Page 1

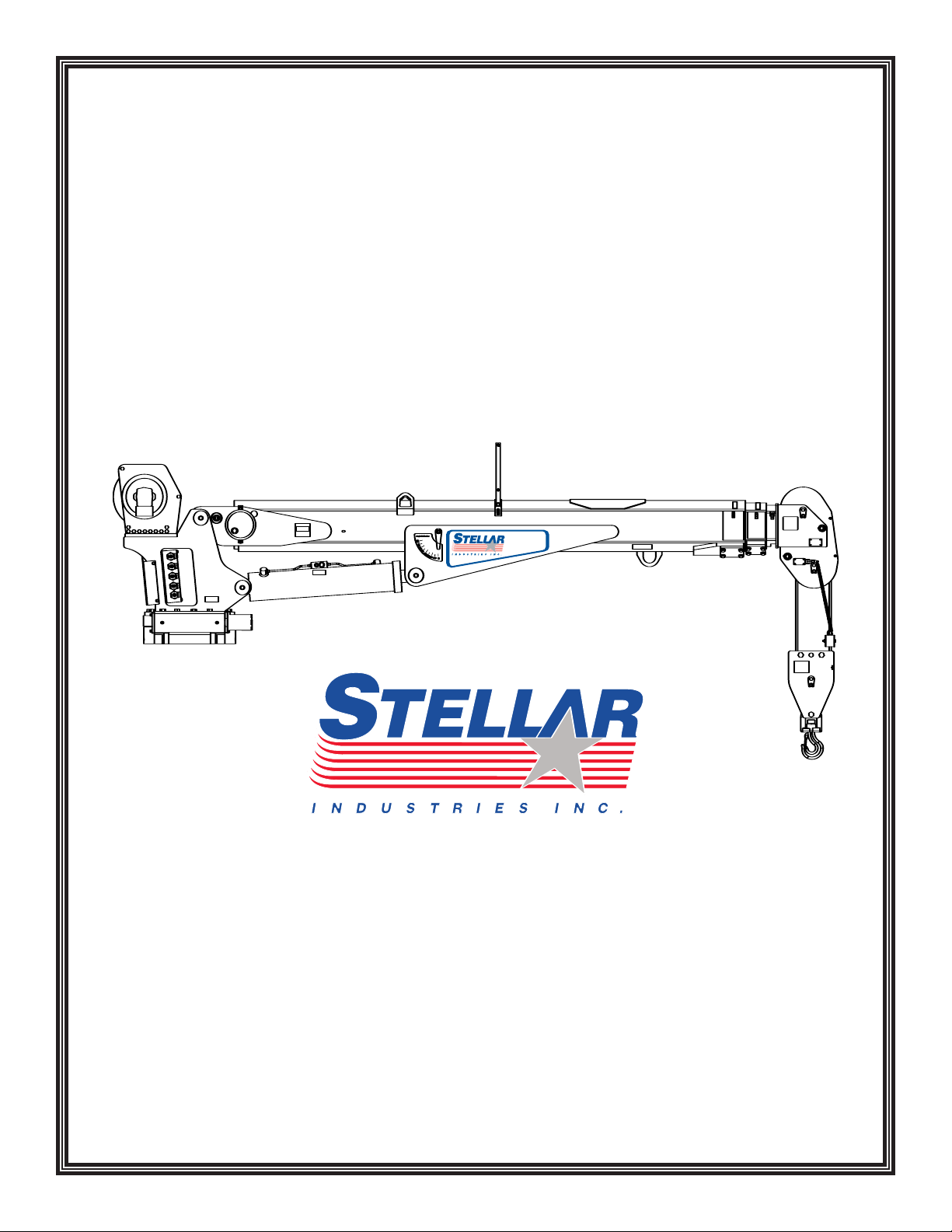

27164

14528

®

OWNER’S MANUAL

Safety, Installation, Maintenance, and Operation

14528 Telescopic Crane

Subject to Change without Notification.

© 2007 Stellar Industries, Inc.

Stellar Industries, Inc.

190 State Street

PO Box 169

Garner, IA 50438

800-321-3741

Fax: 641-923-2811

www.stellarindustries.com

Manual Part No. 31713

Last Revision: 1/11/08

Page 2

14528 Manual Revisions

Date of Revision

September 1, 2005

September 19, 2005

September 9, 2006

November 7, 2006

April 12, 2007

April 30, 2007

June 15, 2007

October 31, 2007

Section Revised

Chapter 7:

Assembly Drawings

Chapter 7:

Assembly Drawings

Chapter 7:

Assembly Drawings

Chapter 7:

Assembly Drawings

Chapter 8:

Hydraulics-Electrical

Chapter 5: Decals

Chapter 7:

Assembly Drawings

Chapter 7:

Assembly Drawings

Chapter 7:

Assembly Drawings

Chapter 8:

Hydraulics-Electrical

Description of Revision

Updated Main Boom and Extension Boom drawings to

reflect engineering changes.

Updated Cable and Hook assembly drawings to reflect

engineering changes.

Updated Cable and Hook assembly drawings to reflect

engineering changes.

Updated Base assembly drawings and Hydraulic

schematics to reflect engineering changes

Updated Decal Kit.

Updated Extension Cylinder assembly drawing to reflect

engineering changes

Updated Main Cylinder assembly drawing to reflect

engineering changes

Updated Mast, Main Boom, Extension Boom, and Control

Kit drawings to reflect engineering changes.

Page 3

Table of Contents i

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Chapter 1 - Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

C

rane Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2 - Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unit Operation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

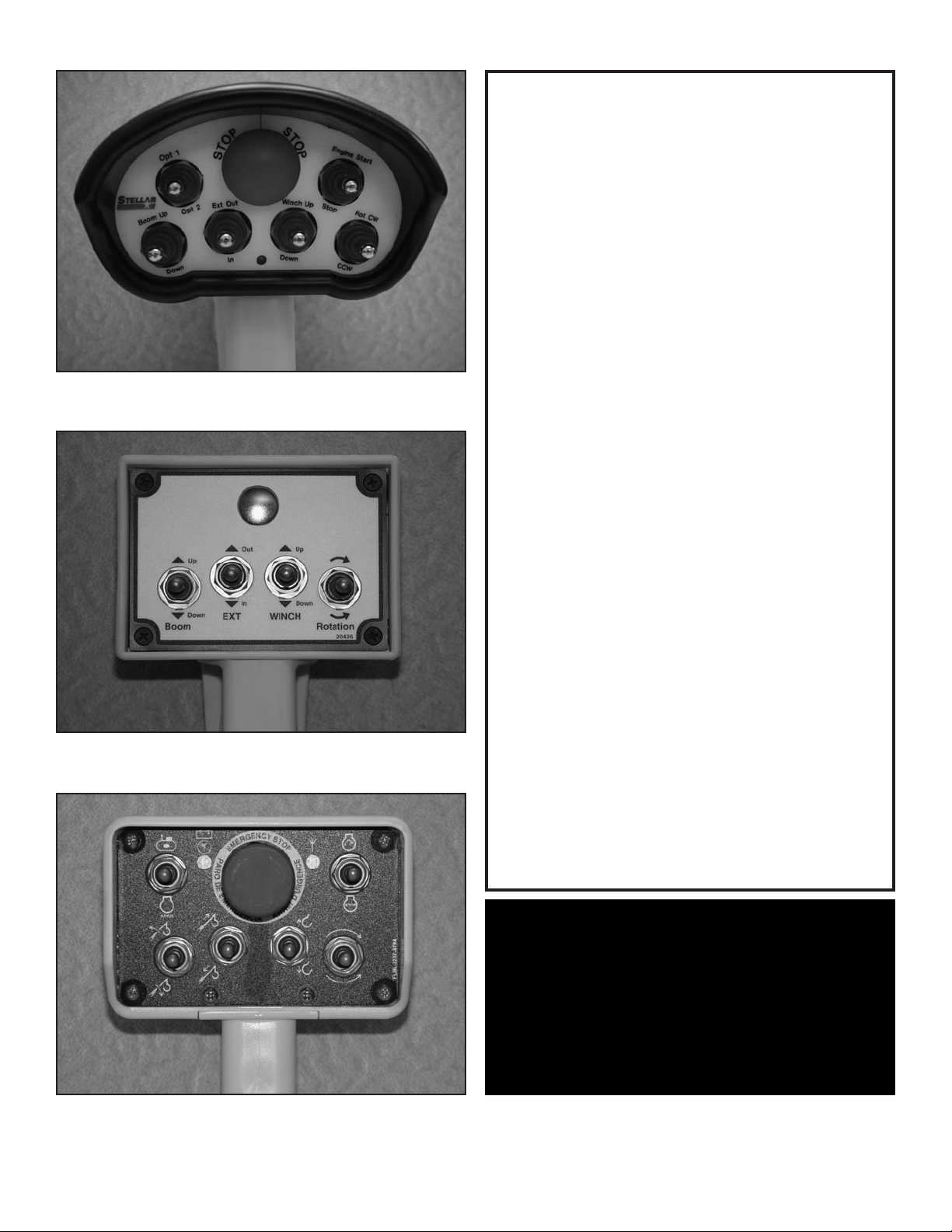

6 Function Hetronic Remote. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operator Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 3 - Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lubrication Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wire Rope Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Torque Data Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Inspection Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Daily Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Monthly Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Quarterly Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Annual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Inspection Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 4 - Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Capacity Chart - Decal PN 26204 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Chapter 5 - Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Decals of Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Decal Kit Placement - PN 27162 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 6 - Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

General Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installation Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installation Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Stability Pr

Stability Capacity Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chapter 7 - Assembly Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Base Assembly - PN 26205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Mast Assembly - PN 41903. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Main Boom - PN 41902 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Extension Boom Assembly - PN 26757

Main Cylinder Assembly - PN 26197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Extension Cylinder Assembly - PN 26756 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Cable & Hook Assembly - PN 26760 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Wire Rope/Sheave Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Chapter 8 - Hydraulics - Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Control Kit - PN 41654 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Wiring Harness - PN 41655 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Hydraulic Kit - PN 26771. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Valve Bank - PN 26209 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Hydraulic Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 9 - Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 10 - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6 Function Hetronic Radio Remote Troubleshooting. . . . . . . . . . . . . . . . . . 53

Transmitter Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Receiver Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4 & 7 Function Hetronic Radio Remote Troubleshooting . . . . . . . . . . . . . . 55

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

ocedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38

Page 4

ii 14528 Owner’s Manual

Introduction

Stellar Cranes are designed to provide safe

and dependable service for a variety of

operations. With proper use and

maintenance, these cranes will operate at

peak performance for many years.

