Page 1

®

TM

)

!$%%"!($$ '#&!$(#%$

Subject to Change without Notification.

© 2012 Stellar Industries, Inc.

Stellar Industries, Inc.

190 State Street

PO Box 169

Garner, IA 50438

800-321-3741

Fax: 641-923-2811

www.stellarindustries.com

Last Revision: 09/17/12

Page 2

7628 Manual Revisions

Date of Revision

September 15th, 2011

Section Revised

Chapter 2: Installation

Chapter 3: Assembly

Drawings

Description of Revision

New Flip Sheave Design Implemented. Updated Extention

Boom Assembly Drawings.

Page 3

Table of Contents

Chapter 1 - Specifications ......................................................................1

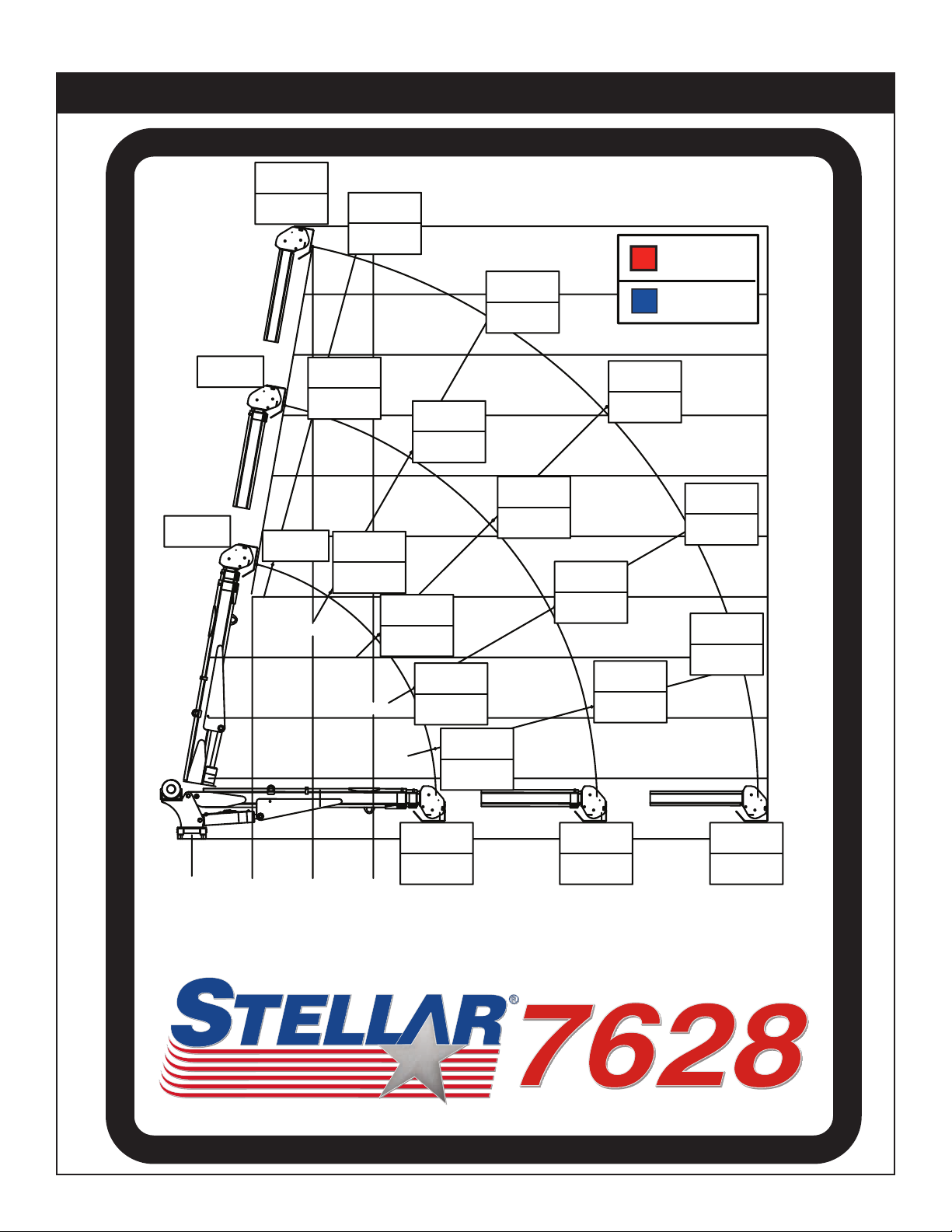

Capacity Chart - Decal PN 55114 .....................................................2

Chapter 2 - Installation ...........................................................................3

Installation Overview ...........................................................................4

Control Kit - PN 54968 ..........................................................................5

Control Kit (Non-Boost) - PN 56490.....................................................6

Hydraulic Kit - PN 52264.......................................................................7

Valve Bank - PN 52265.........................................................................8

Hydraulic Installation ...........................................................................9

Winch Case Drain Installation ..........................................................10

Hydraulic System ................................................................................11

Stability Procedure.............................................................................12

Decal Placement - 54970 .................................................................13

Table of Contents

Chapter 3 - Assembly Drawings ..........................................................15

Base Assembly - PN 50364.................................................................15

Mast Assembly - PN 62795 ................................................................16

Main Boom - PN 54960 ......................................................................17

Extension Boom Assembly - PN 61831 .............................................18

Extension Boom Assembly - PN 61831 (Expanded)........................19

Main Cylinder Assembly - PN 54961.................................................20

Extension Cylinder Assembly - PN 50929 .........................................21

Snatch Block Assembly - PN 56266 ..................................................22

