Page 1

HL 1610 S

HL 1810 S

HL 1910 E

HL 2010 E

HG 2310 LCD

HG 2510 ESD

i

Page 2

English

IMPORTANT SAFETY INSTRUCTIONS

READ THESE INSTRUCTIONS

UL WARNING: Read this instruction book before using. To reduce risk of fire or electric

shock, do not expose to rain or moisture. Store indoors. Double insulated. When servicing,

use only identical replacement parts. When using electric tools, basic safety precautions

should always be followed to reduce risk of fire, electric shock and personal injury. This hot

air gun operates at 1200°F with no visual indication of temperature (no flame). Never leave

device unattended. Otherwise risk of fire. The heat stream at the outlet nozzle will burn flesh.

Do not turn on heat gun with hand in front of nozzle. DO NOT USE NEAR COMBUSTIBLE LIQUIDS. DO NOT USE FOR: ● Heating gas engines ● Heating car batteries ● Thawing

refrigerator equipment.

WAR NING: Some dust created by power sanding, sawing, grinding, drilling and other

construction activities contains chemicals known (to the State of California) to cause cancer,

birth defects, or other reproductive harm. Some examples of these chemicals are:

● lead from lead-based paints,

● crystalline silica from bricks and cement and other masonry products, and

● arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

WAR NING!

This tool is capable of producing temperatures up to 1200° F of flameless heat

at the nozzle. ALWAYS:

● Direct the heat away from yourself and others.

● Prevent ignition of combustible materials on or near the workpiece.

● Prevent blockage of intake and nozzle openings.

● Keep a fully charged fire extinguisher on hand.

● Allow the nozzle and accessory tips to cool to room temperature before storage.

Cautions

1. WARN ING : Hidden areas such as behind walls, ceilings, floors, soffit boards and other

panels may contain flammable materials that could be ignited by the heat gun when

working in these locations. The ignition of these materials may not be readily apparent and

could result in property damage and injury to persons. Do not use if in doubt about this

hazard. When working in these locations, keep the heat gun moving in a back-and-forth

motion. Lingering or pausing in one spot could ignite the panel or the material behind it.

2. This heat gun can produce up to 1200° F of flameless heat at the nozzle. Do not direct

airstream at clothing, hair or other body parts. Do not use as a hair dryer.

3. Do not use near flammable liquids or in an explosive environment (fumes, gases or dust).

Remove materials or debris, that may become ignited, from work area.

4. Always hold tool by plastic enclosure. The metal nozzle requires approximately 20 minutes

to cool to where it can be touched. Do not touch nozzle or accessory tips until cool.

5. Do not store tool until nozzle has cooled to room temperature. Place tool in a clear area

away from combustible materials while cooling.

6. Do not cut off airflow by placing nozzle too close to workpiece. Keep intake vents clean

and clear of obstructions.

7. Place tool on a level surface with the support rubber ring when tool is not hand held.

Place cord in a position that won’t cause tipping.

8. Do not leave tool unattended while running or cooling down. Otherwise risk of fire.

9. Keep a fully charged fire extinguisher nearby.

10. Do not direct airflow directly on glass.

11. Shield materials around the heated area to prevent damage or fire.

12. Use only with 120 V AC voltage.

13. Do not use in wet conditions.

14. Not to be used by children. This is not a toy and should be respected.

15. Do not use in bath or over water.

16. Safety glasses should be worn when using this tool.

17. It is recommended that leather gloves be worn when using a heat gun.

- 2 -

Page 3

English

18. Always unplug after use.

19. WARN ING : Extreme care should be taken when stripping paint. The peelings, residue and

vapors of paint may contain lead, which is poisonous. Any pre-1977 paint may contain lead

and paint applied to homes prior to 1950 is likely to contain lead. Once deposited on surfaces, hand to mouth contact can result in the ingestion of lead. Exposure to even low

levels of lead can cause irreversible brain and nervous system damage; young and unborn

children are particularly vulnerable. Before beginning any paint removal process you should

determine whether the paint you are removing contains lead. This can be done by your

local health department or by a professional who uses a paint analyzer to check the lead

contact of the paint to be removed. LEAD-BASED PAINT SHOULD ONLY BE REMOVED BY

A PROFESSIONAL AND SHOULD NOT BE REMOVED USING A HEAT GUN.

Persons removing materials should follow these guidelines.

1. Move the work piece outdoors. If this is not possible, keep the work area well ventilated.

Open the windows and put an exhaust fan in one of them. Be sure the fan is moving the air

from inside to outside.