To promote this longevity, carefully study the

information contained in this manual before

putting the equipment into service. Though

it is not intended to be a training manual for

beginners, this manual should provide solid

guidelines for the safe and proper usage of

the crane.

Once you feel comfortable with the

material contained in this manual, strive to

exercise your knowledge as you safely

operate and maintain the crane. This

process is vital to the proper use of the unit.

A few notes on this manual:

A copy of this manual is provided with every

crane and shall remain with the crane at all

times. Information contained within this

manual does not cover all maintenance,

operating, or repair instructions pertinent to

all possible situations.

Please be aware that some sections of this

manual contain information pertaining to

Stellar manufactured cranes in general and

may or may not apply to your specific

model.

This manual is not binding. Stellar Industries,

Inc. reserves the right to change, at any

time, any or all of the items, components,

and parts deemed necessary for product

improvement or commercial/production

purposes. This right is kept with no

requirement or obligation for immediate

mandatory updating of this manual.

In closing:

If more information is required or technical

assistance is needed, or if you feel that any

part of this manual is unclear or incorrect,

please contact the Stellar Customer Service

Department by phone at 800-321-3741 or

email at service@stellarindustries.com.

ATTENTION

Failure to adhere to the

instructions could result in

property damage or even serious

bodily injury to the operator or

others close to the crane.

For Technical Questions, Information, Parts, or Warranty, Call Toll-Free at

800-321-3741

Hours: Monday - Friday, 8:00 a.m. - 5:00 p.m. CST

Or email at the following addresses:

Technical Questions, and Information service@stellarindustries.com

Order Parts parts@stellarindustries.com

Warranty Information warranty@stellarindustries.com

Page 5

Chapter 1 - Safety

Safety 1

Please Read the Following Carefully! This

portion of the manual contains information

regarding all Stellar manufactured cranes.

Some items contained within this chapter

may not apply to your specific equipment.

Safety should be the number one thought

on every operator’s mind. Three factors

should exist for safe operation: a qualified

operator, well-maintained equipment, and

the proper use of this equipment. The

following information should be read and

understood completely by everyone

working with or near the crane before

putting the unit into operation.

Please take note that Stellar Industries, Inc.

is not liable for accidents incurred by the

crane because of non-fulfillment from the

operator’s side of current rules, laws, and

regulations.

GENERAL

It is the responsibility of the owner to instruct

the operator in the safe operation of your

equipment and to provide the operator with

properly maintained equipment.

Do not wear rings, wristwatch, jewelry, loosefitting or hanging clothing such as ties, torn

garments, scarves, unbuttoned jackets or

unzipped overalls, which could get caught up

in the moving parts of the crane.

Keep a first-aid box and a fire extinguisher

readily available on the truck. Regularly

check to make sure the fire extinguisher is fully

charged and the first-aid kit is stocked.

Do not use controls and hoses as handholds.

These parts move and cannot provide stable

support.

Never allow anyone to ride the crane hook or

load.

MAINTENANCE SAFETY

Never modify or alter any of the equipment,

whether mechanical, electrical, or hydraulic,

without explicit approval from Stellar Industries.

Do not perform any maintenance or repair

work on the crane unless authorized and

trained to do so.

Trainees or untrained persons shall be under

the direct supervision of qualified persons.

Do not operate equipment under the adverse

influence of alcohol, drugs, or medication.

PERSONAL SAFETY

Keep clear of all moving parts.

Always wear the prescribed personal safety

devices.

Always wear approved accident-prevention

clothing such as: protective helmets, anti-slip

shoes with steel toes, protective gloves, antinoise headphones, protective glasses, and

reflective jackets with breathing apparatus.

Consult your employer r

safety r

equipment.

egulations and accident-pr

egarding current

evention

Release system pr

make any adjustments or repairs.

Do not attempt service or repair when the PTO

is engaged.

Failure to correctly plumb and wire the crane

can cause a malfunction and damage to the

crane and/or operator

Decals are considered safety equipment.

They must be maintained, as would other

safety devices. Do not remove any Decals.

Replace any Decals that are missing,

damaged, or not legible.

The safety instruction plates, notices, load

charts and any other sticker applied to the

crane or service body must be kept legible

and in good condition. If necessary, r

them.

essure before attempting to

.

eplace

Page 6

2 14528 Owner’s Manual

STABILITY

Know the crane components and their

capabilities and limitations. Overloading the

crane may result in serious injury to self and

others, and damage to the equipment and

immediate surroundings.

Never exceed manufacturer’s load ratings.

These ratings are based on the machine’s

hydraulic, mechanical, and structural design

rather than stability.

The supporting surface under the service truck

must be able to support the weight of the

machine and its load. Use outrigger pads if

necessary.

Park the vehicle on level ground and extend

the outriggers fully out and then down.

Keep feet and legs clear when lowering

outrigger jacks.

Never operate the crane without making sure

the outriggers ar

ground.

Set the parking brake and disengage the

drive axle before attempting a lift.

LOAD SAFETY

Operate the crane in compliance with the

load capacity chart at all times. Know the

weight of the load being lifted. Do not r

the overload device to determine maximum

rated loads. If the crane is picking more than

the maximum rated load, the overlor

protection device may be malfunctioning.

Discontinue use immediately and contact

Stellar Customer Service for support.

Never use a sling bar or anything larger than

the hook throat that could prevent the hook

latch fr

safety feature.

Do not apply side loads to the booms.

om closing. This would negate the

e positioned on stable, flat

ely on

d

Do not walk under suspended loads.

Do not position any load over a person nor

should any person be permitted to place him

or herself under a load.

Do not use the boom or the winch to drag a

load.

Do not use the crane boom to push

downward onto anything.

ELECTROCUTION

Allow extra space for swaying power lines in

windy conditions.

Keep a minimum of ten feet between any

portion of the crane and an electrical line.

Add an additional 12" for every additional

30,000 Volts or less.

Remember - Death or serious injury can occur

when working near power lines or during

electrical storms.

Use a signal person when operating near

electrical sources.

ENVIRONMENT

Do not operate the crane during electrical

storms.

In extreme cold, allow adequate time to

m the truck before engaging the PTO. Do

war

not rev the truck engine and over speed the

hydraulic pumps as permanent damage to

the pumps may occur

owner’s manual regarding operating the

vehicle in such adverse conditions.

In dusty work ar

to keep dust and sand out of the moving parts

of the machinery.

In high humidity work areas, keep parts as dry

as possible and well lubricated.

eas, every effort must be taken

. Follow the vehicle

Do not leave a crane load suspended or

unattended.

Page 7

Safety 3

Crane Controls

1. Be familiar with the sequence and

operation of the crane controls.

2. Each individual crane function should

have control function decals. Replace

them immediately if they are missing or

illegible.

3. Keep hands, feet, and control levers

free from mud, grease, and oil.

4. Be familiar with the remote control and

how it operates before attempting to

lift a load.

5. Be prepared before beginning

operation of the crane:

• All protective guards must be in

place.

Be aware of the surroundings: low

•

branches, power lines, unstable

ground.

• Be sure all safety devices provided are

in place and in good operating

condition.

• Be prepared for all situations. Keep

fire extinguisher and first aid kit near.

• Be sure all regular maintenance has

been performed.

• Visually inspect all aspects of the

crane for physical damage.

• Check for fluid leaks.

• Make sure the outriggers are down

and stable.

Be familiar with your remote control and

how it works befor

e operating the crane.

ATTENTION

Stellar Industries, Inc. is not liable

for accidents incurred by the

crane because of the operator’s

non-fulfillment of current rules,

laws and regulations.

Page 8

4 14528 Owner’s Manual

Page 9

Chapter 2 - Operation

Operation 5

This chapter contains information regarding

the operation of Stellar manufactured

telescopic cranes. Please study the

following pages to ensure your familiarity

with the operation process. This

understanding is vital to the safe and

efficient operation of the crane.

Job-Site Set-Up

Thoroughly plan the lift before positioning

the vehicle. Consider the following:

1. The vehicle should be positioned in an

area free from overhead obstructions to

eliminate the need for repositioning.

2. Position the vehicle so that it is impossible

for any portion of the equipment to come

within the minimum required safe distance

of any power line. Maintain a clearance

of at least 10 feet between any part of

the crane, load line, or load, and any

electrical line or apparatus carrying up to

50,000 volts. One foot additional

clearance is required for every additional

30,000 volts or less. Remember to allow

for winds that cause power lines to sway.

It is recommended that a signal person

be used when the vehicle is set-up near

power lines.

3. The vehicle should also be positioned on

a firm and level surface that will provide

adequate support for the outrigger

loading. Use extreme caution when

setting up near over

excavations.

4. The parking brake must be set on the

vehicle and the drive axle disengaged

before performing a crane operation.

5. The outriggers must be extended to

stabilize the truck before beginning

operation.

hanging banks or

Unit Operation Overview

1. Engage the PTO

2. Turn on Power to Crane

. Position Outriggers

3

4. Operate Crane

5. Store Outriggers

6. Turn Off Power to Crane

7. Disengage the PTO

1. Engage the PTO

A. Engage the parking

brake.

B. Place the

transmission in the

Neutral position.

C. Make certain the

PTO switch is in the

‘off’ position.

D. Start the vehicle engine.

E. Depress the clutch on manual

transmission vehicles.

F. Engage the PTO switch for cable and air

type shifters. Turn on the dash switch for

electrical operated style. Consult vehicle

owner’s manual for location and

operation of OEM style in-dash PTO

switch.