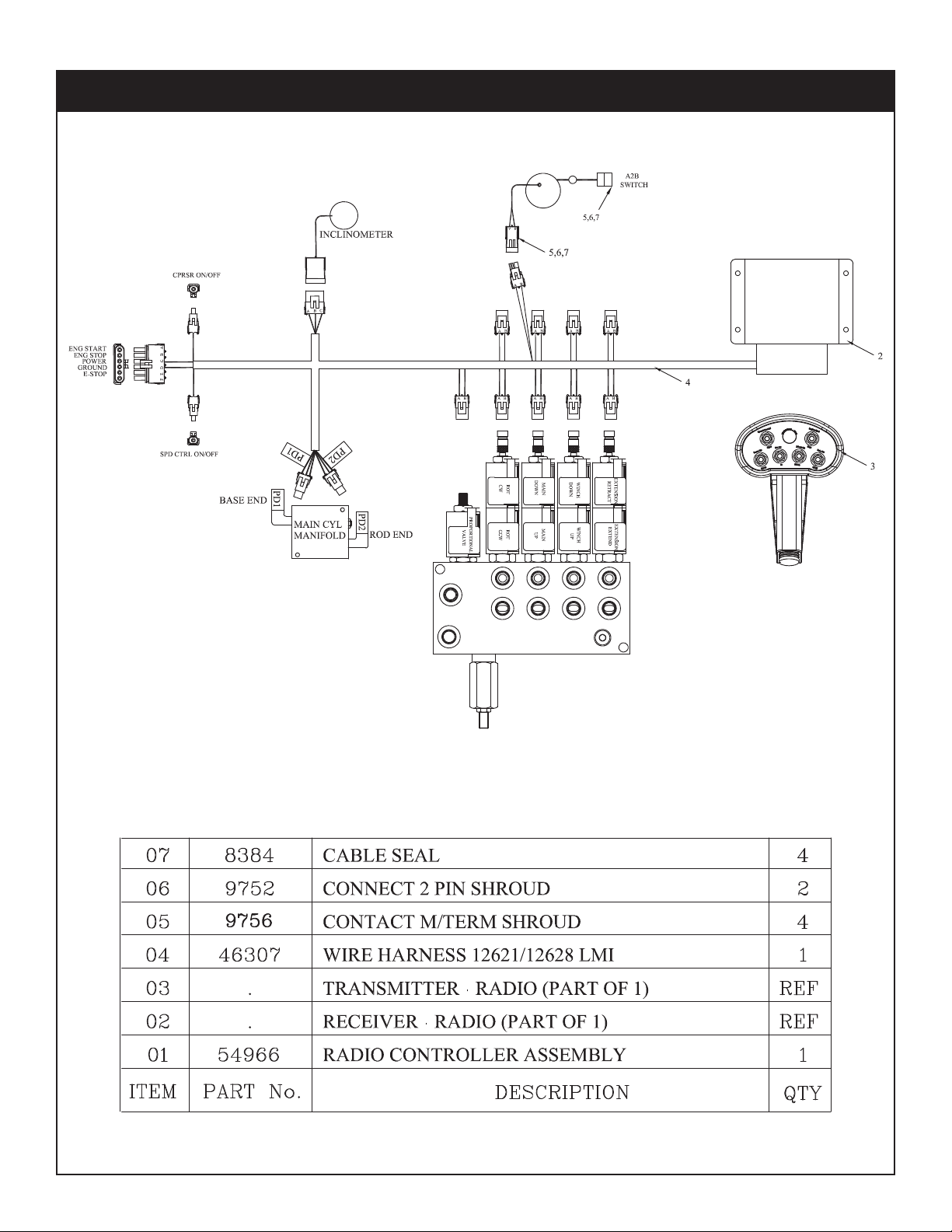

CDT™ Radio Transmitter Assembly - PN 56647 ...............................23

Chapter 4 - Replacement Parts ...........................................................25

For Technical Questions, Information, Parts, or Warranty, Call Toll-Free at

800-321-3741

Hours: Monday - Friday, 8:00 a.m. - 5:00 p.m. CST

Or email at the following addresses:

Technical Questions, and Information service@stellarindustries.com

Order Parts parts@stellarindustries.com

Warranty Information warranty@stellarindustries.com

Page 4

7628 Owner’s Manual

Page 5

Chapter 1 - Specifications

Model 7628 Crane

SPECIFICATION SHEET

Crane Rating: 38,000 ft-lb (5.25 TM)

Standard Boom Length: 12’6” (3.81 m) from CL of Crane

Boom Extension: 1st stage: Hydraulic 90"(228.6 cm)

2nd stage: Hydraulic 90"(228.6 cm)

Maximum Horizontal Reach: 28’6” (8.69 m) from CL of Crane

Maximum Vertical Lift: 30’4” (9.24 m)

(from crane base)

Boom Elevation: -5 to +80 degrees

Specifications

Stowed Height 35.50” (90.2 cm)

(crane only)

Mounting Space Required 20 x 21 inches (50.8 x 53.3 cm)

Approximate Crane Weight 1900 lbs (885 kg)

Controls Radio control standard

for all functions.

Winch Specification

Rope Diameter: 3/8"(.952 cm)

Line pull speed: 60 ft/min (18.29 m/min)

Max. single part line: 3750 lbs (1700 kg)

Max. double part line: 7500 lbs (3400 kg)

Rotation: 400 degree power

(worm gear)

Lifting Capacities 3040 lbs @ 12’6” (375 kg @ 3.81 m)

1335 lbs @ 28’6” (605 kg @ 8.69 m)

Power Supply Required PTO & Pump

(8 gpm @ 3000 psi)

(30.3 lpm @ 207 bar)

*Subject to change without notification

Page 6

7628 Owner’s Manual

0'

0 m3'.914m6'1.83 m9'2.74 m

12'6”

3.81 m

28'6”

8.69 m

20'6”

6.25 m

12'

3.66 m

3'

.914

6'

1.83 m

9'

2.74 m

15'

4.57 m

18'

5.49 m

21'

6.40 m

24'

7.01 m

27'

8.23 m

30' 4”

9.25 m

Weight of load handling devices are

part of the load lifted and must be

deducted from the capacity.

