Page 1

®

Owner’s Manual

Safety, Installation, Maintenance, and Operation

Model SRS-65

Subject to Change without Notification.

© 2006 American Eagle

American Eagle, Inc.

190 State Street

PO Box 169

Garner, IA 50438

800-392-3015

Fax: 641-923-4889

www.americaneagleacc.com

Manual Part No. 37246

Last Revision: 7/18/07

Page 2

Introduction

American Eagle Compressors are designed to

provide safe and dependable service for a

variety of operations. With proper use and

maintenance, American Eagle Compressors will

operate at peak performance for many years.

This manual contains information vital to the

safe use and efficient operation of this unit.

Following the information provided within this

manual can ensure the longevity of the

compressor. Carefully read and study the

operator’s manual before using the unit. Failure

to adhere to the instructions could result in

property damage or even serious bodily injury to

the operator or others close to the compressor.

A copy of this manual is provided with every

compressor and shall remain with the

compressor at all times. Information contained

within this manual does not cover all

maintenance, operating, or repair instructions

pertinent to all possible situations. This manual

is not binding. American Eagle reserves the

right to change, at any time, any or all of the

items, components, and parts deemed

necessary for product improvement or

commercial/production purposes. This right is

kept with no requirement or obligation for

immediate mandatory updating of this manual.

This product manual is not intended as a

training manual for beginners or unskilled

operators. This manual offers guidelines for

correct and safe usage of the compressor,

maintenance, and troubleshooting. If more

information is required or technical assistance is

needed, please contact AE Technical Support.

Some sections of this manual contain

information pertaining to all American Eagle

manufactured compressors and may or may not

apply to your specific model.

If this manual becomes damaged, misplaced, or

unreadable at any point, or if you feel that any

part of this manual is unclear or incorrect,

please contact AE Technical Support at 800321-3741 or email at

service@americaneagleacc.com

For Technical Questions, Information, Parts, or Warranty, Call Toll-Free at

800-321-3741

Hours: Monday - Friday, 8:00 a.m. - 5:00 p.m. CST

Or email at the following addresses:

Technical Questions, and Information service@americaneagleacc.com

Order Parts parts@americaneagleacc.com

Warranty Information warranty@americaneagleacc.com

SRS-65 Manual

1

Page 3

Table of Contents

Safety Page 3

Specifications Page 4

Operation Page 5

Maintenance Page 6

Installation Page 11

Assembly Drawings Page 17

Replacement Parts Page 19

Troubleshooting Page 20

Warranty Page 22

SRS-65 Manual

2

Page 4

Safety

This manual contains vital information for the safe use and efficient

operation of this unit. Carefully read the operators manual before

starting the unit. Failure to adhere to the instructions could result in

serious bodily injury or property damage.

The SRS-65 Rotary Screw Compressor will

provide safe and dependable service if operated

according to instructions. Read and understand

the safety precautions given in this manual and

on the decals attached to the shields. Failure to

do so can result in personal injury or equipment

damage.

Operators and maintenance personnel must

always comply with the safety precautions.

These precautions are given here for your

safety. Review them carefully before operating

the compressor and before performing

maintenance or repairs.

Supervising personnel should develop additional

precautions relating to the specific work area

and local safety regulations.

Precautions

Always wear safety equipment such as goggles,

ear plugs and head protection at all times when

operating the compressor.

Establish a training program for all operators to

ensure safe operation.

Do not operate the compressor unless

thoroughly trained or under the supervision of

an instructor.

Do not operate the compressor if it is damaged,

improperly adjusted or not completely or

properly assembled.

Never operate the compressor with any of the

guards removed.

Do not attempt to adjust or disable the

compressors air pressure relief valve. This

valve limits the air pressure to 150 PSI.

The surface of the air compressor and the

plumbing between the compressor and the

cooler may reach temperatures above 150

degrees. Touching these surfaces during

operation can cause burns.

Do not inspect or clean the compressor while

the power source is connected. Accidental

engagement of the tool can cause serious

injury.

Before performing any maintenance on the

compressor, place a warning tag on the

hydraulic power source or disconnect the hoses

from the compressor motor to prevent

accidental startup of the compressor.

Always connect hoses to the compressor before

energizing the power source. Be sure all hose

connections are tight.

SRS-65 Manual

The air taken in by the air compressor must be

free of flammable fumes and vapors.

Compressor speed should not exceed 8000

RPM.

Use and operate this air compressor only in full

compliance with all pertinent O.S.H.A.

requirements and all Federal, State and Local

codes or requirements.

3

Page 5

Specifications

Compressor System Description

• 19-20 GPM Hydraulic System • 2500 PSI System Pressure

• 2600 PSI Pressure Relief Setting • 12 VDC Solenoid Control Valve

• All Steel Plumbing W/ JIC Fittings • 6061 Aluminum Manifold

• 861 CFM, 12 Volt Cooler Fan • Air Pressure Control Valve

• Belt Drive • Max. Air Pressure 150 PSI

• Compressor RPM (small sprocket) • 65 CFM @ 100 PSI With

7000-7500 RPM Compressor Running @ 7000

RPM @ 20 GPM

General Information

• Model:

• Weight: 313 lbs.

• Cylinders:

• Delivery: 65 CFM @ 100 PSI

• Maximum Working Pressure: 150 PSI

• Relief: 2600 PSI

• Maximum Compressor Speed: 8000 RPM

• Delivery: 65 CFM @ 100 PSI (7000-7500 RPM)

• Dimensions: 29”L x 23”W x 22”H

• Electrical: 12 VDC

• Crankcase Oil Capacity: 5 Quarts

• Oil Reservoir Capacity: Minimum: 26 Gallon Reservoir

SRS-65 Manual

4

Page 6

Operation

Each compressor is bench tested under load at the factory to ensure proper break-in and operation.

While it is not necessary to follow any break-in procedure, the following checks should be made

before putting the unit into service and periodically during use.

Before Start-Up

Inspect unit for any visible signs of damage.

Check the oil level in the compressor with the dipstick on the unit. If oil is needed, use American

Eagle synthetic compressor oil (P/N C0087) or an equivalent synthetic oil.

left in the crankcase from the factory bench test. Overfilling may cause the compressor to

back blow oil. Always check the oil level and fill to the designated marking on the dipstick

before putting the unit into service.