G. Slowly release the clutch on a manual

transmission vehicle.

H. Allow a few moments to warm the

hydraulic system oil. In cold weather, it is

especially important to let the system run

for a few minutes befor

2. Turn on Power to Crane

Activate power to the crane and

outriggers. The power switch is located on

the control panel in the vehicle cab.

3. Position Outriggers

Once the PTO is engaged, extend the

outriggers using the control levers or

switches marked ‘outrigger’. These may be

located on the crane base or in the

compartment under the crane.

PTO Switch

e operating.

Page 10

6 14528 Owner’s Manual

6 Function Hetronic Remote

4.Operate Crane

A. Turn on necessary power to the crane.

B. Activate toggle switch for desired crane

function.

D. Activate the variable speed trigger to

control the desired function.

E. When operation is complete, store

remote handle in a safe, dry location.

5. Store Outriggers

Retract outriggers using the control levers

or switches marked ‘outrigger’.

6. Turn Off Power to Crane

Deactivate power to crane and outriggers.

7. Disengage the PTO

A. On manual transmission vehicles,

depress the clutch pedal completely.

B. Disengage the PTO switch.

C. If vehicle is a manual transmission,

release the clutch pedal gradually.

NOTE: The radio control is an electri-

cal device. Please handle with care!

1

Variable Speed Trigger on remote.

The crane should not function until the trigger has been

activated. The speed of the crane will vary in direct

correlation with how much or how little the trigger is engaged.

Page 11

Operation 7

MAIN

E

XTENSION

E

XTEND

RETRACT

R

OT

CW

MAIN

D

OWN

EXTENSION

D

OWN

ROT

C

CW

UP

U

P

PULL

PUSH

C

ONTROL

F

LOW

WINCH

WINCH

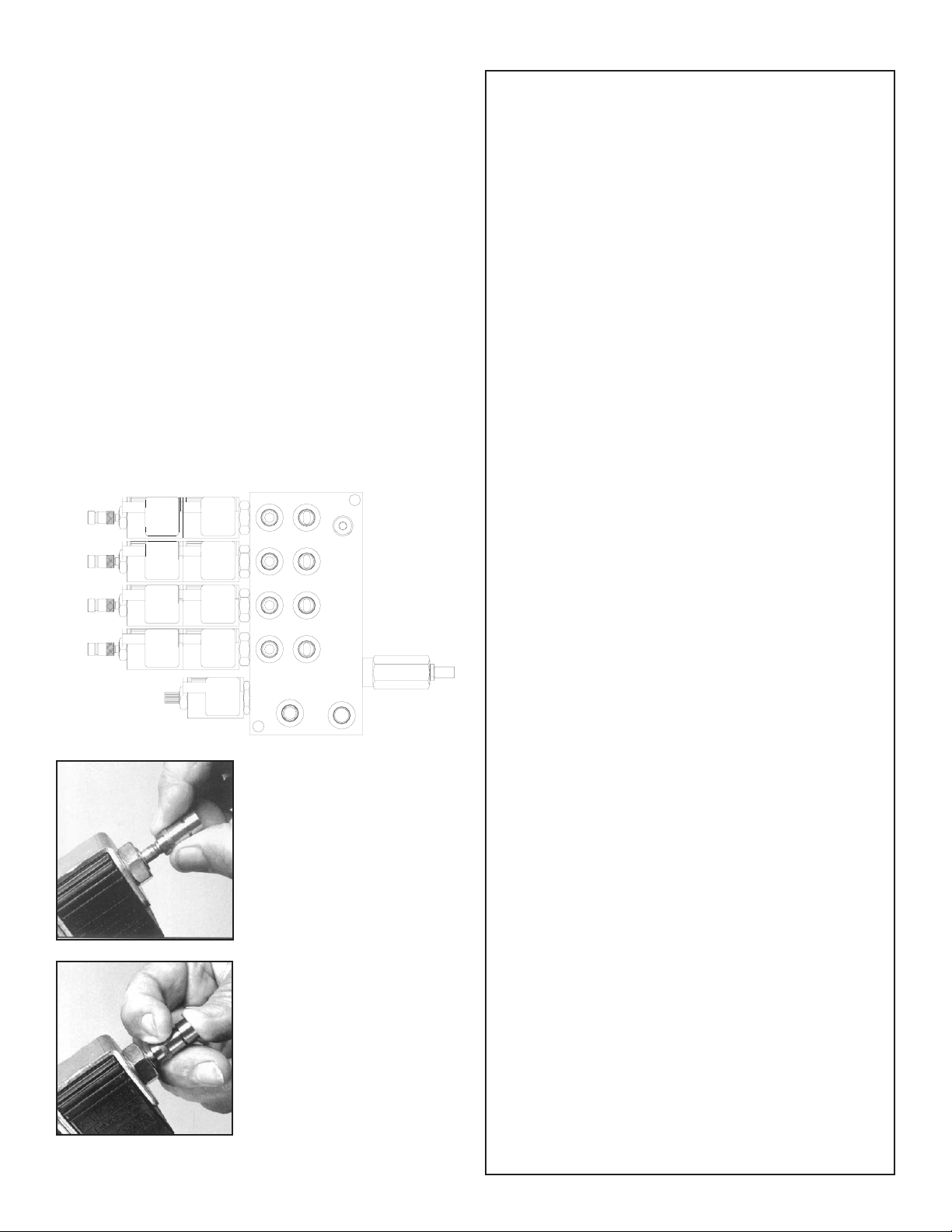

Manual Operation

If the remote control malfunctions, follow

these steps to operate the crane manually:

1. Activate Flow Control. Turn the override

screw on flow control counter-clockwise.

Full adjustment is between three and five

turns.

2.

Operate Solenoids. Slide the knurled sleeve

out and then push or pull to operate, as

shown below. Be sure the sleeve is in the

center, locked, position before returning to

remote operation.

3. Deactivate flow control. Turn the override

screw clockwise until stopped. Full

adjustment is between 3 and 5 turns.

4. Have unit serviced immediately to restore

remote control functionality.

Crane Precautions

1

. Movement of the control levers should be

s

low and smooth to meter oil flow for safe

operation. Avoid jerky and sudden

movements.

2. The crane controls should be clearly

marked with decals. If these are missing or

illegible,replace immediately. (See Chapter

5: Decals)

3. Lift load slightly off the ground to check the

safety of the cargo. Do not use stability to

determine the safety. Consult the capacity

charts and strictly adhere to them.

4. Be constantly aware of the boom position

when operating the controls.

5. The boom tip should be centered directly

over the load before making the lift to

avoid swinging.

6. Do not drag loads with the crane.

7. Do not attempt to lift fixed loads.

8. Do not load boom in a sideways direction.

Know the weight of the rigging and load to

9.

avoid overloading the crane.

10. Do not extend or rotate a load over

anyone.

11. Wear protective gear such as hard hat,

safety glasses, steel-toed boots, and

gloves.

Hook Precautions

Hooks ar

1.

e designed and manufactured to

lift specific loads. The specified rated load

mly in

Manual Override Pull

Function

The knurled sleeve is pulled

all the way out together

with the knob to manually

override the pull solenoid

function.

of a hook applies to loads held unifor

direct tension and does not take into

account shock loads, hook tip loading, side

loading, bending, torsional, or related loads.

2. Do not attempt to lift a load that is larger

than the load rating of the hook.

Never use a hook’s yield point as an

3.

indicator of its capacity.

4. Do not use a hook to lift personnel.

5. Know the rated load of the hook in use.

6. Never weld attachments to a finished hook

Manual Override Push

Function

The knurled sleeve should

first be pulled to unlatch the

ball latching mechanism

and then, while holding the

sleeve back, the override

knob should be pushed all

the way in to override the

push solenoid.

in field applications. This will alter and

oy the design pr

destr

operties of the hook

material.

7. Keep fingers, hands, body, and loose

clothing from between the hook and the

load.

void shock loading.

8. A

9. Inspect the hook regularly for excessive

wear and maintain it in safe operating

condition.

Page 12

8 14528 Owner’s Manual

Operator Information

OPERATOR REQUIREMENTS

1. Operation is limited to the following

people:

A. Designated individual.

B. Trainees under direct supervision

of the designated individual.

C. Test or maintenance individual.

D. Crane Inspector.

2. Operators must meet the following

physical qualifications:

A. Vision of at least 20/30 Snellen in

one eye and 20/50 in the other,

with or without corrective lenses.

B. Ability to distinguish colors if color

ferentiation is required.

dif

C. Adequate hearing, with or

without a hearing aid.

D. No physical or emotional defects

that may create a hazar

operator or others.

E. Normal depth perception and

coordination.

3. In addition to the physical qualifications,

Operators must:

A. Demonstrate the ability to

understand all decals, the

owner’s manual, and any other

information requir

operation of the crane.

B. Be able to demonstrate the ability

to safely control the crane.

C. Know all safety regulations.

D. Be responsible for maintenance

requirements.

E. Understand and be fully capable

of implementing all emergency

procedures.

F. Understand the operating

procedures as outlined by this

manual, ANSI B30.5, and

Federal/State Laws.

ed for safe

d to the

OPERATOR CONDUCT

1. Operators will not engage in any

operation that would cause them to divert

attention away from the operation of the

crane.

2. Operators are responsible for all

operations under their direct control.

3. Operators will not leave a suspended

load unattended.

4. Operators will be familiar with the

equipment and the maintenance required

for proper care.

HANDLING THE LOAD

1. Size of the load:

Do not load the crane beyond

A.

the rated capacity.

It is the responsibility of the

B.

operator to know the weight of

the handled load.

2. Attaching the load:

A. Attach the load to the hook by

means of slings or other approved

devices.

B. Do not wrap the hoist rope

around the load.

3. Moving the load:

A. Make certain that the crane is

level and properly blocked.

B. Ensure that the load is secure and

balanced within the sling before

moving it.

C. Be sur

before moving the load. Use

stabilizer pads to ensure the

proper distribution of weight.