Maximum 1 - part line capacity is

3750 lbs (1700 kg). For greater

loads, use 2 - part line.

PN 55114

Reach in Feet/Meters

Capacity in Pounds/Kilograms

15º

30º

80º

75º

60º

45º

Boost

(If Equipped)

Standard

7500 lbs

3400 kg

7500 lbs

3400 kg

5545 lbs

2515 kg

4260 lbs

1930 kg

5030 lbs

2280 kg

3435 lbs

1555 kg

4850 lbs

2200 kg

3150 lbs

1425 kg

3720 lbs

1685 kg

3040 lbs

1375 kg

3585 lbs

1625 kg

1845 lbs

835 kg

2175 lbs

985 kg

1335 lbs

605 kg

1575 lbs

715 kg

7500 lbs

3400 kg

4685 lbs

2125 kg

5330 lbs

2415 kg

6330 lbs

2870 kg

7470 lbs

3385 kg

2555 lbs

1155 kg

3015 lbs

1365 kg

1880 lbs

850 kg

2220 lbs

995 kg

1525lbs

690 kg

1800 lbs

815 kg

1375 lbs

620 kg

1620 lbs

735 kg

1920 lbs

870 kg

2265 lbs

1025 kg

2110 lbs

955 kg

2490 lbs

1130 kg

2605 lbs

1180 kg

3075 lbs

1395 kg

3500 lbs

1585 kg

4130 lbs

1870 kg

6300 lbs

2855 kg

7430 lbs

3370 kg

6540 lbs

2965 kg

Capacity Chart - Decal PN 55114

Page 7

Chapter 2 - Installation

Notice: Read this Page Before Installation of the Crane

Installation

General Installation

This chapter is designed to serve as a

general guide for the installation of a Stellar

7628 Telescopic Crane on a Stellar Service

Body. Each installation is considered unique

so certain portions of this chapter may or

may not apply to your direct application. If

a question should arise during the installation

process, please contact Stellar Customer

Service at (800) 321 3741.

This crane is designed for use with a Stellar

Service Body installed on a vehicle that

meets the minimum chassis requirements of

the crane. It is the installer’s responsibility to

assure that the crane is mounted on a

platform that will support the maximum

crane rating of this crane.

Notice:

PTO and Pump installation instructions are

provided by the corresponding

manufacturers. For more information on

which PTO and Pump fit your application,

please contact your local Stellar Distributor

or Stellar Customer Service.

Important: When installing welder units to the service

bodies, it is highly recommended that a surge

protector is installed on the chassis batteries to protect

the crane radio receiver, wiring and other electronic

devices from an unexpected electrical spike or surge.

Failure to do so could result in extensive damage to

the service body and crane electrical circuit.

Installation Notice

According to Federal Law (49 cfr part 571),

each final-stage manufacturer shall

complete the vehicle in such a manner that

it conforms to the standards in effect on the

date of manufacture of the incomplete

vehicle, the date of final completion, or a

date between those two dates. This

requirement shall, however, be superseded

by any conflicting provisions of a standard

that applies by its terms to vehicles

manufactured in two or more stages.

Therefore, the installer of Stellar cranes and

bodies is considered one of the

manufacturers of the vehicle. As such a

manufacturer, the installer is responsible for

compliance with all applicable federal and

state regulations. They are required to

certify that the vehicle is in compliance with

the Federal Motor Vehicle Safety Standards

and other regulations issued under the

National Traffic and Motor Vehicle Safety

Act.

Please reference the Code of Federal

Regulations, title 49 - Transportation, Volume

5 (400-999), for further information, or visit

http://www.gpoaccess.gov/nara/index.html

for the full text of Code of Federal

Regulations.

Page 8

7628 Owner’s Manual

2

1

FRONT

Motor

Hole Mounting Detail

Ø1.063

7.38

14.75

7.38

14.75

Ø6.00

4 Places

65382

ITEM NO. PART NO.

15199

QTY.

WASHER 1.00 SAE FLAT YELLOW GR8

CAP SCR 1.00X8X3.00 HHGR8 ZY

DESCRIPTION

4

4

Installation Overview

1. Determine that the mounting location for the 6628 crane is at least 18” x 20” (45.7 x 50.8 cm).

2. Use the detail below to drill 1.06” diameter holes into the mounting plate. Run tap on the threads of the

base to be sure they are clean.

3. Use a crane or lifting device capable of lifting the weight of the Stellar crane. The Stellar 6628 weighs

approximately 1900 lbs (885 kg). Note: cranes are shipped with rotation positioned at 200 degrees of 400

degree system. This will allow for easy installation of the crane and permanent connection of all hydraulic

and electrical components prior to repositioning into the crane saddle.

4. Connect straps or chain from the lifting device to the lifting rings on the Stellar 6628.

5. Use four (4) 1” x 3” #8 bolts and four (4) #8 flat washers.

6. Install a washer on each bolt.

7. Apply Loctite Thread locker #277 to the bolts.

8. Using the lifting device, lower the Stellar 6628 just above the crane compartment and start the bolts.

Have someone assist in leveling the crane. Note: the rotation motor should be to the door side of crane

compartment and the boom should be extended back over the rear bumper.

9. Secure the crane using the mounting hardware provided. Note: longer or shorter cap screws may be

required – recommended thread engagement into crane base is 1.75” – use grade 8, zinc plated cap

screws only.

10. Torque the cap screws to 680 ft-lbs.

11. Remove supporting crane.

12. Hook-up hydraulics and electrical.

Note: If questions should arise during any portion of this installation,

please contact Stellar Customer Service at (800) 321-3741.

WARNING!

The use of this crane on a

body not capable of handling

the loads imposed on it may

result in serious injury or

death.