Check hoses (air and hydraulic) for weak or worn condition and make sure that all connections are

secure.

Check the air intake filters on each head to make certain that they are clean and unobstructed.

Dirty air filters are a possible cause of reduced air output.

Note: There may be oil

General Information

To use the compressor, start the vehicle engine

and engage the hydraulic system. The

compressor can now be activated using the

compressor switch. This energizes the hydraulic

solenoid sending oil to the hydraulic drive motor

and starts the compressor. Through the air

pressure switch and pilot valve, the system will

now function automatically. Once engaged,

adjust the engine speed control to ensure that

the compressor speed does not exceed 8000

RPM under load. Adjustment instructions are

provided with the speed control unit.

Air Pilot Valve Operation

(Head Unloading System)

When the hydraulic system is engaged the

compressor will pump air into the receiver until

the pressure reaches 150 psi. At this time the

air pilot valve senses the pressure in the

receiver and engages an intake valve hold-open

mechanism. The compressor will run free until

the pressure in the receiver falls below 115 psi

and the air pressure valve disengages the

intake valve hold-open mechanism to allow the

compressor to pump air. See head unloading

system for detailed views and adjustment

instructions on the next page.

Operating Notes:

This reciprocating compressor must not be used

for breathing air. To do so will cause serious

injury whether air is supplied direct from the

compressor source or to breathing tanks for

later use. Any and all liabilities for damage or

loss due to injuries, death and/or property

damage, including consequential damages

stemming from the use of this compressor to

supply breathing air will be disclaimed by the

manufacturer.

The use of this compressor as a booster pump

and/or to compress a medium other than

atmospheric air is strictly non-approved and can

result in equipment damage and/or injury. Nonapproved uses will also void the warranty.

Never use plastic pipe or improperly rated

metal pipe. Improper piping materials can burst

and cause injury or property damage.

SRS-65 Manual

5

Page 7

Maintenance

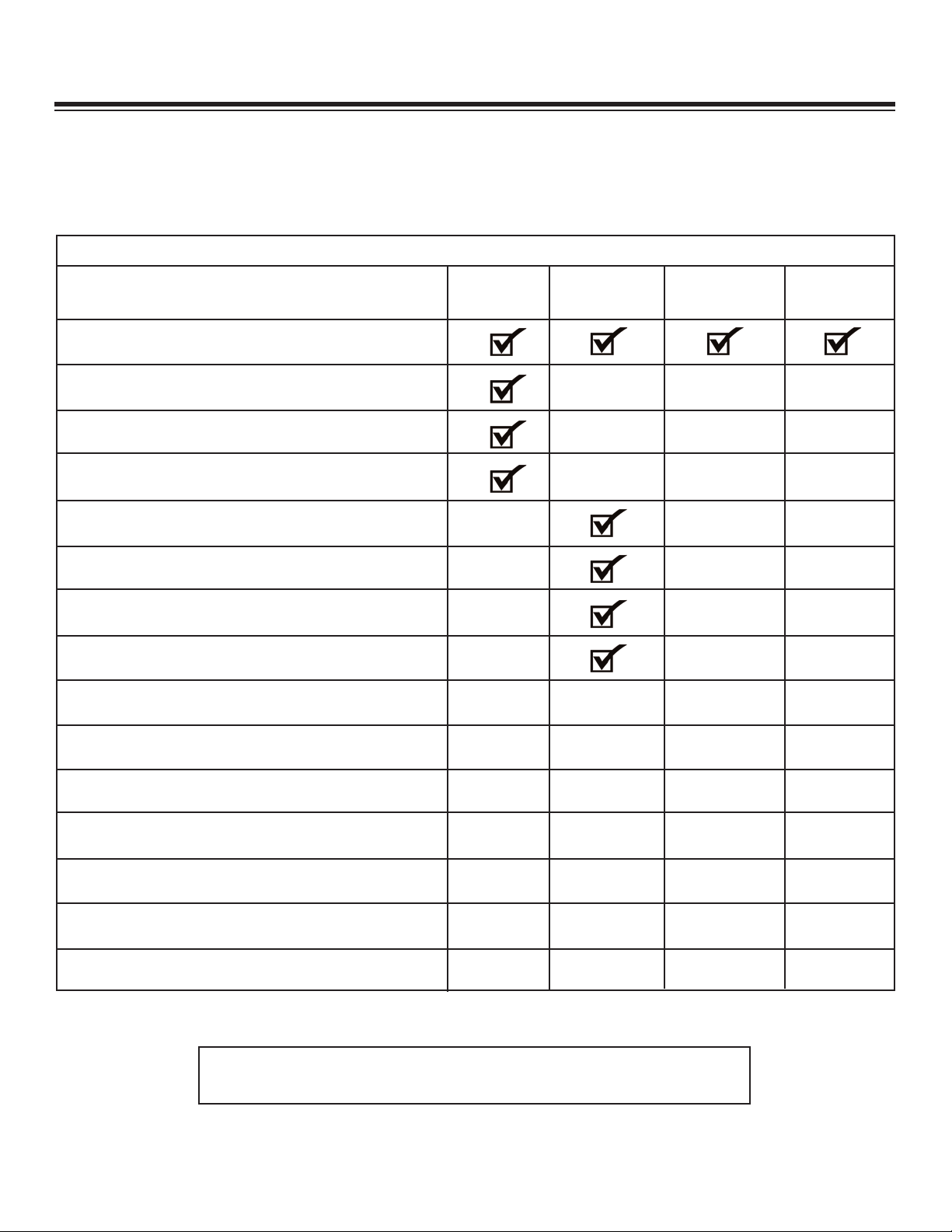

The following table is a list of routine maintenance items, including service intervals. Service

intervals are listed as hours, days, or weeks, whichever occurs first. American Eagle recommends

that these service intervals be followed. Before performing any maintenance function “Lock Out” or

“Tag Out” all sources of power. Be sure all air pressure in unit is relieved. Failure to do so may

result in injury or equipment damage.