2. Remove or cover any carpets, rugs, furniture, clothing, cooking utensils and air ducts.

3. Place drop cloths in the work area to catch any residue. Wear protective clothing such as

extra work shirts, overalls and hats.

4. Work in one room at a time. Furnishings should be removed or placed in the center of the

room and covered. Work areas should be sealed off from the rest of the dwelling by sealing

doorways with drop cloths.

5. Children, pregnant or potentially pregnant women and nursing mothers should not be present

in the work area until the work is done and all clean up is complete.

6. Wear a dust respirator mask or a dual filter (dust and fume) respirator mask which has been

approved by the Occupational Safety and Health Administration (OSHA), the National Institute

of Safety and Health (NIOSH), or the United States Bureau of Mines. These masks and

replaceable filters are readily available at major hardware stores. Be sure the mask fits.

Beards and facial hair may keep masks from sealing properly. Change filters often.

DISPOSABLE PAPER MASKS ARE NOT ADEQUATE.

7. Use caution when operating the heat gun. Keep the heat gun moving as excessive heat will

generate fumes which can be inhaled by the operator.

8. Keep food and drink out of the work area. Wash hands, arms and face and rinse mouth

before eating or drinking. Do not smoke or chew gum or tobacco in the work area.

9. Clean up all removed residue and dust by wet mopping the floors. Use a wet cloth to clean

all walls, sills and any other surface where residue or dust is clinging. DO NOT SWEEP, DRY

DUST OR VACUUM. Use a high phosphate detergent or trisodium phosphate (TSP) to wash

and mop areas.

10. At the end of each work session put the residue and debris in a double plastic bag, close it

with tape or twist ties, and dispose of properly.

11. Remove protective clothing and work shoes in the work area to avoid carrying dust into the

rest of the dwelling. Wash work clothes separately. Wipe shoes off with a wet rag that is then

washed with the work clothes. Wash hair and body thoroughly with soap and water.

SAVE THESE INSTRUCTIONS

- 3 -

Page 4

English

Double Insulated Tools

Tools marked with the words “Double Insulated” are equipped with a two prong plug.

These tools have a special insulation system that complies with applicable UL standards

. They do not require grounding. ”Double Insulated” tools, like this one, have

two prong cords and can use either a two or three prong extension cord.

“This appliance has a polarized plug (one blade is wider than the other). To reduce

the risk of electric shock, this plug is intended to fit in a polarized outlet only one

way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit,

contact a qualified electrician. Do not modify the plug in any way.”

Extension Cords

As the distance from the supply outlet

increases, heavier gauge extension cords

are required. The use of extension cords of

inadequate size wire causes a serious drop

in voltage and loss of power. Protect the cord

from damage. Keep cords away from excessive heat, sharp edges and damp or wet

areas. Repair or replace damaged extension

cords before using.

Note: The HG 2510 ESD is not ”Double Insulated”. It utilizes a 3-prong grounded

plug and, for safety, must only be used with a 3-prong extension cord.