D. Do not drag the load sideways.

E. Make sure the hook is brought

over the load to minimize

swinging.

F. No suspended load should pass

over a person.

G. Avoid sudden starts and stops

when moving a load.

e that the crane is stable

Page 13

Chapter 3 - Maintenance

Maintenance 9

WARNING - Read the Following before

performing any maintenance on the

crane.

1. Only authorized service personnel are

to perform maintenance on the crane.

2. Disengage the PTO before any service

or repair is performed.

3. Do not disconnect hydraulic hoses

while there is still pressure in those

components.

4. Before disconnecting hydraulic

components, place the boom on the

ground or have it supported, shut off the

engine, release any air pressure on the

hydraulic reservoir, and move pedals

and control levers r

their operating positions to relieve all

pressures.

5. Keep the crane and service body

clean and fr

and dirt to prevent slippery conditions.

6. Perform all safety and maintenance

checks before each period of use.

7. Replace parts with Stellar Industries, Inc.

approved parts only.

8. Immediately repair or have repaired

any components found to be

inadequate.

Maintenance Procedures

1. Position the crane where it will be out of

the way of other operations or vehicles in

the area.

2. Be sure boom is lowered to the ground or

otherwise secured from dropping.

3. Place all controls in the off position and

secure operating features from

inadvertent motion.

4. Disconnect power source.

5. Relieve hydraulic oil pressure from all

hydraulic circuits before loosening or

removing hydraulic components.

6. Label or tag parts when disassembling.

ee from grease build-up, oil

epeatedly through

Daily Inspection

Daily Inspection should occur each day

before the crane is put into use. Each day,

inspect the crane for all of the following:

1. Hydraulic oil level.

2. Loose parts or damage to structures or

weld.

3. Cylinder movement due to leakage.

4. Hoses and gearboxes for evidence of oil

leaks.

5. Controls, including hand throttle for

malfunction or adjustment.

6. Truck hand brake operation.

7. All securing hardware such as cotter pins,

snap rings, hairpins, and pin keepers for

proper installation.

8. All safety covers for proper installation.

9. Cylinder holding valves for proper

operation.

10. Wire rope for broken wires, extensive

wear, distortion, and heat damage.

Periodic Inspection

Periodic Inspection should occur while the

crane is in use. For the duration of the

usage, inspect the crane for all of the

following:

1. Loose bolts and fasteners.

2. All pins, bearings, shafts, and gears for

wear, cracks, or distortion to include all

pivots, outriggers, sheave pins, and

bearings.

3. Hydraulic systems for proper operating

essure.

pr

4. Main frame mount bolts.

5. Cylinders for:

A. Damaged rods.

B. Dented barrels.

C. Drift from oil leaking internally.

D. Leaks at rod seals or holding valves.

6. PTO drive line system for proper

alignment, lubrication, and tightness.

7. Hydraulic hose and tubing for evidence of

damage such as blistering, crushing, or

abrasion.

Page 14

10 14528 Owner’s Manual

Weekly Inspection

Weekly Inspection should occur at the

beginning of every work week. Each week,

inspect the crane for all of the following:

1. Lubrication of points required by

lubrication chart located in this chapter.

2. Proper operation of load hook safety

latch.

3. Presence of this owner’s manual.

Monthly Inspection

Monthly Inspection should occur at the

beginning of every work month. Each

month, inspect the crane for all of the

following:

1. Frame bolt tightness - turn barrel nuts and

mounting bolts during the first month of

operation on new machines and then

quarterly thereafter.

2. Cylinders and valves for leaks.

3. Lubrication.

4. Load hook for cracks or having more than

15 percent normal throat opening or 10

degrees twist.

5. Structural members for bends, cracks, or

broken members.

6. All welds for breaks and cracks.

7. All pins and keepers for proper installation.

8. All control, safety, and capacity placards

for readability and secure attachment.

9. Inspect all electrical wires and

connections for worn, cut, or deteriorated

insulation and bare wire. Replace or

repair wires as required.

10. Tightness of all boom wear, pad-retaining

bolts.

Service

The following general suggestions should

be helpful in analyzing and servicing your

crane. Using the following systematic

approach should be helpful in finding and

fixing problems:

1. Determine the problem.

2. List and record possible causes.

3. Devise checks.

4. Conduct checks in a logical order to

determine the cause.

5. Consider the remaining service life of

components against the cost of parts

and labor necessary to replace them.

6. Make the necessary repair.

7. Recheck to ensure that nothing has

been overlooked.

8. Functionally test the new part in its

system.

Inspection Checklist

For a more detailed outline of scheduled

inspection points, refer to the Stellar

Inspection Checklist at the end of this

chapter. This list is an excellent guide for the

inspection tasks that will help maintain the

quality of your Stellar product. Feel free to

photocopy the checklist as needed.

ATTENTION

Every six (6) months,

Stellar Industries recommends the first

filter change to occur after the first 250

hours of service.* The second, and

every subsequent change, should

occur after every 1,000 hours of

service. By following these guidelines,

the hydraulic oil should last up to

6,500 hours.

*Note: These recommendations are based on normal

working parameters. If operating in less than favorable

conditions (excessive dust, moisture, etc.), be sure to check

the filter gauge often for filter change notice.

remove the hydraulic

pump from the PTO and

lubricate the splines using

Chelsea Lubricant #379831

or Stellar PN 20885. Failure

to lubricate shaft splines will

cause damage to the PTO

and Hydraulic pump.

Page 15

Lubrication Recommendations

Component Location Recommendation

Engine Crankcase Apply Manufacturer’s

Recommendations

Maintenance 11

Hydraulic System

Below –5*F

-5*F to 90*F

Above 90*F

Open Gears Hand Precision XL3 Moly EP 2 (NLGI 2 grease

Bearings, grease

(including turntable bearing

inner race)

Worm Drive Gearbox Gearbox Precision Synthetic EP 00 (NLGI 00)

Planetary Gearbox

(including winch)

Reservoir

Petro-Canada Arctic MV 15 (ISO 22)

Petro-Canada HYDREX 32 (ISO 32)

Petro-Canada HYDREX 46 (ISO 46)

with moly)

Gun Precision XL EP 2 (NLGI 2)

Gearbox Traxon Synthetic 75W-90 (API GL-5)

Wear Pad Lubrication Spray Gearshield NC

Compressor Fluids

Reciprocating Single Stage

Reciprocating Double Stage

Screw

-15˚F to 86˚F

-23˚F to 100˚F

32˚F to 113˚F

Crankcase

Crankcase

Crankcase

Compro 100 (ISO 100)

Compro 100 (ISO 100)

Compr

Compr

Compro XL-S 68 (ISO68)

o XL-S 32 (ISO 32)

o XL-S 46 (ISO46)

Greasing the Crane

Lubricate all grease gun points with

Extreme Pressure Grease - Stellar P/N: 22059.

Page 16

12 14528 Owner’s Manual

Wire Rope Maintenance

Wire Rope Inspection Points

While inspection of the entire rope is

required, attention should be directed to

these critical points:

1. Pick-up Points for signs of wear due to

stress from repeated lifts.

2. End Attachments for corrosion and broken

wires at both ends of the rope.

3.

Drums for signs of corrugation and wear

that may lead to wire damage.

Sheaves to ensure that each sheave has

4.

the proper groove size and contour.

5. Abuse Points for heavy amounts of

scuffing and scraping.

It is important to perform detailed

inspections of all ropes associated with the

crane. These inspections can be divided

into two types:

1. Frequent Inspection

A. All running ropes should be inspected

once each working day. These visual

observations will be concerned with

discovering damage that may be an

immediate hazard. The following

concerns should be addressed:

1. Distortion of the rope.

2. General corrosion.

3. Broken or cut strands.

B. Use caution while inspecting sections of

rapid deterioration.

C. Use caution while inspecting boom

hoist ropes. Proper inspection is critical

but difficult.

2.

Periodic Inspection

A. Inspection frequency will be

determined by a qualified person and

will be based on such factors as

expected rope life, environment

conditions, capacity of typical lifts,

rates of usage, and exposure to shock

loads. Periodic inspection needs to be

performed at least annually.

B. Periodic inspections will be performed

by a qualified individual and will cover

the entire length of the rope. Only the

surface wires of the rope need to be

inspected. This inspection will be

concerned with discovering damage

that may be an immediate hazard. The

following concerns should be

addressed:

1. Distortion of the rope.

2. General corrosion.

3. Broken or cut strands.

4. Reduction of rope diameter.

5. Corroded or broken wires at end

connections.

6. Corroded, cracked, bent, worn, or

improperly applied end

connections.

C. Use caution when inspecting the

following:

1. Sections in contact with saddles,

equalizer sheaves, or other sheaves

where rope travel is limited.

2. Sections of the rope at or near ends

with corroded or broken wires.

Wire Rope Replacement

Rope replacement guidelines are as follows:

1. Broken wires, including standing ropes

with more than two broken wires in one

lay or more than one broken wire at an

end connection.

2. Wear of one-third the original diameter of

the outside wires.

3. Distortion of the rope structure.

4. Evidence of heat damage.

5. Reductions from nominal diameters of

more than 1/64 in. (0.4 mm) for diameters

from 5/16 in.(19.0 mm) and 1/32 in. (0.8

mm) for diameters from 3/8 in. (9.5 mm) to

and including 1/2 in. (13.0 mm).

Wire Rope Maintenance

Proper maintenance is key in ensuring a

long lasting rope. These three tips will help:

1. Store the rope to prevent damage.

2. Avoid objects that may scrape, bend, or

crush the wires of the rope.

3. Always keep the rope well-lubricated.

Page 17

Holding Valve Inspection Procedure

The cylinders are equipped with holding

valves that prevent sudden movement of

the cylinder rods in the event of a hydraulic

hose or hydraulic component failure. The

valve is checked in the following manner:

1. Identify the cylinder in question.

2. Identify the holding valves and the

cylinder direction in question.

a. Cylinder Extend.

b. Cylinder Retract.