Service Intervals

Maintenance operation Daily Weekly Monthly Hourly

Drain air tanks

Check crankcase oil level

Check fittings and airlines

Check hydraulic fluid level

Inspect and clean air intake filters

Clean and operate safety valves

Clean cooling fins on radiator/cooler

Inspect check valve

Replace Coalescering/Separator Cartridge

Inspect and clean compressor valves 6

Replace hydraulic filter 6

Replace air filters/oil filter/compressor oil 3

Tighten all fittings and fasteners 3

Check all electrical connections 3

Inspect and clean air check valve 250

Under normal operating conditions, oil changes are required every 3 months. When operating in a

dirty environment, change the oil more frequently as your particular operating condition dictates.

12

USE AE SYNTHETIC COMPRESSOR OIL P/N C0087.

COMPRESSOR CRANKCASE CAPACITY IS 4 QUARTS.

General preventative maintenance includes maintaining proper fluid level in both systems and the

general cleanliness of the equipment. Proper fluids according to the specifications are required.

SRS-65 Manual

6

Page 8

SRS-65 Oil Level

The oil level in the oil receiver container is an important factor for the operational reliability of the system.

Check Intervals:

1. Before starting unit.

2. Every 100 operating hours

Check Procedures:

1. Switch off the unit with main power and prevent it from accidentally being turned on.

2. Allow one full minute to pass after stopping compressor.

3. Unscrew the cap of the inlet connection pipe with the oil receiver discharged.

4. Check the oil level with the dipstick.

5. Add oil to level if necessary.

6. Tighten cap back into place and unit is ready to be put into service

7. Check for impermeability and replace the o-ring if required.

Note:

• The screw-type cap of the compressor crankcase is equipped with a pressure release hole, which

emits air/oil if the pressure has not been alleviated from the separator receiver. In this case wait a few

minutes for the pressure to release before removing cap totally.

• The oil fill is designed in such a way that the unit cannot be over filled. Any excess oil runs out the fill.

Condensation Drain

The condensation in the oil affects the operation safety and the life of the screw compressor unit.

If you operate the screw compressor unit for a short period of time and therefore at a low operation

temperature, i.e. below the switch temperature of the thermal oil bypass valve, you run the risk of

condensation collecting in the oil separator receiver. The relative humidity in the intake air determines the

quantity of condensation.

Possible Malfunctions:

• Insufficient compressor lubrication.

• Insufficient air/oil separation and high differential pressure in the purifier cartridge.

• Corrosion and rust formation due to condensation in the oil.

Drain the condensation regularly when the compressor unit is cold prior to startup.

Maintenance Procedure:

1. Switch off the main power to the unit.

2. Slowly unscrew the oil fill cap.

3. Unscrew the oil drain plug carefully and place a container underneath.

4. Drain the condensation from the separator receiver until oil starts to come out. Then replace the drain

plug.

5. Fill separator receiver with oil up to maximum, then close oil fill.

6. Switch on compressor and run for 3 minutes.

7. Check oil level and fill if necessary.

8. Dispose of condensation in accordance with local and federal regulations.

SRS-65 Manual

7

Page 9

Changing the Oil

OIL FILL

OIL DRAIN

WARNING

You may change the unit oil only when the unit

has been stopped and completely discharged.

Note: Prior to changing the unit oil make sure the unit has an operating temperature 140-175°F

(60-80°C).

Maintenance Procedure:

1. Switch off the main power to the unit.

2. Slowly unscrew the oil fill cap.

3. Unscrew the oil drain plug carefully and place

a container underneath.

4. Drain the oil from the separator receiver until

oil stops draining out. Then replace the drain

plug.

5. Refill separator receiver with oil up to

maximum, then close oil fill.

6. Switch on compressor and run for 3 minutes.

7. Check oil level and fill if necessary. Oil

capacity is 5 quarts.

Oil Recommendation Oil Requirements

Screw compressors must be operated using the most

suitable oil for operation. The compressor manufacturer

must approve this oil for use. The oil must also be

suitable for use in unfavorable conditions such as:

contamination of the intake air by gases, solvent vapors,

exhaust gases, and high ambient temperature

conditions.

Suitable types and brands of oil may be specified on

request. Suitable screw compressor oils can be mineral

oils, synthetic oils, and biological degradable oils.

The substances and materials used in the compressor

such as seals must be taken into account when

selecting the types of oil. Corrosion or other material

degradation must not occur.

Important: Do not mix different types of oil.

Important: In the case of ambient temperatures close to

freezing, prevent the unit from freezing.

Pipeline Materials:

The oil used in screw compressors can degrade plastics

used in air pipelines.

High aging stability

High disperse capacity

Low emulsification tendency

Flash point: above 400°F/ 200°C

Pour-point: 5° below lowest ambient temperature

minimum

Minimum foaming

High corrosion protection

Hydraulic or turbine oil

Basic oil: solvate

Operating temperature: up to 230°F / 110°C

Viscosity class: ISO VG 68

Viscosity at 104°F / 40°C: ca. 42-50 mm2/s (cST)

SRS-65 Manual

8

Page 10

Oil Filter

Oil Filter

P/N 15323

SEPARATOR

CARTRIDGE

P/N 15324

AIR FILTER

P/ 15322

FILTER LID

The oil filter is located in front of the unit. Replace it after the first 50 hours of service.

Then replace it every 1000 hours of service after that (or as soon as differential pressure

is about 25 psig)

Maintenance procedure:

1. Switch off the main power to the unit. Fully relieve the unit

of pressure.

2. Slowly unscrew and remove the oil filter with an oil filter

wrench.

3. Grease the new filter gasket.

4. Before mounting the new filter hold it upright and fill it with

the same type of oil as the compressor crankcase.

5. Thread the new filter onto the compressor by hand without

any tools.

6. Run compressor for 3 minutes.

7. Check oil level and fill if necessary.

Separator Cartridge

The separator cartridge is disposable and is located on top of the filter support.

The cartridge has to be replaced at least once per year and at a maximum of 5000 operating hours. The pressure will

read above 14 psig. If intake air is often contaminated or the oil quality is poor, the cartridge will tend to clog earlier

and will need changed more often.

Maintenance Procedure:

1. Switch off the main power to the unit. Fully relieve the unit

of pressure.

2. Slowly unscrew and remove the cartridge with an oil filter

wrench.

3. Screw the new cartridge onto the filter support using only

your hands.