Ext. Cord Length Wire Size

040 Ft. 16

085 Ft. 14

100 Ft. 12

170 Ft. 10

270 Ft. 08

400 Ft. 06

650 Ft. 04

- 4 -

Page 5

Thank you

English

for deciding to choose a STEIN EL

heat gun. This tool can be used

for completing a wide range of

jobs safely and reliably, such as

soldering, welding PVC, shaping,

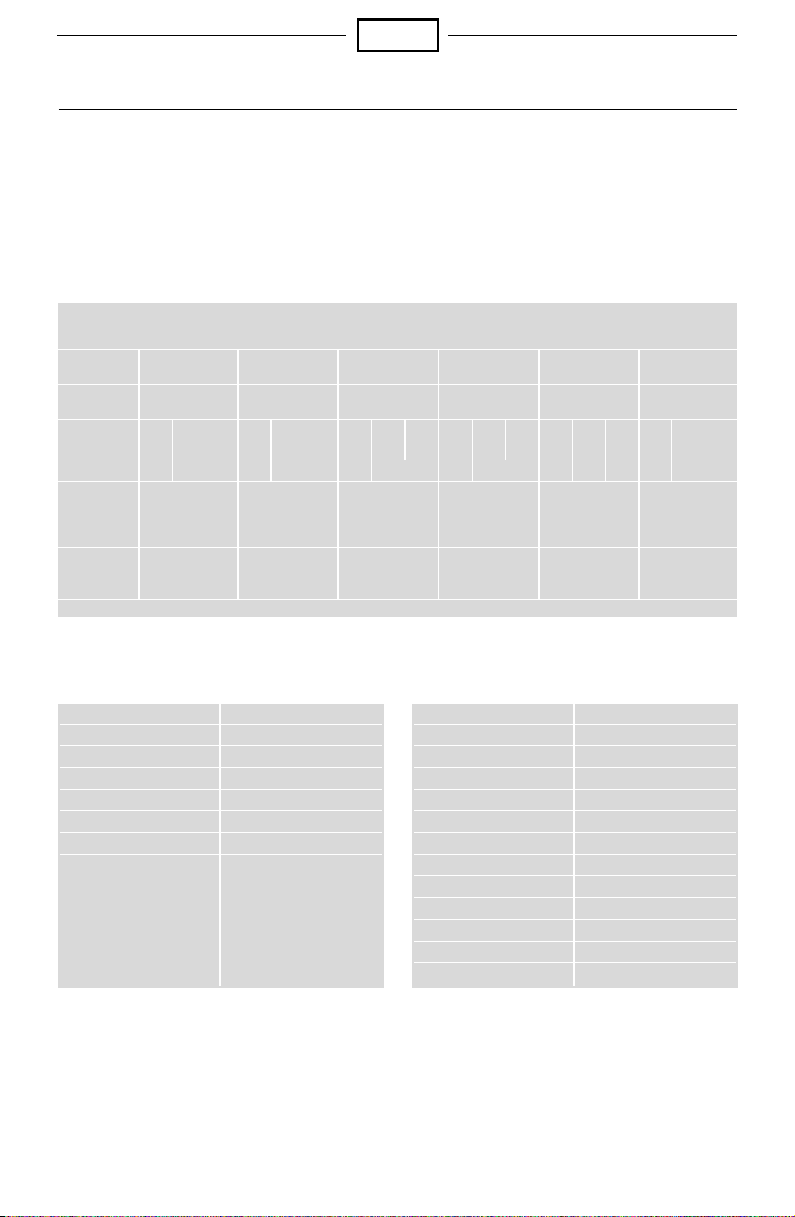

Technical specifications

Voltage

Output

Switch stage

Airflow (cf/min.)

Temperature

Controls

Programs

120 V, 6 0 H z

160 0 W

12

3.6 3.6 – 17.6

120 ° 120 – 12 00 ° F

pushbutton

air/temperature control

in 10 °F increments,

with LCD display

4 preset programs,

with ”LOC” Lockable

Override Control™

120 V, 6 0 H z

160 0 W

12

3.6 3.6 – 17.6

120 ° 120 – 1200 °F

pushbutton

air/temperature control

in 10 °F increments,

with LCD display

4 preset programs,

with ”LOC” Lockable

Override Control™

Conversion °C to °F

°C = °F

100 212

200 392

300 572

400 752

500 932

600 1112

700 1292

drying, shrink-fitting, stripping paint

etc. All STEI NEL tools are manufactured to the highest standards

and undergo a strict process of

quality control.

HL 2010 EHG 2310 LCDHG 2510 ESD

120 V, 6 0 H z

150 0 W

123

3.6 10.6 17.6

120 ° 12 0 – 115 0 ° F

pushbutton

temperature control

in 10 °F increments,

with LCD display

–

H L 1910 E

120 V, 6 0 H z

150 0 W

123

3.6 10.6 17.6

120 ° 12 0 – 110 0 ° F

temperature dial

–

Conversion °F to °C

°F = °C

100 38

200 93

300 149

400 204

500 260

600 316

700 3 71

800 427

900 482

1000 5 3 8

1100 5 9 3

1200 6 4 9

Used in the proper manner, this

heat gun will give you lasting

satisfaction.

H L 1810 S

120 V, 6 0 H z

140 0 W

12 3

3.6 10.0 15.9

12 0 ° 75 0° 110 0 ° F

–

–

Subject to technical modifications

H L 1610 S

120 V, 6 0 H z

130 0 W

12

8.5 14.8

575 ° 95 0 °F

–

–

- 5 -

Page 6

English

Features - Getting started

Please note: The distance from the object you are working on depends on material and intended method

of working. Always try out the airflow and temperature on a test piece first! Using the attachable accessory

nozzles (see accessories page on the cover) the flow of heat can be controlled with maximum precision.

Take care when changing hot nozzles! When using the heat gun in the self-resting position, make sure

it is standing on a stable, non-slip and clean surface.