Page 9

PN 54968

Control Kit - PN 54968

Installation

Page 10

7628 Owner’s Manual

PN 56490

Control Kit (Non-Boost) - PN 56490

Page 11

NOTE: USE 32" OF HOSE PROTECTOR

P/N 17288 OVER THE ROTATION HOSES

NOTE: USE 12" OF HOSE PROTECTOR

P/N 17288 OVER THE 3 WINCH HOSES

PN 52264

Hydraulic Kit - PN 52264

Installation

Page 12

7628 Owner’s Manual 7628 Owner’s Manual

HYDRAULIC SCHEMATIC

4

3

1

4

3

4

3

2

PN 52265

YTQNOITPIRCSEDTRAPMETI

1 25367 RELIEF VALVE 24685/24690 1

25368 SEAL KIT 25367

2 24960 VALVE FLW CTRL PRP/JP04C3150N 0-8 1

25369 SEAL KIT 24960/25381

3 25371 VALVE SOLND 3 POS 4 WAY TAND G04571 4

25373 SEAL KIT 25371/25372

4 44532 COIL 12VDC DUETSCH CAP012H 9

Valve Bank - PN 52265

Page 13

Hydraulic Installation

1. After mounting, locate the pressure and return

lines. Note: Pressure line is 3/8” hose; Winch

Case Drain Line is 3/8” hose; Return line is 1/2”

hose. Hoses are terminated using swivel fittings.

2. Install hydraulic lines per diagram below. See

next page for Case Drain Installation. Note:

Stabilizer valve supplies oil to crane using the

Power Beyond feature.

3. Install hydraulic reservoir with return filter. Attach

pump pressure line to valve, return link to tank.

4. Fill system with hydraulic oil (See Stellar®

Lubrication Recommendations for fluid details).

(Blue)

Stabilizer Functions

Stabilizer Functions

Typical Stabilizer Valve

with Power Beyond Capabilities

Installation

Page 14

7628 Owner’s Manual 7628 Owner’s Manual

Installing the winch case drain

1.

The winch case drain must run directly to the reservoir to ensure no back pressure in the line.

2.

Use 3/8” hydraulic hose and fittings rated for a minimum of 300 psi.

3.

4.

Attach one end of the winch case drain to 3/8 swivel fitting located in step 3.

5. Route the winch case drain hose directly to the reservoir.

6.

Connect the second end of the winch case drain to unshared fitting on the top of the reservoir as

shown in Fig 2.

Fig.1 Fig. 2

Locate the winch case drain line at the bottom of the crane base as shown in Fig. 1 (Blue Hose).

Note: Both the main pressure and winch case drane line use a 3/8” swivel fitting. Verify the winch

case drain is attached to the hose that is connected to the winch motor.

(Blue)

Winch Case Drain Installation

Page 15

Hydraulic System

Installation

Page 16

7628 Owner’s Manual 7628 Owner’s Manual

Stability Procedure

Definition of Stability for the Stellar Telescopic Crane

Products:

A truck is stable until the load cannot be lifted off

the ground with the winch, without tipping over the

truck. Every Stellar crane installed must be tested for

stability to determine the actual load capacity of

the final truck package. The actual test data must

be recorded and supplied with the truck at the time

of in-service and should be kept with the truck at all

times. The following procedure will test the truck

package for stability and will provide a stability

capacity chart. The load limit information shown on

the stability capacity chart is formulated on 85%

tipping.

Set Up:

1. Locate the truck on a test course in position for

loading and engage travel brakes.

2. Set stabilizers so that they make contact with firm,

level footing.

3. Operate the crane under partial load to assure

operator proficiency and proper machine

function.

4. Put the radio into Stability Test Mode:

A. Push the bottom four switches up and hold until

all lights come on (approximately 5 seconds.)

B. At this point ,the crane will have enough

capacity to handle the weight for the stability

test.

C. The radio will timeout of stability mode after 30

minutes or when the E-Stop button is pushed.

7628 Stability Data

Max Horizontal Reach: 342” (From the center of

rotation to boom tip)

Boost Stability Test Weight: 1860 lbs.

Non-Boost Stability Test Weight: 1575 lbs.

Test Procedure

1. Rotate the crane into Zone 1 position.

2. With the crane fully retracted and the boom

horizontal, winch the test weight off the ground.

Note: Keep weight within six inches of the ground

at all times.

3. Extend the boom outward until full extension has

been reached or until the truck becomes unstable

(Again, use the winch to keep the weight within six

inches of the ground.)

4. If the boom goes full extension without becoming

unstable, the crane is termed stable for this zone

and 100% can be written in the Zone 1 data box.

5. If the truck becomes unstable prior to going full

extension, retract the boom until the truck

becomes stable and measure the horizontal

reach in this position (center of rotation to boom

tip). This is the stable horizontal reach for this zone.

Stable horizontal reach divided by Maximum

horizontal reach multiplied by 100 equals the

percentage of rated capacity for this zone. Use

the following formula to determine the

percentage of rated capacity:

Note: The radio can only be put into stability mode

five times. After that, the radio would have to be

returned to Stellar to be reprogrammed to allow

additional stability testing. All other radio functions

will work properly even if stability mode is not available.

6. Record this number in the data box for Zone 1.

This is the revised capacity due to stability for this

zone.

7. Repeat this procedure for each zone until the

worksheet is completed.

8. This is the revised capacity based on stability of

this package.

Page 17

PN 54970

*USE THESE DECALS WITH BODY PACKAGE

**THESE DECALS NOT INCLUDED WITH THE DECAL KIT

1

2

®®

7628

3

26

14,15

27

22

29

28

30

25

9

60

50

0

20

30

10

40

Angle

Indicator

80

70

ITEM

01

*04

02

*03

*05

*06

09

*07

*08

*10

*11

*12

*13

15

14

DECAL HOISTING PERSONNEL

DECAL STELLAR LOGO 6.5 x 18

DESCRIPTION

PART No.