3. Place the machine so that the cylinder

will be located in the appropriate testing

position.

4. Pick the load (Do not exceed capacity,

rated or stability).

5. Disengage hydraulics.

6. Operate crane functions.

A. If the cylinder creeps (lowering the

load), replace the holding valve.

B. If the cylinder does not creep (load

stays suspended), the valve is

operational.

Maintenance 13

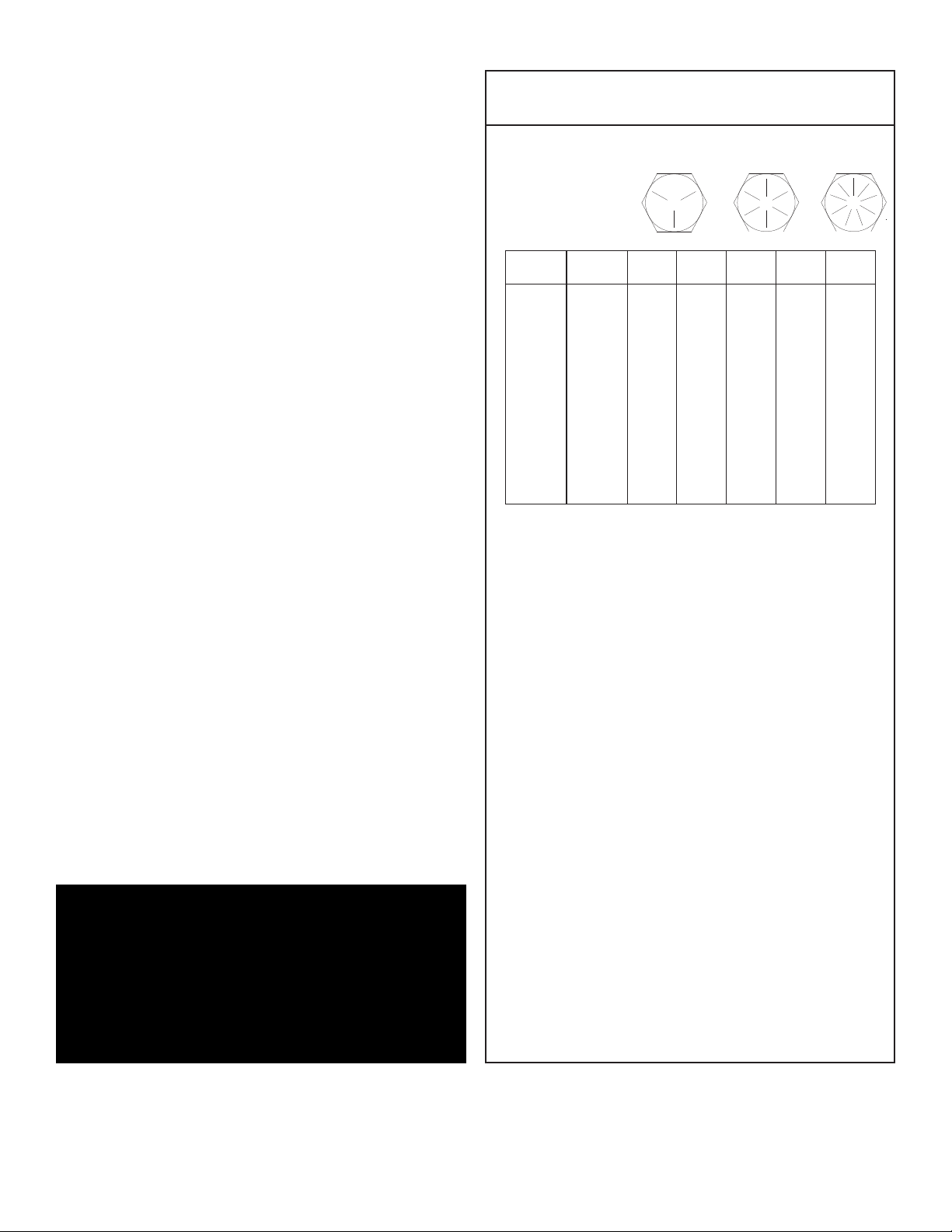

Torque Data Chart

Grade 5

Plated

Size

DIA-TPI)

(

/16-18

5

3/8-16

7/16-14

1/2-13

9/16-12

5/8-11

3/4-10

7/8-9

1-8

1 1/8-7

1 1/4-7

1 3/8-6

1 1/2-6

Bolt DIA

Inches)

(

.3125

0

0.3750

0.4375

0.5000

0.5625

0.6250

0.7500

0.8750

1.000

1.1250

1.2500

1.3750

1.500

Plain

Ft-Lb)

(

7

1

31

49

75

110

150

265

395

590

795

1120

1470

1950

Ft-Lb)

(

1

23

37

57

82

115

200

295

445

595

840

110

1460

When using the torque data in the charts

above, the following rules should be

observed.

Grade 8

Plated

Plain

Ft-Lb)

(

3

5

2

44

70

105

155

220

375

605

910

1290

1815

2380

3160

Ft-Lb)

(

8

1

33

52

80

115

160

280

455

680

965

1360

1780

2370

Grade 9

Plated

Ft-Lb)

(

2

39

63

96

139

192

340

549

823

1167

1646

2158

2865

2

Gear-Bearing Bolt Maintenance

Anytime a gear-bearing bolt is removed, it

must be replaced with a new bolt of the

identical grade and size. Once a bolt has

been torqued to 75% of its proof load and

then removed, the torque coefficient may

no longer be the same as when the bolt was

new thus giving indeterminate damp loads

after torquing.

Warning!

Failure to replace gear-bearing

bolts may result in bolt failure due

to metal fatigue causing serious

injury or even death.

1. Bolt manufacturer’s particular

specifications should be consulted when

provided.

2. Flat washers of equal strength must be

used.

3. All torque measurements are given in

foot-pounds. To convert to inch-pounds,

multiply by 12.

4. Torque values specified are for bolts with

residual oils or no special lubricants

applied. If special lubricants of high stress

ability, such as Never-Seez compound

graphite and oil, molybdenum disulphite,

colloidal copper or white lead are

applied, multiply the tor

que values in the

charts by the factor .90. The use of Loctite

does not affect the tor

que values listed

above.

5. Torque values for socket-head capscrews

are the same as for Grade 8 capscrews.

Page 18

14 14528 Owner’s Manual

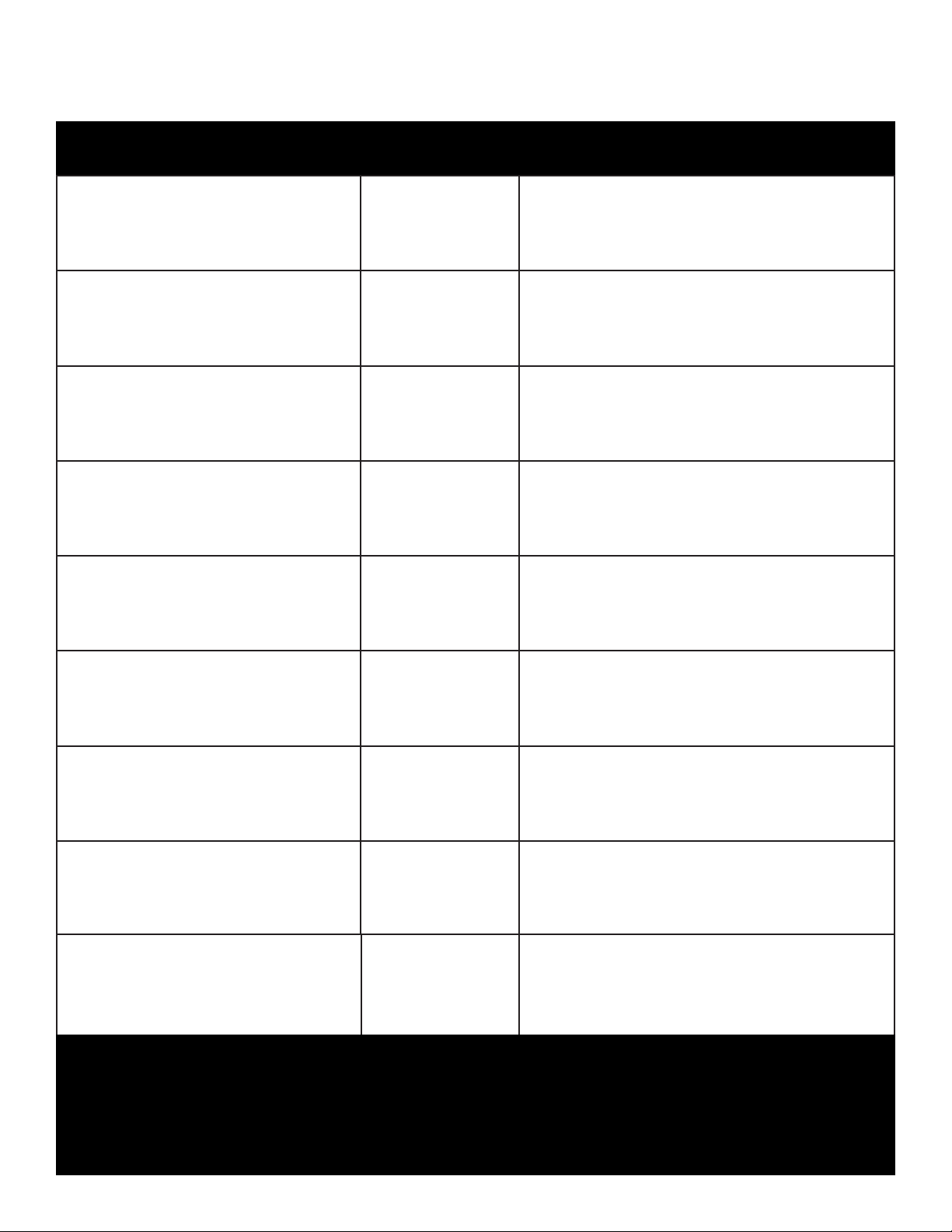

Inspection Checklist

Use of this checklist is subject to terms of the

Stellar Warranty information. Additional copies of

this checklist can be obtained by contacting

Stellar Customer Service at (800) 321-3741.