HL 1610 S

The tool is switched ON and OFF at the two-stage switch on the back of the grip handle. Airflow and temperature can be adjusted to 2 settings. Stage 1 reaches 575 °F at an air flow of 8.5 cf/min, stage 2 reaches

950 °F at 14.8 cf/min.

HL 1810 S

The tool is switched ON and OFF at the three-stage switch on the back of the grip handle. Airflow and

temperature can be adjusted to 3 settings. Stage 1 is a Cool air stage at 120 °F with an airflow rate of

3.6 cf/min. Stage 2 reaches 750 °F at an airflow of 10.0 cf/min., stage 3 delivers 1100 °F at 15.9 cf/min.

The outlet protection tube can be removed in order to install the overhead security hanger.

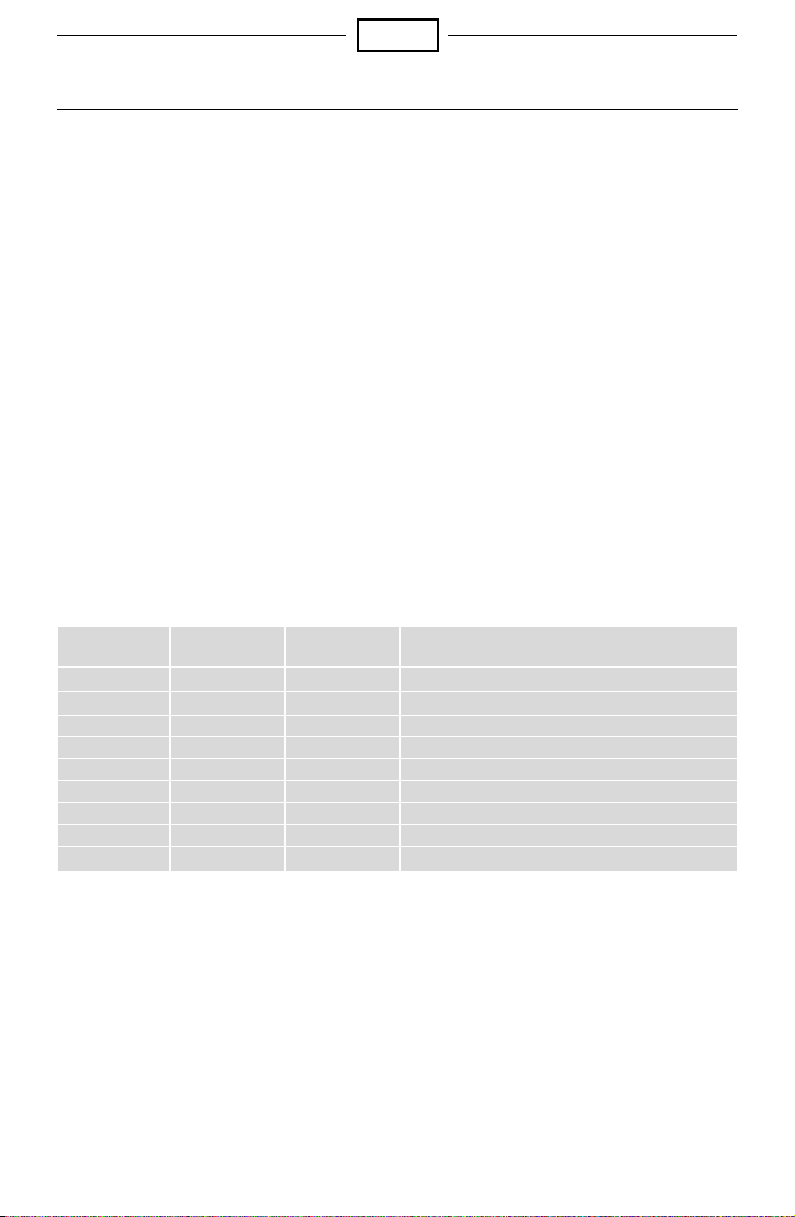

HL 1910 E

The tool is switched ON and OFF at the three-stage switch on the back of the grip handle. In addition to threestage speed/airflow control (stage 1 is a ”Cool-air stage” at 120 °F ), temperature can be continuously adjusted

over a range of 120 °–1100 °F at the thumbwheel. The numbers (1 to 9) on the thumbwheel serve as a guide

only. Whereas ”1” means 120 °F, the maximum temperature of 1100 °F is attained at ”9”.

Airflow can be adjusted to the three stages of 3.6/10.6/17.6 cf/min. The outlet protection tube can be removed

in order to install the overhead security hanger.