4. Write the date of change, and the operating hours on the

cartridge.

5. Check to make sure that the cartridge is tight.

6. Run compressor for 3 minutes.

7. Check cartridge to make sure it is tight.

Intake Filter

The air intake filter element shall be replaced every 100 hours of running time. The filter may require changing more

often if the air pollution level is higher.

Maintenance Procedure:

1. Switch off the main power to the unit. Protect the unit from

accidental re-start.

2. Open the filter lid and carefully remove dust and debris

from the intake tray.

3. Carefully remove old filter and clean or renew it.

• Clean the filter by knocking the filter against your hand.

• Clean the filter with compressed air.

4. Close filter lid.

5. Test run the compressor to ensure proper installation.

ATTENTION: Any dirt or debris that reaches the intake

will be ingested into the compressor and could cause

irreversible damage.

SRS-65 Manual

9

Page 11

Belt Tension

Force Applied

Belt Deflection

Span

ADJUSTING SCREW

LOCK NUT

Oil Cooler

NEW BELT

INSTALLATION TENSION: 98.0 lbf

TENSIONING FORCE: 6.8 lbf

BELT DEFLECTION: 9/64 in

SPAN LENGTH: 9.50 in

USED BELT

INSTALLATION TENSION: 65.4 lbf

TENSIONING FORCE: 4.8 lbf

BELT DEFLECTION: 9/64 in

SPAN LENGTH: 9.50 in

Minimum Pressure Valve

At the factory, the relief valve is set at 64psi. When servicing the screw compressor a check of the

minimum pressure may be necessary.

Minimum Pressure Readjustment Procedure:

1. Remove the locknut.

2. Turn the adjusting screw (turning the screw in

3. Tighten locknut in place.

For the operational safety of the unit clean the cooler regularly. Keep the cooling fins clean, this is

a must to achieve maximum cooling from your cooler. Adequate cooling will prolong the life of your

screw compressor. To clean your cooler use compressed air, steam jet, or a cleaning agent.

Maintenance Procedure:

1. Switch off the main power to the unit. Protect the

2. Remove cooler housing.

3. Clean and remove dirt.

4. Reassemble parts onto unit.

5. Check and fill oil level.

6. Test run the compressor to ensure proper

increases the pressure).

Hydraulic Oil Cooler/Compressor Oil Cooler

unit from accidental re-start.

a. Discharge unit.

b. Drain oil.

c. Remove cooler.

installation and recheck oil level.

SRS-65 Manual

10

Page 12

Installation

FAN

GND

CPRSR

SPD CTRL

PRESSURE

SWITCH

LINE

MOTOR

HYDRAULIC

MANIFOLD

COMPRESSOR (12V INPUT)

GROUND

SPEED CONTROL

C

B

A

C

B

A

COMPONENT INSTALLATION

This section pertains to the installation of the air compressor, PTO, pump and other related items.

The instructions are intended as a guide to assist you with particular installation. These instructions

will provide only general information.

Pump Assembly:

The pump assembly may either be installed

directly on the PTO or as an optional

method, may be driven by a driveline from

the PTO. Pump manufacturers provide

specific installation information for their

products and should be consulted if

questions arise.

Note: A Dual or Tandem

Hydraulic Pump is recommended when

additional hydraulically operated equipment are

added to the hydraulic system.

PTO Assembly:

Check with the PTO manufactures

representative for specific instructions

regarding your particular make, model, and

year of vehicle. As some trucks may require

modification of the transmission cross

member and the exhaust system, the

manufacturer’s instructions should be

followed to insure proper installation of the

PTO.

Electrical Connections:

From the air pressure switch there are two

(2) wires, red and black, running to the

outside of the compressor housing. Connect

the black wire to the vehicle frame or other

suitable ground. Mount a single throw

toggle switch in a convenient location and

connect the red wire from the compressor to

this switch. Connect the other switch

terminal to a fuse holder and then to a 12volt power supply. A third wire is required

from the air compressor switch when

connecting the speed control into the

system. (See drawing on next page)

Electric Speed Control:

An optional electric or electronic speed

control must be used to maintain proper

operating speed of the air compressor. The

engine speed control will automatically

increase from idle to preset speed when

engaged and decrease when disengaged.

Compressor Assembly:

Prepare the mounting location of the

compressor by locating and drilling four (4)

holes, 1/2” diameter as per the mounting

pattern of the air compressor base. Using

four (4) 3/8” x 1.25 GR-5 cap screws, 3/8”

flat washer, and 3/8” nyloc nut, secure the

compressor in place. The compressor is air

cooled, and must have a clean supply of

cooling air to the fan with minimum

restrictions. Adequate space must be

provided for proper circulation of air.

SRS-65 Manual

11

Page 13

BLACK WIRE

RED WIRE

(

NOT USED)

R

ED WIRE

(NOT USED)

SRS-65 Electrical Installation

USE THIS PORT FOR

THE TEMP GAUGE

PROBE

DO NOT ATTEMPT TO INSTALL

TEMPERATURE GAUGE INTO THIS

PORT. DAMAGE WILL RESULT!

Temperature Gauge Installation

SRS-65 Manual

12

Page 14

RETURN LINE

AIR DELIVERY

PRESSURE LINE

Component Installation Continued...

Hydraulic System:

The hydraulic system consists of the pump, oil reservoir, filters and hoses. Installed on the

compressor is a valve block assembly that controls the flow to the hydraulic motor. To this

block, a 1/2” high-pressure hose must be attached. This hose comes from the hydraulic pumps

pressure side. A 3/4” minimum low-pressure return line is connected to the oil cooler outlet and

is routed to the oil reservoir. American Eagle recommends a sufficient sized reservoir be

provided that includes the proper suction and return filters. The cooler on the compressor is

designed and sized to cool the air compressor efficiently. An auxiliary oil cooler is required

when additional hydraulically operated equipment are added to the hydraulic system. Pressure

on the return line exceeding 200 PSI can and will cause damage to the filter, cooler, and

components of the compressor hydraulic system.

Air System:

The airline is routed using a 3/4” (200 psi) air hose. This delivery line should be free

from all obstructions. When connecting to an air tank (American Eagle recommends a

minimum of a ten gallon air tank be installed to maintain proper operation of the air

compressor), a check valve must be installed.