Owner/Company:

Contact Person:

Crane Make/Model:

Crane Serial:

Type of Inspection (check one)

Daily (if deficiency found)

Monthly

Date Inspected:

Hour Meter Reading:

Inspected by: (

Signature of Inspector:

print)

Quarterly

Annual

Type of Inspection Information

Daily and monthly inspections are to be performed by a “designated” person, who has

been selected by the employer or the employer’s representative as being competent to

perform specific duties.

Quarterly and annual inspections are to be performed by a “qualified” person who, by

possession of a recognized degree in an applicable field or certificate of professional

standing, or who, by extensive knowledge, training and experience has successfully

demonstrated the ability to solve or resolve problems related to the subject matter and

work.

One hour of normal crane operation assumes 20 complete cycles per hour

exceeds 20 cycles per hour, inspection frequency should be increased accordingly.

Consult the Stellar Owner’s Manual for additional inspection items.

Before inspecting and operating the crane, make certain that t he crane is set up away

from power lines and leveled with outriggers fully extended.

Daily (D): Before each day of operation, those items with a (D) must be inspected. This

inspection need not be recorded unless a deficiency is found.

Monthly (M): Monthly inspections or 100 hours of normal operation (which ever comes

first) includes all daily and monthly inspection items plus items designated with a (Q). This

inspection must be recorded.

Quarterly (Q): Every three months or 300 hours of normal operation (which ever comes

first) includes all daily and monthly inspection items plus items designated with an (M).

This inspection must be recorded.

Annual (A): Each year or 1200 hours of normal operation (which ever comes first) includes

all items on this form which encompasses daily, monthly, and quarterly inspections plus

those items designated by (A). this inspection must be recorded.

. If operation

Page 19

Daily Inspection

Maintenance 15

Frequency

D

D

D

D

D

D

D

D

D

D

D

Key

Decals

Controls

Station

Hydsystem

Hook

Rope

Pins

General

Operation

Remote Ctrls

Electrical

Inspection Description

All load charts, safety & warning Decals, & control Decals are present and

egible.

l

Check all safety devices for proper operation.

Control mechanisms for proper operation of all functions, leaks, & cracks.

Control mechanisms for proper operation of all functions, leaks, & cracks.

Hydraulic system (hoses, tubes, & fittings) for leakage & proper oil level.

Presence & proper operation of hook safety latches.

Proper reeving of wire rope on sheaves & winch drum.

Proper engagement of all connecting pins & pin retaining devices.

Overall observation of crane for damage or missing parts, cracked welds &

presence of safety covers.

During operation, observe crane for abnormal performance, unusual wear.

If observed, discontinue use & determine cause & severity of hazard.

Operate remote control devices to check for proper operation.

Operate all lights, alarms, etc. to check for proper operation.

Status

D

D

D

Anti 2-Blocking

Operation Aid

Operation Aid

Operate anti 2-blocking device to check for proper operation.

Check presence of boom angle indicator.

Check overload device for proper operation.

Page 20

16 14528 Owner’s Manual

Monthly Inspection

Frequency

M

M

M

M

M

M

M

M

M

M

M

M

Key

Daily

Cylinders

Valves

Valves

Valves

General

Electrical

Structure

Welds

Pins

Hardware

Wear Pads

Inspection Description

All Daily Inspections.

Visual inspection of cylinders for leakage at rod, fittings, & welds. Damage

to rod & case.

Holding valves for proper operation.

Control valve for leaks at fittings & between sections.

Control valve linkages for wear, smoothness of operation & tightness of

fasteners. Relief valve for proper pressure settings.

Bent, broken or significantly rusted/corroded parts.

Electrical systems for presence of dirt, moisture & frayed wires.

All structural members for damage.

All welds for breaks & cracks.

All pins for proper installation & condition.

All bolts, fasteners & retaining rings for tightness, wear & corrosion.

Condition of wear pads.

Status

M

M

M

M

M

M

M

M

M

M

Pump & Motor

PTO

Hyd Fluid

Hyd Lines

Hook

Rope

Manual

Chassis

Chassis

Station

Hydraulic pumps & motors for leakage at fittings, seals & between sections.

Check tightness of mounting bolts.

Transmission/PTO for leakage, abnormal vibration & noise, alignment &

mounting bolt torque.

Quality of hydraulic fluid and for presence of water.

Hoses & tubes for leakage, abrasion damage, blistering, cracking,

deterioration, fitting leakage, & secured properly.

Load hook for abnormal throat distance, twist, wear, & cracks.

Condition of load line.

Presence of operator's manuals with the unit.

Tire wear and air pressure.

Working backup alarm.

Fire extinguisher at cab or machinery housing.

Page 21

Quarterly Inspection

Maintenance 17

Frequency

Q

Q

Q

Q

Q

Key

Daily

Monthly

Rotation Sys

Hardware

Structure

Inspection Description

All daily inspections.

All monthly inspections.

Rotation bearing for proper torque of all mounting bolts.

Base mounting bolts for proper torque.

All structural members for deformation, cracks, & corrosion.

Base

Outrigger beams & legs

Mast

Inner boom

Outer boom

Extension(s)

Jib boom

Status

Q

Hardware

Jib extension(s)

Other

Other

Pins, bearings, shafts, gears, rollers, & locking devices for wear, cracks,

corrosion, & distortion.

Inner boom pivot pin(s) & retainer(s)

Outer boom pivot pin(s) & retainer(s)

Inner boom cylinder pin(s) & retainer(s)

Outer boom cylinder pin(s) & retainer(s)

Extension cylinder pin(s) & retainer(s)

Jib boom pin(s) & retainer(s)

Jib cylinder pin(s) & retainer(s)

Jib extension cylinder pin(s) & retainer(s)

Boom tip attachments

Other

Other

Page 22

18 14528 Owner’s Manual

Quarterly Inspection Continued...

Frequency

Q

Q

Q

Key

Hyd Lines

Pumps&Motors

Valves

Inspection Description

Hoses, fittings, & tubing for proper routing, leakage, blistering, deformation,

excessive abrasion.

&

Pressure line(s) from pump to control valve

Return line(s) from control valve to reservoir

Suction line(s) from reservoir to pump

Pressure line(s) from control valve to each function

Load holding valve pipe(s) and hose(s)

Other

Pumps and motors for loose bolts/fasteners, leaks, noise, vibration, loss of

performance, heating and excess pressure.

Winch motor(s)

Rotation motor(s)

Other

Hydraulic valves for cracks, spool return to neutral, sticking spools, relief

valve failure.

Main control valve

Status

Q

Q

Q

Cylinders

Winch

Hyd Filter

Load holding valve(s)

Outrigger or auxiliary control valve(s)

Other

Hydraulic cylinders for drifting & leakage. Rods for nicks, scores, & dents.

Castor damage. Case & rod ends for damage & abnormal wear.

Outrigger cylinder(s)

Inner boom cylinder(s)

Outer boom cylinder(s)

Extension cylinder(s)

Rotation cylinder(s)

Jib lift cylinder(s)

Jib extension cylinder(s)

Other

Winch, sheaves, & drums for damage, abnormal wear, abrasion, & other

egularities.

irr

Hydraulic filters for r

eplacement per maintenance schedule.

Page 23

Annual Inspection

Maintenance 19

Frequency

A

A

A

A

A

A

A

A

A

A

A

A

Key

Daily

Monthly

Quarterly

Hyd System

Controls

Valves

Valves

Rotation Sys

Lubrication

Hardware

Wear Pads

Loadline

Inspection Description

All daily inspection items.

All monthly inspection items.

All quarterly inspection items.

Hydraulic fluid change per maintenance schedule.

Control valve calibration for correct pressures & relief valve settings.

Safety valve calibration for correct pressures & relief valve settings

Valves for failure to maintain correct settings.

Rotation drive system for proper backlash clearance & abnormal wear,

deformation, & cracks.

Gear oil change in rotation drive system per maintenance schedule.

Check tightness of all fasteners and bolts.

Wear pads for excessive wear.

Loadline for proper attachment to drum.

Status

A

A

A

Historic Data

Historic Data

Historic Data

Monthly inspection records.

Maintenance records.

Repair and modification records.

Page 24

20 14528 Owner’s Manual

Inspection Notes

Page 25

Chapter 4 - Specifications

Model 14528 Crane

SPECIFICATION SHEET

Crane Rating: 70,000 ft-lbs (9.68 ton-meters)

Standard Boom Length: 13’ (3.96 m) from CL of Crane

Boom Extension: 1st stage: Hydraulic 90" (228.6 cm)

2nd stage: Hydraulic 90" (228.6 cm)

Maximum Horizontal Reach: 28’ (8.53 m) from CL of Crane

Specifications 21

Maximum V

(from crane base)

Boom Elevation: -5 to +80 degrees

Stowed Height: 43” (102.9 cm)

(crane only)

Mounting Space Required:

Approximate Shipping Weight: 3100 lbs (1406 kg)

Controls: Radio control standard for all functions.

Winch Specifications

Rope Diameter: 1/2" (1.27 cm)

Line pull speed: 60 ft/min (18.29 m/min)

Max. single part line: 7000 lbs (3175 kg)

Max. double part line: 14,000 lbs (46,350 kg)

Rotation: 400 degree power

(worm gear)

ertical Lift: 29’ 4” (8.94 m)

25” x 22” (63.5 x 55.9 cm)

Lifting Capacities:

Power Supply Required: PTO & Pump

*Subject to change without notification

5375 lbs @ 13’ (2440 kg @ 3.96 m)

2500 lbs @ 28’ (1130 kg @ 8.54 m)

(12 gpm @ 2600 psi)

(45.4 lpm @ 180 bars)

Page 26

22 14528 Owner’s Manual

14528

Reach in Feet/Meters

Capacity in Pounds/Kilograms

Weight of load handling devices are

part of the load lifted and must be

deducted from the capacity.