Temperature

Dial Setting

1

2

3

4

5

6

7

8

9

HL 2010 E

The tool is switched ON and OFF at the three-stage switch on the back of the grip handle. In addition to threestage speed/airflow control, temperature can be continuously adjusted over a range of 120 °–1150 °F by the

pushbuttons. The target temperature can be increased in 10 °F steps by pressing the ”+” side of the tempera-

ture pushbutton or reduced by pressing the ”–” side of the temperature pushbutton. Pressing the button briefly

increases or reduces the target temperature by one 10 °F step. Keeping the button pressed will continue to

increase or reduce the temperature in steps of 10 °F until the button is released or the minimum or maximum

temperature is set.

Blower stage 1 delivers a temperature of 120 °F. The tool will take a short while to cool to 120 °F after switching

down to blower stage 1 when it has been operating at high temperatures on blower stage 2 or 3. While the

tool is cooling down, the LCD display shows the actual temperature at the nozzle outlet. After switching OFF,

the tool stays in the last setting. The outlet protection tube can be removed in order to install the overhead

security hanger.

Temperature

Range °F

100 – 160 ° F

200 – 300 °F

375 – 475 °F

475 – 5 75 °F

600 – 700 °F

725 – 825 °F

850 – 950 °F

975 – 1075 °F

102 5 – 1125 ° F

Temperature

Range °C

37.8 – 71.1 °C

93.3 – 148.9 °C

190. 6 – 2 4 6 .1 ° C

246.1 – 301.7 ° C

315.6 – 371 .1 ° C

385.0 – 440.6 °C

454.4 – 510.0 °C

523.9 – 579.4 °C

551.7 – 607.2 °C

shaping/removing flooring materials

welding PE, LDPE, PP, thawing pipes

welding ABS, PBT, PC; lap welding plastic sheeting

de-soldering circuit boards

stripping paint, loosening nuts/screws

de-soldering copper pipes

Sample

Applications

cleaning surfaces

activating adhesives

soldering

- 6 -

Page 7

Features - Getting started

HG 2310 LCD / HG 2510 ESD

Operation

The tool is switched ON and OFF

at the multi-stage switch on the

back of the grip handle. The distance from the object you are

working on depends on material

and intended method of working.

Always try out the air flow and

Setting the temperature

Stage 1 is the cool air stage. Use

the cool air function for drying

paint, cooling workpieces or to

cool the nozzle before changing

an accessory attachment.

In stage 2 temperature can be

infinitely varied over a range of

120 °F to 1200 °F on the control

panel with LCD display. The actual

temperature is measured at the

nozzle outlet and indicated on the

Setting airflow

The grey button panel on the right

below the display is used for regulating airflow and blower speed.

Airflow can be controlled in sever-

English

temperature on a test piece first.

Using the attachable accessory

nozzles the flow of heat

can be controlled with maximum

precision. Take care when

changing hot nozzles!

display. The red push button on

the left-hand side is used as an

input button with minus/plus function. Temperature settings range

from 120 °F to 1200 °F

max. Briefly pressing the “+” / “–”

push button increases or reduces

the temperature setting in 10 °

steps. Pressing the button for

longer speeds up the temperature

setting process. Once the tempera-

al stages using the “+/–” function

and can be varied from a minimum of 3.6 cf/min. to a maximum of 17.6 cf/min. Use the cool

When using the heat gun in the

self-resting position, make sure it

is standing on a stable, non-slip

and clean surface. The outlet protection tube can be removed in

order to install the overhead security hanger.

ture has been set, the tool takes a

few seconds to reach temperature

(depending on speed/airflow). If

you want to alter the setting, simply

press either button to increase or

reduce the temperature. After

switching OFF, the heat gun stays

in the last setting.

air stage function for drying paint,

cooling workpieces or to cool the

nozzle before changing an accessory attachment.

Programming [P]

Four programs are factory-set for

the most common types of work.

Press button “P” for programming

mode. Number 1 is displayed for

program 1. Continuing to press

the program button will take you

to programs 2 – 4. Pressing the

button again will return the tool to

normal operation.

Memory function [S]

The settings for the four programs

can be changed and saved at any

time. To do this, press the first program button “P” until the display

shows the program you wish to

change. Set the chosen airflow

”LOC” function

Authorized quality Control personnel may lock down the heat gun’s

output to one specific tempera-

Default programs

Program Temp. °F Air cf/min. Application

1 480 approx. 12.4 Shrink tubing

2 660 approx. 14.8 De-soldering circuit boards

3 860 approx. 17.6 Forming plastics

4 1000 approx. 14.8 Soldering

and temperature. Now press the

memory button “–>” until the “–>”

symbol is cleared from the display

(approx. 5 sec). The values

entered are now saved in the

program memory. To return to

ture/airflow combination using the

”LOC” Lockable Override Control™

feature.

normal operation, press the

program button until the program

symbol disappears from the

display.