General Install Note:

When installing any air compressor, good manufacturing processes should be used. It

is critical to allow for proper air circulation around the compressor assembly and all

heated air should be allowed to exhaust to the outside if the compressor is mounted in

an enclosed compartment. Maximum operating temperatures of the air compressor

should not be exceeded.

SRS-65 Manual

13

Page 15

Compressor Pressure Switch

Kick Out (Step 1)

Pressure Setting

Adjustment Screw

(145-150 psi)

Kick On (Step 2)

Pressure Setting

Adjustment Screw

(115-120 psi)

-

-

+

+

Note: Turning adjustment screws clockwise

increases psi settings. Turning adjustment screws

Location inside box of SRS Compressors

Pressure Setting Instructions:

1. Always set the kick out pressure setting first. 145 psi minimum/150 psi maximum.

2. After kick out pressure is set, adjust the kick on screw setting at 115 psi minimum/120 psi

maximum.

3. Cycle compressor to verify correct settings.

4. For questions about this procedure, please contact Stellar Customer Service (Page 1).

SRS-65 Manual

14

counterclockwise decreased psi settings.

Page 16

PN 30533

PN 30532

Typical Hydraulic Circuit for Single Stage Pump with

Multiple Components

Typical Hydraulic Circuit for Tandum (Two Part) Pump with

Multiple Components

SRS-65 Manual

15

Page 17

Typical Hydraulic Circuit for Compressor

COMPRESSOR

RETURN

PRESSURE

AUXILIARY

COOLER

SINGLE

HYDRAULIC

PUMP

SUCTION PORT

FILTER

FILTER SCREEN

HYDRAULIC

RESERVOIR

with Auxiliary Cooler

SRS-65 Manual

16

Page 18

77

74

7

2

63

73

1

61

62

63

64

8

21

44

49

51

34

33

34

32

3

1

45

46

47

11

19

27

28

25

7

24

23

22

40

29

30

10

9

8

71

8

13

12

14

6

11

20

18

19

5

50

53

34

11

48

39

38

35

7

68

43

15

70

67

66

41

55

56

59

58

57

2

4

3

15

16

17

42

60

65

57

36

37

54

34

52

76

64

69

75

26

.YTQNOITPIR

CSEDTR

APMETI

131028 BASE WLDMT CPRSR SRS65 1

229391 CPRSR SRS NK60-2 ROTORCOMP 1

317583 CAP SCR 10MMX30MM HHGR5 4

4

KCOL 83

.0 REHSA

W32

504

16

6 DHS RSRPC

LA KCOLB5703C

5

6 C0910 CAP SCR 0.25-20X2.75 HHGR5 2

70343 WASHER 0.31 USS FLAT ZINC 10

80333 NUT 0.25-20 HHGR5 NYLOC 5

1S-OLO5F 21-8 TPADA GTF0811C9

1S-LNF8 PAC277201

11 C2142 FTG ADAPT ML O'RING/ML 12-F5OLO-S 3

12 C4914 VALVE RELIEF CP-200-1-B-0-A-C 1

1DNLOS EVLAV3194C31

1GED 0

9 GTF5416C

41

15 22860 FTG ADAPT MBSPP/FNPT 1/2-1/2 F4OHG MOD 2

16 13579 NIPPLE 0.50X2.50 BRASS 80300-0825 1

18

-604

5 XE

H EPIP 05.0 PAC6582171

18 C0078 HOSE CLAMP #8 RUBBER COATED 1