PN 26204

Maximum 1 - part line capacity is

7000lbs (3175kg). For greater

loads, use 2 - part line.

5375lbs

2440kg

5475lbs

2485kg

3400lbs

1545kg

2500lbs

1135kg

3500lbs

1590kg

5950lbs

2700kg

3825lbs

1735kg

2500lbs

1155kg

2825lbs

1280kg

7025lbs

3185kg

9350lbs

4240kg

14000lbs

6350kg

14000lbs

6350kg

14000lbs

6350kg

10400lbs

4

720kg

622

5lb

s

2825

kg

4575lbs

2075kg

3400lbs

1545kg

4675lbs

2

120kg

8075lbs

3

660kg

11000lbs

4990kg

Capacity Chart - Decal PN 26204

Page 27

Chapter 5 - Decals

Decals of Note

Foot Crushing Hazard Decal

Location: On each outrigger leg.

Function: To inform the operator and other

personnel in the work area of the hazard

associated with the operation of the outriggers,

the possible consequences should the hazard

occur, and how to avoid the hazard. PN: C4795

Decals 23

Instructional Decal

Location: At Stow Hook area

Function: T

stow hook for any lifting applications. PN: 24712

o caution the operator not to use the

Moving Outrigger Hazard Decal

Location: On each outrigger

Function: To inform the operator of the hazard

associated with outrigger operation, the possible

consequences should the hazard occur, and how

to avoid the hazard. PN: C5918

Page 28

24 14528 Owner’s Manual

Electrocution Hazard Decal

Location: Each side of truck body, Front & Rear

Bumper

Function: To inform the operator and other

personnel in the work area of the hazard

associated with contact or proximity to electrical

lines, the possible consequences should the hazard

occur and how to avoid the hazard.

PN: C4545

Page 29

Decals 25

Two Block Hazard Decal

Location: At Boom Tip

Function: To inform the operator of the hazard

associated with bringing the sheave(s) into

contact with the hook, snatch block or load, the

possible consequences should the hazard occur

and how to avoid the hazard. PN: 12300

Instructional Decal

Location: At Overload Switch

Function: To inform the operator that

tampering with the overload device may

cause a unit failure.

PN: 28256

Page 30

26 14528 Owner’s Manual

Free Falling Manual Boom Decal

Location: Inside Crane Compartment, on

Compartment Door

Function: To inform the operator of the hazard

associated with free falling manual boom

extensions, the possible consequences should

the hazard occur, and how to avoid the

hazard.

PN: 12452

Electrocution Hazard Decal

Location: Inside Crane Compartment, on

Compartment Door

Function: To inform the operator of the hazard

associated with overloading the crane, the

possible consequences should the hazard

occur, and how to avoid the hazard.

PN: C1179

Operation Hazard Decal

Location: Inside Crane Compartment, on

Compartment Door

Function: To inform the operator and other

personnel in the work area of the hazard

associated with improper maintenance and

unauthorized modifications, the possible

consequences should the hazard occur, and

how to avoid the hazard.

PN: 4190

Operation Hazard Decal

Location: Inside Crane Compartment, on

Compartment Door

Function: To inform the operator of the hazard

associated with overloading the crane, the

possible consequences should the hazard

occur, and how to avoid the hazard.

PN: 4189

Page 31

Decals 27

Moving Boom Hazard Decal

Location:Inside Crane Compartment, on

Compartment Door

Function: To inform the operator and other

personnel in the work area of the hazard

associated with a moving boom, especially

while stowing and unfolding the crane, the

possible consequences should the hazard

occur, and how to avoid the hazard.

PN: C4541

Operation Hazard Decal

Location:Inside Crane Compartment, on

Compartment Door

Function: To inform the operator of the need

for proper training, familiarity with safe

operating procedures and, the possible

consequences without training.

PN: C4540

Hoisting Decal:

Location: Inside Crane Compartment, on

Compartment Door

Function: T

associated with lifting personnel with the boom,

boom hook, the load or winch loadline, the

possible consequences of lifting personnel, and

how to avoid the hazard.

PN: 12451

o inform the operator of the hazard

Training Decal:

Location:Inside Crane Compartment, on

Compartment Door

Function: To inform the operator of the need

for proper training, familiarity with safe

operating procedures, and the possible

consequences of operation without training.

PN: C4544

Page 32

28 14528 Owner’s Manual

PN 27162

Decal Kit Placement - PN 27162

Page 33

Installation 29

Chapter 6 - Installation

Notice: Read this Page Before Installation of the Crane

General Installation

This chapter is designed to serve as a

general guide for the installation of a Stellar

14528 Telescopic Crane on a Stellar Service

Body. Each installation is considered unique

so certain portions of this chapter may or

may not apply to your direct application. If

a question should arise during the installation

process, please contact Stellar Customer

Service at (800) 321 3741.

This crane is designed for use with a Stellar

Service Body installed on a vehicle that

meets the minimum chassis requirements of

the crane. Check with Stellar Industries

before installing this crane on a body other

than a Stellar Service Body.

WARNING!

The use of this crane on a

body not capable of

Installation Notice

According to Federal Law (49 cfr part 571),

each final-stage manufacturer shall

complete the vehicle in such a manner that

it conforms to the standards in effect on the

date of manufacture of the incomplete

vehicle, the date of final completion, or a

date between those two dates. This

requirement shall, however, be superseded

by any conflicting provisions of a standard

that applies by its terms to vehicles

manufactured in two or more stages.

Therefore, the installer of Stellar cranes and

bodies is considered one of the

manufacturers of the vehicle. As such a

manufacturer, the installer is responsible for

compliance with all applicable federal and

state regulations. They ar

certify that the vehicle is in compliance with

the Federal Motor Vehicle Safety Standards

and other regulations issued under the

National Traffic and Motor Vehicle Safety

Act.

e required to

handling the loads

imposed on it may result

in serious injury or death.

Optimal Service Body

for the 14528 Crane:

T3-11 Service Body

Applicable Chassis: 33000 GVWR and up.

Cab to Axle: 120” (304.8 cm)

Body Length Nominal: 157” (398.78 cm)

Body Height: 52/60”(132.1/152.4 cm)

Body Width: 94” (238.76 cm)

Compartment Depth: 22” (55.88 cm)

Floor W

Net W

idth:

eight:

50/52” (127/132.1 cm)

5200 lbs (2358.68 kg)

Please reference the Code of Federal

Regulations, title 49 - Transportation, Volume

5 (400-999), for further information, or visit

http://www.gpoaccess.gov/nara/index.html

for the full text of Code of Federal

Regulations.

Notice:

PTO and Pump installation instructions are

provided by the corresponding

manufacturers. For mor

which PTO and Pump fit your application,

please contact your local Stellar Distributor

or Stellar Customer Service.

The following pages will give a basic

overview of the installation process for the

Stellar 14528. Please read through them

entirely and obtain a clear understanding of

the process before proceeding.

e infor

mation on

Page 34

30 14528 Owner’s Manual

Installation Overview

1. Determine that the mounting location for the 14528 crane is at least 25” x 22” (63.5 x 55.9 cm).

2. Use the detail below to drill 1.31” diameter holes into the mounting plate. Run tap on the threads of the

ase to be sure they are clean.

b

3. Use a crane or lifting device capable of lifting the weight of the Stellar crane. The Stellar 14528 weighs

pproximately 3100 lbs (1406 kg). N

a

degree system.

and electrical components prior to repositioning into the crane saddle.

4. Connect straps or chain from the lifting device to the lifting rings on the Stellar 14528.

5. Use eight (8) 3.5” x 1.25” #8 bolts and eight (8) #8 flat washers.

6. Install a washer on each bolt.

7. Apply Loctite Thread locker #277 to the bolts.

8. Using the lifting device, lower the Stellar just above the crane compartment and start the bolts. Have

someone assist in leveling the crane.

compartment and the boom should be extended back over the rear bumper.

9. Secure the crane using the mounting hardware provided (see the detail below). Note: longer or shorter

cap screws may be required – recommended thread engagement into crane base is 1.75” – use grade 8,

zinc plated cap screws only.

10. Torque the cap screws to 1360 ft-lbs.

11. Remove supporting crane.

12. Hook-up hydraulics and electrical using the schematics provided in Chapter 8 - Hydraulics - Electrical.

Note: If questions should arise during any portion of this installation, please contact Stellar Customer

Service at (800) 321-3741.

This will allow for easy installation of the crane and permanent connection of all hydraulic

ote: cranes are shipped with rotation positioned at 200 degrees of 400

Note: the rotation motor should be to the door side of crane

Page 35

Installation 31

Installation Details

1. Determine that the

mounting location

for the 14528 crane

is at least 25” x 22”

(63.5 x 55.9 cm).

2. Use the detail on the

previous page to

drill 1.31” diameter

holes into the

mounting plate. Run

tap on the threads

of the base to be

sure they are clean.

3. Use a crane or lifting device capable of lifting the weight of the Stellar crane. The Stellar

14528 weighs appr

positioned at 200 degrees of 400 degree system.

crane and permanent connection of all hydraulic and electrical components prior to

repositioning into the crane saddle.

oximately 3100 lbs (1406 kg).

Note: cranes are shipped with rotation

This will allow for easy installation of the

4. Connect straps or chain from the lifting device to the

lifting rings on the Stellar 14528.

5. Use eight (8) 3.5” x 1.25” #8 bolts and eight (8) #8

flat washers.

6. Install a washer on each bolt.

7. Apply Loctite Thread locker #277 to the bolts.

The number of bolts used may

vary from model to model

8. Using the lifting device, lower the Stellar just above

the crane compartment and start the bolts. Have

someone assist in leveling the crane.

rotation motor should be to the door side of crane

compartment and the boom should be extended

back over the rear bumper.

Note: the

Page 36

32 14528 Owner’s Manual

Installation Details Continued...

9. Secure the crane using the mounting

hardware provided.

cap screws may be required –

recommended thread engagement into

crane base is 1.75” – use grade 8, zinc

plated cap screws only.