Please call (800) 852-4343 for

more information.

- 7 -

Page 8

Applications

English

Here are some of the applications

you can use STEINEL heat guns

for. This selection is by no means

exhaustive – no doubt you can

immediately think of other examples.

A Stripping paint: Paint is soft-

ened and can be removed with a

stripping knife and paint scraper

to leave a clean surface.

B Shrinking tubing on cables:

The shrink tubing is slipped over

the section you want to insulate

and heated. The tubing shrinks

by approx. 50% in diameter to

give a sealed union. Shrinking

is particularly fast and even using

reflector nozzles. Sealing and

stabilizing cable breaks, insulating

soldered joints, gathering cable

runs, sheathing terminal blocks.

C Forming PVC: Sheeting, pip-

ing or ski boots can be softened

and formed with heat.

D Lighting the barbecue:

Gets charcoal glowing in next to

no time; no more waiting.

E Thawing: Water pipes, frozen

door locks, steps. Gently thaws

and dries all in one go.

F Soft soldering: First, clean

metal parts you want to join. Then,

heat the point you want to solder

and offer up the soldering wire.

Use flux or a soldering wire with a

flux core to prevent oxide forming.

G Welding and joining plastic:

All parts being welded must be of

the same plastic material. Use an

appropriate welding rod.

Material Application types Distinguishing characteristics

Rigid PVC

Plasticised

PVC

Soft PE

(LDPE)

Polyethylene

Hard PE

(HDPE)

Polyethylene

PP

Polypropylene

ABS

Pipes, fittings, sheets, building profiles, technical mouldings

Welding temperature 580 °F

Floor coverings, wallpapers,

hoses, sheets, toys

Welding temperature 760 °F

Domestic and electrotechnical

articles, toys

Welding temperature 480 °F

Baths, baskets, canisters, insulating material, pipes

Welding temperature 580 °F

HT drainage pipes, moulded

seats, packaging, car components

Welding temperature 480 °F

Car components, equipment

housings, cases

Welding temperature 660 °F

H De-soldering: Circuit boards

and other electronic components

may be soldered or de-soldered

using a reduction tip fitted on an

electronic heat gun.

I Joining sheeting: The sheets

are overlapped and welded

together. A slit nozzle is used to

direct heat under the overlap,

then the two sheets are firmly

pressed together with a feed

roller. Also possible: Repairing

PVC tarpaulins by overlap welding with a slit nozzle.

Carbonizes in the flame, pungent odour;

crashing sound

Smoking, yellowish-green flame,

pungent odour; silent

Light yellow flame, drips continue

to burn, smells of a candle being

extinguished; dull sound

Light yellow flame, drips continue

to burn, smells of a candle being

extinguished; crashing sound

bright flame with a blue core,

drips continue to burn, pungent odour;

crashing sound

black, fluffy smoke, sweet odour;

crashing sound

J Accessories

Your dealer has a wide range of accessories for you to choose from. (* for HL 1910 E, HL 2010 E, HG 2310 LCD

and HG 2510 ESD only)

1 Spreader nozzle, 75 mm

Prod. No. 07011

2 Spreader nozzle, 50 mm

Prod. No. 07021

3 Butt welding disc,

80 mm*

Prod. No. 07211

4 Lap welding slit tip

Prod. No. 07471

5 Welding rod tip

Prod. No. 07091

6 Lap welding slit tip

Prod. No. 07101

7 Rod welding slit tip

Prod. No. 07201

8 Deflector nozzle, 75 mm

Prod. No. 07031

9 Deflector nozzle, 50 mm

Prod. No. 07041

10 Seam roller, 45 mm

Prod. No. 01250

11 Plastic welding rods

Rigid PVC 07311

LDPE 07331

HD P E 07121

PP 07341

ABS 07421

12 Overhead Security

Hanger

Prod. No. 01481

Prod. No.