52681

PART No.ITEM

QTY

*16

2

12451

DESCRIPTION

QTY

1

DECAL ASME/ANSI B30.22/B30.5

DECAL GREASE WORM DRIVE BEARINGS

DECAL-ROTATION ALIGNMENT

C4545 DECAL-ELECTROCUTION 5x13

DECAL CAPACITY

DECAL 7628 IDENTIFICATION55113

55114

DECAL-DANGER

DECAL-DANGERC4540

C4544

DECAL MANUAL EXT12452

4

*19

*17

2

C5910

*182C5911

DECAL-STELLAR 4x9.5

DECAL-STELLAR 2x4.5

C0568

1

*20

*21

1

4214

DECAL-DIESEL

DECAL-SERVICE

9188 DECAL-ROTATE/GREASE

DECAL-DANGER

DECAL-ELECTROCUTION 2x2.754186

4189

DECAL-DANGER

DECAL-DANGER O.R.

4190

C4795

4188

1

24

22

1

12300

*23

1

C4541

DECAL-TWO BLOCKING

DECAL-CRANE STOWING

15171

1

25

26

2

15172

1

1

3

2

1

1

1

1

1

1

DECAL VB CONTROL MECH CRANE

DECAL STELLAR MADE IN THE USA

DECAL SNATCH BLOCK CAP 5 TON

DECAL WARNING OVERLOAD DEVICE

DECAL CAUTION STOW HOOK

52270

31

DECAL-ELECTROCUTION 4.5x7.5

DECAL-DANGER MOVING O.R.C5918

C1179

DECAL-ANGLE INDICATOR SS

DECAL ANGLE INDICATOR CS

D1197

D1196

27

2

24712

28

2

28256

35234

30**

1

29

1

38472

1

1

1

1

1

32

25159 DECAL WARNING MANUAL OVERRIDES 1

33

33

54588 DECAL CDT 2.00X2.00 2

Installation

Decal Placement - 54970

Page 18

7628 Owner’s Manual 7628 Owner’s Manual

Page 19

.YTQNOITPIRCSEDTRAPMETI

1 47869 BEARING SWING DRIVE CAST 6620 GEARTEK 1

1EDILS 004 0283 POTS245112

3C6069 MOTOR HYD ROSS MK080613AAAB1

11-65001-800 ROTOM TEKSAG151124

5D1345 FTG CPRSN 0.12NPT/0.25 TUBE2

6D1810 TBE AIR SAEJ844 TYPE A .25 (RM)1

131.0 EPIP RELPUOC GTF6522C7

8 56589 ZERK 1/8 NPT STRAIGHT LONG THREAD 1

2HS 00.2X31-05.0 RCS PAC594359

NOTE: ITEMS 1 INCLUDE GUARD & GUARD FASTENERS

8

2

3

GASKET SHOWN AS REFERENCE

4

5

6

5

7

9

1

PN 50364

Chapter 3 - Assembly Drawings

Base Assembly - PN 50364

Assembly Drawings

Page 20

7628 Owner’s Manual 7628 Owner’s Manual

PN 62795

DO NOT GREASE

THESE BUSHINGS

2

1

3

4

5

3

6

10

8

7

8

9

11

13

.YTQNOITPIRCSEDTRAPMETI

112621/12601 TSAM384341

252265VB 4 SECT W/PROP STER8GPM DEUTSCH1

3C5902 WASHER 0.63 SAE FLAT YELLOW GR818

4D1034 CAP SCR 0.63-11X3.00 HHGR8 RED PATCH14

5 63517 WINCH 3750 TH2CC230246 W/120 FT ROPE 1

6 11693 CAP SCR 0.63-11X1.75 HHGR8 4

7 27813 COLLAR 0.38X0.75X0.38 UHMW2

4CNIZ TALF SSU 13.0 REHSAW34308

9C0933 CAP SCR 0.31-18X4.50 HHGR52

2COLYN 5RGHH 81-13.0 TUN243001

11 44533 BUSHING HSG3235012S 2.00X0.754

13 52490 CAP SCR 6MMX30MM HH 8.8(GR5) 4

Mast Assembly - PN 62795

Page 21

32

12

11

10

6

2

16

19

7

POSITION OF INCLINOMETER

3

4

16

26

19

15

19

20

28

21

26

27

17

9

23

22

1

24

25

8

17

12

5

17

5

12

12

17

5

18

31

30

29

13

NOTE: INCLINOMETER MOUNTS

INSIDE THE BOOM. VIEW SHOWS

14

33

2PLATE ANGLE INDICATORD1194PC9

2PIN CAP 0.44X1.75X0.19 SS93208

1PIN 1.00X8.38 D&T9712ZP7

1PIN 2.00X8.88 D&T9711ZP6

6PIN CAP 0.56X2.50X0.1991425

2CAP SCR 0.38-16X9.00 HHGR51216814

1CAP SCR 0.25-20X0.50 HHGR5047813

14CAP SCR 0.50-13X1.00 HHGR81017212

2PLATE WEAR PAD SUPPORT9545PC11

2WEAR PAD 1.12X2.00 RND NYLATRON936310

.YTQNOITPIRCSEDTRAPMETI

18266 MOOB RENNI643051

2 54961 CYLINDER ASM 7628 INNER 1

242-8161-ISQ GNIHSUB86003

2T&D 91.01X00.2 NIPPZ90794

.YTQNOITPIRCSEDTRAPMETI

15 0335 CAP SCR 0.38-16X1.25 HHGR52

16 9843 CAP SCR 0.38-16X0.75 HHGR82

17 D0790 WASHER 0.50 SAE FLAT YELLOW GR818

18 0340 WASHER 0.25 USS FLAT ZINC2

19 C6353 WASHER 0.38 SAE FLAT YELLOW GR86

10269 EDIUG EPOR TKRBCP5343102

21 27720 SPACER ROPE GUIDE 6620 UHMW2

22 0480 CAP SCR 0.25-20X1.00 HHGR51

18275 LEER DROC6619132

24 0425 MACHY WASHER 1.25ID 10GA2

1THGIARTS TPN 8/1 KREZ2951c52

26 4381BUSHING BPC32DXR32 2.00X2.00 4

27 C6106 NUT 0.50-13 HHGR5 NYLOC 2

28 0347 NUT 0.38-16 HHGR5 NYLOC 4

1GED 06 RETEMONILCNI3943592

30 18765 WASHER #6 SAE FLAT ZINC2

31 18618 SCREW #6-32X1.00 PHMS PH2

2SS COLYN HH 23-6# TUN6700D23

1LYNIV KLB 52.0 PMALC6065C33

PN 54960

Main Boom - PN 54960

Assembly Drawings

Page 22

7628 Owner’s Manual 7628 Owner’s Manual

PN 61831

See Next Page for

Expanded View.