10. Torque the cap screws to 1360 ft-lbs.

Note: Longer or shorter

11. Remove supporting crane.

12. Hook-up hydraulics and electrical using the schematics provided in

Hydraulics - Electrical.

Note: If questions should arise during any portion of this installation, please contact Stellar

Customer Service at (800) 321-3741.

Chapter 8 -

Page 37

Installation 33

Stability Procedure

Definition of Stability for the Stellar Telescopic Crane Products:

A truck is stable until the load cannot be lifted off the ground with the winch, without

tipping over the truck. Every Stellar crane installed must be tested for stability to

determine the actual load capacity of the final truck package. The actual test data

must be recorded and supplied with the truck at the time of in-service and should be kept

with the truck at all times. The following procedure will test the truck package for stability

and will provide a stability capacity chart. The load limit information shown on the

stability capacity chart is formulated on 85% tipping.

Set Up:

1. Locate the truck on a test course in position for loading and engage travel brakes.

2. Set outriggers so that they make contact with firm, level footings.

3. Operate the crane under partial load to assure operator proficiency and proper

machine function.

14528 Stability Data

Max Horizontal Reach: 336” (From the center of rotation to boom tip)

Stability Test Weight: 2950 lbs.

Test Procedure

1. Rotate the crane into Zone 1 position.

2. With the crane fully retracted and the boom horizontal, winch the test weight off the

ground. Note: Keep weight within six inches of the ground at all times.

3. Extend the boom outward until full extension has been reached or until the truck

becomes unstable (Again, use the winch to keep the weight within six inches of the

ground.)

4. If the boom goes full extension without becoming unstable, the crane is termed stable

for this zone and 100% can be written in the Zone 1 data box.

5. If the truck becomes unstable prior to going full extension, retract the boom until the

truck becomes stable and measure the horizontal reach in this position (center of

rotation to boom tip). This is the stable horizontal reach for this zone. Stable horizontal

reach divided by Maximum horizontal reach multiplied by 100 equals the percentage

of rated capacity for this zone. Use the following formula to determine the percentage

of rated capacity:

Record this number in the data box for Zone 1. This is the revised capacity due to

6.

stability for this zone.

7. Repeat this procedure for each zone until the worksheet is completed.

8. This is the revised capacity based on stability of this package.

Page 38

34 14528 Owner’s Manual

STABILITY CAPACITY CHART

Stability Capacity Chart

For a decal version of this capacity chart, please contact Stellar Customer Service at (800) 321-3741

Page 39

Assembly Drawings 35

15

7

6

5

3

5

1

4

8

GASKET SHOWN AS REFERENCE

9

10

9

11

14

.YTQ

NOITPIRC

SEDTRA

P

MET

I

125140 BEARING SWING DRIVE CAST BASE 14528 1

2

8RG TALF 05.0 REH

SA

W0970

D2

3D1295 CAP SCR 0.50-13X1.50 SH GR5 2

1EDILS 004 82541 POTS702624

5 26206P MOTOR HYD ROSS MK080613AAAB 1

1ENARC 82541 BTT DRAUG855426

726774 CAP SCR 1.25-7X0.63 PLASTIC 2

8 21151 GASKET MOTOR 008-10056-1 1

9D1345 FTG CPRSN 0.12NPT/0.25 TUBE 2

10 D1810 TBE AIR SAEJ844 TYPE A .25 (28") 1

1

31.0

EPIP RELPUOC GTF6522C11

14 0343 WASHER 0.31 USS FLAT ZINC 2

15 0420 CAP SCR 0.31-18X0.75 HHGR5 2

PN 26205

Chapter 7 - Assembly Drawings

Base Assembly - PN 26205

Page 40

36 14528 Owner’s Manual

.YTQNOITPIRCSEDTRAPMETI

1

82541 TSAM

8

45421

2 4380 BUSHING 32DXR24 2.00X1.50 GARLOCK 4

3C6219 WASHER 0.75 SAE FLAT YELLOW GR8 13

44975 CAP SCR 0.75-10X3.50 HHGR8 ZY 13

257.0X96.0

X83.0 RAL

LO

C765925

626209 VB 4 SECT ELECT W/PROP STERLING12GPM 1

7 0343 WASHER 0.31 USS FLAT ZINC 4

87011 CAP SCR 0.31-18X5.50 HHGR5 2

2COL

YN HH 81

-13.0 TUN243

0

9

1TSA

M 82

541 REVOC

0

126201

6TALF 52.0 REHSAW043011

12 0420 CAP SCR 0.31-18X0.75 HHGR5 4

1W707 ASLUT 0007 HC

NIWP577623

1

14 C5902 WASHER 0.63 SAE FLAT YELLOW GR8 8

15 D1034 CAP SCR 0.63-11 X 3.00 HHGR8 ZY 8

16 24868 NUT 0.63-11 HHGR8 NYLOCK ZY 8

17 0220 CAP SCR 0.25-20 X 1.50 HHGR5 2

18 0333 NUT 0.25-20 HHGR5 NYLOC 2

18

6

2

3

4

1

1

3

17

10

11

12

8

7

7

9

2

2

2

15

14

16

11

5

PN 41903

Mast Assembly - PN 41903

Page 41

Assembly Drawings 37

.YTQNOITPIRCSEDTRAPMETI

182541 RENNI MOOB277431

2T&D 96.21X00.2 NIP463312

34381 BUSHING 32DXR32 2.00X2.00 GARLOCK 4

426197 CYLINDER ASM 14528 INNER 1

1T&D 36.9X00.2 NIP312625

1T&D 91.9X52.1 NIP412626

70249 BUSHING BPC-2022-20 1.25X1.25 4

652.X05.3X65.0 PAC NIP77388

818RG TALF 05.0 REHSAW0970D9

10 10172 CAP SCR 0.50-13X1.00 HHGR8 ZY 6

2252.X05.2X44.0 PAC NIP304

7

11

68RG TALF 83.0 REHSAW3536C21

13 9843 CAP SCR 0.38-16X0.75 HHGR8 2

14 26215 WEAR PAD 3.00X3.00X1.50 2

15 10548 CAP SCR 0.50-13X1.50 HHGR8 8

16 D1194 PLATE ANGLE INDICATOR 2

17 C6106 NUT 0.50-13 HHGR5 NYLOC 2

18275 LEER DROC66191

8

1

2TALF 52.0 REHSAW043091

20 0478 CAP SCR 0.25-20X0.50 HHGR5 2

282541 EDIUG EPOR TKRBCP2576212

22 0335 CAP SCR 0.38-16X1.25 HHGR5 2

4

COLYN

HH 61-83.0 TUN

74303

2

24 26753 SPACER ROPE GUIDE 14528 UHMW 2

25 26755 CAP SCR 0.38-16X10.00 HHGR5 2

1THGIARTS TPN 8/1 KREZ2951c62

27 D0178 WASHER #10 SAE FLAT ZINC 2

28 D0894 SCREW #10-24X0.75 BTN HD SS 2

30 26751PC PLATE WEAR PAD SUPPORT 14528 2

27

14

30

9

15

10

9

8

5

4

8

9

10

10

9

8

2

8

9

10

3

17

9

16

9

2

3

24

21

25

13

10

9

1

2

1

1

8

3

7

3

6

2

8

1

2

13

9

10

11

20

19

18

1

26

7

28

PN 41902

Main Boom - PN 41902

Page 42

38 14528 Owner’s Manual

7

7

81

91

1

1

3

1

2

1

8

9

0

1

71

6

1

5

1

41

2

1

6

5

4

3

3

02

02

9

01

1

2

3

1

.YT

QNOITPIRC

SEDTRAP

ME

TI

TS1 M

O

OB TXE07

743118254

1

T

XE DN2 MOOB17743

2

182541

4NORTALYN DNR 00.2X52.0 DAP RAEW

1

99

9

3

MSA REDNILY

C65

76241TXE 82541

18RG WOLLEY TALF EAS 57.0 RE

HS

AW9126C5

1

YZ 8RGHH

05.2X01-57.

0 R

CS PAC47946

EVAEHS7554

2

72KHT 49.1/R05. AID 00.01 8254

1

118.3X00.1 PORD RAET NIP993318

2CNIZ TALF SSU 13.0 RE

HS

AW3430

9

25RGHH 57.0X81-13.0 RCS PAC024001

PIT

M

OOB RECAP

S91

7721

1

2W

M

HU 0266

25RGHH 05.3X81-13.0 RCS PAC

0

94021

2COLYN HH 81-13.0 TUN243031

2NORTALYN 05.1X05.2X05.2 DAP RAEW857624

1

TROPPUS DAP RA

EW

ETALP9576251

28254

1

88RG TALF 05.0 REHSAW0970D61

05.1X31-05.0 RCS PAC845017188RGHH

205.4X00.1 HCTIH NIP428218

1

2HCNYL 65.1X91.0 NIP357591

M EVAEHS ETALP6554202282541 GNITNUO

183.4X00.1 PORD RAET NIP004311

2

PN 26757

Extension Boom Assembly - PN 26757

Page 43

3

4

1

8

*CYLINDER BUSHINGS FOR REFERENCE ONLY

7

8

4

4

4

1

3

9

.YTQNOITPIRCSE

D

TRAPMETI

1C1854 FTG ADAPT 6-8 F5OLO-S 2

2S-OLO5F-6 TPADA GTF97203

423-5323-ISQ GNIHSUB66004

6 16154 MANIFOLD DOUBLE T11A 3500 PSI 1

726198 CYLINDER INNER 6.00X25.75 1

841514 TUBE ASM 0.38X9.00 MAIN CYL 14528 2

939425 MANIFOLD CBAL DOUBLE T11A WITH RELIEF 1

PN 26197

Main Cylinder Assembly - PN 26197

Note: Main Cylinder uses

Stellar Seal Kit P/N 35649

Assembly Drawings 39

Page 44

40 14528 Owner’s Manual

5

6

4

2

1

3

7

.YT

QNOITP

IRCSEDTRA

P

METI