13 Reflector nozzle, 75 mm

Prod. No. 07301

14 Reflector nozzle, 39 mm

Prod. No. 07051

15 Reflector nozzle, 14 mm*

Prod. No. 07461

16 Reflector nozzle, 9 mm

Prod. No. 07061

17 Reducer nozzle,

9 mm*

Prod. No. 07062

18 Reducer nozzle, 14 mm*

Prod. No. 07071

19 Reducer nozzle, 20 mm*

Prod. No. 07081

20 Angle slit nozzle

Prod. No. 07511

21 Wire protection tube

Prod. No. 07402

- 8 -

Page 9

English

HL 1610 S / H L 1810 S / H L 1910 E / H L 2010 E / HG 2310 LCD / HG 2510 ESD

920 - 1100 °F

480 - 580 °F

A B C

920 - 1100 °F

D

480 - 580 °F 1100 ° F

E

HL 1910 E / HL 2010 E / HG 2310 LCD / HG 2510 ESD

480 - 760 °F

650 - 750 °F 580 - 760 °F

480 - 920 °F

F

G

J

Accessories

H

- 9 -

I

21

Page 10

English

Tool elements / spare parts list HG 2310 LCD

Spare Parts List HL 1610 S

9

1

11

3

8

6

5

4

10

2

7

HL 1610 S, Type 3480

Housing Set incl. Labels

Switch with Markings (external)

Power Cord with Strain Relief

Power Cord Connector

Set of 5 Housing Screws

PCB/IC Block with Switch (internal)

Motor/Fan Assembly

Heating Element 1300W/120V

Switch (internal)

Pos.

1+2

4+5

10

11

Part No.

02816

02416

3

02723

—

6

02829

7

02316

8

02216

9

02116

02417

Wiring Diagram HL 1610 S

blue

red

black

white

red

violet

yellow

- 10 -

Page 11

Spare Parts List HL 1810 S

English

1

15

3

4

12

7

8

10

Wiring Diagram HL 1810 S

blue

red

5

13

14

6

2

11

Pos.

9

HL 1810 S, Type 3481

Housing Set incl. Labels

End Cap

Switch with Markings (external)

Softgrip

Outlet Protection Tube

Rubber Soft Stand

Power Cord with Strain Relief

Power Cord Connector

Set of 5 Housing Screws

PCB/IC Block with Switch (internal)

Motor/Fan Assembly

Heating Element 1400W/120V

Switch (internal)

1 +2

3

4

5

6

7

8 + 10

9

11

12

13

14

15

Part No.

02818

—

02420

02621

02523

02629

02723

—

02829

02318

02218

02118

02426

white

blue

red

yellow

black

- 11 -

Page 12

Spare Parts List HL 1910 E

1

14

3

11

5

6

8

English

4

12 13

7

2

10

Part No.

9

HL 1910 E, Type 3484

Housing Set incl. Labels

Switch with Markings (external)

Softgrip

Rubber Soft Stand

Power Cord with Strain Relief

Outlet Protection Tube

Power Cord Connector

Set of 5 Housing Screws

PCB/IC Block with Switch and End Cap

Motor/Fan Assembly

Heating Element 1500W/120V

Switch (internal)

Pos.

1 + 2

6 + 8

10

11

12

13

14

02819

3

02420

4

02621

5

02629

02723

7

02523

9

—

02829

02319

02225

02120

02426

Wiring Diagram HL 1910 E

white

black

- 12 -

green

red

2:1

red

blue

yellow

blue

yellow (fuse)

Page 13

Spare Parts List HL 2010 E

14

3

11

5

6

8

1

412

9

English

13

2

10

HL 2010 E, Type 3482

Housing Set incl. Labels

Switch with Markings (external)

Softgrip

Rubber Soft Stand

Power Cord with Strain Relief

Outlet Protection Tube

Power Cord Connector

Set of 5 Housing Screws

PCB/IC Block with Switch and Controls

Motor/Fan Assembly

Heating Element 1500W/120V

Switch (internal)

7

Part No.Pos.

02820

1 + 2

02420

3

02621

4

02629

5

02723

6 + 8

02523

7

—

9

02829

10

02320

11

02225

12

02120

13

02426

14

Wiring Diagram HL 2010 E

white

black

- 13 -

2:1

green

red

red

blue

yellow

blue

yellow (fuse)

Page 14

Spare Parts List HG 2310 LCD

14

3

11

5

6

8

English

1314 12

7

2

10

Part No.

9

HG 2310 LCD, Type 3483

incl. Labels

Housing Set

Switch with Markings (external)

Softgrip

Rubber Soft Stand

Power Cord with Strain Relief

Outlet Protection Tube

Power Cord Connector

Set of 5 Housing Screws

PCB/IC Block with Switch and Controls

Motor/Fan Assembly

Heating Element 1600W/120V

Switch (internal)

Pos.