.YTQNOITPIRCSEDTRAPMETI

18266 TS1 MOOB TXE867431

18267 DN2 MOOB TXE238162

3 50929CYLINDER EXT ASM 6628 2.0/2.01

4 9991 WEAR PAD 0.19X2.50 RND NYLATRON4

183.4X00.1 PORD RAET NIPPZ004315

6 27719SPACER BOOM TIP 6620 UHMW2

7 13339 SHEAVE 7621 8.00 DIA .38R/1.88THK2

2HCNYL 65.1X91.0 NIP35758

9 9363 WEAR PAD 1.12X2.00 RND NYLATRON2

2TROPPUS DAP RAEW ETALPCP545901

11 0425 MACHY WASHER 1.25ID 10GA2

12 61050 PLATE SHEAVE MOUNTING FS/CRADLE 106/1262

105.4X00.1 HCTIH NIP4282131

14 61051 MNT CRADLE LH FS/CRADLE A2B 106/1261

15 61048 CRADLE FS/CRADLE A2B 106/1261

16 61049 LINK FS/CRADLE A2B 106/126 W/HOLES1

17 35105 SWITCH LIMIT E1117-B9111-6C1

18 61054 MNT CRADLE RH FS/CRADLE A2B 106/1261

1RS 91.4X00.1 NIPPZ0867391

20 27710SPRING ANTI 2 BLOCK CRADLE A2B 2

2LYNIV KLB 83.0 PMALC8700C12

1LYNIV KLB 13.0 PMALC9721322

23 C6353 WASHER 0.38 SAE FLAT YELLOW GR86

24 C6219 WASHER 0.75 SAE FLAT YELLOW GR81

25 D0790 WASHER 0.50 SAE FLAT YELLOW GR818

2CNIZ TALF SSU 13.0 REHSAW343062

2CNIZ TALF SSU 52.0 REHSAW043072

2CNIZ TALF EAS 01# REHSAW8710D82

29 0867 MACHY WASHER 1.00ID 14GA2

30 58681 CAP SCR 0.75-10X2.50 HHGR81

31 10666 CAP SCR 0.50-13X1.25 HHGR88

32 0490 CAP SCR 0.31-18X3.50 HHGR52

33 0420 CAP SCR 0.31-18X0.75 HHGR5 1

34 0478 CAP SCR 0.25-20X0.50 HHGR52

35 0484 CAP SCR 0.31-18X0.50 HHGR51

36 C1000 CAP SCR 0.50-13X5.00 HHGR52

37 C1002 CAP SCR 0.50-13X6.00 HHGR51

38 9843 CAP SCR 0.38-16X0.75 HHGR82

39 0489 CAP SCR 0.31-18X2.50 HHGR51

3COLYN 5RGHH 81-13.0 TUN243004

3COLYN 5RGHH 31-05.0 TUN6016C14

42 31132 CAP SCR #10-24X0.550 SH SS 18-82

43 61053 BOLT SHOULDER 0.38X0.50 0.31-18X0.504

252.X05.3X65.0 PAC NIP023944

104HCS 31.3 X05.0 EPIPCP8451654

46 61549COLLAR 1.13X2.00X1.13 W/HOLE 1

1CCPK KROF 00.1 HCTIH NIP5215474

1621/601 B2A ELDARC/SF KNIL8395684

36

42

5

7

26

44

29

21

40

31

6

8

25

10

9

1

30

24

32

3

4

23

37

11

12

38

8

12

28

19

4

25

41

44

23

38

33

16

43

34

23

27

18

14

17

15

45

40

39

46

47

13

25

48

3

Extension Boom Assembly - PN 61831

Page 23

PN 61831

See Parts Breakdown

on Previous Page.

Assembled View

47

45

6

23

13

8

38

6

29

42

12

21

27

7

34

12

43

18

23

26

33

5

8

40

16

44

19

44

23

38

14

28

17

41

25

35

26

22

20

32

36

37

25

41

25

46

40

39

25

48

Extension Boom Assembly - PN 61831 (Expanded)

Assembly Drawings

Page 24

7628 Owner’s Manual 7628 Owner’s Manual

.YTQNOITPIRCSEDTRAPMETI

150928 CYLINDER 4.50X21.38 NEW MAST 1

4S-OLO5F-6 TPADA GTF97202

341910 MANIFOLD ASM DUAL 10-1CBAL-RLF-CHK 1

444066TUBE ASM 0.38X8.25 MAIN 10628/12628 2

PN 54961

2

4

1

2

4

2

3

2

Cylinder

Serial Tag

Location

Note: This cylinder uses

Stellar Seal Kit PN 35655

.YTQNOITPIRCSEDTRAPMETI

139425 MANIFOLD CBAL DOUBLE T11A WITH RELIEF 1

1NCX-DEXC KCEHC EVLAV809142

1ISP 008 NAL-ADDR EVLAV709143

441906 VALVE C-BAL SUN CBCH-LJN 3500 2

5C4961 PLUG STR HOLLOW HEX 0.38 6-HP5ON 1

3

5

4

1

2

4

Manifold Assembly

PN 41910

Main Cylinder Assembly - PN 54961

Page 25

PN 50929

.YTQNOITPIRCSEDTRAPMETI

150919 CYLINDER EXT 6628 2 STAGE 2.0/2.0 1

214115MANIFOLD ASM 6620 EXT CBBD-LJN-XVN 1

311882 CAP SCR 0.38-16X1.75 SH ZC 2

414601 CAP SCR 0.38-16X2.25 SH ZC 1

531652 TUBE ASM 0.38X 72.86 EXT CYL 6628 1

631651 TUBE ASM 0.38X 119.75 EXT CYL 6628 1

724729 HOSE CLAMP #52 3.00 - 3.75 2

7

1

5

2

4

6

3

7

Cylinder

Serial Tag

Location

Extension Cylinder Uses:

