner must present evidence

of date of delivery of the product. The owner shall be obligated to pay for any overtime labor requested of the servicing company by the owner, any

field service call charges, and any towing and/or transportation charges associated with moving the equipment to the designated repair/service

provider.

All obligations of Stellar and its authorized dealers and service providers shall be voided if someone other than an authorized Stellar dealer provides

other than routine maintenance service without prior written approval from Stellar. In the case repair work is performed on a Stellar-manufactured

product, original Stellar parts must be used to keep the warranty in force. The warranty may also be voided if the product is modified or altered in any

way not approved, in writing, by Stellar.

The owner/operator is responsible for furnishing proof of the date of original purchase of the Stellar product in question. Warranty registration is the

ultimate responsibility of the owner and may be accomplished by the completion and return of the Stellar product registration card provided with the

product. If the owner is not sure of registration, he is encouraged to contact Stellar at the address below to confirm registration of the product in

question. This warranty covers only defective material and workmanship. It does not cover depreciation or damage caused by normal wear and tear,

accident, mishap, untrained operators, or improper or unintended use. The owner has the obligation of performing routine care and maintenance

duties as stated in Stellar’s written instructions, recommendations, and specifications. Any damage resulting from owner/operator failure to perform such

duties shall void the coverage of this warranty. The owner will pay the cost of labor and supplies associated with routine maintenance.

The only remedies the owner has in connection with the breach or performance of any warranty on the Stellar product specified are those set above.

In no event will Stellar, the Stellar distributor/dealer, or any company affiliated with Stellar be liable for business interruptions, costs of delay, or for any

special, indirect, incidental, or consequential costs or damages. Such costs may include, but are not limited to, loss of time, loss of revenue, loss of use,

wages, salaries, commissions, lodging, meals, towing, hydraulic fluid, or any other incidental cost.

All products purchased by Stellar from outside vendors shall be covered by the warranty offered by that respective manufacturer only. Stellar does not

participate in, or obligate itself to, any such warranty.

Stellar reserves the right to make changes in design or improvement upon its products without imposing upon itself the same upon its products

theretofore manufactured.

This warranty will apply to all Stellar Cranes, Stellar Hooklift Hoists, Stellar Cable Hoists, Stellar Container Carriers, Stellar Service Trucks, Stellar X-Tra-Lift

Systems, and Stellar Tarper Systems shipped from Stellar’s factory after January 1st, 2010. The warranty is for the use of the original owner only and is not

transferable without prior written permission from Stellar.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE. REMEDIES UNDER THIS WARRANTY ARE LIMITED TO THE PROVISION OF MATERIAL AND SERVICES, AS SPECIFIED HEREIN. STELLAR

INDUSTRIES, INC. IS NOT RESPONSIBLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Revision Date: February 2010

Document Number: 37040

EC2000 Owner’s Manual

Loading...

Loading...