1 + 2

6 + 8

10

11

12

13

14

02823

02423

3

02621

4

02629

5

02723

02523

7

—

9

02829

02323

02225

02123

02426

Wiring Diagram HG 2310 LCD

white

black

- 14 -

2:1

green

red

red

blue

yellow

blue

yellow (fuse)

Page 15

Spare Parts List HG 2510 ESD

English

1

14

3

11

5

6

8

Wiring Diagram HG 2510 ESD

124

13

7

2

10

Part No.

HG 2510 ESD, Type 3488

9

Housing Set incl. Labels (ESD)

Switch with Markings (external)

Softgrip

Rubber Soft Stand

Power Cord with Strain Relief (ESD)

Outlet Protection Tube (ESD)

Power Cord Connector

Set of 5 Housing Screws

PCB/IC Block with Switch and Controls (ESD)

Motor/Fan Assembly

Heating Element 1600W/120V (ESD)

Switch (internal)

Pos.

1 + 2

6 + 8

10

11

12

13

14

02825

02425

3

02621

4

02629

5

02725

02525

7

—

9

02829

02325

02225

02125

02426

white

black

green

- 15 -

2:1

green

red

red

blue

yellow

blue

yellow (fuse)

Page 16

English

Limited Warranty

STEINEL warranties its heat guns and glue guns, if properly operated and maintained, and used under normal conditions, for a period of one (1) year from the

date of purchase. For heat guns, this warranty includes the heating element.

Specifically EXCLUDED from warranty are tools that have been subject to abuse,

tools that have been opened or repaired by anyone other than STEINEL, tools

that have been modified in any way or mounted onto machinery/equipment, and

tools that have been put into continuous operation. These are hand held power

tools and are intended for use as such. Any other use voids STEINEL’s warranty.

Warranty and Repair Procedures

In the event of product failure, please call STEINEL customer service directly

at (800) 852-4343. We will attempt to troubleshoot the difficulty via phone.

If warranty work or other repair appears necessary, we will issue an RGA#

and ask that the tool be returned to us at the below address (postage paid

by the customer), with the RGA# clearly marked, and accompanied by a brief

description of the difficulty as well as your original dated sales receipt phone

number and return address.

When received, STEINEL will diagnose the problem and determine if it is

covered under warranty. If we determine that it is covered by warranty, we will

repair or replace the defective tool, at our option, and return it to the customer

(postage paid by STEINEL). If we determine that the tool is not defective and/

or that it is not covered by warranty, we will contact the customer to discuss

his options prior to performing any repair work not covered under warranty.

All non-warranty repair work is billed at standard rates and will be quoted prior

to repair.

Consequential Damages

The company shall not be liable for any incidental or consequential damages

arising from the use of the Product by the Purchaser, the breach of any warranties, the failure to deliver, delay in delivery, delivery in non-conforming condition, or for any other breach of contract or duty between the Company and

the Purchaser.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

- 16 -

Page 17

English

Disclaimers of warranties

The warranties contained herein are expressly in lieu of any other expressed

or implied warranties, or any other obligation on the part of the Company.

Any implied warranty of merchantability or fitness for a particular purpose

shall expire one (1) year after the date the product is purchased by the

original end-user Purchaser. Any models, drawings, plans, specifications,

affirmations of fact, promises, or other communications by the Company with

reference to the performance of the product are solely for the convenience

of the Purchaser and shall not in any way modify the expressed warranties

and disclaimers set forth herein. The Purchaser acknowledges it is purchasing

the Product solely on the basis of the commitments of the Company as

expressly set forth herein. No agents or other parties are authorized to make

any warranties on behalf of the Company or to assume for the Company any

other liability in connection with the Product. Some states do not allow

limitations on how long an implied warranty lasts, so the above limitation

may not apply to you.

Limitation of actions

Any action resulting from the breach of any warranty contained herein by

the Company must be commenced within one (1) year after the cause of

action accrues. In no event shall the Company’s total liability for any or all

breaches of any warranty exceed the actual purchase price of the Product.

Other rights

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

STEINEL

9051 Lyndale Avenue South

Bloomington, MN 55420

Tel.: 952-888-5950

Fax: 952-888-5132

Toll free: 1-800-852-4343

E-mail: sales@steinel.net

Visit our website: www.steinel.net

- 17 -

Page 18

German Quality

0000000 Subject to technical change without prior notice

Loading...

Loading...