Upper Seal Kit - PN 54778

Lower Seal Kit - PN 20310

Extension Cylinder Assembly - PN 50929

Assembly Drawings

Page 26

7628 Owner’s Manual 7628 Owner’s Manual

3

12

6

9

1

4

4

11

2

2

7

7

13

2

9

8

14

12

10

5

10

PN 56266

ITEMPARTDESCRIPTION

Defau

lt

1 13339 SHEAVE 7621 8.00 DIA .38R/1.88THK1

2 53263PC PLATE SNATCH BLOCK 76/96/106/1262

1RETTOC 60.4X00.1 NIPPZ478933

200.2X57.0X44.0 RALLOC346444

5 0347 NUT 0.38-16 HHGR5 NYLOC 2

6C0538 NUT 0.75-10 HHGR8 NYLOC 1

7 0532 CAP SCR 0.38-16X3.75 HHGR52

8 5841 CAP SCR 0.75-10X4.50 HHGR8 1

9C6219 WASHER 0.75 SAE FLAT YELLOW GR82

10 0867 MACHY WASHER 1.00ID 14GA2

1SS KOOH V GNIHSUBPZ4489311

2HCNYL 65.1X91.0 NIP357521

13 25831 HOOK 5 TON SWIVEL CROSBY 10286231

14 13436 PIN .38X4.00 QUICK RELEASE 1

Snatch Block Assembly - PN 56266

Page 27

PN 56647

.YTQNOITPIRCSEDTRAPMETI

1 20088 CONTROL HANDLE HOUSING 4 FCTN HET1

2 56657 CONTROL HANDLE FACE PLT W/LABEL 6 FCTN CDT 1

1NTCF 4 HCTIWS OIDAR DRAUG583423

4 35447 CONTROL HANDLE GRIP W/TRIGGER HT H21

524958RUBBER BOOT TRIGGER GUARD HET1

6 22600 SWITCH TOGGLE HET RADIO 630193006

7 35441 BATTERY TUBE AA HETRONIC RADIO1

1LX AVON POTS E HCTIWS658748

3

SEE NOTE

7

5

4

1

2

8

6

NOTE: 1) P/N'S 25999 & 24958 ARE OPTIONAL COVERS

FOR THE SWITCHES AND TRIGGER

CDT™ Radio Transmitter Assembly - PN 56647

Assembly Drawings

Page 28

7628 Owner’s Manual

Page 29

Chapter 4 - Replacement Parts

PART# DESCRIPTION

C6069 HYDRAULIC SWING MOTOR

25367 RELIEF VALVE

25368 SEAL KIT - RELIEF VALVE (25367)

24960 FLOW CONTROL VALVE

25369 SEAL KIT - FLOW VALV E (24960)

25371 SOLENOID VALVE TAND G04571

25373 SEAL KIT - SOLENOID VALVE (25371)

44532 COIL - 12VDC

39425 MANIFOLD - MAIN LIFT CYLINDER

9803 C-BALANCE VA LVE - MAIN LIFT CYLINDER

41907 RELIEF VALV E - MAIN LIFT CYLINDER

41908 CHECK VALVE - MAIN LIFT CYLINDER

28485 PRESSURE TRANSDUCER

9803 C-BALANCE VA LVE - EXTENSION CYLINDER

6397 HYD PRESSURE GUAGE

C2027 O'RING - # 4 FACE SEAL

C2028 O'RING - # 6 FACE SEAL

C2029 O'RING - # 8 FACE SEAL

D1245 O'RING - # 4 SAE

D1246 O'RING - # 6 SAE

D1247 O'RING - # 8 SAE

44066 HYD TUBE ASS Y - MAIN LIFT CYLINDER

14442 HYD TUBE ASS Y - EXTENSION CYLINDER

14443 HYD TUBE ASS Y - EXTENSION CYLINDER

35655 SEAL KIT (MAIN LIFT CYLINDER)

54778 SEAL KIT - EXTENSION CYLINDER (UPPER)

20310 SEAL KIT - EXTENSION CYLINDER (LOWER)

55827 WORM GEAR - BEARING SWING DRIVE

55829 BEARING & SEAL KIT - BEARING SWING DRIVE

55830 WORM GEAR / BEARING & SEAL KIT - BEARING SWING DRIVE

0068 BUSHING 1.00" X 1.50"

4381 BUSHING 2.00" X 2.00"

44533 BUSHING 2.00" X 0.75"

23454 WIRE ROPE

9363 WEAR PAD - 2.00" RND

9991 WEAR PAD - 2.50" RND

12824 HITCH PIN - 1.00" X 4.50"

5753 LYNCH PIN - 0.19" X 1.56"

13339 SHEAVE 8.00"

53493 INCLINOMETER 60 DEGREE

11938 LIMIT SWITCH - FLIP SHEAVE

31670 CHAIN & WEIGHT KIT - LIMIT SWITCH (FLIP SHEAVE)

35105 LIMIT SWITCH - CRADLE / BASKET

43488PC CRADLE PLATE - ANTI-2-BLOCK (CRADLE/BASKET STYLE)