19 0479 CAP SCR 0.25-20X0.75 HHGR5 5

20 21393 FTG BULKHEAD 12WGTX-WLN 1

156SRS MSA LIO RELOOC451031

2

1TNM NAF 56SRS DUORHS2301322

23 0485 CAP SCR 0.31-18X1.25 HHGR5 4

4K

COL 13.0 REH

SAW225042

25 5735 NUT SERT 0.31-18X0.50 OD 4

1

T

LOV 21 HSUP 00.61 NAF142862

.YTQNOITPIR

CSEDTR

APM

ETI

4KCOL 52.0 REHS

AW1

25072

28 19589 NUT SERT 0.25-20X0.38 OD 4

29 12122 BOLT 0.38X1.00 EYE 567-23-ZN 1

1HH

6

1-83. T

UN53500

3

31 21400 FTG SWIVEL NUT/MSTR .50 8F65OX 1

32 21299 FTG ADAPT MBSPP/MJIC 8-8M40M 1

33 22018 VALVE THERMO R-2323 SRS40 1

34 21297 FTG 90 MBSPP/MJIC 8-8C4MX 4

156SRS TNM ROTOM TKRB7660353

1

M

M53 X H GNIHSUB240136

3

37 34538 SPROKET GOODYEAR EAGLE PD Y-36S-H 1

100

.1 GNI

HSUB8816C

83

39 34539 SPROKET GOODYEAR EAGLE PD Y-90S-QD 1

40 31043 BELT GOODYEAR EAGLE PD Y1000 1

41 31035 MOTOR HYD PLM3022SO-33S5-LOD/OF-N-C 1

1OLO5F 61-21 TPADA GTF9622C24

43 7351 FTG ST TH ELBOW 45 DEG 12V5OLO 1

44 C4498 FTG ORB/JIC STRT CONNT 12-F5OX-S 1

45 4594 FTG STRGHT THRD CONNECT 8F5OX 1

46 4593 FTG SWIVEL NUT TEE 8R6X 1

47 33715 HOSE 0.75(381-JC-J9-12-12-12-13.00) 1

48 33716 HOSE 0.75(381-JC-JC-12-12-12-14.00) 1

49 33691 TUBE ASM 0.75 COOLER/MANIFOLD SRS65 1

50 33692 TUBE ASM 0.75 AIR/BULKHEAD SRS65 1

51 33693 TUBE ASM 0.50 COOLER/THERMVLV SRS65 1

52 33694 TUBE ASM 0.50 CPRSR/COOLER SRS65 1

.YTQ

NO

ITPIRCSEDTRAPMETI

53 33695 TUBE ASM 0.50 CPRSR/THERMVLV SRS65 1

54 21300 FTG 90 MJIC/MBSPP 12-8C40M 1

55 C0863 SWITCH PRES COMPRESSOR 1

56 8277 FTG ST L 0.25 MNPT/0.125 FNPT SPL 1

57 C6245 ELBOW 0.25 OD BRASS AIR 2

58 8158 NIPPLE 0.25 X CLOSE BRASS 1

59 21298 FTG ADAPT MBSPP/FNPT 1/4-1/4 F4OHG 1

60 21549 PANEL GAUGE MNT SRS40 1

61 21649 GAUGE AIR SWICHGAGE PSB20PHL200 1

62 21650 GAUGE OIL TEMP TSB20TVD3006125SR240 1

63 C6021 CAP SCR 0.25-20X0.75 BTNHD SS 8

6TALF 52.0 REHSAW043046

1

S

SARB 31.0 RELPUOC161225

6

66 5419 FTG 0.50-0.25 BUSH RED BRASS 1

1#002 FEILER EVLAV4055C76

68 26025 CAP SCR 0.50-13X2.25 HHGR5 2

69 0352 WASHER 0.50 USS FLAT ZINC 4

70 C6106 NUT 0.50-13 HHGR5 NYLOC 2

71 4591 PLUG STR HOLLOW HEX 0.75 12-HP5ON 1

156SRS MSA DU

ORHS224132

7

73 19592 WASHER 0.25 FLAT NYLON 6

256-SRS LACED408947

75 31030 ANGLE MNT FRONT CPRSR SRS65 1

76 0480 CAP SCR 0.25-20X1.00 HHGR5 2

2COLYN HH 81-13.0 TUN243077

78 C6072 BOSCH RELAY 1

79 19590 WIRING HARNESS 1

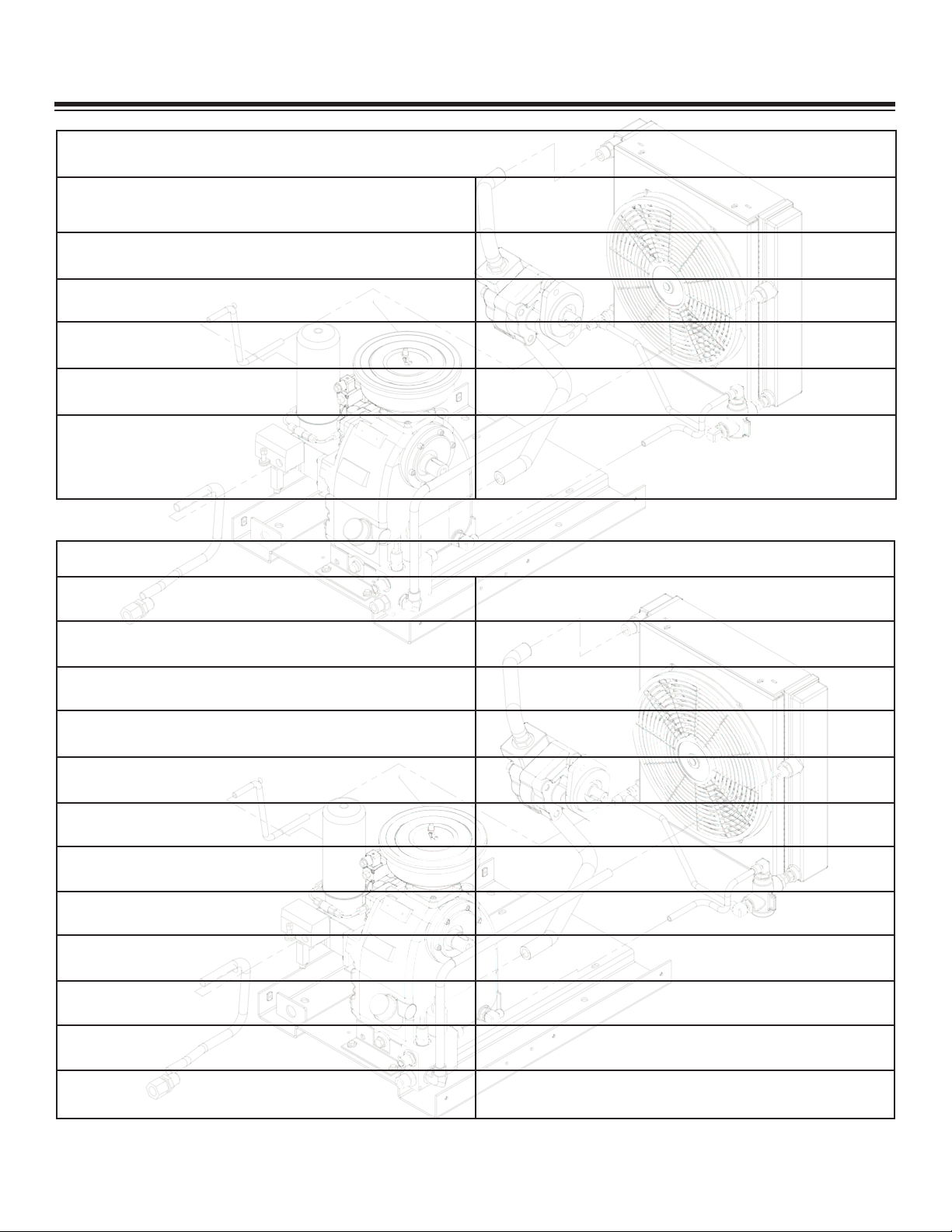

Assembly Drawings

Compressor Assembly

SRS-65 Manual

17

Page 19

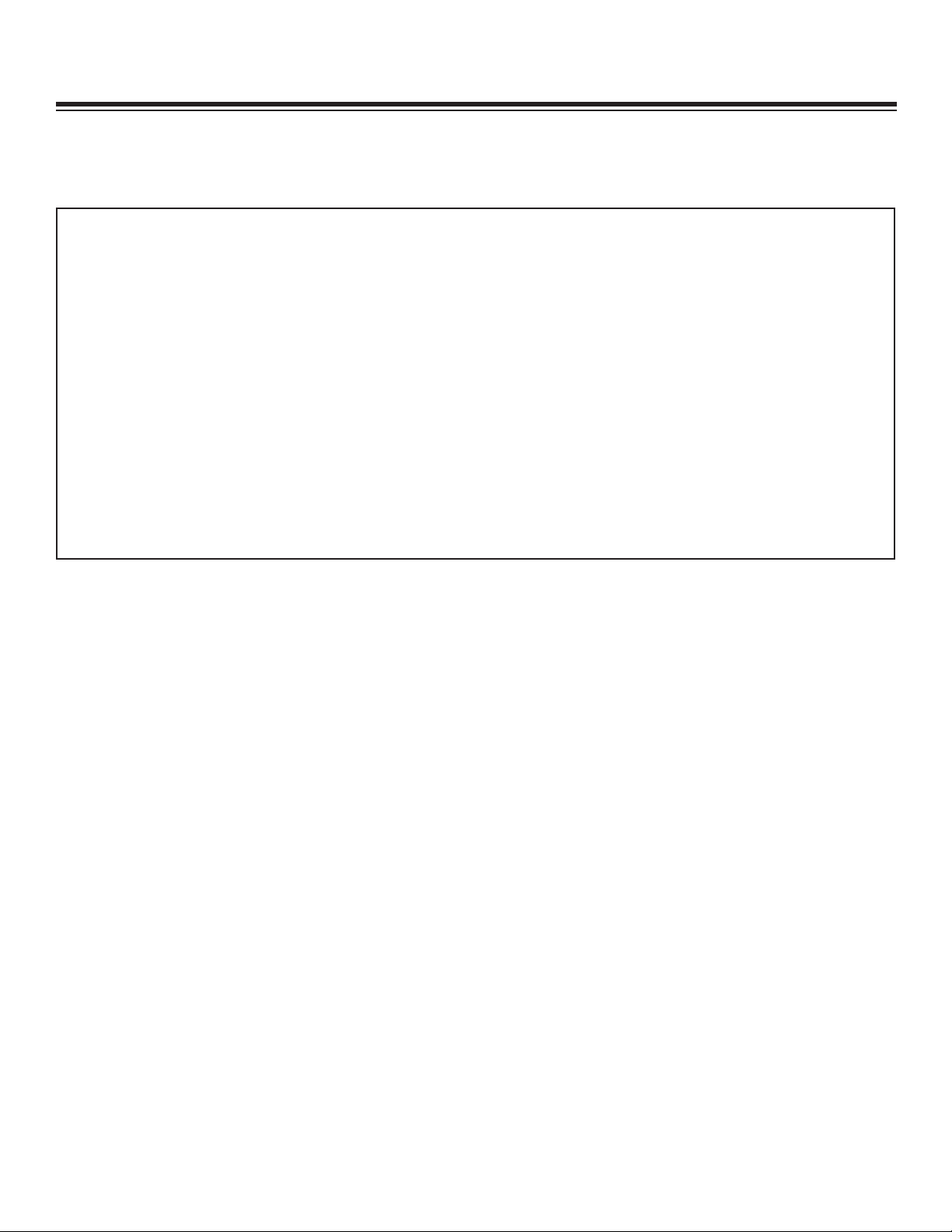

SRS-65 Tube Routing

SRS-65 Manual

18

Page 20

Replacement Parts

HYDRAULIC COMPONENTS/DRIVE PARTS

PART# DESCRIPTION