61048 CRADLE FS/CRADLE A2B (After 8/1/2011)

27710 SPRING - LIMIT SWITCH CRADLE / BASKET

19166 CORD REEL

56647 RADIO TRANSMITTER (HETRONIC RADIO)

34557 HANDLE ASM - TRANSMITTER

47856 E-STOP SWITCH (HETRONIC RADIO)

35441 BATTERY TUBE (AA) HOLDER (HETRONIC RADIO)

35916 BACK UP CORD 25FT (RADIO REMOTE SYSTEM)

25831 5-TON HOOK

19501 SAFETY LATCH ASM - 5 TON HOOK

C1592 GREASE ZERK

4460 GEAR BEARING GREASE - MOLUBE (Open Teeth)

Replacement Parts

Page 30

Limited Warranty Statement

Stellar Industries, Inc. (Stellar) warrants products designed and manufactured by Stellar to be free from defects in material and workmanship under

proper use and maintenance. Products must be installed and operated in accordance with Stellar’s written instructions and capacities. This warranty

shall cover the following:

Stellar Cranes, Stellar Hooklift Hoists, Stellar Cable Hoists, Stellar Container Carriers, Stellar Service Trucks, and Stellar X-Tra-Lift Systems:

Twelve (12) month warranty on parts from the date recorded by Stellar as the in-service date, not to extend beyond twenty-four (24) months from date

ofmanufacture,

Twelve (12) month repair labor from the date recorded by Stellar as the in-service date, not to extend beyond twenty-four (24) month from date of

manufacture, and

Thirty-six (36) month warranty on all Stellar Manufactured structural parts from the date recorded by Stellar as the in-service date, not to extend beyond

forty-eight (48) months from date of manufacture.

Stellar Tarper Systems:

Twelve (12) month warranty on parts from the date recorded by Stellar as the in-service date, not to extend beyond twenty-four (24) months from date

of manufacture and

Three (3) month repair labor from the date recorded by Stellar as the in-service date, not to extend beyond fifteen (15) month from date of

manufacture.

The in-service date will be derived from the completed warranty registration card. In the event a warranty registration card is not received by Stellar, the

factory ship date will be used.

Stellar’s obligation under this warranty is limited to, and the sole remedy for any such defect shall be, the repair and/or replacement (at Stellar’s option)

of the unaltered part and/or component in question. Stellar after-sales service personnel must be notified by telephone, fax, or letter of any warrantyapplicable damage within fourteen (14) days of its occurrence. If at all possible, Stellar will ship the replacement part within 24-hours of notification by

the most economical, yet expedient, means possible. Expedited freight delivery will be at the expense of the owner.

Warranty claims must be submitted and shall be processed in accordance with Stellar’s established warranty claim procedure. Stellar after-sales service

personnel must be contacted prior to any warranty claim. A return materials authorization (RMA) account number must be issued to the claiming party

prior to the return of any warranty parts. Parts returned without prior authorization will not be recognized for warranty consideration. All damaged parts

must be returned to Stellar freight prepaid; freight collect returns will be refused. Freight reimbursement of returned parts will be considered as part of

the warranty claim.

Warranty service will be performed by any Stellar new equipment distributor, or by any Stellar-recognized service center authorized to service the type

of product involved, or by the Stellar factory in the event of a direct sale. At the time of requesting warranty service, the owner must present evidence

of date of delivery of the product. The owner shall be obligated to pay for any overtime labor requested of the servicing company by the owner, any

field service call charges, and any towing and/or transportation charges associated with moving the equipment to the designated repair/service

provider.

All obligations of Stellar and its authorized dealers and service providers shall be voided if someone other than an authorized Stellar dealer provides

other than routine maintenance service without prior written approval from Stellar. In the case repair work is performed on a Stellar-manufactured

product, original Stellar parts must be used to keep the warranty in force. The warranty may also be voided if the product is modified or altered in any

way not approved, in writing, by Stellar.

The owner/operator is responsible for furnishing proof of the date of original purchase of the Stellar product in question. Warranty registration is the

ultimate responsibility of the owner and may be accomplished by the completion and return of the Stellar product registration card provided with the

product. If the owner is not sure of registration, he is encouraged to contact Stellar at the address below to confirm registration of the product in

question. This warranty covers only defective material and workmanship. It does not cover depreciation or damage caused by normal wear and tear,

accident, mishap, untrained operators, or improper or unintended use. The owner has the obligation of performing routine care and maintenance

duties as stated in Stellar’s written instructions, recommendations, and specifications. Any damage resulting from owner/operator failure to perform such

duties shall void the coverage of this warranty. The owner will pay the cost of labor and supplies associated with routine maintenance.

The only remedies the owner has in connection with the breach or performance of any warranty on the Stellar product specified are those set above.

In no event will Stellar, the Stellar distributor/dealer, or any company affiliated with Stellar be liable for business interruptions, costs of delay, or for any

special, indirect, incidental, or consequential costs or damages. Such costs may include, but are not limited to, loss of time, loss of revenue, loss of use,

wages, salaries, commissions, lodging, meals, towing, hydraulic fluid, or any other incidental cost.

All products purchased by Stellar from outside vendors shall be covered by the warranty offered by that respective manufacturer only. Stellar does not

participate in, or obligate itself to, any such warranty.

Stellar reserves the right to make changes in design or improvement upon its products without imposing upon itself the same upon its products

theretofore manufactured.

This warranty will apply to all Stellar Cranes, Stellar Hooklift Hoists, Stellar Cable Hoists, Stellar Container Carriers, Stellar Service Trucks, Stellar X-Tra-Lift

Systems, and Stellar Tarper Systems shipped from Stellar’s factory after January 1st, 2010. The warranty is for the use of the original owner only and is not

transferable without prior written permission from Stellar.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE. REMEDIES UNDER THIS WARRANTY ARE LIMITED TO THE PROVISION OF MATERIAL AND SERVICES, AS SPECIFIED HEREIN. STELLAR

INDUSTRIES, INC. IS NOT RESPONSIBLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Revision Date: February 2010

Document Number: 37040

Loading...

Loading...