C4914 Relief Valve

C4913 Solenoid Valve

31035 Hydraulic Motor

34539 Sprocket (Hyd Motor)

34538 Sprocket (Compressor)

C6188 Bushing (Hyd Motor)

31043 Belt

30154 Oil Cooler

C3075 Aluminum Manifold Block

33692 Tube Assembly Air/Bulkhead 0.75

33691 Tube Assembly Cooler/Manifold 0.75

33693 Tube Assembly Cooler/Thermo-Valve 0.50

33694 Tube Assembly Compressor/Cooler 0.50

33695 Tube Assembly Compressor/Thermo-Valve 0.50

22018 Thermo Valve

ELECTRICAL/AIR PRESSURE COMPONENT

PART# DESCRIPTION

C0863 Pressure Switch

8241 Fan 16.00” Pull 12 Volt

C6072 Bosch Relay

19590 Wire Harness

21649 Air Switch Gauge

21650 Oil Temperature Gauge

C5504 Valve Relief 200 # (Air)

AIR/OIL FILTER COMPONENTS

PART# DESCRIPTION

15322 Air Filter

15323 Oil Filter

15324 Coalescering Filter (Separator Cartridge)

C0087 Synthetic Compressor Oil

33147 SRS65 Compressor Service Kit (Includes all items above)

COMPRESSOR COMPONENTS

PART# DESCRIPTION

NA Inlet Solenoid Control Valve

NA Inlet Solenoid Control Valve Assembly Complete

NA Shaft Seal Kit

NA Shaft Bearing Kit

NA Solenoid 24 Volt DC

29391 Compressor (Air End)

NA Separator Head Maintenance Kit

SRS-65 Manual

19

Page 21

Troubleshooting

If symptoms of poor performance develop, the following chart can be used as a guide to investigate

and correct the problem. When diagnosing faults in operations of the air compressor, always check

that the hydraulic power source is supplying the correct hydraulic flow and pressure that is listed in

the compressor specification section of this manual.

Problem

Compressor shuts down

with air demand:

Compressor will not build

up pressure:

Possible Cause

Compressor temperature.

Low oil level.

Fan not operating.

Plugged oil filter.

Dirty cooler core.

Contaminated cooler core.

Hydraulic pressure and flow incorrect.

Worn hydraulic motor.

Air demand too great.

Air filter plugged.

Pressure switch out of adjustment

Solution

Add compressor oil to level.

Check ground wire and fan switch/relay.

Replace filter.

Clean cooler fins.

Remove and clean.

Adjust and reset according to specifications.

Replace.

Tighten air hose clamps. Repair air leaks.

Clean or replace.

Readjust to specifications.

Compressor over

pressures:

Faulty pressure switch.

Compressor speed too slow.

Drive belt slipping.

Service valve wide open.

Solenoid valve on.

Hyd. manifold valve stuck (closed).

Defective pressure switch.

Air control line leaking.

Inlet valve stuck.

Restriction in control line (dirt/ice).

SRS-65 Manual

20

Replace.

Check hydraulic flow and pressure.

Readjust and tighten.

Close valve.

Clean or replace.

Replace.

Check and correct.

Clean and replace.

Clean and free up.

Page 22

Problem

Possible Cause

Solution

Compressor Stalls:

Belt Slipping.

Insufficient hydraulic system pressure

or flow.

*This can occur if another

hydraulically activated component is

used off the same pump system.

Activating the secondary component

may drop hydraulic supply system

pressure/flow and leave insufficient

for compressor. Not: Even a

momentary drop in hydraulic supply

pressure or flow may initiate

compressor blowdown to commence.

Pressure relief set too low.

Pressure relief seals leaking.

Air pressure set to high for hydraulic

system.

Solenoid valve cartridge seals leaking

on hydraulic manifold assembly.

Readjust and tighten.

Check the following:

1. Setting on supply pressure system relief

valve.

2. Ensure adequate pressure and flow.

3. Check and see if other hydraulic system’s

activated off same hydraulic supply.

Readjust.

Replace.

Adjust pressure switch to reduce air pressure.

Replace with new cartridge.

Compressor noisy or loud

when starting compressor

in cold weather:

Compressor synthetic oil

has a milky appearance:

Excessive oil level in

compressor:

Hydraulic reservoir low on oil.

ICE buildup inside compressor from

condensation.

Coalescering/Separator cartridge

clogged or plugged.

Internal crack inside oil cooler.

Add to level.

Engage PTO and allow hydraulic fluid to

circulate and warm system up before engaging

compressor.

Replace cartridge and change compressor oil.

Replace cooler, change filters and compressor

oil.

SRS-65 Manual

21

Page 23

Limited Warranty Statement

®

American Eagle warrants products designed and manufactured by Stellar to be free from defects in material and workmanship under proper use

and maintenance. Products must be installed and operated in accordance with Stellar’s written instructions and capacities. The warranty period

shall cover the following:

Twelve (12) month warranty on parts and

Twelve (12) month repair labor

The warranty period shall begin from the date recorded by American Eagle as the in-service date. This date will be derived from the completed

warranty registration card. In the event a warranty registration card is not received by American Eagle, the factory ship date will be used. New

compressors will be issued on all returns within 90 days of this factory ship date. After 90 days, American Eagle reserves the right to issue

remanufactured compressors. Regardless of in-service date, warranty coverage does not extend beyond twenty-four (24) months from date of

manufacture.

American Eagle’s obligation under this warranty is limited to, and the sole remedy for any such defect shall be, the repair and/or replacement (at

American Eagle’s option) of the unaltered part and/or component in question. American Eagle after-sales service personnel must be notified by

telephone, fax, or letter of any warranty-applicable damage within fourteen (14) days of its occurrence. If at all possible, American Eagle will ship

the replacement part within 24-hours of notification by the most economical, yet expedient, means possible. Expedited freight delivery will be at

the expense of the owner.

Warranty claims must be submitted and shall be processed in accordance with American Eagle’s established warranty claim procedure. American

Eagle after-sales service personnel must be contacted prior to any warranty claim. A return materials authorization (RMA) account number must

be issued to the claiming party prior to the return of any warranty parts. Parts returned without prior authorization will not be recognized for

warranty consideration. All damaged parts must be returned to American Eagle freight prepaid; freight collect returns will be refused. Freight

reimbursement of returned parts will be considered as part of the warranty claim.

Warranty service will be performed by any American Eagle new equipment distributor, or by any American Eagle-recognized service center

authorized to service the type of product involved, or by the American Eagle factory in the event of a direct sale. At the time of requesting

warranty service, the owner must present evidence of date of delivery of the product. The owner shall be obligated to pay for any overtime labor

requested of the servicing company by the owner, any field service call charges, and any towing and/or transportation charges associated with

moving the equipment to the designated repair/service provider.

All obligations of American Eagle and its authorized dealers and service providers shall be voided if someone other than an authorized American

Eagle dealer provides other than routine maintenance service without prior written approval from American Eagle. In the case repair work is

performed on a American Eagle-manufactured product, original American Eagle parts must be used to keep the warranty in force. The warranty

may also be voided if the product is modified or altered in any way not approved, in writing, by American Eagle.

The owner/operator is responsible for furnishing proof of the date of original purchase of the American Eagle product in question. Warranty

registration is the ultimate responsibility of the owner and may be accomplished by the completion and return of the American Eagle product

registration card provided with the product. If the owner is not sure of registration, he is encouraged to contact American Eagle at the address

below to confirm registration of the product in question. This warranty covers only defective material and workmanship. It does not cover

depreciation or damage caused by normal wear and tear, accident, mishap, untrained operators, or improper or unintended use. The owner has

the obligation of performing routine care and maintenance duties as stated in American Eagle’s written instructions, recommendations, and

specifications. Any damage resulting from owner/operator failure to perform such duties shall void the coverage of this warranty. The owner will

pay the cost of labor and supplies associated with routine maintenance.

The only remedies the owner has in connection with the breach or performance of any warranty on the American Eagle product specified are

those set above. In no event will American Eagle, the American Eagle distributor/dealer, or any company affiliated with American Eagle be liable

for business interruptions, costs of delay, or for any special, indirect, incidental, or consequential costs or damages. Such costs may include, but

are not limited to, loss of time, loss of revenue, loss of use, wages, salaries, commissions, lodging, meals, towing, hydraulic fluid, or any other

incidental cost.

All products purchased by American Eagle from outside vendors shall be covered by the warranty offered by that respective manufacturer only.

American Eagle does not participate in, or obligate itself to, any such warranty.

American Eagle reserves the right to make changes in design or improvement upon its products without imposing upon itself the same upon its

products theretofore manufactured.

This warranty will apply to all American Eagle Drawer Sets and Compressed Air Systems shipped from American Eagle’s factory after July 1,

2005. The warranty is for the use of the original owner only and is not transferable without prior written permission from American Eagle.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. REMEDIES UNDER THIS WARRANTY ARE LIMITED TO THE

PROVISION OF MATERIAL AND SERVICES, AS SPECIFIED HEREIN. AMERICAN EAGLE INDUSTRIES, INC. IS NOT RESPONSIBLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Revision Date: March 2006 Document Number: 37042

Page 24

Page 25

Loading...

Loading...